Page 1

DATA SHEET

BIPOLAR ANALOG INTEGRATED CIRCUIT

µ

PC8100GR

SILICON UP/DOWN CONVERTERS IC

FOR 800 MHz to 900 MHz MOBILE COMMUNICATIONS

DESCRIPTION

µ

PC8100GR is a silicon monolithic integrated circuit designed as up/down converters for 800 MHz to 900 MHz mobile

communications, mainly CT2. This IC consists of upconverter and downconverter, which are packaged in 20 pin SSOP.

Quadrature modulator IC (µPC8101GR) is also available as for kit-use with this IC. So, these pair devices contribute to

make RF block small, high-performance and low power-consumption.

This product is manufactured using NEC’s 20 GHz f

passivation film and gold electrodes. These materials can protect chip surface from external pollution and prevent corrosion

and migration. Thus, this product has excellent performance, uniformity and reliability.

T NESAT

III silicon bipolar process. This process uses silicon nitride

FEATURES

• Operating frequency – fRF = 800 MHz to 900 MHz, fIF = 50 MHz to 150 MHz, fLo = 650 MHz to 1 050 MHz

• Upconverter and downconverter are integrated in 1 chip.

• 20 pin SSOP suitable for high-density surface mounting.

• Wide operating voltage V

• Equipped with Power Save Function.

• Excellent linearity

CC = 2.7 to 4.5 V

APPLICATIONS

• Typical application – Digital cordless phone CT2.

• Further application – Digital cellular, etc.

ORDERING INFORMATION

PART NUMBER PACKAGE SUPPLYING FORM

µ

PC8100GR-E2 20 pin plastic SSOP Embossed tape 12 mm wide. QTY 2.5 kp/Reel.

(225 mil) Pin 1 indicates roll-in direction of tape.

Remark To order evaluation samples, please contact your local NEC sales office. (Order number: µPC8100GR)

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for availability

and additional information.

Document No. P10817EJ3V0DS00 (3rd edition)

Date Published October 1999 N CP(K)

Printed in Japan

Caution electro-static sensitive devices

The mark shows major revised points.

©

1995,1999

Page 2

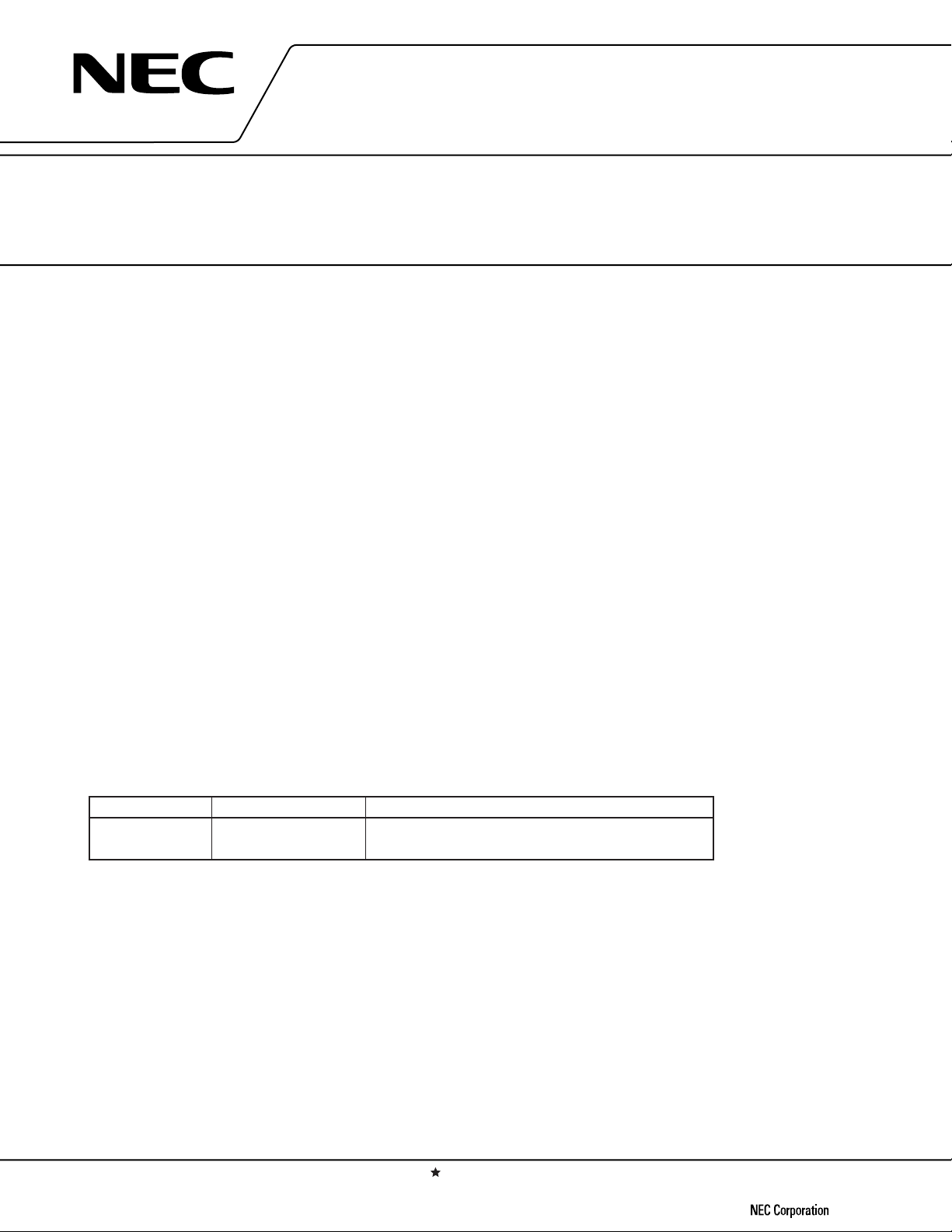

INTERNAL BLOCK DIAGRAM AND PIN CONNECTIONS

µ

PC8100GR

20 19 18 17 16 15 14 13 12 11

REG. REG.

