Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

PD16312

1/4- to 1/11-DUTY FIPTM (VFD) CONTROLLER/DRIVER

The

PD16312 is a FIP (fluorescent Indicator Panel, or Vacuum Fluorescent Display) controller/driver that is

driven on a 1/4- to 1/11 duty factor. It consists of 11 segment output lines, 6 grid output lines, 5 segment/grid output

drive lines, a display memory, a control circuit, and a key scan circuit. Serial data is input to the PD16312 through a

three-line serial interface. This FIP controller/driver is ideal as a peripheral device for a single-chip microcomputer.

FEATURES

•Multiple display modes (11-segment & 11-digit to 16-segment & 4-digit)

•Key scanning (6 4 matrix)

•Dimming circuit (eight steps)

•High-voltage output (VDD 35 V max).

•LED ports (4 chs., 20 mA max).

•General-purpose input port (4 bits)

•No external resistors necessary for driver outputs (P-ch open-drain + pull-down resistor output)

•Serial interface (CLK, STB, DIN, D

OUT

)

ORDERING INFORMATION

Part Number Package

PD16312GB-3B4 44-pin plastic QFP ( 10)

Document No. IC-3307 (1st edition)

Date Published March 1997 P

Printed in Japan

1993©

Page 2

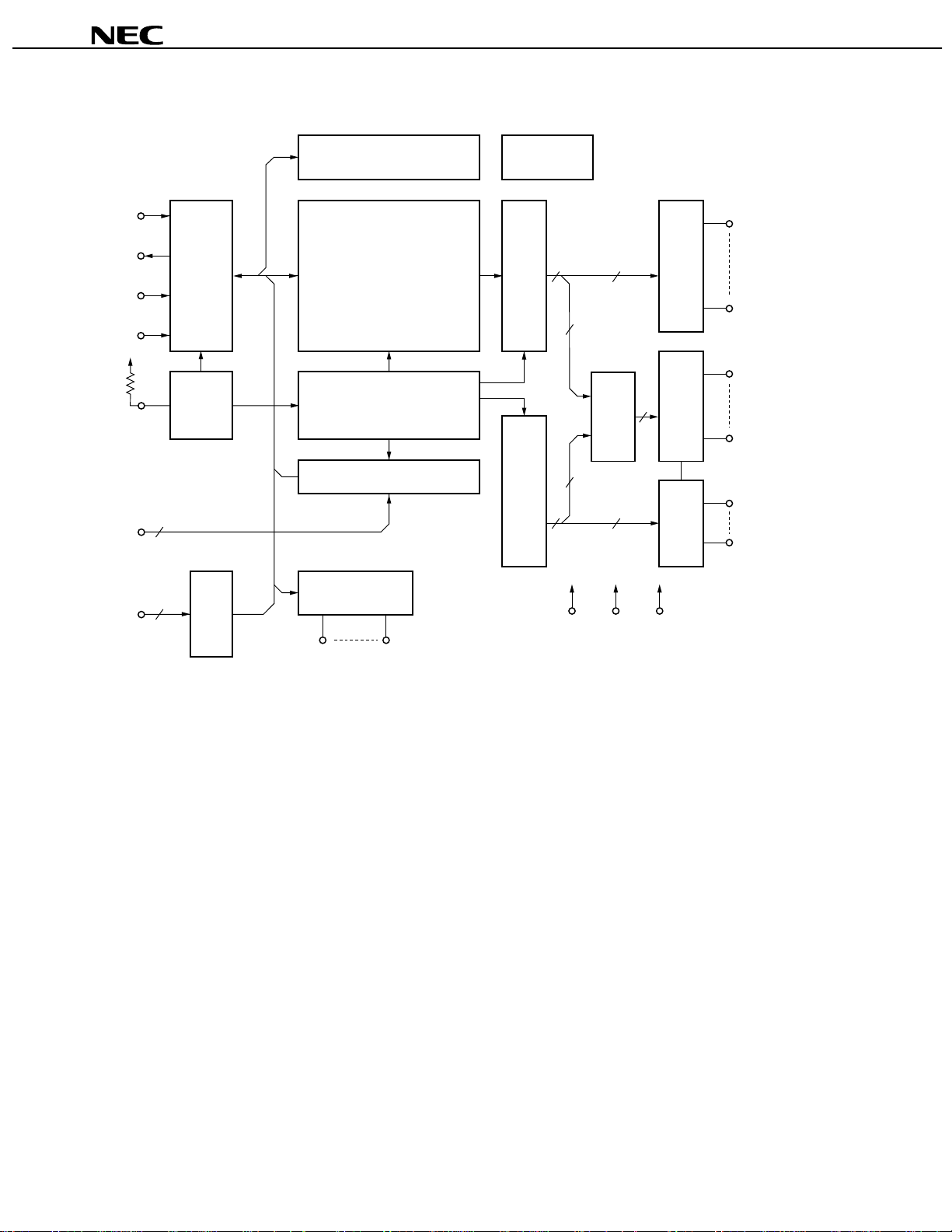

BLOCK DIAGRAM

PD16312

D

CLK

STB

V

DD

Key

to

Key

SW

to

SW

D

OUT

Command decoder

IN

Serial I/F

Display memeory

16 bits × 11 words

Dimming circuit

16-bit

16 11

output

latch

Segment

driver

Seg

Seg

1

11

5

R

OSC

Timing generator key scan

Key data memory (4 × 6)

11-bit

shift

Data

selector

5

5

Multip lexed

register

V

EE

(−30 V)

Grid

driver

1

4

4

1

4

4-bit

latch

4

4-bit latch

LED

1

LED

4

11 6

V

V

DD

(+5 V)

(0 V)

SS

Seg12/Grid

diver

Seg16/Grid

Grid

Grid

11

7

1

6

Key data memory (4 × 6)

