Page 1

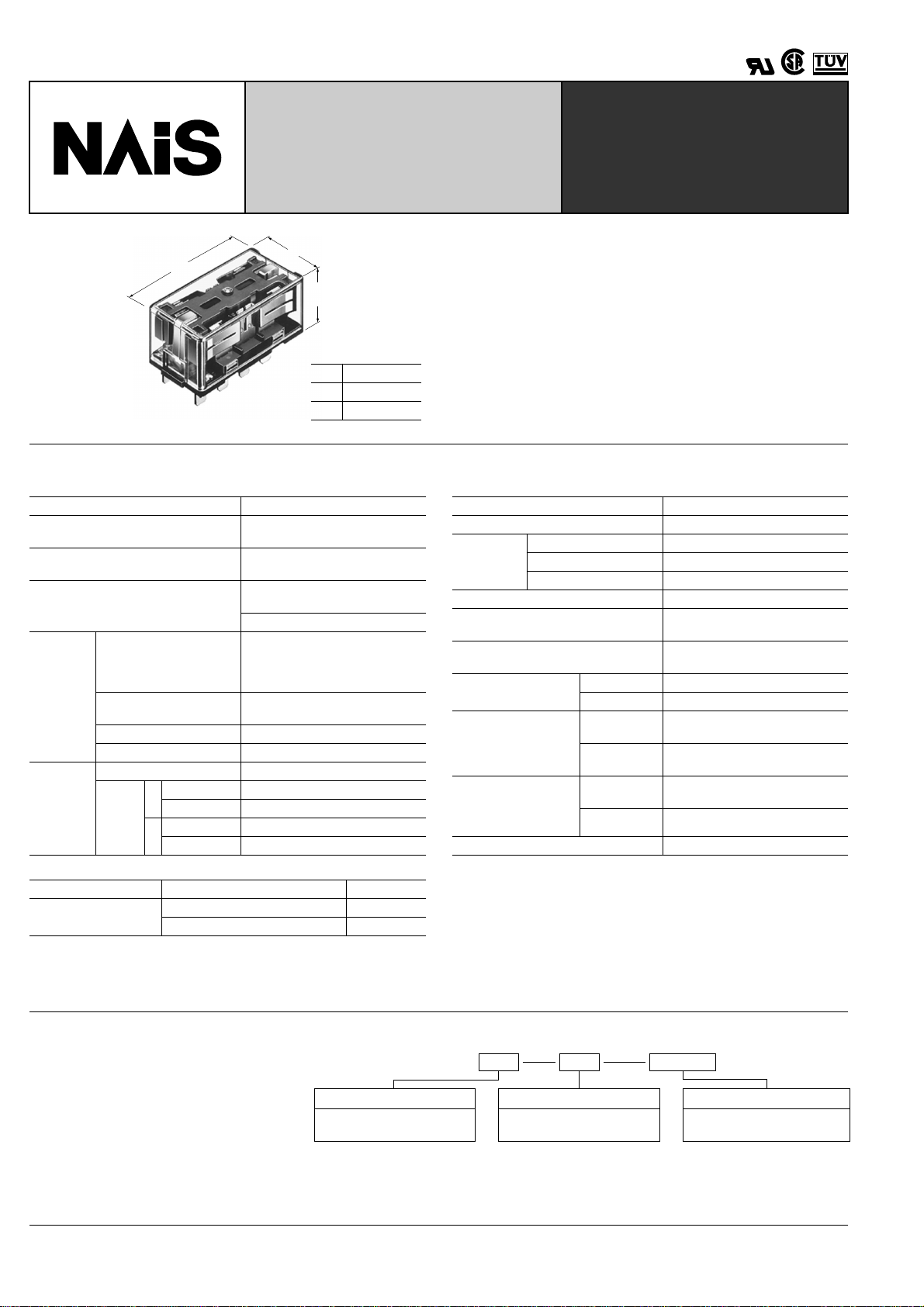

Contact arrangement Operating function Coil voltage

2: 2 Form C

4: 4 Form C

Nil: Single side stable

L2: 2 coil latching

DC 3, 5, 6, 12,

24, 48 V

2 L2 DC24VSPEx.

(Notes) 1. PC board terminal types available as option. Please consult us for details.

2. 2 Form C: Carton: 20 pcs., Case: 200 pcs.

