Page 1

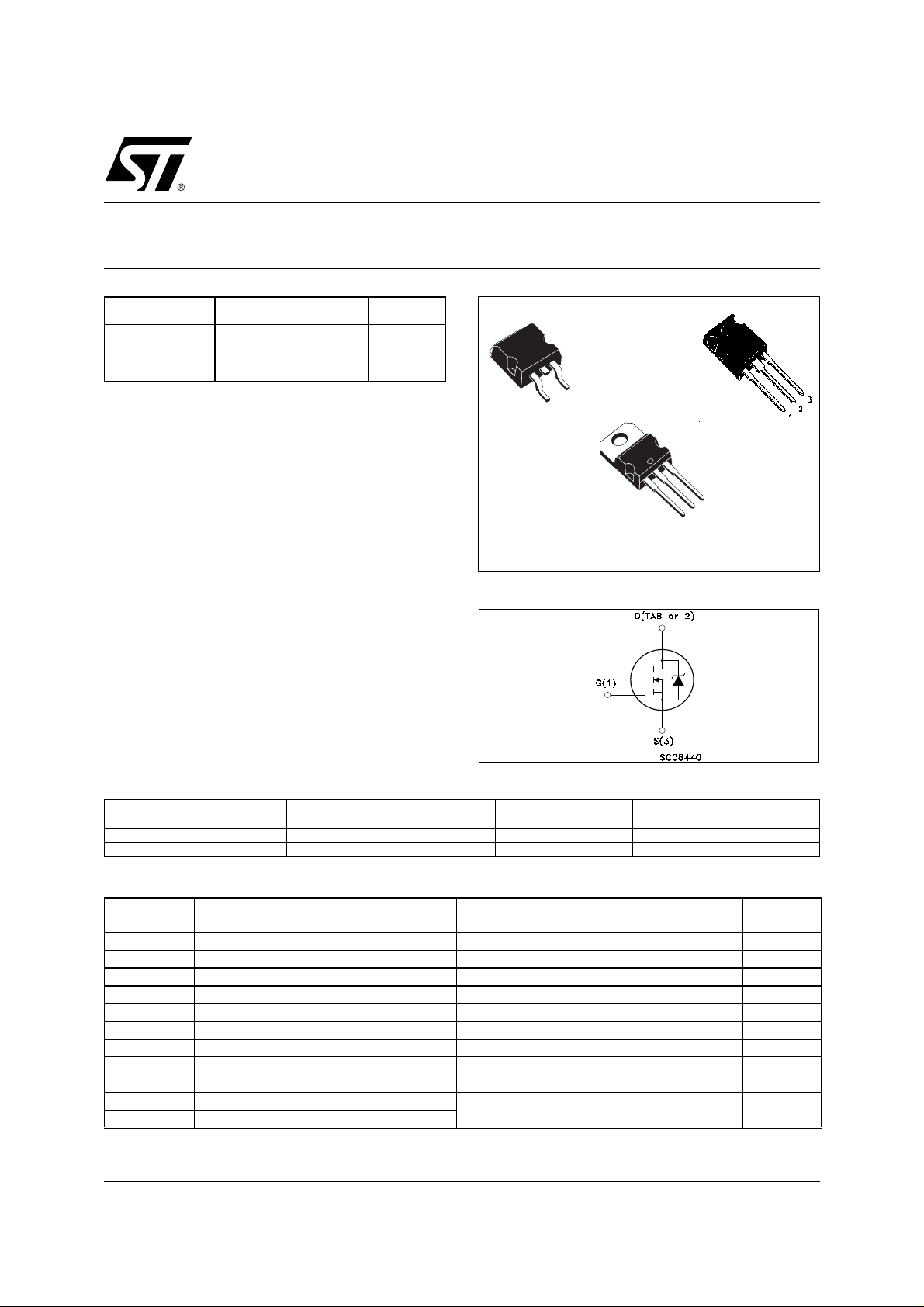

N-CHANNEL 55V - 0.005 Ω -120A D²PAK/TO-220/TO-247

TYPE

STB150NF55

STP150NF55

STP150NF55

■ TYPICAL R

■ SURFACE-MOUNTING D

V

DSS

55 V

55 V

55 V

(on) = 0.005 Ω

DS

POWER PACKAGE

DESCRIPTION

This Power MOSFET is the latest dev elo pment of

STMicroelectronis unique "Single Feature Size™"

strip-based process. The resulting transistor

shows extremely high packing density for low onresistance, rugged avalanche characteristics and

less critical alignment steps therefore a

remarkable manufacturing reproducibility.