2

Page 3

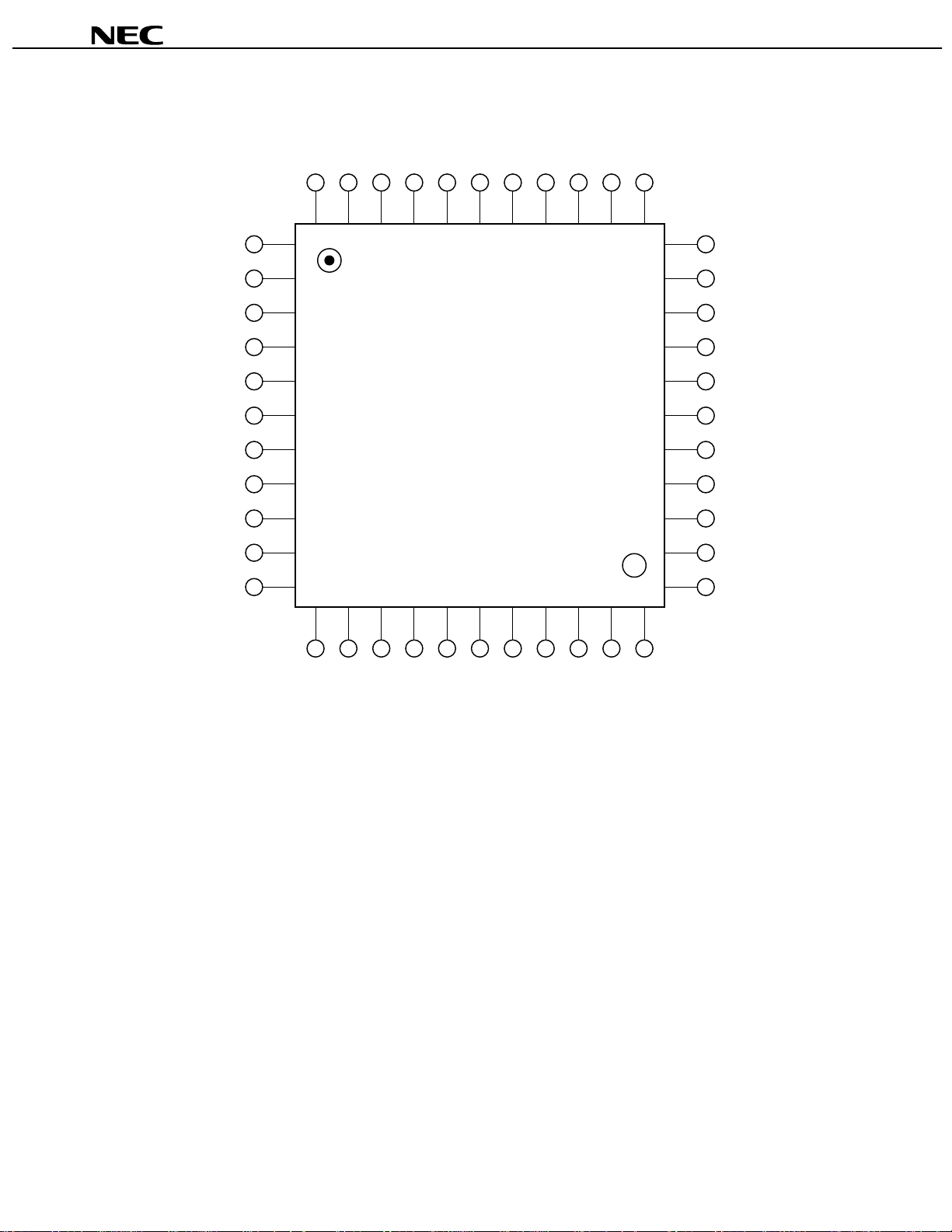

PIN CONFIGURATION (Top View)

SS43

OSC44

V

142

LED

241

LED

340

LED

439

LED

DD38

V

137

Grid

236

Grid

335

Grid

434

Grid

PD16312

SW1 1

2 2

SW

3 3

SW

4 4

SW

OUT 5

D

IN 6

D

SS 7

V

CLK 8

STB 9

1 10

KEY

2 11

KEY

KEY3 12

4 13

KEY

DD 14

V

1/KS1 15

Seg

2/KS2 16

Seg

3/KS3 17

Seg

4/KS4 18

Seg

5/KS5 19

Seg

6/KS6 20

Seg

7 21

Seg

8 22

Seg

Grid533

Grid

Seg

Seg

Seg

Seg

EE27

V

Seg

Seg

Seg

Seg

632

16/Grid731

15/Grid830

14/Grid929

13/Grid1028

12/Grid1126

1125

1024

923

Use all power pins.

