Page 1

QUAD LINE FEED CONTROLLER

■ BATTERY VOLTAGE UP TO 120V

■ SUPPLIES POWE R FOR UP TO FOUR

DIGITAL TELEPHONE LINES

■ PROGRAMMABLE CURRENT LIMITING

■ LONGITUDINAL CURRENT CANCELLATION

■ ETSI ETR80 COMPL IAN T

■ OUTPUT CURRENT UP TO 140 mA

■ STATUS CONDITION DETECTION FOR

EACH LINE

■ AUTOMATIC THERMAL PROTECTION

■ AUTO POWER ON SEQUENCE

■ OUTPUT STAGE OPTIMIZED FOR MINIMAL

OUTPUT OVERVOLTAGE PROTECTION

■ TWO EXTERNAL RELAY DRIVERS PER LINE

■ PARALLEL OR MPI CONTROL INTERFACE

■ HI-QUAD PACKAGE 64 PIN

DESCRIPTION

The QUAD LINE FEED CONTROLLER provides a

power source for up to four U line interfaces. The

power source to the device is a local battery or a centralized regulated power supply. Each powered line is

individually controll ed and monitored by the device

interface.

A MPI or a simple parallel interface can be selected

STLC5445

HiQUAD-64

ORDERING NUM BER: STLC 5445

by a pin strap.

Each line can be individually powered and monitored:

therefore overload and faults can easi ly be detected

and localized even in a large system. The status conditions detected by the device are: Current Overload,

Thermal Overload, Open Loop. If activated (by

means of a dedicated pin strap), a self generated

power on sequence avoids the thermal over stress

when a simultaneous power on has been r equested

for more than one channel. The current limiting value

can globally be programmed for the four channels by

means of an external resistor. The device has two integrated relay drivers per line to drive the test relays

of the ISDN system.

October 2002

1/23

Page 2

STLC5445

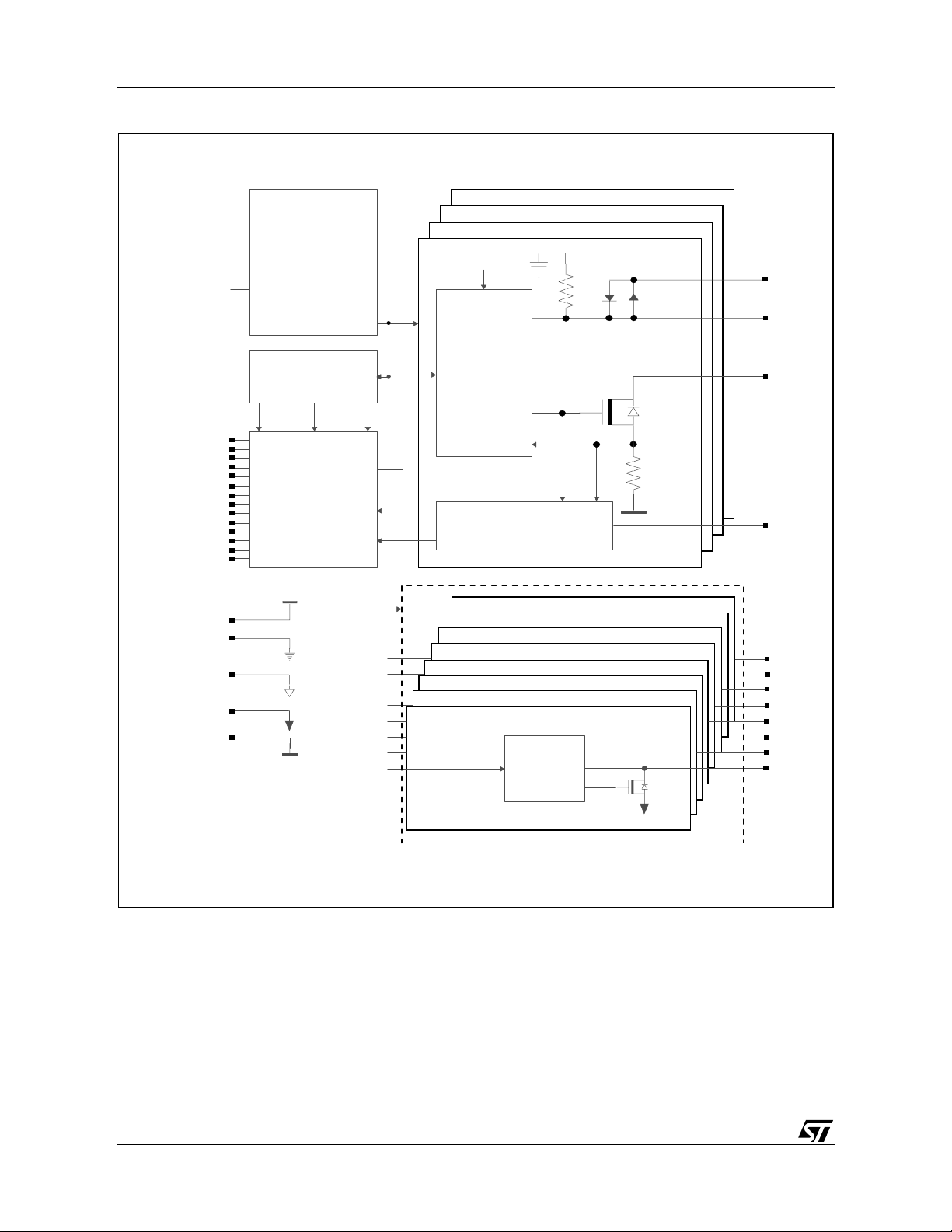

BLOCK DIAGRAM

ILIM

110°C

PSC

PBIT

CKILC

RESETN

INTN

ALE

ES0 (A0)

ES1 (CSN)

ES2 (RDN)

ES3 (WRN)

NACK0 (D0)

NACK1 (D1)

NACK2 (D2)

NACK3 (D3)

Reference & biasing

generation

Thermal

monitoring

130°C

160°C

Logic

interface

Limiting

current

reference

Voltage

and

current

biasing

COD

OLD

Channel 3

Channel 2

Channe l 1

Channel 0

On / Off

&

line current

control

COD & OLD

generation

WBP0

WB0

WA0

V

BAT

CODC0

V

CC

VCC

BGND

EREL3B

DGND

EREL3A

EREL2B

RGND

VBAT

V

BAT

EREL2A

EREL1B

EREL1A

EREL0B

EREL0A

I / O conne ctions on channels 1, 2 and

3 are similar to those

shown for channel 0 but have been omitted for clarity

reasons.

