Simple Controller for Fast Charge Systems

Description

The bipolar IC U2407B is a fast charge battery controller

for drained NiCd/ NiMH batteries. Apart from phase

control, it is identical with U2405B, but has four LED

outputs. The IC enables the designer to create an efficient

and economic charge system. The U2407B incorporates

an intelligent multiple-gradient battery-voltage monitoring combined with temperature and failure mode

detection. With automatic top-off charging, the

integrated circuit ensures that the charge device stops

regular charging before the critical stage of overcharging

is achieved. It incorporates an additional algorithm for

reactivating fully drained batteries especially after long

time storage. It has four LED driver outputs for different

indications of the charge status.

U2407B

Features

D

Multiple gradient monitoring

D

Temperature window (T

D

Exact currentless measurement

D

Four LED status outputs

D

Linear power control

D

Preferred for externally regulated current sources

D

Preformation algorithm for drained batteries

D

Programmable top-off charge function

6.5 V/10 mA

16

14

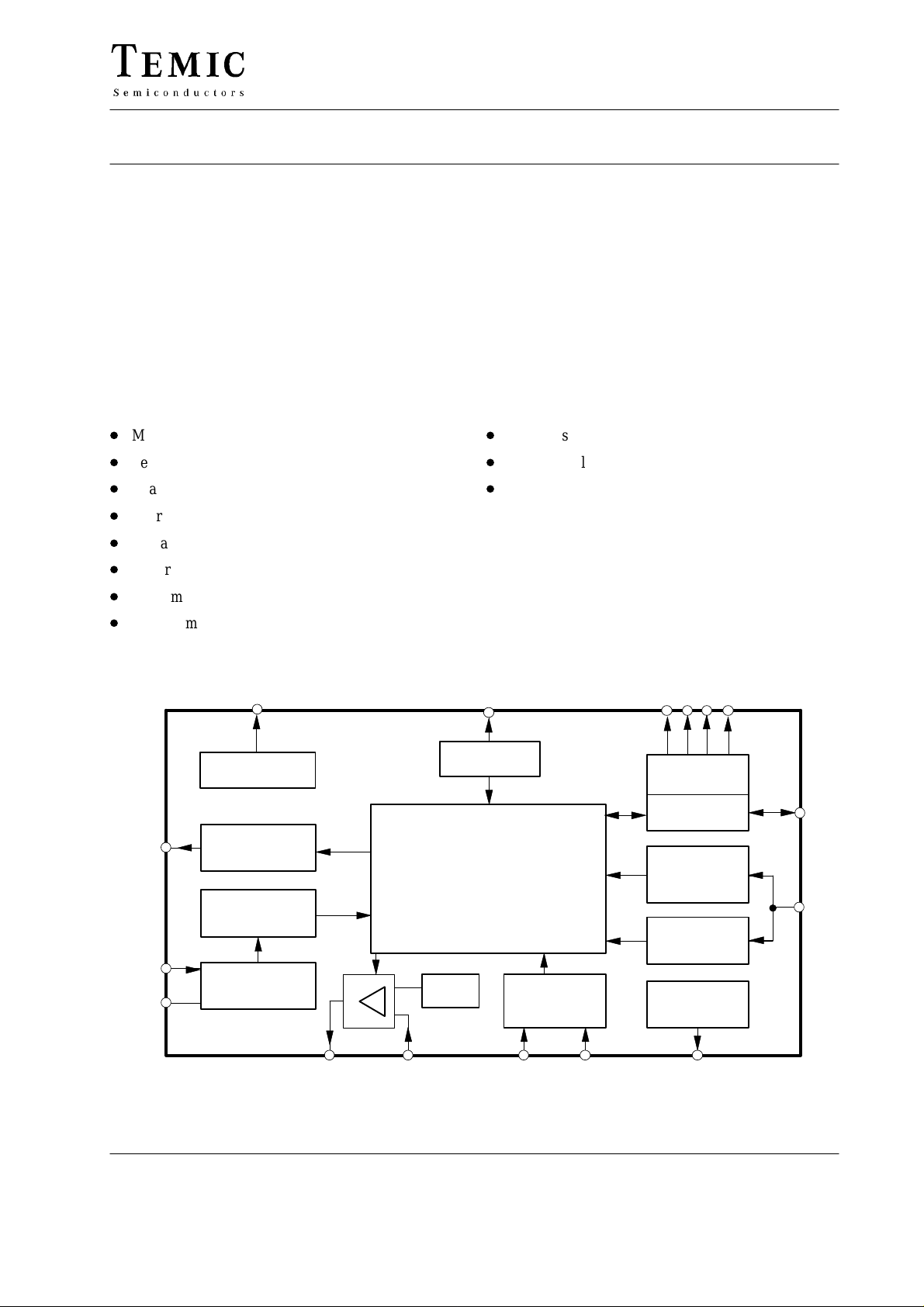

1

Switch output

Power - on control

Power supply

= 8 to 26 V

V

S

V

min/Tmax

13

Ref

)

Applications

D

D

D

Package: DIP16/ SO16

12

Oscillator

Control unit

Gradient

2

d

V/dt2 and –dV

160 mV

Ref

Primary switch mode

AC/ DC wall plug adapter

Ultra fast charger (10 minutes)

2

15

Status control

Scan path

Battery

detection

V

Ref

V

Batt

0.1 to 4 V

Temp. control

max

Sensor

T

Charge break

output

3

= 5 V

monitor

10

11

9

95 10648

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

4

5

Figure 1. Block diagram

67

8

1 (16)