3

Page 4

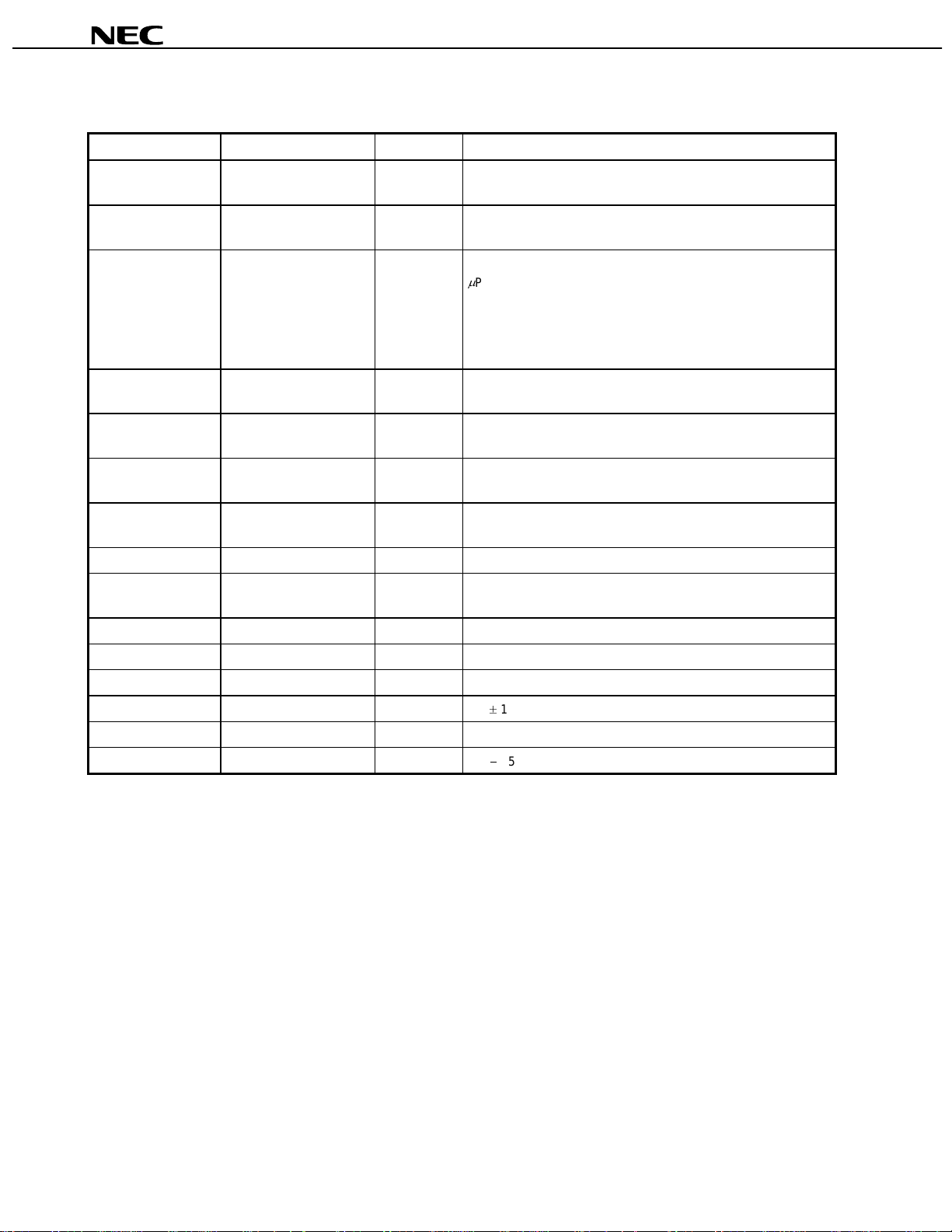

PD16312

Pin Function

Symbol Pin Name Pin No Description

IN

D

OUT

D

STB Strobe 9 Initializes serial interface at the rising or falling edge of the

CLK Clock input 8 Reads serial data at the rising edge, and outputs data at the

OSC Oscillator pin 44 Connect resistor to this pin to determine the oscillation frequency

Seg1/KS1 to

6

6

/KS

Seg

Seg7 to Seg

Grid1 to Grid

11

6

Seg12/Grid11 to

16

7

/Grid

Seg

LED1 to LED

KEY1 to KEY

SW1 to SW

DD

V

SS

V

EE

V

4

4

4

Data input 6 Input serial data at rising edge of shift clock, starting from the low

order bit.

Data output 5 Output serial data at the falling edge of the shift clock, starting

from low order bit. This is N-ch open-drain output pin.

PD16312. It then waits for reception of a command. Data input

after STB has fallen is processed as a command. While

command data is processed, current processing is stopped, and

the serial interface is initialized. While STB is high, CLK is

ignored.

falling edge.

to this pin.

High-voltage output 15 to 20 Segment output pins (Dual function as key source)

High-voltage output

21 to 25 Segment output pins

(segment)

High-voltage output (grid) 37 to 32 Grid output pins

High-voltage output

26, 28 to 31

These pins are selectable for segment or grid driving.

(segment/grid)

LED output 42 to 39 CMOS output. +20 mA max.

Key data input 10 to 13 Data input to these pins is latched at the end of the display cycle.

Switch input 1 to 4 These pins constitute a 4-bit general-purpose input port.

Logic power 14, 38 5 V 10 %

Logic ground 7, 43 Connect this pin to system GND.

Pull-down level 27 VDD 35 V max.

4

Page 5

PD16312

Display RAM Address and Display Mode

The display RAM stores the data transmitted from an external device to the PD16312 through the serial interface,

and is assigned addresses as follows, in 8 bits unit:

