Page 1

DATA SHEET

BIPOLAR ANALOG INTEGRATED CIRCUIT

µ

PC8102T

RF AMPLIFIER IC FOR 150 MHz TO 330 MHz PAGER SYSTEM

DESCRIPTION

µ

PC8102T is a silicon monolisic integrated circuit designed as RF amplifier for 150 MHz to 330 MHz pager system.

Due to 1 V supply voltage, this IC is suitable for low voltage pager system. The package is a 6 pin mini mold suitable

for high-density surface mounting.

This IC is manufactured using NEC’s 20 GHz f

nitride passivation film and gold electrodes. These materials contribute excellent DC, AC performance. Thus, this

process is utilized for 1 V voltage IC.

T NESAT

TM

III silicon bipolar process. This process uses silicon

FEATURES

• 1 V supply voltage: VCC = 0.9 V to 2.0 V

• Low noise figure: 2.3 dBTYP. @ fin = 150 MHz (with external matching circuit to optimize NF)

• Low current consumption: I

• Gain available frequency: fRF = 150 MHz to 330 MHz (with external matching circuit)

• High-density surface mounting: 6 pin mini mold

CC = 0.5 mATYP. @ VCC = 1.0 V

ORDERING INFORMATION

PART NUMBER PACKAGE MARKING SUPPLYING FORM

µ

PC8102T-E3 6 pin mini mold C2B Embossed tape 8 mm wide. Pin 1, 2, 3 face to

perforation side of tape. QTY 3 kp/Reel

* For evaluation sample order, please contact your local NEC sales office.

(Order number: µPC8102T).

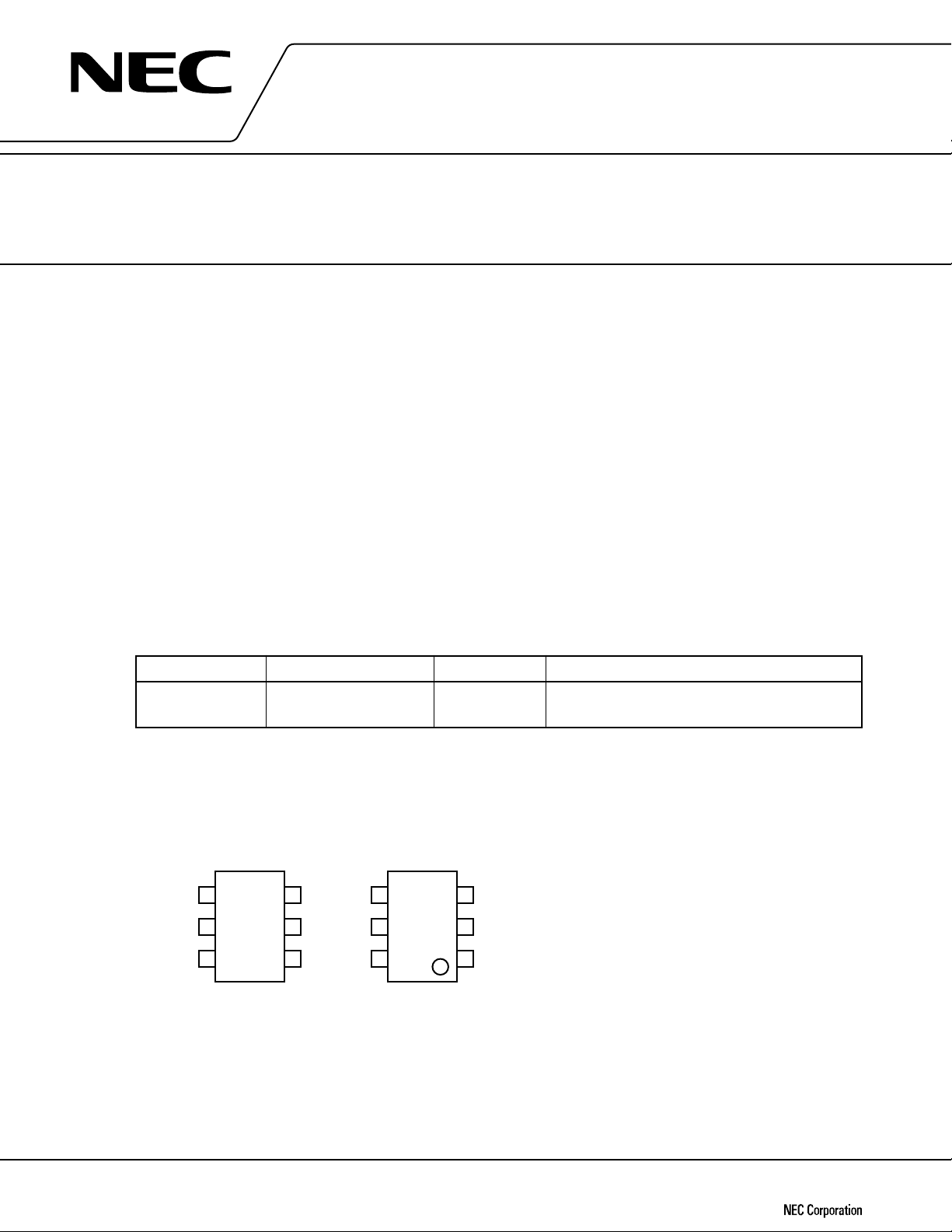

PIN CONNECTIONS

(Top View) (Bottom View)