12345678 910

1.

GND

2.

RF BYPASS

3.

RF INPUT

4.

PEAKING OUT

5.

P/S (for DOWN CONV.)

6.

P/S (for UP CONV.)

CC

(for UP CONV.)

7.

V

RF OUTPUT

8.

GND

9.

MIX OUTPUT1

10.

MIX OUTPUT2

11.

GND

12.

IF BYPASS

13.

IF INPUT

14.

OSC INPUT (for UP CONV.)

15.

OSC BYPASS (for UP CONV.)

16.

OSC BYPASS (for DOWN CONV.)

17.

OSC INPUT (for DOWN CONV.)

18.

CC

(for DOWN CONV.)

V

19.

IF OUTPUT

20.

10

(Top View)

1

2

3

4

5

6

7

8

9

20

19

18

17

16

15

14

13

12

11

2

Data Sheet P10817EJ3V0DS00

Page 3

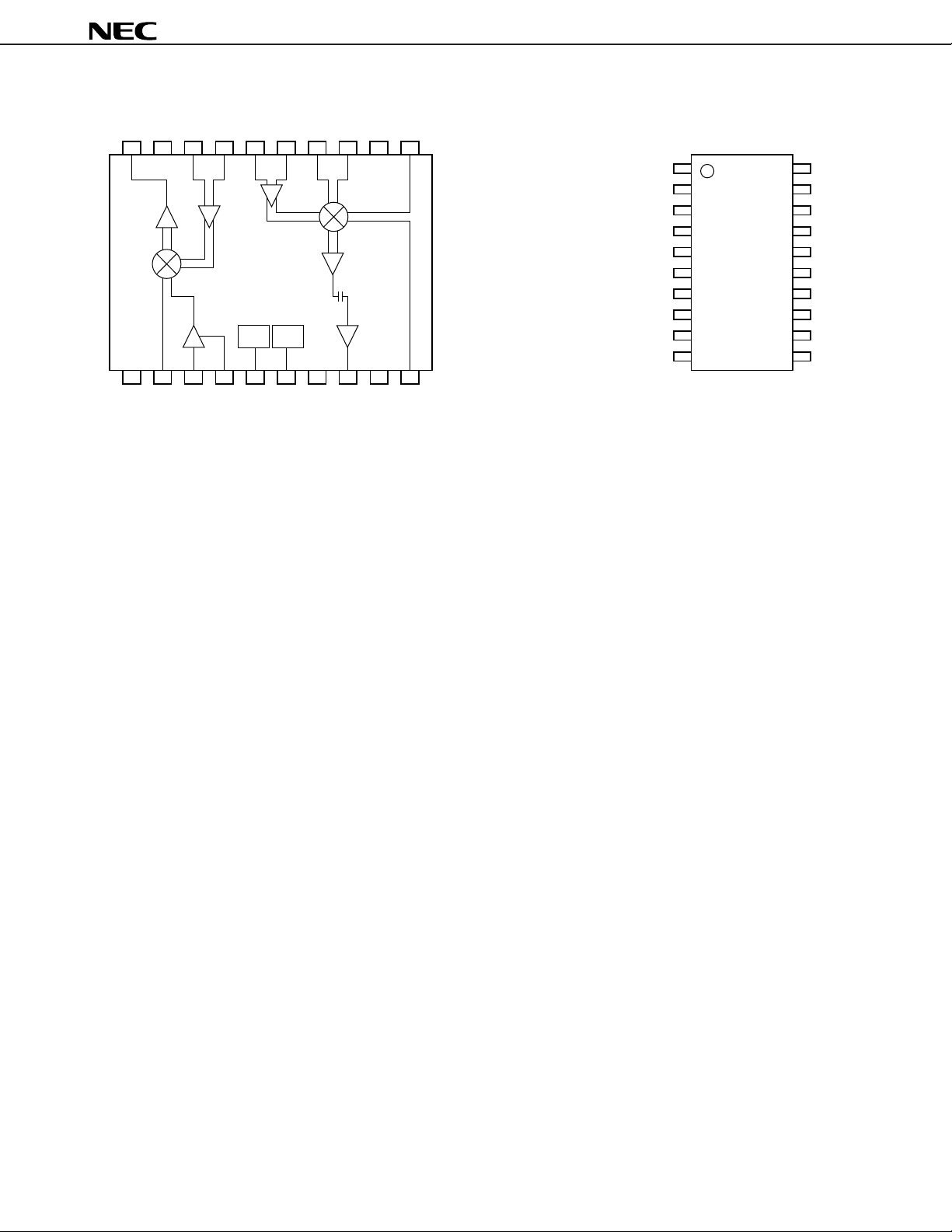

PIN EXPLANATION

µ

PC8100GR

PIN

ASSIGNMENT

NO.