Seg

0

b

1

00H

02H

04H

06H

08H

0AH

0CH

0EH

10H

12H

14H

xxH

L

L

L

L

L

L

L

L

L

L

L

L

Seg

b3b

4

00H

02H

04H

06H

08H

0AH

0CH

0EH

10H

12H

14H

4

xxH

Lower 4 bits Higher 4 bits

8

Seg

U

U

U

U

U

U

U

U

U

U

U

U

01H

03H

05H

07H

09H

0BH

0DH

0FH

11H

13H

15H

7

b

Seg

L

L

L

L

L

L

L

L

L

L

L

12

01H

03H

05H

07H

09H

0BH

0DH

0FH

11H

13H

15H

U

U

U

U

U

U

U

U

U

U

U

Seg

16

1

DIG

2

DIG

3

DIG

4

DIG

5

DIG

6

DIG

7

DIG

8

DIG

9

DIG

10

DIG

11

DIG

5

Page 6

PD16312

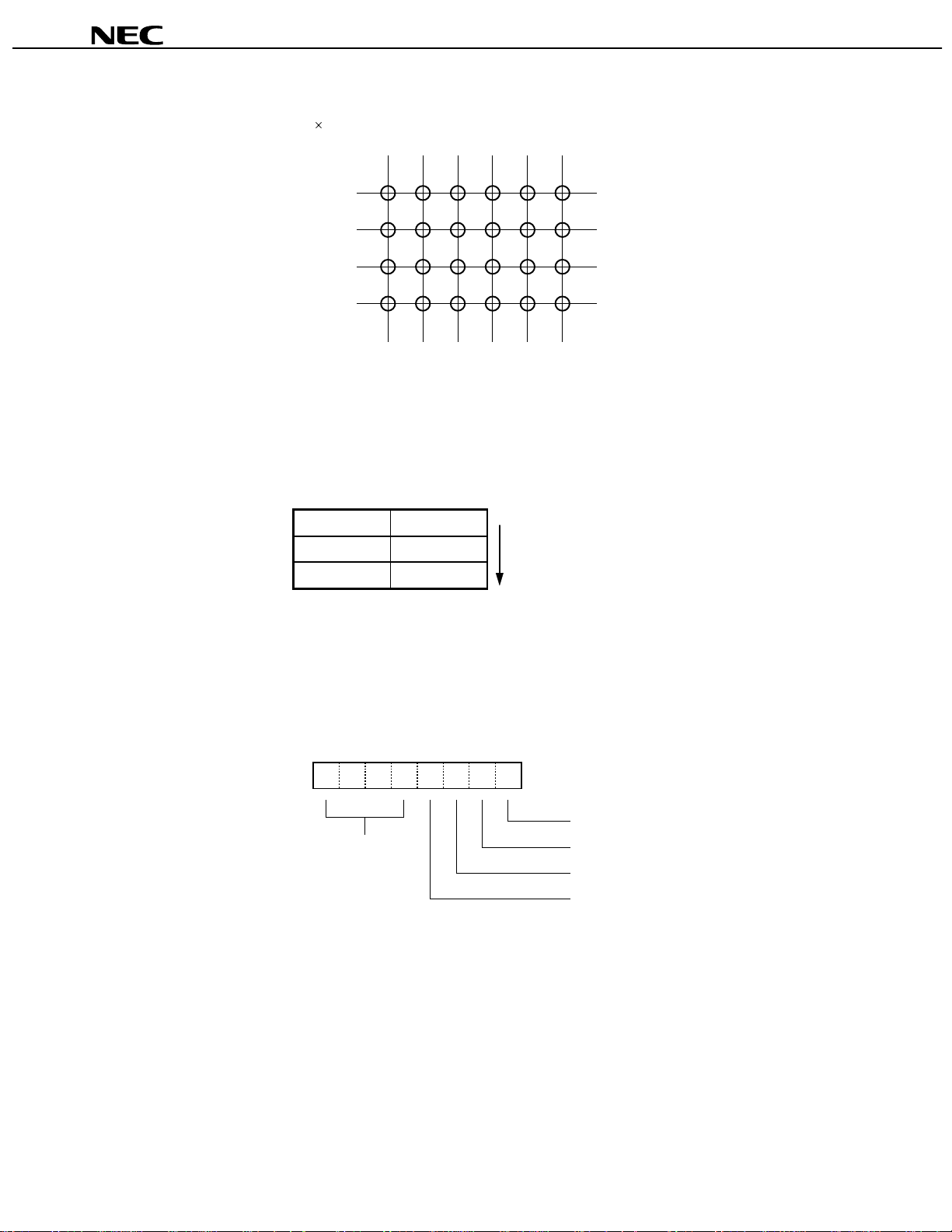

Key Matrix and Key-Input Data Storage RAM

The key matrix is made up of a 6 4 matrix, as shown below.

