Page 1

Ultrasonic sensor UB2000-F42S-E6-V15

Technical data

General specifications

Sensing range 60 ... 2000 mm

Adjustment range 90 ... 2000 mm

Dead band 0 ... 60 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 175 kHz

Response delay approx. 150 ms

Indicators/operating means

LED green solid green: Power on

Model Number

UB2000-F42S-E6-V15

Single head system

Features

• 2 independent switch outputs

• Extremely small unusable area

• TEACH-IN

• Interference suppression (adjustable divergence of sound cone in

close range)

• Temperature compensation

• Synchronization options

• NO/NC selectable

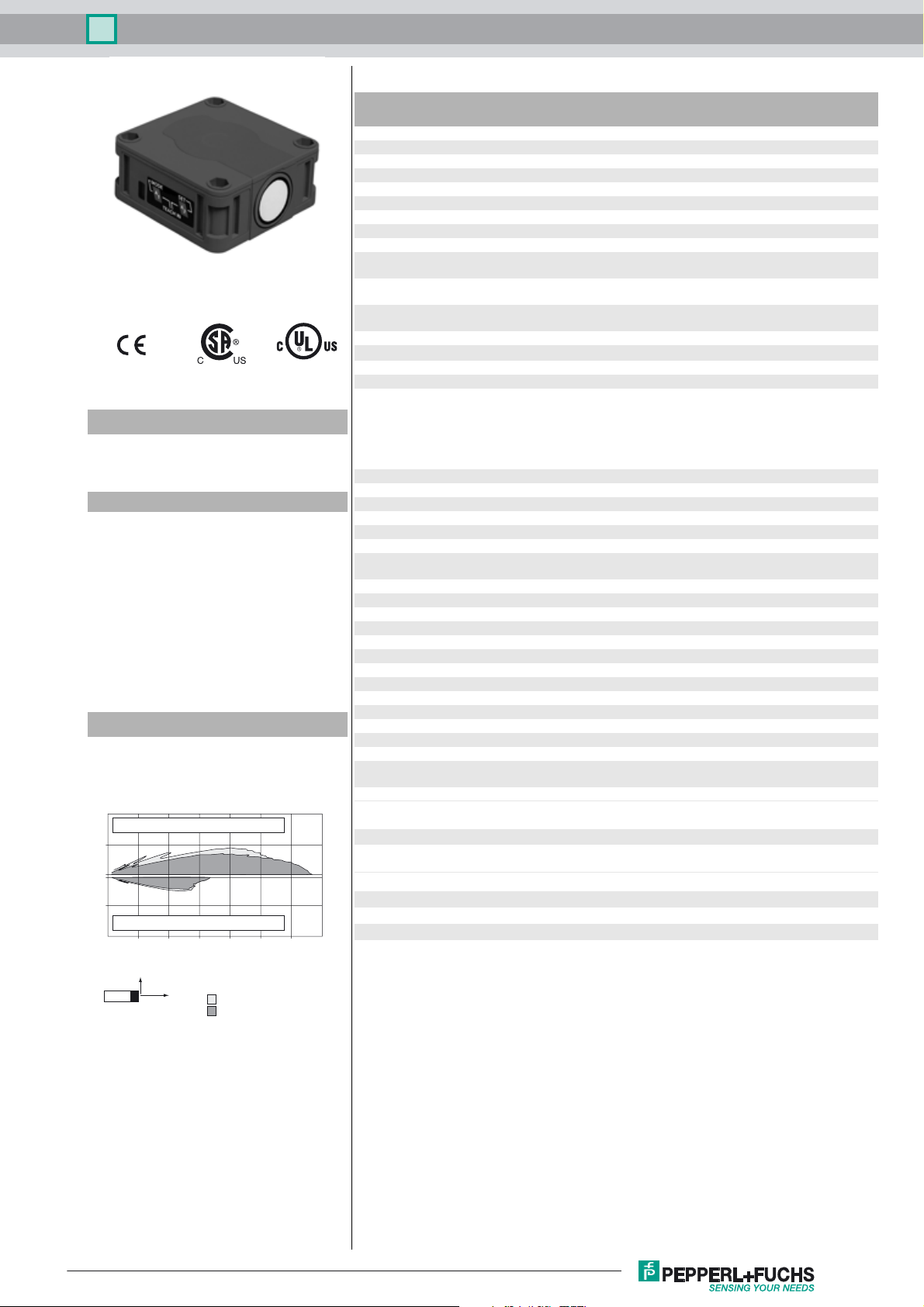

Diagrams

Characteristic response curve

Distance Y [m]

