Page 1

LOW DROPPOWER SCHOTTKY RECTIFIER

MAINPRODUCTSCHARACTERISTICS

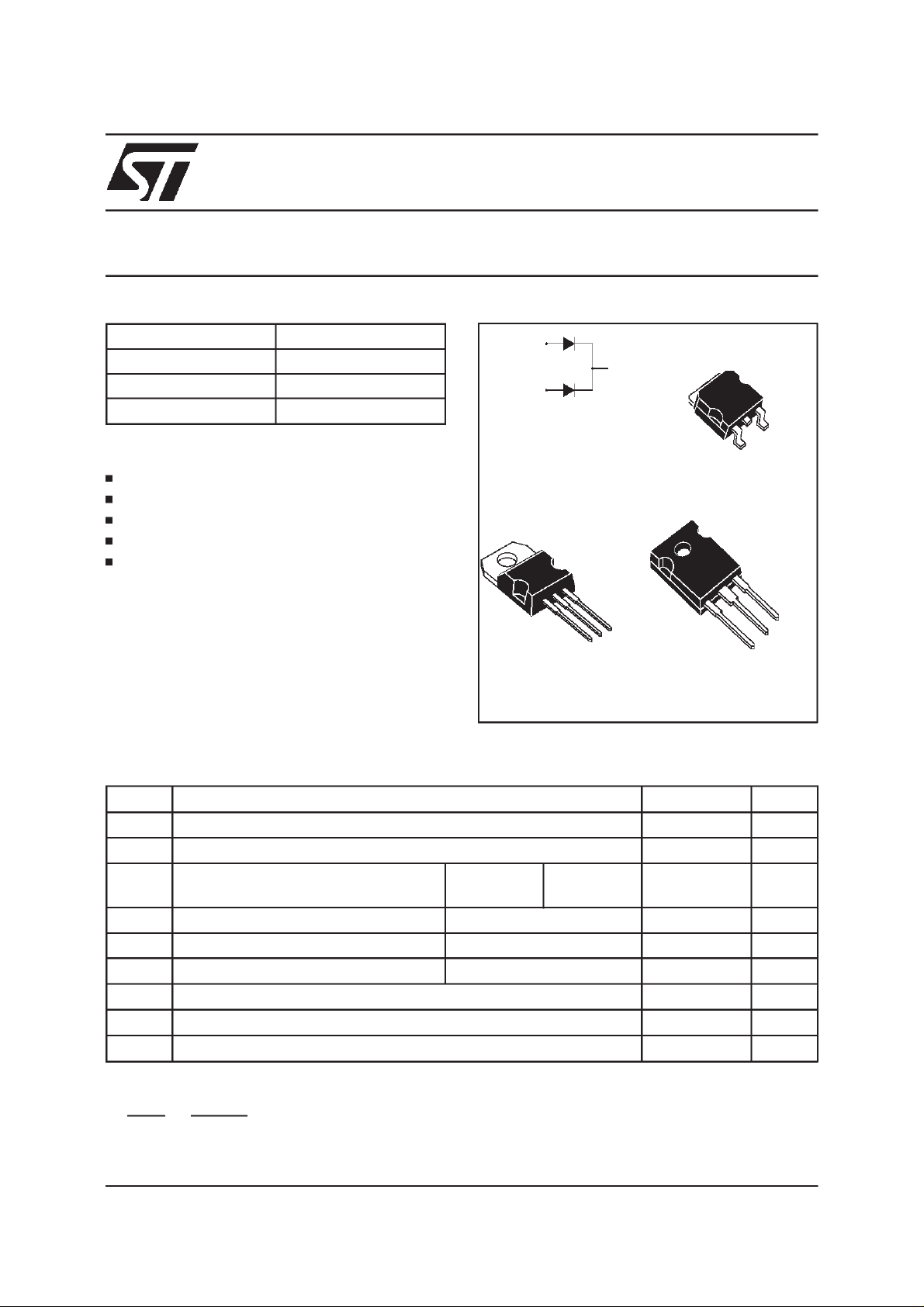

STPS30L40CG/CT/CW

I

F(AV)

V

RRM

2 x 15A

40 V

Tj (max) 150 °C

V

(max) 0.50 V

F

FEATURESAND BENEFITS

VERYSMALLCONDUCTION LOSSES

NEGLIGIBLESWITCHINGLOSSES

LOWFORWARD VOLTAGEDROP

LOWTHERMALRESISTANCE

AVALANCHERATED

DESCRIPTION

Dual center tap schottky rectifiers suited for

Switched Mode Power Supplies and high

frequencyDC to DCconverters.