4 Form C: Carton: 10 pcs., Case: 100 pcs.

3. UL/CSA, TÜV approved type is standard.

15A (2C), 10A (4C) COMPACT

POWER RELAYS WITH HIGH

SP-RELAYS

SENSITIVITY

1.969

50

a

22

.866

mm inch

a

2C 25.6 1.008

4C 36.8 1.449

SPECIFICATIONS

Contacts

Arrangement 2 Form C, 4 Form C

Initial contact resistance, max.

(By voltage drop 6 V DC 1 A)

Initial contact pressure

Contact material

2C: Approx. 0.392 N (40 g 1.41 oz )

4C: Approx. 0.196 N (20 g 0.71 oz )

Gold flashed silver alloy

Movable contact: Silver alloy

Nominal switching

capacity

Rating

(resistive

load)

Max. switching power

Max. switching voltage 2C, 4C: 250 V AC, 30 V DC

Max. switching current

2C: 15 A (AC) 10 A (DC), 4C: 10 A

Mechanical (at 180 cpm) 5 × 10

Expected

life (min.

operations)

Electrical

(at 20 cpm)

(resistive

load)

15 A 250 V AC

2C

10 A 30 V DC

10 A 250 V AC

4C

10 A 30 V DC

Coil (polarized) at 20 ° C 68 ° F

Single side stable Nominal operating power 300 mW

Latching

Minimum set and reset power 150 mW

Nominal set and reset power 300 mW

30 m Ω

Stationary contact:

2C: 15 A 250 V AC

10 A 30 V DC

4C: 10 A 250 V AC

10 A 30 V DC

2C: 3,750 VA, 300 W

4C: 2,500 VA, 300 W

7

5

10

5

10

5

10

5

10

FEATURES

• High Vibration/Shock Resistance

Vibration resistance: 18 G, amplitude 3 mm (10 to 55 Hz)

Shock resistance: 40 G (11 ms)

• Latching types available

• High Sensitivity in Small Size 150 mW pick-up, 300 mW

nominal operating power

• Wide Switching Range

From 1 mA to 15 A (2C) and 10 A (4C)

Characteristics (at 25 ° C 77 ° F 50% Relative humidity)

Max. operating speed (at rated load) 20 cpm

Initial insulation resistance*

Initial

breakdown

voltage*

Operate time*

Between open contacts

Between contact sets 3,000 Vrms

2

Between contact and coil

3

(at nominal voltage) Max. 30 ms (Approx. 25 ms)

Release time(without diode)*

(at nominal voltage)

Temperature rise

(at nominal voltage)

Shock resistance

Vibration resistance

Conditions for operation,

transport and storage*

7

(Not freezing and condensing at low temperature)

Unit weight

Remarks

* Specifications will vary with foreign standards certification ratings.

1

*

Measurement at same location as "Initial breakdown voltage" section

2

*

Detection current: 10 mA

3

Excluding contact bounce time

*

4

*

Half-wave pulse of sine wave: 11ms; detection time: 10 µ s

5

Half-wave pulse of sine wave: 6ms

*

6

*

Detection time: 10 µ s

7

Refer to 5. Conditions for operation, transport and storage mentioned in

*

AMBIENT ENVIRONMENT (Page 61).

1

1,000 M Ω at 500 V DC

1,500 Vrms

3,000 Vrms

3

Max. 20 ms (Approx. 15 ms)

Max. 40 ° C with nominal coil voltage

and at nominal switching capacity

Functional*

Destructive*

Functional*

Destructive

Ambient

temp.

4

5

6

Min. 392 m/s

Min. 980 m/s

176.4 m/s

at double amplitude of 3 mm

176.4 m/s

at double amplitude of 3 mm

–50 ° C to +60 ° C

–58 ° F to +140 ° F

2

{40 G}

2

{100 G}

2

{18 G}, 10 to 55 Hz

2

{18 G}, 10 to 55 Hz

Humidity 5 to 85% R.H.

2C: 50 g 1.76 oz ; 4C: 65 g 2.29 oz

TYPICAL APPLICATIONS

ORDERING INFORMATION

NC machines, remote control panels,

sophisticated business equipment.

