Page 1

Color Television Chassis

TC5.1U

CA

G_16340_000.eps

100306

Contents Page

1. Technical Specifications, Connections and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 3

3. Directions for Use 6

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 7

6. Block Diagrams, Test Point Overviews, and

Waveforms

Chassis Block Diagram 9

7. Circuit Diagrams and CBA Layouts Diagram CBA

Main Board 10 11-12

CRT Panel 13 14

Layout Side AV Board 14

Layout Keyboard Panel 40-P25207-KEA1X 14

Layout Keyboard Panel 40-P25207-KEB1XG 14

8. Alignments 15

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 18

10. Spare Parts List 24

11. Revision List 26

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by WS 0663 TV Service Printed in the Netherlands Subject to modification EN 3122 785 16340

Page 2

EN 2 TC5.1U CA1.

Technical Specifications, Connections and Chassis Overview

1. Technical Specifications, Connections and Chassis Overview

1.1 Technical Specifications

Tuning - technology : PLL

Tuning - presets/channels : 181

Freq Bands : Full-Cable

TV Systems Off Air/ Cable : NTSC M (3.58 - 4.5)

TV Systems Multi : NTSC

Mains voltage : 90-140V

Mains frequency : 50/60Hz

Standby Power consumption : <1W

Sound Systems : BTCS SAP

Audio output (RMS) : 2x3W

Scan Modes : 4:3

Sound Features : AVL, Mute

Sound Control : 4 sound modes

: Balance

: Bass Boost

: Treble Boost,

Menu Languages : American English,

: Volume

French, Spanish

Clock/Timer Function : Sleep timer

Terrestrial Antenna in : 75 Ohm (F type)

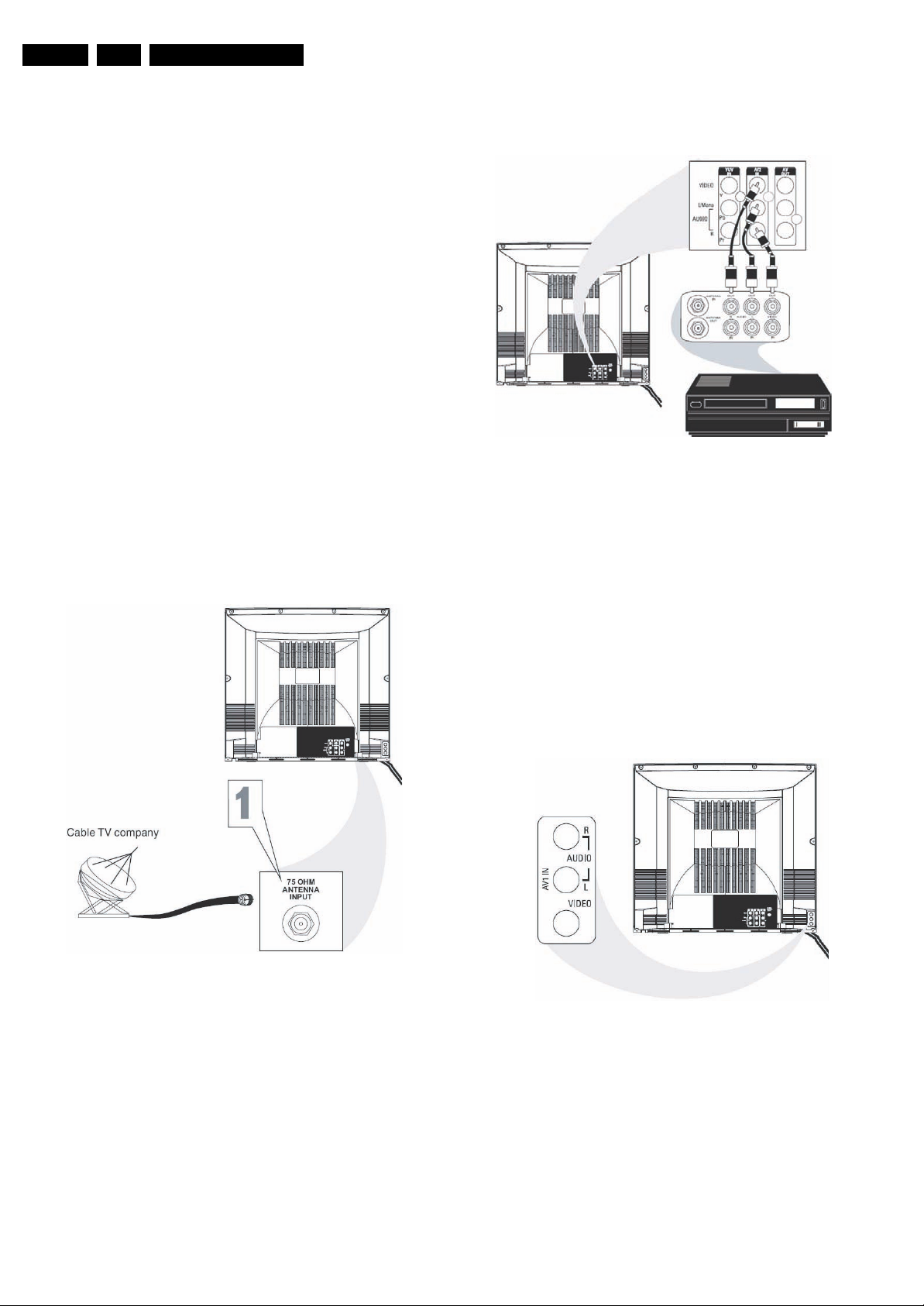

Figure 1-2 Rear audio and video connections

G_16340_002.eps

100306

1.2 Connection overview

1.2.1 Connections

G_16340_001.eps

100306

Cinch: Video CVBS - Out, Audio - Out

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm kq

PP

/10 kohm kq

RMS

/ 10 kohm kq

RMS

Cinch: Video YUV- In

Gn - Video Y 1 V

Bu - Video U 0.7 V

Rd - Video V 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

Figure 1-1 Aerial connection

Aerial - In

- - F-type Coax, 75 ohm D

Figure 1-3 Side audio and video connections

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

1.3 Chassis Overview

See Chapter 10, Parts List.

G_16340_003.eps

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

100306

Page 3

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 3TC5.1U CA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current flows. In particular this is valid

for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function, to prevent the cord from touching the CRT,

hot components, or heat sinks.