1

Flat surface 100 mm x 100 mm

0.5

0

-0.5

Round bar, Ø 25 mm

-1

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

Y

X

wide sonic beam

narrow sonic beam

Distance X [m]

LED yellow 1 solid: switching state switch output 1

LED yellow 2 solid: switching state switch output 2

LED red normal operation: "fault"

Electrical specifications

Operating voltage U

No-load supply current I

Input/Output

Synchronization bi-directional

Synchronization frequency

Common mode operation ≤ 30 Hz

Multiplex operation ≤ 30/n Hz, n = number of sensors

Output

Output type 2 switch outputs PNP, NO/NC selectable

Rated operating current I

Default setting Switch point A1: 90 mm , Switch point A2: 2000 mm , wide

Voltage drop U

Repeat accuracy ≤ 0.5 % of switching point

Switching frequency f ≤ 2.7 Hz

Range hysteresis H 1 % of the set operating distance

Temperature influence ± 1 % of full-scale value

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector M12 x 1 , 5-pin

Degree of protection IP54

Material

Housing ABS

Transducer epoxy resin/hollow glass sphere mixture; foam

Mass 140 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated

B

0

e

d

flashing: program function

flashing: program function

program function: no object detected

10 ... 30 V DC , ripple 10 %

≤ 50 mA

0 level -U

1 level: +4 V...+U

input impedance: > 12 KOhm

synchronization pulse: ≥ 100 µs, synchronization interpulse

period: ≥ 2 ms

200 mA , short-circuit/overload protected

sound lobe

≤ 2.5 V

polyurethane, cover PBT

IEC 60947-5-2:2007 + A1:2012

≤36 V

...+1 V

B

B

SS

Release date: 2016-02-26 11:31 Date of issue: 2016-02-26 133995_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Page 2