2

PackagedinTO-247,TO-220ABandD

PAKthese

devicesare intended for use in low voltage,high

frequency inverters, free-wheeling and polarity

protectionapplications.

ABSOLUTE RATINGS

(limitingvalues,per diode)

A1

A2

A1

TO-220AB

STPS30L40CT

K

K

A2

A1

2

PAK

D

STPS30L40CG

A2

K

A2

K

A1

TO-247

STPS30L40CW

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

F(AV)

I

FSM

I

RRM

I

RSM

T

stg

Tj

dV/dt

dPtot

*:

dTj

July 1999 -Ed: 3A

Repetitivepeak reverse voltage

RMSforwardcurrent

Averageforward current Tc= 135°C

Surgenonrepetitiveforwardcurrent tp = 10 ms Sinusoidal

Repetitivepeak reverse current tp=2µs square F=1kHz

Non repetitivepeakreverse current tp = 100 µs square

Storagetemperaturerange

Maximumoperatingjunction temperature*

Criticalrateof riseofreversevoltage

<

Rth(j

δ =0.5

1

thermal runawayconditionfor a diode on its own heatsink

a

)

−

Per diode

Per device

40 V

30 A

15

30

220 A

1A

3A

- 65 to+ 150 °C

150 °C

10000 V/µs

A

1/6

Page 2

STPS30L40CG/CT/CW

THERMAL RESISTANCES

Symbol Parameter Value Unit

R

th (j-c)

R

th (c)

Junctionto case

Whenthediodes1 and2 areused simultaneously:

∆ Tj(diode1)= P(diode1)x R

(Perdiode) + P(diode2)x R

th(j-c)

Per diode

Total

Coupling 0.10 °C/W

th(c)

1.60

0.85

°C/W

STATICELECTRICALCHARACTERISTICS

(per diode)