APPLICATIONS

■ HIGH CURRENT, HIGH SWITCHING SPEED

■ SOLENOID AND RELAY DRIVERS

■ MOTOR CONTROL, AUDIO AMPLIFIERS

■ DC-DC & DC-AC CONVERTERS

■ AUTOMOTIVE

R

DS(on)

<0.006

Ω

<0.006

Ω

<0.006

Ω

2

PAK (TO-263)

I

D

120 A(**)

120 A(**)

120 A(**)

STB150NF55 STP150NF55

STW150NF55

STripFET™ II POWER MOSFET

AUTOMOTIVE SPECIFIC

3

1

D2PAK

TO-263

(Suffix “T4”)

2

1

TO-220

INTERNAL SCHEMATIC DIAGRAM

TO-247

3

Ordering Information

STB150NF55T4 B150NF55

SALES TYPE MARKING PACKAGE PACKAGING

STP150NF55 P150NF55 TO-220 TUBE

STW150NF55 W150NF55 TO-247 TUBE

2

D

PAK

T APE & REEL

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

DS

V

DGR

V

GS

(**) Drain Current (continuous) at T

I

D

I

D

(

I

DM

P

tot

Drain-source Voltage (VGS = 0)

Drain-gate Voltage (RGS = 20 kΩ)

55 V

55 V

Gate- source Voltage ± 20 V

= 25°C

C

Drain Current (continuous) at TC = 100°C

•)

Drain Current (pulsed) 480 A

Total Dissipation at TC = 25°C

120 A

106 A

300 W

Derating Factor 2.0 W/°C

(1)

dv/dt

E

AS

T

stg

T

j

Pulse widt h l i m i ted by safe op erating area.

(

•)

(**) Curre nt Limited by Pac kage

Peak Diode Recovery voltage slope 8 V/ns

(2)

Single Pulse Avalanche Energy 850 mJ

Storage Temperature

Operating Junction Temperature

(1) ISD ≤120A, di/dt ≤200A/µs, VDD ≤ V

(2) Starting Tj = 25 oC, ID = 60 A, VDD = 30V

-55 to 175 °C

(BR)DSS

, Tj ≤ T

October 2002

JMAX

1/14

Page 2

STB150NF55 STP150NF55 STW150NF55

THERMA L D ATA

Rthj-case

Rthj-amb

T

Thermal Resistance Junction-case

Thermal Resistance Junction-ambient

Maximum Lead Temperature For Soldering Purpose

l

Max

Max

Typ

0.5

62.5

300

°C/W

°C/W

°C

ELECTRICAL CHARACTERISTICS (T

= 25 °C unless otherwise specified)

case

OFF

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

V

(BR)DSS

Drain-source

= 250 µA VGS = 0

D

55 V

Breakdown Voltage

V

= Max Rating

DS

V

= Max Rating TC = 125°C

DS

V

= ± 20 V

GS

1

10

±100 nA

ON

(*)

I

DSS

I

GSS

Zero Gate Voltage

Drain Current (V

GS

Gate-body Leakage

Current (V

DS

= 0)

= 0)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

GS(th)

R

DS(on)

Gate Threshold Voltage

Static Drain-source On

= VGS I

DS

V

= 10 V ID = 60 A

GS

= 250 µA

D

24V

0.005 0.006

V

Resistance

DYNAMIC

Symbol Parameter Test Conditions Min. Typ. Max. Unit

(*)

g

fs

C

iss

C

oss

C

rss

Forward Transconductance

Input Capacitance

Output Capacitance

Reverse Transfer

Capacitance

V

15 V ID= 60 A

DS =

= 25V, f = 1 MHz, VGS = 0

V

DS

160 S

4400

1050

350

µA

µA

Ω

pF

pF

pF

2/14

Page 3

STB150NF55 STP150NF55 STW 150NF55

ELECTRICAL CHARACTERISTICS (continued)

SWITCHING ON

Symbol Parameter Test Conditions Min. Typ. Max. Unit

= 27.5 V ID = 60 A

t

d(on)

Turn-on Delay Time

t

r

Rise Time

V

DD

R

= 4.7 Ω VGS = 10 V

G

(Resistive Load, Figure 3)

Q

g

Q

gs

Q

gd

Total Gate Charge

Gate-Source Charge

Gate-Drain Charge

VDD=27.5 V ID=120A VGS= 10V

SWITCHING OFF

Symbol Parameter Test Conditions Min. Typ. Max. Unit

= 27.5 V ID = 60 A

t

d(off)

Turn-off Delay Time

t

f

Fall Time

V

DD

R

= 4.7Ω, V

G

GS

= 10 V

(Resistive Load, Figure 3)

SOURCE DRAIN DIODE

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

SD

I

SDM

V

SD

t

rr

Q

rr

I

RRM

(*)

Pulsed: P ul se duration = 300 µs, duty cycle 1.5 %.

(

•)Pulse width limited by s af e operatin g area.