U2407B

Input Voltage

8 V to 24 V

Mounted

heatsink

BYW52

Battery

10 mF

on

0.2

10

W

R

T

2

BC237

R

1 k

R

10 k

R

10 k

1

B1

W

B2

W

B3

W

R

1 k

W

BD649

T

1

I

ch

7

C

10

D

1

R

sh

W

2.2 k

10 k

R

R

4

W

100 k

6

W

R

8

W

1 mF

C

R

2.2 k

R

C

1 mF

C

1 mF

5

W

LED1

LED2

LED3

LED4

OP

V

7

Sensor

4

Batt

OP

O

I

V

S

10

2

3

15

4

U2407B

9

7

5

14

220 mF

C

1

GND

1

C

2

0.22 mF

V

Ref

13

R

T3

1.5 k

R

100 k

W

R

270 k

T2

W

O

W

95 10677

T

max

6

Output

16

Osc

12

C

O

8

t

S

p

TM

11

10 nF

Pin Description

Package: DIP16/ SO16

GND

LED2

LED3

OP

OP

T

Sensor

t

p

O

max

1

2

3

4

5

I

6

7

8

Figure 2. Scheme for DC linear regulation

Pin Symbol Function

1 GND Ground

Output

16

15

LED4

2 LED2 Display output “top-off/ trickle

3 LED3 Display output “Fast charge”

4 OP

14

V

S

5 OPIOperational amplifier input

6 T

13

V

Ref

7 Sensor Temperature sensor

8 t

12

Osc

9 V

10 LED1 Display output “failure mode”

11 S

12 Osc Oscillator

13 V

14 V

15 LED4 Display output “top-off charge”

16 Output Trigger output

95 10618

11

10

9

S

TM

LED1

V

Batt

charge”

Operational amplifier output

O

Maximum temperature

max

Charge break output

p

Battery voltage

Batt

Test mode switch (status control)

TM.

Reference output voltage

Ref

Supply voltage

S

2 (16)

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

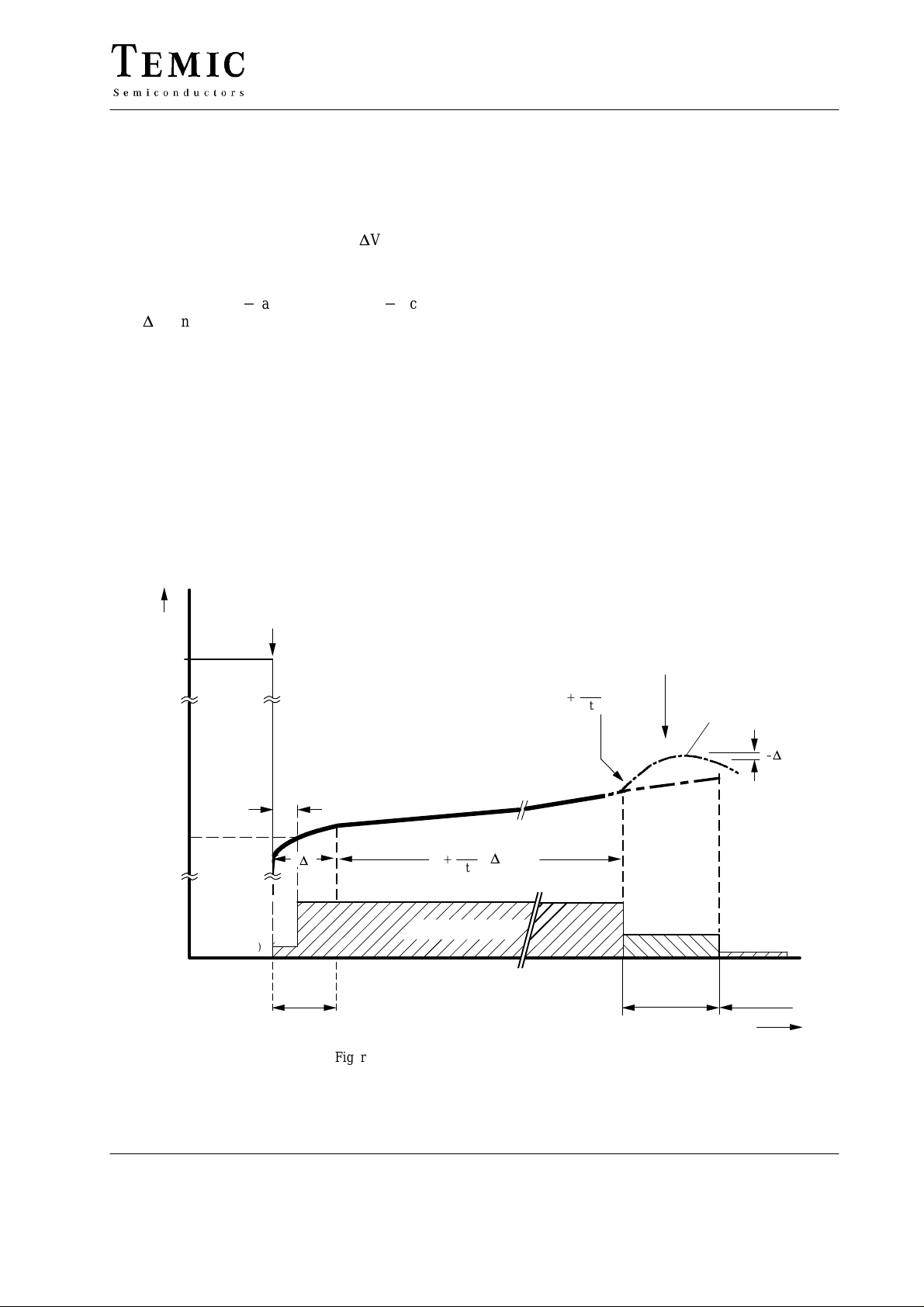

General Description

The integrated circuit, U2407B, is designed for charging

Nickel-Cadmium (NiCd) and Nickel-Metal-Hydride

(NiMH) batteries. Fast charging results in voltage lobes

when fully charged (figure 3). It supplies two

identifications (i.e., + d

charge operation at the proper time.