KEY

1

KEY

2

KEY

3

KEY

4

1

2

3

4

5

6

/KS

/KS

/KS

/KS

/KS

1

Seg

2

Seg

3

Seg

4

Seg

5

Seg

/KS

6

Seg

The data of each key is stored as illustrated below, and is read with the read command, starting from the least

significant bit.

KEY1…KEY4KEY1…KEY

4

Seg1/KS

Seg3/KS

Seg5/KS

1

3

5

Seg2/KS

Seg4/KS

Seg6/KS

2

4

6

Reading sequence

b0------------b3 b4------------b7

LED Port

Data is written to the LED port with the write command, starting from the least port’s least significant bit. When a

bit of this port is 0, the corresponding LED lights; when the bit is 1, the LED truns off. The data of bits 5 through 8 are

ignored.

MSB

−−−−b3 b2 b1 b0

Don't care

LSB

LED1

LED2

LED3

LED4

On power application, all LEDs are unlit.

6

Page 7

PD16312

SW Data

SW data is read with the read command, starting from the least significant bit. Bits 5 through 8 of the SW data are

0.

MSB

0 0 0 0 b3 b2 b1 b0

LSB

SW1

SW2

SW3

SW4

Commands

Commands set the display mode and status of the FIP driver.

The first 1 byte input to the PD16312 through the D

IN

pin after the STB pin has fallen is regarded as a command.

If STB is set high while commands/data are transmitted, serial communication is initialized, and the

commands/data being transmitted are invalid (however, the commands/data previously transmitted remain valid).

(1) Display mode setting commands

These commands initialize the PD16312 and select the number of segments and the number of grids (1/4 to

1/11 duty, 11 segments to 16 segments).

When these commands are executed, the display is forcibly turned off, and key scanning is also stopped. To

resume display, the display command “ON” must be executed. If the same mode is selected, however, nothing

happens.

MSB

00−−−b2 b1 b0

Irrelevant

LSB

Display mode settings

000

001

010

011

100

101

110

111

On power application, the 11-digit, 11-segment mode is selected.

: 4 digits, 16 segments

: 5 digits, 16 segments

: 6 digits, 16 segments

: 7 digits, 15 segments

: 8 digits, 14 segments

: 9 digits, 13 segments

: 10 digits, 12 segments

: 11 digits, 11 segments

7

Page 8

(2) Data setting commands

These commands set data write and data read modes.

PD16312

MSB

01−−b3 b2 b1 b0

Irrelevant

LSB

Data write and read mode settings

00

: Write data to display memory

01

: Write data to LED port

10

: Read key data

11

: Read SW data

Address increment mode settings (display memory)

01: Increments address after data has been written

: Fixes address.

Test mode settings

01: Normal operation

: Test mode

On power application, the normal operation and address increment modes are set.

(3) Address setting commands

These commands set an address of the display memory.

MSB

11−b4 b3 b2 b1 b0

LSB

Address (00H - 15H)

If address 16H or higher is set, data is ignored, until a valid address is set.

On power application, the address is set to 00H.

8

Page 9

(4) Display control commands

PD16312

MSB

10−−b3 b2 b1 b0

Irrelevant

LSB

Dimming quantity settings

000

: Set pulse width to 1/16.

001

: Set pulse width to 2/16.

010

: Set pulse width to 4/16.

011

: Set pulse width to 10/16.

100

: Set pulse width to 11/16.

101

: Set pulse width to 12/16.

110

: Set pulse width to 13/16.

111

: Set pulse width to 14/16.

Turns on/off display.

01: Display off (key scan continues

: Display on

On power application, the 1/16 pulse width is set and the display is turned off.

On power application, key scanning is stopped.

Note

Note

)

9

Page 10

Key Scanning and Display Timing

T

DISP

= 500 s

µ

Key scan data

PD16312

SEG output DIG1

G

1

DIG2 DIG3

DIGn 1 5 6342

1/16

T

G

2

G

3

G

n

DISP

1 frame = T

DISP

× (n + 1)

One cycle of key scanning consists of one frame, and data in a 6 4 matrix is stored in RAM.

DIG1

10

Page 11

Serial Communication Format

Reception (command/data write)

STB

PD16312

If data continues

D

CLK

IN

b0 b1 b2 b6 b7

123 78

Transmission (data read)

STB

D

IN

CLK 123456 12345678

D

OUT

Because the D

b0 b1 b2 b3 b4 b5

A data read command is set. Data is read.