Source-drain Current

(•)

Source-drain Current (pulsed)

(*)

Forward On Voltage

Reverse Recovery Time

Reverse Recovery Charge

Reverse Recovery Current

I

= 120 A VGS = 0

SD

= 120 A di/dt = 100A/µs

I

SD

V

= 25 V Tj = 150°C

DD

(see test circuit, Figure 5)

35

180

140

35

70

140

80

130

350

7.5

170 nC

120

480

1.5 V

ns

ns

nC

nC

ns

ns

A

A

ns

nC

A

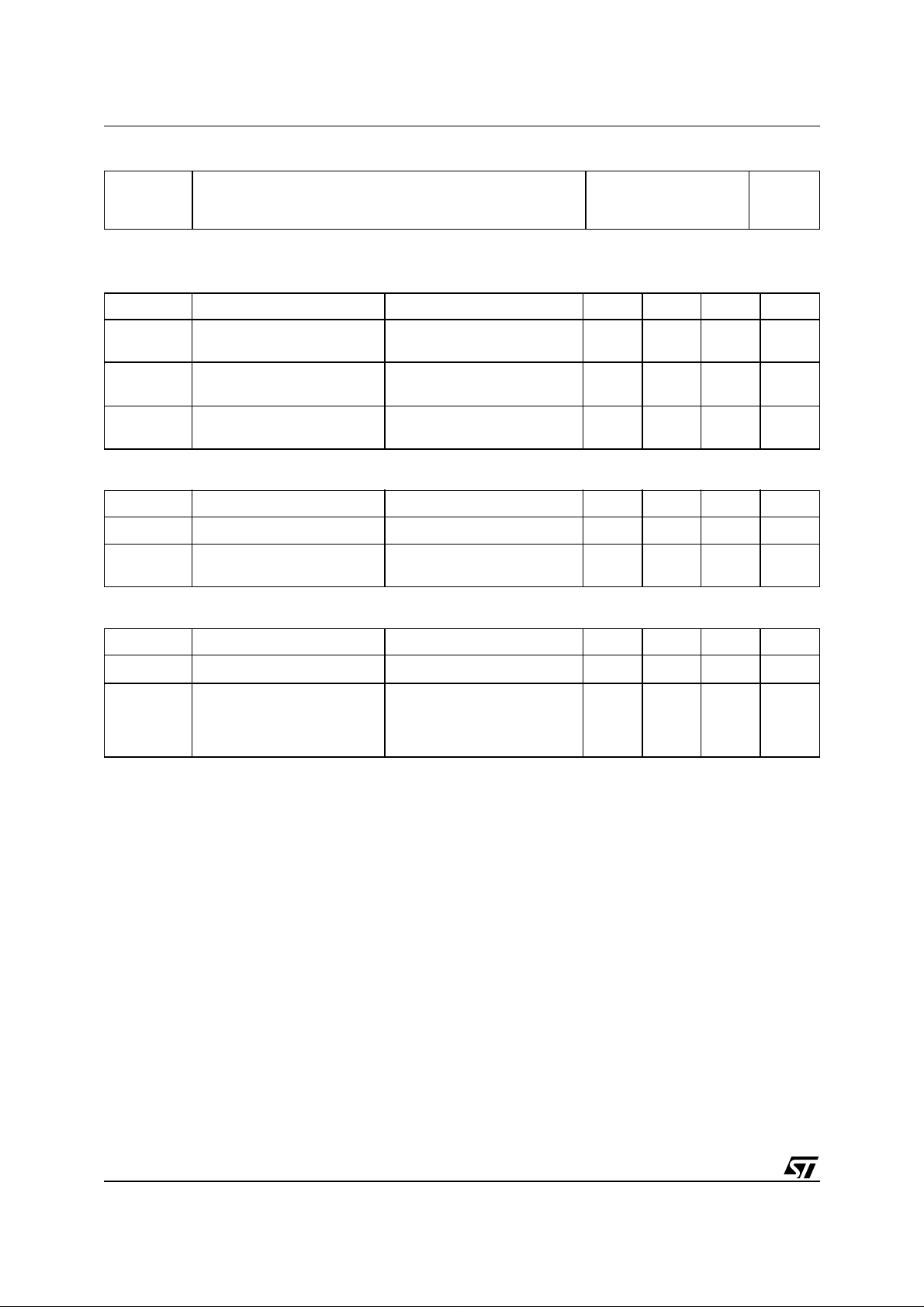

Thermal ImpedanceSafe Operating Area

3/14

Page 4

STB150NF55 STP150NF55 STW150NF55

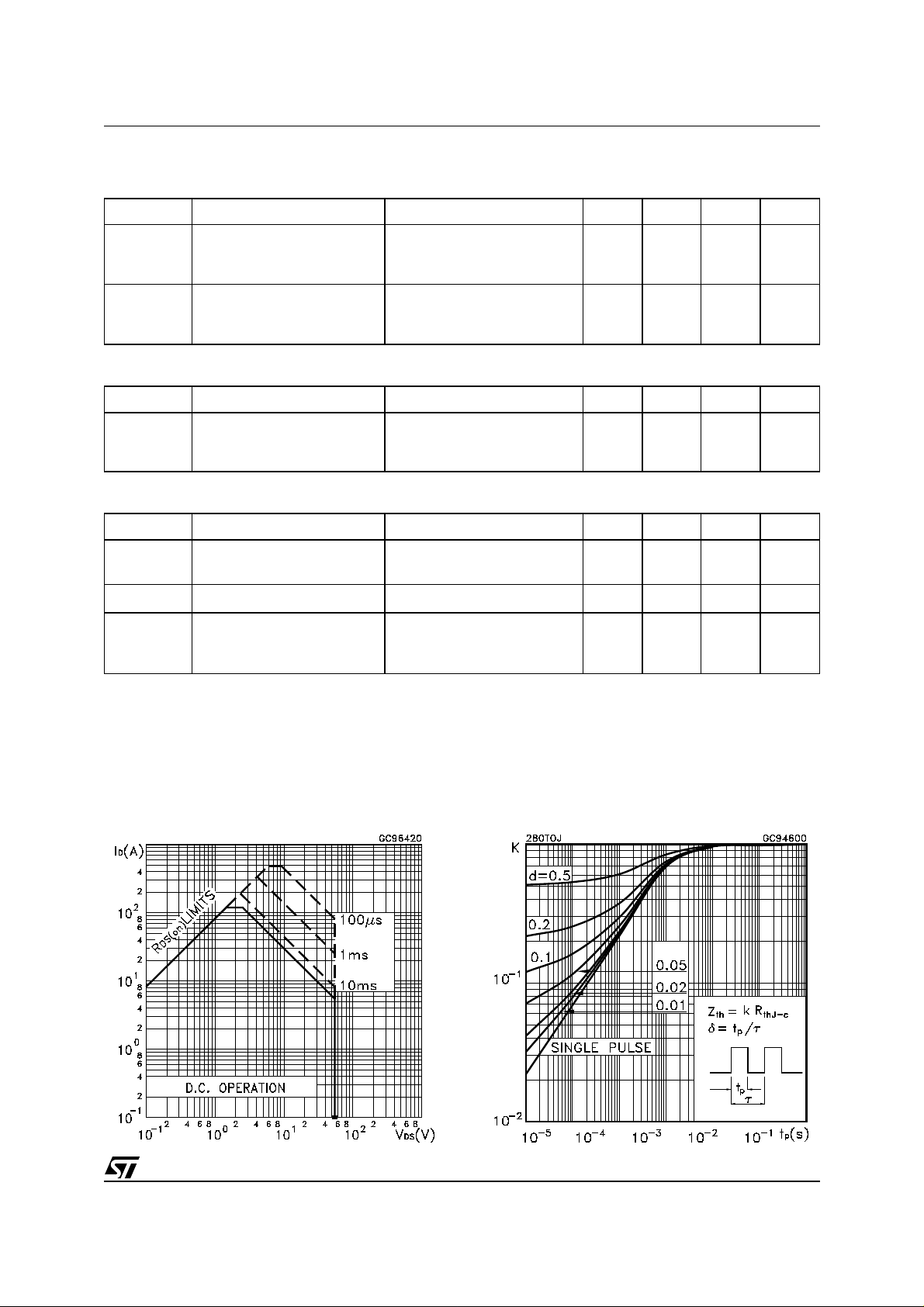

Output Characteristics Transfer Characteristics

Transconductance Static Drain-source On Resistance

Gate Charge vs Gate-source Voltage Capacitance Variations

