Page 1

TP3076

COMBO

®

II Programmable PCM CODEC/Filter for ISDN

and Digital Phone Applications

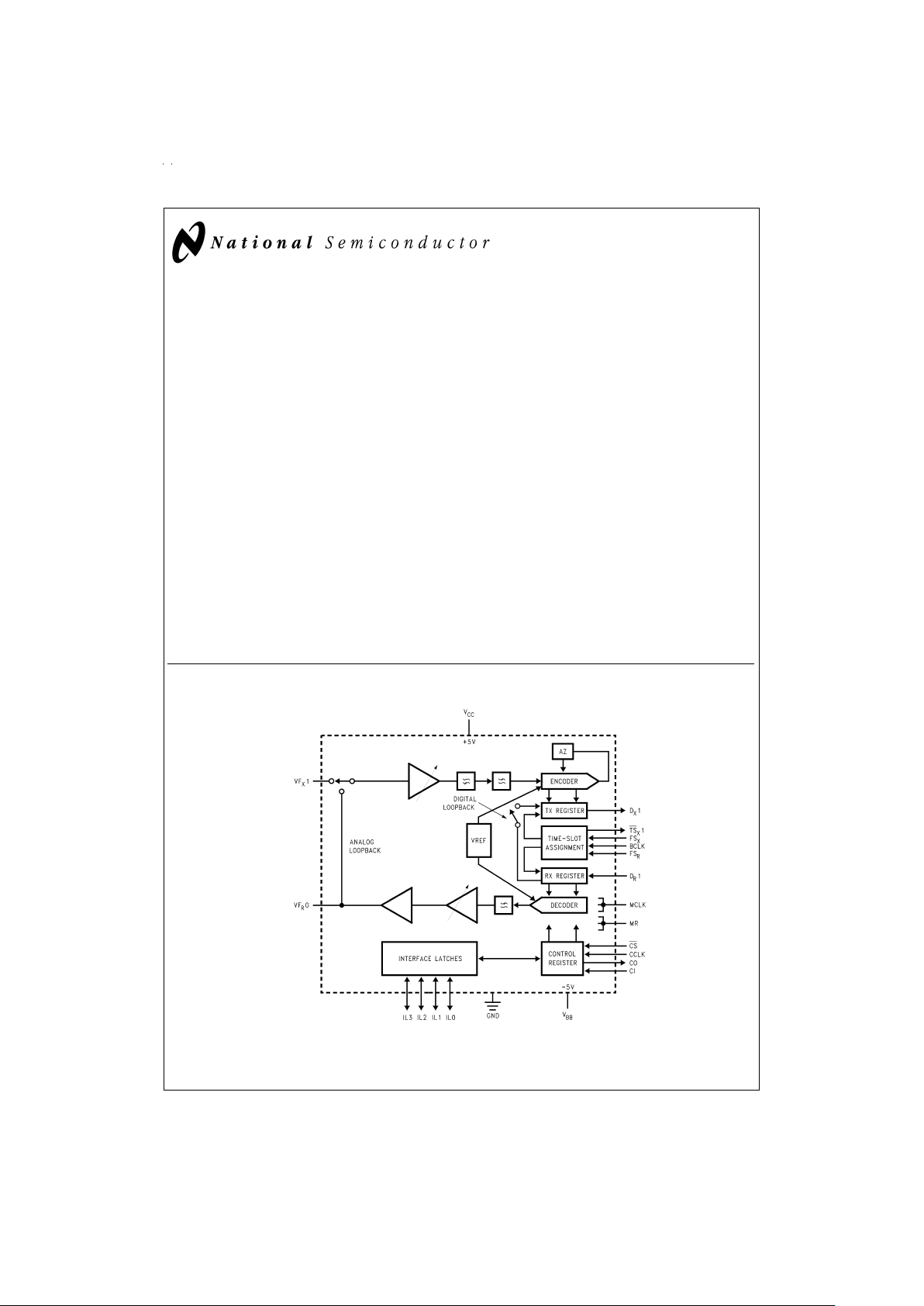

General Description

The TP3076 is a second-generation combined PCM CODEC

and Filter devices optimized for digital switching applications

on subscriber line and trunk cards and digital phone applications. Using advanced switched capacitor techniques,

COMBO II combines transmit bandpass and receive lowpass channel filters with a companding PCM encoder and

decoder. The devices are A-law and µ-law selectable and

employ a conventional serial PCM interface capable of being

clocked up to 4.096 MHz. A number of programmable functions may be controlled via a serial control port.

Channel gains are programmable over a 25.4 dB range in

each direction.

To enable COMBO II to interface to the SLIC control leads, a

number of programmable latches are included; each may be

configured as either an input or an output. The TP3076 provides 4 latches.

Features

n Complete CODEC and Filter system including:

— Transmit and receive PCM channel filters

— µ-law or A-law companding coder and decoder

— Receive power amplifier drives 300Ω

— 4.096 MHz serial PCM data (max)

n Programmable functions:

— Transmit gain: 25.4 dB range, 0.1 dB steps

— Receive gain: 25.4 dB range, 0.1 dB steps

— Time-slot assignment; to 64 slots/frame

— 4 interface latches

— A or µ-law

— Analog loopback

— Digital loopback

n Direct interface to solid-state SLICs

n Standard serial control interface

n 80 mW operating power (typ)

n 1.5 mW standby power (typ)

n Designed for CCITT and LSSGR specifications

n TTL and CMOS compatible digital interfaces

Note: See also AN-614 COMBO II application guide.

Block Diagram

TRI-STATE®and COMBO®are registered trademarks of National Semiconductor Corporation.

MICROWIRE/PLUS

™

is a trademark of National Semiconductor Corporation.

DS009758-1

FIGURE 1.

April 1994

TP3076 COMBO II Programmable PCM CODEC/Filter for ISDN and Digital Phone Applications