OUT

pin is an N-ch, open-drain output pin, be sure to connect an external pull-up resistor to this pin

b6 b7

(1 k to 10 k).

When data is read, a wait time t

Note

WAIT

of 1 s is necessary since the rising of the eighth clock that has set the

command, until the falling of the first clock that has read the data.

t

WAIT

Note

b0 b1 b2 b3 b4 b5

11

Page 12

PD16312

ABSOLUTE MAXIMUM RATINGS (Ta = 25

C, VSS = 0 V)

PARAMETER SYMBOL RATINGS UNIT

Logic Supply Voltage V

Driver Supply Voltage V

Logic Input Voltage V

FIP Driver Output Voltage V

LED Driver Output Current I

FIP Driver Output Current I

Power Dissipation P

Operating Ambient temperature T

Storage Temperature T

Derate at 6.4 mW/C at T

Note

DD

EE

I1

O2

O1

O2

D

opt

stg

a

= 25 C or higher.

VDD +0.5 to VDD 40 V

VEE 0.5 to VDD +0.5 V

RECOMMENDED OPERATING RANGE (Ta =

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

0.5 to +7.0 V

DD

0.5 to V

+0.5 V

+25 mA

40 (grid)

15 (segment)

Note

800

40 to +85

65 to +150

20 to 70

C, VSS = 0 V)

mA

mW

C

C

Logic Supply Voltage V

High-Level Input Voltage V

Low-Level Input Voltage V

Driver Supply Votlage V

Maximum power consumption P

DD

IH

IL

EE

MAX

. = FIP driver dissipation + RL dissipation + LED driver dissipation + dynamic

4.5 5 5.5 V

DD

0.7 V

0 0.3 V

0V

DD

V

DD

DD

35 V

V

V

power consumption

Where segment current = 3 mA, grid current = 15 mA, and LED current = 20 mA,

FIP driver dissipation = number of segments 6 + number of grids/(number of grids + 1) 30 (mW)

RL dissipation = (VDD VEE)2/50 (number of segments + 1) (mW)

LED driver dissipation = number of LEDs 20 (mW)

Dynamic power consumption = VDD 5 (mW)

Example

Where VEE = 25 V, VDD = 5 V, and in 16-segment and 6-digit modes,

FIP driver dissipation = 16 6 + 6/7 30 = 122

RL dissipation = 302/50 17 = 306

LED driver dissipation = 4 20 = 80

Dynamic power consumption = 5 5 = 25

Total 553 mW

12

Page 13

PD16312

ELECTRICAL CHARACTERISTICS (Ta =

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

High-Level Output Voltage V

Low-Level Output Voltage V

Low-Level Output Voltage V

High-Level Output Current I

High-Level Output Current I

Driver Leakage Current I

Output Pull-Down Resistor R

Input Current I

High-Level Input Voltage V

Low-Level Input Voltage V

Hysteresis Voltage V

Dynamic Current Consumption I

OH1

OL1

OL2

OH21

OH22

OLEAK

L

I

IH

IL

H

DDdyn

SWITCHING CHARACTERISTICS (Ta =

20 to +70

DD

0.9 V

3mAV

15 mA V

50 100 150 K

DD

0.7 V

C, VDD = 4.5 to 5.5 V, VSS = 0 V, VEE = VDD

1

4

V LED

1 V LED1 LED4, I

0.4 V D

OUT

, I

O

= VDD 2 V, Seg1 to Seg

O

= VDD 2 V, Grid1 to Grid

Seg12/ Grid11 to Seg

10

1

AV

Driver output

AV

O

= VDD 35 V, driver off

I

= VDD or V

V

DD

0.3 V

V

LED

OL2

= 4 mA

OH1

, I

OL1

SS

= 1 mA

= 20 mA

16/

0.35 V CLK, DIN, STB

5 mA Under no load, display off

20 to +70

C, VDD = 4.5 to 5.5 V, VEE =

30 V)

Grid

35 V)

11

6

7

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

Oscillation Frequency t

Propagation Delay Time t

Rise Time t

Fall Time t

Maximum Clock Frequency f

Input Capacitance C

TIMING CONDITIONS (Ta =

20 to 70

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

Clock Pule Width PW

Strobe Pulse Width PW

Data Setup Time t

Data Hold Time t

Clock-Strobe Time t

Wait Time t

OSC

PLZ

PZL

t

TZH1

TZH2

t

THZ

max.