4/14

Page 5

STB150NF55 STP150NF55 STW 150NF55

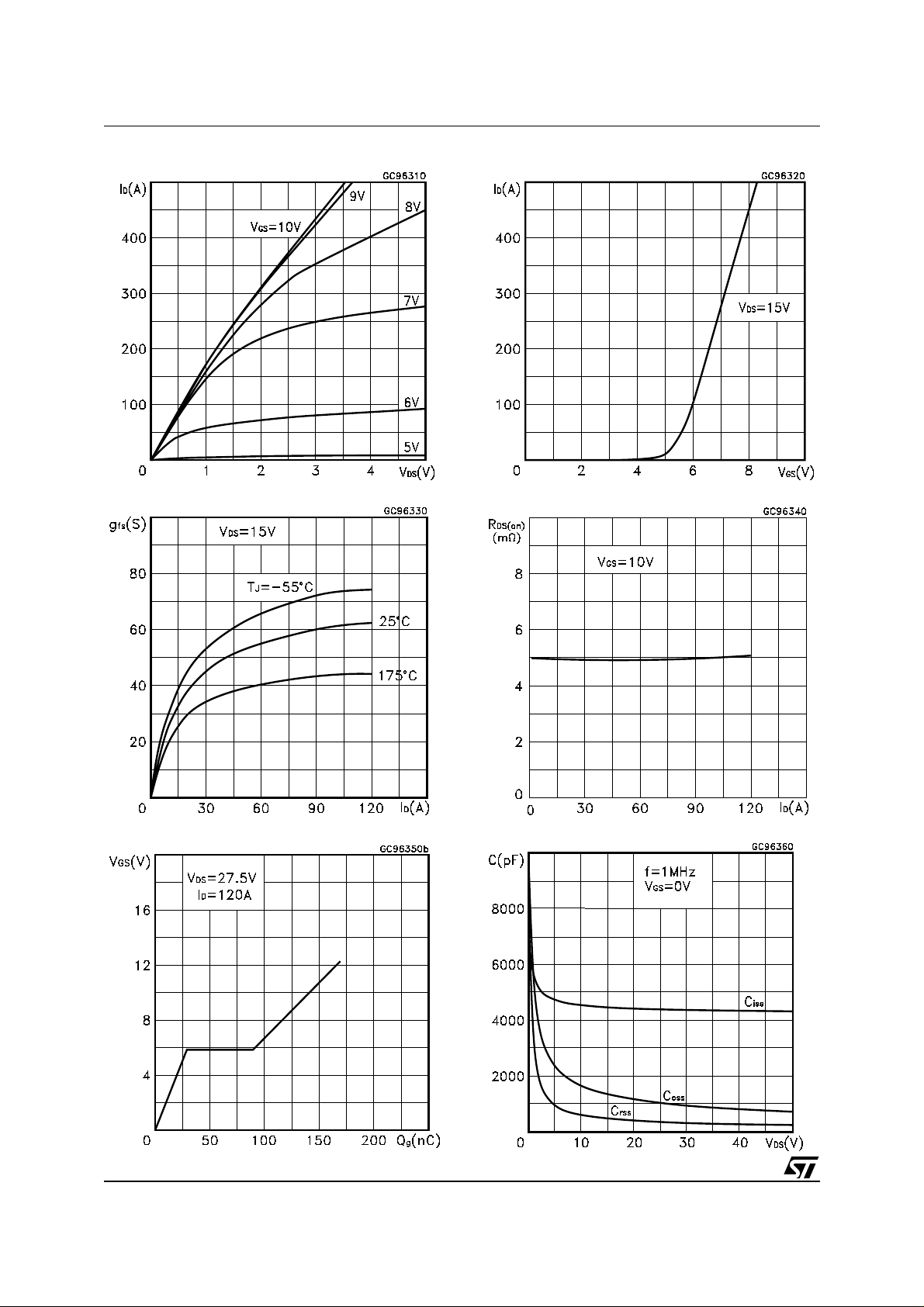

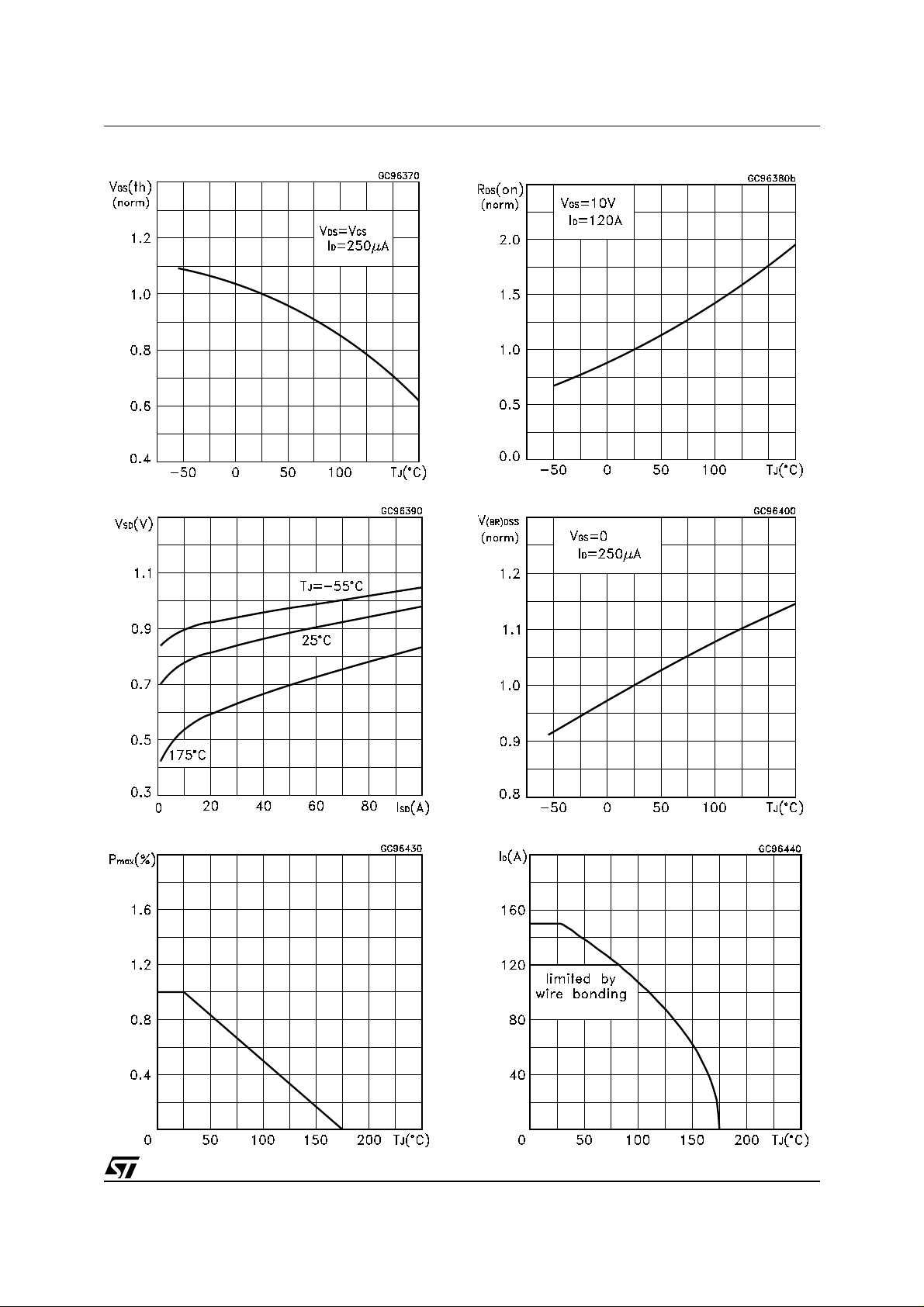

Normalized Gate Threshold Voltage vs Temperature Normalized on Resistance vs Temperature

Source-drain Diode Forward Characteristics Normalized Breakdown Voltage vs Temperature.