Relay driver 3B

Relay driver 3A

Relay driver 2B

Relay driver 2A

Relay driver 1B

Relay driver 1A

Relay driver 0B

Relay driver 0A

Driving

&

output

clamping

REL3B

REL3A

REL2B

REL2A

REL1B

REL1A

REL0B

REL0A

2/23

Page 3

STLC5445

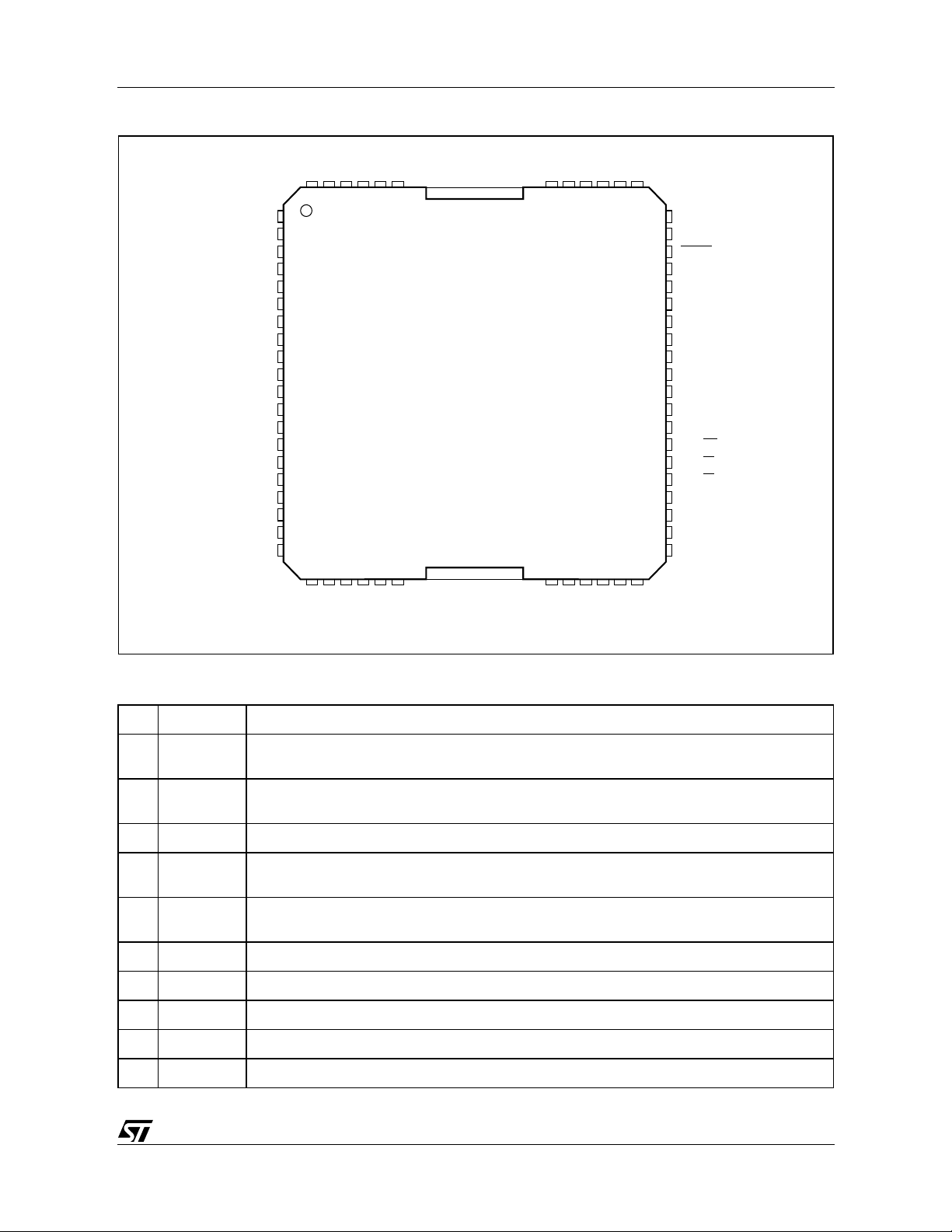

PIN CONNECTION

NACK0(D0)

NACK1(D1)

*EREL0A

*EREL0B

*EREL1A

*EREL1B

(Top view)

CODC0

CODC1

RGND

CK_ILC

REL0A

REL0B

REL1A

REL1B

ALE

PBIT

PSC

INTN

BGND

N.C.

WA0

BGND

63

64

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

21 22 23 24 25

62

VBAT

WB0

WBP0

RGND

60

61

59 58 57 56 55 54 53

26

VBAT

WB3

WBP3

ILIM

N.C.

271128 29 30 31 32

WA3

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

N.C.

BGND

*RESET

NACK3(D3)

NACK2(D2)

REL3B

*EREL3B

*EREL3A

REL3A

REL2B

*EREL2B

*EREL2A

REL2A

*ES3(WR)

*ES2(RD)

*ES1(CS)

*ES0(A0)

RGND

CODC3

CODC2

CC

V

N.C.

WA1

*INTERNAL PULL DOWN TO GROUND

WBP1

WB1

VBAT

VBAT

WB2

WBP2

DGND

WA2

BGND

D99TL437

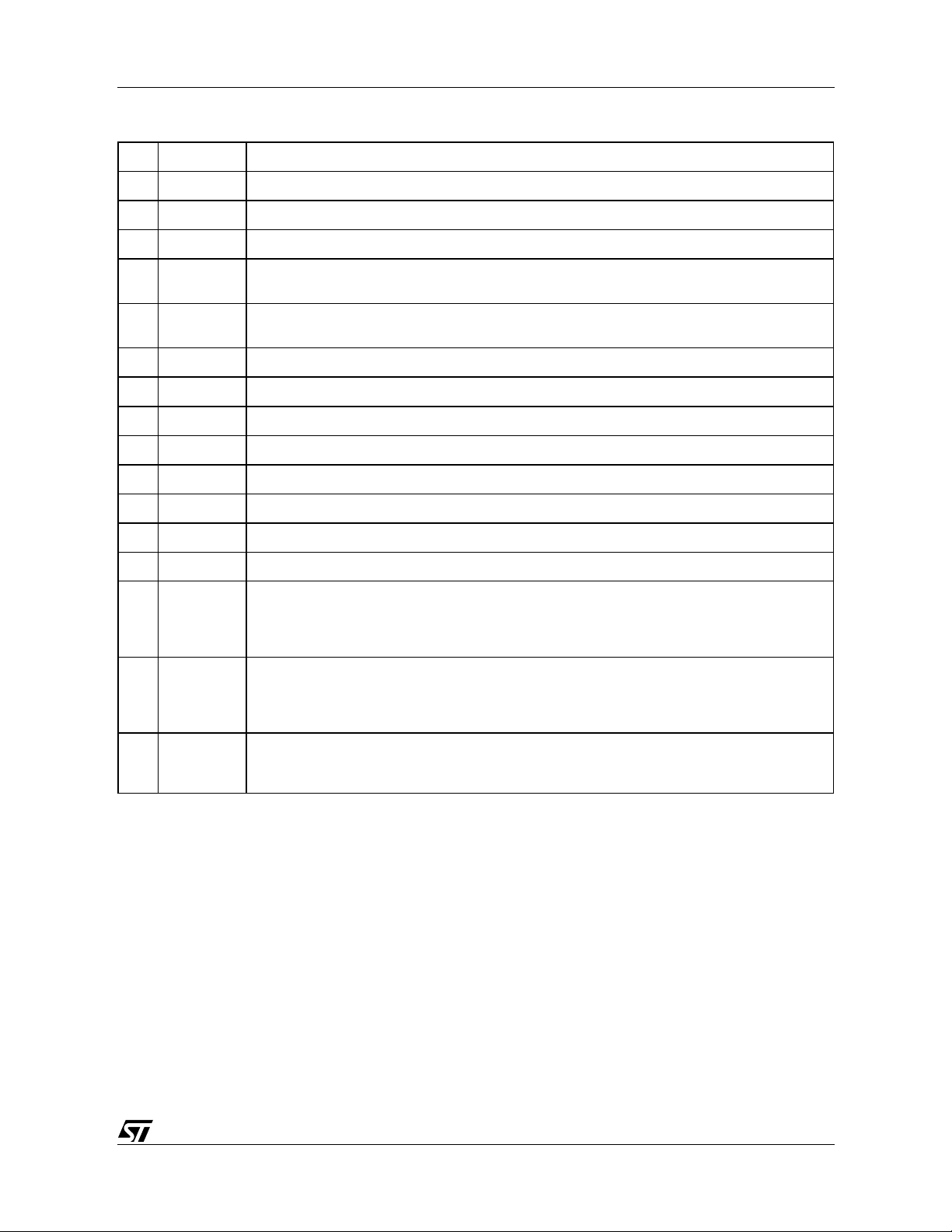

PIN FUNCTION

N° Pin Name Description

1 CODC0 Pin for connection of the external capacitor (100nF/6.3V) to GND for COD signal filtering on

channel 0.

2 CODC1 Pin for connection of the external capacitor (100nF/6.3V) to GND for COD signal filtering on

channel 1

4 CKILC External clock input pin for the internal power on sequencer

5 NACK0(D0) Logic pin: with PSC = 0, Line 0 status information output

6 NACK1(D1) Logic pin: with PSC = 0, Line 1 status information output

7 REL0A Output of the 0A relay driver

8 *EREL0A Logic input pin: relay 0A output driver’s ON/OFF (high = ON)

9 *EREL0B Logic input pin: relay 0B output driver’s ON/OFF (high = ON)

10 REL0B Output of the 0B relay driver

with PSC = 1, Line 0 I/O tristate data bus

with PSC = 1, Line 1 I/O tristate data bus

11 REL1A Output of the 1A relay driver

3/23

Page 4

STLC5445

PIN FUNCTION

N° Pin Name Description

12 *EREL1A Logic input pin: relay 1A output driver’s ON/OFF (high = ON)

13 *EREL1B Logic input pin: relay 1B output driver’s ON/OFF (high = ON)

14 REL1B Output of the 1B relay driver

15 ALE Logic input pin: with PSC = 0, Don’t care

16 PBIT Power on sequencer enable: PBIT = 0: power on sequencer ON

17 PSC Parallel or MPI mode input selection pin:

18 INTN Logic output pin; open drain: with PSC = 0 high impedance

21 WA1 Output feeder’s switch side of line 1; negative respect to WB1

23 VCC Positive supply voltage. It is referred to DGND

24 WBP1 Internal protection diodes for line 1

25 WB1 Output feeder’s resistive side of line 1; positive respect to WA1

28 WB2 Output feeder’s resistive side of line 2; positive respect to WA2

(continued)

with PSC = 1, Address Latch Enable (active high)