252

Page 2

1

28910

567

1

SET

RST

2

3

48910

567

1

28910

14 15 16

567

11 12 13

1

SET

RST

2

3

48910

14 15 16

567

11 12 13

Ω ( ±

°

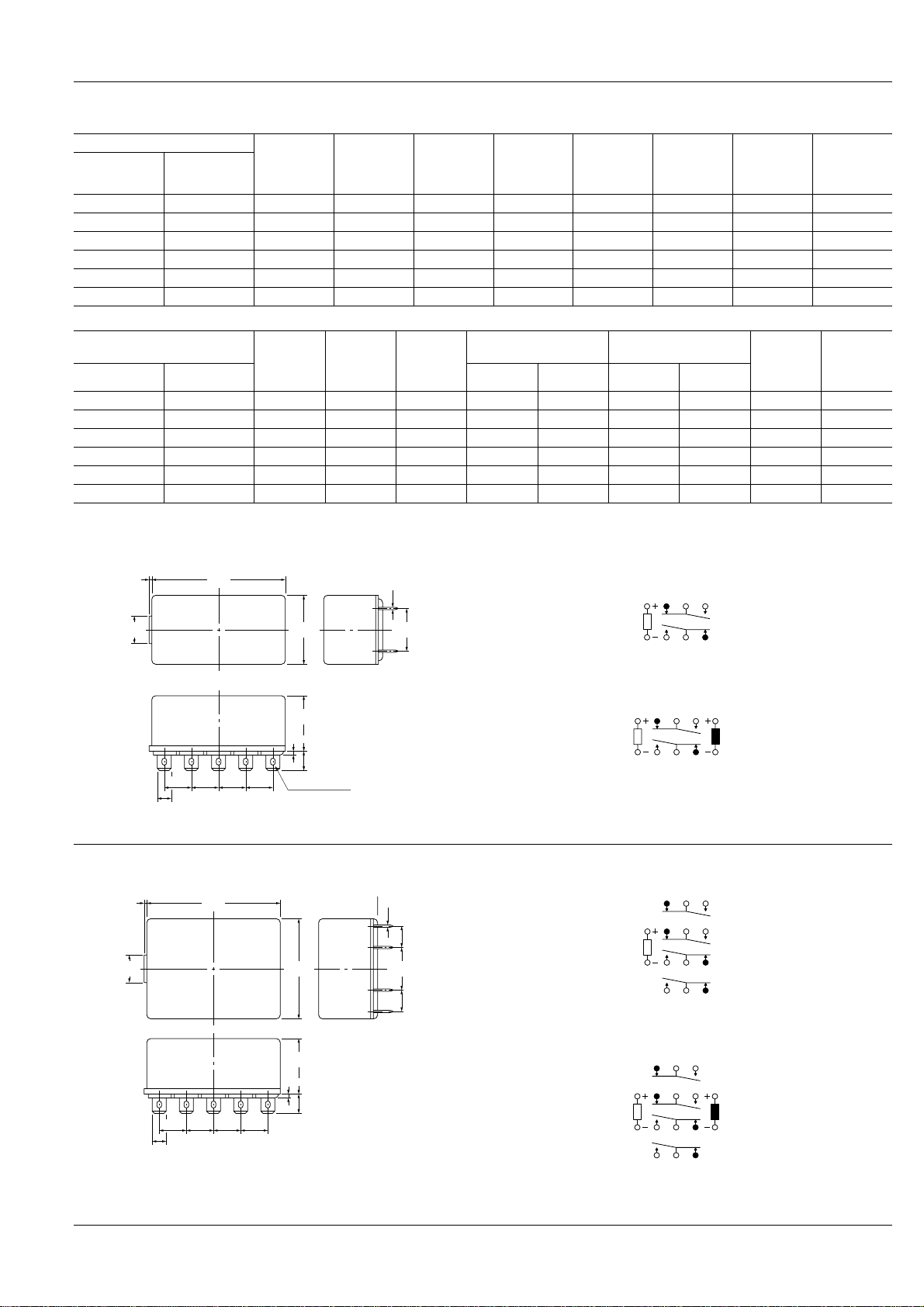

TYPES AND COIL DATA (at 20 ° C 68 ° F)

Single side stable

Part No.

2 Form C 4 Form C

Nominal

voltage,

V DC

Pick-up

voltage,

V DC (max.)

Drop-out

voltage,

V DC (min.)