As compared to the existing charge concepts where the

charge is terminated * after voltage lobes * according

to – DV and temperature gradient identification, the

U2407B takes into consideration the additional changes

in positive charge curves, according to the second

derivative of the voltage with respect to time (d

The charge identification is the sure method of switching

off the fast charge before overcharging the battery. This

helps to give the battery a long life by hindering any

marked increase in cell pressure and temperature.

Even in critical charge applications, such as a reduced

charge current or with NiMH batteries where weaker

2

V/dt2, and – DV) to end the

2

V/dt2).

U2407B

charge characteristics are present multiple gradient

control results in very efficient switch-off.

An additional temperature control input increases not

only the performances of the charge switching

characteristics but also prevents the general charging of

a battery whose temperature is outside the specified

window.

A specific preformation algorithm is implemented for

reactivating fully drained batteries especially in the case

of batteries that have been stored for a long time.

A constant charge current is necessary for continued

charge-voltage characteristic. This constant current is

generated from an external power supply and can be regulated with the help of an internal op-amp regulator

(figure 2). An external current source can also be controlled by the switch output Pin 16 (see figure 12).

For further information please refer to the applications.

Battery

voltage

5 V

1.6 V

95 10616

Battery insertion

preformation

I (R

B1)

t1 = 5 min

–DV

)

Fast charge rate I

Figure 3. Charge function diagram, f

Fast charge stop

d

)

dt

2

d

V

,–DV

2

dt

O

= 800 Hz

osc

2

V

2

Top-off charge stop

without

charge control

Top-off

charge rate

1/4 I

O

t2 = 20 min

–DV

Trickle

charge rate

1/256 I

O

t

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

3 (16)