© 1999 National Semiconductor Corporation DS009758 www.national.com

Page 2

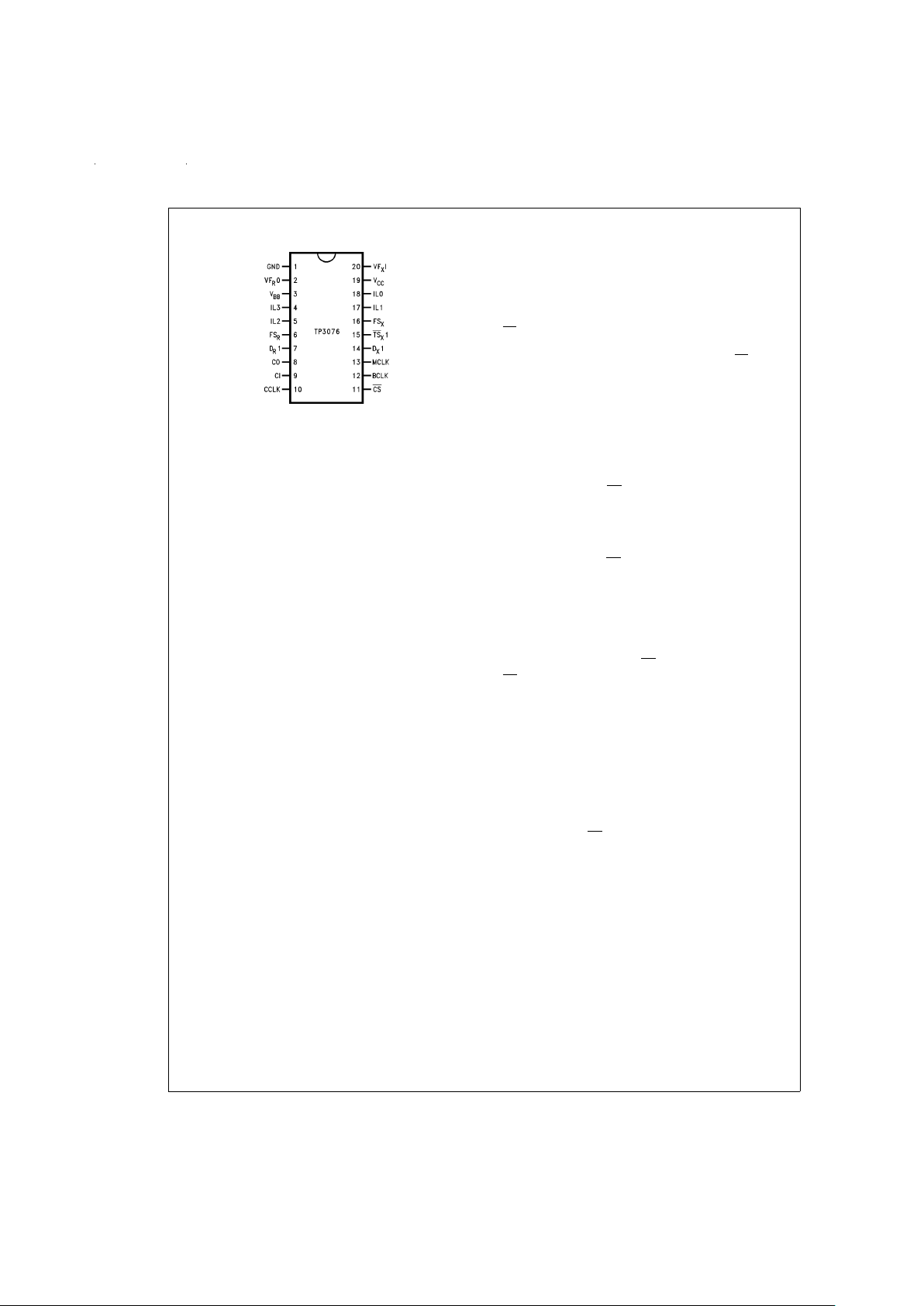

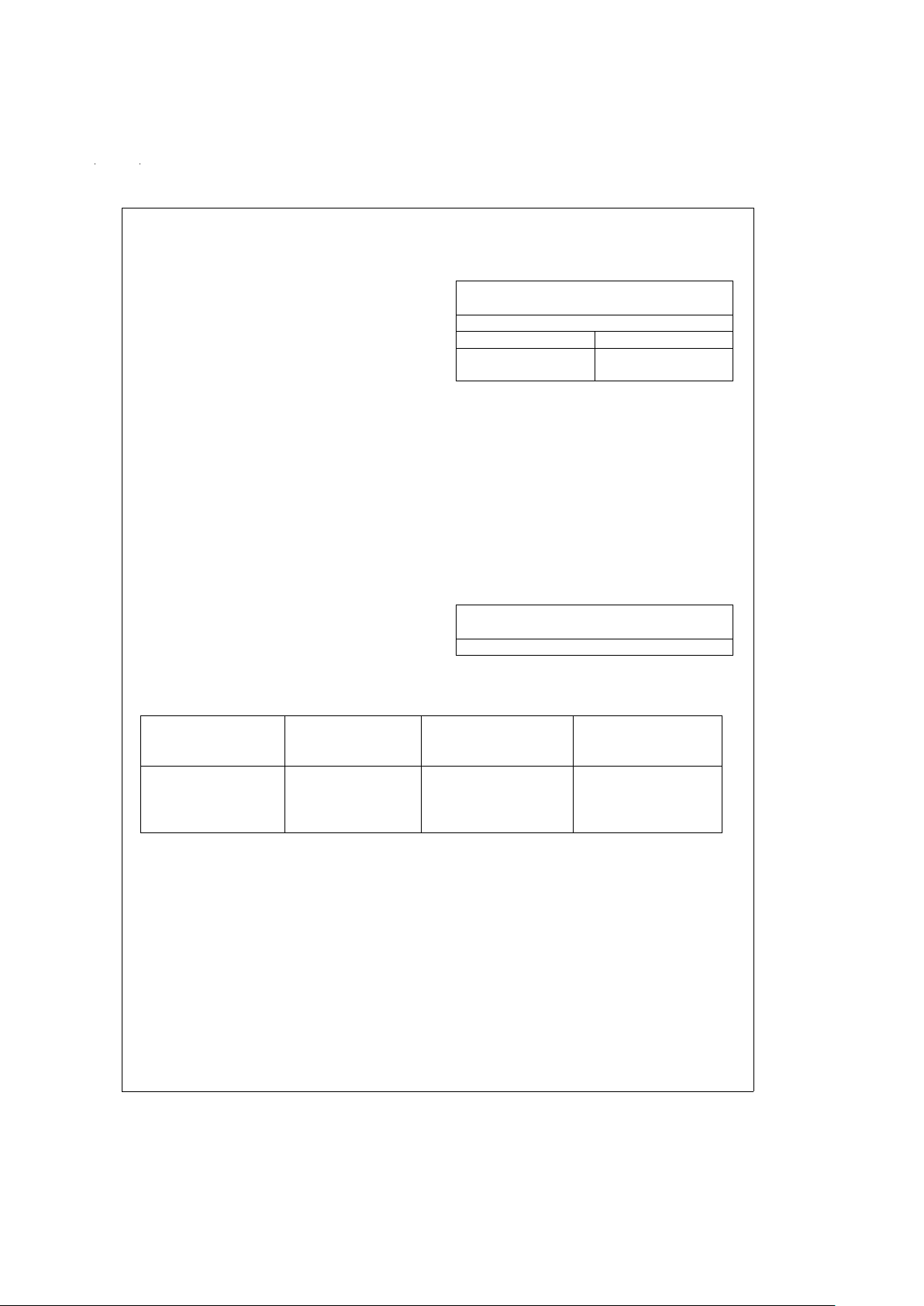

Connection Diagram

Pin Descriptions

Pin Description

V

CC

+5V±5%power supply.

V

BB

−5V±5%power supply.

GND Ground. All analog and digital signals are

referenced to this pin.

FS

X

Transmit Frame Sync input. Normally a pulse

or squarewave with an 8 kHz repetition rate is

applied to this input to define the start of the

transmit time slot assigned to this device

(non-delayed data timing mode), or the start of

the transmit frame (delayed data timing mode

using the internal time-slot assignment

counter).

FS

R

Receive Frame Sync input. Normally a pulse

or squarewave with an 8 kHz repetition rate is

applied to this input to define the start of the

receive time slot assigned to this device

(non-delayed data timing mode), or the start of

the receive frame (delayed data timing mode

using the internal time-slot assignment

counter).

BCLK Bit clock input used to shift PCM data into and

out of the D

R

and DXpins. BCLK may vary

from 64 kHz to 4.096 MHz in 8 kHz

increments, and must be synchronous with

MCLK.

MCLK Master clock input used by the switched

capacitor filters and the encoder and decoder

sequencing logic. Must be 512 kHz,

1.536/1.544 MHz, 2.048 MHz or 4.096 MHz

and synchronous with BCLK.

VF

X

I The Transmit analog high-impedance input.

Voice frequency signals present on this input

are encoded as an A-law or µ-law PCM bit

stream and shifted out on the selected D

X

pin.

VF

R

O The Receive analog power amplifier output,

capable of driving load impedances as low as

300Ω (depending on the peak overload level

required). PCM data received on the assigned

D

R

pin is decoded and appears at this output

as voice frequency signals.

Pin Description

D

X

1 This transmit data TRI-STATE®output

remains in the high impedance state except

during the assigned transmit time slot on the

assigned port, during which the transmit PCM

data byte is shifted out on the rising edges of

BCLK.

TS

X

1 Normally this open drain output is floating in a

high impedance state except when a time-slot

is active on the D

X

output, when the TSX1

output pulls low to enable a backplane

line-driver.

D

R

1 This receive data input is inactive except

during the assigned receive time slot of the

assigned port when the receive PCM data is

shifted in on the falling edges of BCLK.

CCLK Control Clock input. This clock shifts serial

control information into CI or out from CO

when the CS input is low, depending on the

current instruction. CCLK may be

asynchronous with the other system clocks.

CI Control Data Input pin. Serial control

information is shifted into COMBO II on this

pin when CS is low. Byte 1 of control

information is always written into COMBO II,

while the direction of byte 2 data is

determined by bit 2 of byte 1, as defined in

Table 1

.

CO Control Data Output pin. Serial control or

status information is shifted out of COMBO II

on this pin when CS is low.

CS Chip Select input. When this pin is low, control

information can be written to or read from

COMBO II via CI or CO.

IL3–IL0 Each Interface Latch I/O pin may be

individually programmed as an input or an

output determined by the state of the

corresponding bit in the Latch Direction

Register (LDR). For pins configured as inputs,

the logic state sensed on each input is latched

into the Interface Latch Register (ILR)

whenever control data is written to COMBO II,

while CS is low, and the information is shifted

out on the CO pin. When configured as

outputs, control data written into the ILR

appears at the corresponding IL pins.

Functional Description

POWER-ON INITIALIZATION

When power is first applied, power-on reset circuitry initializes the COMBO II and puts it into the power-down state.