. .

Power Derating vs Tc Max Id Current vs Tc.

5/14

Page 6

STB150NF55 STP150NF55 STW150NF55

Thermal Resistance Rthj-a vs PCB Copper Area Max Power Dissipation vs PCB Copper Area

Allowable Iav vs. Time in Avalanche

The previous curve gives the safe operating area for unclamped inductive loads, single pulse or repetitive,

under the following conditions:

P

E

= 0.5 * (1.3 * BV

D(AVE)

= P

AS(AR)

D(AVE)

* t

AV

DSS

* IAV)

Where:

I

is the Allowable Current in Avalanche

AV

P

t

AV

To derate above 25

is the Average Power Dissipation in Avalanche (Single Pulse)

D(AVE)

is the Time in Avalanche

o

C, at fixed IAV, the following equation must be applied:

= 2 * (T

I

AV

jmax

- T

CASE

)/ (1.3 * BV

DSS

* Zth)

Where:

Z

= K * Rth is the value coming from Normalized Thermal Response at fixed pulse width equal to TAV .

th

6/14

Page 7

STB150NF55 STP150NF55 STW 150NF55

SPICE THERMAL MODEL

Parameter

CTHERM1 5 - 4 0.011

CTHERM2 4 - 3 0.0012

CTHERM3 3 - 2 0.05

CTHERM4 2 - 1 0.1

RTHERM1 5 - 4 0.09

RTHERM2 4 - 3 0.02

RTHERM3 3 - 2 0.11

RTHERM4 2 - 1 0.17

Node Value

7/14

Page 8

STB150NF55 STP150NF55 STW150NF55

Fig. 1: Unclamped Inductive Load Test CircuitFig. 1: Unclamped Inductive Load Test Circuit Fig. 2: Unclamped Inductive Waveform

Fig. 3: Switching Times Test Circuits For Resistive

Load

Fig. 4: Gate Charge Test Circuit

Fig. 3.1: Inductive Load Switching and Diode Re-

covery Ti m e s Wav e form

Fig. 4.1: Gate Charge Test Waveform

8/14

Page 9

STB150NF55 STP150NF55 STW 150NF55

Fig. 5: Unclamped Inductive Load Test Circuit Fig. 5.1: Diode Recovery Times Waveform

