Page 1

Double plate sensor UDCM-30GM-085-3E3

Technical data

General specifications

Sensing range 50 ... 150 mm , optimal distance: 80 mm

Transducer frequency 85 kHz

Indicators/operating means

LED green indication: single sheet metal detected

LED yellow Indication: No sheet metal detected (Air)

LED red indication: double sheet metal detected

Electrical specifications

Model Number

UDCM-30GM-085-3E3

Features

• Ultrasonic system for reliable

detection of no, one, or two

overlapping sheet materials,

preferably sheet metal

• No TEACH-IN required

• Insensitive to printing, colors, and

shining surfaces

• Programmable

Operating voltage U

No-load supply current I

Time delay before availability t

Input

Input type Function input

Pulse length ≥ 100 ms

Function in normal operation mode, the function input has to be

Impedance ≥ 4 kΩ

Output

Output type 3 switch outputs PNP, NC

Rated operating current I

Voltage drop U

Switch-on delay t

Switch-off delay t

Pulse extension min. 120 ms programmable

Ambient conditions

Ambient temperature 0 ... 50 °C (32 ... 122 °F)

Storage temperature -40 ... 70 °C (-40 ... 158 °F)

Mechanical specifications

Connection type cable PVC , 2 m

Core cross-section 0.14 mm

Degree of protection IP65

Material

Housing nickel plated brass; plastic components: PBT

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Mass 300 g

General information

Supplementary information Switch settings of the external programming adapter:

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose, Class 2 Power Source

CSA approval cCSAus Listed, General Purpose, Class 2 Power Source

CCC approval CCC approval / marking not required for products rated ≤36 V

B

0

v

e

d

on

off

18 ... 30 V DC , ripple 10 %

< 200 mA

< 500 ms

0-level: -U

1-level: +U

connected with UB+ or UB-

3 x 100 mA , short-circuit/overload protected

≤ 3 V

approx. 30 ms

approx. 30 ms

"output load": pull-down

"output logic": inv

IEC 60947-5-2:2007 + A1:2012

... -UB + 1V

B

- 1 V ... +U

B

2

SS

B

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193142_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Page 2