The gain control registers for the transmit and receive gain

sections are programmed for no output, the power amp is

disabled and the device is in the non-delayed timing mode.

The Latch Direction Register (LDR) is pre-set with all IL pins

programmed as inputs, placing the SLIC interface pins in a

high impedance state. The CO pin is in TRI-STATE condition. Other initial states in the Control Register are indicated

in Section 2.0.

DS009758-4

Order Number TP3076J

See NS Package Number J20A

www.national.com 2

Page 3

Functional Description (Continued)

The desired modes for all programmable functions may be

initialized via the control port prior to a Power-up command.

POWER-DOWN STATE

Following a period of activity in the powered-up state the

power-down state may be re-entered by writing any of the

control instructions into the serial control port with the “P” bit

set to “1” as indicated in

Table1

. It is recommended that the

chip be powered down before writing any additional instructions. In the power-down state, all non-essential circuitry is

de-activated and the D

X

1 output is in the high impedance

TRI-STATE condition.

The data stored in the Gain Control registers, the LDR and

ILR, and all control bits remain unchanged in the

power-down state unless changed by writing new data via

the serial control port, which remains active. The outputs of

the Interface Latches also remain active, maintaining the

ability to monitor and control the SLIC.

TRANSMIT FILTER AND ENCODER

The Transmit section input, VF

X

I, is a high impedance input.

No external components are necessary to set the gain. Following this is a programmable gain/attenuation amplifier

which is controlled by the contents of the Transmit Gain Register (see Programmable Functions section). An active

pre-filter then precedes the 3rd order high-pass and 5th or-

der low-pass switched capacitor filters. The A/D converter

has a compressing characteristic according to the standard

CCITT A or µ255 coding laws, which must be selected by a

control instruction during initialization (see

Table1

and

Table

2

). A precision on-chip voltage reference ensures accurate

and highly stable transmission levels. Any offset voltage arising in the gain-set amplifier, the filters or the comparator is

canceled by an internal auto-zero circuit.

Each encode cycle begins immediately following the assigned Transmit time-slot. The total signal delay referenced

to the start of the time-slot is approximately 165 µs (due to

the Transmit Filter) plus 125 µs (due to encoding delay),

which totals 290 µs. Data is shifted out on D

X

1 during the se-

lected time slot on eight rising edges of BCLK.

DECODER AND RECEIVER FILTER

PCM data is shifted into the Decoder’s Receive PCM Register via the D

R

1 pin during the selected time-slot on the 8 falling edges of BCLK. The Decoder consists of an expanding

DAC with either A or µ255 law decoding characteristic, which

is selected by the same control instruction used to select the

Encode law during initialization. Following the Decoder is a

5th order low-pass switched capacitor filter with integral Sin

x/x correction for the 8 kHz sample and hold. A programmable gain amplifier, which must be set by writing to the Receive Gain Register, is included, and finally a Power Amplifier capable of driving a 300Ω load to

±

3.5V,a 600Ω load to

±

3.8V or a 15 kΩ load to±4.0V at peak overload.

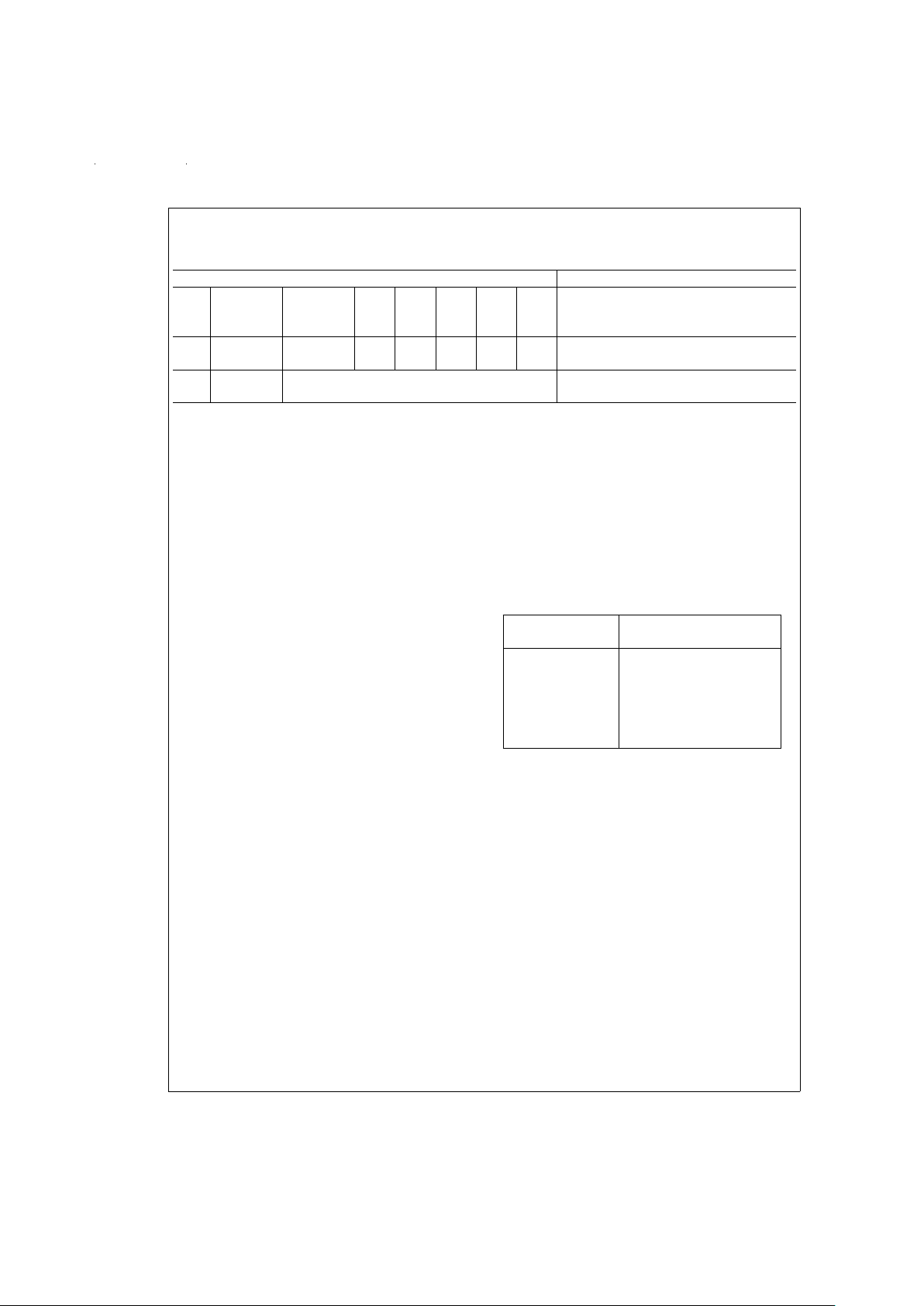

TABLE 1. Programmable Register Instructions

Function Byte 1 (Notes 1, 2, 3) Byte 2 (Note 1)

7654321076543210

Single Byte Power-Up/Down PXXXXX0X None

Write Control Register P 000001X See

Table 2

Read-Back Control Register P 000011X See

Table 2

Write to Interface Latch Register P 000101X See

Table 4

Read Interface Latch Register P 000111X See

Table 4

Write Latch Direction Register P 001001X See

Table 3

Read Latch Direction Register P 001011X See

Table 3

Write Receive Gain Register P 010001X See

Table 8

Read Receive Gain Register P 010011X See

Table 8

Write Transmit Gain Register P 010101X See

Table 7

Read Transmit Gain Register P 010111X See

Table 7

Write Receive Time-Slot/Port P 100101X See

Table 6

Read-Back Receive Time-Slot/Port P 100111X See

Table 6

Write Transmit Time-Slot/Port P 101001X See

Table 6

Read-Back Transmit Time-Slot/Port P 101011X See

Table 6

Note 1: Bit 7 of bytes 1 and 2 is always the first bit clocked into or out from the CI or CO pin. X=don’t care.

Note 2: “P” is the power-up/down control bit, see Power-up/Down Control section. (“0”=Power Up, “1”=Power Down)

Note 3: Other register address codes are invalid and should not be used.

A decode cycle begins immediately after the assigned receive timeslot, and 10 µs later the Decoder DAC output is

updated. The total signal delay is 10 µs plus 120 µs (filter delay) plus 62.5 µs (

1

⁄2frame) which gives approximately 190

µs.

PCM INTERFACE

The FS

X

and FSRframe sync inputs determine the beginning of the 8-bit transmit and receive time-slots respectively.