U2407B

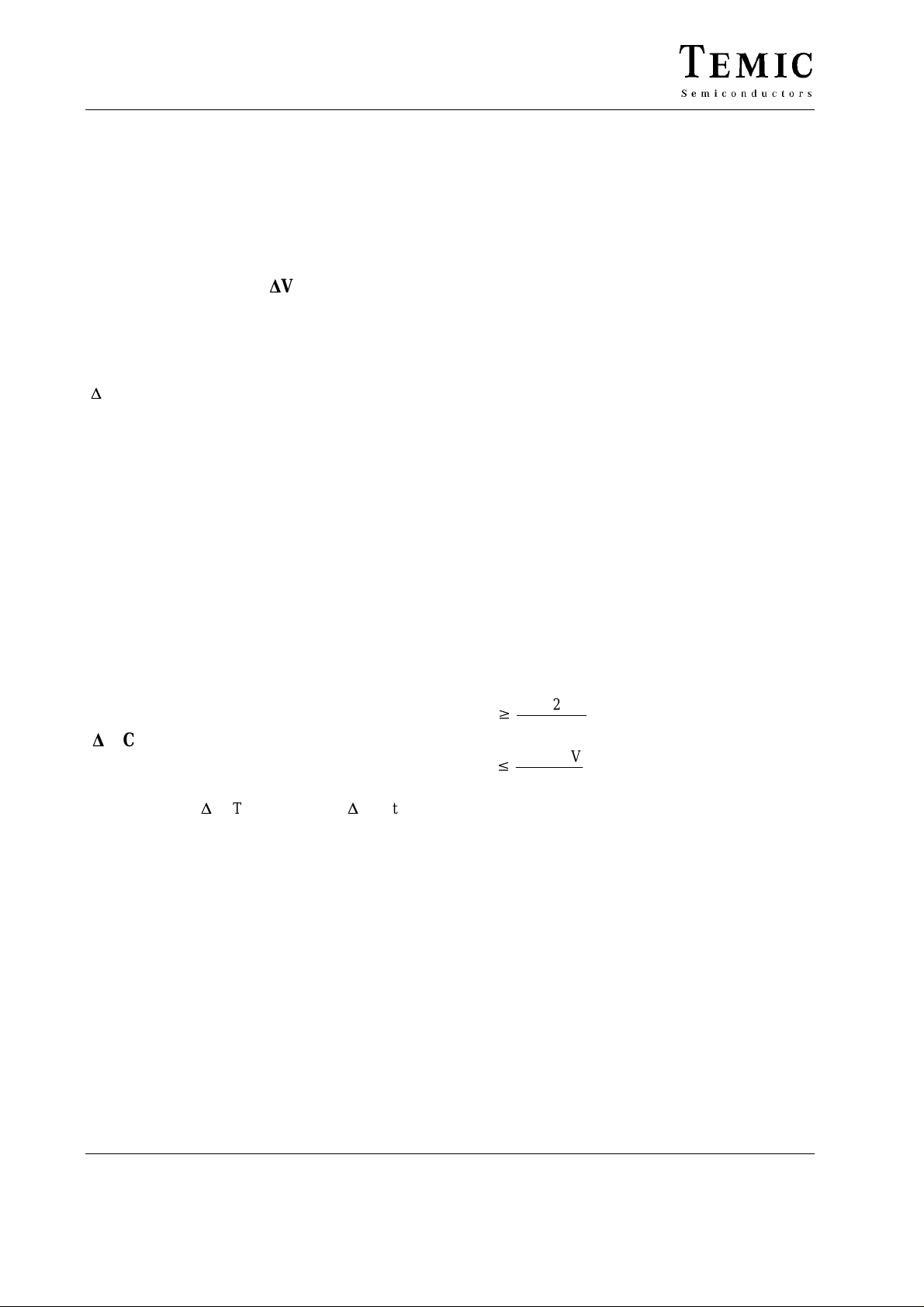

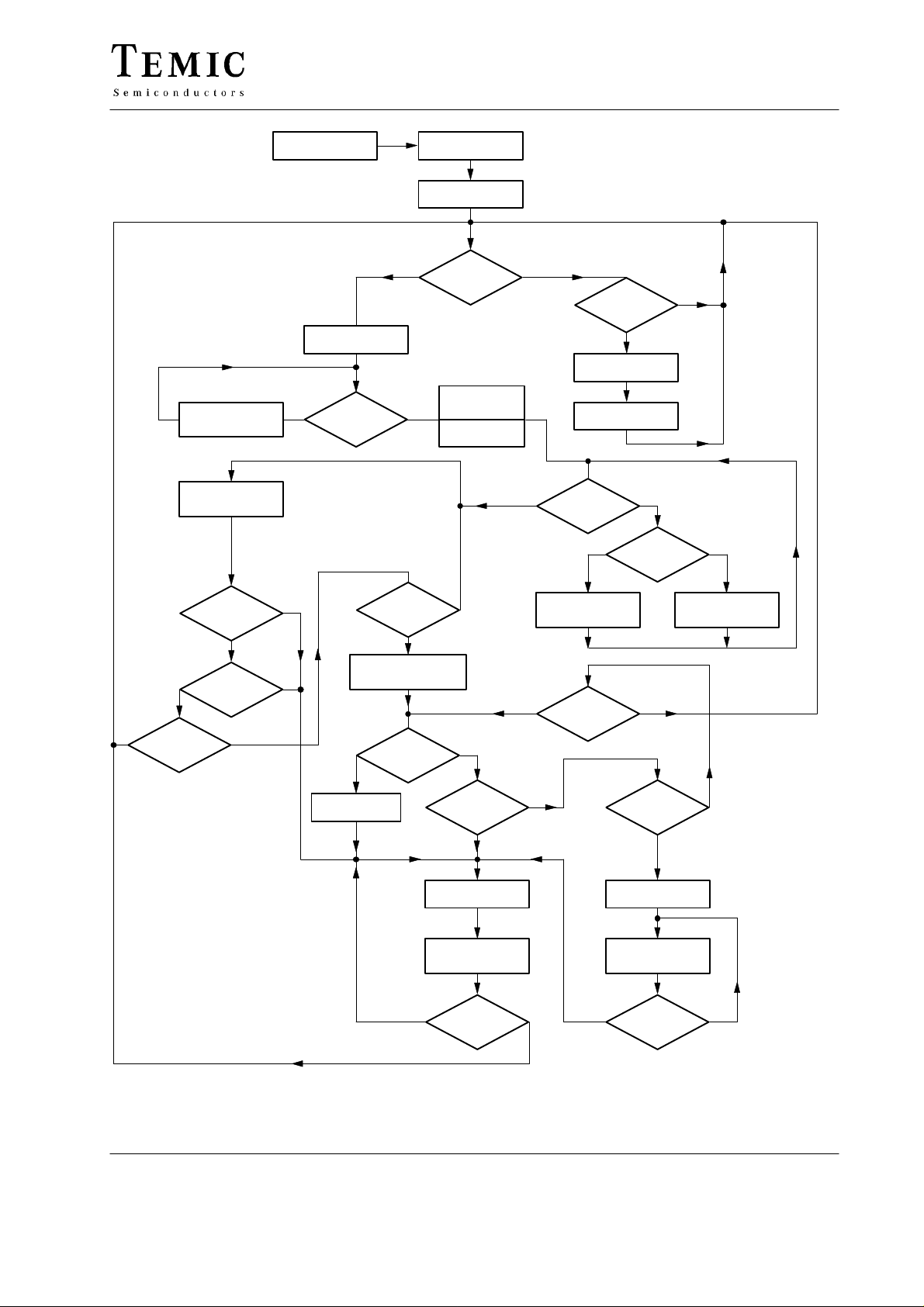

Flow Chart Explanation, f

= 800 Hz

osc

(Figures 2, 3 and 4)

Battery pack insertion disables the voltage lock at battery

detection input Pin 9. All functions in the integrated

circuit are reset. For further description, DIP-pinning is

taken into consideration.

Battery Insertion and –DV

Monitoring

After battery insertion fast charge Io begins when the

input voltage V

5 minutes the d

–DV monitoring is activated. In case the detected V

voltage is less then 1.6 V the special preformation

procedure will be activated. The reference level with

respect to the cell voltage can be adjusted by the resistor

(see figure 2).

R

B3

Preformation Procedure

Before fast charge of fully drained or long-time stored

batteries begins, a reactivation of it is necessary. The

preformation current is dependent on pull-up resistor

. The fast charge starts only after the V

R

B1

than 1.6 V. During the first 10 minutes the green LED2 is

blinking. If after 10 minutes, V

reached the reference level, the indication changes to red

blinking LED1. The charge will continue with

preformation rate I (R

reference level, the fast charge rate current, I

switched-on and the green LED2 is blinking.

