Page 1

TK6593x

20P

LARGE EL LAMP DRIVER

FEATURES

■ High Ratio of Brightness / Input Power

■ Constant Brightness Versus Input Supply Changes

■ Optimized for 15 nf to 45 nf Panel Capacitance

■ Panel Voltage Slew Rates Controlled for Life

Enhancement

■ Panel Peak to Peak Voltage Independent of Input

Voltage and Temperature

■ Panel Peak to Peak Frequency Independent of

Input Voltage and Temperature

■ Miniature Package (SOT23L-6)

■ Operates with Miniature Coil

■ Minimum External Components

■ Laser-Trimmed Fixed Frequency Operation

■ PWM Control Method

■ Adjustable Output Voltage

■ Lower Noise (Audio and EMI)

■ Intensity Control Application (Refer to Application

Information)

DESCRIPTION

The TK6593x Electroluminescent (EL) Lamp Driver has

been optimized for battery controlled systems where power

consumption and size are primary concerns. The miniature

device size (SOT23L-6), together with the miniature Toko

EL coils (D32FU, D31FU, D52FU), further helps system

designers reduce the space required to drive the small EL

panels.

APPLICATIONS

■ Battery Powered Systems

■ Cellular Telephones

■ Pagers

■ LCD Modules

■ Wrist Watches

■ Consumer Electronics

The oscillator circuits for the boost converter and lamp

driver are both internally generated in the TK6593x, without

the need for external components. The clock frequency of

the boost converter is laser-trimmed to ensure good initial

accuracy that is relatively insensitive to variations in

temperature and supply voltage. The clock frequency of

the lamp driver tracks the frequency of the boost converter

by a constant scaling factor.

Furthermore, the drive architecture of the TK6593x has

been designed to limit peak drive current delivered to the

lamp. This approach limits the slew rate of the voltage

across the lamp and has the potential to improve lamp life

and decrease RF interference.

The TK6593x is available in a miniature, 6-pin

SOT23L-6 surface mount package.

TK6593x

+

EL

V

CC

The proprietary architecture (detailed in the Theory of

Operation section) of the TK6593x provides a constant

output power to the lamp, independent of variations in the

HV

EL

GND

-

IND

battery voltage. This architecture allows the output voltage

to remain relatively constant as battery voltages decay,

without the need for directly sensing the high voltage

BLOCK DIAGRAM

output of the EL driver.

ORDERING INFORMATION

TK6593 MTL

LAMP FREQUENCY CODE

TK65930 175 Hz

TK65931* 200 Hz

TK65932 225 Hz

TK65933* 250 Hz

TK65934 275 Hz

TK65935* 300 Hz

TK65936 325 Hz

TK65937* 350 Hz

TK65938 375 Hz

TK65939* 400 Hz

Lamp Frequency Code

TAPE/REEL CODE

TL: Tape Left

* Consult factory for availability

of other frequencies.

V

CC

HV BOOST

CONTROL

OSCILLATOR

H

BRIDGE

IND

GND

HV

EL

EL

+

-

May 2000 TOKO, Inc. Page 1

Page 2

TK6593x

ABSOLUTE MAXIMUM RATINGS

VCC Pin.................................................................... 6.5 V

All Pins Except V

and GND ...............................V

CC

CLAMP

Power Dissipation (Note 1) ................................ 600 mW

TK6593x ELECTRICAL CHARACTERISTICS

VCC = 3.6 V, TA = Tj = 25 °C, unless otherwise specified.

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Storage Temperature Range ................... -55 to +150 °C

Operating Temperature Range ...................-30 to +80 °C

Junction Temperature ........................................... 150 °C

V

CC

I

Q

I

PEAK

F

LAMP

F

BOOST

V

CLAMP

D

(MAX)

V

OUT

I

CONV

Note 1: Power dissipation is 600 mW when mounted as recommended (200 mW In Free Air). Derate at 4.8 mW/°C for operation above 25 °C.

Note 2: Converter supply current is dependent upon the DC resistance of inductor L1. Lower DC resistances will result in lower supply currents.

Note 3: When using test circuit below.

Note 4: Refer to Page 5 graph of Peak Current Threshold vs. Supply Voltage.

Gen. Note: Refer to “INDUCTOR VALUE SELECTION” and “INDUCTOR TYPE SELECTION” of Design Considerations Section for choosing

inductor.

