Page 1

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

device symbol

SD5XAB

2

1

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

TELECOMMUNICATION SYSTEM HIGH CURRENT OVERVOLTAGE PROTECTORS

●

Analogue Line Card and ISDN Protection

- Analogue SLIC

- ISDN U Interface

- ISDN Power Supply

●

8 kV 10/700, 200 A 5/310 ITU-T K20/21 rating

●

Ion-Implanted Breakdown Region

Precise and Stable Voltage

Low Voltage Overshoot under Surge

FORWARD-CONDUCTING

JANUARY 1998 - REVISED MARCH 1999Copyright © 1999, Power Innovations Limited, UK

SMBJ PACKAGE

(TOP VIEW)

12

MDXXBGB

V

DRM

DEVICE

‘5070 -58 -70

‘5080 -65 -80

‘5110 -80 -110

‘5150 -120 -150

●

Rated for International Surge Wave Shapes

WAVE SHAPE STANDARD

2/10 µs GR-1089-CORE 500

8/20 µs ANSI C62.41 300

10/160 µs FCC Par t 68 250

10/700 µs ITU-T K20/21 200

10/560 µs FCC Par t 68 160

10/1000 µs GR-1089-CORE 100

MINIMUM

V

V

(BO)

MAXIMUM

V

I

TSP

A

description

These devices are designed to limit overvoltages on the telephone and data lines. Overvoltages are normally

caused by a.c. power system or lightning flash disturbances which are induced or conducted on to the

telephone line. A single device provides 2-point protection and is typically used for the protection of ISDN

power supply feeds. Two devices, one for the Ring output and the other for the Tip output, will provide

protection for single supply analogue SLICs. A combination of three devices will give a low capacitance

protector network for the 3-point protection of ISDN lines.

PRODUCT INFORMATION

Information is current as of publication date. Products conform to speci fic ations in accordance

with the terms of Power Innovations standard warranty. Production processing does not

necessarily include testing of all parameters.

The protector consists of a voltage-triggered unidirectional thyristor with an anti-parallel diode. Negative

overvoltages are initially clipped by brea kdown clamping until the voltage r ises to the breakover level, which

causes the device to crowbar into a low-voltage on state. This low-voltage on state causes the current

resulting from the overvoltage to be safely diverted through the device. The high crowbar holding current

prevents d.c. latchup as the diver te d cu rrent s ubsides. Positive overvoltages are limi ted by the conduc tion o f

the anti-parallel diode.

This TISP5xxxH3BJ range consists of four voltage variants to meet vari ous maximum sys tem voltage levels

(58 V to 120 V). They are guaranteed to voltage limit and withstand the listed international lightning surges in

both polarities. The se hi gh (H ) c urre nt pr otecti on devices ar e in a pla stic pa ckage SMB J ( JEDE C DO- 21 4AA

with J-bend leads) and supplied in embossed carrier reel pack.

1

Page 2

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

T

absolute maximum ratings,

Repetitive peak off-state voltage, (see Note 1)

Non-repetitive peak on-state pulse current (see Notes 2, 3 and 4)

2/10 µs (GR-1089-CORE, 2/10 µs voltage wave shape) 500

8/20 µs (IEC 61000-4-5, 1.2/50 µs voltage, 8/20 current combination wave generator) 300

10/160 µs (FCC Part 68, 10/160 µs voltage wave shape) 250

5/200 µs (VDE 0433, 10/700 µs voltage wave shape) 220

0.2/310 µs (I3124, 0.5/700 µs voltage wave shape) 200

5/310 µs (ITU-T K20/21, 10/700 µs voltage wave shape) 200

5/310 µs (FTZ R12, 10/700 µs voltage wave shape) 200

10/560 µs (FCC Part 68, 10/560 µs voltage wave shape) 160

10/1000 µs (GR-1089-CORE, 10/1000 µs voltage wave shape) 100

Non-repetitive peak on-state current (see Notes 2, 3 and 5)

20 ms (50 Hz) full sine wave

16.7 ms (60 Hz) full sine wave

1000 s 50 Hz/60 Hz a.c.

Initial rate of rise of on-state current, Exponential current ramp, Maximum ramp value < 140 A di

Junction temperature T

Storage temperature range T

= 25°C (unless otherwise noted)

A

RATING SYMBOL VALUE UNIT

‘5070

‘5080

‘5110

‘5150

- 58

V

DRM

I

TSP

I

TSM

/dt 400 A/µs

T

J

stg

- 65

- 80

-120

55

60

2.1

-40 to +150 °C

-65 to +150 °C

V

A

A

NOTES: 1. See Figure 9 for voltage values at low er temperatures.