–DV Cut-Off (Monitoring)

When the signal at Pin 9 of the DA converter is 12 mV

below the actual value, the comparator identifies it as a

voltage drop of –DV. The validity of –DV cut-off is

considered only if the actual value is below 12 mV for

three consecutive cycles of measurement.

d2V/dt2-Gradient

If there is no charge stop within the first 5 minutes after

battery insertion, then d

In this actual charge stage, all stop-charge criteria are

active.

is higher than 1.6 V. For the first

Batt

2

V/dt2-gradient recognition is suppressed,

is higher

Batt

voltage has not

Batt

). In case V

B1

2

V/dt2 monitoring will be active.

increases to 1.6 V

Batt

o

Batt

, is

Top-Off Charge Stage

By charge disconnection through the +d2V/dt

device switches automatically to a defined protective

top-off charge with a pulse rate of 1/4 I

= 5.12 s, period, T = 20.48 s).

t

p

The top-off charge time is specified for a time of

20 minutes @ 800 Hz.

During top-off mode the LED4 is in ON mode.

2

mode, the

(pulse time,

O

Trickle Charge Stage

When top-off charge is terminated, the device switches

automatically to trickle charge with 1/256 I

(tp = 5.12 s,

O

period = 1310.72 s). The trickle continues until the

battery pack is removed.

During trickle mode the LED2 output is in on mode,

LED4 is in OFF-mode.

Basic Description

Power Supply, Figure 2

The charge controller allows the direct power supply of

8 to 26 V at Pin 14. Internal regulation limits higher input

voltages. Series resistance, R

, to a maximum value of 25 mA. Series resistance

rent, I

S

is recommended to suppress the noise signal, even below

26 V limitation. It is calculated as follows.

1min

R

1max

v

25 mA

V

min

–8V

I

tot

–26 V

V

max

w

R

where

I

= IS + I

tot

V

max, Vmin

I

= Current consumption (IC) without load

S

I

= Current through resistance, R

RB1

+ I

RB1

1

= Rectified voltage

I1 = Trigger current at Pin 1

, regulates the supply cur-

1

B1

When close to the battery’s capacity limit, the battery

2

voltage curve will typically rise. As soon as the +d

V/dt

stop-charging criteria are met, the device will stop the fast

charge activities.

4 (16)

2

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

U2407B

*) 70 mV > V

LED1 blinking

Fast charge

begins

Batt

> 5V

Start

no

Reset

Temp. range

ok ?

Power on reset

LED1,2,3,4 off

yes

Batt. inserted

yes

*)

Preformation

current I

RB1

LED3 blinking

yes

no

V

Temp. range

Charge stop

LED1 blinking

> 1.6 V

Batt

yes

no

ok ?

yes

no

tch > 10 min

V

4 V

Batt

yes

–dV

switch off

no

no yes

Batt. inserted

*)

no

yes

Charge time

t

–dV and d2V/dt

monitoring activated

no

LED1 blinking

> 5 min ?

1

Batt temp

range?

yes yes

no

2

yes

–dV

disconnect

LED2 on

Trickle charge

1/256 I

O

Batt. inserted

*)

yes

no

LED1 blinking

Batt. inserted

*)

no

no

2

d2V/dt

disconnect ?

LED2 on

LED4 on

Top off charge

1/4 I

O

t2 > 20 min

LED3 off

no

no

95 10671

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

Figure 4. Flow chart

5 (16)

U2407B

Battery Voltage Measurement

The battery voltage measurement at Pin 9 (ADCconverter) has a range of 0 V to 4 V, which means a

battery pack containing two cells can be connected

without a voltage divider.

If the AD converter is overloaded (V

switch-off occurs. The fast charge cycle is terminated by

automatically changing to trickle charge.

Precaution should be taken that under specified charge

current conditions, the final voltage at the input of the

converter, Pin 9, should not exceed the threshold voltage

level of the reset comparator, which is 5 V. When the

battery is removed, the input (Pin 9) is terminated across

the pulled-up resistance, R

to the value of 5 V-reset-

B1,

threshold. In this way, the start of a new charge sequence

is guaranteed when a battery is reinserted.

If the battery voltage exceeds the converter range of 4 V,

adjusting it by the external voltage divider resistance, R

and RB3 is recommended.

w 4 V) a safety

Batt

B2

Value of the resistance, R

= 1 kW, RB2 = 10 kW, as follows:

R

B1

V

RB3+

R

B2

10max

V

Bmax–V10max

The minimum supply voltage, V

is calculated by assuming

B3

, is calculated for

smin

reset function after removing the inserted battery

according to:

ǒ

R

B3

B1

smin

0.03mA@R

+

V

)

Ǔ

R

)

5VǒR

B2

R

B3

)

RB2)

B1

R

B3

where:

V

V

V

= Max voltage at Pin 9

9max

= Min supply voltage at the IC (Pin 14)

Smin

= Max battery voltage

Bmax

The voltage conditions mentioned above are measured

during charge current break (switch-off condition).