1 GND 0.0 –

2 RF bypass – 1.1

3 RF input – 0.9

4 Peaking out – 0.12

APPLIED

VOLTAGE (V)

PIN VOLTAGE

(V)

FUNCTION AND APPLICATION EQUIVALENT CIRCUIT

Ground for downconverter.

Must be connected to the system ground

with minimum inductance. Ground pattern on the board should be formed as

wide as possible.

(Track length should be kept as short as

possible.)

Bypass of RF input for downconverter.

This pin is RF input for downconverter

designed as double balanced mixer.

This high-impedance input should be

matched with external chip inductor. (eg

4.7 nH).

Open emitter pin of low noise amplifier.

Grounded with capacitor (eg 3 pF) and

register (eg 22 Ω) serially.

REG.

3

4

CC

V

2

REG.

5

Power-save pin

for

downconverter

6

Power-save pin

for

upconverter

7VCC for 2.7 to 4.5 –

upconverter

8 RF output same as –

0 to 4.5 –

0 to 4.5 –

VCC through

intactor

This pin can control downconverter’s

ON/OFF operation with bias as follows;

Bias: V Operation

VPS

This pin can control upconverter’s ON/

OFF operation with bias as follows;

V

PS

Supply voltage for upconverter.

Must be connected bypass capacitor

(e.g 1 000 pF) to minimize ground impedance.

F output from upconverter.

Connect the VCC through inductor (eg 15

nH).

≥1.8 ON

0 to 1.0 OFF

Bias: V Operation

≥1.8 ON

0 to 1.0 OFF

5

6

REG.

or

8

9 GND 0.0 –

Ground for RF amplifier of upconverter.

Data Sheet P10817EJ3V0DS00

3

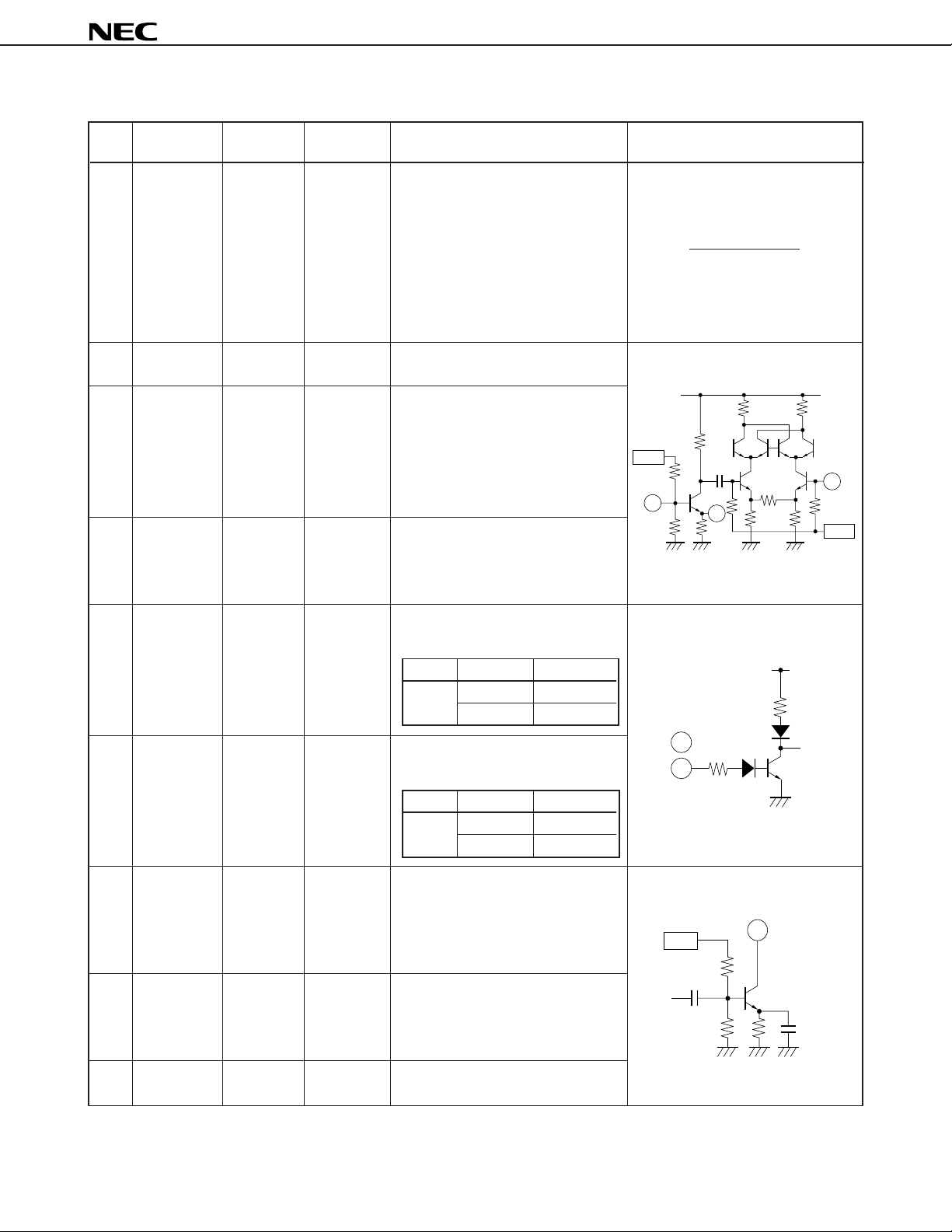

Page 4

PIN EXPLANATION

µ

PC8100GR

PIN

NO. (V)