Symbol Parameter TestsConditions Min. Typ. Max. Unit

*

I

R

V

F

Reverseleakage

current

*

Forward voltagedrop Tj =25°CI

Tj = 25°CV

Tj = 100°C

Tj = 125°CI

Tj = 25°CI

Tj = 125°CI

R=VRRM

=15A

F

=15A

F

=30A

F

=30A

F

20 50 mA

0.42 0.50

0.59 0.67

360 µA

0.55 V

0.74

Pulsetest: * tp = 380µs,δ<2%

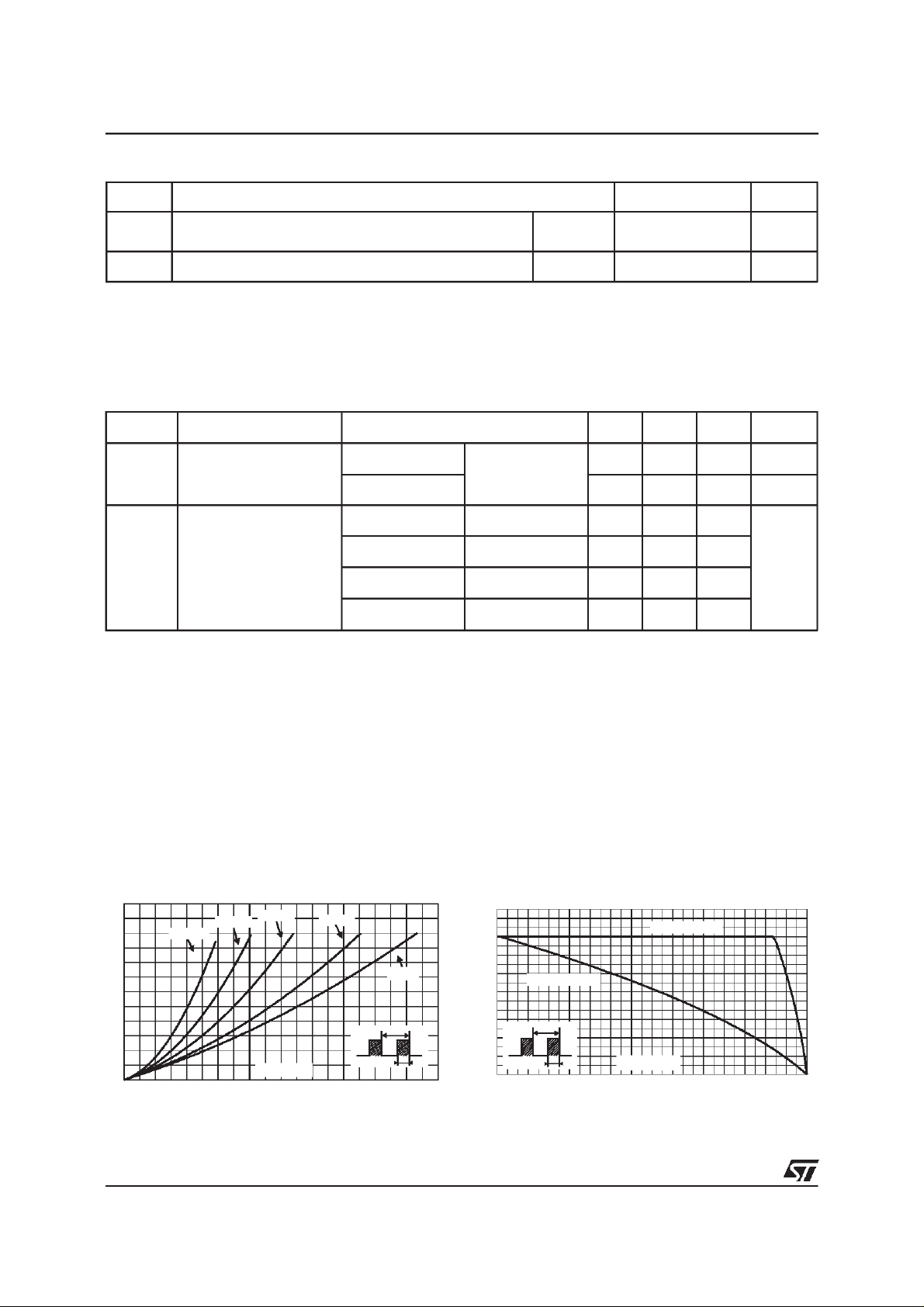

Toevaluatethe conductionlossesusethe followingequation:

P = 0.330 x I

F(AV)

+0.011I

F2(RMS)

Fig. 1: Average forward power dissipation versus

averageforwardcurrent(per diode).

PF(av)(W)

12

10

8

6

4

2

0

02468101214161820

2/6

δ = 0.05

δ = 0.1

δ = 0.2

IF(av)A

δ= 0.5

δ =1

T

=tp/T tp

δ

Fig. 2:

Average current versus ambient

temperature(δ=0.5) (perdiode).

IF(av)(A)

18

16

14

12

10

Rth(j-a)=15°C/W

8

6

4

2

0

0 25 50 75 100 125 150

δ

=tp/T

T

tp

Rth(j-a)=Rth(j-c)

Tamb(°C)

Page 3

STPS30L40CG/CT/CW

Fig. 3: Non repetitive surge peak forward current

versus overload duration (maximum values) (per

diode).

IM(A)

200

180

160

140

120

100

80

60

IM

40

20

0

1E-3 1E-2 1E-1 1E+0

δ=0.5

t

t(s)

Tc=25°C

Tc=75°C

Tc=125°C

Fig. 5: Reverse leakage current versus reverse

voltageapplied (typicalvalues)(perdiode).

IR(mA)

2E+2

1E+2

1E+1

1E+0

Tj=150°C

Tj=100°C

Tj=75°C

Fig. 4: Relative variation of thermal transient

impedancejunctionto caseversuspulseduration.

Zth(j-c)/Rth(j-c)

1.0

0.8

δ = 0.5

0.6

0.4

δ = 0.2

δ = 0.1

0.2

0.0

1.0E-4 1.0E-3 1.0E-2 1.0E-1 1.0E+0

Fig. 6:

Single pulse

tp(s)

Junction capacitance versus reverse

T

=tp/T tp

δ

voltageapplied(typicalvalues)(perdiode).

C(pF)

2000

1000

500

F=1MHz

Tj=25°C

1E-1

1E-2

0 5 10 15 20 25 30 35 40

Fig. 7:

Forward voltage drop versus forward

Tj=25°C

VR(V)

current(maximumvalues)(per diode).

IFM(A)

200

100

10

1

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Typicalvalues

Tj=150°C

Tj=125°C

Tj=25°C

VFM(V)

200

100

12 51020 50

Fig. 8 :

Thermal resistance junction to ambient

VR(V)

versus copper surface under tab (Epoxy printed

circuitboardFR4,copperthickness: 35µm)

(STPS30L40CGonly).