9/14

Page 10

STB150NF55 STP150NF55 STW150NF55

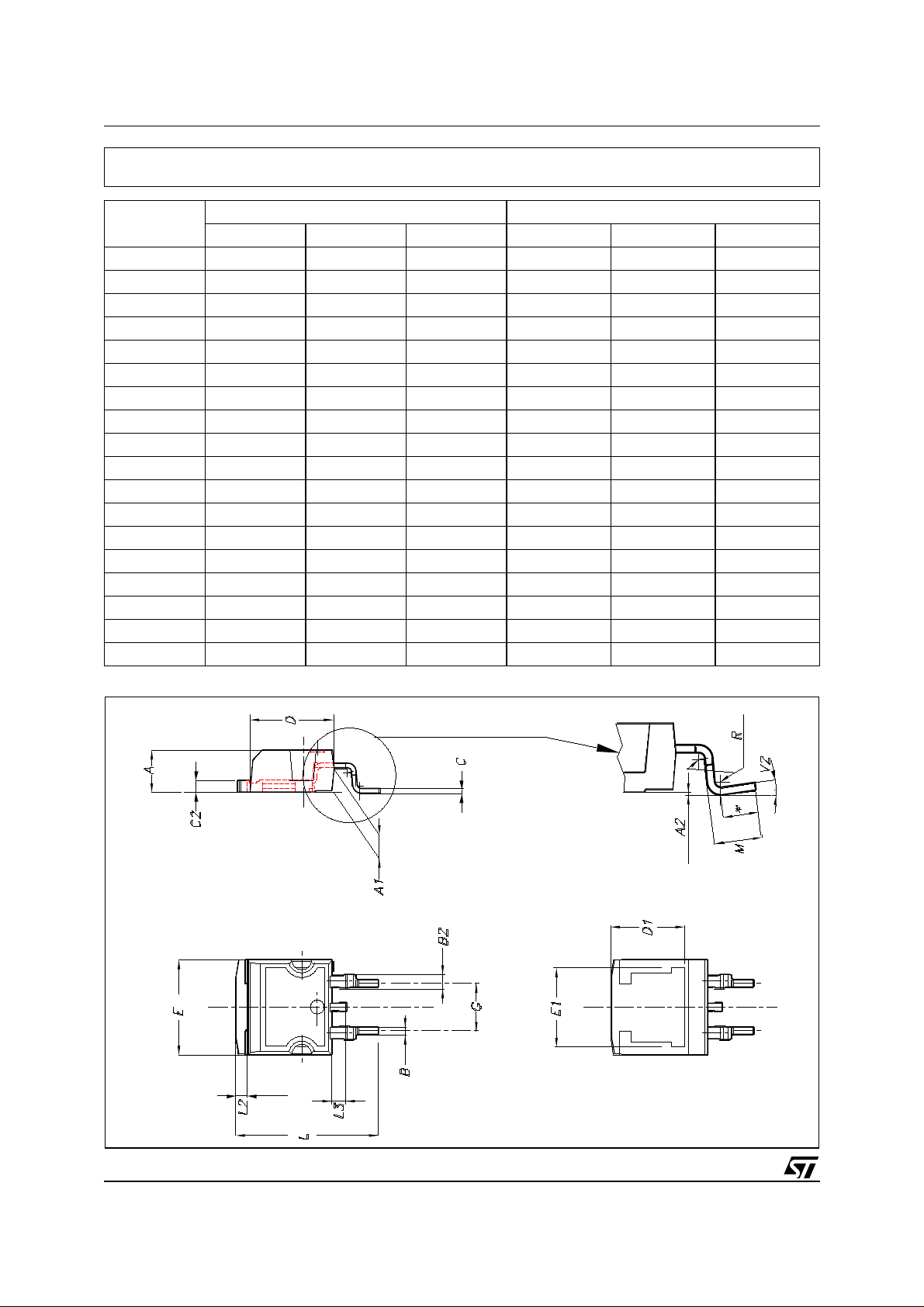

D2PAK MECHANICAL DA TA

DIM.

A 4.4 4.6 0.173 0.181

A1 2.49 2.69 0.098

A2 0.03 0.23 0.001 0.009

B 0.7 0.93 0.028 0.037

B2 1.14 1.7 0.045 0.067

C 0.45 0.6 0.018 0.024

C2 1.21 1.36 0.048 0.054

D 8.95 9.35 0.352 0.368

D1 8 0.315

E 10 10.4 0.394 0.409

E1 8.5 0.334

G 4.88 5.28 0.192 0.208

L 15 15.85 0.591 0.624

L2 1.27 1.4 0.050 0.055

L3 1.4 1.75 0.055 0.069

M 2.4 3.2 0.094 0.126

R 0.4 0.015

V2 0° 8° 0° 8°

MIN. TYP. MAX. MIN. TYP. TYP.

mm. inch.