Input Supply Range 2.7 3.6 6 V

Quiescent Current Current into pin 6 200 µA

Peak Current Threshold (Note 4) 87 97 107 mA

Lamp Frequency See Table 1 Hz

Boost Frequency See Table 2 kHz

Boost Clamp Voltage Force 100 µA into HV pin 90 105 120 V

Maximum Duty Cycle 88 92 96 %

Peak to Peak Lamp Voltage (Note 3) 125 140 155 V

Converter Supply Current (Notes 2, 3) See Table 3 mA

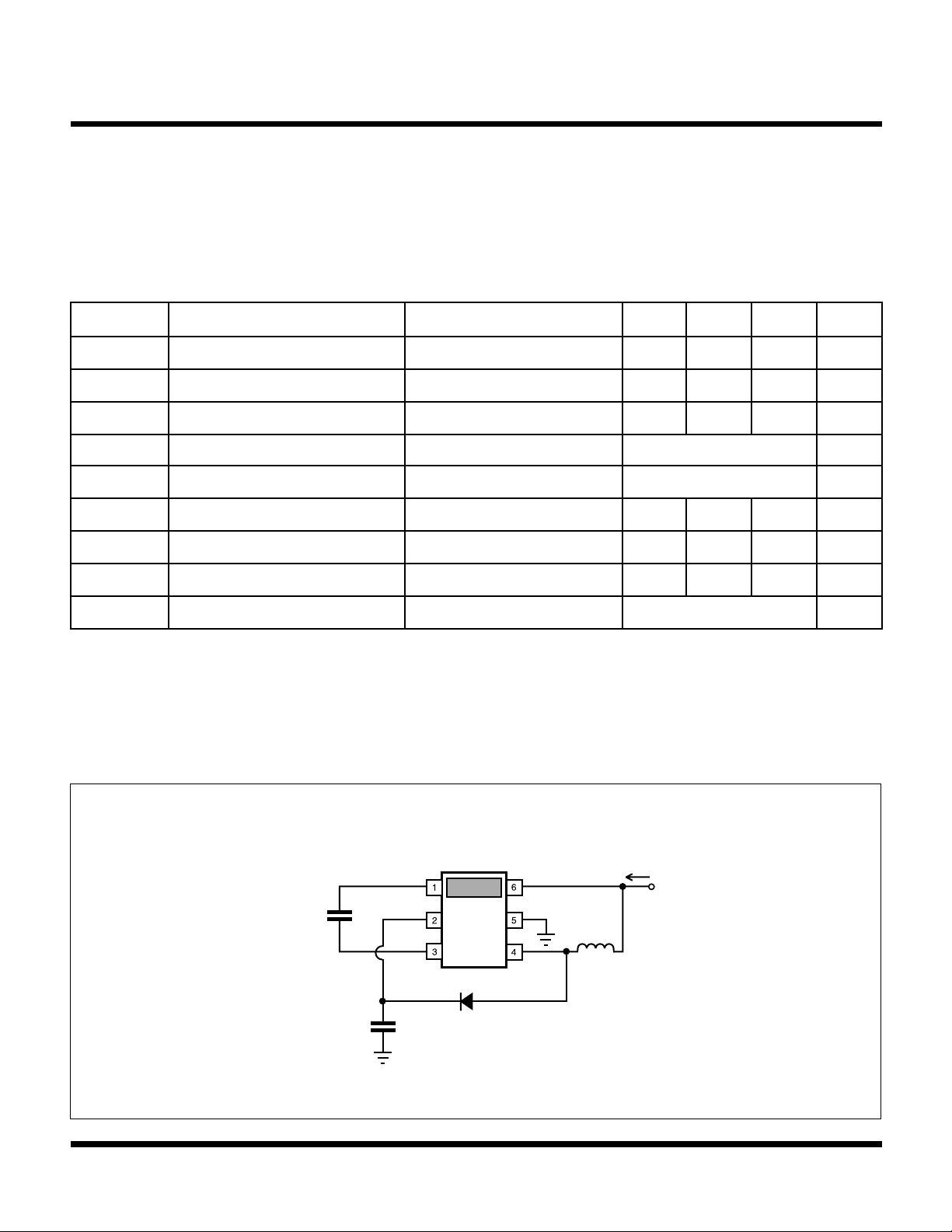

TEST CIRCUIT

I

L

1

330 µH

CONV

V

CC

C

EL

20 nF

+

EL

HV GND

-

EL

D

C

1

100 nF

1

V

CC

IND

Note: L1 = Toko Low Profile D52FU Series: 875FU-331 M

D1 = DIODES INC. DL4148

C1 = AVX 12061C104KAT2A

Page 2 May 2000 TOKO, Inc.

Page 3

TK6593x ELECTRICAL CHARACTERISTICS

VIN = 3.6 V, TA = Tj = 25 °C, unless otherwise specified.

TABLE 1: LAMP FREQUENCY

TOKO PART NO. MIN. TYP. MAX.

TK65930 157 Hz 175 Hz 193 Hz

TK65931 180 Hz 200 Hz 220 Hz

TK65932 202 Hz 225 Hz 248 Hz

TK65933 225 Hz 250 Hz 275 Hz

TK65934 247 Hz 275 Hz 303 Hz

TK65935 270 Hz 300 Hz 330 Hz

TK65936 292 Hz 325 Hz 358 Hz

TK65937 315 Hz 350 Hz 385 Hz

TK65938 337 Hz 375 Hz 413 Hz

TK65939 360 Hz 400 Hz 440 Hz

TABLE 2: OSCILLATOR FREQUENCY

TK6593x

TOKO PART NO. MIN. TYP. MAX.

TK65930 20.1 kHz 22.4 kHz 24.7 kHz

TK65931 23.0 kHz 25.6 kHz 28.2 kHz

TK65932 25.9 kHz 28.8 kHz 31.7 kHz

TK65933 28.8 kHz 32.0 kHz 35.2 kHz

TK65934 31.6 kHz 35.2 kHz 38.8 kHz

TK65935 34.5 kHz 38.4 kHz 42.3 kHz

TK65936 37.4 kHz 41.6 kHz 45.8 kHz

TK65937 40.3 kHz 44.8 kHz 49.3 kHz

TK65938 43.2 kHz 48.0 kHz 52.8 kHz

TK65939 46.1 kHz 51.2 kHz 56.3 kHz

TABLE 3: CONVERTER SUPPLY CURRENT

TOKO PART NO. MIN. TYP. MAX.