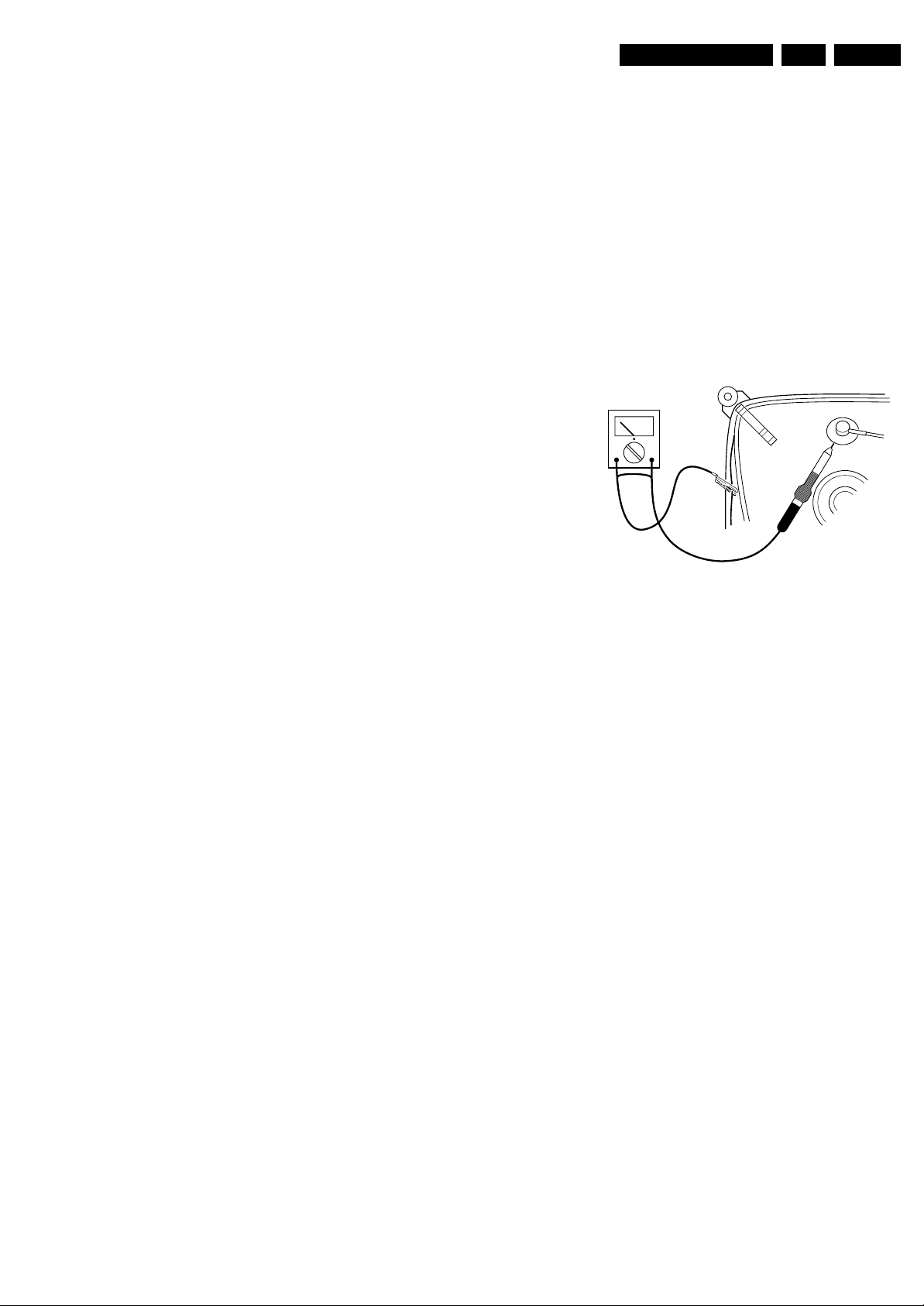

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the “general repair instruction” noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in figure “Discharge

picture tube”, to discharge the picture tube. Use a high

voltage probe and a multi-meter (position V

until the meter reading is 0 V (after approx. 30 s).

V

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and prevents circuits

from becoming unstable.

2.4 Notes

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

). Discharge

DC

E_06532_007.eps

250304

Page 4

EN 4 TC5.1U CA2.

Safety Instructions, Warnings, and Notes

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.4.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

-9

), or pico-farads (p= x10

-12

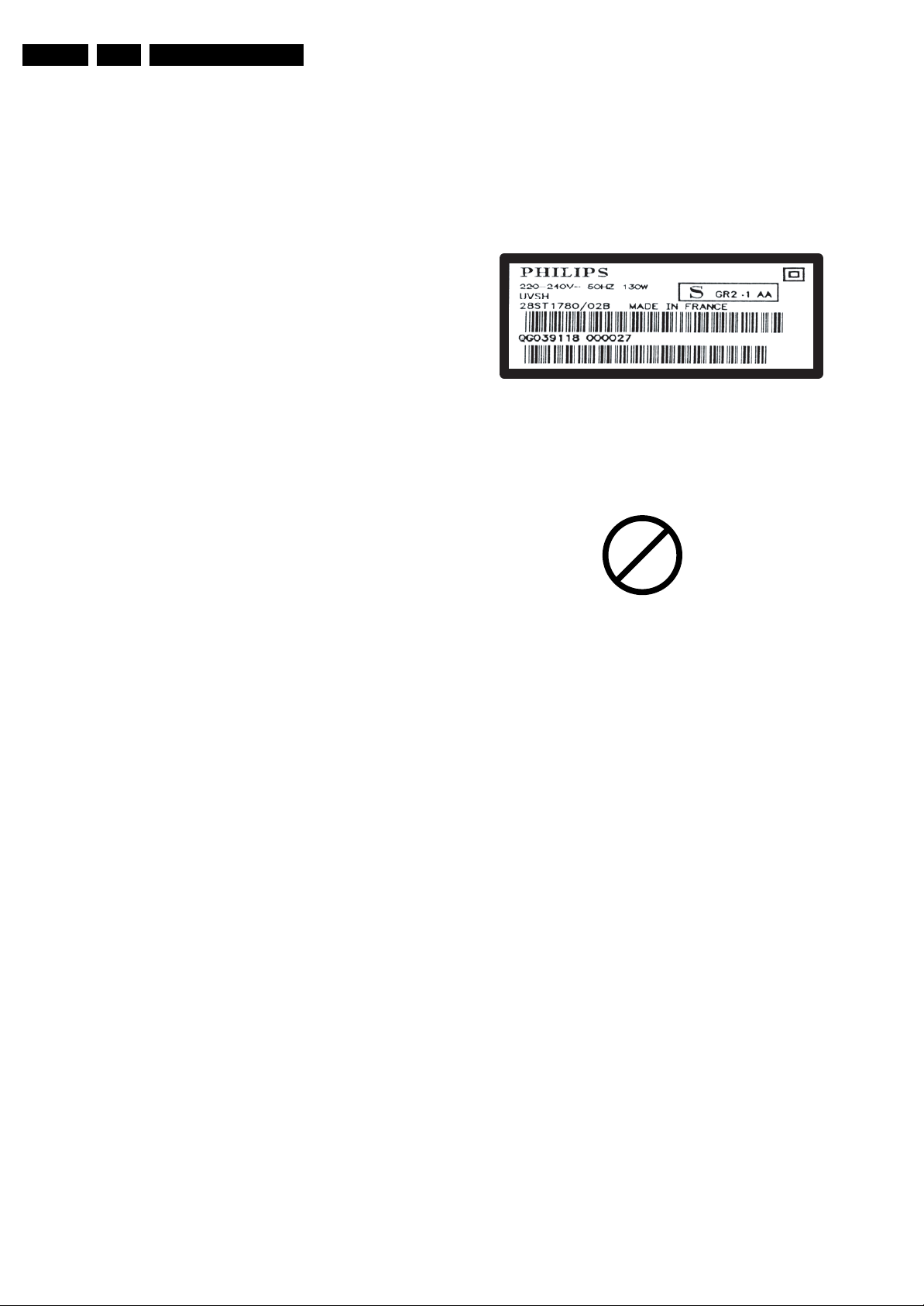

2.4.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

-6

),

).

E_06532_024.eps

230205

Figure 2-2 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

P

b

Figure 2-3 Lead-free logo

Device Removal

As is the case with any component that is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature. A

uniform temperature reduces the risk of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has been shown to

result in problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighboring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clean the solder-joint from old tin and re-solder with new

tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

Page 5

Safety Instructions, Warnings, and Notes

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.4.5 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering the

correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

EN 5TC5.1U CA 2.

2.4.6 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

Page 6

EN 6 TC5.1U CA3.

3. Directions for Use

Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

4. Mechanical Instructions

See Chapter 10, Parts List.