They may have any duration from a single cycle of BCLK

HIGH to one MCLK period LOW. Two different relationships

may be established between the frame sync inputs and the

actual time-slots on the PCM busses by setting bit 3 in the

Control Register (see

Table 2

). Non-delayed data mode is

similar to long-frame timing on the TP3050/60 series of de-

www.national.com3

Page 4

Functional Description (Continued)

vices (COMBO); time-slots begin nominally coincident with

the rising edge of the appropriate FS input. The alternative is

to use Delayed Data mode, which is similar to shortframe

sync timing on COMBO, in which each FS input must be high

at least a half-cycle of BCLK earlier than the timeslot. The

Time-SlotAssignment circuit on the device can only be used

with Delayed Data timing.

When using Time-Slot Assignment, the beginning of the first

time-slot in a frame is identified by the appropriate FS input.

The actual transmit and receive time-slots are then determined by the internal Time-Slot Assignment counters.

Transmit and Receive frames and time-slots may be skewed

from each other by any number of BCLK cycles. During each

assigned Transmit time-slot, the D

X

1 output shifts data out

from the PCM register on the rising edges of BCLK. TS

X

1

also pulls low for the first 71⁄2bit times of the time-slot to control the TRI-STATE Enable of a backplane line-driver. Serial

PCM data is shifted into the D

R

1 input during each assigned

Receive time-slot on the falling edges of BCLK.

SERIAL CONTROL PORT

Control information and data are written into or read-back

from COMBO II via the serial control port consisting of the

control clock CCLK, the serial data input, CI, and output, CO,

and the Chip Select input, CS. All control instructions require

2 bytes, as listed

Table1

, with the exception of a single byte

power-up/down command. The Byte 1 bits are used as follows: bit 7 specifies power up or power down; bits 6, 5, 4 and

3 specify the register address, bit 2 specifies whether the instruction is read or write; bit 1 specifies a one or two byte instruction; and bit 0 is not used.

To shift control data into COMBO II, CCLK must be pulsed

high 8 times while CS is low. Data on the CI input is shifted

into the serial input register on the falling edge of each CCLK

pulse. After all data is shifted in, the contents of the input

shift register are decoded, and may indicate that a 2nd byte

of control data will follow.This second byte may either be defined by a second byte-wide CS pulse or may follow the first

contiguously,i.e, it is not mandatory for CS to return high between the first and second control bytes. At the end of

CCLK8 in the 2nd control byte the data is loaded into the appropriate programmable register. CS may remain low continuously when programming successive registers, if desired. However, CS must be set high when no data transfers

are in progress.

To readback Interface Latch data or status information from

COMBO II, the first byte of the appropriate instruction is

strobed while CS is low, as defined in

Table 1

. CS must be

kept low, or be taken low again for a further 8 CCLK cycles,

during which the data is shifted onto the CO pin on the rising

edges of CCLK. When CS is high the CO pin is in the

high-impedance TRI-STATE, enabling the CI and CO pins of

many devices to be multiplexed together.

If CS returns high during either byte 1 or byte 2 before all

eight CCLK pulses of that byte occur, both the bit count and

byte count are reset and register contents are not affected.

This prevents loss of synchronization in the control interface

as well as corruption of register data due to processor interrupt or other problem. When CS returns low again, the device will be ready to accept bit 1 of byte 1 of a new instruction.

Programmable Functions

POWER-UP/DOWN CONTROL

Following power-on initialization, power-up and power-down

control may be accomplished by writing any of the control instructions listed in

Table1

into COMBO II with the “P” bit set

to “0” for power-up or “1” for power-down. Normally it is recommended that all programmable functions be initially programmed while the device is powered down. Power state

control can then be included with the last programming instruction or the separate single-byte instruction. Any of the

programmable registers may also be modified while the device is powered-up or down by setting the “P” bit as indicated. When the power-up or down control is entered as a

single byte instruction, bit one (1) must be reset to a 0.

When a power-up command is given, all de-activated circuits

are activated, but the TRI-STATEPCM output(s), D

X

1 will re-

main in the high impedance state until the second FS

X

pulse

after power-up.

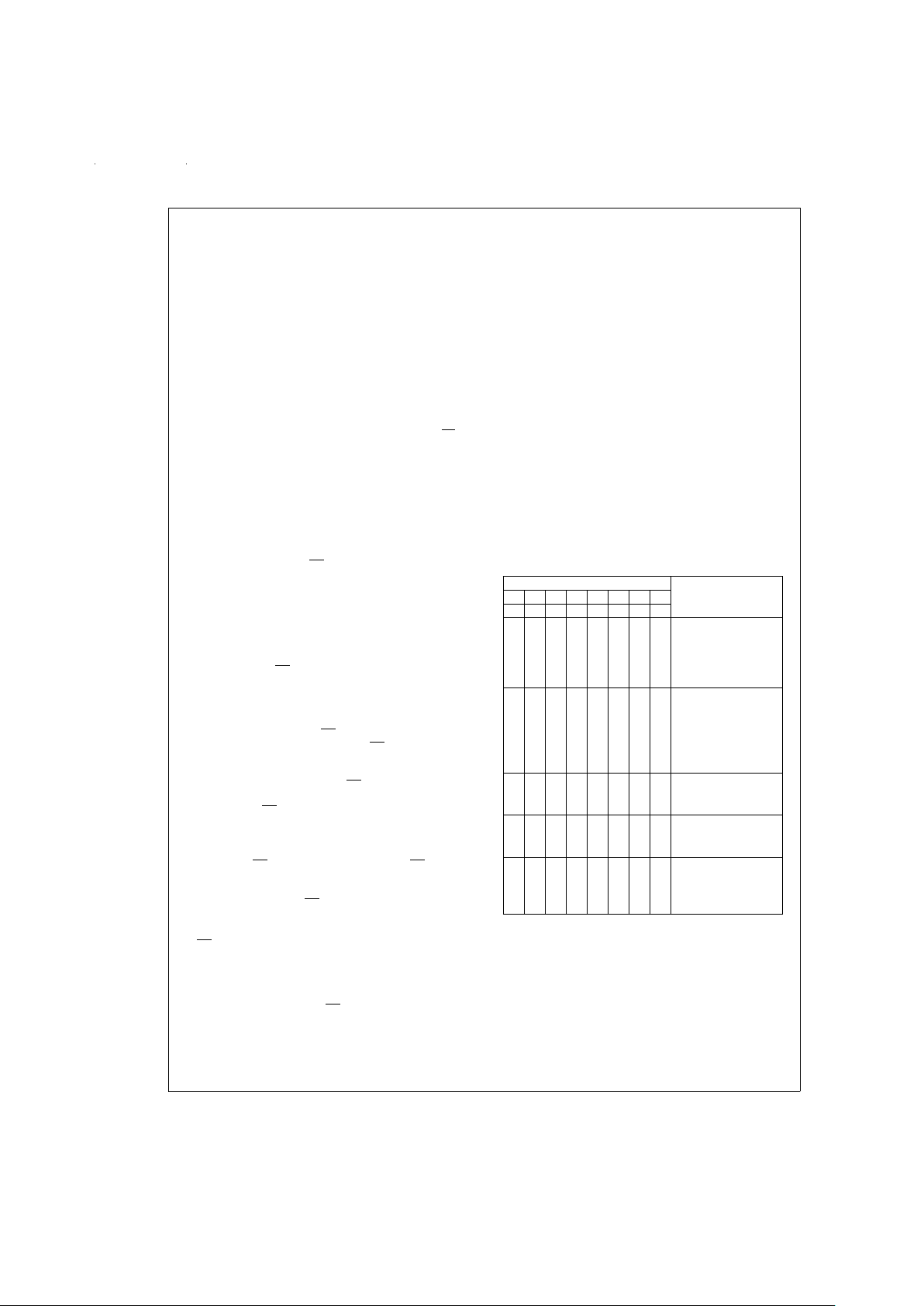

CONTROL REGISTER INSTRUCTION

The first byte of a READ or WRITE instruction to the Control

Register is as shown in

Table1

. The second byte has the fol-

lowing bit functions:

TABLE 2. Control Register Byte 2 Functions

Bit Number and Name

76543210 Function

F

1F0

MA IA DN DL AL PP

0 0 MCLK=512 kHz

0 1 MCLK=1.536 MHz

or 1.544 MHz

1 0 MCLK=2.048 MHz (Note 4)

1 1 MCLK=4.096 MHz

0 X Select µ255 Law (Note 4)

1 0 A-Law, Including

Even Bit

Inversion

1 1 A-Law, No Even Bit

Inversion

0 Delay Data Timing

1 Non-Delayed

Data Timing (Note 4)

0 0 Normal Operation (Note 4)

1 X Digital Loopback

0 1 Analog Loopback

0 Power Amp

Enabled in PDN

1 Power Amp

Disabled in PDN (Note 4)

Note 4: state at power-on initialization.