Ǔ

14

V

S

V

DAC

- dV Recognition

R

B1

–

+

V

=

Ref

12 mV

=

V

DAC

DAC control

comparator

9

–

+

Reset

7 V

V

Ref

4.3 V

=

comparator

–

+

Reset

V

= 0.1 V

Ref

V

B

95 10623

Table 1. valid when V

V

6

10max

I

ch

R

Battery

R

sh

Figure 5. Input configuration for the battery voltage measurement

= 3.5 V

B2

R

B3

V

Batt

Cell No. 1 2 3 4 5 6 7 8 9 10 11 12

V

(V) 8 8 8 9 11 13 15 17 19 21 23 25

Smin

RB3 (k

W)

– – 51 16 10 7.5 5.6 4.7 3.9 3.3 3 2.7

6 (16)

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

U2407B

Analog-Digital-Converter (ADC),

Test Sequence

A special analog-digital-converter consists of a five-bit

coarse and a five-bit fine converter . It operates by a linear

count method which can digitalize a battery voltage of

4 V at Pin 9 in 6.5 mV steps of sensitivity.

In a duty cycle, T, of 20.48 s, the converter executes the

measurement from a standard oscillator frequency of f

= 800 Hz. The voltage measurement is during the charge

break time of 2.56 s (see figure 6), i.e., no-load voltage

(or currentless phase). Therefore it has optimum measurement accuracy because all interferences are cut-off

during this period (e.g., terminal resistances or dynamic

load current fluctuations).

After a delay of 1.28 s the actual measurement phase of

1.28 s follows. During this idle interval of cut-off

conditions, battery voltage is stabilized and hence

measurement is possible.

An output pulse of 10 ms appears at Pin 8 during charge

break after a delay of 40 ms. The output signal can be used

in a variety of way, e.g., synchronising the test control

(reference measurement).

osc

Plausibility for Charge Break

There are two criteria considered for charge break

plausibility:

– DV Cut-Off

When the signal at Pin 9 of the DA converter is 12 mV

below the actual value, the comparator identifies it as a

voltage drop of – DV. The validity of – DV cutt-off is

considered only if the actual value is below 12 mV for

three consective cycles of measurement.

d2V/dt2 Cut-Off

A four bit forward/ backward counter is used to register

the slope change (d

clocked by each tracking phase of the fine AD-counter.

Beginning from its initial value, the counter counts the

first eight cycles in forward direction and the next eight

cycles in reverse direction. At the end of 16 cycles, the

actual value is compared with the initial value. If there is

a difference of more than two LSB-bit (13.5 mV) from the

actual counter value, then there is an identification of

slope change which leads to normal charge cut-off. A

second counter in the same configuration is operating in

parallel with eight clock cycles delay, to reduce the total

cut-off delay, from 16 test cycles to eight test cycles.

2

V/dt2, V

– slope). This counter is

Batt

Status

charge

break

output

ADC

conversion

time

(internal)

Charge break

2.56 s

10 ms

40 ms

1.28 s 1.28 s

94 8693

Charge

t

T= 20.48 s

t

t

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

Figure 6. Operating sequence of voltage measurements

7 (16)

U2407B

Temperature Control, Figure 7

When the battery temperature is not inside the specified

temperature windows, the overal temperature control will

not allow the charge process. Sensor short circuit or

interruption also leads to switch-off (faulty mode).

A permanent switch-off follows after a measurement

period of 20.48 s, if the temperature exceeds a specified

level, which is denoted by a status of LED1. A charge

sequence will start only when the specified window

temperature range is attained.

The temperature window is specified between two

voltage transitions. The upper voltage transition is

specified by the internal reference voltage of 4 V, and the

lower voltage transition is represented by the external

voltage divider resistances R

and RT3.

T2

V

V

Ref

Ref

13

NTC sensors are normally used to control the temperature

of the battery pack. If the resistance values of NTC are

known for maximum and minimum conditions of

allowable temperature, then other resistance values, R

and RT3 are calculated as follows:

R

T2

suppose R

= 100 kW, then

T2

R

+

R

T1

RT3+

R

NTCmax

NTCmin

V

–4V

Ref

4V

R

T2

R

T1

T1

If NTC sensors are not used, then select the circuit

configuration according to figure 10.

,

R

T2

T

max

7

R

T1

R

T3

7 V

Sensor

8

NTC

sensor

Figure 7. Temperature window

7 V

Current Regulation

The charge concept requires a constant charge current

supply outside of the circuit. This is achieved by an

external switchable current source or by an internal error

amplifier regulation of an externally situated power

stage.

+

–

V

= 4 V

Ref

+

–

High

temperature

Low

temperature

95 10622

Charge Current Regulation, Figure 2

According to figure 2 the operational amplifier (OpAmp)

regulates the charge current, I

age value. The OpAmp detects the voltage drop across the

shunt resistor (R

) at input Pin 5 as an actual value. The

sh

actual value will then be compared with an internal reference value of 160 mV.

(= 160 mV/ Rsh), aver-

ch

8 (16)

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

U2407B

Status Control

Different status control modes can be designed by four LED outputs. Status control regards the running charge cycle

before it has been started and also after it has been terminated.

LED1 LED2 LED3 LED4 Status

OFF OFF OFF OFF No battery (V

OFF OFF Blinking OFF Fast charge

OFF ON OFF ON Top-off charge

OFF ON OFF OFF Trickle charge

Blinking OFF OFF OFF Failure mode

Failure mode: Temperature out of window, also before battery insertion or power-on.

Battery break, short circuit, V

Batt

< 0.1 V

To achieve custom specific display modes, several combinations between LED outputs 1 to 4 are recommended.

(see applications)

The blink frequency of LED outputs can be calculated as follows:

Batt

> 5 V)

(LED)

1024

Oscillator frequency, f

+

f

Example 1:

Display mode similar to U2402B and U2405B:

LED1

LED2

LED3

10

2

3

red

1 k

green

1 k

Figure 8.