PBIT = 1: power on sequencer OFF

0 = parallel interface; 1 = MPI interface

with PSC = 1 interrupt (active low)

29 WBP2 Internal protection diodes for line 2

30 DGND Digital ground

31 WA2 Output feeder’s switch side of line 2; negative respect to WB2

33 CODC2 Pin for connection of the external capacitor (100nF/6.3V) to GND for COD signal filtering on

channel 2

34 CODC3 Pin for connection of the external capacitor (100nF/6.3V) to GND for COD signal filtering on

channel 3

36 *ES0(A0) Logic input pin: with PSC = 0, Line 0 ON/OFF request (high=ON)

37 *ES1(CSN) Logic input pin: with PSC = 0, Line 1 ON/OFF request (high=ON)

38 *ES2(RDN) Logic input pin: with PSC = 0, Line 2 ON/OFF request (high=ON)

39 *ES3(WRN) Logic input pin: with PSC = 0, Line 3 ON/OFF request (high=ON)

40 REL2A Output of the 2A relay driver

41 *EREL2A Logic input pin: relay 2A output driver’s ON/OFF (high = ON)

42 *ERL2B Logic input pin: relay 2B output driver’s ON/OFF (high = ON)

43 REL2B Output of the 2B relay driver

with PSC = 1, Address bit for R/W operations

with PSC = 1, chip select (active low)

with PSC = 1, Read command (active low)

with PSC = 1, Write command (active low)

44 REL3A Output of the 3A relay driver

4/23

Page 5

STLC5445

PIN FUNCTION

N° Pin Name Description

45 *EREL3A Logic input pin: relay 3A output driver’s ON/OFF (high = ON)

46 *ERL3B Logic input pin: relay 3B output driver’s ON/OFF (high = ON)

47 REL3B Output of the 3B relay driver

48 NACK2 (D2) Logic pin: with PSC = 0, Line 2 status information output

49 NACK3 (D3) Logic pin: with PSC = 0 line 3 status information output

50 *RESETN Logic input pin: reset (active low)

53 WA3 Output feeder’s switch side of line 3; negative respect toWB3

55 ILIM Current limit programming input

56 WBP3 Internal protection diodes for line 3

57 WB3 Output feeder’s resistive side of line 3; positive respect to WA3

60 WB0 Output feeder’s resistive side of line 0; positive respect to WA0

61 WBP0 Internal protection diodes for line 0

0 WA0 Output feeder’s switch side of line 0; negative respect to WB0

(continued)

with PSC = 1, Line 2 I/O tristate data bus

with PSC = 1 line 3 I/O tristate data bus

26

27

58

59

19

32

51

64

3

35

62

* Internal pull down to ground

VBAT Negative battery supply voltage. It is referred to BGND

BGND Battery ground

RGND Relay ground

5/23

Page 6

STLC5445

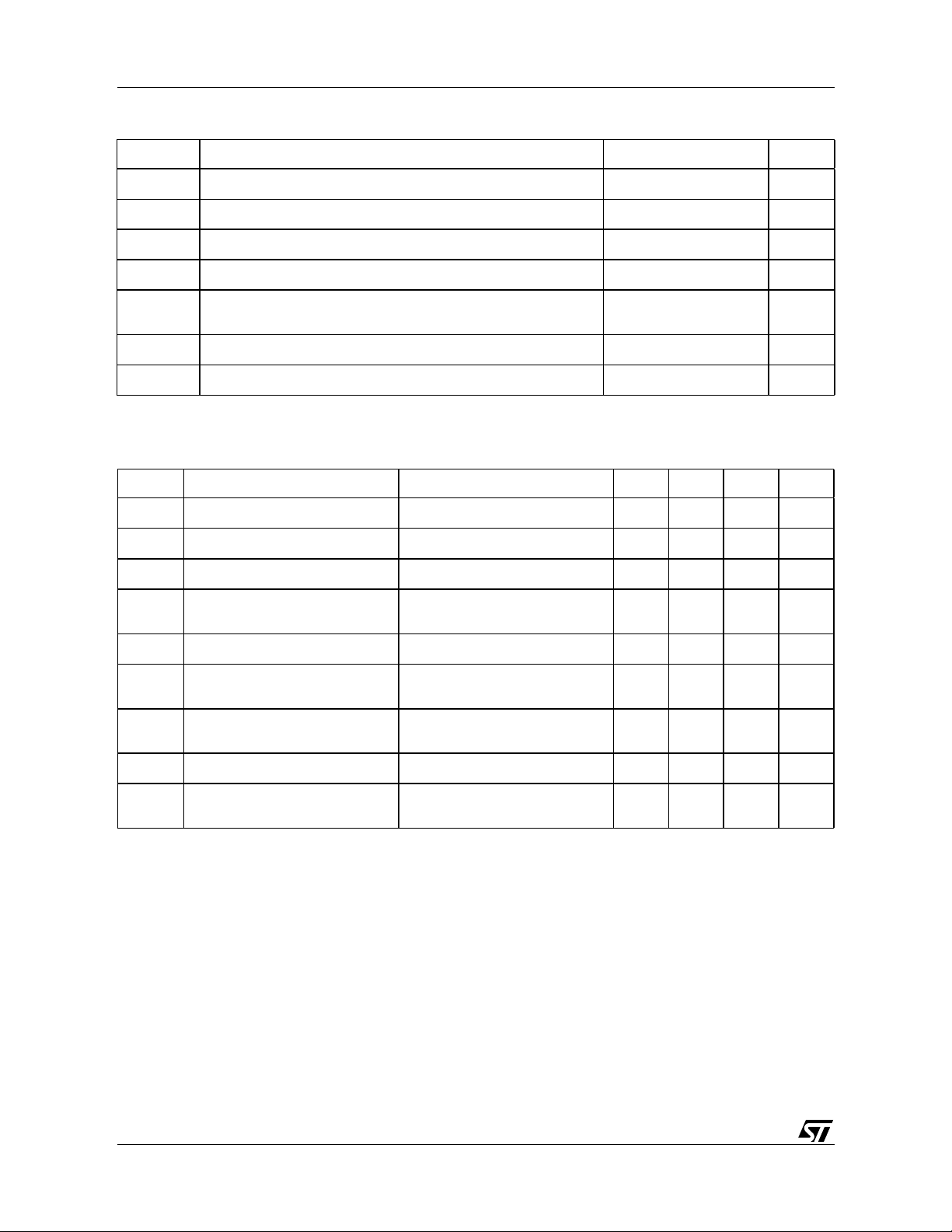

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

V

V

V

I

WBn

I

NEG

T

DD

CD

BB

BD

stg

Voltage from digital input to DGND – 0.5 to VCC + 0.5 V

Voltage from VCC to DGND – 0.4 to +7 V

Voltage from VBAT to BGND – 143 to + 0.4 V

Voltage from BGND to DGND – 3 to +0.5 V

AC Current into the WBn outputs

(WBPn not connected to GND

250 mA

peak

Negative current injected in the WAn outputs (-40 to +85°C) 50 mA

Storage temperature – 60 to 150 °C

RECOMMENDED OPERATING CONDITION

Symbol Parameter Test Condition Min. Typ. Max. Unit

VCC supply voltage 4.75 5.25 V

CC

V

BAT

supply voltage – 120 – 38 V

BAT

BGND/DGND voltage – 3 0.5 V

(1)