Master Clock Frequency Selection

A Master clock must be provided to COMBO II for operation

of the filter and coding/decoding functions. The MCLK frequency must be either 512 kHz, 1.536 MHz, 1.544 MHz,

2.048 MHz, or 4.096 MHz and must be synchronous with

BCLK. Bits F

1

and F0(see

Table2

) must be set during initial-

ization to select the correct internal divider.

www.national.com 4

Page 5

Programmable Functions (Continued)

Coding Law Selection

Bits “MA” and “IA” in

Table 2

permit the selection of µ255

coding or A-law coding, with or without even bit inversion.

Analog Loopback

Analog Loopback mode is entered by setting the “AL” and

“DL” bits in the Control Register as shown in

Table 2

.Inthe

analog loopback mode, the Transmit input VF

X

I is isolated

from the input pin and internally connected to the VF

R

O output, forming a loop from the Receive PCM Register back to

the Transmit PCM Register. The VF

R

O pin remains active,

and the programmed settings of the Transmit and Receive

gains remain unchanged, thus care must be taken to ensure

that overload levels are not exceeded anywhere in the loop.

Digital Loopback

Digital Loopback mode is entered by setting the “AL” and

“DL” bits in the Control Register as shown in

Table 2

. This

mode provides another stage of path verification by enabling

data written into the Receive PCM Register to be read back

from that register in any Transmit time-slot at D

X

1. PCM de-

coding continues and analog output appears at VF

R

0. The

output can be disabled by programming ‘No Output’ in the

Receive Gain Register (see

Table 8

).

INTERFACE LATCH DIRECTIONS

Immediately following power-on, all Interface Latches assume they are inputs, and therefore all IL pins are in a high

impedance state. Each IL pin may be individually programmed as a logic input or output by writing the appropriate

instruction to the LDR, see

Table 1

and

Table 3

. For minimum power dissipation, unconnected latch pins should be

programmed as outputs. For the TP3076, bits 2 and 3 should

always be programmed as “1” (outputs).

Bits L

3–L0

must be set by writing the specific instruction to

the LDR with the L bits in the second byte set as follows:

TABLE 3. Byte 2 Functions of Latch Direction Register

Byte 2 Bit Number

76543210

L

0

L1L2L311XX

L

n

Bit IL Direction

0 Input

1 Output

X=Don’t Care

INTERFACE LATCH STATES

Interface Latches configured as outputs assume the state

determined by the appropriate data bit in the 2-byte instruction written to the Interface Latch Register (ILR) as shown in

Table1

and

Table4

. Latches configured as inputs will sense

the state applied by an external source, such as the

Off-Hook detect output of a SLIC. All bits of the ILR, i.e.

sensed inputs and the programmed state of outputs, can be

read back in the 2nd byte of a READ from the ILR.

It is recommended that during initialization, the state of IL

pins to be configured as outputs should be programmed first

followed immediately by the Latch Direction Register.

TABLE 4. Interface Latch Data Bit Order

Bit Number

76543210

D

0

D1D2D3D4D5XX

TABLE 5. Coding Law Conventions

µ255 Law True A-Law with A-Law without

Even Bit Inversion Even Bit Inversion

MSB LSB MSB LSB MSB LSB

V

IN

=

+Full Scale 10000000 10101010 111111111

V

IN

=

0V 11111111 11010101 100000000

11111111 01010101 000000000

V

IN

=

−Full Scale 00000000 00101010 011111111

Note 5: The MSB is always the first PCM bit shifted in or out of COMBO II.

www.national.com5

Page 6

Programmable Functions (Continued)

TABLE 6. Time-Slot and Port Assignment Instruction

Bit Number and Name Function

7 6 5 43210

EN PS T

5

T

4

T

3

T

2

T

1

T

0

(Note 6) (Note 7)

0 1 X XXXXXDisable D

X

1 Output (Transmit Instruction)

Disable D

R

1 Input (Receive Instruction)

1 1 Assign One Binary Coded Time-Slot from 0–63 Enable D

X

1 Output (Transmit Instruction)

Assign One Binary Coded Time-Slot from 0–63 Enable D

R

1 Input (Transmit Instruction)

Note 6: The “PS” bit MUST be set to “1” for both transmit and receive for the TP3076.

Note 7: T5 is the MSB of the time-slot assignment bit field. Time-slot bits should be set to “000000” for both transmit and receive when operating in non-delayed data

timing mode.

TIME-SLOT ASSIGNMENT

COMBO II can operate in either fixed time-slot or time-slot

assignment mode for selecting the Transmit and Receive

PCM time-slots. Following power-on, the device is automatically in Non-Delayed Timing mode, in which the time-slot always begins with the leading (rising) edge of frame sync inputs FS

X

and FSR. Time-Slot Assignment may only be used

with Delay Data timing; see

Figure 4

.FSXand FSRmay

have any phase relationship with each other in BCLK period

increments.

Alternatively, the internal time-slot assignment counters and

comparators can be used to access any time-slot in a frame,

using the frame sync inputs as marker pulses for the beginning of transmit and receive time-slot 0. In this mode, a

frame may consist of up to 64 time-slots of 8 bits each. A

time-slot is assigned by a 2-byte instruction as shown in

Table 1

and

Table 6

. The last 6 bits of the second byte indicate the selected time-slot from 0–63 using straight binary

notation. When writing a time-slot and port assignment register,if the PCM interface is currently active, it is immediately

deactivated to prevent possible bus clashes. A new assignment becomes active on the second frame following the end

of the Chip-Select for the second control byte. Rewriting of

the register contents should not be performed during the

talking period of a connection to prevent waveform distortion

caused by loss of a sample which will occur with each register write. The “EN” bit allows the PCM input, D

R

1, or output,

D

X

1, as appropriate, to be enabled or disabled.

Time-Slot Assignment mode requires that the FS

X

and FS

R

pulses conform to the delayed data timing format shown in

Figure 4

.

PORT SELECTION

On the TP3076, the “PS” bit MUST always be set to 1.

Table 6

shows the format for the second byte of both trans-

mit and receive time-slot and port assignment instructions.

TRANSMIT GAIN INSTRUCTION BYTE 2

The transmit gain can be programmed in 0.1 dB steps by

writing to the Transmit Gain Register as defined in

Table 1

and

Table7

. This corresponds to a range of 0 dBm0 levels at

VF

X

I between 1.375 Vrms and 0.074 Vrms (equivalent to

+5.0 dBm to −20.4 dBm in 600Ω).

To calculate the binary code for byte 2 of this instruction for

any desired input 0 dBm0 level in Vrms, take the nearest integer to the decimal number given by:

200 x log

10

(V/0.07299)

and convert to the binary equivalent. Some examples are

given in

Table 7

. A complete tabulation is given in Appendix

I of AN-614.

It should be noted that the Transmit (idle channel) Noise and

Transmit Signal to Total Distortion are both specified with

transmit gain set to 0 dB (gain register set to all ones). At

high transmit gains there will be some degradation in noise

performance for these parameters. See Application Note

AN-614 for more information on this subject.

TABLE 7. Byte 2 of Transmit Gain Instruction

Bit Number 0 dBm0 Test Level (Vrms)

76543210 atVF

X

I

00000000 NoOutput (Note 8)

00000001 0.074

00000010 0.075

——

11111110 1.359

11111111 1.375

Note 8: Analog signal path is cut off, but DXremains active and will output

codes representing idle noise.

RECEIVE GAIN INSTRUCTION BYTE 2

The receive gain can be programmed in 0.1 dB steps by writing to the Receive Gain Register as defined in

Table 1

and

Table8

. Note the following restrictions on output drive capa-

bility:

1. 0 dBm0 levels ≤ 1.96 Vrms at VF

R

O may be driven into

a load of ≥ 15 kΩ to GND; Receive Gain set to 0 dB (gain

register set to all ones).

2. 0 dBm0 levels ≤ 1.85 Vrms at VF

R

O may be driven into

a load of ≥ 600Ω to GND; Receive Gain set to 0.5 dB.