Double plate sensor UDCM-30GM-085-3E3

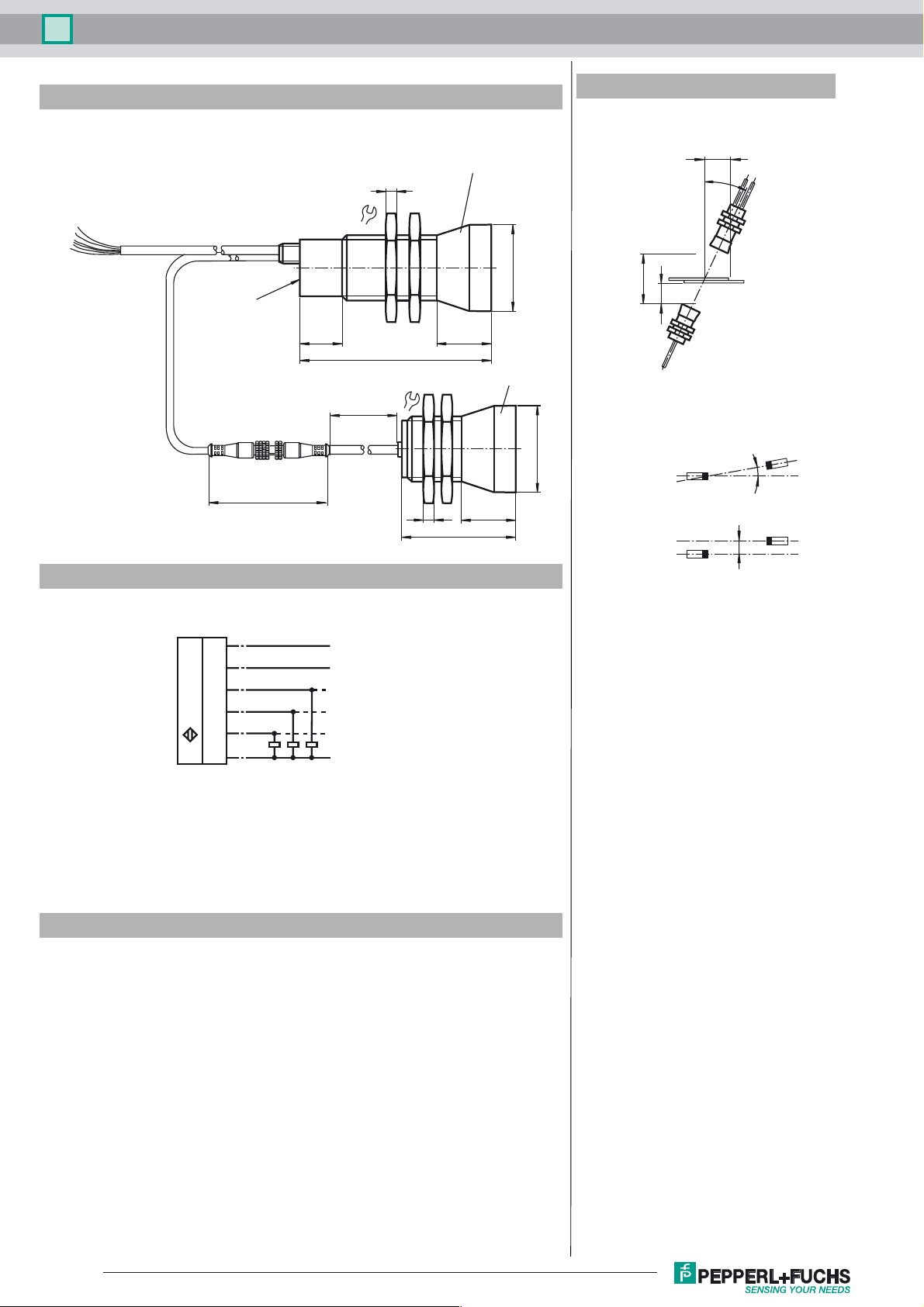

Dimensions

wires 70 mm with

wire end ferrules

l = 2 m

l = 0.5 m

LEDs

ø 15

70

Evaluation unit with

receiver unit

5

36

22 25

88

36

0.5 m

5

52

ø 40

Emitter unit

25

Additional Information

Mounting/Adjustment

Recommended distances

a = 20 ... 30 mm

b ≥ 75 mm

d = 50 ... 150 mm

β = 20 ... 30°

Angular misalignment

ø 40

< +/- 1°

α

Sensor offset

s < +/- 1 mm

b

β

d

a

α

s

Electrical Connection

(BN)

(PK)

(WH)

(BK)

U

(GY)

(BU)

Accessories

UC-PROG1-USB

Programming adapter

MH-UDB02

Mounting bracket for double sheet metal monitor

UDB-Cable-2M

+U

B

-U

B

UDB-Cable-1M

V15S-G-0,3M-PUR-WAGO

Male cordset, M12, 5-pin, PUR cable with WAGO terminals

Ultraschall-Sensoren DTM

DTM devices for communication with cube style and UMC... sensors

PACTware 4.1

FDT Framework

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193142_eng.xml

Page 3

Double plate sensor UDCM-30GM-085-3E3

Description of sensor functions

The ultrasonic double-sheet monitor is deployed in all situations in which the automatic distinction between single and double sheets

is required in order to protect machines or avoid waste production. The double-sheet monitor is based on the ultrasonic through-beam

principle. The following can be detected:

- no sheet, i.e. air,

- single sheets

- double sheets or multiple sheets

A microprocessor system evaluates the signals. The appropriate switch outputs are set as a result of the evaluation. Changes in ambient conditions such as temperature and humidity are compensated for automatically. The evaluation electronics are integrated into

an evaluation unit together with a sensor head in a compact M30 metal housing.

Electrical connection

The sensor is equipped with 6 connections. The functionality of the connections is described in the following table. The function input

(PK) is used to assign parameters to the sensor. (see Output pulse extension, Alignment aid and Program selection). During normal

operation, the function input must always be securely connected with +U

ality.

Color Switching on Comments

BN +U

WH Switch output for single sheets Pulse width corresponds to the event

BK Switch output for double sheets Pulse width corresponds to the event

GY Switch output for air Pulse width corresponds to the event

PK -U

BU -UB

B

B

/+U

B

Function input for parameter assignment/

pulse prolongation

or -UB to avoid possible interference or improper function-

B

Normal mode

The sensor is working in normal mode if the function input (PK) is applied to -UB or +UB when the power source (Power-On) is supplied,

as shown in the output pulse extension table (see below).

Displays:

LED yellow: Detection of air

LED green: Detection of single sheets

LED red: Detection of double sheets

Switch outputs:

The switch outputs are only active in normal mode!

White: WH Single sheet output

Black: BK Double sheet output

Gray: GY Air output

Output pulse extension

Switching the function input (PK) on to -UB or +UB makes it possible to select a minimum pulse width of 120 ms for all output pulses of

the three switch outputs.

Switching on (PK) Operating behavior (after Power-On)

-U

B

+U

B

Please note:

This can result in a condition in which more than one switch output is switched through!

Display mode

The selected parameter assignment of the sensor can be displayed by switching the function input (PK) to voltage-free during normal

operation. The green LED displays the program number (the number of flashing pulses (1..4) = the program number).

The outputs are inactive during this time.