3

2

1

4

5

C2B

6

4

5

6

3

2

1

1: INPUT

2: GND

3: OUTPUT

4: V

CC

5: C1

6: C2

Document No. P11501EJ2V0DS00

(Previous No. ID-3534)

Date Published May 1996 P

Printed in Japan

Caution Electro-static sensitive devices

©

1996

Page 2

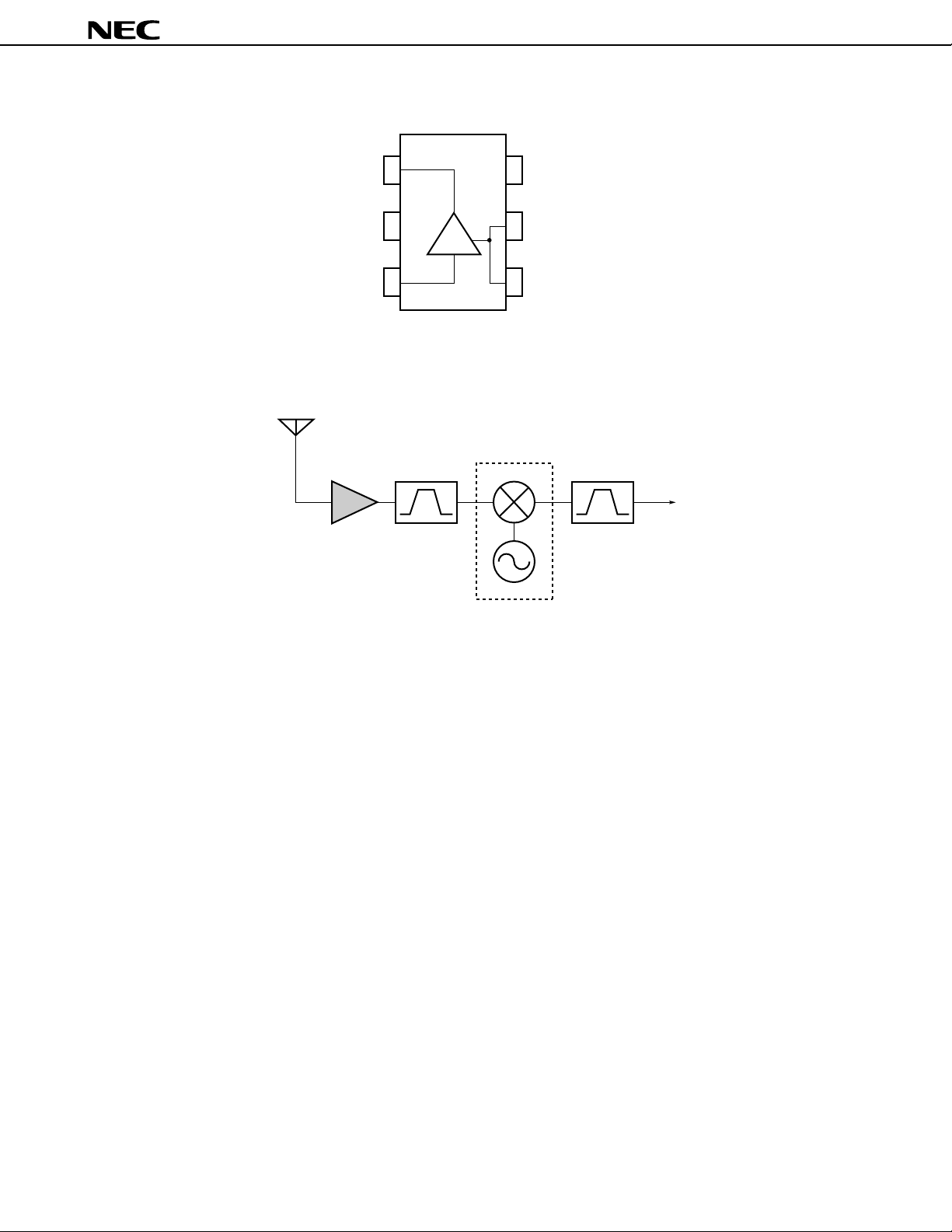

INTERNAL BLOCK DIAGRAM

µ

PC8102T

3

2

1

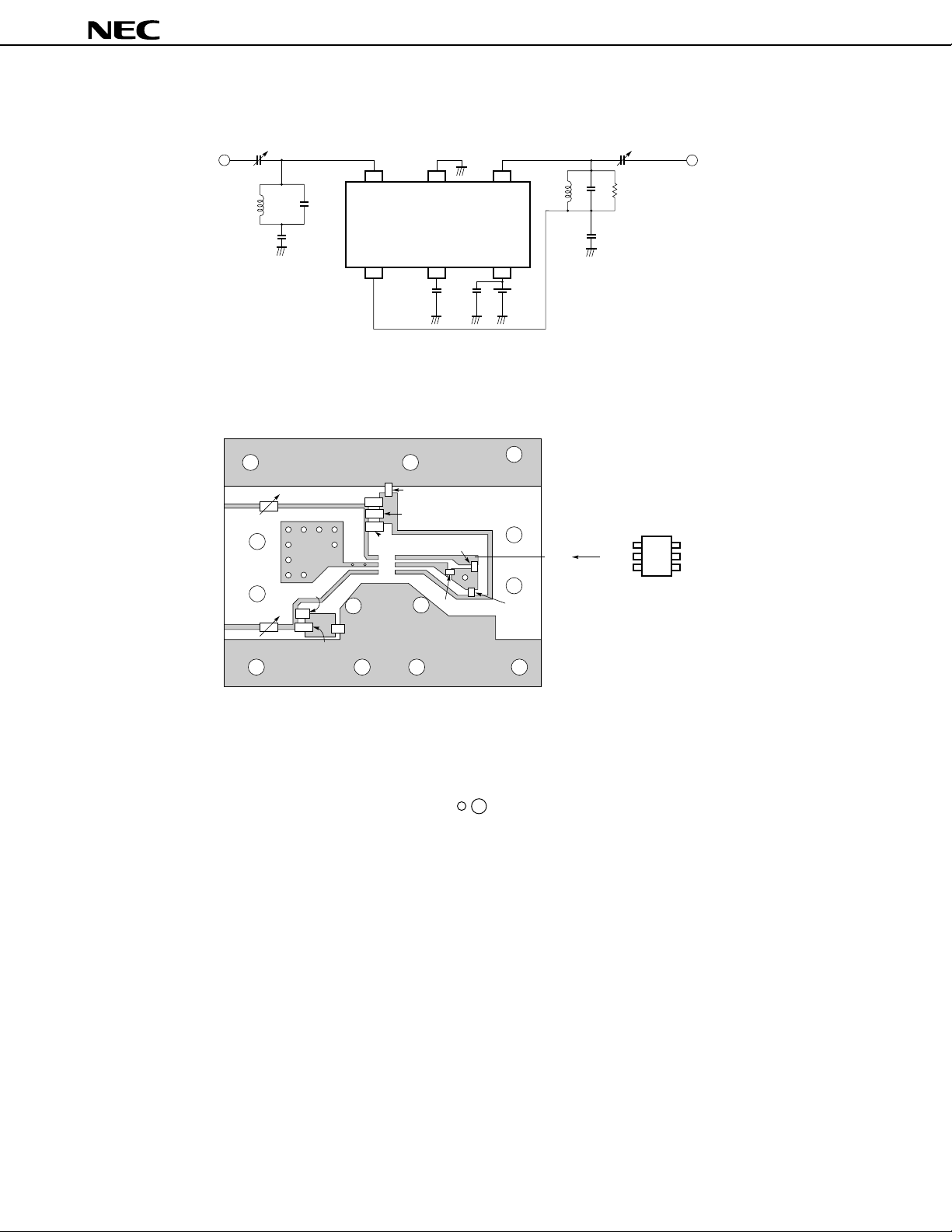

SYSTEM APPLICATION EXAMPLE AS PAGER

150 MHz to 330 MHz

µ

PC8102T BPF

µ

PC8103T

4

5

6

BPF

IF

2

Page 3