http://www.p4c.philips.com

Page 7

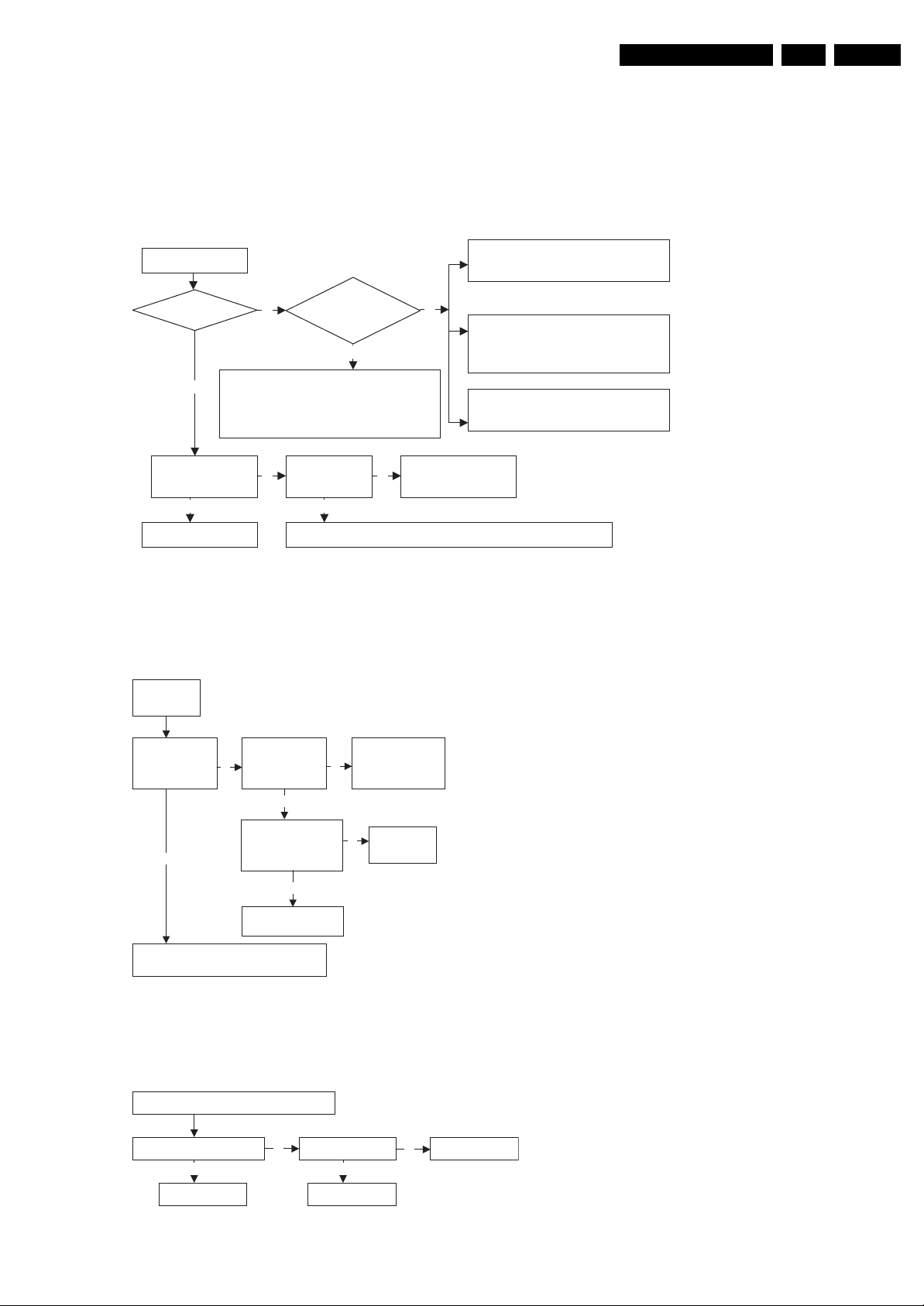

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

5.1 Trouble Shooting

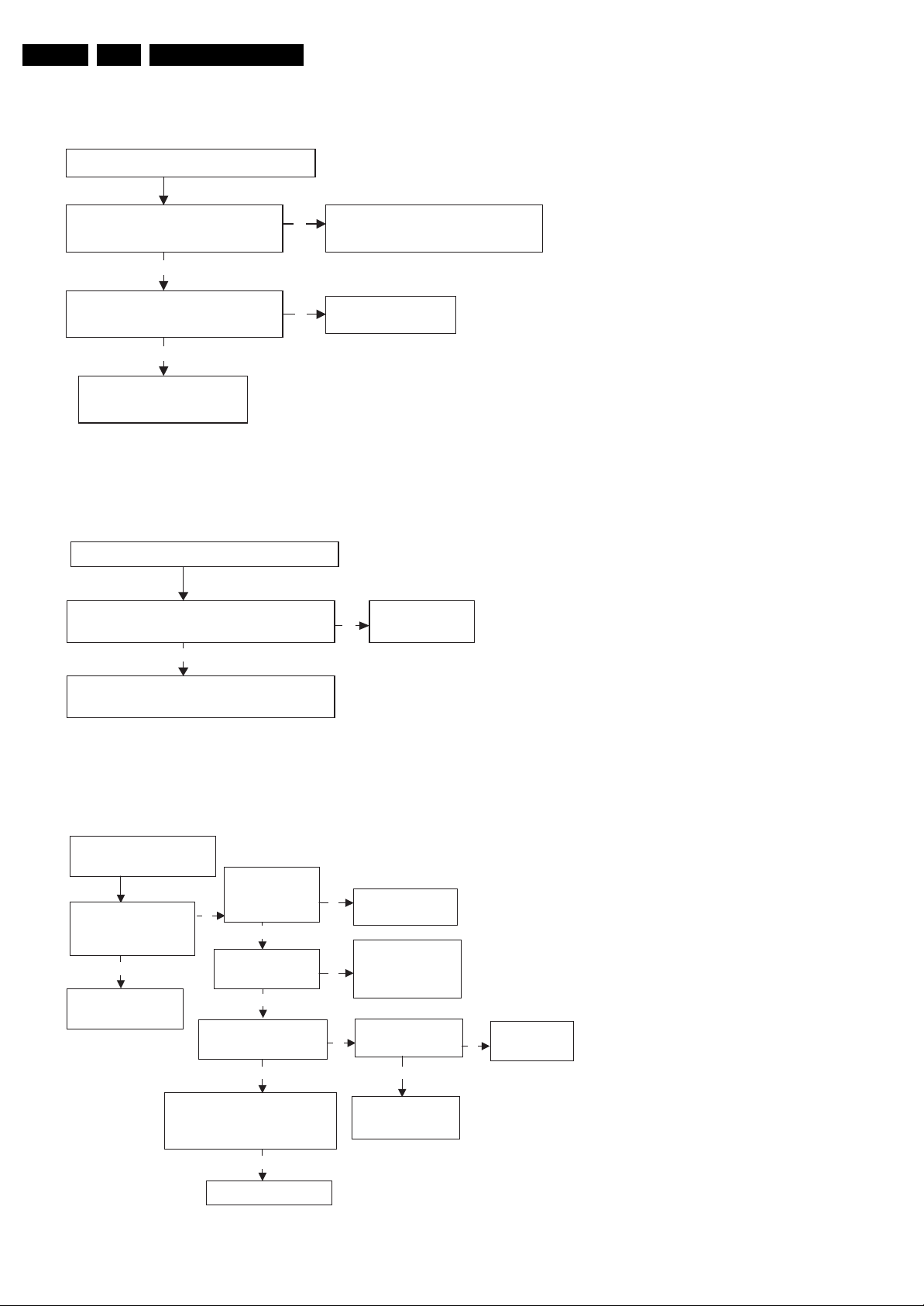

5.1.1 Can not Power On

EN 7TC5.1U CA 5.

Can not Power On

Fuse OK?

(1) Check if B+ shorted to earth.

(2) To check whether D822 and R821 are

N

(3) To check whether D823 and R823 are

Is it IC801 Pin 1

shorted to earth?

Y

Check/Replace IC801

5.1.2 No Raster, Sound OK

No Raster

Sound OK

Check B+,

Y Y

turnoff.

turnoff. And whether C836 shorted.

+12V, Ok?

N

Is DB801 OK?

NN

Y

Check the components such as C801, C802, C806, C807 and C815

Is power supply for IC101 correct?

If not, check Q820, Q821, Q007, Q008,

D001

Check Horizontal Scan circuit:

Check H-Vcc and H-out of IC 101

Check Q401, T401 and Q411

Check standby circuit: Check Pin64 of

IC101, Check Q825, Q824, Q823, Q822.

Replace DB801

Figure 5-1 Can not Power On

G_16340_004.eps

100306

Is the power

supply of Q401

and Q411 ok?

N

To check whether R404, C401, T401,

Q401, R422 are ok?

Check Pin 13

(H-OUT) voltage

ok?

Y

Is there any shorted

in the scan part of

the circuit?

Change IC101

Y

N

Y

N

5.1.3 Raster OK, Sound OK, No TV/AV picture

Raster OK, Sound OK, No TV/AV picture

Check whether Q917 is

ok?

N

Replace Q917

Y Y

Replace C238

N

Check each

output voltage of

FBT

Change the

shorted part.

G_16340_005.eps

100306

Figure 5-2 No Raster, Sound OK

Change IC901 Check C238, ok?

G_16340_008.eps

100306

Figure 5-3 Raster OK, Sound OK, No TV/AV picture

Page 8

EN 8 TC5.1U CA5.

5.1.4 Raster OK, Sound OK, No AV picture

Raster OK, Sound OK, No AV picture

Service Modes, Error Codes, and Fault Finding

Is the signal waveform at Pin 12 and

Pin 14 of IC901 right?

Y

Check Q917, Q918, Q919, ok?

N

Replace the fail component.

5.1.5 Raster OK, Sound OK, No TV picture

Raster OK, Sound OK, No TV picture

Is the signal waveform at Pin 15 of IC901

right?

N

To check whether R903, C903, R902

N

and R905, C908, R908 are ok?

Replace IC901

Y

G_16340_006.eps

100306

Figure 5-4 Raster OK, Sound OK, No AV picture

Replace

IC901

Y

Check R234, Q204, R235, C229

5.1.6 No picture, dense noise dots

No picture, dense noise

dots

Is the antenna feed line

or the adapter broken?

Y

Handing the antenna

fault

N

Is the signal at IF

pin of the tuner ok?

Is the signal at Pin SCL,

SDA of tuner ok?

Check signal at P5, P57, P58,

P59, and P60 of IC101 and

replace the abnormal relative

circuit

Figure 5-5 Raster OK, Sound OK, No TV picture

Is the signal at

Pin41, Pin42 of

IC101 ok?