I

CLK

STB

SETUP

HOLD

CLK-STB

WAIT

350 500 650 kHz R = 51 k

300 ns CLK D

100 ns CL = 15 pF, RL = 10 k

2

0.5

120

sCL = 300 pF Seg1 to Seg

s Grid1 to Grid6,

sCL = 300 pF, Segn, Grid

1 MHz Duty = 50 %

15 pF

C, VDD = 4.5 to 5.5 V)

400 ns

1

100 ns

100 ns

1

1

s

s CLK STB

s

OUT

CLK CLK

Seg

Seg

Note

12

/Grid11 to

16

/Grid

n

11

7

Refer to page 11.

Note

13

Page 14

Switching Characteristic Waveforms

f

OSC

OSC

50 %

STB

PD16312

PWSTB

CLK

DIN

DOUT

Sn/Gn

PWCLK PWCLK

tSETUP tHOLD

90 %

10 %

tCLK-STB

tPZL

tTHZ tTZH

tPLZ

14

Page 15

Applications

Updating display memory by incrementing address

STB

CLK

D

IN

Command 2 Command 3 Data 1 Data n Command 4Command 1

Command 1:sets display mode

Command 2:sets data

Command 3:sets address

Data 1 to n: transfers display data (22 bytes max.)

Command 4:controls diplay

PD16312

Updating specific address

STB

CLK

D

IN

Command 1:sets data

Command 2:sets address

Data: display data

Command 2 Data Command 2 DataCommand 1

15

Page 16

PD16312

RECOMMENDED SOLDERING CONDITIONS

The following conditions (see table below) must be met when soldering this product. Please consult with our sales

offices in cae other soldering process is used, or in case soldering is done under different conditions.

PC16312GB-3B4

Soldering process Soldering conditions Symbol

Infrared ray reflow Peak package’s surface temperature: 235 C or below,

Reflow time: 30 seconds or below (210 C or higher),

Number of reflow process: 2, Exposure limit*: None

VPS Peak package’s surface temperature: 215 C or below,

Reflow time: 40 seconds or below (200 C or higher),

Number of reflow process: 2, Exposure limit*: None

Wave soldering Solder temperature: 260 C or below,

Flow time: 10 seconds or below

Number of flow process: 1, Exposure limit*: None

Partial heating method Terminal temperature: 300 C or below,

Flow time 10 seconds or below,

Exposure limit*: None

Exposure limit before soldering after dry-pack package is opened.

*

Storage conditions: 25 C and relative humidity at 65 % or less.

Do not apply more than a single process at once, except for “Partial heating method”.

Note

IR35-00-2

VP15-00-2

WS60-00-1

16

Page 17

44 PIN PLASTIC QFP ( 10)

A

B

PPPP

PD16312

34

33

23

22

C D

44

1

11

12

F

G

H

M

I

J

K

P

N

NOTE

Each lead centerline is located within 0.15 mm (0.006 inch) of

its true position (T.P.) at maximum material condition.

M

L

detail of lead end

S

13.6±0.4

10.0±0.2

10.0±0.2

+0.10

–0.05

R

Q

ITEM MILLIMETERS INCHES

A

B

C

D 13.6±0.4 0.535

F 1.0 0.039

G 1.0 0.039

H 0.35±0.10 0.014

I 0.15 0.006

J 0.8 (T.P.) 0.031 (T.P)

K 1.8±0.2 0.071

L 0.8±0.2 0.031

M 0.15 0.006

N 0.10 0.004

P 2.7 0.106

Q 0.1±0.1 0.004±0.004

R 5˚±5˚ 5˚±5˚

S 3.0 MAX. 0.119 MAX.

+0.017

0.535

–0.016

+0.008

0.394

–0.009

+0.008

0.394

–0.009

+0.017

–0.016

+0.004

–0.005

+0.008

–0.009

+0.009

–0.008

+0.004

–0.003

P44GB-80-3B4-3

17

Page 18

[MEMO]

PD16312

18

Page 19

[MEMO]

PD16312

19

Page 20

PD16312

FIPTM is a trademark of NEC Corporation.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...