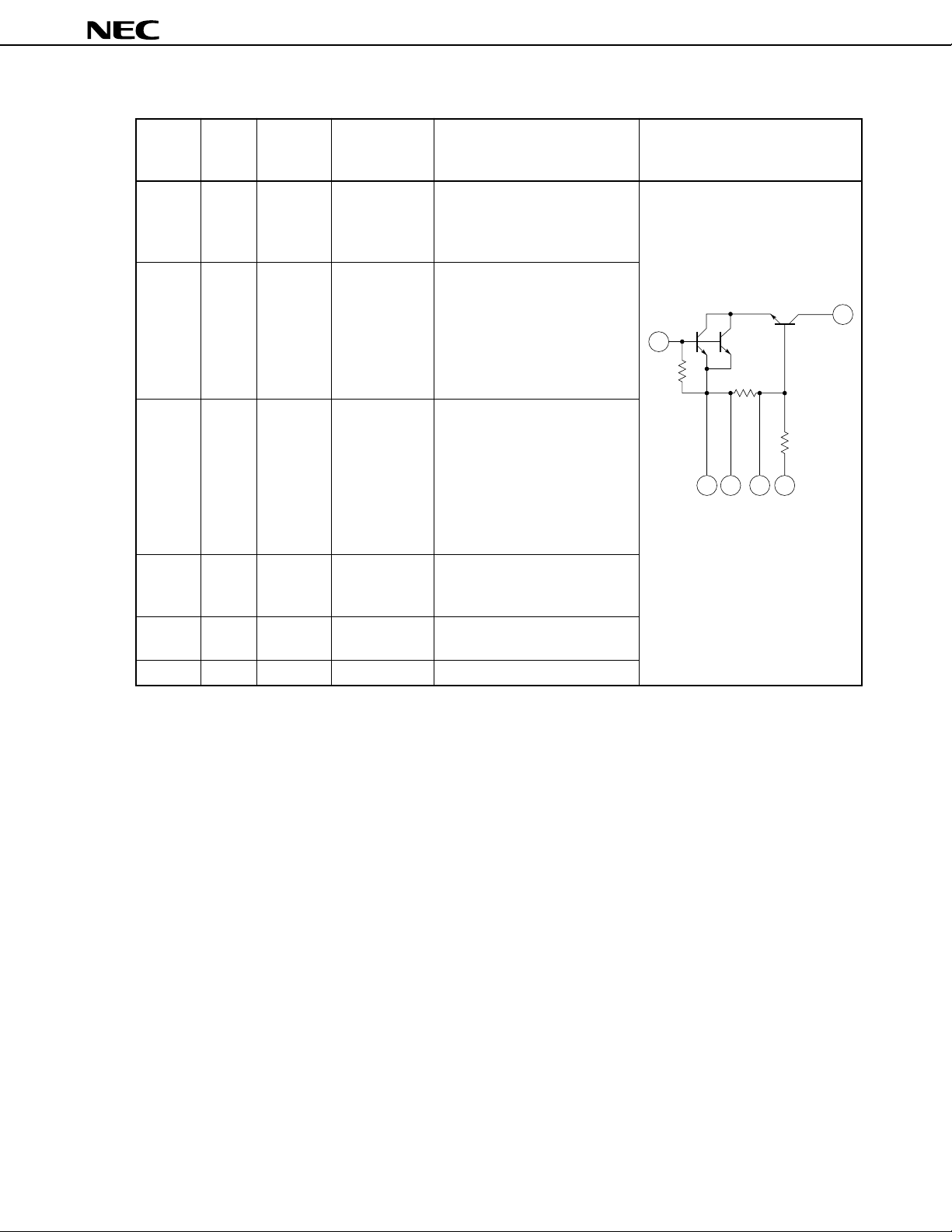

PIN EXPLANATION

1

26 54

3

µ

PC8102T

SUPPLY

PIN NO. NAME VOLTAGE

(V)

1 INPUT — 0.75 RF signal input pin. This pin

2 GND 0 — This ground pin must be

3 OUTPUT — Amplified signal output pin.

4VCC 0.9 to 2.0 — Supply voltage pin. Connect

5 C1 — 0.88 Ground with capacitance pin (eg

6 C2 — 0.85 AC ground pin for output

C2 pin

voltage

must be

applied

through

external

matching

inductor

PIN VOLTAGE

(V)

FUNCTION AND APPLICATION EQUIVALENT CIRCUIT

should be externally equipped

with matching circuit in accordance with desired frequency.

connected to the system ground

with minimum inductance.

Ground pattern on the board

should be formed as wide as

possible. Track length should

be kept as short as possible.

This pin should be externally

equipped with matching circuit

in accordance with desired

frequency.

bypass capacitor (eg 1000 pF)

to minimize ground impedance.

1000 pF).

Note Pin voltage values are described at VCC = 1 V.