Programmable range of the

current limiting function

20 140 mA

V

V

I

LIMT

V

BGND

I

Relay

T

a normal

Relay driver current 70 mA

Ambient temperature normal

range

T

a extend ed

Ambient temperature extended

range

Max operating loop current 140 mA

External, short circuit resistive

MIN

R

I

loop

load from WAn to WBn

070°C

– 40 85 °C

55 W

6/23

Page 7

STLC5445

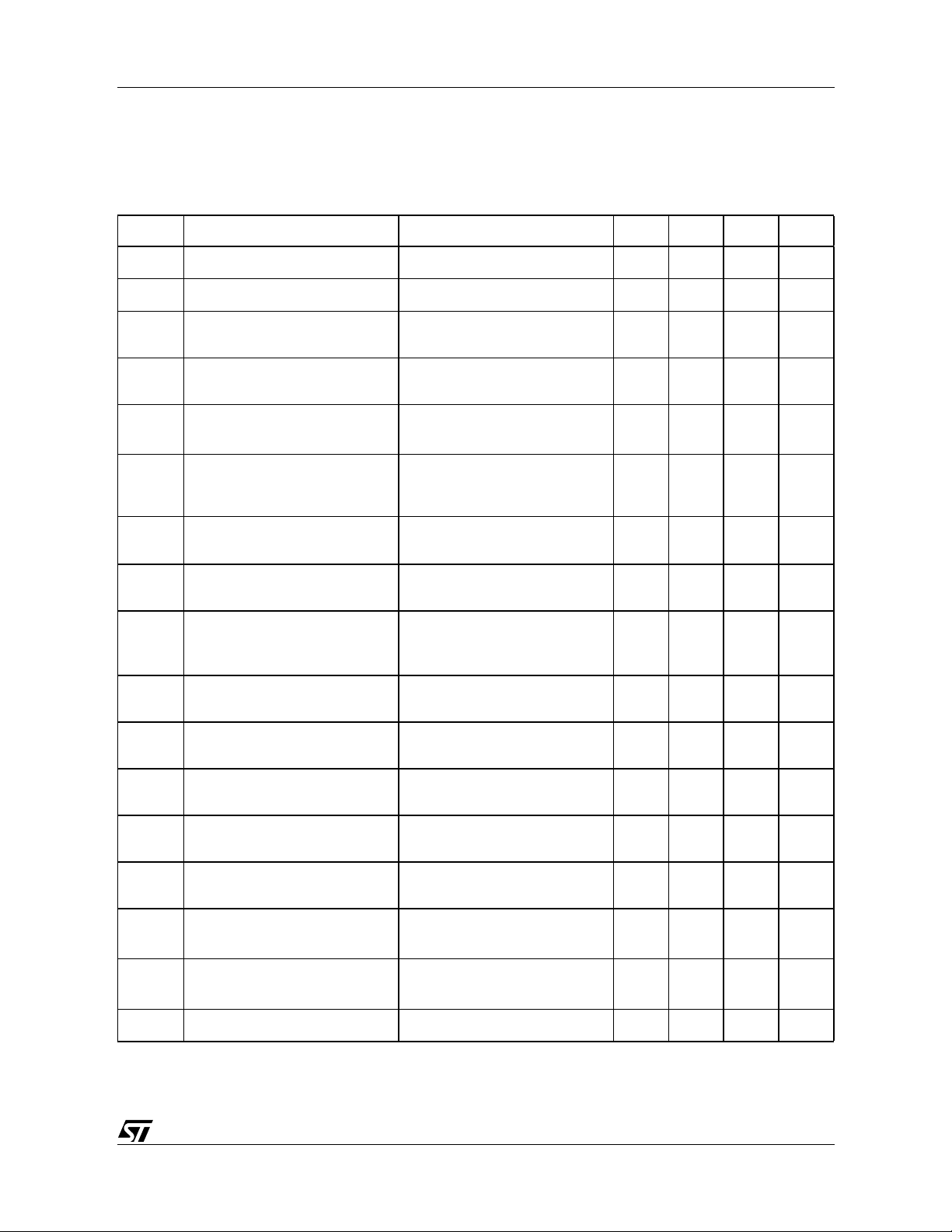

ELECTRICAL CHARACTERISTCS

Unless otherwise specified the below listed parameters' values are referred to the following conditions:

V

= –115V, VCC = 5V, R

BAT

range [0°C to 70°C]. The presence of an asterisk mark (*) indicates that the marked parameter must remain

within the specified tolerance in the extended temperature range [-40°C to 85°C].

Symbol Parameter Test Condition Min. Typ. Max. Unit

= 53.6 kW, CODCn RC series = 100nF ±10% and 510Ω ±1%, normal temperature

lim

I

I

VBAT

I

LIMT

I

LIMTL

I

LIM%

R

R

∆R

T

Vcc

I

HZ

WA

WB

j110

VCC supply current All the switches on Νo load 2.5 mA

V

supply current All the switches on Νo load 1.5 1.8 mA

BAT

Current limiting value with

I

= 0 42.5 50 57.5 mA

long

transversal line current only

Current limiting value with added

See Fig.1 37.5 50 62.5 mA

longitudinal line current

Current limiting accuracy in the

range 20 to 140 mA

(1)

I

= 0 ±15 %

long

Leakage current of each WAn

output to ground with output

driver disabled

Resistance from WAn to

V

BAT

Resistance from WBn to

IWA = 30mA 3.15 5.5 7.85 Ω

IWB = 30mA 3.5 5.5 7.5 Ω

BGND

Absolute value of the difference

OUT

between R

R

WBn

and its related

WAn

110°C thermal monitoring

IWA = IWB = =30mA 0.7

110 °C

threshold

50* µA

Ω

1(*)

LV

V

V

I

T

j130

T

j160

T

hyst

out

Rel33

Rel70

Rleak

130°C thermal monitoring

130 °C

threshold

160°C thermal monitoring

160 °C

threshold

Thermal monitoring

10 °C

hysteresis

(2)

Longitudinal output component of

See Fig. 2 – 60 dBV

the fCKILC clock signal

Relay drivers’ output voltage All the relay drivers activated at a

load current of 33mA.

(3)

Relay drivers output voltage All the relay drivers activated at a

load current of 70mA.

(3)

Relay driver leakage current ERLn = Low 100 µA

0.5 V

1.2 V

7/23

Page 8

STLC5445

ELECTRICAL CHARACTERISTICS

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

SOC

OLDH Open Loop detector Hysteresis 0.6 1.6 mA

Notes: 1. Our characterizations show that in t he range 15mA - 2 0mA the accuracy is ±20% over the 0°C - 70°C tempe rat ure range.

Open circuit detector threshold 1.5 3 4 mA

2. The longitudinal component of the signal detected by the spectrum analyzer must have an RMS voltage value, in any 4kHz equivalent ban dwi dth, ave rag ed in an y 1 seco nd peri od, not grea ter of the sp ecifi ed valu e (–6 0d BV) ove r the 100 Hz - 150kH z rang e

(for details see ETS I E TR80 and ANSI 601).

3. All th e output lines act i vated at a line c urrent of 35mA; no current limi tation conditi on. Rth(j-a ) ≤ 20°C/W

(continued)

Please note that, in order to assure the frequency stability of the output drivers, a 1µF capacitor must always

be connected between WAn and Wbn or, as shown in Fig. 6, immediately after the resistive protection elements

used in the actual application.

The R

value can be calculated starting from the value of the needed current limitation threshold I

LIM

R

LIM

2664

---------------=

I

LIMIT

LIMT

:

SWITCHING TIMING

Symbol Parameter Test Condition Min. Typ. Max. Unit

t

ENP

t

DISP

f

CKILC

Output driver’s enable time Parallel interface mode 20 µs

Output driver’s disable time Parallel interface mode 500 µs

Frequency of CKILC Duty cycle 60% max

Pulse width 500ns min

8 200 kHz

Figure 1.

WBn

STLC5445 output driver

(one of four)

WAn

Ω

25

±

0.01%

I

LIMTL

Ω

25

±

0.01%

Ω

30

±

0.01%

1.3kΩ ±1%

Ω

30

±

0.01%

20µF ±1%

20µF ±1%

8.5V

RMS

16.6Hz

8/23

Page 9

Figure 2.

STLC5445

67.5Ω

10µ F ±1%

±0.01%

WBn

STLC5445 output driver

(one of four)

3.9kΩ

±

1%

Spectrum analyzer

100Ω ±1%

WAn

67.5

±

0.01%

150nF ±10%

10µF ±1%

Ω

STATIC CHARACTERISTICS

Unless otherwise spe cified the below listed param eters values are referred to the following cond itions: VCC = 5V,

mal temperature range.

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

Input low voltage 0.8 V

IL

nor-

V

V

V

I

I

I

Input high voltage 2 V

IH

Output low voltage Io = 1mA 0.4 V

OL

Output high voltage

OH

(Open drain with PSC = 0)

Input high current 0 1 0 µA

LH

Input low current -10 0 µA

LL

Output current in High impedance

OZ

state

Io = –1 mA 2.4 V

-10 10 µA

9/23

Page 10

STLC5445

SWITCHING CHARACTERISTICS

MICROPROCESSOR WRITE / READ TIMING

Unless otherwise specified the below listed parameters’ values are referred to the following conditions:

VCC=5V, normal temperature range.