N

N

N N

Y

Y

Y

Y

G_16340_007.eps

Check/Replace

IC101

Check the relative

circuit of Q101,

Z141 etc

Is the supply

voltage of tuner ok?

Check/Replace

IC201, IC202,

D101.

100306

Y

Check/Replace

Tuner

Check EEPROM

G_16340_009.eps

Figure 5-6 No picture, dense noise dots

100306

Page 9

Block Diagrams, Test Point Overviews, and Waveforms

6. Block Diagrams, Test Point Overviews, and Waveforms

Chassis Block Diagram

EN 9TC5.1U CA 6.

G_16340_010.eps

100306

Page 10

Circuit Diagrams and CBA Layouts

7. Circuit Diagrams and CBA Layouts

Main Board

12

23MT2336/37

A

B

C

P501

1

S501

CRT

!

EHT

EHT

1

2

SCREEN

S

FOCUS

3

1 342

P502

HEATER

200V

FOCUS

L502

*JUMP

SCREEN

CRT BOARO.

GND

C505

1000P

2KV

*10uH

L503

!

L504

0

KR

KG

KB

40-02501C-CRG

2.7K 1/2W

2.7K 1/2W

2.7K 1/2W

R519

R520

R521

R518

15K

2W

1

R517

2

15K

2W

3

R516

15K 2W

C504

10u

+

250V

C508

10n

L505

D

TU101

AGC

E

VT

+

C101

4.7u

50V

R903

22K

D

SDA

VCC

SCL

+5VA

L101

+

47uH

F

C903

47u

P902

V1

R1

G

L1

V2

R2

H

L2

Y

Cr

Cb

I

*P904

V0

J

R0

L0

*P905

K

16V

+

+9V

R902

82

R904

1K

R906

1K

P903

R910

R912

+9V

R923

75

R924

1K

R925

1K

F

R932A

1K

F

C904

R954

10u

22k

16V

+

F

C905

10u

16V

+

Q902

C1815

C908

47u

16V

R908

82

C909

10u

16V

1K

F

C910

10u

16V

1K

+

Q903

C1815

R914

82

R915

82

R920

47

C926

220u

16V

+

C927

10u

16V

+

Q914

C1815

+

C928

10u

16V

Q901

C1815

+9V

R953

22k

R916

D

1K

R917

R905

1K

+

F

+

+9V

R951

22k

R913

1K

22K

+9V

R952

22k

Q904

C1815

R911

1K

R937

+

C930

100u

16V

Q913

C1815

R926

1K

R936

100

Q912

A1015

C929

0.01u

Q911

C1815

R931

R930

220

R929

1K

220

D

+9V

+

R934A

C912

C911

100u

0.01u

16V

R932

1K

+

C914

C913

100u

1K

0.01u

16V

3

Q501

C4544

1

Q502

C1815

R503

680

2

Q503

C4544

Q504

C1815

R508

3

680

Q505

C4544

Q506

C1815

R513

680

L506

C105

C106

100u

0.01

50V

76 8

5

34

1 2

C

IC901

4052

R501

560

R502

680

R504

0

C501

390P

C506

470u

+

R505

16V

560

R506

R509

680

R507

0

C511

C502

220u

390P

16V

R510

560

R511

680

R512

0

R523

1K

C503

470P

Q507

A562

33V

10 9

11

V1

12

0

3

V_OUT

3

1

1

V2

2

14 13

2

TV

0

+9V

16 15

4

D504

1N4001

L501

0

C509

10n

680

+

IF33V

C107

0.01

R947

100K

B

G

R514

2.7K

R

4132

54312

D501

1N4148

D502

1N4148

R515

R101

100

R101A

100

5

P503

R522

680

1K

L102

C108

0.01

R106

1K

R107

56

R108

Q101

150

C3779

R945

10K

R944

10K

+9V

+9V

Q917

C1815

R948

1K

P201

R102

150

R103

1uH

470

C109

1000

Z101

F1859

1

3

2

4

Q919

DTC124

Q918

DTC124

R946A

2.2k

+

R946

2.2k

+9V

L950

+9V

22uH

R942

R940

2K2

Cr

680

Q916

A1015

Cb

+

R935

C924

22K

10u/16V

1K

R933

C925

15K

33p

C1024

1n

+9V

R934

1K

C922

180

R941

68K

+

C923

Q915

1u

A1015

50V

R939

560K

R938

12K

R1023

1K

R1022

C1023

1K

1n

56

+5V

SDA0

1

2

P002

R005

+5V

22K

C002

R007

C003

1500

3.9K

RESET

ROTAT E

SDA0

SCL0

MUTE

R

G

B

MUTE

RESET

C1016

2SA817A

SIF

10u

C1011

100n

C1008

100n

SIF

S-SW

S-SW

R209

Q208

10K

C211

0.1u

16V

R1006

C1013

1

2

3

4

47

+

10u

C1009

10u

+

+5VA

2700

R008

3.9K

Q003

C1815

C009

R009

10K

10u

+

R026

87

IC001

24C08

6

5

C023

C024

22P

22P

C209

+12V

+

16V10u

+

C212

R212

4.7K

1N4148

RGB

D202-D204

1N4148X3

R219

30K

+

C216

0.22u

50V

+9V

R222

100K

R223

100K

Q1003

C1815

R1005

C

1015

10u

3k3

+

R1007

1k5

+

34

NC

VCC

CAPL-M

35

GND

36 37

AGNDC

IN-L2

38

IN-R2

39

GND

40

IN-L1

41

IN-R1

42

REF

43

MONOIN

44

GND

VCC

SIF IN+

1

2 3 4 5 6 7 8 91011

C1006

100n

C1005

56p

10K

+9V

R211

4K7

DTC124

+5VA

C1012

C1004

R025

10K

Q209

C217

2200p

+5VA

1.5n

C1025

470P

S-OUT-L

SIF IN-

56p

SYNC

+9V

B

G

R

STD-BY

D215

1N4148

+

C210

47u

16V

R213

10K

AGC

SCL0

SDA0

+9V

AGC

5

AV1/AV 2

TV/AV

+9V

C229

47u

16V

SYNC

+9V

C1010

3u3

+

EN 10TC5.1U CA 7.

7

8

9

CIRCUIT CONTAINS AND CIRCUIT ITSELF ARE SUBJECT TO CHANGE WITHOUT NOTICE.

S001A

S003A

S002A

TV/AV

VOL DN VOL UP

MENU

R024A

R023A

1.8K

1K5

R030

Q007

4.7

C1815

1/4W

+

C028

R031

10u

1K

16V

R033

Q008

1K

R247

330

C248

0.47u

16V

+

R244

10

R032

A1015

1K

D001

5V1

9V

Y

9V

C281

0.1u

+

L209

10uH

X201

10n

D209

2V4

D208

1N4148

L208

22uH

+9V

+9V

R235A

***

R235

120

Q204

C1815

R258

150

R255

22K

C624

470u

R611

25V

0.47 2W

+

+13V

C627

R612

1K

R608

1K

+12V

R605

47K

Q601

C1815

0.22u

R607

C626

4.7K

3300P

C631

0.22u

R609

C630

4.7K

3300P

+

R610

Q603

47K

C124

4

3

R006

+5V

R018

C021

10u

+

R220

220K

L205

22uH

L204

22uH

C226

680P

+

GND

S-OUT-R

IC1001

MSP 3425G

GND

XT-IN

C1001

1.5p

X1001

18.432M

+5V

SCL0

R001

R001A

10K

64

STD BY

63

RMT-IN

62

TV Sync

S-SW

61

R023

100

60

ROTATE

SW

59

+5V

58

SCL0

57

SDA0

56

EXT.MUTE

55

5V

54

GND

53

TV AGND

R214

270

52

B-OUT

R215

270

51

G-OUT

R216

270

50

R-OUT

C214

0.01

+

49

49

RGB 9V

RGB 9V

48

48

IK-IN

U COM PORT

47

APC FIL

BLACK DET

46

SVM OUT

45

Y/C 5V

44

C220

0.01

RF AGC

43

IF IN

42

IF IN

41

IF GND

40

+

IF AGC

39

SF OUT

38

C223

4.7u

16V

+

S-Reg

IF VCC(5V)