3

Page 4

µ

PC8102T

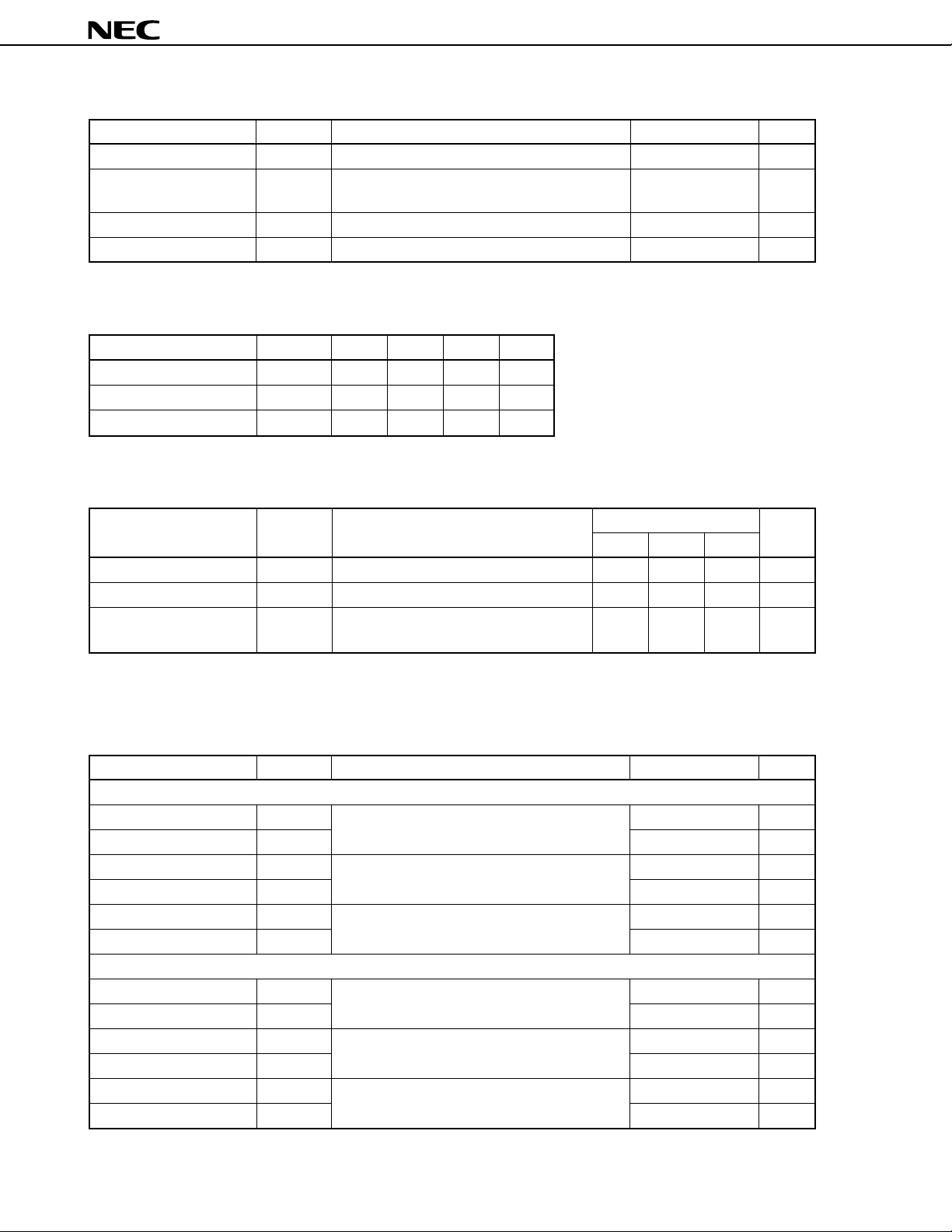

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL CONDITION RATINGS UNIT

Supply Voltage VCC TA = +25 ˚C 2.2 V

Power Dissipation PD Mounted on 50 × 50 × 1.6 mm double copper 280 mW

clad epoxy glass PWB at TA = +85 ˚C

Operating Temperature Topt –40 to +85 ˚C

Storage Temperature Tstg –55 to +150 ˚C

RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Supply Voltage VCC 0.9 1.0 2.0 V

Operating Temperature Topt –40 +25 +85 ˚C

Operating Frequency fopt 150 330 MHz

Electric characteristic (TA = +25 ˚C, VCC = 1.0 V, ZS = ZL = 50

PARAMETER SYMBOL TEST CONDITIONS

Circuit Current ICC No input signal, TEST CIRCUIT 1 0.30 0.5 0.65 mA

Power Gain GP f = 280 MHz, TEST CIRCUIT 3 10.0 13.5 16.5 dB

Output 3rd order OIP3 f1 = 150.000 MHz, f2 = 150.025 MHz — –5 — dBm

intercept point TEST CIRCUIT 2

ΩΩ

Ω)

ΩΩ

µ

PC8102T

MIN. TYP. MAX.

Note External matching circuits should be attached to input and output pins.