ASSIGNMENT

10 MIX OUT 1 2.3

11 MIX OUT 2 2.3

12 GND 0*

13 IF bypass 1.03

14 IF input 1.03

PIN VOLTAGE

FUNCTION AND APPLICATION EQUIVALENT CIRCUIT

Mixer output from upconverter.

Mixer output from upconverter.

10 and 11 pins should be externally

equipped with tank circuit of inductor (eg

4.7 nH) and capacitor (eg 3.5 pF).

10 11

Ground for oscillator buffer amplifier and

mixer of upconverter.

Must be connected to the system ground

with minimum inductance. Ground

pattern on the board should be formed

as wide as possible.

(Track length should be kept as short as

possible.)

Bypass of IF input for upconverter.

This pin is IF input for upconverter

designed as double balanced mixer.

This high-impedance input should be

externally equipped with matching circuit

of inductor (eg 220 nH) and capacitor

(eg 1.5 pF).

14

V

CC

13

REG.

15 OSC input 1.8

(for upconverter)

16 OSC bypass 1.8

(for upconverter)

17 OSC bypass 1.85

(for downconverter)

18 OSC input 1.85

(for downconverter)

19 VCC supply for 2.7 to 4.5*

for downconverter

20 IF output 1.45

* Externally supply voltage

Local oscillator input for upconverter. Required for matching with register 51 Ω.

Bypass of local oscillator input for

upconverter.

Bypass of local oscillator input for

downconverter.

Local oscillator input for downconverter. Required for matching with

register 51 Ω.

Supply voltage for downconverter.

It must be connected bypass capacitor

(e.g 1 000 pF) to minimize ground

impedance.

IF output from downconverter.