2. Initially the TISP5xxxH3BJ must be in thermal equilibrium with T

3. The surge may be repeated after the TISP5xxxH3BJ returns to its initial conditions.

4. See Figure 10 for current ratings at other temperatures.

5. EIA/JESD51-2 environment and EIA/JESD51-3 PCB with standard footprint dimensions connected with 5 A rated printed w iring

track widths. See Figure 8 for the current ratings at other durations. Derat e current v alues at -0.61%/°C for ambient temperatures

above 25 °C

=25°C.

J

electrical characteristics for terminal pair, TA = 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

DRM

V

V

I

(BO)

V

V

V

I

H

Repetitive peak offstate current

Breakover voltage dv/dt = -750 V/ms, R

(BO)

Impulse breakover

(BO)

voltage

Breakover current dv/dt = -750 V/ms, R

Forward voltage IF= 5 A, tW= 500 µs ‘5070 thru ‘5150 3 V

F

Peak forward recovery

FRM

voltage

On-state voltage IT=-5A, tW= 500 µs -3 V

T

Holding current IT= -5 A, di/dt = +30 mA/ms -0.15 -0.6 A

V

= V

D

DRM

Ω

= 300

SOURCE

dv/dt≥-1000 V/µs, Linear voltage ramp,

Maximum ramp value = -500 V

di/dt = -20 A/µs, Linear current ramp,

Maximum ramp value = -10 A

Ω

= 300

SOURCE

dv/dt≤+1000 V/µs, Linear voltage ramp,

Maximum ramp value = +500 V

di/dt = +20 A/µs, Linear current ramp,

Maximum ramp value = +10 A

TA = 25°C

T

= 85°C

A

‘5070

‘5080

‘5110

‘5150

‘5070

‘5080

‘5110

‘5150

-0.15 -0.6 A

‘5070 thru ‘5150 5 V

-5

-10

-70

-80

-110

-150

-80

-90

-120

-160

µA

V

V

PRODUCT INFORMATION

2

Page 3

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MARCH 1999

electrical characteristics for terminal pair, TA = 25°C (unless otherwise noted) (continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

dv/dt

I

C

Critical rate of rise of

off-state voltage

Off-state current VD=-50V TA = 85°C -10 µA

D

Off-state capacitance

off

Linear voltage ramp, Maximum ramp value< 0.85V

f = 100 kHz, V

(see Note 6)

f = 100 kHz, V

f = 100 kHz, V

f = 100 kHz, V

= 1 Vrms, VD=-1V,

d

= 1 Vrms, VD=-2V

d

= 1 Vrms, VD=-50V

d

= 1 Vrms, VD= -100 V

d

DRM

‘5070

‘5080

‘5110

‘5150

‘5070

‘5080

‘5110

‘5150

‘5070

‘5080

‘5110

‘5150

‘5150

-5 kV/µs

300

280

240

140

260

245

205

120

90

80

65

35

30

420

390

335

195

365

345

285

170

125

110

90

50

40

pF

NOTE 6: Up to 10 MHz the capacitance is essentially independent of frequency. Above 10 MHz the effective capacitance is strongly

dependent on connection inductance.

thermal characteristics

PARAMETER

EIA/JESD51-3 PCB, I

= 25 °C, (see Note 7)

T

R

NOTE 7: EIA/JESD51-2 environment and PCB has standard footprint dimensions connected with 5 A rated printed wiring track widths.

Junction to free air thermal resistance

θ

JA

A

265 mm x 210 mm populated line card,

4-layer PCB, I

TEST CONDITIONS

= I

T

TSM(1000)

= I

T

TSM(1000)