Standared characteristics for reference (Sample: I

PARAMETER SYMBOL CONDITIONS Reference value UNIT

matched with 50 Ω

Power Gain 1 GP1 f = 150 MHz, TEST CIRCUIT 2 20.6 dB

Noise Figure 1 NF1 3.6 dB

Power Gain 2 GP2 f = 280 MHz, TEST CIRCUIT 3 14.7 dB

Noise Figure 2 NF2 4.0 dB

Power Gain 3 GP3 f = 330 MHz, TEST CIRCUIT 5 14.5 dB

Noise Figure 3 NF3 4.1 dB

matched to optimize NF

Power Gain 4 GP4 f = 150 MHz, TEST CIRCUIT 2 19.4 dB

Noise Figure 4 NF4 2.3 dB

Power Gain 5 GP5 f = 280 MHz, TEST CIRCUIT 4 14.0 dB

Noise Figure 5 NF5 2.9 dB

Power Gain 6 GP6 f = 330 MHz, TEST CIRCUIT 6 11.6 dB

Noise Figure 6 NF6 3.1 dB

CC = 0.55 mA, Condition: TA = +25 ˚C, VCC = 1.0 V)

UNIT

4

Page 5

TEST CIRCUIT 1

123

IN GND OUT

µ

PC8102T

C2 C1 V

654

CC

A

5

Page 6

µ

PC8102T

TEST CIRCUIT 2 (150 MHz) <Matched with 50

(Note)

7.5 pF

68 nH

10 pF

1 000 pF

ΩΩ

Ω or matched to optimize NF>

ΩΩ

213

IN

C2

1 000 pF

GND OUT

CCC1

564

1 000

pF

V

84 nH

7.5 pF

10

47 kΩ

pF

1 000 pF

(Note)

Note Matching can be adjusted with trimmer condenser.

ILLUSTRATION OF THE TEST CIRCUIT 2 ASSEMBLED ON EVALUATION BOARD

47k

1 000 pF

84 nH

Ω

1 000 pF

1 000 pF

8102/07

1 000 pF

3

V

CC

2

C2B

1

Mounting direction

OUT

10 pF

7.5pF

10 pF

7.5pF

IN

1 000 pF

68 nH

4

5

6

Note

(*1) 35 × 42 × 0.4 mm double copper clad polyimide board

(*2) Back side: GND pattern

(*3) Solder plated on pattern

: Through holes

(*4)

6

Page 7

µ

C2B

3

2

1

4

5

6

1 000 pF

Mounting direction

1 000 pF

VCC

OUT

IN

PC8102/07

TYPE2

µ

PC8102T

IN

C2

1 000 pF

ΩΩ

Ω>

ΩΩ

213

GND OUT

C1

564

1 000

pF

23 nH

V

CC

2 pF

10

47 kΩ

pF

1 000 pF

TEST CIRCUIT 3 (280 MHz) <Matched with 50

0.5 pF

5 pF

23 nH

2 pF

0.5 pF

1 000 pF

ILLUSTRATION OF THE TEST CIRCUIT 3 ASSEMBLED ON EVALUATION BOARD

OUT

47 kΩ

1 000 pF

0.5 pF

2 pF

10 pF

23 nH

2 pF

0.5 pF

1 000 pF

23 nH

IN

5 pF

Note

(*1) 35 × 42 × 0.4 mm double copper clad polyimide board

(*2) Solder plated on pattern

: Through holes

(*3)

7

Page 8

TEST CIRCUIT 4 (280 MHz) <Matched to optimize NF>

27 nH

10 pF

IN

213

GND OUT

23 nH

10

pF

2 pF

47 kΩ

µ

PC8102T

2 pF

1 000 pF

C2

1 000 pF

V

C1

564

1 000

pF

CC

1 000 pF

ILLUSTRATION OF THE TEST CIRCUIT 4 ASSEMBLED ON EVALUATION BOARD

1 000 pF

1 000 pF

IN

µ

PC8102/07

TYPE2

OUT

VCC

3

2

1

C2B

Mounting direction

4

5

6

OUT

47 kΩ

1 000 pF

2 pF

10 pF

23 nH

2 pF

0.5 pF

1 000 pF

27 nH

IN

10 pF

Note

(*1) 35 × 42 × 0.4 mm double copper clad polyimide board

(*2) Solder plated on pattern

: Through holes

(*3)

8

Page 9

µ

C2B

3

2

1

4

5

6

1 000 pF

Mounting direction

1 000 pF

VCC

OUT

IN

PC8102/07

TYPE2

µ

PC8102T

IN

C2

1 000 pF

ΩΩ

Ω>

ΩΩ

213

GND OUT

564

1 000

pF

23 nH

VCCC1

1.5 pF

5

47 kΩ

pF

1 000 pF

TEST CIRCUIT 5 (330 MHz) <Matched with 50

6 pF

17 nH

3 pF

1 000 pF

ILLUSTRATION ON THE TEST CIRCUIT 5 ASSEMBLED ON EVALUATION BOARD

OUT

1.5 pF

47 kΩ

1 000 pF

6 pF

5 pF

23 nH

3 pF

1 000 pF

17 nH

IN

Note

(*1) 35 × 42 × 0.4 mm double copper clad polyimide board

(*2) Solder plated on pattern

: Through holes

(*3)