Symbol Parameter Test Condition Min. Typ. Max. Unit

(refers to figures 3 and 4).

t

RLRH

t

RHRL

t

RLDA

t

RHDZ

t

AHAL

t

ADAL

t

ADAZ

t

AZRL

t

AZWL

t

ADDA

t

WLWH

t

WHWL

t

DAWH

t

WHDZ

RDN, CSN pulse width 260 ns

RDN, recovery time

T

= – 40 to 0°C and +70°C to +85°C

amb

200

220

ns

RDN, CSN low to data available 260 ns

RDN or CSN high to data Z

T

= – 40 to 0°C and +70°C to +85°C

amb

130

160

ns

ALE pulse width 100 ns

Address setup time 60 ns

Address hold time 50 ns

Address Z to RDN low 0 ns

Address Z to WRN Low 0 ns

Address stable to data available

T

= – 40 to 0°C and +70°C to +85°C

amb

360

390

ns

WRN or CSN pulse width 200 ns

Write recovery time 200 ns

Data setup time 100 ns

Data hold time

T

= – 40 to 0°C and +70°C to +85°C

amb

20

40

ns

t

RESN

10/23

Reset Pulse with 200 ns

Page 11

STLC5445

Figure 3. Microprocessor WRITE timing

t

ALE

A

O

CS

RD

Notes: 1. If tCLWL is negative tW LWH is measured from CS_ ra ther than fromWR_.

2. If tW HCH is negative, tWHWL, tWLWH, tDAWH and tWHDZ ar e measured fro m CS_ rather than fromWR_.

The propagation delay from the writing of the T/I bit to the effect on the INT pin is approximately 1ms for both ma sk and enable operatio ns.

AHAL

t

ADALtADAZ

t

ADDA

t

AZRL

t

CLRL

(Note 1)

t

RLDA

t

RLRH

t

RHCH

Read DataDATA

(Note 2)

t

RHDZ

t

RHRL

D94TL108A

Figure 4. Microprocessor READ timing

t

ALE

A

O

CS

WR

INT

Notes: 1. If tCLRL is negative, tRHRL, tRLRH , tAZRL, and tRLDA are meas ured from CS _ rat h er than RD_.

2. If tR HCH is negative, tRHRL, tRLRH and tRHDZ are measured from CS_ rather than RD_.

When a read from the LER immediately follows a write to the LER a minimum of 1ms is required between these operations

AHAL

t

ADALtADAZ

t

CLWL

(Note 1)

t

AZWL

t

WLWH

t

DAWH

Write DataDATA

t

WHCH

t

WHDZ

(Note 2)

(Note 3)

t

WHWL

D94TL109A

11/23

Page 12

STLC5445

Figure 5. Typical Application Circuit

Z1

2 x SM6T68A

C4 100nF

VBAT

RELAYS

COMAND

RELAYS

C3 100nF

C2 100nF

C1 100nF

VBAT

BGND

VBAT

BGND

VBAT

BGND

VBAT

EREL0A

EREL0B

EREL1A

EREL1B

EREL2A

EREL2B

EREL3A

EREL3B

REL0A

REL0B

REL1A

REL1B

REL2A

REL2B

REL3A

REL3B

N.C.

59

51

58

32

27

19

26

8

9

12

13

41

42

45

46

7

10

11

14

40

43

44

47

20,22,52,54

RGND V

C5

100nF

BGND

CC

ILIMDGND

64

235,35,62

CODC0 CODC1 CODC2 CODC3

C6

100nFC7100nFC8100nFC9100nF

5530

343321

50

4

18

17

16

15

36

37

38

39

5

6

48

49

61

24

29

56

60

25

28

57

63

21

31

53

RESET

CK_ILC

INTN

PSC

PBIT

ALE

ES0/A0

ES1/CS

ES2/RD

ES3/WR

NACK0(D0)

NACK1(D1)

NACK2(D2)

NACK3(D3)

WBP_0

WBP_1

WBP_2

WBP_3

WB_0

WB_1

WB_2

WB_3

WA_0

WA_1

WA_2

WA_3

JP0

JP1

JP2

JP3

D99TL440

DIGITAL

CONTROL

OUTPUTS

CLAMPING

DRIVER

OUTPUTS

External Component List

Coponents Description Value

C1, C2, C3, C4 & C5 Power Supply Filter Capacitance 100nF

C6, C7, C8 & C9 Signal Filter Capacitance 100nF

Programmable Limiting Current Resistor 53.6kΩ

Transil Clamping Protection 136V

12/23

R

LIN

Z

1

Page 13

Figure 6. Typical Protection Diagram (only channel 0 and 1 shown )

STLC5445

TIP

SM5908

16ΩPTC

1µF

RING

2 x

SM6T68A

W

BAT

TIP

1µF

RING

Note: The 1µF capacitors are required for output driver's stability

16ΩPTC

16ΩPTC

16ΩPTC

22Ω

22Ω

SM5908

22Ω

22Ω

D02TL549

B

GND

W

BP1

W

B1

CHANNEL's 1 OUTPUT

W

A1

W

BAT

B

GND

W

BP0

W

B0

W

A0

W

BAT

DRIVER's STAGE

CHANNEL's 0 OUTPUT

DRIVER's STAGE

FUNC TIONAL DESCRIPTION

(n=0-3) Drivers (output pins).

WAn

Each WAn output can sink up to 140mA. When the ESn input is High and the activation request

is approved by the internal control circui t ry, the respecti ve WAn output is internall y connected

to VBAT through a DMOS switch and the low side sensing resistor.

WBn

(n=0-3) Resistor to BGND.

Each WBn output connects the wire B to ground through a 5W resistor used to perform the

longitudinal balance and the high side current sensing function.

WBPn

(n=0-3) Protection diodes connection (see the block diagram at page 3).

Each channel of the STLC5445 has two internal, back to back connected diodes, whose clamping action can be used to protect t he WBn outputs during l ighti ng and power crossi ng events.

The diodes' clamping action is normally disabled and can be activated by connecting the WBPn

pin to BGND. In this case however, if the line current exceeds 57.5mA the forward drop across

the high side sensing resistor (and then across the diodes) reaches the diodes' conduction

threshold, strongly degrading the current l imiting action and the longi tudinal balance. For line

currents higher than 57.5mA external clamping elements must then be connected in place of

the internal diodes or in series to them in order to increase the clamping voltage value.

BGND

DGND

Battery ground.

Digital ground.

13/23

Page 14

STLC5445

RGND

CKILC

Logic input.

Ground connection of the relay drivers.

External clock input for the

block diagram at page 3). The Power On Sequencer controls (if activated) the power on sequence of the lines. Thi s will limit the chip's t emperature increase that occurs, at channels

switch on, due to the charging current of the capacitances used by the external ISDN circuitry.

If used, the Power on sequencer is the only block of the circuit that needs an external clock signal.

ESn

(n=0-3) Logic inputs.

These pins have double names (see the block diagram at page 3) because they perform a double function: one in

In Parallel mode ESn acts as an activation or deactivation request for the respective line driver:

In MPI mode the pins perform the following functions:

RESETN

Reset pin. It initializes the Power on sequencer, the TOR register and, in the MPI interface, the

registers and the INTN (interrupt output pin). When applied it leaves all the line drivers switched

off.

It has no effect in Parallel interface mode if the power on sequencer is not used.

When the supply voltages are applied t o the ci rcuit, an equival ent RESETN pulse (power on

reset) is automatically, internally generated.

ALE A

ddress Latch Enable. ALE is a logic input pin. It is used to strobe the address bit applied at

the A0 pin, into the address latch. The address is latched on the H igh to Low transition of ALE.

While ALE is High the address latch is transparent. For a non multiplexed microprocessor bus,

ALE must be tied High.

ILIM

The current limiting pr ogramming input, ILIM, is used to program the current limi t of the four

drivers by means of an external resistor connected between this pin and DGND. The voltage at

ILIM pin is a replica of the internal bandgap voltage (1.236V).

When a line driver is in current limitation, its output current is 2155 times higher than the current

flowing in the external current limiting programming resistor.

INTN

The INTN (interrupt) open drain type output can only be used in MPI interface mode. INTN can

be used to alerts an external microprocessor when a current overload condition occurs. It is not

Power On Sequencer

Parallel mode

( PSC = 0 ), and another in

ESn = 0: Line driver deactivation request.

ESn = 1: Line driver activation request.

A0:

Selects the source and destination locations for read and write operations on the

data bus. A0 must be valid on the falling edge of ALE or during RDN and WRN

if ALE is tied High. Data transfer occurs over the D0-D3 lines.

CSN:

This pin acts as a chip select. It must be Low to enable the read or write operations of the device.

RDN:

Read command. The active Low read signal is conditi oned by CSN and transfers internal information t o the data bus. If A0 is a logi cal 0, the logic lev els of

the

I

ndirect Address Register (

IAR

be transferred to D3-D0. If A0 is a logical 1, the data addressed by the

be transferred to D3-D0.