Nominal

operating

current, mA

Coil resis-

tance, Ω

( ± 10%) 20 ° C

Inductance,

H

(at 120 Hz)

Nominal

operating

power, mW

SP2-DC3V SP4-DC3V 3 2.1 0.3 100.0 30 Approx. 0.05 300 4.5

SP2-DC5V SP4-DC5V 5 3.5 0.5 60.2 83 0.1 300 7.5

SP2-DC6V SP4-DC6V 6 4.2 0.6 50.0 120 0.2 300 9

SP2-DC12V SP4-DC12V 12 8.4 1.2 25.0 480 0.7 300 18

SP2-DC24V SP4-DC24V 24 16.8 2.4 12.5 1,920 3.0 300 36

SP2-DC48V SP4-DC48V 48 33.6 4.8 6.2 7,700 11.2 300 72

2-coil latching

Part No. Nominal

voltage,

2 Form C 4 Form C Coil I Coil II Coil I Coil II

V DC

Set and

reset

voltage,

V DC (max.)

Nominal

operating

current,

mA

SP2-L2-DC3V SP4-L2-DC3V 3 2.1 100.0 30 30

SP2-L2-DC5V SP4-L2-DC5V 5 3.5 60.2 83 83 0.07 0.07 300 7.5

SP2-L2-DC6V SP4-L2-DC6V 6 4.2 50.0 120 120 0.1 0.1 300 9

SP2-L2-DC12V SP4-L2-DC12V

SP2-L2-DC24V SP4-L2-DC24V

SP2-L2-DC48V SP4-L2-DC48V

12 8.4 25.0 480 480 0.4 0.4 300 18

24 16.8 12.5 1,920 1,920 1.4 1.4 300 36

48 33.6 6.2 7,680 7,680 5.6 5.6 300 72

Coil resistance,

10%)

H (at 120 Hz)

Approx.

Inductance,

0.03

Approx.

Nominal

operating

power, mW

0.03 300 4.5

DIMENSIONS

2 Form C

Plug-in terminal

1

.039

50

1.969

0.5

.020

Schematic (Bottom view)

Single side stable

Maximum

allowable

voltage,

V DC (40 ° C)

Maximum

allowable

voltage,

V DC (40

mm inch

SP

C)

4 Form C

Plug-in terminal

10

.394

25.6

1.008

15.24

.600

(Deenergized condition)

2 coil latching

20.5

.807

1.5

.059

7.15

.281

(Reset condition)

4.75

.187

10.16

.400

10.16

.400

10.16

.400

10.16

.400

FASTON #187

Diagram shows the "reset" position when terminals 3 and 4 are

energized. Energize terminals 1 and 2 to transfer contacts.

General tolerance: ± 0.3 ± .012

Schematic (Bottom view)

Single side stable

.039

.394

1

10

50

1.969

36.8

1.449

0.5

.020

15.24

.600

7.62

.300

7.62

.300

(Deenergized condition)

2 coil latching

20.5

.807

1.5

.059

7.15

.281

10.16

10.16

10.16

.400

.400

4.75

.187

.400

10.16

.400

General tolerance: ± 0.3 ± .012

(Reset condition)

Diagram shows the "reset" position when terminals 3 and 4 are

energized. Energize terminals 1 and 2 to transfer contacts.

253

Page 3

SP

REFERENCE DATA

Operate and release time (Single side stable)

SP2 SP4

50

40

30

20

Operate/release time, ms

10

0

Operate time

Release time

80 90 110

Coil applied voltage,%V

100

Max.

Min.

Max.

Min.

50

40

30

20

Operate/release time, ms

10

0

80 90 110

Coil applied voltage,%V

Operate time

Release time

100

Max.

Min.

Max.

Min.

Coil temperature rise

Sample: SP2-DC24V

Ambient temperture: 20 to 22 ° C 68 to 72 ° F

50

40

30

20

Temperature rise, °C

10

0

19.2 21.6 26.4 28.8 31.2 33.6 36.024.0

Coil applied voltage,%V

15 A

10 A

5 A

0 A

Sample: SP4-DC24V

Ambient temperature: 27 to 29 ° C 81 to 84 ° F

50

40

10 A

30

5 A

20

Temperature rise, °C

10

0

19.2 21.6 26.4 28.8 31.2 33.6 36.024.0

Coil applied voltage,%V

0 A

Electrical life (SP4, 10 A 250 V AC resistive

load)

15

10

Pick-up/drop-out voltage, V

5

0

Pick-up voltage

Drop-out voltage

12345678910

No. of operations, ×10

Max.

x

Min.

