Page 1

U3

Force Transducers

Special features

– Tensile / compressive force

transducers

– Nominal forces 500 N ... 100 kN

– Integrated lateral force compen-

sation

– Low overall height

– Flanged ends on both side

– Sturdy design through high

dynamic load–carrying capacity

– Stainless steel housing

Data Sheet

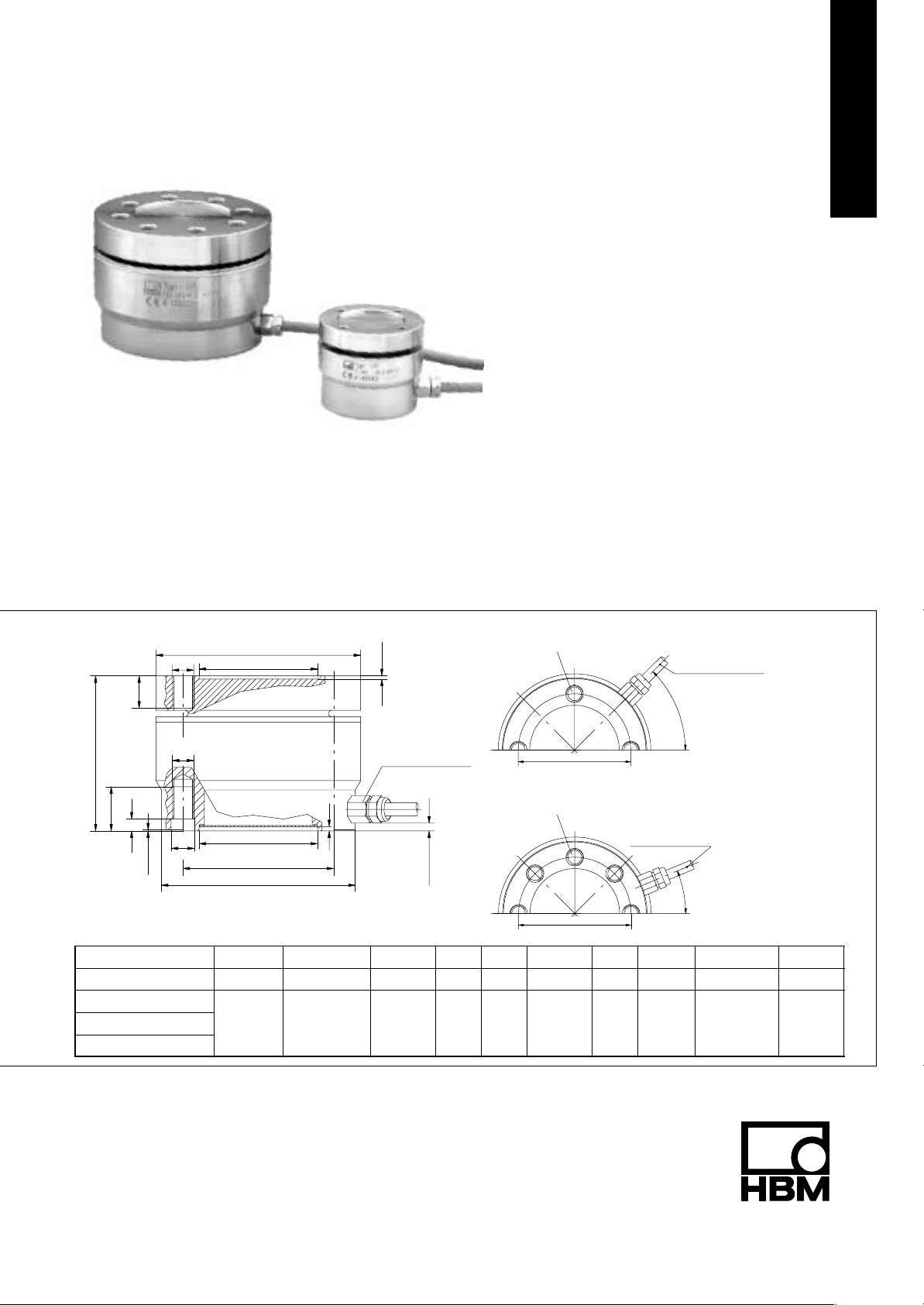

Dimensions (in mm; 1 mm= 0.03937 inches)

∅A

M

D

G

F

E

* only at 50 kN and 100 kN

Nominal force ∅A ∅B

U3/0.5–10 kN 54 50 34 8.5 5 13 47 5.5 42 M5

U3/20 kN

U3/50 kN

U3/100 kN

M

∅H

0.5*

∅C

3

∅C

∅K

∅B

–0.02

95 90 55 15 5.5 20.5 72 11 70 M10

1.5

Mini screwed joint

M8x1; a.f.11

approx. 3.5

H8

∅C

D E F G ∅H ∅K

4 x 90

∅K

8 x 45

∅K

o

o *

Cable length 3 m

U3: 0.5 – 20 kN

Cable length 3 m

o

45

U3: 50 kN/100 kN

o

22.5

"