WRN:

Write command. The active Low write signal is conditioned by CSN and transfers information from the data bus to one of the two internal registers selectable

by A0: if A0 is a logical 1, D3-D0 is written into the

if A0 is a logical 0, D2-D0 are writt en into the

and D3 is written as bit 3 and manages the generation of the interrupt signal for

the external microprocessor.

LER

the device.

embedded in the

Logic interface

MPI mode

(see the

( PSC = 1).

) and of the Thermal Shutdown Status bit will

IAR

will

L

and

ine Enable Register (

I

ndirect Address Register (

IAR

are the only two writable registers in

LER

IAR

);

)

14/23

Page 15

STLC5445

latched and is active (Low level) when at least one of the CODn status detector bits is active

(High level). When the four CODn status detector bits are Low, INTN goes inactive (High). INTN

will also go inactive if (due to thermal overload) the QLFC automatically disables the output driver of the channel that caused the int errupt, or i f t he ext ernal microprocessor disabl es t hat li ne

via the Line Enable Register (LER). The interrupt function can be disabled (INTN remains permanently High) via the Indirect Address Register (IAR) or a Low level on the RESETN pin.

NACKn

PSC

ERLn

RLn

CODCn

(n=0-3) When a line over current condition exists, the output driver of the overloaded channel instanta-

(n=0-3)Logic I/O.

These pins have double names (see the block diagram at page 3) because they perform a double function: one in

Parallel mode

In

each NACKn acts as an open drai n output and gives the ch annel's status in-

formation.

The NACKn bit goes in high impedance state (bit = 1 if a NACKn pull up is provided) when at

least one of these conditions is verified:

The current on the relative line reaches the current limit programmed by the user.

The chip's temperature reach the thermal alarm threshold.

The line driver is in the Power on phase.

When the ESn input is set Low, the corresponding NACKn is set to zero.

In

MPI mode

the four pins become

capability. The four bidirectional data bus lines are used to exchange information with an external microprocessor. D0 is the least significant bit and D3 is the most significant bit. An High Level on the data bus corresponds to a logical 1. When the chip select bit (CSN) is Low, these lines

act as inputs when WRN is Low and as outputs when RDN is Low. When CSN is High the D3

- D0 pins are in a high impedance state.

Logic input.

This pin is used to select one of the two available logic interfaces.

PSC = 0: Parallel mode.

PSC = 1: MPI mode.

(n=0A-3B) Logic inputs.

Each ERLn pin controls directly the respective relay driver's DMOS:

ERLn = 0 : Switch off the relay driver.

ERLn = 1 : Switch on the relay driver.

(n=0A-3B) Relay drivers' output.

Each of the eight RLn pins is connected to the drain of an internal DMOS switch (see the block

diagram at page 3) which acts as a dri ver f or an ex ternal rel ay to be s uppl ied f rom VCC. The

relay drivers' current flows to ground through the RGND pins. Each output can sink up to 70

mA. An internal clamping circuit is provided, so no external kickback diodes are required.

neously limits the line current at the value programmed by means of the e xternal RLIM resistor.

In this condition the

When operating in MPI mode this bit can, for each of the four channels, be red by the external

microprocessor in order to check which channel (if any) is overloaded.

When in parallel mode each COD bit is internal l y OR combined with t wo other bi t s i n order t o

generate the NACKn bit.

Since in the ISDN application it can happens that the sum of the DC line current and the superimposed signal peaks, easily exceeds the needed DC current limit, the COD generation circuitry

has been arranged in such a way that the COD bit will be pushed H igh

load persists for at least 20ms: this eliminates any spurious High level COD / NACK. The men-

Parallel mode

C

urrent Overload Detector bit (COD) switches to a High logic level.

( PSC = 0 ), and another in

D3 - D0

and act as a bidirectional data bus with three state

MPI mode

only

( PSC = 1).

if the current over-

15/23

Page 16

STLC5445

tioned delaying function requires, for each of the four channels, one Capacitor of 100nF has to

be connected between each CODCn and ground.

OPERATIVE DESCRIPTION

The device compr ises t hree main blocks : the

The Analog section feeds the four lines and detects their status.

The Logic section allows to exchange information and commands between the QLFC and the external digital

system.

The Relay driver section is completely independent: each relay command input is related to its own driver with-

out any conditioning.

Analog section

, the

Logic section

and the

Relay driver section

.

Analog Section

The ANALOG section comprises the

and the

Thermal monitoring

(see the Block diagram at page 3)

Channel 0-Channel 3

block.

block, the

Reference & biasing generation

block

As shown in the channel's card of the block diagram, the WBn and WAn pins to which the line is connected are

respectively routed to the battery ground and to the VBAT line: WBn goes to BGND through the upper side sensing resistor; WAn goes to V BAT through a pow er DM OS a nd the lower side s ensing resistor. The ON/OFF control for the power DMOS comes from the outside world through the

Logic interface

block.

The implemented topology for the circuit used to cancel the longitudinal current effect is a DC coupled topology:

it doesn't need external capacitors and its frequency band starts from DC.

The QLFC has a double protection provided by its

current limiting

and

thermal monitoring capabilities

.

The current limit threshold (ILIMT) of the four channels is hardware programmable by means of a single, external resistor (RLIM):

I

LIMIT

1.236 2155⋅

--------------------------------=

R

.

LIM

The protection implemented by the thermal monitoring is based on a three levels control system:

A first temperature threshold controls the Power on sequencer (see the Logic Section for a detailed description of its behaviour). When activated (PBIT pin Low), the Power on sequencer

manages the channels' activation requests received through the Parallel (PSC pin Low) or the

MPI (PSC pin High) interface. The incoming channels' activation requests are stored in the

Power on sequencer and then satisfied, one at a time, only when the previously activated channel leaves the current limiting condition that normally occurs at power on, due to the capacitive

element that is part of the ISDN load. However when the chip's internal temperature reaches

110°C, only the already stored activation requests will be satisfied; the new, eventually incoming o nes , w ill be reje c te d and w ill be processed when the internal temperature decreases down

to 100°C.

A second temperature threshold is set at 130°C. When this value is reached the channels that

are in current limiting condition are switched off and their reactivation will only b e po s sible when

the chip's internal temperature has decreased down to 120°C or, if the Power on sequencer is

activated, down to 100°C.

The third temperature threshold is set at 160°C. When this temperature is reached the activated

channels will all be switched off and their r eacti vat ion will onl y be possible when the chip's i nternal temperature has decreased down to 150°C. The user must however take into account

that if (like in ISDN application) the load seen by the channel has a high capacitive component,

at channel's turn on a current limiting condition will alw ay s o ccu r a n d th e e ve ntu al ly r eac ti vat ed

channels will almost instantaneously be switched off by the 130°C monitoring circui t, if the

chip's internal temperature is still higher than 120°C. More over (as explained at the previous

point) if the Power on sequencer is activated it will not be poss ible to swit ch o n an y channel until

the chip has cooled down to 100°C.

16/23

Page 17

STLC5445

Each of the four channels generates two stat us detector bits ( see the block di agram at page 3): the COD bit

(

C

urrent Overload Detector) and the OLD bit (Open Loop Detector). The functions of the two bits are the follow-

ing:

The COD bit goes in a High logic state when its channel is in current limiting condition. Since in

the ISDN application it can happens that the sum of the DC line current and the superimposed

signal peaks, easily exceeds the needed DC current limit, the COD generation circuitry has

been arranged in such a way that the COD bit will be pushed High only if the current overload

persists for at least 20ms: this eliminates any spurious High level CO D. The mentioned delaying

function requires, for each of the four channels, one Capacitor of 100nF has to be connected

between each CODCn and ground.

The OLD bit goes in a High state logic when the current t hat the channel suppli es to the line

falls below a typical value of 3mA, indicating a probable open line condition.

As explained in the following pages, when operating in MPI mode the COD and OLD bits can, for each of the

four channels, be red by an ext ernal microprocessor i n order to check which channel (i f any ) is over or under

loaded. When in Parallel mode a single status bit (the NACKn bit) is provided for each channel and is di rec tly

available on a dedicated pin. The NACKn bit is internally generated by OR combining the COD bit with two other

bits (see the Logic section for a more detailed explanation).

Logic Section

The Logic section comprises the

block diagram shown at page 3 the three functions have been condensed in a single entity: the

Parallel interface

, the

MPI interface

and the

Power on sequencer

Logic interface

block.