3. 0 dBm0 levels ≤ 1.71 Vrms at VF

R

O may be driven into

a load of ≥ 300 Ω to GND. Receive Gain set to −1.2 dB.

To calculate the binary code for byte 2 of this instruction for

any desired output 0 dBm0 level in Vrms, take the nearest integer to the decimal number given by:

200 x log

10

(V/0.1043)

and convert to the binary equivalent. Some examples are

given in

Table8

.A complete tabulation is given in Appendix I

or AN-614.

www.national.com 6

Page 7

Programmable Functions (Continued)

TABLE 8. Byte 2 of Receive Gain Instruction

Bit Number 0 dBm0 Test Level (Vrms)

76543210 atVF

R

O

00000000 NoOutput (Low Z to GND)

00000001 0.105

00000010 0.107

——

11111110 1.941

11111111 1.964

Applications Information

Figure 2

shows a typical ISDN phone application of the

TP3076 together with a TP3420 ISDN Transceiver “S” Interface Device and HPC16400 High-Performance Microcontroller with HDLC Controller. The TP3076 device is programmed

over its serial control interface via the HPC16400

MICROWIRE/PLUS

™

serial I/O port.

POWER SUPPLIES

While the pins of the TP3076 COMBO II device are well protected against electrical misuse, it is recommended that the

standard CMOS practice of applying GND to the device before any other connections are made should always be followed. In applications where the printed circuit card may be

plugged into a hot socket with power and clocks already

present, an extra long ground pin on the connector should be

used and a Schottky diode connected between V

BB

and

GND.

To minimize noise sources all ground connections to each

device should meet at a common point as close as possible

to the GND pin in order to prevent the interaction of ground

return currents flowing through a common bus impedance.

Power supply decoupling capacitors of 0.1 µF should be

connected from this common point to V

CC

and VBBas close

to the device pins as possible.

Further guidelines on PCB layout techniques are provided in

Application Note AN-614, “COMBO II

™

Programmable PCM

CODEC/Filter Family Application Guide”.

www.national.com7

Page 8

Applications Information

DS009758-5

Note 9: Primo type EM80–PMI2 or similar.

Note 10: Primo type DH31 or similar.

Note 11: Sidetone

≅

−9.2 dB for 200Ω,

Sidetone

≅

−21.5 dB for 1200Ω.

FIGURE 2. Typical Application in an ISDN Phone

www.national.com 8

Page 9

Absolute Maximum Ratings (Note 12)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

CC

to GND 7V

Voltage at VF

X

IV

CC

+0.5V to VBB−0.5V

Voltage at Any Digital Input V

CC

+0.5V to GND −0.5V

Storage Temperature Range −65˚C to +150˚C

V

BB

to GND −7V

Current at VF

R

0

±

100 mA

Current at Any Digital Output

±

50 mA

Lead Temperature

(Soldering, 10 sec.) 300˚C

Electrical Characteristics

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%,V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. All other limits are assured by correlation with other production

tests and/or product design and characterization. All signals referenced to GND. Typicals specified at V

CC

=

+5V, V

BB

=

−5V,

T

A

=

25˚C.

Symbol Parameter Conditions Min Typ Max Units

DIGITAL INTERFACES

V

IL

Input Low Voltage All Digital Inputs (DC Meas.) 0.7 V

V

IH

Input High Voltage All Digital Inputs (DC Meas.) (Note 13) 2.0 V

V

OL

Output Low Voltage DX1, TSX1, and CO, I

L

=

3.2 mA,

0.4 V

All Other Digital Outputs, I

L

=

1mA

V

OH

Output High Voltage DX1 and CO, I

L

=

−3.2 mA, 2.4 V

All Other Digital Outputs (except TS

X

), I

L

=

−1 mA

All Digital Outputs, I

L

=

−100 µA V

CC

− 0.5 V

I

IL

Input Low Current Any Digital Input, GND<V

IN

<

V

IL

−10 10 µA

I

IH

Input High Current Any Digital Input, except MR, V

IH

<

V

IN

<

V

CC

−10 10 µA

MR Only −10 100

I

OZ

Output Current in DX1, TSX1and CO

High Impedance IL3–IL0 when Selected as Inputs −10 10 µA

State (TRI-STATE ) GND

<

V

OUT

<

V

CC

ANALOG INTERFACES

I

VFXI

Input Current, VFXI −3.3V<VFXI<3.3V −1.0 1.0 µA

R

VFXI

Input Resistance −3.3V<VFXI<3.3V 1.0 MΩ

VOS

X

Input Offset Voltage Transmit Gain=0 dB 200 mV

Applied at VF

X

I Transmit Gain=25.40 dB 10 mV

RL

VFRO

Load Resistance Receive Gain=0 dB 15k

Receive Gain=−0.5 dB 600 Ω

Receive Gain=−1.2 dB 300

CL

VFRO

Load Capacitance RL

VFRO

≥ 300Ω 200 pF

CL

VFRO

from VFROtoGND

RO

VFRO

Output Resistance Steady Zero PCM Code Applied to DR1 1.0 3.0 Ω

VOS

R

Output Offset Voltage Alternating±Zero PCM Code Applied −200 200 mV

at V

FRO

DR1, Maximum Receive Gain

POWER DISSIPATION

I

CC

0 Power Down Current CCLK, CI, CO=0.4V, CS=2.4V

Interface Latches Set as Outputs with No Load, 0.1 0.6 mA

All Other Inputs Active, Power Amp Disabled

I

BB

0 Power Down Current As Above −0.1 −0.3 mA

I

CC

1 Power Up Current CCLK, CI, CO=0.4V, CS=2.4V

No Load on Power Amp 8.0 11.0 mA

Interface Latches Set as Outputs with No Load

I

BB

1 Power Up Current As Above −8.0 −11.0 mA

I

CC

2 Power Down Current As Above, Power Amp Enabled 2.0 3.0 mA

I

BB

2 Power Down Current As Above, Power Amp Enabled −2.0 −3.0 mA

Note 12: “Absolute Maximum Ratings” indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits.

www.national.com9

Page 10

Electrical Characteristics (Continued)

Note 13: See definitions and timing conventions section.

Timing Specifications

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%;V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. All other limits are assured by correlation with other production

tests and/or product design and characterization. All signals referenced to GND. Typicals specified at V

CC

=

+5V, V

BB

=

−5V,

T

A

=

25˚C.

All timing parameters are measured at V

OH

=

2.0V and V

OL

=

0.7V.

See Definitions and Timing Conventions section for test methods information.

Symbol Parameter Conditions Min Typ Max Units

MASTER CLOCK TIMING

f

MCLK

Frequency of MCLK Selection of Frequency is Programmable 512 kHz

(See

Table 5

) 1536 kHz

1544 kHz

2048 kHz

4096 kHz

t

WMH

Period of MCLK High Measured from VIHto VIH(Note 14) 80 ns

t

WML

Period of MCLK Low Measured from VILto VIL(Note 14) 80 ns

t

RM

Rise Time of MCLK Measured from VILto V

IH

30 ns

t

FM

Fall Time of MCLK Measured from VIHto V

IL

30 ns

t

HBM

HOLD Time, BCLK LOW 50 ns

to MCLK HIGH

t

WFL

Period of FS

X

Measured from VILto V

IL

1 MCLK

or FS

R

Low Period

PCM INTERFACE TIMING

f

BCLK

Frequency of BCLK May Vary from 64 kHz to 4096 kHz 64 4096 kHz

in 8 kHz Increments

t

WBH

Period of BCLK High Measured from VIHto V

IH

80 ns

t

WBL

Period of BCLK Low Measured from VILto V

IL

80 ns

t

RB

Rise Time of BCLK Measured from VILto V

IH

30 ns

t

FB

Fall Time of BCLK Measured from VIHto V

IL

30 ns

t

HBF

Hold Time, BCLK Low 30 ns

to FS

X/R

High or Low

t

SFB

Setup Time, FS

X/R

30 ns

High to BCLK Low

t

DBD

Delay Time, BCLK High Load=100 pF Plus 2 LSTTL Loads 80 ns

to Data Valid

t

DBZ

Delay Time, BCLK Low to DX1D

X

1 disabled is measured

Disabled if FS

X

Low, FSXLow to at VOLor VOHaccording

D

X

1 disabled if 8th BCLK to

Figure 5

15 80 ns

Low, or BCLK High to D

X

1

Disabled if FS

X

High

t

DBT

Delay Time, BCLK High to Load=100 pF Plus 2 LSTTL Loads

TS

X

Low if FSXHigh, or 60 ns

FS

X

High to TSXLow if

BCLK High (Nondelayed mode); BCLK

High to TS

X

Low (delayed data mode)

t

ZBT

TRI-STATE Time, BCLK Low to

TS

X

High if FSXLow, FSXLow

to TSXHigh if 8th BCLK Low, or 15 60 ns

BCLK High to TS

X

High if FSXHigh

t

DFD

Delay Time, FS

X/R

Load=100 pF Plus 2 LSTTL Loads,

www.national.com 10

Page 11

Timing Specifications (Continued)

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%;V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. All other limits are assured by correlation with other production

tests and/or product design and characterization. All signals referenced to GND. Typicals specified at V

CC

=

+5V, V

BB

=

−5V,

T

A

=

25˚C.