0.106

10/14

Page 11

STB150NF55 STP150NF55 STW 150NF55

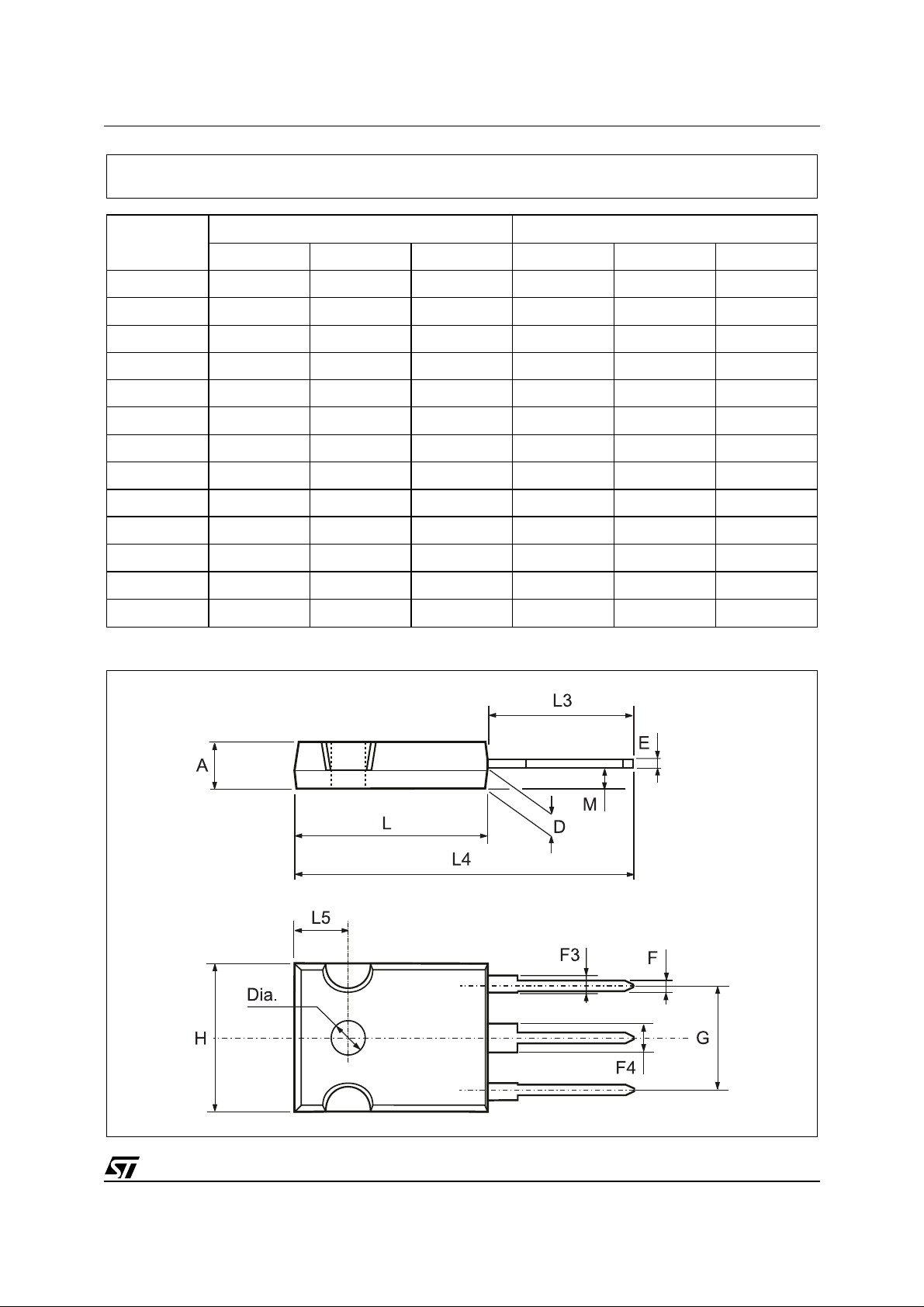

TO-247 MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.7 5.3 0.185 0.209

D 2.2 2.6 0.087 0.102

E 0.4 0.8 0.016 0.031

F 1 1.4 0.039 0.055

F3 2 2.4 0.079 0.094

F4 3 3.4 0.118 0.134

G 10.9 0.429

H 15.3 15.9 0.602 0.626

L 19.7 20.3 0.776 0.779

L3 14.2 14.8 0.559 0.582

L4 34.6 1.362

L5 5.5 0.217

M 2 3 0.079 0.118

mm inch

P025P

11/14

Page 12

STB150NF55 STP150NF55 STW150NF55

TO-220 MECHANICAL DATA

DIM.

A 4.4 4.6 0.173 0.181

C 1.23 1.32 0.048 0.051

D 2.40 2.72 0.094 0.107

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.067

F2 1.14 1.70 0.044 0.067

G 4.95 5.15 0.194 0.203

G1 2.40 2.70 0.094 0.106

H2 10 10.40 0.393 0.409

L2 16.40 0.645

L3 28.90 1.137

L4 13 14 0.511 0.551

L5 2.65 2.95 0.104 0.116

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.260

L9 3.50 3.93 0.137 0.154

DIA 3.75 3.85 0.147 0.151

MIN. TYP. MAX. MIN. TYP. TYP.

mm. inch.

12/14

Page 13

STB150NF55 STP150NF55 STW 150NF55

D2PAK FOOTPRINT

TAPE AND REEL SHIPMENT (suffix ”T4”)*

TUBE SHIPMENT (no suffix)*

REEL MECHANICAL DATA

DIM.

A 330 12.992

B 1.5 0.059

C 12.8 13.2 0.504 0. 520

D 20.2 0.795

G 24.4 26.4 0.960 1.039

N 100 3.937

T 30.4 1.197

mm inch

MIN. MAX. MIN. MAX.

TAPE MECHANICAL DATA

DIM.

A0 10.5 10.7 0.413 0.421

B0 15.7 15.9 0.618 0.626

D 1.5 1.6 0.059 0.063

D1 1.59 1.61 0.062 0.063

E 1.65 1.85 0.065 0.073

F 11.4 11.6 0.449 0.456

K0 4.8 5.0 0.189 0.197

P0 3.9 4.1 0.153 0.161

P1 11.9 12.1 0.468 0.476

P2 1.9 2.1 0075 0.082

R50 1.574

T0.25 0.35 .0.0098 0.0137

W 23.7 24.3 0.933 0.956

mm inch

MIN. MAX. MIN. MAX.

* on sales type

BASE QTY BULK QTY

1000 1000

13/14

Page 14

STB150NF55 STP150NF55 STW150NF55

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or p atent rights of STMi croelectr oni cs. Spec i fications mentioned i n this publicatio n are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi t hout expres s written approval of STMi croelectr o nics.

The ST logo is registered trademark of STMicroelectronics

2002 STMi croelectr onics - All Rights Rese rved

All other na m es are the prop erty of their respectiv e owners.

Australi a - Brazil - Canada - Chin a - F i nl and - Franc e - Germany - Hong Kong - India - Israel - It al y - Japan - Mal aysia - Malta - Morocco -

Singap ore - Spain - Sw eden - Switze rl and - United Kingdom - U n i t ed States.

STMicroelectronics GROUP OF COMPANIES

http:// www.st.com

14/14

Loading...

Loading...