36

C225

0.01

PIF PLL

35

DC NF

34

+

SIF-IN

33 32

10u

C230

16V

R229

0.1

R228

10K

C1037

10n

2333 32 31 30 29 28 27 26 25 24

NC

NC

RESET

GND

I2S

DVSS

D-VCC

ADR

I2S

I2S

I2S

I2S

SDA

SCL

IO

ST BY

ADR-SEL

+5VA

+5VA

R1011

100

C1034

10n

R003

1K

IC101

TMPA8859

TCL-A27V01-TO

V/C/D

47K

+9V

22

2120

9

1

181716

15

4

1

R1002

100

13

12

R1001

100

C1017

470n

C1035

22P

10K

C008

10K

100P/27P

R019

10K

10K

C022

10n

R024

47

R027

22

R028

22

C026

+5V

0.1u

+

C025

10u

16V

B

G

R

C213

+9V

47u

L212

10uH

C215

R217

4K7

180

+

C218

1u

50V

+

C219

100u

16V

C221

1u

16V

+

C224

100u

25V

C227

+

0.47

50V

R227

C228

270

C1038

10n

1014

C

10u

ROLONC

IO

TP

XT-OUT

10n

C1031

C1002

1.5p

R1010

100

C1033

10n

R043

10K

TV AGND

SCP-OUT

TV-DGND

DVCC(3.3V)

Fsc OUT

ABCL-IN

EW-OUT

IF-VCC(9V)

SIF-OUT

EHT IN

R230

24K

C1036

TV/AV

FBP-IN

V-SAW

TV-OUT

22P

X-RAY

RESET

X-TAL

X-TAL

H-OUT

H-AFC

V-OUT

H-VCC

Cb IN

Cr IN

V2-IN

TV/AV

STD-BY

R004

+5V

C041

R044

C043

2.2K

10u

+

1

2

R036

470

KEY

3

GND

4

5

C031

X001

39P

8M

6

C032

39P

7

TEST

8

L002

C034

10uH

0.01

5V

9

+

C033

10u

GND

Ys IN

Y-I N

C-IN

C253

47

R1004

100K

R1003

***

16V

10

11

12

13

14

C246

0.47u

50V

+

15

16

17

C244

R248

10n

1K

18

C243

+

19

1u

50V

C242

100n

20

C241

+

21

1u

50V

22

23

C238

100n

24

25

C236

10n

26

C280

27

+

C235

D205

33u

1N4148

16V

2837

29

R232

100

30

Q203

C1815

31

R233A

3K3

C231

R231

33K

2200

C254

R226

47

100

X202

L206

4.5MBF

22uH

L1001

C1018

22uH

100n

+

C1019

47u

16V

D602

+9V

1N4148

SDA0

SCL0

R656

*1K

0.1u

R036A

10K

C027

220p

+5V

C029

10n

C030

220P

R034

10K

+5V

C247

R246

8K2

8200p

R245

470

L201

22uH

+

C245

2200u

16V

R243

100

Cb

R242

100

Cr

R241

100

+

C237

10u

50V

0.1u

R239

1K

R238

470

C233

C234

100u

10n

16V

R234

R233

330

330

4.5MBF

+9V

R225

330

+5VA

C626A

C630A

C661

10n

100u

25V

+

10K

R606

10K

Q602

A1015

01-2336PH-MA2

2006-01-11

10

S005A

S004A

S006A

CH DN

CH UP

R026A

R027A

R025A

2K7

4K3

6K2

R0334

470

4K7

4

4

C263

100u

16V

LIN

IC602

TDA7266

RIN

ST-BY

MUTE

P-GND

3

3

+5V

R010

Q006

C1815

uPC574J

+

C833

4700u

16V

Q825

C1815

7805

+

R254

100K

313

VCC1 VCC2

LOUT+

LOUT-

ROUT+

ROUT-

S-GND

8

NC

+33V

+12V

1N4148

D214

Q202

C1815

12

12

D101

Q824

C1815

9

P001B

P001

Q821

4544

R829

10K

R832

1K

R262

1K2

D834

9V1

R833

1K

C262

220u

16V

IN4148

C250

R256

5K6

D206

IN4148

1

2

15

14

1

+12V

D02

IN4148

C104

100n

R826

10 2W

Q820

C2230

R827

4K7/5W

D826

8V2

C834

0.01u

R837

10K

+9V

+

R261

D261

330

R260

OPEN

D213

47u

3V9

50V

+

R249

0

R250

150

9V

R257

4K7

P601 P602

2

W601

L

+5VA

5

5

J025

R838

10K

C264

0.1u

50V

C625

100n

12

4

7

6

C634

0.1u

50V

11

12

10

11

12

!

S008

POWER

IR001A

R0333

3

R070A

120K

47

+

C070A

47u

16V

+

C01

100u

D01

IN4001

R01

4K7

R02

27K

R266

22K

2W

C261

10n

R828

22K/2W

D210

24V

RL01

Q01

C2236

+130V

L801

100uH

R830

1K

1

IC802

!

615A

2

R836

1K

1/4W

Q822

C1815

D828

6V2

Q823

D827

1N4148

C1815

C834A

0.1u

IC201IC202

7809

Q205

A1015

D262

IN4148

+14V

D212

220u

IN4148

D211

C251

IN4148

4.7u

50V

R251

470

+

C249

R253

4u7

100K

50V

R311

4.7k

+130V

1 2

C401

+

4.7u

160V

Q401

2482

R401

!

220

L411

1uH

18

D1001A

D1001B

LED

LED

12

R033B

NC

C821

1000u

25V

+

+13V

+

C828

330u

160V

R835

120K

1/2W

C835

R831

0.1u

33K

VR802

R834A

C836

6K8

820K

470u

R834

16V

R834B

+

*470

D829

1N4148

D824

+12V

1N4001

+

C260

47u

16V

INPUT

VCC

1 2

+

C301

C302

100u

35V

35V

+

D301

IN4001

+

C303

50V

-14V

10u

3

R404

4K7

7W

S702

MOF

2 3

R402

2K4

C403

1W

390P

500V

1 4

C402

3n3

16

500V

C411

Q411

*3300p

3DD3402

1.6KV

!

!

D412

FR104

19

L412

0.6uH

R418

6.8K

Q413

A1015

Q412

R417

A1015

2.2K

R420

2.2K

C822

0.1u

C827

330

+

C422

220u

160V

!

!

R412

2K

R420A

2.2K

10n

500V

POMP UP

T401

D411

RS3FS

C832

1000u

16V

*6800P

D820

!

RU4YX

C820

220P

500V

C826

470P

2KV

D822

RU4AM

C829

10u

50V

D823

RU4YX

C830

+

220P

500V

C831

100n

IC301

TDA8172

OUT

GND

43 75 6

R304

1.5 1W

C305

0.33

C308

100u

+

35V

C306

R314

10K

+

C421

10u

200V

!

C412

*8200p

1.6KV

C413

*0.022

400V

PPN

R413

15K

R416

4.7K

D410

1N4148

+

!

!

R414

47K

IRF630MFP

AC 120V

+14V

Q414

5A/250V

3A/250V

+

2A/250V

Vp

R315

5K6

R432

*6K8

C432

1000u

35V

+9V

!

R820

R821

R823

!

R302

3.9K

R312

22K

C414

*7200p

1.6KV

S801

33

11

!

BCK-4201-78

16

17

18

10

12

15

14

8.2M 1/2W

!

Vref

D311

***

+

C304

4.7u

16V

D303

8V2

C311

2700P

100V

R422

0.33

R421

10K/2W

D421

FR104

-14V

D431

!

FR105

L431

+

C431

220p

500V

!

L413

*600uH

R415

3.9

2W

+

C415

4u7

50V

P801

22

T803

R840

C840

2200P

AC400V

R303

33K

R313

1.5

2W

R316

10K

2W

L432

A1

!

F801

-14V

+33V

1/2W

C435

1000u

+

25V

A4

C419

*470n

400v

!

!

T801

36-LIF007-XX0

!

1M

C801

R801

220n

1/2W

AC250V

!

C807

10n

15 1/2W

1K5 1/4W

*S237-479

500V

R813

D810

FR104

C814

D811

10uF

FR104

35V

R814

C812

1000p

7

9

1

4

!

D309

1.3W 51V

R310

D310

10K

1N4148

-14V

C441

220P 500V

!

D441

+

FR104

C442

22u

250V

A3

+

C443

C433

220P

500V

D432

FR104

2W FUS

A1`

R433

0.68

2W FUS

R431

0.68

!

20

NO D.F

A2

C802

+

MF

D420

FR104

4u7

50V

220n

AC250V

RT802

+

!

IC802(1/2)

SFH615A-3

D813

6V2

R812

1K

C813

100n

R308

120

MOF

1/2W

+200V

!

-14V

+14V

COL

AFC

A6

250V AC

C806

680u

200V

B+

C804-C805

3 4

C309

330n

100V

400V

PTC

!

!