Max.

x

Min.

4

Electrical life (SP2, 15 A 250 V AC resistive

load)

15

10

Pick-up/drop-out voltage, V

5

0

50

40

30

20

Contact resistance, mΩ

10

0

Pick-up voltage

Drop-out voltage

12345678910

No. of operations, ×10

12345678910

No. of operations, ×10

4

N.C.

N.O.

4

Max.

x

Min.

Max.

x

Min.

Max.

x

Min.

15

10

Contact resistance, mΩ

5

0

12345678910

No. of operations, ×10

N.C.

N.O.

4

Max.

x

Max.

x

Min.

Min.

254

Page 4

ACCESSORIES

Soldering socket

SP2-SS SP4-SS

38±0.6

1.496±.024

35±0.6

1.378±.024

7.5±0.3

.295±.012

MADE IN JAPAN

20.32±0.4

.800±.016

40.64±0.4

1.600±.016

56±1

2.205±.039

R2.25

R.089

4.5±0.3

.177±.012

15.24±0.4

.600±.016

48±1

1.890±.039

5±0.3

.197±.012

23±1

.906±.039

7.7±0.3

.303±.012

12±0.3

.472±.012

24.5±0.4

.965±.016

4.5±0.3

.177±.012

48±0.6

1.890±.024

7.5±0.3

.295±.012

MADE IN JAPAN

20.32±0.4

.800±.016

40.64±0.4

1.600±.016

56±1

2.205±.039

R2.25

R.089

30.48±0.4

1.200±.016

15.24±0.4

.600±.016

60±1

2.362±.039

5±0.3

.197±.012

23±1

.906±.039

.472±.012

.303±.012

12±0.3

1.496±.024

7.7±0.3

mm inch

38±0.6

SP

52.8±0.6

2.079±.024

Wrapping socket

SP2-WS SP4-WS

38±0.6

1.496±.024

35±0.6

1.378±.024

7.5±0.3

.295±.012

MADE IN JAPAN

20.32±0.4

.800±.016

40.64±0.4

1.600±.016

56±1

2.205±.039

52.8±0.6

2.079±.024

R2.25

R.089

4.5±0.3

.177±.012

15.24±0.4

.600±.016

48±1

1.890±.039

l1.5

l.059

5±0.3

.197±.012

23±1

.906±.039

12±0.3

.472±.012

.965±.016

25±0.4

.984±.016

24.5±0.4

4.5±0.3

.177±.012

48±0.6

1.890±.024

7.5±0.3

.295±.012

52.8±0.6

2.079±.024

MADE IN JAPAN

20.32±0.4

.800±.016

40.64±0.4

1.600±.016

56±1

2.205±.039

52.8±0.6

2.079±.024

R2.25

R.089

30.48±0.4

1.200±.016

15.24±0.4

.600±.016

60±1

2.362±.039

l1.5

l.059

5±0.3

.197±.012

23±1

.906±.039

12±0.3

.472±.012

1.496±.024

25±0.4

.984±.016

38±0.6

Mounting hole drilling diagram

2-DIA. HOLES 5.0±0.1

2-DIA. HOLES .197±.004

25.2±0.2

.992±.008

38±0.2

1.496±.008

35±0.2

1.378±.008

53.7±0.2

2.114±.008

Notes:

(1) Mounting screws and the fastening

bracket are included in the package.

(2) Mount the relay with the proper mounting direction — i.e. with the direction of the

NAIS mark on top of the relay case match-

Performance profile

53.7±0.2

2.114±.008

Withstand voltage

38.9±0.2

1.531±.008

48±0.2

1.890±.008

Insulation

resistance

Ambient working

temperature

2-DIA. HOLES 5.0±0.1

2-DIA. HOLES .197±.004

Maximum current,

ON current

Note: Do not remove the relay while it is ON.

ing the direction of the NAIS mark on the

terminal block. (The

;

direction of the

terminal block is the upward direction of

the relay.)