V

CC

,

1815

,

1716

VCC

20

4

Data Sheet P10817EJ3V0DS00

Page 5

µ

PC8100GR

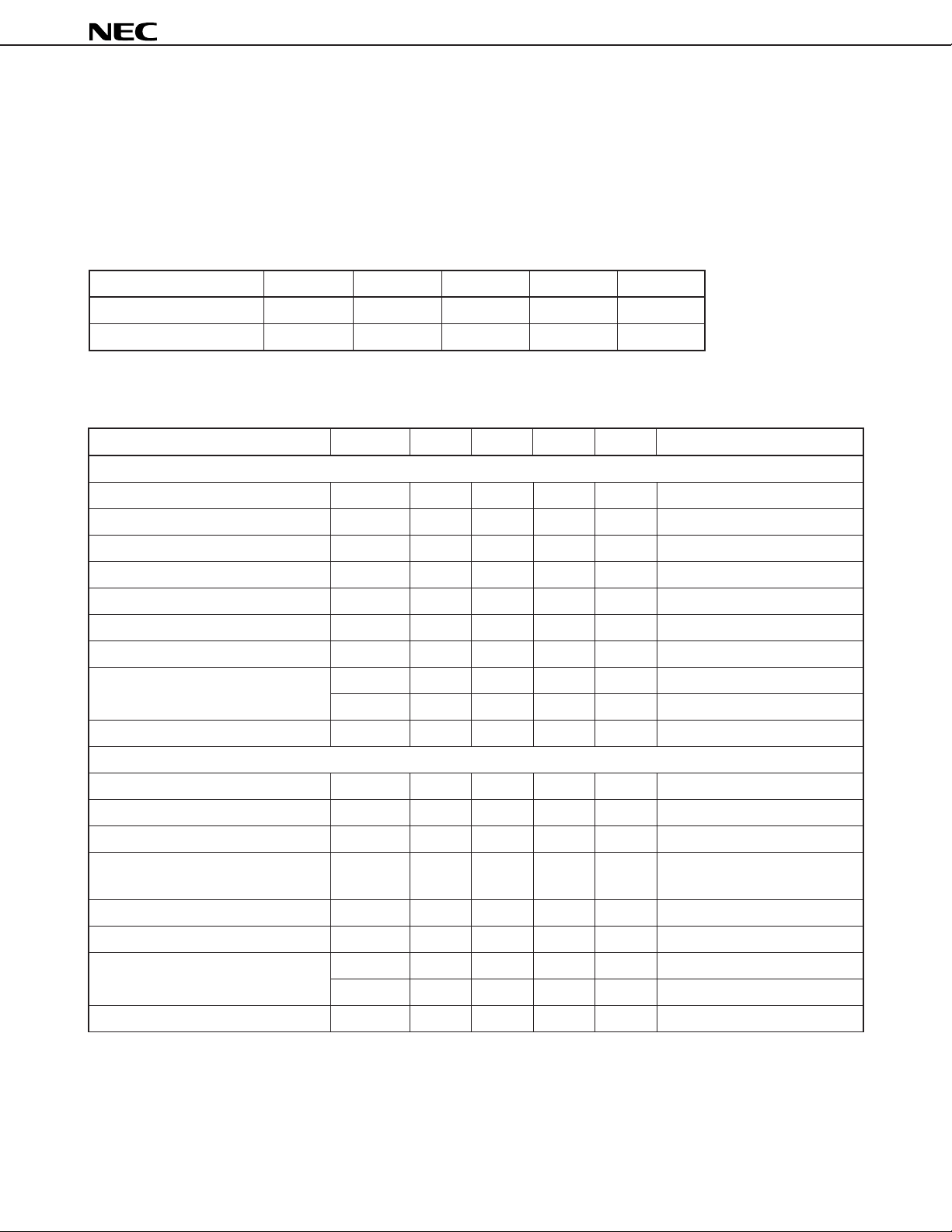

ABSOLUTE MAXIMUM RATINGS

Supply Voltage VCC TA = +25 °C 5.0 V

Power Dissipation P

D Mounted on 50 × 50 × 1.6 mm double copper 530 mW

of package allowance clad epoxy glass board at TA = +70 °C

Operating Temperature Topt –20 to +70 °C

Storage Temperature T

stg –65 to +150 °C

RECOMMENDED OPERATING CONDITIONS

PARAMETERS SYMBOL MIN. TYP. MAX. UNIT

Supply Voltage VCC 2.7 3.0 4.5 V

Operating Temperature Topt –20 +25 +70 °C

ELECTRICAL CHARACTERISTICS (TA = +25 °C, VCC = 2.7 V, ZL = ZS = 50 Ω, unless otherwise specified;

VP/S ≥ 1.8 V)

PARAMETERS SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

UPCONVERTER BLOCK*

1

Circuit current ICC 13.0 25.0 35.0 mA No input signal

Conversion gain CG 17.5 20.5 25.5 dB PIFin = –40 dBm

RF output level PRFout 0 3 dBm PIFin = –10 dBm, 50 Ω load

Noise figure NF 13 18 dB DSB mode

Local leakage at RFout Lorf –25.0 –10.0 dBm PIFin = –10 dBm

IF leakage at RFout IFrf –12.0 –5.0 dBm PIFin = –10 dBm

Circuit current in power-save mode*

Power-save control voltage VP/S(ON) 1.8 4.5 V

Rise up time T up 2.5 5.0

DOWNCONVERTER BLOCK*

Circuit current ICC 8.0 15.0 22.0 mA No input signal

Conversion gain CG 15.0 18.0 23.0 dB PRFin = –40 dBm

IF output level PIFout –4.5 –2.0 dBm PRFin = –10 dBm, 50 Ω load

3rd order intermodulation distortion IM3 –45.0 –49.0 dBc

Noise figure NF 7.5 10 dB DSB mode

Circuit current in power-save mode*

3

ICC(P/S) 220 350

VP/S(OFF) 1.0 V

2

3

ICC(P/S) 220 350

µ

A 6PIN(P/S) ≤ 1.0 V

µ

s

fRFin1 = 866.4 MHz, PRFin1 = –40 dBm

fRFin2 = 866.8 MHz, PRFin2 = –40 dBm

µ

A 5PIN(P/S) ≤ 1.0 V

Power-save control voltage VP/S(ON) 1.8 4.5 V

VP/S(OFF) 1.0 V

Rise up time T up 2.5 5.0

*1 :fIFin = 150.05 MHz, fRFout = 864.05 to 868.05 MHz

fLoin = 1014.10 to 1018.1 MHz (–9 dBm)

*2 :fRFin = 864.05 to 868.05 MHz, fIFout = 150.05 MHz

fLoin = 1014.10 to 1018.1 MHz (–9 dBm)

*3 : Circuit current in power-save mode is total value of upconverter+downconverter

Data Sheet P10817EJ3V0DS00

µ

s

5

Page 6

µ

PC8100GR

STANDARD CHARACTERISTIC FOR REFERENCE (TA = 25 °C, VCC = 2.7 V, ZL = ZS = 50 Ω, unless otherwise

specified; VP/S ≥ 1.8 V)

PARAMETERS SYMBOL REFERENCE UNIT TEST CONDITIONS

UPCONVERTER BLOCK

3rd order intermodulation distortion IM3 –39.0 dBc fIFin1 = 150.4 MHz, PIF1 = –30 dBm