R811

1K

!

D812

IN4148

1

11

2

7

10

8

4

5

P803

100n

C803

RT801

!

4n7

FB

6

OLP/SS

R309

120

MOF

2W

R461

1.5

1W FUS

!

T802

36-LIF007-XX0

C804A

470p

AC400V

C805A

470p

AC400V

!

DB801

D3SB60

!

R810

68K/2W

IC801

STR-W6735

4 1

VCC

OCP/BD

S/GND

5 37

C810

220P

+

C811

R815

3.3uF

100

50V

L301

35-332220-00X

L414

21uH

680

R419

2W

MOF

HV

T402

!

A

!

B

!

D

C815

1500p

2KV

C

D

R816

0.12/2W

P411

E

VERT

COIL

!

HOR

COIL

EHT

Q402

C1815

R453

1K

C451

100n

FOCUS

A5

SCREEN

ABL

9

HEATER

1

F

G

2

3

4

200V

3

H

2

1

P421

I

J

1

W602

2

G_16340_011.eps

R

140306

K

Page 11

Circuit Diagrams and CBA Layouts

Layout Main Board (Top Side)

EN 11TC5.1U CA 7.

G_16340_012.eps

100306

Page 12

Circuit Diagrams and CBA Layouts

Layout Main Board (Bottom Side)

EN 12TC5.1U CA 7.

G_16340_013.eps

100306

Page 13

CRT Panel

Circuit Diagrams and CBA Layouts

EN 13TC5.1U CA 7.

G_16340_014.eps

100306

Page 14

Circuit Diagrams and CBA Layouts

EN 14TC5.1U CA 7.

Layout CRT Panel

Layout Side AV Board

Layout Keyboard Panel 40-P25207-KEA1X

G_16340_017.eps

100306

Layout CRT Panel

G_16340_015.eps

150306

Layout Keyboard Panel 40-P25207-KEB1XG

G_16340_018.eps

100306

G_16340_019.eps

100306

G_16340_016.eps

130306

Page 15

8. Alignments

Alignments

EN 15TC5.1U CA 8.

8.1 How to Put the Set into Factory Mode

• Press the “VOL-” button to minimize the volume.

• Hold the “VOL-” button and simultaneously press the

“DISPLAY” button on the remote control.

• Press the “CH+” or the “CH-” button to select the parameter

you want to adjust.

• Press the “VOL+” or the “VOL-” button to adjust the

selected parameter.

• To put the new values into the memory, leave the factory

mode with the “STANDBY” button on the remote control, or

switch the set off with the “ON/OFF” button.

2

8.2 Adjustment of the B+ (BAT) voltage

1. Apply the Philips standard test pattern to the RF input.

2. Connect a DC voltmeter (range >200 Volt) to pins 1 (GND)

and 3 (+) of S804 [1].

3. Adjust potentiometer VR802 [2] in STANDARD mode in

such a way the voltage reading is 130 +/- 0.5 Volt.

1

Figure 8-1 Test pin & potentiometer position

8.3 RF AGC Alignment:

1. Apply an 8-scale gray signal (60dB).

2. Adjust the AGC data in Factory Mode in such a way the

noise just disappears.

3. Change the signal to 90dB.

4. Measure the voltage at test Pin C of Q101 (this is the PreAmplifier output).

5. Write down this voltage, and call it V1P-P.

6. Apply an 8-scale gray signal with Color Bar (90Db)

7. Adjust the AGC data in Factory Mode in such a way the

picture is without distortion and interference.

8. Change the signal to 8-scale gray signal (90dB).

9. Measure the voltage at test Pin C of Q101 (Pre-Amplifier

output)

10. Write down this voltage and call it V2P-P.

11. Calculate the value VP-P with the following formula: VPP={(V2P-P)-(V1P-P)}/3.

G_16340_020.eps

100306

12. Apply 8-scale gray signal (90dB).

13. Measure the voltage at test Pin C of Q101 (Pre-Amplifier

output)

14. Adjust AGC data until the voltage of Pin C of Q101 reaches

the value of VP-P (=(V2P-P-V1P-P)/3)

G_16340_021.eps

100306

Figure 8-2 Test circuit

Page 16

EN 16 TC5.1U CA8.

Alignments

8.4 Screen & Focus Voltage Adjustment

1. Apply the test pattern signal in normal status.

2. Enter the Factory mode

3. Press the "AV/CH" button to stop the vertical scan (Note:

the RC/GC/BC is preset to 80, GD/BD to 40)

4. Adjust the SCREEN potentiometer on the line output

transformer in such a way the horizontal line is just visible

on the screen.

5. Turn on the vertical output, and adjust the "FOCUS"

potentiometer on the line output transformer in such a way

the focus is maximized.

8.5 White Balance Adjustment (NORMAL)

1. Apply the black and white pattern in normal status.

2. Alignment of the normal color temperature

a. Change the Color Temperature to the normal status

b. Use a color analyzer to measure the black side of the

screen.

c. By changing the value of RC, GC and BC, set the

reading of the color analyzer to PHILIPS standard

– x=285+/-4

– y=296+/-4.

d. Use a color analyzer to measure the white side of the

screen.

e. By changing the value of GD, BD, set the reading of the

color analyzer to PHILIPS standard

– x=285+/-4

– y=296+/-4.

f. Separately set the brightness and contrast from

minimum to maximum, repeat the step -b- up to and

including -e- until the reading of the color analyzer is

correct.

The PHILIPS standard is:

– Warm:X=315+/-10, Y=321+/-10

– Cool:X=269+/-10, Y=275+/-10

8.6 Adjustment of Sub-brightness

1. Apply the Grey-scale / Color bar (NTSC signal) to the AV

input, in normal status.

2. Enter factory alignment menu 5.

3. Select BRTC

4. Adjust the sub-brightness, until the 2nd dark bar of 8 level

Grey scales can just be seen.

8.7 Picture Geometry Adjustment

1. Apply the Philips standard testing pattern in normal status

2. Then enter menu 3

3. Adjust the following data to get the minimum distortion:

a. HPOS6 (Horizontal Centre)

b. PARA6 (Level)

c. TRAP6 (Trapezium)

d. HSIZE6 (Horizontal Size)

e. CNRT6 (Top)

f. CNRB6 (Bottom)

4. Apply the Philips standard testing pattern in normal status.

5. Enter menu 3.

6. Adjust the following data to get the minimum distortion:

a. HIGH6 (Height)

b. VP60 (Vertical Center)

c. VLIN6 (Linearity)

d. VSC6 (Vertical-S Correction)

Page 17

Alignments

EN 17TC5.1U CA 8.

8.8 Initialization

Put the set into “Factory Mode” (see “How to Put the Set into

Factory Mode”, the first item of this chapter). Press the

"SOUND" button, the screen displays "WAIT". When the

screen displays FGSFGSFGSFG "OK", the initialization is

finished. Now you can enter the following working procedure.