Item

SP2, socket

with solder

SP4, socket

with solder

SP2, wrapping socket

AC 3,000V, 1 min., between each terminal

1,000 M Ω min

–50 to +60 ° C –58 to +140 °F

15 A 10 A 12 A 10 A

SP4, wrap-

ping socket

255

Page 5

SP

BC

Minus screwdriver

A

Fastening

bracket

SP relay

Terminal block

BC

Minus screwdriver

A

Fastening

bracket

SP relay

Terminal block

Mounting and removal of fastening bracket

1. Mounting

Insert the A part of the fastening bracket

into the mounting groove of the socket,

and then fit the B part into groove, while

pressing with the tip of a minus screwdriver.

2. Removal

Slide the B part of the fastening bracket

from the groove in the sock et, while pressing with the tip of a minus screwdriver.

While the bracket is in this position, keep

pressing the C part of the bracket to the

relay side with your finger, and lift up to

the left side and remove from the groov e ,

as in the diagram at right.

Screw terminal socket

67±1

2.638±.039

40.64±0.4

1.600±.016

20.32±0.4

.800±.016

52±1

2.047±.039

15.24±0.4

.600±.016

.906±.039

23±1

19.5±0.6

.768±.024

Mounting hole drilling diagram

30±0.2

1.181±.008

2-DIA. HOLES 4.5±0.1

2-DIA. HOLES .177±.004

Notes:

(1) Mounting screws and the fastening

bracket are included in the package.

(2) Mount the relay with the proper mounting direction — i.e. with the direction of the

NAIS mark on top of the relay case matching the direction of the NAIS mark on the

terminal block. (The

; direction of the

terminal block is the upward direction of

the relay.)

11±0.4

.433±.016

40.64±0.4

1.600±.016

20.32±0.4

.800±.016

52±1

2.047±.039

4.5±0.4

.177±.016

6.5±0.4

.256±.016

30±0.6

1.181±.024

97±1

3.819±.039

Fastening bracket mounting and

removal

1. Mounting

Insert the A part of the fastening bracket

into the mounting groove of the terminal

block, and then fit the B part into groove,

while pressing with the tip of a minus

screwdriver.

2. Removal

Slide the B part of the fastening bracket

from the groove in the terminal block,

while pressing with the tip of a minus

screwdriver. While the bracket is in this

position, keep pressing the C part of the

bracket to the relay side with your finger,

32±0.6

1.260±.024

2.776±.039

30.48±0.4

1.200±.016

15.24±0.4

.600±.016

21±0.4

.827±.016

23±1

.906±.039

70.5±1

40.5±0.6

1.594±.024

19.5±0.6

.768±.024

6.5±0.3

.256±.012

and lift up to the left side and remove from

the groove, as in the diagram at right.

mm inch

30±0.6

1.181±.024

4.5±0.3

.177±.012

Mounting plate

18.4

.724

256

57.2

2.252

25

.984

23.2

.913

18.4

.724

Panel cutout

2-DIA. HOLES 3.2

2-DIA. HOLES .126

Tolerance: ±0.1 ±.004

The SP-Relay with

SP-MA attached

SP-MA

Direct chassis mounting possible,

and applicable to DIN rail.

[DIN 46277 (35 mm width) is applicable.]

Page 6

Use method

1. Both the SP relay 2c and 4c can be

mounted to the mounting slats.

2. Use the mounting slats either b y attaching them directly to the chassis, or by

mounting with a DIN rail.

(A) When attaching directly to chassis

Use two M3 screws.

For the mounting pitch, refer to the specification diagram.

(B) When mounting on a DIN rail

Use a 35mm 1.378inch wide DIN rail

(DIN46277).

The mounting method should be as indicated in the diagram at right.

Method for mounting on DIN rail

Fig. 1

Press

Fit into mounting

grooves.

Fit in

Press relay in

Mounting

slat

DIN rail

Fig. 2

Fig. 3

To remove the

relay, press down

the mounting slats

so the claws move

to the outside.

(1) First fit the arc shaped claw of the

mounting slat into the DIN rail.

(2) Press on the side as shown in the diagram below.

(3) Fit in the claw part on the opposite

side.

Precautions for use

When mounting to a DIN rail, use a commercially available fastening bracket if

there is a need to stop sliding of the

mounting slat in the rail direction.

For Cautions for Use, see Relay Technical Information (Page 48 to 76).

SP

9/1/2000 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

257

Go To Online Catalog

Loading...

Loading...