Ultrasonic sensor UB2000-F42S-E6-V15

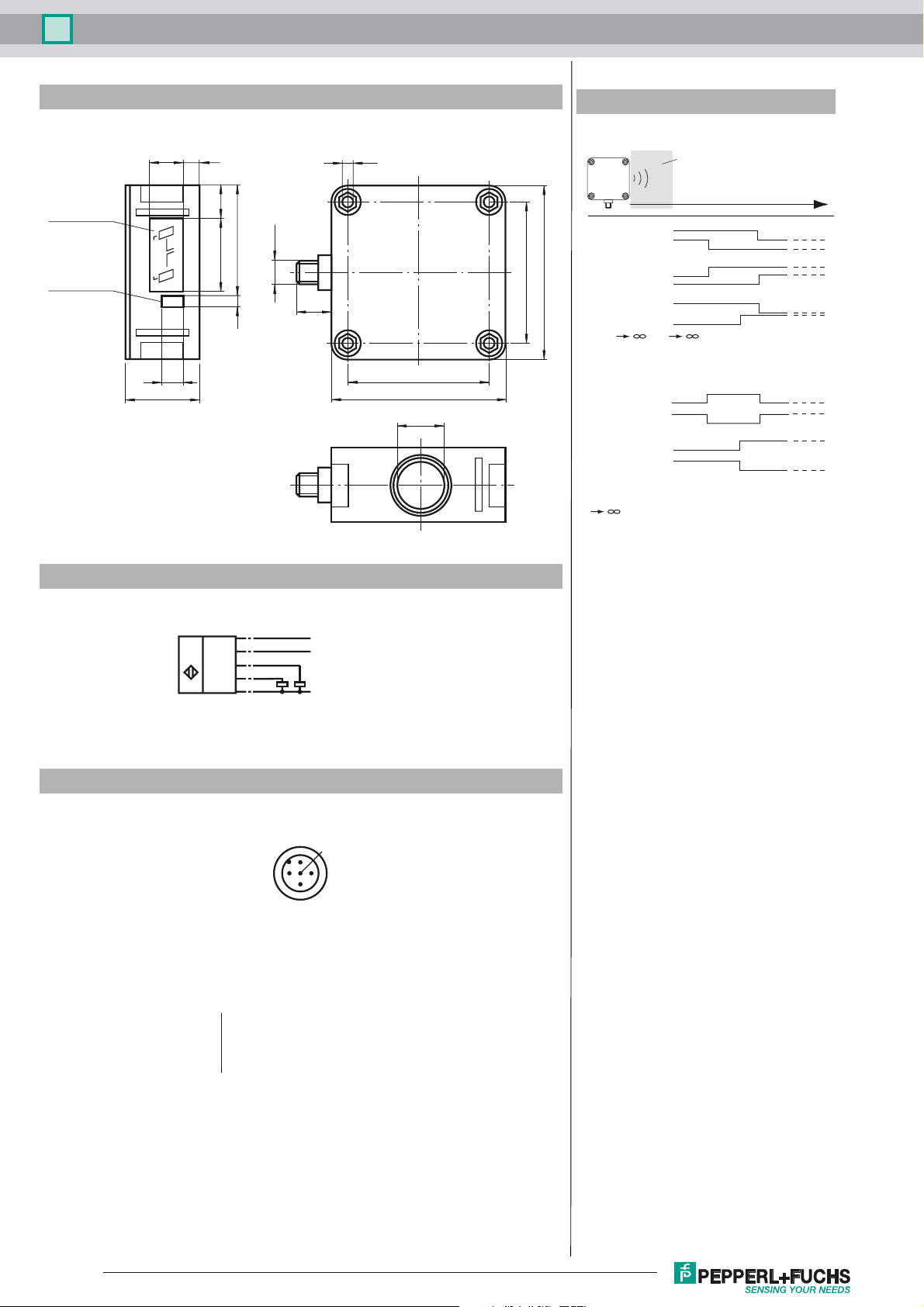

Dimensions

Membrane keys

LED window

Additional Information

Switching output programmation

7.5

15

15.5

2

A

TEACH IN

1

MODE SET

A

10

34

52.5

34

M12x1

5

16

5.2

Unusable area

Object distance

Mode 1:

output 1

output 2

Mode 2:

80

65

65

80

22

output 1

output 2

Mode 3:

output 1

output 2

A1 , A2 : Object presence detection.

Both outputs operate according to the selected mode,

if an object is located within the detection range.

Window and Switching point:

output 1

output 1

output 2

output 2

Note:

means: cover transducer surface with your hand,

while programming the output.

If A1 = A2, the output work like A1 < A2

A2

A1

A2

A2

A3

A3

A1

A2

A1

A2A1

A1

prog. with A1 key

prog. with A2 key

Electrical Connection

Standard symbol/Connections:

(version E6, pnp)

U

Core colours in accordance with EN 60947-5-2.

Pinout

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

5 GY

(BN)

1

(GY)

5

(BK)

4

(WH)

2

(BU)

3

2

+ U

B

Sync.

Switch output 1

Switch output 2

- U

B

1

5

4

3

(brown)

(white)

(blue)

(black)

(gray)

Release date: 2016-02-26 11:31 Date of issue: 2016-02-26 133995_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Page 3

Ultrasonic sensor UB2000-F42S-E6-V15

Accessories

MH 04-3505

Mounting aid for FP and F42 sensors

MHW 11

Mounting brackets for sensors

V15-G-2M-PVC

Female cordset, M12, 5-pin, PVC cable

Functional description

The sensor can be completely parameterised using 2 keys on the side of the housing. One special feature of this sensor is the

option of adapting the ultrasonic beam width to the ambient conditions at the place where the sensor is used.

Teach-in of switching points:

Teach-in of switching points is used to determine the points at which the switching outputs will change their state. In addition,

the order of switching points A1 < A2, or A1 > A2 also determines the effective direction (normally closed/open function) of the

window in the output function (operating mode) "Window + Switching point“ (see below).

Teach-in of switching point A1 with key A1

Press key A1 > 2 seconds The sensor goes into learning mode for switching point

Position the target object at

the desired distance

Press key A1 briefly The sensor completes the Teach-in process for switch-

A1

The sensor indicates by rapid flashing of the yellow

LED that the target object has been detected. If no object is detected, the red LED flashes.

ing point A1 and stores the value in permanent memory. If the object is uncertain (red LED lit irregularly) the

Teach-in value is not valid. Teach-in mode closes.

The process for Teach-in of switching point A2 is similar to what was described above, using key A2.