fIFin2 = 150.8 MHz, PIF2 = –30 dBm

DOWNCONVERTER BLOCK

IF output 1 dB compression P1dB –7.0 dBm

Local leakage at IFout Pin Loif –29.0 dBm Pin = –40 dBm

RF leakage at IFout Pin RFif –44.0 dBm Pin = –40 dBm

6

Data Sheet P10817EJ3V0DS00

Page 7

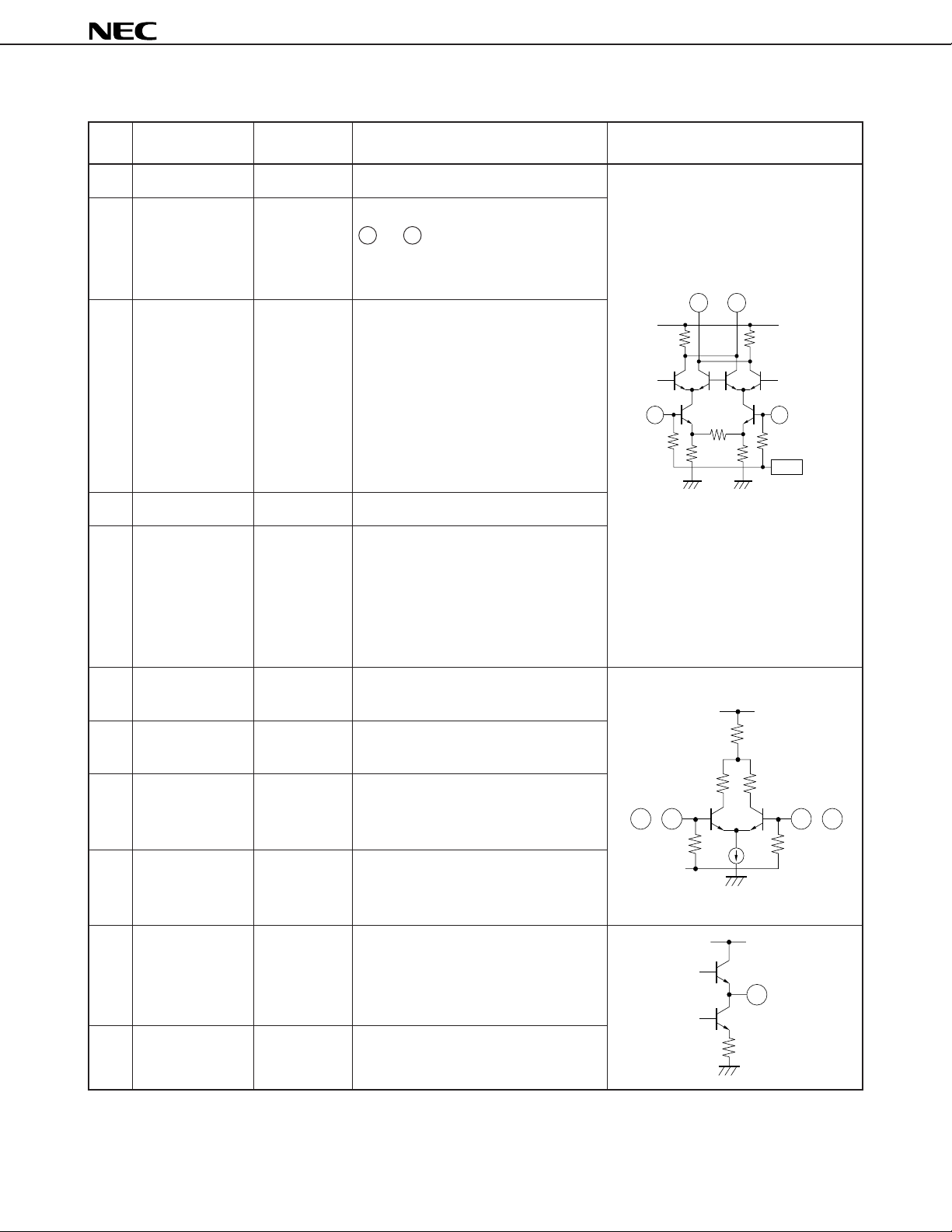

TEST CIRCUIT

Signal

Generator

(LO)

µ

PC8100GR

(IF)

Spectrum Analyzer

50 Ω

120 pF

Signal Generator

51 Ω

51 W

1.5 pF

220 nH

30

1 500 pF

30 pF30 pF30 pF

pF

120 pF120 pF

20 19 18 17 16 15 14 13 12 11

in

out

IF

GND

(D)

(D)

in

CC

V

LO

RFbyRFinPEAKING

(D)

(U)

by

by

LO

LO

PC8100GR

µ

out

P/S (D)

(U)

in

LO

P/S (U)

IF

(U)

CC

V

by

IF

out

RF

GND

GND

out2

MIX

out1

MIX

12345678910

120 pF 120 pF 3 pF

50 Ω

4.7 nH

22 Ω

180 pF

1 500 pF

15 nH

4.7 nH

120 pF

Spectrum Analyzer

50 Ω

(IF)

Signal Generator

50 Ω

4.7 nH

Data Sheet P10817EJ3V0DS00

7

Page 8

TEST CIRCUIT ASSEMBLED ON EVALUATION BOARD

IC MOUNTED SIDE

30 pF

OSC IN

30 pF

NEC

PC8100

µ

120 pF

Trimer condenser

µ

PC8100GR

OSC IN

OSC IN

IF IN

RF IN

RF OUT

120 pF

3 pF

22 Ω

COMPONENT MOUNTED SIDE

51 Ω

30 pF

120 pF

30 pF

120 pF

0 Ω

150 nH

1.5 pF

4.7 nH

IF IN

IF OUT

OSC IN

51 Ω

RF IN

IF OUT

8

120 pF

22 nH

4.7 nF

Data Sheet P10817EJ3V0DS00

4.7 nF

120 pF

RF OUT

Page 9

TYPICAL PERFORMANCE (Unless otherwise specified VCC = 2.7 V Vps ≥ 1.8 V)