0.1

M

20.U3.21 en

Page 2

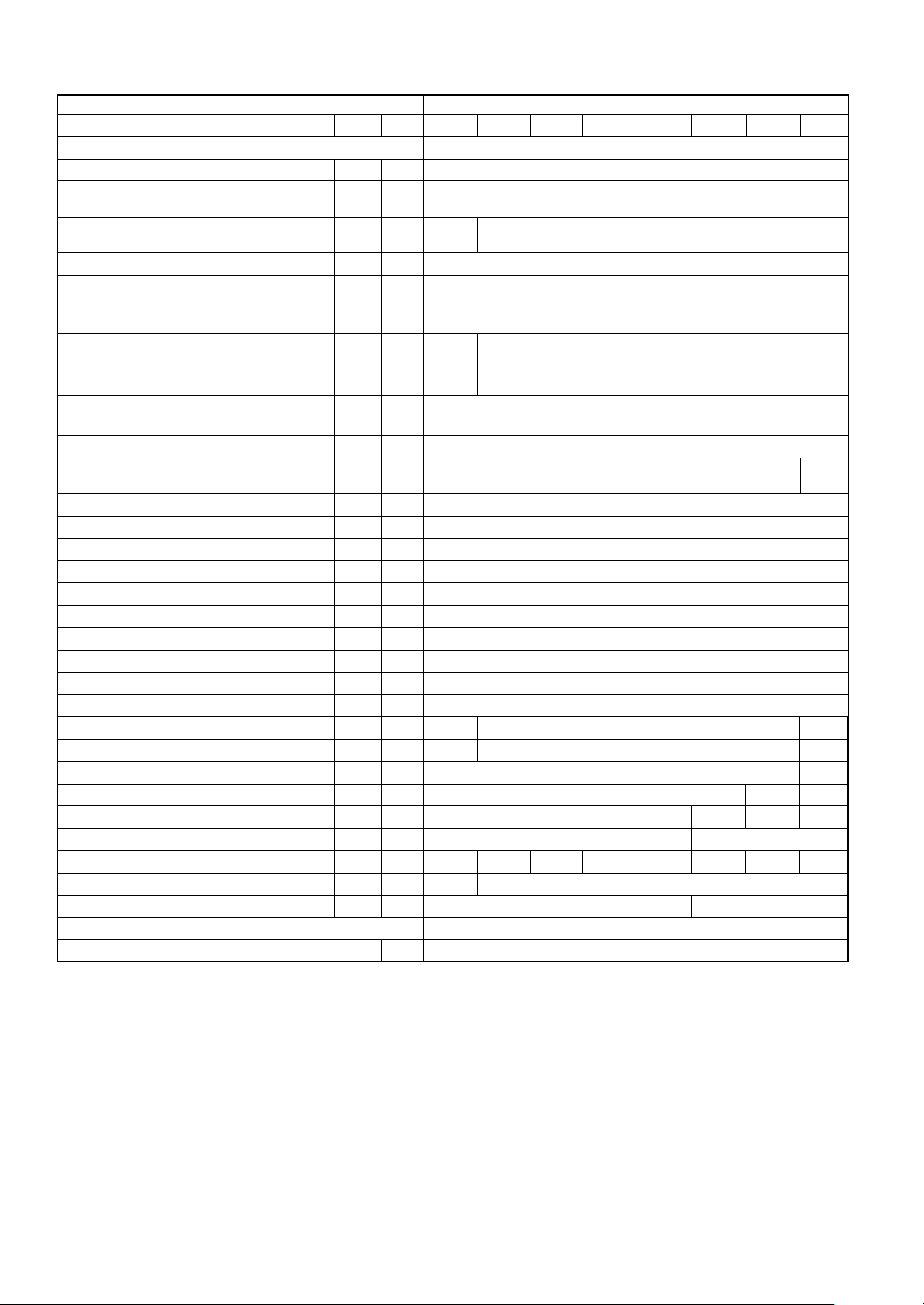

Specifications (VDI/VDE 2638)

Type U3

Nominal force F

Accuracy class 0.2

Nominal sensitivity C

Rel. sensitivity deviation compressive

force

Rel. tensile/compressive force sensitivity

diff.