If the function input (PK) is switched to voltage-free when power is supplied (Power-On), the sensor will also work in display mode.

If the function input (PK) is switched to voltage-free during operation due to an error (broken cable, coming loose because of vibration),

the display mode acts as a fault display.

No output pulse extension for switch outputs

Output pulse extension of all switch outputs to at least 120 ms

Parameter assignment

The sensor is equipped with 4 programs for different ranges of application. This makes it possible to work with a wide range of materials. The user can select the program best suited for a specific application.

The default setting, Program 1, is designed so that no change in the setting is required for most applications.

Programs

Program number Notes*

1 Default setting. Covers a wide spectrum of materials

2 Thick, heavy sheets

3 Thin sheets

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193142_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4 Thin fine sheet metal, metal foils

3

Page 4

Double plate sensor UDCM-30GM-085-3E3

The specified intended uses of program 1 ... 4 show orientation values for the user. In specific individual cases, the appropriate program

to be selected for the respective material used must be empirically determined. The starting point here should be standard program 1.

Procedure for assigning parameters

It is possible to switch to additional parameter assignment modes from the display mode:

Alignment mode -->

Program selection mode -->

Alignment aid mode --> (for checking)

When the function input (PK) is applied to -U

ing on function input (PK) to +U

(for > 500 ms) selects the next program level.

B

Disconnecting the power supply causes the system to exit the current mode with the selected program change.

The switch outputs are not active while parameters are being assigned to the sensor!

(for > 500 ms), the mode changes. When the "Program selection“ mode is active, switch-

B

... and function input (PK)

Power ON Normal mode

... and function input

(PK) unconnected

connected to +U

Indication mode

-U

B

Alignment aid

(yellow LED)

+U

B

no function toggle cyclically

B

or -U

-U

B

Indication mode

B

Program select

(green LED)

+U

B

next program

-U

B

Function input

(PK) unconnected

activate/deactivate

+U

B

output pulse

prolongation

Modes

Amplitude control

During installation, the amplitude control can be used to check whether the ultrasonic amplitude at the receiver is sufficient. If the transmitter is not aligned properly in relation to the receiver, maximum sound energy is not transmitted to the receiver, which may result in

the incorrect detection of materials.

When the sensor detects an area of air (yellow LED lights up), the UDC begins to display the strength of the measured amplitude signal:

- if the signal is weak, the yellow LED flashes at low frequency

- the flashing frequency increases in line with the signal strength

- the yellow LED lights up continuously when the signal strength is sufficient.

The single sheet function (green LED) and double sheet function (red LED) are now active. This can be used to check the correct

function of the sensor.

Program selection

In the program selection mode, the current program is displayed by the green LED (number of flashing pulses = program number).

Applying the adjustment input (PK) to +U

(for > 500 ms) causes the next program to be selected in cyclic sequence (program 1 follows

B

through to program 4).

Notes:

A complete device consists of an ultrasonic emitter and an evaluation unit with an ultrasonic receiver. The sensor heads are optimally

adjusted to each other when they leave the factory. Therefore, they must not be used separately or exchanged with other devices of

the same type. The plug connector on the emitter/receiver connection cable is only intended to be used for easier mounting, not to

replace units.

During installation, ensure that the ultrasonic signal cannot bypass the material being detected through multiple reflections. This can

happen if, for example, large surfaces for sound reflection exist transverse to the direction of sound transmission. This can be caused

by the use of unsuitable holding devices or large-surface system components. In the case of reflective system components, they must

be covered with sound-absorbing material or a different installation site must be chosen.

To ensure problem-free detection of double sheets, an air gap is required between the sheets. This prerequisite might not be met in

cases where two sheets adhere to each other by means of an oil film, thus resulting in the detection of a single sheet only.

If two or more UDCM double sheet controls are used in the immediate vicinity of each other, there may be mutual interference between

them, which can result in improper functionality of the devices. Mutual interference can be prevented by introducing suitable countermeasures when planning systems.

Parameterization using PA C Twa r e DTM

The double sheet sensor can be connected using a V15S-G-0.3M-PUR-WAGO terminal adapter.

M12 socket for

the UC-PROG1

V15S-G-0.3M-PUR-WAGO

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193142_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Connection cable for

the double sheet sensor

4

Page 5

Double plate sensor UDCM-30GM-085-3E3

Connect the sensor to the terminal adapter according to the table below.

Terminal adapter wire color Sensor cable wire color

Brown Brown

Blue Blue

Black Black

Gray Pink

The sensor features a time lock. If no communication request occurs, the time lock blocks parameterization of the sensor 30 seconds

after the supply voltage is connected. Start PACTware before switching on the sensor so that the communication request can be made

in time.

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193142_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

5

Loading...

Loading...