, TA = 25 °C

,

MIN TYP MAX UNIT

113

°C/W

50

PRODUCT INFORMATION

3

Page 4

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

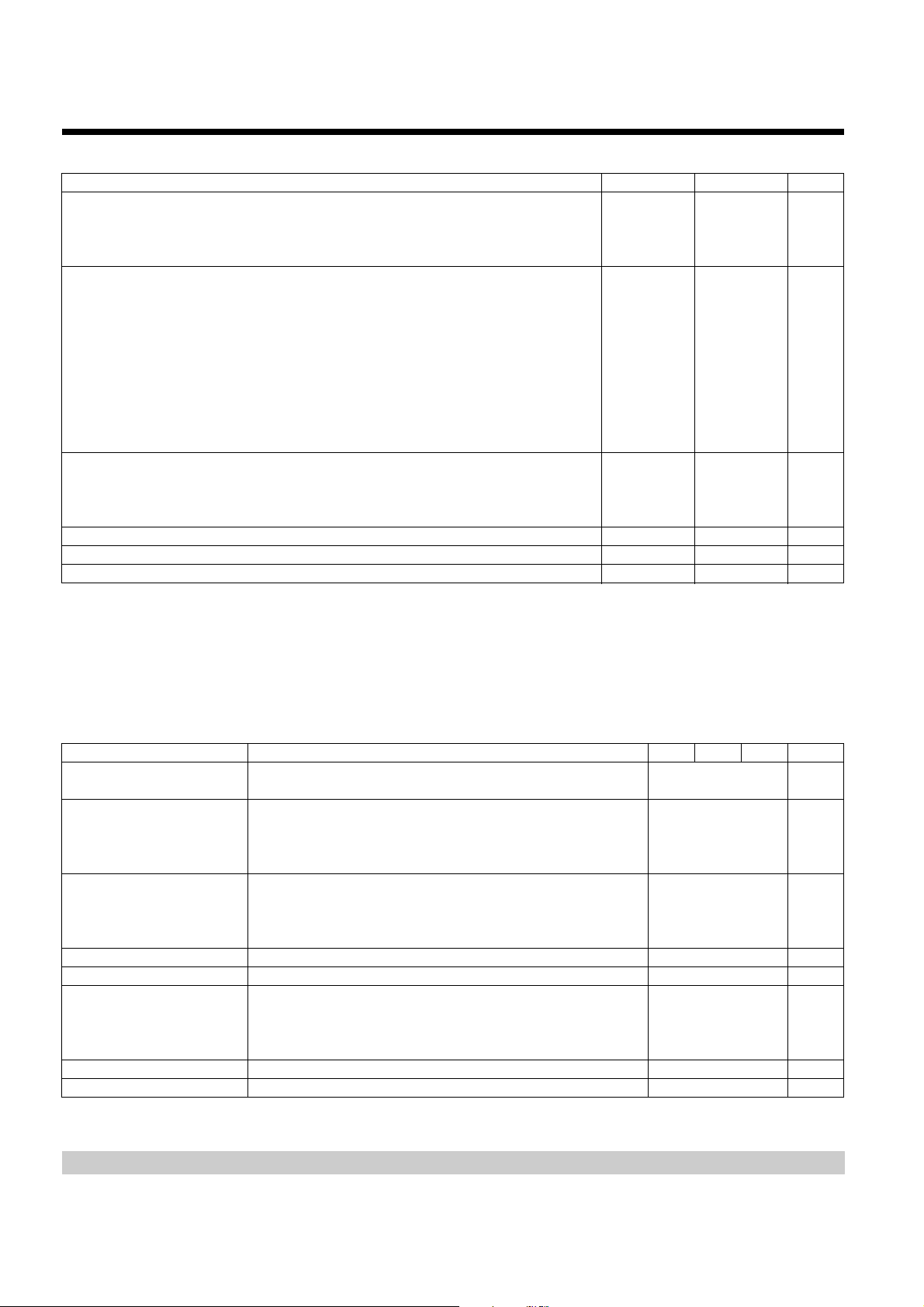

PARAMETER MEASUREMENT INFORMATION

+i

I

TSP

I

TSM

I

F

V

F

Quadrant I

Forward

Conduction

Characteristic

V

-v

I

(BO)

DRM

I

DRM

V

(BO)