For each of the four channels, both types of the two provided interfaces use the COD, OLD and TOR (

O

verload Register) status detector bits:

The COD (

C

urrent Overload Detector) bit is in a High logic state when its channel is in current

limiting condition since at least 20ms.

The OLD (

O

pen Loop Detector) bit is in a High logic state when the current that the channel

supplies to the line falls below a typical value of 3mA (ISOC spec's parameter), indicating a possible open line condition.

Each of the four output line drivers can be switched on,

only

if their corresponding TOR bit is

High.

The TOR bits are automatically set High by the internal power on reset when the chip is initially

connected to its power supplies but can, however, also be globally set High by applying a reset

pulse to the RESETN pin. Alternatively the TOR bits that are latched in a Low state can individually be set High by applying to the selected interface the switch off command relative to their

channel.

The T OR b its w ill go in a Lo w sta te ( de ter mining the shut off of t heir re lati ve c hannel's driver) in

two cases:

The activated channel is in current limiting condition and the chip's temperature reaches 130°C.

In this case the TOR will be latched in Low state.

The chip's temperature reaches 160°C: in this case the TOR bits wi ll all be set Low but only the

TOR of the activated channels will be latched.

. In the

T

hermal

Power on sequencer

When activated (PBIT pin Low), the Power on sequencer manages the channels' activation requests received

through the Parallel (PSC pin Low) or the MPI (PSC pin High) interface. The incoming channels' activation requests are stored in the Power on sequencer and then sati sfied, one at a t i me, onl y when the pr eviousl y acti vated channel exit the current limiting condition that normally occurs at power on, due to the capacitive element

that is part of the ISDN load. It must be noted that once a channel exits from the channel's turn on c urrent limiting

phase, the fact that it can for example because of a new line overload fal l again in a cur rent l imiti ng c onditi on

17/23

Page 18

STLC5445

has no influence in the activation sequence of the next channels. The stored activation requests are satisfied

starting from the lower index of the actually stored requests: if (for example) while channel 2 is in the activation

phase, additional power on requests arrive for (in the order) channels 1, 3 and 0, when the channel's 2 activation

phase will be conc luded the stored activation requests will be satisfied in the order 0, 1 and 3. It must be noted

that the channels' deactivation requests are not conditioned by the Power on sequencer.

Figure 7. Power on sequence exam ple

DAR0

COD0

POF0

DAR1

COD1

POF1

DAR2

COD2

POF2

Notes: D ARn are the line Drivers' Activation Request bits sent to t he Power on sequencer. They are internally generated sta rting from the

activatio n r eques ts c omin g f rom the outs ide w orl d thr ough t h e selec ted int erfa ce (P ar allel or MPI) . PO Fn a re th e Power On Flags.

Each POFn goes High with its relative DARn bit and returns to a Low state when the current limiting condition ends: a POF High state

indicates that the rel at iv e channel is in th e power on phase .

The figure 6 shows, for three of the four available channels, a typical power on sequence example. The COD n

pulse duration represents the time needed to charge the capacitive element that is part of the ISDN load, with

part of the constant current that each line driver provides with the actually programmed current limiting value. It

must be realized that if (for example) has been required the activation of the lines 0, 2 and 3 but line 2 is overloaded and cannot leave the current limiting condition, the activation sequence will rem ain blo ck ed at the line 2

activation step. In this case the external software has to identify and shut off the overloaded line in order to allow

the activation of the line 3.

The previously mentioned RESETN pin will also influence the Power on sequencer: when RESETN is pushed

Low the Power on sequencer is reset, switching off the actually activated drivers.

The Power on sequencer is the only block of the circuit that needs an external clock signal to be applied at the

CKILC pin. The clock frequency is not critical and has a nominal value of 8kHz.

When PBIT=1 the power on sequencer is disabled and the incoming channels' activation request s wil l instantaneously be satisfied. In this case the user as to take into account the actual operative condition (VBAT, the

programmed current limiting value, the load applied to the lines, the ambient temperature) and implement his

own power on sequence in order to li mit the chip' s temperature increas e induced by the c hannels' switch on

transients.

18/23

Page 19

STLC5445

Parallel interface mode

In Parallel interf ace mode (PSC pin Low), for each of the four output driv ers a dedi c ated act ivati on pi n i s provided (ES0-ES3):

Each driver will unconditionally be switched off when its ESn is pushed Low.

If the Power on sequencer is not used, each driver will b e switc hed on (under the s upervision of the pre-

viously described Thermal monitoring block) when its ESn is pushed High.

If the Power on sequencer is activated the drivers' activation requests coming from the ESn inputs will

(under the supervision of the previously described Thermal monitoring block) be processed by the Power on sequencer block (see the previous Power on sequencer's description).

In Parallel interface mode a single status bit is provided for each of the four channels at the open drain NACK0

- NACK3 output pins. The NACKn bit is generated by OR combining the three previously described status detector bits: CODn, POFn and the complemented TOR. This means that each N ACKn bit goes in high impedance

state (bit=1 if a NACKn pull up is externally provided) when at least one of these conditions is verified:

The current on the relative line reaches the current limit programmed by the user (the NACKn High state

in this case will not be latched).

The chip's temperature reaches 130°C and the channel is in current limiting condition (the NACKn High

state will in this case be latched).

The chip's temperature reaches 160°C (in this case all the NACKn will go in High state, but only the

NACKn of the activated channels will be latched).

The line driver is i n t he power on phase (i n thi s cas e the NACKn will remain in High state only for the

time during which its channel is in current limiting condition).

When the ESn input is set Low, the corresponding NACKn is always set to zero.

In Parallel interface mode the output pin INTN and the input pin ALE are not used (ALE must in this case be tied

High or Low).

MPI interface mode

In MPI mode (PSC pin High), the ALE and INTN pins become active and the pins NACK0-N ACK3 and ES0-ES3

have a function that is completely different from that performed in Parallel mode:

The four NACK0-NACK 3 pins become D 0 -D3 and act as a bidirectional data bus with three state capa-

bility.

The four ES0-ES3 pins become respectively A0, CSN, RDN and WRN.

L

In MPI mode the above mentioned four bits data bus and three internal four bits regis ters, LER (

R

egister), LEC (Line Enable Control) and IAR (Indirect Address Register) are used to perform the following op-

ine Enable

erations:

Channels' output drivers switch on and switch off.

Enabling/disabling of the INTN (interrupt) signal generation.

Status detector bits reading.

T bit reading (this bit is High only when the internal chip's temperature exceeds 160°C).

The read/write operations on the data bus can only be performed when the CSN (Chip Select) pin is Low since

when CSN is High the data bus is inactive (high impedance state).

The active Low RDN and WRN signals are used to perform the read and write operations on the registers se-

lected by the logic level applied at the A0 pin:

A0=0 selects: The IAR register if a write operation is performed (status detector bits type selection and

enabling/disabling of the INTN signal generation via the I bit).

The reading of the bits actually written in the IAR register if a read operation is performed.

A0=1 selects: The LER register if a write operation is performed (switch on and switch off requests pro-

gramming for the output drivers).

19/23

Page 20

STLC5445

The status detector bits reading if a read operation is performed.

A0 must be valid on the falling edge of the signal applied at the ALE (Address Latch Enable) pin or during the

read and write operations if ALE is tied High.

NOTE: A delay of at least 1ms is required between a LER writing and the next LER reading. Subsequent LER

reading operations do not have this constraint.

The line output drivers' switch on or switch off requests are implemented by first selecting the LER register and

then by writing in its D0-D3 bits a 1 (turn on request) or a 0 (turn off request). D0 co ntrols channel 0, D1 channel

1 and so on. If the requests are accepted by the Thermal moni tori ng bl ock and (i f activated) by the Power on

sequencer, the bits stored in the LER register are copied in the LEC register whose status (1 = turn on; 0 = turn

off) directly controls the output drivers' ON/OFF condition.

For each of the four channels, in MPI mode the following six status detector bits are available:

The COD, OLD and TOR bits whose function has already been described at the beginning of the Logic

Section paragraph.

The LER and the LEC bits.

The POF (

The status detector bits reading is performed by first writing in t he 2 - 0 bits of the IAR register (via the D2-D0

bus lines) a three bits code used to select which of the six available status detector bits type has to be red. A0

must then to be set at 1 and the reading cycle has to be performed. The status detector bits' selection codes

are listed in the following table.

If (for example) a 010 code has be en written in the IAR, the output on the D0 - D 3 lines at the end of the reading

cycle will be the COD0 - COD3 bi ts.

Please, note that since the red data are not l atched (apart f rom the TOR status detector bits of the channels

whose output drivers are switched on), the user should filter them (multiple samples) to ensure theirs integrity.