9

Page 10

TEST CIRCUIT 6 (330 MHz) <Matched to optimize NF>

µ

PC8102T

23 nH

10 pF

3 pF

1 000 pF

IN

C2

1 000 pF

213

GND OUT

C1

564

1 000

pF

23 nH

V

CC

2 pF

6

47 kΩ

pF

1 000 pF

ILLUSTRATION ON THE TEST CIRCUIT 6 ASSEMBLED ON EVALUATION BOARD

1 000 pF

1 000 pF

IN

µ

PC8102/07

TYPE2

OUT

VCC

3

2

1

C2B

Mounting direction

4

5

6

OUT

47 kΩ

1 000 pF

10 pF

2 pF

6 pF

23 nH

3 pF

1 000 pF

23 nH

IN

Note

(*1) 35 × 42 × 0.4 mm double copper clad polyimide board

(*2) Solder plated on pattern

: Through holes

(*3)

10

Page 11

CHARACTERISTICS (TA = +25 ˚C unless otherwise specified)

TA = +85˚C

TA = –40˚C

CIRCUIT CURRENT vs. SUPPLY VOLTAGE

5

4

3

2

1

0.5 1.0 1.5 2.0 2.5

0

V

CC

- SUPPLY VOLTAGE - V

I

CC

- CURCUIT CURRENT - mA

TA = +25˚C

– TEST CIRCUIT 1 –

µ

PC8102T

– TEST CIRCUIT 2 (matched with 50

ΩΩ

Ω) –

ΩΩ

150 MHz VCC = 1.0 V , ICC = 0.55 mA NF = 3.55 dB

CH1 S

11

C2

1 U FS 1: 54.377

MARKER 1

150 MHz

–5.166

Ω

205.30 nH

Ω

150.000 000 MHz

CH1 S

C2

12

log MAG 10 dB/ REF 0 dB 1: –41.406 dB

150.000 000 MHz

MARKER 1

150 MHz

1

1

CENTER 150.000 000 MHz SPAN 200.000 000 MHz

CH1

O21log MAG 10 dB/ REF 0 dB 1: 20.543 dB

C2

MARKER 1

150 MHz

150.000 000 MHz

1

CENTER 150.000 000 MHz SPAN 200.000 000 MHz

CH1 S

22

1 U FS 1: 47.934

C2

0.7613Ω826.93 pH

Ω

150.000 000 MHz

MARKER 1

150 MHz

1

CENTER 150.000 000 MHz

SPAN 200.000 000 MHz

CENTER 150.000 000 MHz SPAN 200.000 000 MHz

11

Page 12

– TEST CIRCUIT 2 (matched to optimize NF) –

150 MHz VCC = 1.0 V , ICC = 0.55 mA NF = 2.25 dB

11

CH1 S

1 U FS 1: 76.062

73.316

Ω

77.791 nH

Ω

150.000 000 MHz

CH1 S

12

log MAG 10 dB/ REF 0 dB 1: –43.251 dB

150.000 000 MHz

µ

PC8102T

C2

1

CENTER 150.000 000 MHz SPAN 200.000 000 MHz

CH1

S21log MAG 10 dB/ REF 0 dB 1: 19.418 dB

C2

150.000 000 MHz

1

C2

1

CENTER 150.000 000 MHz SPAN 200.000 000 MHz

22

CH1 S

C2

1 U FS 1: 53.445

– 1.0137Ω1.0467 nF

Ω

150.000 000 MHz

1

CENTER 150.000 000 MHz

SPAN 200.000 000 MHz

CENTER 150.000 000 MHz SPAN 200.000 000 MHz

12

Page 13

µ

PC8102T

– TEST CIRCUIT 3 (matched with 50

ΩΩ

Ω) –

ΩΩ

280 MHz VCC = 1.0 V , ICC = 0.55 mA NF = 4.0 dB

11 1 U FS 1: 84.699

CH1 S

C2

De1

–2.8789

Ω

197.44 pF

Ω

280.000 000 MHz

1

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

CH1 S21 log MAG 10 dB/ REF 0 dB 1: 14.748 dB

280.000 000 MHz

C2

De1

1

CH1 S12 log MAG 10 dB/ REF 0 dB 1: –32.145 dB

C2

De1

260.000 000 MHz

1

CENTER 260.000 000 MHz SPAN 200.000 000 MHz

CH1 S

22 1 U FS 1: 51.172

C2

De1

4.5469

Ω

2.5845 nH

Ω

280.000 000 MHz

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

1

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

13

Page 14

– TEST CIRCUIT 4 (matched to optimize NF) –

µ

PC8102T

V

CC

75.09

280.000 000 MHz

CH1 S

C2

De1

11

1 U FS 1: 81.02

280 MHz

Ω

1

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

21

CH1 S

C2

De1

log MAG 10 dB/ REF 0 dB 1: 14.087 dB

280.000 000 MHz

1

= 1.0 V , ICC = 0.55 mA

12

Ω

42.682 nH

CH1 S

C2

De1

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

CH1 S

C2

De1

TA = 25 ˚C

log MAG 10 dB/ REF 0 dB 1: –33.561 dB

NF = 2.93 dB

280.000 000 MHz

1

22

1 U FS 1: 56.415

–6.4043Ω67.633 pF

Ω

280.000 000 MHz

1

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

CENTER 280.000 000 MHz SPAN 200.000 000 MHz

14

Page 15

µ

PC8102T

– TEST CIRCUIT 5 (matched with 50

330 MHz

11

CH1 S

C2

De1

CH1 S

C2

De1

1 U FS 1: 57.111

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

21

log MAG 10 dB/ REF 0 dB 1: 14.479 dB