Quadrant III

Switching

Characteristic

Figure 1. VOLTAGE-CURRENT CHARACTERISTIC FOR TERMINAL PAIR

V

D

I

D

I

H

V

T

I

T

I

TSM

I

TSP

-i

ALL MEASUREMENTS ARE REFERENCED TO TERMINAL 1

+v

PMXXACA

PRODUCT INFORMATION

4

Page 5

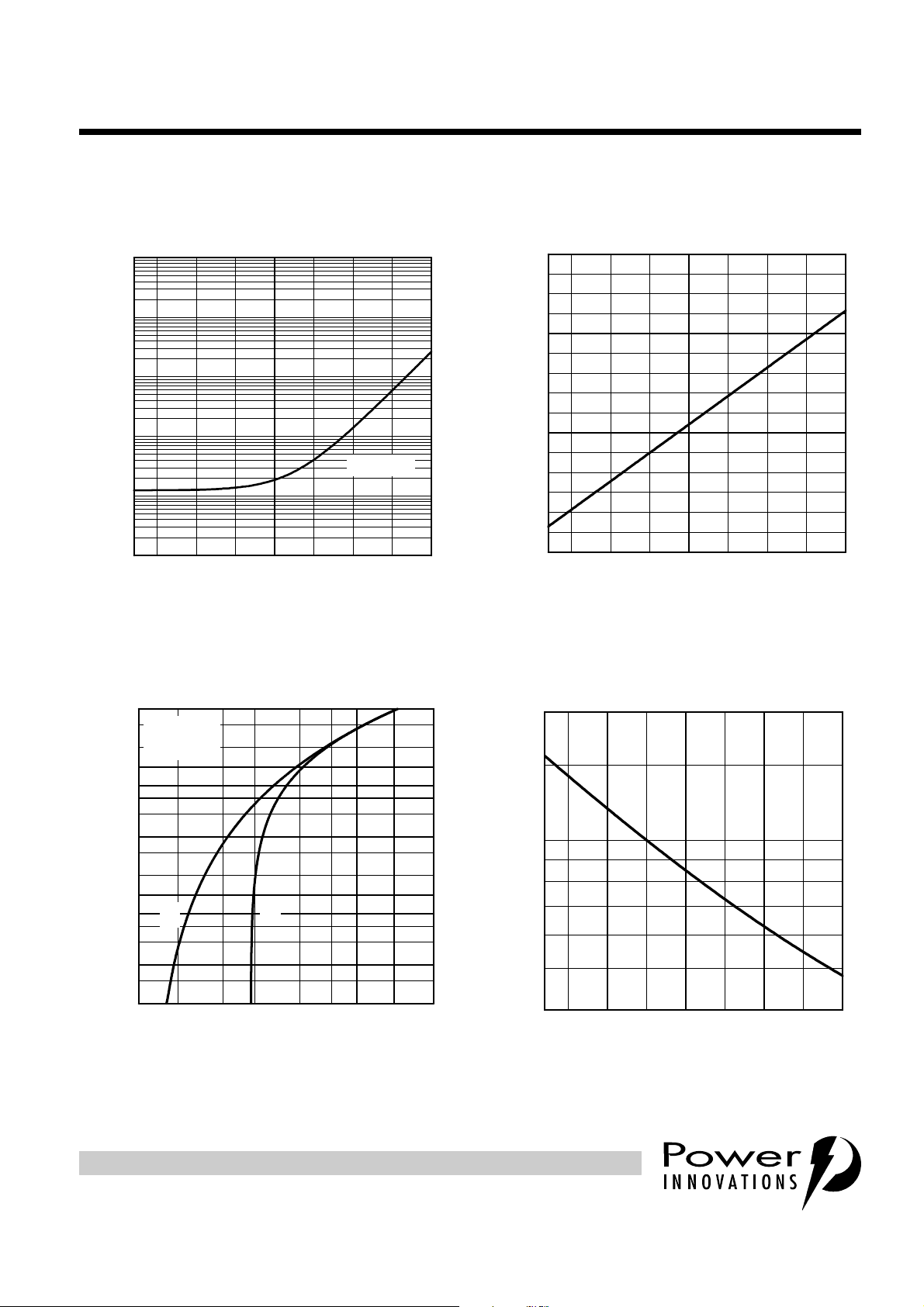

- Off-State Current - µA

NORMALISED BREAKO V ER VOLTAGE

vs

JUNCTION TEM P ERATURE

TJ - Junction Temperature - °C

-25 0 25 50 75 100 125 150

Normalised Breakover Voltage

0.95

1.00

1.05

1.10

TC5XAIA

NORMALISED HOLDING CURRENT

vs

JUNCTION T EM PERATURE

TJ - Junction Temperature - °C

-25 0 25 50 75 100 125 150

Normalised Holding Current

0.4

0.5

0.6

0.7

0.8

0.9

1.5

2.0

1.0

TC5XAD

D

I

100

10

0·1

0·01

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MARCH 1999

TYPICAL CHARACTERISTICS

OFF-ST AT E CURRE NT

vs

JUNCTION TEM P ERATURE

1

TC5XAFA

VD = -50 V

0·001

-25 0 25 50 75 100 125 150

T

- Junction Temperature - °C

Figure 2. Figure 3.