– Downconverter block –

µ

PC8100GR

RF input frequency vs. Noise figure

15.0

Vcc = 2.7 V

LO sweep (–9 dBm)

TA = +25 ˚C

A

= +80 ˚C

T

T

A

= –30 ˚C

10.0

Noise Figure NF (dB)

5.0

100 500 1000

RF input frequency f

15.0

RF input frequency vs. Noise figure

Vcc = 4.5 V

LO sweep (–9 dBm)

TA = +25 ˚C

T

A

= +80 ˚C

T

A

= –30 ˚C

10.0

Noise Figure NF (dB)

5.0

100 500 1000

RF input frequency f

RFin

RFin

(MHZ)

(MHZ)

RF input frequency vs. Conversion Gain

20.0

15.0

Vcc = 2.7 V

LO sweep (–9 dBm)

RF sweep (–40 dBm)

Conversion Gain CG (dB)

IF = 150 MH

Z

10.0

100 500 1000

RF input frequency f

25.0

RF input frequency vs. Conversion Gain

20.0

Vcc = 4.5 V

15.0

LO sweep (–9 dBm)

RF sweep (–40 dBm)

Conversion Gain CG (dB)

IF = 150 MH

Z

10.0

100 500 1000

RF input frequency f

TA = +25 ˚C

T

T

RFin

(MHZ)

TA = +25 ˚C

T

T

RFin

(MHZ)

A

= +80 ˚C

A

= –30 ˚C

A

= +80 ˚C

A

= –30 ˚C

RF input level vs. IF output level and IM

10

(dBm)

3

0

–10

–20

–30

, 3rd order distortion IM

–40

out

RF

–50

–60

–70

IF output level P

–80

–40

–30 –20 –10 0 10

RF input level P

3

Vcc = 2.7 V

1

= 866.4 MH

RF

RF2 = 866.8 MH

Z

Z

LO = 1016 MHZ (–9 dBm)

TA = +25 ˚C

T

A

= +80 ˚C

A

= –30 ˚C

T

RFin

(dBm)

25

Vcc = 2.7 V

RF = 866 MH

LO = 1016 MH

20

15

Conversion Gain CG (dB)

10

5

–27

Data Sheet P10817EJ3V0DS00

LO input level vs. Conversion Gain

Z

(– 40 dBm)

Z

(– 9 dBm)

TA = +25 ˚C

T

A

= +80 ˚C

A

= –30 ˚C

T

–24 –21 –18 –15 –12 –9 –6 –3 0

LO input level P

LOin

(dBm)

9

Page 10

– Downconverter block –

µ

PC8100GR

RF input level vs. IF output level and IM

10

0

(dBm)

3

–10

–20

–30

Vcc = 4.5 V

–40

1

= 866.4 MH

RF

RF2 = 866.8 MH

–50

LO = 1016 MHZ (– 9 dBm)

–60

–70

IF output level 3rd order distortion IM

–80

–40 –30 –20 –10 0 10

RF input level P

RFin

(dBm)

P/S control voltage vs. Circuit Current

30.0

Vcc = 2.7 V

25.0

Z

Z

TA = +25 ˚C

TA = +80 ˚C

TA = –30 ˚C

3

LO input level vs. Conversion Gain

25

20

15

Vcc = 4.5 V

RF = 866 MHZ (–40 dBm)

Conversion Gain CG (dB)

10

LO = 1016 MHZ (–9 dBm)

TA = +25 ˚C

TA = +80 ˚C

TA = –30 ˚C

5

–27 –24 –21 –18

–15 –12 –9 –6 –3 0

LO input level P

LOin

(dBm)

P/S control voltage vs. Circuit Current

30.0

Vcc = 4.5 V

25.0

20.0

15.0

10.0

Circuit Current Icc (mA)

5.0

0

Power-save-control voltage V

Supply voltage vs. Circuit Current

50

Vcc = V

P/S

40

TA = +25 ˚C

TA = +80 ˚C

30

TA = –30 ˚C

20

TA = +25 ˚C

TA = +80 ˚C

TA = –30 ˚C

4.03.02.01.00

P/S

5.0

20.0

15.0

10.0

Circuit Current Icc (mA)

5.0

0

Power-save-control voltage V

TA = +25 ˚C

TA = +80 ˚C

TA = –30 ˚C

4.03.02.01.00

P/S

5.0

Circuit Current Icc (mA)

10

0

10

2.7 4.5

Supply Voltage Vcc (V)

4.03.02.01.00

Data Sheet P10817EJ3V0DS00

5.0

Page 11

– Upconverter block –

)

)

µ

PC8100GR

F input level vs. RF outpint level and IM

10

0

(dBm)

3

–10

–20

–30

–40

–50

Vcc = 2.7 V

IF

1

= 150.4 MH

IF2 = 150.8 MH

LO = 1016 MHZ (– 9 dBm)

–60

RFin

(dBm)

TA = +25 ˚C

TA = +80 ˚C

TA = –30 ˚C

3

–70

RF output level 3rd order distortion IM

–80

–40 –30 –20 –10 0 10

IF input level P

Pin - Pout, IM

10

0

(dBm)

3

–10

–20

3

LC input level vs. Conversion Gain

25

20

15

Z

Z

10

Conversion Gain CG (dB)