Table 8-1 EEPROM Data

FAC 01 FAC 02

RC* GC* BC* GD* BD* HIGH5 VP50 VLIN5 VSC5 VBLK5 VCEN5

80 80 80 40 40 13 03 0A 0C 00 18

FAC 02

HIGH6* VP60* VLIN6* VSC6* VBLK6 VCEN6 VP60*

27 04 0A 0B 00 2C 04

FAC 03

HPOS5 PARA5 TRAP5 HSIZE5 CNRT5 CNRB5 VEHT5 HEHT5

0C 10 29 13 0A 06 03 03

FAC 03

HPOS6* PARA6* TRAP6* HSIZE6* CNRT6* CNRB6* VEHT6 HEHT6

13 15 12 1D 0B 0C 03 03

FAC 04

CNCX CNTX BRTX BRTN COLX COLN TNTX TNTN

7F 08 20 20 35 00 28 28

FAC 05

BRTC* COLC COLP SCOL SCNT CNTC TNTCT TNTCV

40 2C 00 07 0C 4C 40 40

FAC 06

ST3 SV3 SV4 SVD ASSH SHPN SHPN

20 20 19 19 07 10 2A

FAC 07

MOD1 MOD2 MOD3 OPT OPTM1 OPTM2 HDCNT HSTOP

60 B0 70 37 C0 00 00 FF

FAC 08

RFAGC* BRTS OSD OSDF CCD OSD CCD OSDF TXCN RGCN

25 00 21 53 4A 65 1F 16

FAC 09

V01 V25 V50 V100 VOLMAX CURTCEN GATE COL-OUT

46 64 68 6E 32 A5 2A 73

FAC 10

MODE4 MODE5 MODE6 MODE7 MODE8 MODE9

22 0B 19 54 2D 02

FAC 11

MPB-STR MPB-HMC MPB-HP MPB-LP MPB-LIM SUB-FRE SUB-HP VOL-MAI

43 0D 07 11 00 28 02 00

FAC 12

SVM SVM1 OSD2 OSDF2 PYNX PYNN PYXS PYNS

05 05 20 64 28 18 22 10

FAC 13

CLTM CLVO CLVS ABL DCBS FLG0 FLG1

44 43 43 27 14 82 0D

FAC 14 FAC 15

HAFC AGCC NOIS ONTM NSHP PVLVL PLMT RC-C GC-C BC-C GD-C

09 1C 01 08 1A 80 80 00 00 00 00

FAC 16 FAC 17

RC-W GC-W BC-W GD-W BD-W YUVGC YUVBC D-COL D-BRI D-CON D-SHP

00 00 00 00 00 03 03 32 32 5A 32

FAC 18 FAC 19

S-COL S-BRI S-CON S-SHP M-COL M-BRI M-CON M-SHP

32 32 32 32 32 32 1E 32

FAC 20

SEG-PO INT1 SEG-POINT2 DATA-VL DATA-VH DATA-UF SPE-POS1 SPE-DATA1 SENSI-ON SENSI -OFF

173 407 01 02 08 06 05 00 00

FAC 21 FAC 22

T-Hz120 -BAS T-Hz500 -TRE T-Hz1K5 T-Hz5K T-Hz10K C-Hz120-BAS C-Hz500 -TRE C-Hz1K5 C-Hz1K C-Hz10K

2D 4A 0C 0C 0C 38 3E 0C 0C 0C

FAC 23 FAC 24

B-Hz120-BAS B-Hz500-TRE B-Hz1K5 B-Hz5K B-Hz10K COMB1 COMB2 COMB3 AV GAIN OPTM3

19 2C 0C 0C 0C 00 05 00 19 08

8.9 EEPROM Data:

Note: although all items are adjustable, we only recommend to

adjust the items with an asterisk (*). The other items are

adjustable as well, but we strongly discourage adjusting them.

EEPROM data

Page 18

EN 18 TC5.1U CA9.

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9. Circuit Descriptions, Abbreviation List, and IC Data Sheets

9.1 Brief Introduction of the Chassis

9.1.1 Chassis block diagram

9.1.2 Power Supply Section

This section mainly consists of

• IC STR-W6735 (IC801).

• Transformer (T803).

• Bridge rectifier (DB801).

• Accessory circuits.

The supply voltage for this chassis should be AC 110V. The

allowed voltage range is 90V to 140V, the frequency range is

50/60Hz.

The AC power with high/low frequency interference goes

through an RC filter, consisting of C801, T801, C802, R801,

and T802. The filter removes the high/low frequency

interference. Then DB801 transforms the AC power to DC

power. T803 and IC 801 work in standby state. T803 will

provide a power voltage to IC101. IC101 scans for the "KEY IN"

signal (Pin 3 of IC101) from the ON/OFF switch on the

keyboard. If "KEY IN" = "power on" signal, pin 64 (IC101) will

generate a signal to drive the photo coupler (IC8021). It acts as

a feed back circuit (feed back to Pin 6 of IC801) for controlling

IC801 to adjust MOSFET.

Transformer T803 provides the following voltages:

• +13V voltage from Pin16.

Figure 9-1 Chassis block diagram

• +130V (B+) voltage from Pin1.

• +12V from Pin 15.

• Pin 15 is also connected to two Positive Voltage

The picture below shows IC201 and IC202:

G_16340_010.eps

100306

Regulators (IC201, IC202) in-series. The outputs of these

regulators are +9V and +5V respectively.

G_16340_022.eps

100306

Figure 9-2 IC 201/202

Page 19

Circuit Descriptions, Abbreviation List, and IC Data Sheets

6

9.1.3 Tuning Section

This section mainly consists of the tuner (TU101), the IF preamplifier circuit and the SAWFILTER.

Table 9-1 Tuning section 1

Pin Symbol Description

1 AGC Auto gain control

2 AS I2C bus address select

3 SCL I2C bus serial clock

4 SDA I2C bus serial data

5

6 BP Supply voltage tuner section +5V

7 BT Supply voltage tuning section +31V

8 IF Intermediate frequency out

Table 9-2 Short specification of the tuner

Receiving

Channel

Receiving

System

Intermediate

Frequency

Antenna Input

Impedance

Output Impedance

Band changeover system

VHF LOW BAND: CH2~B(55.25~127.25MHz)

VHF HIGH BAND: CH C~CH W+11(133.25~361.25MHz)

CH W+12~69(367.25~801.25MHz)

NTSC

Picture carrier: 47.74MHz

Colour carrier: 42.17MHz

Sound carrier: 41.25MHz

Unbalanced 75Ohms

Unbalanced 75Ohms

Digital change by PLL IC

G_16340_023.eps

10030

Figure 9-3 Pre-amplifier circuit

9.1.4 Sound Process Section

The SIF signal is sent out together with the TV signal from

Pin30 of IC101. It passes through Q203, R225. X202 and a

High-pass filter (consisting of C254, L206, C253) filters out the

video signal and low frequency interference.

G_16340_024.eps

100306

EN 19TC5.1U CA 9.

From Pin58 of IC101 the I2C bus clock signal goes to the tuner.

The tuner works during the clock time. IC101 will send out a

data signal from Pin57 to control the tuner's working state by

controlling the +33V voltage. +33V is provided from Pin10 of

T803. That voltage is put into the tuner at Pin7. A circuit inside

the tuner transforms +33V into a voltage between 0 and +33V

(as a function of the data, sent by IC101).

The AGC signal is a close loop control voltage that keeps the

amplitude of the signal constant.

Output of tuner is the Intermediate Frequency signal (IF signal).

The IF signal will pass pre-amplifier circuit (refer to the picture

below). The amplified IF signal passes the SAW filter and is

then sent to IC101 Pin41/42.

IC101 creates a CVBS signal and sends it out from Pin30.

CVBS will be selected by IC901, and then pass from Pin13 of

IC901 to Pin20/24 if IC101. IC101 will demodulate the CVBS

signal into an R, G, B signal. Next IC101 will send this R, G, B

signal from Pin50/51/52 to the CRT board.

Figure 9-4 Sound process section 1

SIF will be finally sent into Pin2 of IC1001. An analog automatic

gain control circuit (AGC) allows a wide range of input levels.

The analog-to-digital conversion of the IF sound signal is done

by an A/D-converter. The high pass filter, formed by a coupling

capacitor at SIF_IN1+ suppresses video components.

IC1001 is controlled via the I2C bus slave interface.

The AV sound signal will be directly sent to Pin37/38 or Pin40/

41 of IC1001. Q901/2 and Q903/4 form Emitter-Follower

circuits to provide a better load ability.

The (analog) sound signal will go from Pin26/27 of IC1001 to

Pin4/12 of IC602. IC602 is a dual bridge amplifier. The output

voltage of IC602 drives the speakers. The volume is adjusted

via the I2C bus.

G_16340_025.eps

100306

Figure 9-5 Sound process section 2

Page 20

EN 20 TC5.1U CA9.

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9.1.5 Vertical Output Section

This section mainly consists of IC301 (TDA8172), the Vertical

Coil and the related circuit. The supply voltage of IC301 are

+14V and -14V. These two voltages are provided by the LOT

section. For the vertical scan, IC101 creates a Saw-tooth

waveform at Pin16. This is the input signal of IC301. The main

task of IC101 is to create the vertical scan waveform. The

output signal of IC301 drives the Vertical Coil. If IC301 works in

normal state, Pin6 will send a square-signal to maintain a high

voltage at D214. If it does not, D214 will get a low voltage, Pin2

of IC101 senses this change and IC101 sends out a standby

signal.

9.1.6 Horizontal Output and LOT Section

The horizontal drive pulse is a square wave. IC101 creates this

waveform at Pin13. Via Q401 the signal goes to the input of

Q411. Q411 is a horizontal output triode with a damper inside.

The signal from Pin C of Q411 drives the Horizontal Coil.

When Q411 goes into cut-off state, a sub-coil inside the LOT

will generate an EHT by inductance.

9.2 IC description

9.2.1 Main IC (IC101)

Description:

The main IC is a TMPA8857CSNG, provided by TOSHIBA. It is

an integrated circuit, suited for PAL, NTSC and SECAM TV. An

MCU and a TV signal processor are integrated in a 64 pin DIP

package.

The MCU contains an 8-bit CPU, ROM, RAM, I/O-ports, timer/

counters, A/D-converters, an on-screen display controller,

remote control interfaces, IIC bus interfaces, and the closed

caption decoder.