ON-STATE AND F ORWARD CURRENTS

vs

ON-STATE AND F ORWARD VOL TAGES

200

150

TA = 25 °C

100

t

= 100 µs

W

70

50

40

30

20

15

10

7

V

5

F

4

3

- On-State Curren t, Forward Current - A

F

2

, I

T

I

1.5

1

0.7 1.5 2 3 4 5 7110

TC5LAC

VT , VF- On-State Voltage, Forward Voltage - V

V

Figure 4. Figure 5.

T

PRODUCT INFORMATION

5

Page 6

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

E

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

TYPICAL CHARACTERISTICS

OFF-ST ATE CAPACITANCE

vs

OFF-STATE VOLTAGE

300

200

150

100

90

80

70

60

- Capacitance - pF

50

off

C

40

30

20

1 2 3 5 10 20 30 50 100

VD - Negative Off-state Voltage - V

TJ = 25°C

= 1 Vrms

V

d

Figure 6. Figure 7.

TC5XAB

'5070

'5080

'5110

'5150

DIFFERENTIAL OFF-STATE CAPACITANCE

vs

RATED REPETITIVE PEAK OFF-STATE VOLTAG

190

C - Differential Off-State Capacitance - pF

∆

∆∆

∆

180

170

160

150

140

130

120

110

100

90

80

'5070

'5080

58 65 80 120

V

- Negative Repetitive Peak Off-State Voltage - V

DRM

'5110

∆∆∆∆C = C

off(-2 V)

- C

TC5XAE

'5150

off(-50 V)

PRODUCT INFORMATION

6

Page 7

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

IMPULSE RATING

vs

AMBIENT T EM P ERATURE

TA - Ambient Temperature - °C

-40-30-20-100 1020304050607080

Impulse Current - A

80

90

100

120

150

200

250

300

400

500

600

700

IEC 1.2/50, 8/20

ITU-T 10/700

FCC 10/560

BELLCORE 2/10

BELLCORE 10/1000

FCC 10/160

TC5XAA

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

RATING AND THERMAL INFORMATIO N

NON-REPETITIVE PEAK ON-ST AT E CURRENT

vs

30

20

15

10

CURRENT DURATION

V

= 600 Vrms, 50/60 Hz

GEN

GEN

/I

TSM(t)

= 1.4*V

R

GEN

EIA/JESD51-2 ENVIRONMENT

EIA/JESD51-3 PCB

= 25 °C

T

A

9

8

7

6

5

4

3

TI5HAC

FORWARD-CONDUCTING

JANUARY 1998 - REVISED MARCH 1999

- Non-Repetitive Peak On-State Current - A

2

TSM(t)

I

1.5

0·1 1 10 100 1000

t - Current Duration - s

Figure 8.

V

DERATING F ACTOR

DRM

vs

MINIMUM AM BI ENT TEMPERATURE

1.00

0.99

0.98

0.97

0.96

Derating Factor

0.95

0.94

0.93

PRODUCT INFORMATION

-35 -25 -15 -5 5 15 25-40 -30 -20 -10 0 10 20

T

- Minimum Ambient Temperature - °C

AMIN

Figure 9. Figure 10.

TI5XAD

7

Page 8

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

APPLICATIONS INFORMATION

deployment

These devices are two terminal overvoltage prote ctors. They may be used either singly to limi t the voltage

between two points (Figure 11) or in multiples to limit the voltage at several points in a circuit (Figure 12)

SIGNAL

AI4XAC

R1a

R1b

Figure 11. POWER SUPPLY PROTECTION

TISP5xxxH3BJ

-

D.C.

.

In Figure 11, the TISP5xxxH3B J limits the maximum voltage of the negati ve supply to -V

and +VF. This

(BO)

configuration can be used for protecting circuits where the voltage polarity does not reverse in normal

operation. In Figure 12, the two TISP5xxxH3BJ protectors, Th4 and Th5, lim it the maximum voltage of the

SLIC (Subscriber Line Interface Circuit) outputs to -V

and +VF. Ring and test protection is given by

(BO)

protectors Th1, Th2 and Th3. Pro tectors Th1 and Th2 limit the maximum tip and ri ng wire voltages to the

±V

of the individual protector. Protector Th3 limits the maximum voltage between the two conductors to its

(BO)

±V

value. If the equipment being protected has all its vulnerable components connected between the

(BO)

conductors and ground, then protector Th3 is not required.