TK65930 - 14.2 mA 28.4 mA

TK65931 - 16.2 mA 32.4 mA

TK65932 - 18.3 mA 36.6 mA

TK65933 - 20.3 mA 40.6 mA

TK65934 - 22.3 mA 44.6 mA

TK65935 - 24.3 mA 48.6 mA

TK65936 - 26.4 mA 52.8 mA

TK65937 - 28.4 mA 56.8 mA

TK65938 - 30.4 mA 60.8 mA

TK65939 - 32.4 mA 64.8 mA

May 2000 TOKO, Inc. Page 3

Page 4

TK6593x

V

(V)

V

(V)

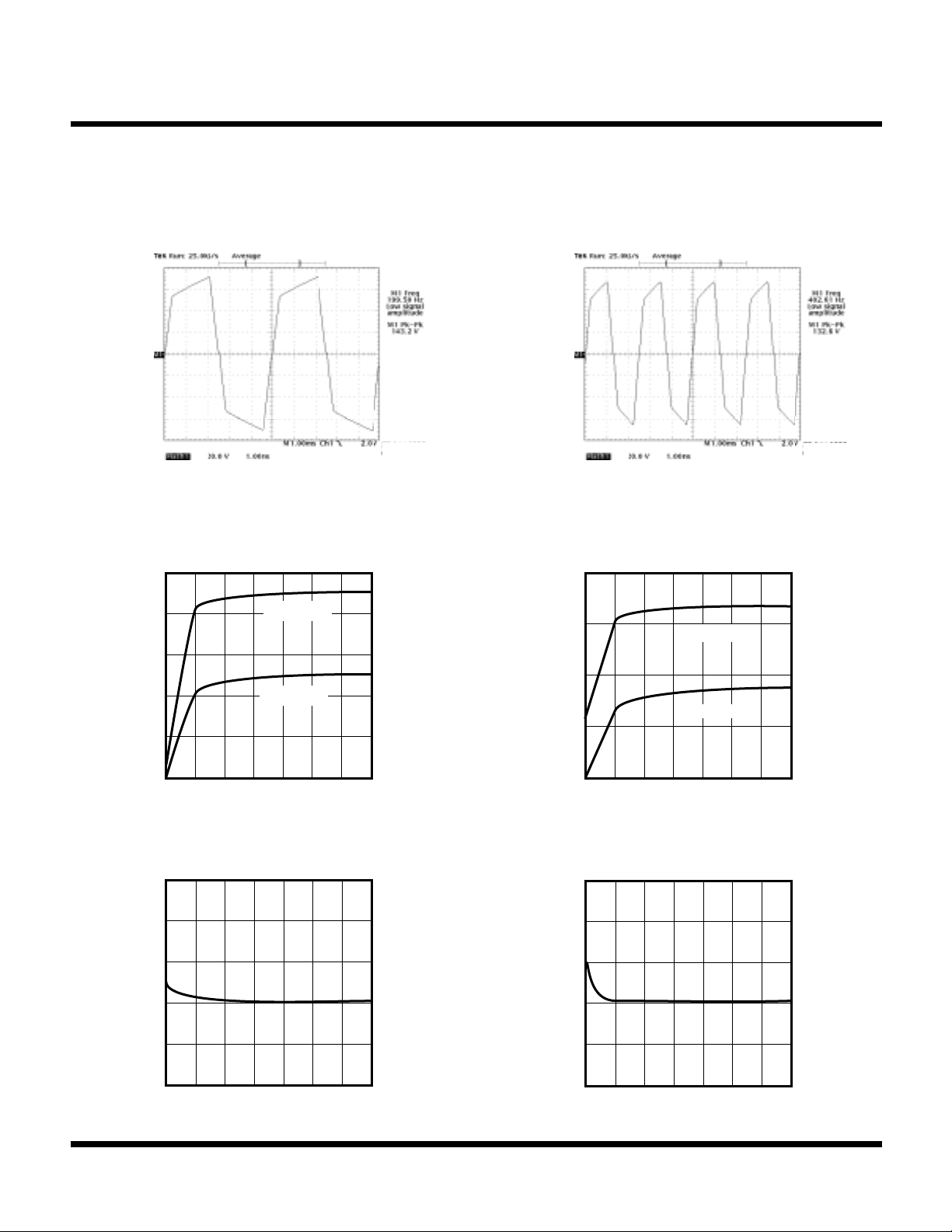

TYPICAL PERFORMANCE CHARACTERISTICS

USING TEST CIRCUIT

TK65931 Voltage Waveform

PEAK TO PEAK LAMP VOLTAGE

150

140

130

OUT

120

110

100

2.5 3 3.5 4 4.5 5 5.5 6

230

220

TK65931

vs. SUPPLY VOLTAGE

L1 = 330 µH

L1 = 220 µH

VCC (V)

TK65931

LAMP FREQUENCY

vs. SUPPLY VOLTAGE

TK65939 Voltage Waveform

PEAK TO PEAK LAMP VOLTAGE

140

130

120

OUT

110

100

2.5 3 3.5 4 4.5 5 5.5 6

460

440

TK65939

vs. SUPPLY VOLTAGE

L1 = 330 µH

L1 = 220 µH

VCC (V)

TK65939

LAMP FREQUENCY

vs. SUPPLY VOLTAGE

210

(Hz)

200

LAMP

F

190

180

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

420

(Hz)

400

LAMP

F

380

360

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

Page 4 May 2000 TOKO, Inc.