V

W

V

W

95 10672

Example 2:

LED1

LED2

LED3

10

2

3

red

V

S

green

1 k

1 k

osc

LED1 (red) LED2 (green)

S

(LED1) (LED2/ LED3)

Status

OFF OFF No battery

(V

> 5 V)

Batt

S

OFF Blinking Fast charge

OFF ON Top-off, trickle charge

Blinking OFF All failure mode

Batt

Status

> 5 V)

LED1 (red) LED2 (green)

V

S

W

V

S

W

(LED1/ LED3) (LED2)

OFF OFF No battery

(V

ON OFF Fast charge

OFF ON Top-off, trickle charge

Blinking OFF All failure mode

Figure 9.

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

95 10673

9 (16)

U2407B

Top-off Charge Rate Reduction

The current amplitude during top-off charge can be

reduced as shown in figure 10. During top-off mode, both

the LED4 output (Pin 15) and transistor T are on. The

actual current amplitude is influenced with the help of

resistor R

input OP

depends on the reciprocal value of R

LED4

, which is detected by the operational amplifier

x

(Pin 5). The decrease of the current flow

1

95 10674

T

.

x

V

Ref

15

R

x

5

OP

I

Figure 10.

Battery

R

sh

Oscillator

Time sequences regarding measured values and

evaluation are determined by the system oscillator. All

the technical data given in the description are with the

standard frequency 800 Hz.

It is possibe to alter the frequency range in a certain

limitation. Figure 11 shows the frequency versus

resistance curves with different capacitance values.

Oscillation Frequency Adjustment

Recommendations:

0.5C charge 0.5 500 Hz = 250 Hz

1C charge 500 Hz

2C charge 2 500 Hz = 1000 Hz

3C charge 3 500 Hz = 1500 Hz

10000

1000

W

O

R ( k )

95 11408

CO=2.2nF

CO=10nF

100

10

0.1 1

fO ( kHz )

Figure 11. Frequency versus resistance for different capacitance values

CO=4.7nF

10

10 (16)

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

Absolute Maximum Ratings

Reference point Pin 2 (GND), unless otherwise specified

Parameters Symbol Value Unit

Supply voltage Pin 14 V

Voltage limitation IS = 10 mA

Current limitation Pin 14

t < 100 ms

Voltages at different pins Pins 16, 2, 3, 10 and 15

Pins 11 up to 13, 4 up to 9

Currents at different pins Pin 1

Pins 3 up to 14 and 16 up to 18

Power dissipation T

= 60°C P

amb

Ambient temperature range T

Junction temperature T

Storage temperature range T

Thermal Resistance

Parameters Symbol Maximum Unit

Junction ambient R

S

26 V

31

I

S

25

100

V 26

I 25

10

tot

amb

j

stg

thJA

650 mW

– 10 to +85 °C

125 °C

– 40 to +125 °C

100 K/W

U2407B

mA

V

7

mA

Electrical Characteristics

VS = 12 V, T

Power supply Pin 14

Voltage range V

Power-on threshold ON

Current consumption without load I

Reference Pin 13

Reference voltage I

Reference current – I

Temperature coefficient TC – 0.7 mV/K

Operational amplifier OP

Output voltage range I5 = 0 Pin 4 V

Output current range V5 = 3.25 V Pin 4 ±I

Output pause current Pin 4 –I

Non-inverting input voltage Pin 5 V

Non-inverting input current Pin 5 ±I

Comparator or temperature control

Input current Pins 6 and 7 ±I

Input voltage range Pins 6 and 7 V

Threshold voltage Pin 7 V

Charge break output Pin 8

Output voltage High, I8 = 4 mA

Output current V8 = 1 V I

= 25°C, reference point Pin 1 (GND), unless otherwise specified

amb

Parameters Test Conditions / Pins Symbol Min. T yp. Max. Unit

8 26 V

3.0

4.7

3.8

5.7

3.9 9.1 mA

6.19

6.14

6.5

6.5

6.71

6.77

10 mA

0.15 5.8 V

80

100

m

m

0 5 V

0.5

0.5

m

m

0 5 V

3.85 4.15 V

8.4

100

mV

10 mA

V

V

V

V

V

OFF

= 5 mA

Ref

I

= 10 mA

Ref

Low, I

= 0 mA

8

V

V

pause

V

S

S

S

Ref

Ref

4

4

5

5

6, 7

6, 7

7

8

8

A

A

A

A

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

11 (16)

U2407B

11

m

Battery detection Pin 9

Analog-digital converter Conversion range

Full scale level

Input current

0.1 V v V

v 4.5 V

Batt

Input voltage for reset V

Input current for reset

V

Batt

y 5 V

Battery detection Maximum voltage

Hysteresis Maximum voltage V

Mode select Pin 11

Treshold voltage Testmode V

Input current I

Input current Normal mode Pin 11 open

Sync. oscillator Pin 12

Frequency R = 150 kW, C = 10 nF f

Threshold voltage High level

Low level

Input current I

– I

D

V

V

V

I

V

Batt

Batt

Batt

Batt

Batt

hys

11

11

osc

T(H)

T(L)