TIP

WIRE

RING

WIRE

OVER-

CURRENT

PROTECTION

R1a

R1b

RING/TEST

PROTECTION

Th3

Th1

Th2

TEST

RELAY

S1a

S1b

S2b

RING

RELAY

S2a

SLIC

RELAY

S3a

S3b

SLIC

PROTECTION

TISP5xxxH3BJ

Th4

Th5

SLIC

V

BAT

TEST

EQUIP-

MENT

Figure 12. LINE CARD SLIC PROTECTION

PRODUCT INFORMATION

8

RING

GENERATOR

AI4XAA

Page 9

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MARCH 1999

broad-band protection.

The star-connection of th ree TISP5xxxH3 BJ protectors g ives a protection circui t which has a low differential

capacitance to ground (Figure 13). This example, a -100 V ISDN line is protect ed. In Figure 13, the ci rcuit

illustration A shows that protector Th1 will be forward biased as it is connected to the most negative potential.

The other two protectors, Th2 and Th3 will be reverse biased as protector Th1 will pull their common

connection to within 0.5 V of the negative voltage supply.

C

Th1

Th2

Th3

SIGNAL

0.5 V

600 pF

C

-99.5 V

29 pF

29 pF

C

-99.5 V

26 pF

26 pF

1 pF

A) STAR-CONNECTED

U-INTERFACE

PROTECTOR

- 100 V - 100 V - 100 V

B) EQUIVALENT

TISP5150H3BJ

CAPACITANCES

C) DELTA EQUIVALENT

SHOWS 25 pF

LINE UNBALANCE

AI4XAB

Figure 13. ISDN LOW CAPACITANCE U-INTERFACE PROTECTION

Illustration B shows the equivalent capacitances of the two reverse biased protectors (Th2 and Th3) as 29 pF

each and the capacitance of the forward biased protector (Th1) as 600 p F. Illustration C shows the delta

equivalent of the star capacitances of illustration B. The protector circuit differential capacitance will be 26 - 1

= 25 pF. In this circuit, th e differential capacita nce value cannot exceed the cap acitance value of the ground

protector (Th3).

A bridge circuit can be used for low capacitance differential. Whatever the potential of the ring and tip

conductors are in Figure 14, the array of steering diodes, D1 through to D6, ensure that terminal 1 of

protector Th1 is always positive with respect to terminal 2. The protection voltage will be the sum of the

protector Th1, V

, and the forward voltage of the appropr iate series diodes. It is important t o select the

(BO)

correct diodes. Diodes D3 through to D6 divert the currents from the ring and tip lines. Diodes D1 and D2 will

carry the sum of the ring and tip cu rrents and so conduct twice the current of the othe r four diodes. The

diodes need to be specified for forward recovery voltage, V

, under the expected impulse conditions.

FRM

(Some conventional a.c. rectifiers c an p roduc e a s muc h a s 70 V of forward recovery voltage, which would b e

an extra 140 V added to the V

of Th1). In principle the bridge circuit can be extended to protect more than

(BO)

two conductors by adding extra legs to the bridge.

RING

TIP

1

2

Th1

AI5XAC

Figure 14. LOW CAPACITANCE BRIDGE PROTECTION CIRCUIT

PRODUCT INFORMATION

D1D2D3D4D5

D6

9

Page 10

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

ISDN device selection

The ETSI Techn ical Report ETR 0 80:1993 d efines several range values in ter ms of maximum an d minimum

ISDN feeding voltages. The following table shows that ranges 1 and 2 can use a TISP5110H3BJ protector

and ranges 3 to 5 can use a TISP5150H3BJ protector.

FEEDING VOLTAGE STANDOFF VOLTAGE

RANGE

V

151 69

266 70

391 99

5 105 115

V

DRM

V

-80 TISP5110H3BJ

-120 TISP5150H3BJ4 90 110

impulse testing

To verify the withstand capabil ity and safety of the equipment , standards require that the equipm ent is test ed

with various impulse wave forms. The table below shows some common values.