Page 5

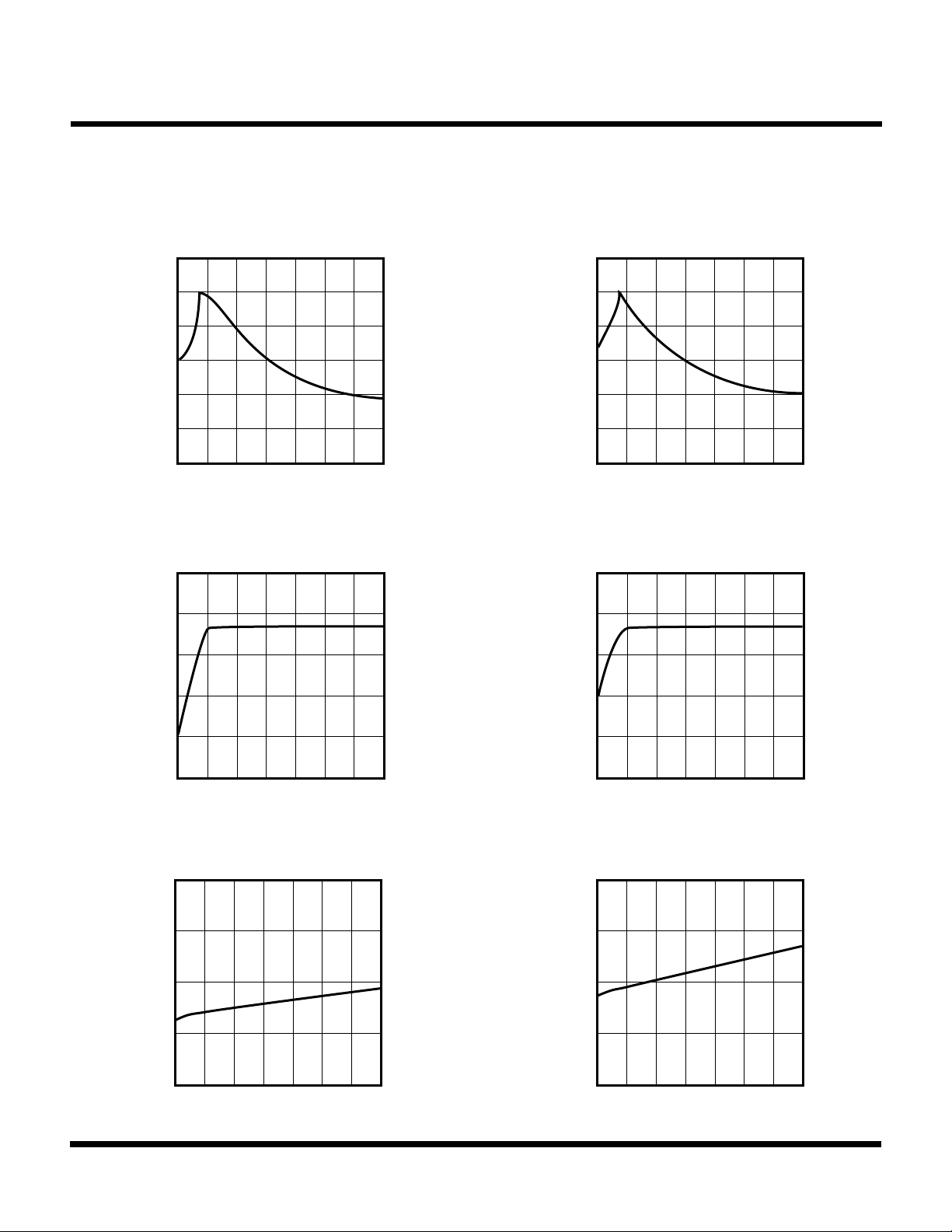

TYPICAL PERFORMANCE CHARACTERISTICS (CONT.)

6

I

(

A)

I

(

A)

USING TEST CIRCUIT

TK6593x

AVERAGE CONVERTER SUPPLY

CURRENT vs. SUPPLY VOLTAGE

30

25

20

(mA)

15

CONV

I

10

5

0

2.5 3 3.5 4 4.5 5 5.5

PEAK CURRENT THRESHOLD

110

100

90

m

TK65931

VCC (V)

TK65931

vs. SUPPLY VOLTAGE

AVERAGE CONVERTER SUPPLY

CURRENT vs. SUPPLY VOLTAGE

60

50

40

(mA)

30

CONV

I

20

10

0

2.5 3 3.5 4 4.5 5 5.5 6

PEAK CURRENT THRESHOLD

110

100

90

m

TK65939

VCC (V)

TK65939

vs. SUPPLY VOLTAGE

80

PEAK

70

60

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

TK65931

QUIESCENT CURRENT

vs. SUPPLY VOLTAGE

0

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

(µA)

I

200

150

100

Q

50

80

PEAK

70

60

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

TK65939

QUIESCENT CURRENT

vs. SUPPLY VOLTAGE

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

(µA)

I

200

150

100

Q

50

0

May 2000 TOKO, Inc. Page 5

Page 6

TK6593x

V

(V)

V

(V)

F

(H

)

F

(H

)

(°C)

(°C)

TYPICAL PERFORMANCE CHARACTERISTICS (CONT.)