Special feature for output function "Window + switching point“

In the case of the output function (operating mode) "Window + switching point“ (see below), switching points A1 and A2 define

the window limits of switch output 1.

A third switching point A3 can also be defined here at which switch output 2 switches.

Teach-in of switching point A3 with keys A1 and A2

(only for operating mode window + switching point, see below)

Press key A1 + A2 > 2 seconds

Position the target object at

the desired distance

Press key A1 briefly

(output 2: normally closed)

or

Press key A2 briefly

(output 2: normally open)

The sensor goes into learning mode for switching point

A3

The sensor indicates by rapid flashing of the yellow

LEDs that the target object has been detected. If no object is detected, the red LED flashes.

The sensor completes the Teach-in process for switching point A3 and stores the value in permanent memory.

If the object is uncertain (red LED lit irregularly) the

Teach-in value is not valid. Teach-in mode closes.

Teach-in for switching points can only be performed within the first 5 minutes after turning on the power supply. If the switching

points need to be changed at a later time, this cannot be done until there is a new Power On.

Parameter assignment of the output function and ultrasound beam width

If you press the A1 key while the power supply is being turned on and then hold it down for 1 second, the sensor goes into the

two-level parameterisation of operating modes.

Level 1, parametrisation of the output function

Pressing the A2 key briefly will cause the possible output functions to be selected one after the other (depending on the last

output function to be parameterised). The functions are indicated by a flashing sequence of the green LED.

Release date: 2016-02-26 11:31 Date of issue: 2016-02-26 133995_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Page 4

Ultrasonic sensor UB2000-F42S-E6-V15

Operating mode Flashing sequence of green LED A2 key

2 x normally open function

(default)

2 x normally closed function

2 switching points

n.o. (output 1) +

n.c. (output 2)

Window (output 1) +

switching point (output 2)

Pause

Pause

Paus e

Paus e

Pressing the A1 key for 2 seconds saves the selected output operating mode. The parameter assignment process is then complete and the sensor returns to normal mode. If you press the A1 key briefly instead, you go to Level 2 (parameter assignment

of ultrasonic beam range).

Level 2, parameter assignment of ultrasonic beam width

The ultrasonic beam width can be adjusted to match the requirements of the application in Level 2.

Pressing the A2 key briefly will cause the possible beam widths to be selected one after the other (depending on the last beam

width to be parameterised). The functions are indicated by a flashing sequence of the red LED.

Beam width Flashing sequence of red LED A2 key

Narrow beam width

Average beam width

Pause

Pause

Wide beam

(default)

Paus e

Pressing the A1 key for 2 seconds saves the selected type of beam width. The parameter assignment process is then complete

and the sensor returns to normal mode. If you press the A1 briefly instead, you go back to Level 1 (parameter assignment of

output function).

If parameterisation is not complete within 5 minutes (pressing the A1 key for 2 seconds), the sensor interrupts parameterisation

mode without changing the settings.

Synchronisation

The sensor is equipped with a synchronisation connection to suppress mutual interaction. If it is not turned on, the sensor works

at an internally generated cycle rate. Synchronisation of more than one sensor is possible in a number of different ways.

External synchronisation:

The sensor can be synchronised by the application of a square wave voltage externally. A synchronisation pulse on the synchronisation input results in the execution of a measurement cycle. The pulse width must be greater than 100 µs. The measurement cycle must be started with the falling signal edge. A Low level > 1 s or an open synchronisation input results in normal

operation of the sensor. A High level on the synchronisation input deactivates the sensor.

Two different operating modes are possible

- Multiple sensors can be controlled by the same synchronisation signal. The sensors work on synonymous cycle.

- Synchronisation pulses are sent cyclically to only one sensor each time. The sensors work in Multiplex mode.

Self synchronisation:

The synchronisation connections of up to 5 sensors with option for self-synchronisation are connected with each other. These

sensors work after turning on the operating voltage in Multiplex mode. The On delay increases depending on the number of

sensors to be synchronised. Synchronisation is possible during Teach-in and vice-versa. Sensors must be operated unsynchronised to perform Teach-in of switching points.

Note:

If the option for synchronisation is not used, the synchronisation input can be connected with ground (0 V) or the sensor can be

operated with a V1 connection cable (4-pin).

Release date: 2016-02-26 11:31 Date of issue: 2016-02-26 133995_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...