The TV signal processor contains PIF, SIF, Video, multistandard chroma, deflection, and RGB processors.

TV Processor

IF

• Integrated PIF VCO, aligned automatically

• Negative demodulation PIF

• Multi-frequency SIF demodulator, without external tankcoil

Video

• Integrated chroma traps

• Black stretch

• Y-gamma

Chroma

• Integrated chroma BPF’s

• PAL/NTSC/SECAM demodulation

RGB/Base-band

• Integrated 1 H base-band delay line

• Base-band TINT control

• Internal OSD interface

• Half-tone and transparent for OSD

• External YCbCr interface for DVD

• RGB cut-off/drive controls by bus

• ABCL (ABL and ACL combined)

Synchronization

• Integrated fH x 640 VCO

• DC coupled vertical ramp output (single)

• EW correction with EHT output

•Sync out

Features:

MCU:

• High speed 8-bit CPU

• 12 I/O ports

• I2C bus interface (multi-master)

• 14-bit PWM output, 1 channel, for a voltage synthesizer

• 7-bit PWM output, 1 channel

• 8-bit A/D converter, 3 channels

• Remote control signal preprocessor

• Two 16-bit internal timer/counters, 2 channels

• Two 8-bit internal timer/counters, 2 channels

• Time base timer

• Watchdog timer

• 16 interrupt sources: 5 external, 11 internal

• Stop and Idle power saving modes

CCD decoder

• Digital data slicer for NTSC

OSD

• Clock generation for OSD display

• Font ROM characters: 384 characters

• Characters display: 32 columns x 12 lines

• Composition: 16 x 18 dots

• Size of character: 3 (line by line)

• Color of character: 8 (character by character)

• Display position: H 256 / V 512 steps

• BOX function

• Fringing, smoothing, italic, underline function

• Conform to CCD regulation

• Jitter elimination

Page 21

Circuit Descriptions, Abbreviation List, and IC Data Sheets

EN 21TC5.1U CA 9.

Figure 9-6 Block Diagram Main IC 1

G_16340_026.eps

100306

Page 22

EN 22 TC5.1U CA9.

Circuit Descriptions, Abbreviation List, and IC Data Sheets

9.2.2 Vertical Deflection Booster (IC 301)

The STV8172A is a vertical deflection booster, designed for TV

and monitor applications.

This device, supplied with up to 35 V, provides a maximum

output current of 2.5 A, to drive the vertical deflection yoke.

The internal fly back generator delivers fallback voltages of up

to 75 V.

Figure 9-8 Vertical Deflection Booster

Figure 9-7 Block Diagram Main IC 2

G_16340_028.eps

100306

G_16340_027.eps

100306

Page 23

Circuit Descriptions, Abbreviation List, and IC Data Sheets

EN 23TC5.1U CA 9.

9.2.3 Demultiplexer (IC 901)

The HCF4052B is a monolithic integrated circuit, fabricated in

Metal Oxide Semiconductor technology, available in DIP and

SOP packages.

The HCF4052B analog multiplexer/demultiplexer is a digitally

controlled analog switch, having low ON impedance, and very

low OFF leakage current. This multiplexer circuit dissipates

extremely low quiescent power over the full supply voltage

range, independent of the logic states of the control signals.

When a logic “1” is present at the inhibit input, all channels are

off. This device is a differential 4-channel multiplexer, having 2

binary control inputs, A and B, and an inhibit input. The two

binary input signals select 1 of 4 pairs of channels to be turned

on and connect the analog inputs to the outputs.

G_16340_029.eps

100306

Figure 9-9 Demultiplexer

Table 9-3 Demultiplexer

PIN Symbol

1 and 2 Y CHANNELS IN/OUT

3 COMMON "Y" OUT/IN

4 and 5 Y CHANNELS IN/OUT

6INH

7 VEE

8 VSS

9B

10 A

11 and 12 X CHANNELS IN/OUT

13 COMMON "X" OUT/IN

14 and 15 X CHANNELS IN/OUT

16 VDD

9.2.4 Sound Processor (IC1001)

Pin No. Pin Name Type Short Description

19 DVSUP Digital power supply +5

V

20 DVSS Digital ground

21 I2S_DA_IN2 I2S2 data input

22 RESETQ IN Power-on-reset

23 NC Not connected

24 NC Not connected

25 VREF2 Reference ground 2

High-voltage part

26 DACM_R OUT Loudspeaker out, right

27 DACM_L OUT Loudspeaker out, left

28 NC Not connected

29 VREF1 Reference Ground 1

High voltage part

30 SC1_OUT_R OUT Audio 1 output, right

31 SC1_OUT_L OUT Audio 1 output, left

32 NC Not connected

33 AHVSUP Analog power supply

8.0V

34 CAPL_M Volume capacitor MAIN

35 AHVSS Analog ground

36 AGNDC Analog reference voltage

High-voltage part

37 SC2_IN_L IN Audio 2 input, left

38 SC2_IN_R IN Audio 2 input, right

39 ASG Analog shield Ground

40 SC1_IN_L IN Audio 1 input, left

41 SC1_IN_R IN Audio 1 input, right

42 VREFTOP Reference voltage IF A/D

converter

43 MONO_IN IN Mono input

44 AVSS Analog ground

9.2.5 Dual Bridge Amplifier (IC 602)

The TDA7266SA is a dual bridge amplifier, specially designed

for LCD monitor, PC motherboard, TV, and portable radio

applications.

Table 9-4 Sound Processor

Pin No. Pin Name Type Short Description

1 AVSUP Analog power supply

+5V

2 ANA_IN+ IN IF Input 1

3 ANA_IN- IN IF common

4 TESTEN IN Test pin

5 XTAL_IN IN Crystal oscillator

6 XTAL_OUT OUT Crystal oscillator

7 TP Test pin

8 D_CTR_I/O_1 IN/OUT D_CTR_I/O_1

9 D_CTR_I/O_0 IN/OUT D_CTR_I/O_0

10 ADR_SEL IN I2C BUS address select

11 STANDBYQ IN Stand-by ( Low-active)

12 I2C_CL IN/OUT I2C clock

13 I2C_DA IN/OUT I2C data

14 I2S_CL I2S clock

15 I2S_WS I2S word strobe

16 I2S_DA_OUT I2S data output

17 I2S_DA_IN1 I2S1 data input

18 ADR_CL ADR clock

G_16340_031.eps

100306

Figure 9-10 Dual Bridge Amplifier

Page 24

EN 24 TC5.1U CA10.

10. Spare Parts List

Spare Parts List

G_16340_032.eps

Figure 10-1 Spare Parts

Table 10-1 Spare Parts List

ITEM NAME QTY. REMARK

1 Side AV PWB 1

2 S/T Screw W 3 X 10 AB 2 MGT Side AV PWB.

3 Speaker 2

4 Speaker Rubber Cushion 8

5 S/T Screw W 3 X 14 HS 4 MGT Speaker

6 Side AV Inlay 1

7 Plate Model NO. 1

8 S/T Screw F 3 X 10 BT 2 MGT Rear AV Jack

9 Rear AV Inlay 1

10 S/T Screw B 4 X 20 AB 8 MGT Rear and Front Cabinet

11 Rear Cabinet 1

12 Cushion (25mm X 7mm) 2

13 S/T Screw W 3 X 10 AB 3 MGT Main Board

14 Main Board 1

15 Main Board Bracket 1

16 CRT Screw HA 6 X 30 4 MGT CRT & Front Cabinet

17 Metal Cushion 4

18 CRT 1

19 Fibre Sheet 4

20 S/T Screw W 3 X 10 AB 6 MGT KEY Board & Front Cabinet

21 Key Board 1

22 S/T Screw W 3 X 10 AB 4 MGT Push Button

100306

Page 25

Spare Parts List

ITEM NAME QTY. REMARK

23 Push Button 1

24 S/T Screw W 3 X 10 AB 1 MGT Lens

25 Lens 1

26 Decorative Piece for Power Knob 1

27 Power Knob 1

28 Power Spring 1

29 Logo 1

30 Front Cabinet 1

31 S/T Screw W 3 X 10 AB 4 MGT CRT Support

32 S/T Screw W 3 X 10 AB 4 MGT Guide Rail

33 Cushion (25mm X 7mm) 2

34 Power Line Block 1

35 Guide Rail (Left) 1

36 CRT Support 2

37 Guide Rail (Right) 1

EN 25TC5.1U CA 10.

Page 26

EN 26 TC5.1U CA11.

11. Revision List

Manual xxxx xxx xxxx.0

• First release.

Revision List

Loading...

Loading...