Rth(j-a) (°C/W)

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25 30 35 40

S(Cu) (cm )

3/6

Page 4

STPS30L40CG/CT/CW

PACKAGEMECHANICALDATA

TO-220AB

H2

Dia

L5

L6

L2

F2

F1

F

G1

G

L9

L4

DIMENSIONS

REF.

A

C

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

Millimeters Inches

Min. Max. Min. Max.

D 2.40 2.72 0.094 0.107

L7

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.066

F2 1.14 1.70 0.044 0.066

G 4.95 5.15 0.194 0.202

D

G1 2.40 2.70 0.094 0.106

H2 10 10.40 0.393 0.409

L2 16.4typ. 0.645typ.

L4 13 14 0.511 0.551

L5 2.65 2.95 0.104 0.116

M

E

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.259

L9 3.50 3.93 0.137 0.154

M 2.6typ. 0.102 typ.

Diam. 3.75 3.85 0.147 0.151

Coolingmethod: C

Recommendedtorque value: 0.55m.N

Maximumtorque value : 0.70m.N

4/6

Page 5

PACKAGEMECHANICAL DATA

2

PAK

D

L2

L

L3

E

A1

B2

B

G

C2

STPS30L40CG/CT/CW

DIMENSIONS

REF.

A

A 4.40 4.60 0.173 0.181

A1 2.49 2.69 0.098 0.106

A2 0.03 0.23 0.001 0.009

D

B 0.70 0.93 0.027 0.037

B2 1.14 1.70 0.045 0.067

C 0.45 0.60 0.017 0.024

C2 1.23 1.36 0.048 0.054

D 8.95 9.35 0.352 0.368

E 10.00 10.40 0.393 0.409

C

R

G 4.88 5.28 0.192 0.208

L 15.00 15.85 0.590 0.624

L2 1.27 1.40 0.050 0.055

L3 1.40 1.75 0.055 0.069

A2

M 2.40 3.20 0.094 0.126

R 0.40typ. 0.016 typ.

V2 0° 8° 0° 8°

M

*

V2

Millimeters Inches

Min. Max. Min. Max.

* FLATZONE NO LESSTHAN 2mm

Coolingmethod: byconduction(method C)

FOOT PRINT (in millimeters)

2

PAK

D

16.90

10.30

1.30

8.90

3.70

5.08

5/6

Page 6

STPS30L40CG/CT/CW

PACKAGEMECHANICAL DATA

TO-247

V

V

H

L5

L

F2

F4

L1

F3

L3

F1

V2

F(x3)

G

==

Dia.

L4L2

ME

A

D

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 4.85 5.15 0.191 0.203

D 2.20 2.60 0.086 0.102

E 0.40 0.80 0.015 0.031

F 1.00 1.40 0.039 0.055

F1 3.00 0.118

F2 2.00 0.078

F3 2.00 2.40 0.078 0.094

F4 3.00 3.40 0.118 0.133

G 10.90 0.429

H 15.45 15.75 0.608 0.620

L 19.85 20.15 0.781 0.793

L1 3.70 4.30 0.145 0.169

L2 18.50 0.728

L3 14.20 14.80 0.559 0.582

L4 34.60 1.362

L5 5.50 0.216

M 2.00 3.00 0.078 0.118

V5° 5°

V2 60° 60°

Dia. 3.55 3.65 0.139 0.143

Coolingmethod: C

Recommendedtorquevalue: 0.8m.N

Maximumtorque value : 1.0m.N

Orderingtype Marking Package Weight Baseqty Delivery mode

STPS30L40CT STPS30L40CT TO-220AB 2g 50 Tube

STPS30L40CG STPS30L40CG D

STPS30L40CG-TR STPS30L40CG D

2

PAK 1.8g 50 Tube

2

PAK 1.8g 500 Tape& reel

STPS30L40CW STPS30L40CW TO-247 4.4g 30 Tube

EpoxymeetsUL94,V0

Informationfurnished is believedto beaccurate andreliable. However, STMicroelectronics assumes noresponsibility for theconsequences of

use ofsuch informationnor forany infringementof patentsor otherrights of third parties which mayresult fromitsuse. Nolicense is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics.Specifications mentioned in this publication are subject to

change without notice. This publication supersedes andreplacesall informationpreviously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval ofSTMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

1999 STMicroelectronics- Printed inItaly - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia -Brazil - China - Finland - France - Germany - Hong Kong- India - Italy -Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom -U.S.A.

http://www.st.com

6/6

Loading...

Loading...