USING TEST CIRCUIT

PEAK TO PEAK LAMP VOLTAGE

160

150

140

130

OUT

120

110

100

90

-50 -25 0 25 50 75 100 125

220

210

z

200

TK65931

vs. TEMPERATURE

VCC = 3.6 V

VCC = 2.7 V

TEMPERATURE (°C)

TK65931

LAMP FREQUENCY

vs. TEMPERATURE

PEAK TO PEAK LAMP VOLTAGE

160

150

140

130

OUT

120

110

100

z

90

440

420

400

VCC = 2.7 V

-50 -25 0 25 50 75 100 125

TK65939

vs. TEMPERATURE

VCC = 3.6 V

TEMPERATURE (°C)

TK65939

LAMP FREQUENCY

vs. TEMPERATURE

LAMP

190

180

170

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

AVERAGE CONVERTER SUPPLY

CURRENT vs. TEMPERATURE

25

20

15

(mA)

CONV

10

I

5

0

-50 -25 0 25 50 75 100 125

TK65931

TEMPERATURE

LAMP

380

360

340

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

AVERAGE CONVERTER SUPPLY

CURRENT vs. TEMPERATURE

45

40

35

(mA)

CONV

30

I

25

20

-50 -25 0 25 50 75 100 125

TK65939

TEMPERATURE

Page 6 May 2000 TOKO, Inc.

Page 7

TYPICAL PERFORMANCE CHARACTERISTICS (CONT.)

I

(

A)

I

(

A)

I

(

A)

I

(

A)

USING TEST CIRCUIT

TK6593x

PEAK CURRENT THRESHOLD

110

100

m

90

PEAK

80

70

60

-50 -25 0 25 50 75 100 125

100

90

80

µ

Q

70

TK65931

vs. TEMPERATURE

VCC = 3.6 V

VCC = 2.7 V

TEMPERATURE (°C)

TK65931

QUIESCENT CURRENT

vs. TEMPERATURE

PEAK CURRENT THRESHOLD

110

100

m

90

PEAK

80

70

60

-50 -25 0 25 50 75 100 125

120

110

100

µ

Q

90

TK65939

vs. TEMPERATURE

VCC = 3.6

VCC = 2.7

TEMPERATURE (°C)

TK65939

QUIESCENT CURRENT

vs. TEMPERATURE

60

50

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

80

70

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

May 2000 TOKO, Inc. Page 7

Page 8

TK6593x

D

(%)

TYPICAL PERFORMANCE CHARACTERISTICS (CONT.)

USING D

TEST CIRCUIT

(MAX)

TK65931

MAXIMUM DUTY CYCLE

95

94

93

(MAX)

92

91

90

95

94

(%)

93

vs. SUPPLY VOLTAGE

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

TK65931

MAXIMUM DUTY CYCLE

vs. TEMPERATURE

TK65939

MAXIMUM DUTY CYCLE

95

94

(%)

93

(MAX)

D

92

91

90

95

94

(%)

93

vs. SUPPLY VOLTAGE

2.5 3 3.5 4 4.5 5 5.5 6

VCC (V)

TK65939

MAXIMUM DUTY CYCLE

vs. TEMPERATURE

(MAX)

D

92

91

90

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

D

+

EL

HV GND

-

EL

TEST CIRCUIT

(MAX)

V

IND

CC

(MAX)

D

92

91

90

-50 -25 0 25 50 75 100 125

V

CC

R

1

Note: R1 = 470 Ω

TEMPERATURE (°C)

Page 8 May 2000 TOKO, Inc.

Page 9

THEORY OF OPERATION

TK6593x

An Electroluminescent (EL) Lamp is a strip of plastic,

coated with a phosphorous material that emits light when

a high voltage AC signal is applied to the terminals of the

device. EL panels have the ability to light the entire panel

uniformly. Because of this, they are gradually becoming

more popular and widespread than LEDs. The amount of

light emitted from an EL Lamp is typically proportional to

the magnitude of the voltage applied to the lamp.

Furthermore, the color of the light emitted by an EL Lamp

is somewhat dependent upon the frequency of the applied

drive signal. For most applications, a peak-to-peak voltage

of 100 to 170 V, with a drive frequency of 175 to 400 Hz,

provides optimal trade-off between lamp intensity and

power consumption.

The capacitance of the EL Panel is typically proportional to

the size of the lamp (a 1 square inch EL Panel typically

exhibits approximately 5 nF of capacitance load). The

TK6593x series of devices has been optimized to drive EL

panels, which are approximately 3-6 square inches in size.

The Boost section of the TK6593x consists of a controller

for stepping up a relatively low voltage (2.7 to 6 V) to a

much higher voltage (50 to 90 V) needed to drive the EL

Lamp. The boost section of the TK6593x uses a proprietary

architecture which provides a relatively constant output

power, independent of the input supply, without the need

for sensing the high voltage output of the boost converter.

By controlling the peak current through the switching

element of the boost converter, the boost section provides

a constant output power independent of the input supply.

The H-Bridge section of the TK6593x switches the high

voltage output of the boost converter to the two terminals

of the EL Lamp. By alternately switching the terminals of

the lamp between the high voltage supply and ground, the

peak-to-peak voltage developed across the lamp is

effectively twice the high voltage generated by boost

converter. Furthermore, the TK6593x limits the magnitude

of the drive currents through the H-Bridge switches in

order to minimize the edge rates developed across the EL

Lamp. This approach protects the EL Panel from large

current spikes and reduces the likelihood of high frequency

noise components being injected into neighboring circuitry.

clock is generated by dividing the high frequency clock by

128; this lower frequency clock corresponds to the drive

frequency of the EL Lamp. The laser-trimmed oscillators

are relatively insensitive to variations in temperature and

supply voltage. Therefore, they provide good control of the

lamp color emitted by the panel.