Vcc = 2.7 V

IF = 150 MHZ (–40 dBm)

LO = 1016 MH

Z

TA = +25 ˚C

TA = +80 ˚C

LOin

(dBm)

TA = –30 ˚C

5

–27

–24 –21 –18 –15 –12 –9 –6 –3 0

LO input level P

LO input level - CG

25

20

–30

–40

–50

Vcc = 4.5 V

IF

1

= 150.4 MH

IF2 = 150.8 MH

LO = 1016 MHZ (–9 dBm)

–60

RFin

(dBm

TA = +25 ˚C

TA = +80 ˚C

TA = –30 ˚C

–70

RF output level 3rd order distortion IM

–80

–40 –30 –20 –10 0 10

IF input level P

15

Z

Z

10

Conversion Gain CG (dB)

Vcc = 2.7 V

IF = 150 MHZ (–40 dBm)

LO = 1016 MH

Z

TA = +25 ˚C

TA = +80 ˚C

LOin

(dBm

TA = –30 ˚C

5

–27

–24 –21 –18 –15 –12 –9 –6 –3 0

LO input level P

Data Sheet P10817EJ3V0DS00

11

Page 12

– Downconverter block –

µ

PC8100GR

P/S control voltage vs. Circuit Current

50

Vcc = 2.7 V

No input signal

40

30

20

Circuit Current Icc (mA)

10

0

Power-save-control voltage V

Supply voltage vs. Circuit Current

50

Vcc = V

P/S

No input signal

40

TA = +25 ˚C

T

A

= +80 ˚C

T

A

30

= –30 ˚C

TA = +25 ˚C

A

= +80 ˚C

T

T

A

= –30 ˚C

4.03.02.01.00

P/S

5.0

P/S control voltage vs. Circuit Current

50

40

30

20

Circuit Current Icc (mA)

10

0

Power-save control voltage V

Vcc = 4.5 V

No input signal

TA = +25 ˚C

A

= +80 ˚C

T

T

A

= –30 ˚C

4.03.02.01.00

P/S

5.0

20

Circuit Current Icc (mA)

10

0

Supply Voltage Vcc (V)

Recommended

operating range

2.7 4.5

4.03.02.01.00

5.0

12

Data Sheet P10817EJ3V0DS00

Page 13

TYPICAL APPLICATION

CT2 BLOCK DIAGRAM

µ

PC8100GR

RX

PLL

SW

µ

PG131GR

0°

TX

µ

PC8100GR

The application circuits and their parameters are for references only and are not intended for use in actual design-in's.

F/F

90°

µ

PC8101GR

DEMO

PLL

I

Q

I

Q

Data Sheet P10817EJ3V0DS00

13

Page 14

PACKAGE DIMENSIONS

20 PIN PLASTIC SSOP (225 mil) (UNIT: mm)

µ

PC8100GR

20

11

110

6.7 ± 0.3

1.8 MAX.

1.5 ± 0.1

detail of lead end

3˚

6.4 ± 0.2

4.4 ± 0.1

+7˚

–3˚

1.0 ± 0.2

0.5 ± 0.2

0.65

0.22

+0.10

–0.05

0.10

0.15

M

0.575 MAX.

0.15

+0.10

–0.05

0.1 ± 0.1

NOTE Each lead centerline is located within 0.10 mm of its true position (T.P.) at maximum material condition.

14

Data Sheet P10817EJ3V0DS00

Page 15

µ

PC8100GR

NOTE ON CORRECT USE

(1) Observe precautions for handling because of electrostatic sensitive devices.

(2) Form a ground pattern as wide as possible to minimize ground impedance (to prevent undesired oscillation).

(3) Keep the track length of the ground pins as short as possible.

(4) Connect a bypass capacitor (e.g. 1 000 pF) to the V

CC pin.

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered in the following recommended conditions. Other soldering method and conditions than

the recommended conditions are to be consulted with our sales representatives.

µ

PC8100GR

Soldering

process

Infrared ray reflow

VPS

Wave soldering

Partial heating method

Peak package’s surface temperature: 235 °C or below,

Reflow time: 30 seconds or below (210 °C or higher),

Number of reflow process: 2, Exposure limit*: None

Peak package’s surface temperature: 215 °C or below,

Reflow time: 40 seconds or below (200 °C or higher),

Number of reflow process: 2, Exposure limit*: None

Solder temperature: 260 °C or below,

Flow time: 10 seconds or below

Number of flow process: 1, Exposure limit*: None

Terminal temperature: 300 °C or below,

Flow time: 10 seconds or below,

Exposure limit*: None

Soldering conditions

*: Exposure limit before soldering after dry-pack package is opened.

Storage conditions: 25 °C and relative humidity at 65 % or less.

Note: Apply only a single process at once, except for “Partial heating method”.

For details of recommended soldering conditions for surface mounting, refer to information document SEMICONDUCTOR

DEVICE MOUNTING TECHNOLOGY MANUAL (C10535E).

Symbol

IR35–00-2

VP15–00-2

WS60–00-1

Data Sheet P10817EJ3V0DS00

15

Page 16

µ

PC8100GR

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

NESAT (NEC Silicon Advanced Technology) is a trademark of NEC Corporation.

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights

or other intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated “quality assurance program“ for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98.8

Loading...

Loading...