All timing parameters are measured at V

OH

=

2.0V and V

OL

=

0.7V.

See Definitions and Timing Conventions section for test methods information.

Symbol Parameter Conditions Min Typ Max Units

PCM INTERFACE TIMING

High to Data Valid Applies if FS

X/R

Rises Later Than 80 ns

BCLK Rising Edge in Non-Delayed Data

Mode Only

t

SDB

Setup Time, DR1 30 ns

Valid to BCLK Low

t

HBD

Hold Time, BCLK 15 ns

Low to D

R

1 Invalid

SERIAL CONTROL PORT TIMING

f

CCLK

Frequency of CCLK 2048 kHz

t

WCH

Period of CCLK High Measured from VIHto V

IH

160 ns

t

WCL

Period of CCLK Low Measured from VILto V

IH

160 ns

t

RC

Rise Time of CCLK Measured from VILto V

IH

50 ns

t

FC

Fall Time of CCLK Measured of VIHto V

IL

50 ns

t

HCS

Hold Time, CCLK Low CCLK1 10 ns

to CS Low

t

HSC

Hold Time, CCLK CCLK8 100 ns

Low to CS High

t

SSC

Setup Time, CS 60 ns

Transition to CCLK Low

t

SSC0

Setup Time, CS To Insure CO is Not Enabled 60 ns

Transition to CCLK High for Single Byte

t

SDC

Setup Time, CI 50 ns

Data In to CCLK Low

t

HCD

Hold Time, CCLK 50 ns

Low to CO Invalid

t

DCD

Delay Time, CCLK High Load=100 pF Plus 2 LSTTL Loads 80 ns

to CO Data Out Valid

t

DSD

Delay Time, CS Low Applies Only if Separate 80 ns

to CO Valid CS Used for Byte 2

t

DDZ

Delay Time, CS or 9th CCLK Applies to Earlier of CS 15 80 ns

High to CO High Impedance High or 9th CCLK High

INTERFACE LATCH TIMING

t

SLC

Setup Time, IL to Interface Latch Inputs Only 100 ns

CCLK 8 of Byte 1

t

HCL

Hold Tme, IL Valid from 50 ns

8th CCLK Low (Byte 1)

t

DCL

Delay Time CCLK8 of Interface Latch Outputs Only 200 ns

Byte2toIL C

L

=

50 pF

Note 14: Applies only to MCLK Frequencies ≥ 1.536 MHz. At 512 kHz a 50:50±2%Duty Cycle must be used.

www.national.com11

Page 12

Timing Diagrams

DS009758-6

FIGURE 3. Non-Delayed Data Timing Mode

DS009758-7

FIGURE 4. Delayed Data Timing Mode

www.national.com 12

Page 13

Timing Diagrams (Continued)

DS009758-8

FIGURE 5. Control Port Timing

www.national.com13

Page 14

Transmission Characteristics

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%,V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. f=1015.625 Hz, VF

X

I=0 dBm0, DR1=0 dBm0 PCM code.

Transmit and receive gains programmed for maximum 0 dBm0 test levels (0 dB Gain). All other limits are assured by correlation with other production tests and/or product design and characterization. All signals referenced to GND. Typicals specified

at V

CC

=

+5V, V

BB

=

−5V, T

A

=

25˚C.

Symbol Parameter Conditions Min Typ Max Units

AMPLITUDE RESPONSE

Absolute Levels The Maximum 0 dBm0 Levels Are:

VF

X

I 1.375 Vrms

VF

R

O (15 kΩ Load) 1.964 Vrms

The Minimum 0 dBm0 Levels are:

VF

X

I 73.8 mVrms

VF

R

O (Any Load ≥ 300Ω) 105.0 mVrms

G

XA

Transmit Gain Transmit Gain Programmed for Maximum

Absolute Accuracy 0 dBm0 Test Level.

Measure Deviation of Digital Code from

Ideal 0 dBm0 PCM Code at D

X

1.

T

A

=

25˚C −0.15 0.15 dB

G

XAG

Transmit Gain T

A

=

25˚C, V

CC

=

5V, V

BB

=

5V

Variation with Programmed Gain from 0 dB to 19 dB

Programmed Gain (0 dBm0 Levels of 1.619 Vrms to 0.182 Vrms) −0.1 0.1 dB

Programmed Gain from 19.1 dB to 25.4 dB

(0 dBm0 Levels of 0.180 Vrms to 0.087 Vrms) −0.3 0.3 dB

Note:±0.1 dB Min/Max is Available as a Selected Part

G

XAF

Transmit Gain Relative to 1015.625 Hz, (Note 18)

Variation with Minimum Gain

<

G

X

<

Maximum Gain

Frequency f=60 Hz −26 dB

f=200 Hz −1.8 −0.1 dB

f=300 Hz to 3000 Hz −0.15 0.15 dB

f=3400 Hz −0.7 0.0 dB

f=400 Hz −14 dB

f ≥ 4600 Hz. Measure Response −32 dB

at Alias Frequency from 0 kHz to 4 kHz

G

X

=

0.0 dB, VF

X

I=1.375 Vrms

Relative to 1015.625 Hz

f=62.5 Hz −24.9 dB

f=203.125 Hz −1.7 −0.1 dB

f=343.75 Hz −0.15 0.15 dB

f=515.625 Hz −0.15 0.15 dB

f=2140.625 Hz −0.15 0.15 dB

f=3156.25 Hz −0.15 0.15 dB

f=3406.250 Hz −0.74 0.0 dB

f=3984.375 Hz −13.5 dB

Relative to 1062.5 Hz (Note 18)

f=5250 Hz, Measure 2750 Hz −32 dB

f=11750 Hz, Measure 3750 Hz −32 dB

f=49750 Hz, Measure 1750 Hz −32 dB

G

XAT

Transmit Gain Measured Relative to GXA,V

CC

=

5V,

Variation with V

BB

=

−5V, −0.1 0.1 dB

Temperature Minimum gain

<

G

X

<

Maximum Gain

www.national.com 14

Page 15

Transmission Characteristics (Continued)

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%,V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. f=1015.625 Hz, VF

X

I=0 dBm0, DR1=0 dBm0 PCM code.

Transmit and receive gains programmed for maximum 0 dBm0 test levels (0 dB Gain). All other limits are assured by correlation with other production tests and/or product design and characterization. All signals referenced to GND. Typicals specified

at V

CC

=

+5V, V

BB

=

−5V, T

A

=

25˚C.

Symbol Parameter Conditions Min Typ Max Units

AMPLITUDE RESPONSE

G

XAL

Transmit Gain Sinusoidal Test Method.

Variation with Reference Level=0 dBm0

Signal Level VF

X

I=−40 dBm0 to +3 dBm0 −0.2 0.2 dB

VF

X

I=−50 dBm0 to −40 dBm0 −0.4 0.4 dB

VF

X

I=−55 dBm0 to −50 dBm0 −1.2 1.2 dB

G

RA

Receive Gain Receive Gain Programmed for Maximum

Absolute Accuracy 0 dBm0 Test Level. Apply 0 dBm0 −0.15 0.15 dB

PCM Code to D

R

1. Measure VFR0.

T

A

=

25˚C

G

RAG

Receive Gain T

A

=

25˚C, V

CC

=

5V, V

BB

=

−5V

Variation with Programmed Gain from 0 dB to 19 dB

Programmed Gain (0 dBm0 Levels of 1.964 Vrms to 0.220 Vrms) −0.1 0.1 dB

Programmed Gain from 19.1 dB to 25.4 dB

(0 dBm0 Levels of 0.218 Vrms to 0.105 Vrms) −0.3 0.3 dB

Note:±0.1 dB Min/Max is Available as a Selected Part

G

RAT

Receive Gain Measured Relative to GRA.