The circuit below illustrates a typical application where the

TK6593x is driving a 3-square-inch EL Lamp with a

capacitance of approximately 20 nF.

I

L

1

330 µH

CONV

V

CC

C

EL

20 nF

+

EL

HV GND

-

EL

D

C

1

100 nF

1

V

IND

CC

FIGURE 1: TYPICAL APPLICATION

By keeping the ratio of the boost frequency and the HBridge frequency constant, the peak-to-peak output voltage

from the TK6593x becomes primarily dependent upon the

capacitance of the EL Lamp, the peak current threshold of

the boost converter, and the value of the inductive element

used in the boost converter. For the TK6593x, the peak

current threshold is laser-trimmed to 97 mA. The capacitive

load of the EL Lamp is a function of panel size and is

typically fixed. Therefore, the high voltage output of the

boost converter can be set to a desired voltage by selecting

the appropriate value of the inductive element used in the

boost converter.

I

= Boost Peak Current Threshold (97 mA)

PEAK

C

= Capacitance of EL Lamp

EL

The Oscillator section of the TK6593x generates a fixed

L = Inductance Value

frequency clock source for the previously described Boost

and H-Bridge sections, without the need for external

VHV = (I

/ 2) x (L /CEL) x 128

PEAK

components. The high frequency output of the oscillator is

used for driving the boost controller. A lower frequency

May 2000 TOKO, Inc. Page 9

Page 10

TK6593x

HV

HVP HVP

UL UR

EL Panel

LL LR

Current Source 1

Current Source 2

EL

-

EL

+

THEORY OF OPERATION (CONT.)

With properly selected components, the TK6593x will

nominally support peak output voltages to 90 V

(180 V

from the driver outputs, the removal of the load can cause

the output voltage to increase beyond 90 V. To protect

against this fault condition, a clamp circuit exists on the

high voltage output which nominally limits the output

voltage to a typical value of 105 V (210 V

H-BRIDGE SECTION OPERATION

In an effort to extend EL lamp life, reduce EMI emissions,

and reduce the power draw of the IC, current sources to

control the charging and discharging of the EL lamp panel

and special sequencing control of the H-bridge FETs were

added to the H-bridge of TK659xx.

). Should the EL Panel become disconnected

PK-PK

).

PK-PK

DETAILS CONCERNING THE

FIGURE 2: H-BRIDGE SCHEMATIC

BOTH OFF

Current sources were added between ground and the

sources of the low-side N-channel FETs (Figure 2).

Therefore, the current into and out of the EL panel is

controlled and limited.

The FETs are turned off and on in the sequence shown in

Figure 3. As is noted in Figure 3, there is a period of time

when both of lower N-channel FETs are turned on and both

of upper P-channel FETs are turned off. This provides a

period of time to discharge the EL panel capacitance

completely; before starting to recharge it again with current

from HV voltage rail. Therefore, this special sequencing

method prevents taking current off the HV voltage rail

during the discharge of EL panel capacitance and operates

more efficiently.

UL

OFF

UR

OFF

LL

ON

LR

ON

-

V

EL

+

V

EL

+

V

=

V

EL

EL

-

V

-

EL

ON

OFF

BOTH ON

OFF

ON

Discharging

EL Panel

Capacitance

OFF

OFF

ON

ON

OFF

ON

ON

OFF

Page 10 May 2000 TOKO, Inc.

FIGURE 3: H-BRIDGE SEQUENCING WAVEFORMS

Page 11

TK6593x

PIN DESCRIPTIONS

SUPPLY PIN (VCC)

This pin is the positive input supply for the TK6593x. Good design practices dictate capacitive decoupling to the ground

pin.

GROUND PIN (GND)

The pin provides the ground connection for the IC.

IND PIN

This pin is periodically pulled to ground by a power transistor acting as an internal switch to the TK6593x. Externally, this

pin is typically connected to an inductor and a rectifying diode. By modulating the switching action of the internal switch,

the TK6593x can boost the relatively low voltage of the battery to the high voltage required to drive the EL Lamp.

HV PIN

This pin is connected to the filter capacitor and the cathode of the rectifying diode in order to generate a high voltage

supply. This high voltage supply is switched to the terminals of the EL Lamp through the H-Bridge.

EL+ PIN

This pin is connected to one side of the EL Panel.

EL- PIN

This pin is connected to the other side of the EL Panel.

Note: Measuring the voltage across the EL lamp (EL+ pin to EL- pin) should be done with balanced scope probes using

differential measurement techniques to obtain a true waveform of the voltage across the EL lamp.

May 2000 TOKO, Inc. Page 11

Page 12

TK6593x

DESIGN CONSIDERATIONS

INDUCTOR VALUE SELECTION

Designing an EL Driver utilizing the TK6593x is a very simple task. The primary component affecting the behavior of the

converter is the inductor. Essentially, the entire design task primarily consists of selecting the proper inductor value and

type given the operating conditions of the EL Panel (e.g., lamp capacitance, frequency, output voltage, supply range).

The following tables and charts are intended to simplify the selection of the inductor.

Given the capacitance of the EL Lamp, and the peak output voltage requirements, the following table can be utilized to

select the value of the inductive component.