DEVICE #MINIMUMVMAXIMUM

PEAK VOLTAGE

STANDARD

GR-1089-CORE

FCC Part 68

(March 1998)

I3124 1500 0.5/700 37.5 0.2/310 200 0

ITU-T K20/K21

† FCC Part 68 terminology for the waveforms produced by the ITU-T recommendation K21 10/700 impulse generator

SETTING

V

2500 2/10 500 2/10 500

1000 10/1000 100 10/1000 100

1500 10/160 200 10/160 250 0

800 10/560 100 10/560 160 0

1500 9/720 † 37.5 5/320 † 200 0

1000 9/720 † 25 5/320 † 200 0

1500

4000

VOLTAGE

WAVE FORM

µs

10/700

PEAK CURRENT

VALUE

A

37.5

100

CURRENT

WAVE FORM

µs

5/310 200 0

TISP5xxxH3

25 °C RATING

A

SERIES

RESISTANCE

Ω

0

If the impulse generator current exceeds the protectors current rating then a series resistance can be used to

reduce the curren t to the prot ectors rat ed value and so prevent possible failure. The required value of se rie s

resistance for a given waveform is given by the following calculations. First, the minimum total circuit

impedance is found by dividing the impulse generators peak voltage by the protectors rated current. The

impulse generators fictive impedance (generators pea k voltage divided by peak shor t circuit current) is then

subtracted from the m inimum total circ uit impe dance to give the requi red value of s eri es res istance. In so me

cases the equipme nt will require verifi cation over a temperature range. By usin g the rated waveform values

from Figure 10, the appropriate series resistor value can be calculated for ambient temperatures in the range

of -40 °C to 85 °C.

If the devices are used in a st ar-connectio n, then the ground r eturn pr otector, Th3 in Figure 13, will co nduct

the combined cu rre nt of p ro tec tors Th1 and Th2. Similarly in the br i dge c onn ect ion ( Fig ur e 1 4) , t he pr otec to r

Th1 must be rated for the sum of the conductor currents. In these cases, it may be necessary to include some

series resistance in the conductor feed to reduce the impulse current to within the protectors ratings.

a.c. power testing

The protector can withsta nd currents ap plied for times not exceeding tho se shown in Figu re 8. Current s that

exceed these times must be terminated or reduced to avoid protector failure. Fuses, PTC (Positive

Temperature Coefficient) resistors and fusible resistors are overcurrent protection devices which can be used

PRODUCT INFORMATION

10

Page 11

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MARCH 1999

to reduce the current fl ow. Pr otective fuses may range from a few hundred milliamperes to one ampere. In

some cases it may be necessar y to add some extra series res istance to prevent the fuse opening durin g

impulse testing. The current versus time cha racteristic of the overcurrent protector must be below the line

shown in Figure 8. In some ca ses there may be a further time limit imposed by the test standard ( e.g. UL

1459 wiring simulator failure).

capacitance

The protector characteristic off-state capacitance values are given for d.c. bias voltage, VD, values of -1 V,

-2 V and -50 V. The TISP5150H3BJ is also given for a bias of -100 V. Values for other voltages may be

determined from Figure 6. Up to 10 MHz the capacitance is essentially independent of frequency. Above

10 MHz the effective capacitance is s trongly dependent on connection inductan ce. In Figure 12, the typic al

conductor bias voltages will be about -2 V and -50 V. Figure 7 shows the differential (line unbalance)

capacitance caused by biasing one pr otector at -2 V and the other at -50 V. For example, the TISP5070H3BJ

has a differential capacitance value of 166 pF under these conditions.

normal system voltage levels

The protector should not clip or limit the voltages that occur in nor mal s ystem operatio n. Figure 9 al lows the

calculation of the protector V

than the maximum normal system volt ages. The TISP5150H3BJ, with a V

protect ISDN feed voltages having maximum values of -99 V, -110 V and -115 V (range 3 through to range 5).

These three range voltages represent 0.83 (99/120), 0.92 (110/120) and 0.96 (115/120) of the -120 V

TISP5150H3BJ V

-40 °C. Thus the supply feed voltages of -99 V (0.83) and -110 V ( 0.92) will not be c lipped at temperatures

down to -40 °C. The -115 V (0.96) feed supply may be clipped if the ambient temperature falls below -21 °C.

. Figure 9 shows that the V

DRM

value at temperatures below 25 °C. The calculated value should not be less

DRM

will have decreased to 0.944 of its 25 °C value at

DRM

of -120 V, can be used to

DRM

JESD51 thermal measurement method

To standardise thermal measurements, the EIA (Electronic Industries Alliance) has created the JESD51

standard. Part 2 of the standard (JESD51-2, 1995) describes the test environment. This is a 0.0283 m

cube which contains the test PCB (Printed Ci rcuit Board) horizontally mou nted at the centre. Part 3 of the

standard (JESD51-3, 199 6) defines two test PCB s for surface mount components; one for packages smaller

than 27 mm on a s ide and the othe r for packages up to 48 mm. The SMBJ measurements used the sm aller

76.2 mm x 114.3 mm (3. 0 “ x 4.5 “) PCB. The JESD51-3 PCBs are designed to have low effective thermal

conductivity (high th er mal resi stance) and represen t a worse case con dition . The PCBs us ed in the ma jority

of applications will a chieve lower values of thermal resis tance and s o can dis sipate higher power levels than

indicated by the JESD51 values.