Relative zero signal deviation d

Relative range of inversion (0.5 Fnom to

u

Fnom)

Linearity deviation compressive force d

Linearity deviation tensile force d

Effect of temperature on sensitivity/10 K

TK

by reference to nominal sensitivity

Effect of temperature on zero signal/10 K

TK

by reference to nominal sensitivity

Effect of eccentricity at 1 mm d

Effect of transverse forces transverse force

10 % F

Relative creep over 30 min d

nom

1)

crF+E

Input resistance R

Output resistance R

Isolation resistance R

Reference excitation voltage U

Operating range of the excitation voltage B

Nominal temperature range B

Operating temperature range B

Storage temperature range B

Reference temperature t

Maximum operating force (FG) % 130 150 130

Limit force (FL) % 130 150 130

Breaking force (FB) % >300 250

Static lateral limit force

1)

(FQ) % 100 80 50

Permissible eccentricity e

Nominal displacement S

Fundamental resonance frequency F

Relative permissible vibrational stress F

Weight kg approx. 0.6 approx. 2.5

Degree of protection to DIN EN60529 IP65

Cable length, six–wire connection m 3

1)

by reference to a force introduction point on the force–introduction surface

kN 0.5 1 2 5 10 20 50 100

nom

mV/V 2

nom

< "0.2

d

% <2 <1

zd

% <1

s.o

% <0.2

0.5

% <0.2

lin

% <0.3 <0.2

lin

% <0.2 <0.1

c

% <0.1

0

% <"0.1

E

d

% <"0.1 <"0.2

Q

% <"0.1

Ω >345

e

Ω 300 – 400

a

Ω >2x 10

is

V 5

ref

U.GT

t.nom

V 0.5 to 12

o

C –10 to +70

o

C –30 to +85

t.G

o

C –50 to +85

t.S

o

C +23

ref

mm 25 40 32 20

G

mm <0.08 <0.1

nom

kHz 1.3 2.1 3.1 5.2 7.1 3.7 5.7 7.25

G

% 100 160

rb

9

Accessories (to order):

’Complete adapter’ for knuckle eye mounting Knuckle eye 1–ZGUW

0.5–10 kN Order no. 2–9289.1956 0.5–10 kN Order no. 1–U2A/1t/ZGUW

20 kN Order no. 2–9289.1957 20 kN Order no. 1–U2A/2t/ZGUW

50 kN Order no. 2–9289.1958 50 kN Order no. 1–U2A/5t/ZGUW

100 kN Order no. 2–9289.2280 100 kN Order no. 1–Z4/100kN/ZGUW

D 20.U3.21 enHBM 2

Page 3

Installation and accessories

Installation without Adapter

M

A

provided by customer

Flange

Base

provided by customer

M

A

Nominal force (kN) Starting torque MA (Nm) Thread

0.5 – 10 5 4 x M5

20 40 4 x M10

50 40 8 x M10

100 94 8 x M10–12.9 DIN912 galvanised

Installation with adapter and knuckle eye

M2 (MA)

provided by customer

base

Hmax.

adapter

flange

flat

M1 (MA)

lock nut, M

B

ZGUW/1 – 5T/100kN

Nominal force

(kN)

0.5 – 10 108 5 60 M5x12 M5

20 170 40 300 M10x25 M10

50 180 40 500 M10x25 M10

100 187 94 1000 M10x25 M10

H

Max

(mm)

Starting torque MA (Nm) Starting torque MB (Nm) Screws for adapter mounting

M1 M2

D 20.U3.21 en HBM

3

Page 4

Mounting accessories

Knuckle eye ZGUW

W

H

H7

B

∅

a.f.

A

G

Material: tempering steel, galvanised; rolled steel and PTFE/bronze fabric foil

D

G

N

F

Adapter

A

C

D

f8

M

K

SW

L

S

R

Q

P

Knuckle eye

H7

H7

D F G H M X W a./f. Weight (kg)

70 110 145 25 M30x2 24 37 46 1.1

Nominal force

(kN)

0.5...10 33.5 12 32 54.5 70.5 12 M12 7 16 19 0.1

20 47 20 50 79.8 104.8 18 M20x1.5 9 25 30 0.4

50 57 25 60 94.5 124.5 22 M24x2 10 31 36 0.6

100 66 30

A ∅B

Adapter

Nominal

force

(kN)

0.5...10 50 42 34 M12 14 22 4x5.5 4.5 19 25.1 0.9 19 0.15

20 90 70 55 M20x1.5 22 34 4x11 4.5 15 40.1 0.9 30 1.3

50 90 70 55 M24x2 26 42 8x11 6 20 45.1 0.9 36 1.45

100 90 70 55 M30x2 26 42 8x11 6 20 45.1 0.9 41 1.45

1)

including screws

∅A ∅C ∅D

f8

M ∅K ∅L ∅N P Q R S a./f. Weight1) (kg)

Modifications reserved.

All details describe our products in general form only. They

are not to be understood as express warranty and do not

constitute any liability whatsoever.

D 20.U3.21 en

Hottinger Baldwin Messtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt

Im Tiefen See 45, D-64293 Darmstadt

Tel.: +49/61 51/ 8 03-0; Fax: +49/61 51/ 8039100

E–mail: support@hbm.com www.hbm.com

Loading...

Loading...