TABLE 4: PEAK OUTPUT VOLTAGE VS. INDUCTOR VALUE AND LAMP CAPACITANCE

INDUCTOR

VALUE

100 µH 45 V 39 V 35 V 32 V 29 V 27 V 26 V

120 µH 49 V 43 V 38 V 35 V 32 V 30 V 28 V

150 µH 55 V 48 V 43 V 39 V 36 V 34 V 32 V

180 µH 60 V 52 V 47 V 43 V 39 V 37 V 35 V

220 µH 66 V 58 V 51 V 47 V 44 V 41 V 38 V

270 µH 74 V 64 V 57 V 52 V 48 V 45 V 43 V

330 µH 81 V 70 V 63 V 58 V 53 V 50 V 47 V

390 µH 88 V 77 V 69 V 63 V 58 V 54 V 51 V

470 µH 84 V 75 V 69 V 64 V 59 V 56 V

560 µH 82 V 75 V 69 V 65 V 61 V

680 µH 83 V 76 V 72 V 67 V

820 µH 84 V 79 V 74 V

1000 µH 87 V 82 V

Note: The voltages indicated in the table above may not be achievable under certain circumstances (i.e., low battery or higher drive frequencies).

Refer to the charts on page 12 to determine which output voltage/coil combination can be supported by the EL driver.

15.0 nF

LAMP

Close to 100 V operation check capacitor C1 voltage rating

20.0 nF

LAMP

25.0 nF

LAMP

30.0 nF

LAMP

35.0 nF

LAMP

40.0 nF

LAMP

45.0 nF

LAMP

As an example as to how the above table is to be used, assume that we have a 4-square-inch panel (30 nF capacitance)

and we would like the peak-to-peak voltage across the lamp to be 140 V. The peak voltage on either terminal would be

70 V (140 V / 2). Referring to the table above, we can see that using a 470 µH coil the peak voltage developed across

a 30 nF Lamp would be approximately 69 V. In this particular example, the inductive component should have a value of

470 µH.

INDUCTOR TYPE SELECTION

After the value of the inductor has been selected, an appropriate coil type needs to be selected taking into account such

factors as DC resistance and current capability. The following charts can be utilized for selecting the proper family of Toko

Coils. Furthermore, the following charts will also indicate if the TK6593x is the appropriate driver given the frequency and

input supply requirements. The following charts will indicate whether or not the TK6593x has sufficient drive capability,

Page 12 May 2000 TOKO, Inc.

Page 13

TK6593x

INDUCTOR

VALUE

(

H)

INDUCTOR

VALUE

(

H)

INDUCTOR

VALUE

(

H)

INDUCTOR

VALUE

(

H)

DESIGN CONSIDERATIONS (CONT.)

given the input supply and frequency requirements. A high-current solution for driving larger panels is currently under

development. To utilize the following charts in selecting an appropriate coil, perform the following steps:

1) From the following charts, select the chart that matches the part number of the Toko EL Driver that will be used in

the application. The part number of the Toko EL Driver will be dependant upon the desired frequency of the EL panel

(e.g., TK65931 = 200Hz).

2) Determine input supply voltage range (e.g., 4 to 6 V). The x-axis of the following charts represent the minimum

expected supply voltage. Below this minimum supply voltage the EL Driver output may begin to droop. On the

appropriate chart, draw a vertical line upward from the minimum supply voltage represented on the x-axis (e.g., 4V).

3) Draw a horizontal line passing through the chosen inductor value on the y-axis (e.g., 470 µH).

4) The vertical and horizontal lines drawn in steps 2 and 3 respectively will intersect at a point. This point will lie in one

of four regions of the chart (e.g., D52FU). These four regions suggest which family of Toko Coils to use.

Of the three coil families suggested in these charts, the D31FU has the smallest physical size but also has higher DC

resistance. The D52FU series of coils has the largest physical size and the lowest DC resistance. The D52FU or the

D32FU can be used as a reasonable substitute for the D31FU. Similarly, the D52FU can be used as a replacement for

the D32FU. Substituting a coil with lower DC resistance will generally result in a system that will consume less power

supply current.

1000

µ

1000

µ

820

680

560

470

390

330

270

220

180

100

820

680

560

470

390

330

270

220

180

TK65930, TK65931

(NOTE 1)

X

D31FU

3 4 5 6

MINIMUM SUPPLY (V)

TK65936, TK65937

(NOTE 1)

D31FU

D52FU

D32FU

D52FU

D32FU

TK65932, TK65933

1000

820

680

560

470

390

330

270

INDUCTOR VALUE (µH)

220

180

100

1000

820

µ

680

560

470

390

330

270

220

180

(NOTE 1)

3 4 5 6

MINIMUM SUPPLY (V)

TK65938, TK65939

(NOTE 1)

D31FU

D31FU

D32FU

D32FU

D52FU

D52FU

TK65934, TK65935

1000

820

µ

680

560

470

390

330

270

220

180

100

Note 1: A high-current solution for driving

larger panels is currently under development.

(NOTE 1)

D52FU

D32FU

D31FU

3 4 5 6

MINIMUM SUPPLY (V)

100

3 4 5 6

MINIMUM SUPPLY (V)

100

3 4 5 6

MINIMUM SUPPLY (V)

May 2000 TOKO, Inc. Page 13

Page 14

TK6593x

APPLICATION INFORMATION

EL LAMP INTENSITY CONTROL APPLICATION

In driving EL lamp panels, it is sometimes desirable to be able to adjust the intensity of the EL lamp. The TK6593x can

be used in such an application. By reducing the voltage supplied to the VCC pin of the TK6593x, one can reduce the peak

current regulation point of the IC. This translates into a reduction in the peak to peak output voltage across the EL panel,

which reduces the intensity of the light being emitted from the EL lamp.