Variation with V

CC

=

5V, V

BB

=

−5V. −0.1 0.1 dB

Temperature Minimum Gain

<

G

R

<

Maximum Gain

G

RAF

Receive Gain Relative to 1015.625 Hz, (Note 18)

Variation with D

R

1=0 dBm0 Code.

Frequency Minimum Gain

<

G

R

<

Maximum Gain

f=200 Hz −0.25 0.15 dB

f=300 Hz to 3000 Hz −0.15 0.15 dB

f=3400 Hz −0.7 0.0 dB

f=4000 Hz −14 dB

G

R

=

0 dB, D

R

1=0 dBm0 Code,

G

X

=

0 dB (Note 18)

f=296.875 Hz −0.15 0.15 dB

f=1875.00 Hz −0.15 0.15 dB

f=2906.25 Hz −0.15 0.15 dB

f=2984.375 Hz −0.15 0.15 dB

f=3406.250 Hz −0.74 0.0 dB

f=3984.375 Hz −13.5 dB

G

RAL

Receive Gain Sinusoidal Test Method.

Variation with Reference Level=0 dBm0.

Signal Level D

R

1=−40 dBm0 to +3 dBm0 −0.2 0.2 dB

D

R

1=−50 dBm0 to −40 dBm0 −0.4 0.4 dB

D

R

1=−55 dBm0 to −50 dBm0 −1.2 1.2 dB

DR

1

=

3.1 dBm0 −0.5

R

L

=

600Ω,G

R

=

−0.5 dB −0.2 0.2 dB

R

L

=

300Ω,G

R

=

1.2 dB −0.2 0.2 dB

ENVELOPE DELAY DISTORTION WITH FREQUENCY

D

XA

Tx Delay, Absolute f=1600 Hz 315 µs

www.national.com15

Page 16

Transmission Characteristics (Continued)

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%,V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. f=1015.625 Hz, VF

X

I=0 dBm0, DR1=0 dBm0 PCM code.

Transmit and receive gains programmed for maximum 0 dBm0 test levels (0 dB Gain). All other limits are assured by correlation with other production tests and/or product design and characterization. All signals referenced to GND. Typicals specified

at V

CC

=

+5V, V

BB

=

−5V, T

A

=

25˚C.

Symbol Parameter Conditions Min Typ Max Units

ENVELOPE DELAY DISTORTION WITH FREQUENCY

D

XR

Tx Delay, Relative to DXA f=500 Hz–600 Hz 220 µs

f=600 Hz–800 Hz 145 µs

f=800 Hz–1000 Hz 75 µs

f=1000 Hz–1600 Hz 40 µs

f=1600 Hz–2600 Hz 75 µs

f=2600 Hz–2800 Hz 105 µs

f=2800 Hz–3000 Hz 155 µs

D

RA

Rx Delay, Absolute f=1600 Hz 200 µs

D

RR

Rx Delay, Relative to DRA f=500 Hz–1000 Hz −40 µs

f=1000 Hz–1600 Hz −30 µs

f=1600 Hz–2600 Hz 90 µs

f=2600 Hz–2800 Hz 125 µs

f=2800 Hz–3000 Hz 175 µs

NOISE

N

XC

Transmit Noise, C Message (Note 15) 11111111 12 15 dBrnC0

Weighted, µ-Law Selected in Gain Register

N

XP

Transmit Noise, P Message (Note 15) 11111111 −74 −67 dBm0p

Weighted, A-Law Selected in Gain Register

N

RC

Receive Noise, C Message PCM Code is Alternating Positive 8 11 dBrnC0

Weighted, µ-Law Selected

N

RP

Receive Noise, P Message PCM Code Equals Positive Zero −82 −79 dBm0p

Weighted, A-Law Selected

N

RS

Noise, Single Frequency f=0 kHz to 100 kHz, Loop Around −53 dBm0

Measurement, VF

X

I=0 Vrms

PPSR

X

Positive Power Supply V

CC

=

5.0 V

DC

+ 100 mVrms

Rejection, Transmit f=0 kHz–4 kHz (Note 16) 36 dBC

f=4 kHz–50 kHz 30 dBC

NPSR

X

Negative Power Supply V

BB

=

−5.0 V

DC

+100 mVrms

Rejection, Transmit f=0 kHz–4 kHz (Note 16) 36 dBC

f=4 kHz–50 kHz 30 dBC

PPSR

R

Positive Power Supply PCM Code Equals Positive Zero

Rejection, Receive V

CC

=

5.0 V

DC

+ 100 mVrms

Measure VF

R

O

f=0 Hz–4000 Hz 36 dBC

f=4 kHz–25 kHz 40 dB

f=25 kHz–50 kHz 36 dB

NPSR

R

Negative Power Supply PCM Code Equals Positive Zero

Rejection, Receive V

BB

=

−5.0 V

DC

+ 100 mVrms

Measure VF

R

O

f=0 Hz–4000 Hz 36 dBC

f=4 kHz–25 kHz 40 dB

f=25 kHz–50 kHz 36 dB

www.national.com 16

Page 17

Transmission Characteristics (Continued)

Unless otherwise noted, limits printed in BOLD characters are guaranteed for V

CC

=

+5V

±

5%,V

BB

=

−5V

±

5%;T

A

=

0˚C to

+70˚C by correlation with 100%electrical testing at T

A

=

25˚C. f=1015.625 Hz, VF

X

I=0 dBm0, DR1=0 dBm0 PCM code.

Transmit and receive gains programmed for maximum 0 dBm0 test levels (0 dB Gain). All other limits are assured by correlation with other production tests and/or product design and characterization. All signals referenced to GND. Typicals specified

at V

CC

=

+5V, V

BB

=

−5V, T

A

=

25˚C.

Symbol Parameter Conditions Min Typ Max Units

NOISE

SOS Spurous Out-of-Band 0 dBm0 300 Hz to 3400 Hz Input PCM Code

Signals Applied at the at D

R

1

Channel Output 4600 Hz–7600 Hz −30 dB

7600 Hz–8400 Hz −40 dB

8400 Hz–50,000 Hz −30 dB

DISTORTION

STD

X

Signal to Total Distortion Sinusoidal Test Method

STD

R

Transmit or Receive Level=3.0 dBm0 33 dBC

Half-Channel, µ-Law

=

0 dBm0 to −30 dBm0 36 dBC

Selected

=

−40 dBm0 30 dBC

=

−45 dBm0 25 dBC

STD

RL

Single to Total Distortion Sinusoidal Test Method

Receive with Resistive Level=+3.1 dBm0

Load R

L

=

600Ω,G

R

=

−0.5 dB 33 dBC

R

L

=

300Ω,G

R

=

−1.2 dB 33 dBC

SFD

X

Single Frequency −46 dB

Distortion, Transmit

SFD

R

Single Frequency −46 dB

Distortion, Receive

IMD Intermodulation Distortion Transmit or Receive

Two Frequencies in the Range −41 dB

300 Hz–3400 Hz

CROSSTALK

CT

X-R

Transmit to Receive Crosstalk, f=300 Hz–3400 Hz −90 −75 dB

0 dBm0 Transmit Level D

R

=

Idle Code

CT

R-X

Receive to Transmit Crosstalk, f=300 Hz–3400 Hz −90 −70 dB

0 dBm0 Receive Level (Note 16)

Note 15: Measured by grounded input at V

FXI

.

Note 16: PPSR

X

, NPSRX, and CT

R-X

are measured with a −50 dBm0 activation signal applied to VFXI.

Note 17: A signal is Valid if it is above V

IH

or below VILand Invalid if it is between VILand VIH. For the purposes of this specification the following conditions apply:

a) All input signals are defined as: V

IL

=

0.4V, V

IH

=

2.7V, t

R

<

10 ns, t

F

<

10 ns.

b) t

R

is measured from VILto VIH.tFis measured from VIHto VIL.

c) Delay Times are measured from the input signal Valid to the output signal Valid.

d) Setup Times are measured from the data input Valid to the clock input Invalid.

e) Hold Times are measured from the clock signal Valid to the data input Invalid.

f) Pulse widths are measured from V

IL

to VILor from VIHto VIH.

Note 18: A multi-tone test technique is used.

www.national.com17

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

the body, or (b) support or sustain life, and whose failure to perform when properly used in accordance

with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury

to the user.

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Ceramic Dual-In-Line Package (J)

Order Number TP3076J

NS Package Number J20A

TP3076 COMBO II Programmable PCM CODEC/Filter for ISDN and Digital Phone Applications

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...