12

0

4.0 V

3.85

0.5

4.8 5.0 5.3 V

8 35

80 120 mV

15 mV

4.7 V

20

0

800 Hz

4.3"3%

2.2"3%

– 0.5 0.5

UnitMax.Typ.Min.SymbolTest Conditions / PinsParameters

m

A

m

A

m

A

V

m

A

Applications

Input voltage

8 V to 26 V

current source

Battery

10

R

C

10

10 mF

Controlled

I

ch

C

100 mF

10

15

1

V

S

14

2

3

GND

1

13

C

2

0.22 mF

V

Ref

OP

4

O

W

1

R

B1

1 k

W

off

on

2.2 k

R

2

W

R

5

2.2 k

W

LED1

LED2

LED3

LED4

U2407B

R

B2

10 k

R

B3

16 k

Output

W

R

W

C

4.7 mF

T1

100 k

7

Sensor

R

14

510 k

16

V

Batt

9

W

7

W

8

11

12

OP

T

max

Osc

10 nF

I

R

O

270 k

W

C

O

5

6

12 (16)

t

p

Figure 12. Minimum charge system with external current source

S

TM

95 10675

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

U2407B

1

C

S

V

1

R

1

R

Master Slave

S

V

1

C

F

m

10

C

10

typ 12 V

Input voltage

W

10

W

10

m

R

R

R

R

R

R

m

F

100

5

4

7

7

4

5

F

100

W

2.2k

W

1M

W

1k

on

mounted

W

1k

W

1M

W

2.2k

1

14

green

red

1

T

heatsink

1

T

red

green

14

1

GND

S

V

BD649

BD649

S

V

GND

2

2

16

LED2

LED2

16

Ref

V

OUTPUT

LED1

10

3

D

1N4148

1

D

1

D

3

D

1N4148

10

LED1

OUTPUT

Ref

V

13

Ref

V

LED3

3

9

R

+

1/2LM393

BYW52

BYW52

8

1/2LM393

9

R

3

LED3

Ref

V

13

2

C

W

1k

3

C

–

2

T

2

T

3

C

W

1k

2

C

m

0.22 F

U2407B

F

m

4.7

Ref

V

BC237

I

I

BC237

4

Ref

V

F

m

4.7

U2407B

m

0.22 F

W

T2

R

15

6

LED4

O

OP

4

8

R

c

c

8

R

4

O

W

W

47k

47k

9

R

F

C

m

1

10

R

W

A2

10k

R

W

A2

R

10k

R

F

C

m

1

9

OP

LED4

15

6

T2

R

W

T3

100k

2.7k

R

max

T

Batt

V

Sensor

7

F

7

m

1

C

W

10k

W

A3

10k

R

W

A3

R

10k

7

F

C

m

1

7

Batt

V

Sensor

max

T

W

T3

W

R

2.7k

100k

W

O

R

270k

O

C

10nF

12622

12

OSC

TM

11

S

p

8

t

I

OP

4

5

F

C

m

1

W

... 1M

W

11

R

100k

Top off /

trickle

reduction

W

6

R

10k

R

W

6

R

10k

11

R

sh

W

0.2

W

... 1M

W

3

T

BC212

13

R

2

D

trickle

Top off /

reduction

12

R

W

100k

1N4148

W

100k

Ref

V

Ref

V

100k

F

4

m

1

C

5

I

OP

p

8

t

TM

11

S

OSC

12

W

270k

O

C

10nF

O

R

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

Figure 13. Dual–slot charger

13 (16)

U2407B

Package Information

Package DIP16 (CEI)

Dimensions in mm

1.60

0.64

0.58

0.38

1.65

1.14

20.57

18.92

0.81

2.79

2.29

3.81

3.05

3.81

3.05

0.76

0.13

0.89

0.38

technical drawings

according to DIN

specifications

7.87

7.37

6.60

6.10

0.38

0.20

9.40

7.62

13014

Package DIP16

Dimensions in mm

Alternative

20.0 max

4.8 max

3.3

0.5 min

17.78

0.58

0.48

2.54

technical drawings

according to DIN

specifications

1.64

1.44

16 9

18

7.82

7.42

6.4 max

0.39 max

9.75

8.15

13015

14 (16)

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

Package Information

Package SO16

Dimensions in mm

0.4

1.27

16 9

10.0

9.85

8.89

1.4

0.25

0.10

5.2

4.8

3.7

3.8

6.15

5.85

technical drawings

according to DIN

specifications

U2407B

0.2

13036

18

TELEFUNKEN Semiconductors

Rev . A4, 05-Mar-97

15 (16)

U2407B

Ozone Depleting Substances Policy Statement

It is the policy of TEMIC TELEFUNKEN microelectronic GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating systems

with respect to their impact on the health and safety of our employees and the public, as well as their impact on

the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances (ODSs).

The Montreal Protocol ( 1987) and its London Amendments (1990) intend to severely restrict the use of ODSs and

forbid their use within the next ten years. Various national and international initiatives are pressing for an earlier ban

on these substances.

TEMIC TELEFUNKEN microelectronic GmbH semiconductor division has been able to use its policy of

continuous improvements to eliminate the use of ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2. Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency (EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C (transitional substances) respectively.

TEMIC can certify that our semiconductors are not manufactured with ozone depleting substances and do not contain

such substances.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use TEMIC products for any unintended or unauthorized

application, the buyer shall indemnify TEMIC against all claims, costs, damages, and expenses, arising out of,

directly or indirectly, any claim of personal damage, injury or death associated with such unintended or

unauthorized use.

16 (16)

TEMIC TELEFUNKEN microelectronic GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 (0)7131 67 2831, Fax number: 49 (0)7131 67 2423

TELEFUNKEN Semiconductors

Rev . A3, 05-Mar-97

Loading...

Loading...