By decreasing the input voltage to the V

53 mA. This correlates to about a 2/3 reduction in the peak to peak voltage appearing across the EL lamp panel.

pin from 2.9 V to 2.1 V, the peak current regulation point will be reduced about

CC

The VCC pin only takes 200 µA max. when the EL driver is in operation. Therefore, it can normally be controlled by logic

power level signals. One way of accomplishing this with two digital logic signals is shown in Figure 4.

R1 = 1.5 kΩ

R2 = 3.0 kΩ

C2 = 10 nF

C

EL

20 nF

+

EL

HV GND

-

EL

D

1

C

1

100 nF

V

IND

CC

C

10 nF

2

3 V ~ 1 mA source

R

1

1.5 k

R

3 k

L

1

2

3 V PWM

10% to 90%

200 KHz to 300 KHz

~ 1 mA sink

Vpower

1.8 to 7 V

FIGURE 4: INTENSITY CONTROL APPLICATION

NOISE CONSIDERATIONS

There are two specific noise types relevant to the user when it comes to choosing EL Drivers: the Audio Noise and the

Electromagnetic Interference (EMI) Noise.

The EMI Noise would most likely come from the boost converter section of the EL Driver circuit. The Toko EL Driver has

specifically been designed to address this issue.

The device runs at a fixed frequency and the frequency is controlled tightly in order to avoid interference.

Furthermore, the panel frequency is forced to be a 128 submultiple of the boost frequency avoiding any type of beating

frequencies.

By choosing shielded coils, the EMI noise problem can further be reduced.

The Audio Noise can come from several components which make up the system.

The coil, if operated in the audio range would be a source of noise. The Toko EL Driver was carefully designed to give

the user the choice of 10 frequencies such that the coil frequency will always be above audio range. Since the device

operates at a fixed frequency in discontinuous conduction mode, there are no possible submultiples which would cause

audible noise.

The filter capacitor can be a source of audio noise. Furthermore, depending on how this cap is mounted, the mounting

can act as an amplifier (as a speaker box). Certain ceramic caps driven from a high voltage source as in the EL Driver

case, demonstrate a PIEZOELECTRIC effect which is distinguishable in the Audio Range.

Other types of caps, such as film type do not denote an audio noise.

The panel itself, being operated well into the Audio Range (175 Hz to 400 Hz) and of a capacitive nature driven from high

voltage may also display Audible Noise. Mounting of this panel can enhance or diminish this natural effect of the panel.

Page 14 May 2000 TOKO, Inc.

Page 15

LAYOUT

2x

TK6593x

Actual Size

SPLIT SUPPLY LAYOUT

2x

Actual Size

May 2000 TOKO, Inc. Page 15

Page 16

TK6593x

(

)

PACKAGE OUTLINE

SOT23L-6

6

123

Dimensions are shown in millimeters

Tolerance: x.x = ± 0.2 mm

Marking Information

+0.15

0.4

- 0.05

e

e

0.95

0.95

+0.3

- 0.1

3.5

(3.4)

0.1

M

Marking

+0.15

- 0.05

0.32

5 PL

unless otherwise specified

0.6

1.0

3.0

e1

e

e

0.1

M

0.3

1.2

1.4 max

+0.15

- 0.05

0 - 0.1

0.15

0.95

0.95

Recommended Mount Pad

2.2

+ 0.3

3.3

15 max

0.4

Marking

TK65930 C0

TK65931 C1

TK65932 C2

TK65933 C3

TK65934 C4

TK65935 C5

TK65936 C6

TK65937 C7

TK65938 C8

TK65939 C9

Toko America, Inc. Headquarters

1250 Feehanville Drive, Mount Prospect, Illinois 60056

Tel: (847) 297-0070 Fax: (847) 699-7864

TOKO AMERICA REGIONAL OFFICES

Midwest Regional Office

Toko America, Inc.

1250 Feehanville Drive

Mount Prospect, IL 60056

Tel: (847) 297-0070

Fax: (847) 699-7864

Western Regional Office

Toko America, Inc.

2480 North First Street , Suite 260

San Jose, CA 95131

Tel: (408) 432-8281

Fax: (408) 943-9790

Eastern Regional Office

Toko America, Inc.

107 Mill Plain Road

Danbury, CT 06811

Tel: (203) 748-6871

Fax: (203) 797-1223

Semiconductor Technical Support

Toko Design Center

4755 Forge Road

Colorado Springs, CO 80907

Tel: (719) 528-2200

Fax: (719) 528-2375

Visit our Internet site at http://www.tokoam.com

The information furnished by TOKO, Inc. is believed to be accurate and reliable. However, TOKO reserves the right to make changes or improvements in the design, specification or manufacture of its

products without further notice. TOKO does not assume any liability arising from the application or use of any product or circuit described herein, nor for any infringements of patents or other rights of

third parties which may result from the use of its products. No license is granted by implication or otherwise under any patent or patent rights of TOKO, Inc.

Page 16 May 2000 TOKO, Inc.

All Rights Reserved

IC-xxx-TK6593x

0798O0.0K

Printed in the USA© 1999 Toko, Inc.

Loading...

Loading...