11.426

Ω

1

1

ΩΩ

Ω) –

ΩΩ

V

CC

= 1.0 V , ICC = 0.55 mA

5.5105 nH

Ω

330.000 000 MHz

330.000 000 MHz

12

CH1 S

C2

CH1 S

C2

De1

log MAG 10 dB/ REF 0 dB 1: –30.38 dB

CENTER 330.000 000 MHz

22

1 U FS 1: 60.922

NF = 4.1 dB

1

SPAN 200.000 000 MHz

Ω

– 91.797Ω5.2539 nF

330.000 000 MHz

330.000 000 MHz

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

1

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

15

Page 16

– TEST CIRCUIT 6 (matched to optimize NF) –

330 MHz VCC = 1.00 V , ICC = 0.55 mA NF = 3.14 dB

11

CH1 S

1 U FS 1: 157.77

–17.273Ω27.921 pF

Ω

330.000 000 MHz

CH1 S

12

log MAG 10 dB/ REF 0 dB 1: –30.649 dB

330.000 000 MHz

µ

PC8102T

C2

De1

1

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

21

CH1 S

C2

De1

log MAG 10 dB/ REF 0 dB 1: 11.58 dB

330.000 000 MHz

1

C2

De1

1

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

22

CH1 S

C2

De1

1 U FS 1: 47.793

–6.7441Ω71.512 pF

Ω

330.000 000 MHz

1

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

CENTER 330.000 000 MHz SPAN 200.000 000 MHz

16

Page 17

– TEST CIRCUIT 2 –

IM

+10

0

–10

3

AND OUTPUT LEVEL vs. INPUT LEVEL (150 MHz)

µ

PC8102T

(dBm)

3

3rd order intermodulation distortion IM

–20

P

–30

–40

Output level Pout [dBm]

–50

–60

–70

–80

–70 –60 –50 –40 –30 –20 –10

INPUT LEVEL Pin [dBm]

OUT

IM

3

17

Page 18

6 PIN MINI MOLD PACKAGE DIMENSIONS (Unit: mm)

µ

PC8102T

+0.2

2.8 –0.3

+0.2

123

1.5 –0.1

654

0.95 0.95

2.9 ±0.2

+0.1

0.3 –0.05

1.9

0.8

+0.2

1.1 –0.1

0.13 ±0.1

0 to 0.1

18

Page 19

µ

PC8102T

NOTE ON CORRECT USE

(1) Observe precautions for handling because of electro-static sensitive devices.

(2) Form a ground pattern as wide as possible to minimize ground impedance (to prevent undesired oscillation).

(3) Keep the track length of the ground pins as short as possible.

(4) The bypass capacitor (eg 1 000 pF) should be attached to the V

CC pin.

(5) The matching circuit must be each attached to input and output pins.

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered in the following recommended conditions. Other soldering methods and conditions

than the recommended conditions are to be consulted with our sales representatives.

µ

PC8102T

Soldering process Soldering conditions

Infrared ray reflow Package peak temperature: 235 ˚C, IR35-00-3

Hour: within 30 s. (more than 210 ˚C),

Time: 3 time, Limited days: no.*

VPS Package peak temperature: 215 ˚C, VP15-00-3

Hour: within 40 s. (more than 200 ˚C),

Time: 3 time, Limited days: no.*

Wave Soldering Soldering tub temperature: less than 260 ˚C, Hour: within 10 s. WS60-00-1

Time: 1 time, Limited days: no.*

Pin part heating Pin area temperature: less than 300 ˚C, Hour: within 3 s/pin.

Limited days: no.*

Recommended condition

symbol

* It is the storage days after opening a dry pack, the storage conditions are 25 ˚C, less than 65 % RH.

Note The combined use of soldering method is to be avoided (However, except the pin area heating method).

For details of recommended soldering conditions for surface mounting, refer to information document SEMICON-

DUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL (C10535EJ7V0IF00).

19

Page 20

µ

PC8102T

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

“Standard“, “Special“, and “Specific“. The Specific quality grade applies only to devices developed based on

a customer designated “quality assurance program“ for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in “Standard“ unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

20

M4 94.11

Loading...

Loading...