IAR2 IAR1 IAR0 Selected status detector bits type

P

ower On Sequencer) bit already described at the Power on sequencer paragraph.

000 POF

001 OLD

010 COD

0 1 1 LEC

1 0 0 RESERVED

1 0 1 RESERVED

110 LER

1 1 1 TOR

As already explained the IAR is a four bits register but only three bits (D2 - D0) are required to select one of the

six available status detector bi ts types. The fourth I AR bit ( D3) is the

I bit

and is used to enable (1) or disable

(0) the generation of the interrupt signal INTN that, via the INTN pin, can alerts an external microprocessor when

a current overload condition occurs. INTN is active (Low level) when at least one of the CODn status detector

bits is active (High level). When the four CODn status detector bits are Low, INTN goes inactive (High): this

clearly means that INTN will also go inactiv e if (due to t hermal overload) t he QLFC automatical ly di sables the

output driver of the channel that caused the interrupt or if the external microprocessor disables that line via the

LER register.

The interrupt function can also be disabled (INTN remains permanently High) by applying a Low level on the

RESETN pin.

As previously explained, when a reading operation is performed while A0 = 0 the four bits actually written in the IAR

register can be read on the D 3 - D0 bus lines. We alr eady know that the D2 - D0 bits represent the status detector bits

selection code. The D3 bit is the T bit: it is High only when the internal chip's temperature exceeds 160°C.

20/23

Page 21

The IAR bits' function has been summarized in the following table:

Bit Symbol Bit function

0 IAR0 Bit 0 of the status detector bits selection code

1 IAR1 Bit 1 of the status detector bits selection code

2 IAR2 Bit 2 of the status detector bits selection code

STLC5445

3 IAR3:

T (read)

I (write)

T bit (read only): Logical 0 when chip’s temperature is below 160°C

Logical 1 when chip’s temperature exceeds 160°C

I bit (write only): Logical 0 to disable the interrupt generation

Logical 1 to enable the interrupt generation

The logic behaviour of the MPI's chip select and read/write operations has been summarized in the following

table:

CSN RDN WRN A0 Performed operation

0100Write IAR

0010Read IAR

0101Write LER

0011Read the status detector bits types selected via the IAR

1 X X X No access

21/23

Page 22

STLC5445

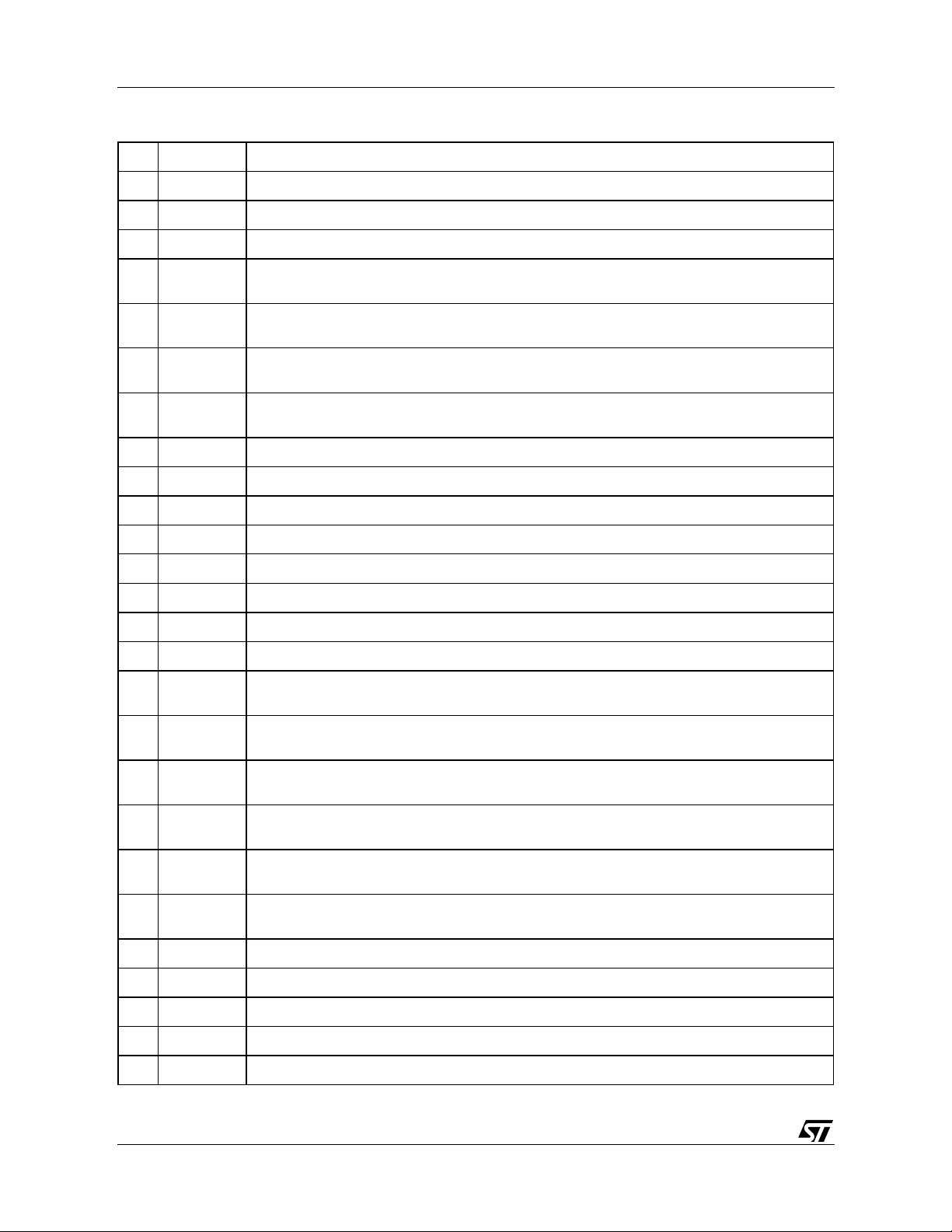

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.15 0.124

A1 0 0.25 0 0.010

A2 2.50 2.90 0.10 0.114

A3 0 0.10 0 0.004

b 0.22 0.38 0.008 0.015

c 0.23 0.32 0.009 0.012

D 17.00 17.40 0.669 0.685

D1 (1) 13.90 14.00 14.10 0.547 0.551 0.555

D2 2.65 2.80 2.95 0.104 0.110 0.116

E 17.00 17.40 0.669 0.685

E1 (1) 13.90 14.00 14.10 0.547 0.551 0.555

e 0.65 0.025

E2 2.35 2.65 0.092 0.104

E3 9.30 9.50 9.70 0.366 0.374 0.382

E4 13.30 13.50 13.70 0.523 0.531 0.539

F 0.10 0.004

G 0.12 0.005

L 0.80 1.10 0.031 0.043

N10°(max.)

S 0°(min.), 7˚(max.)

(1): "D1" and "E1" do not include mold flash or protusions

- Mold flash or protusions shall not exceed 0.15mm(0.006inch) per side

OUTLINE AND

MECHANICAL DATA

HiQUAD-64

A

53

D2

(slug tail width)

64

N

c

A

b

slug

(bottom side)

1

E4 (slug lenght)

D1

D

⊕

33

M

F AB

21

e

E1

B

E

Gauge Plane

POQU64ME

0.35

A1

E2

A2

BOTTOM VIEW

E3

E3

S

A3

SEATING PLANE

L

C

G

COPLANARITY

C

22/23

Page 23

STLC5445

ESD - The STMicroelectronics Internal Quality Standards set a target of 2KV that each pin of the device should withstand in a series of tests

based on the Human Body Model (MIL-STD 883 Method 3015): with C = 100pF; R = 1500Ω and performing 3 pulses for each pin versus V

and GND.

Device characterization showed that, in front of t he STMicroel ectronics In ternaly Quali t y S tandards, all pi ns of STLC5445 withstand at least

1500V.

The above points are not expected to represent a pratical limit for the correct device u tilization nor for its reliability in the field. Nonetheless

they must be mentionned in connection with the applicability of the different SURE 8 requirements to STLC5445.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise under any patent or patent rights of STMicroel ectronics. Specificat i ons mentioned in this p ublicatio n are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics product s are not

authorized for use as critical components in life su pport device s or systems wit hout express wri t ten approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2001 STMicroelectronics - All Rights Reserved

Australi a - Brazil - China - Finland - France - Germany - Hong Ko ng - India - Italy - Ja pan - Malaysia - Mal ta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw i tzerland - United Kingdom - U.S.A.

http://www.s t. com

CC

23/23

Loading...

Loading...