3

(1 ft3)

PRODUCT INFORMATION

11

Page 12

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

MECHANICAL DATA

SMBJ (DO-214AA)

plastic surface mount diode package

This surface mount package consis ts of a ci rcuit mounted on a lead frame and e ncaps ulated within a plas tic

compound. The compound will withstand soldering temperature with no deformation, and circuit performance

characteristics will remain stable when operated in high humidity conditions. Leads require no additional

cleaning or processing when used in soldered assembly.

SMB

4,57

4,06

3,94

3,30

2,40

2,00

1,52

0,76

Index

Mark

(if needed)

2,10

1,90

5,59

5,21

2

0,20

0,10

2,32

1,96

ALL LINEAR DIMENSIONS IN MILLIMETERS

PRODUCT INFORMATION

12

MDXXBHA

Page 13

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

recommended printed wiring footprint.

SMB Pad Size

2.40

ALL LINEAR DIMENSIONS IN MILLIMETERS

FORWARD-CONDUCTING

JANUARY 1998 - REVISED MARCH 1999

MECHANICAL DATA

2.54

2.16

MDXXBI

device symbolization code

Devices will be coded as below. Terminal 1 is identified by a bar index mark.

DEVICE

TISP5070H3BJ 5070H3

TISP5080H3BJ 5080H3

TISP5110H3BJ 5110H3

TISP5150H3BJ 5150H3

SYMOBLIZATION

CODE

carrier information

The carrier for production q uantities is embosse d tape reel p ack. Evaluation quanti ties will be shipped in the

most practical carrier.

CARRIER ORDER #

Embossed Tape Reel Pack

(3000 Devices are on a Reel)

TISP5xxxH3BJR

PRODUCT INFORMATION

13

Page 14

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MA RCH 1999

MECHANICAL DATA

tape dimensions

SMB Package Single-Sprocket Tape

8,10

7,90

Direction of Feed

4,10

3,90

2,05

1,95

ø 1,5 MIN.

Carrier Tape

Embossment

Index

Mark

1,65

1,55

20°

1,85

1,65

5,55

5,45

0 MIN.

Maximium com ponent

rotation

Typical compon ent

cavity centre line

Typical compon ent

centre line

0,40 MAX.

12,30

11,70

Cover

Tape

8,20

MAX.

4,5 MAX.

ALL LINEAR DIMENSIONS IN MILLIMETERS

NOTES: A. The clearance between the component and the cavity must be within 0,05 mm MIN. to 0,65 mm MAX. so that the

component cannot rotate more than 20° within the determined cavity.

B. Taped devices are supplied on a reel of the following dimensions:-

Reel diam et e r: 33 0 ±3 , 0 mm

Reel hub diameter 75 mm MIN.

Reel axial hole: 13,0 ±0,5 mm

C. 3000 devices are on a reel .

PRODUCT INFORMATION

14

MDXXBJ

Page 15

TISP5070H3BJ, TISP5080H3BJ, TISP5110H3BJ, TISP5150H3BJ

FORWARD-CONDUCTING

UNIDIRECTIONAL THYRISTOR OVERVOLTAGE PROTECTORS

JANUARY 1998 - REVISED MARCH 1999

IMPORTANT NOTICE

Power Innovations Limited (PI) reserves the right to make changes to its products or to discontinue any semiconductor product

or service without notice, and advises its customers to ver ify, before placing orders, that the information being relied on is

current.

PI warrants performance of its semiconductor products to the specifications applicable at the time of sale in accordance with

PI's standard w arr a nty. Testing and other quality contro l techniques are u til ized to the extent PI deems n ec es sa ry to suppo rt thi s

warranty. Specific testing of all parameters of each device is not necessarily performed, except those mandated by government

requirements.

PI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents

or services described herein. Nor is any license, either express or implied, granted under any patent right, copyright, design

right, or other intellectual property right of PI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used.

PI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORISED, OR WARRANTED TO BE SUITABLE

FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES OR SYSTEMS.

Copyright © 1999, Power Innovations Limited

PRODUCT INFORMATION

15

Loading...

Loading...