Page 1

SCANPSC100F

Embedded Boundary Scan Controller

(IEEE 1149.1 Support)

General Description

The SCANPSC100F is designed to interface a generic parallel processor bus to a serial scan test bus. It is useful in improving scan throughput when applying serial vectors to system test circuitry and reduces the software overhead that is

associated with applying serial patterns with a parallel processor. The ’PSC100F operates by serializing data from the

parallel bus for shifting through the chain of 1149.1compliant

components (i.e., scan chain). Scan data returning from the

scan chain is placed on the parallel port to be read by the

host processor. Up to two scan chains can be directly controlled with the ’PSC100F via two independent TMS pins.

Scan control is supplied with user specific patterns which

makes the ’PSC100F protocol-independent. Overflow and

underflow conditions are prevented by stopping the test

clock.A32-bit counter is used to program the number of TCK

cycles required to complete a scan operation within the

boundary scan chain or to complete a ’PSC100F Built-In Self

Test (BIST) operation. SCANPSC100F device drivers and

1149.1 embedded test application code are available with

National’s SCANEase software tools.

Features

n Compatible with IEEE Std. 1149.1 (JTAG) Test Access

Port and Boundary Scan Architecture

n Supported by National’s SCAN Ease (Embedded

Application Software Enabler) Software

n Uses generic, asynchronous processor interface;

compatible with a wide range of processors and PCLK

frequencies

n Directly supports up to two 1149.1 scan chains

n 16-bit Serial Signature Compaction (SSC) at the Test

Data In (TDI) port

n Automatically produces pseudo-random patterns at the

Test Data Out (TDO) port

n Fabricated on FACT

™

1.5 µm CMOS process

n Supports 1149.1 test clock (TCK) frequencies up to

25 MHz

n TTL-compatible inputs; full-swing CMOS outputs with

24 mA source/sink capability

n Standard Microcircuit Drawing (SMD) 5962-9475001

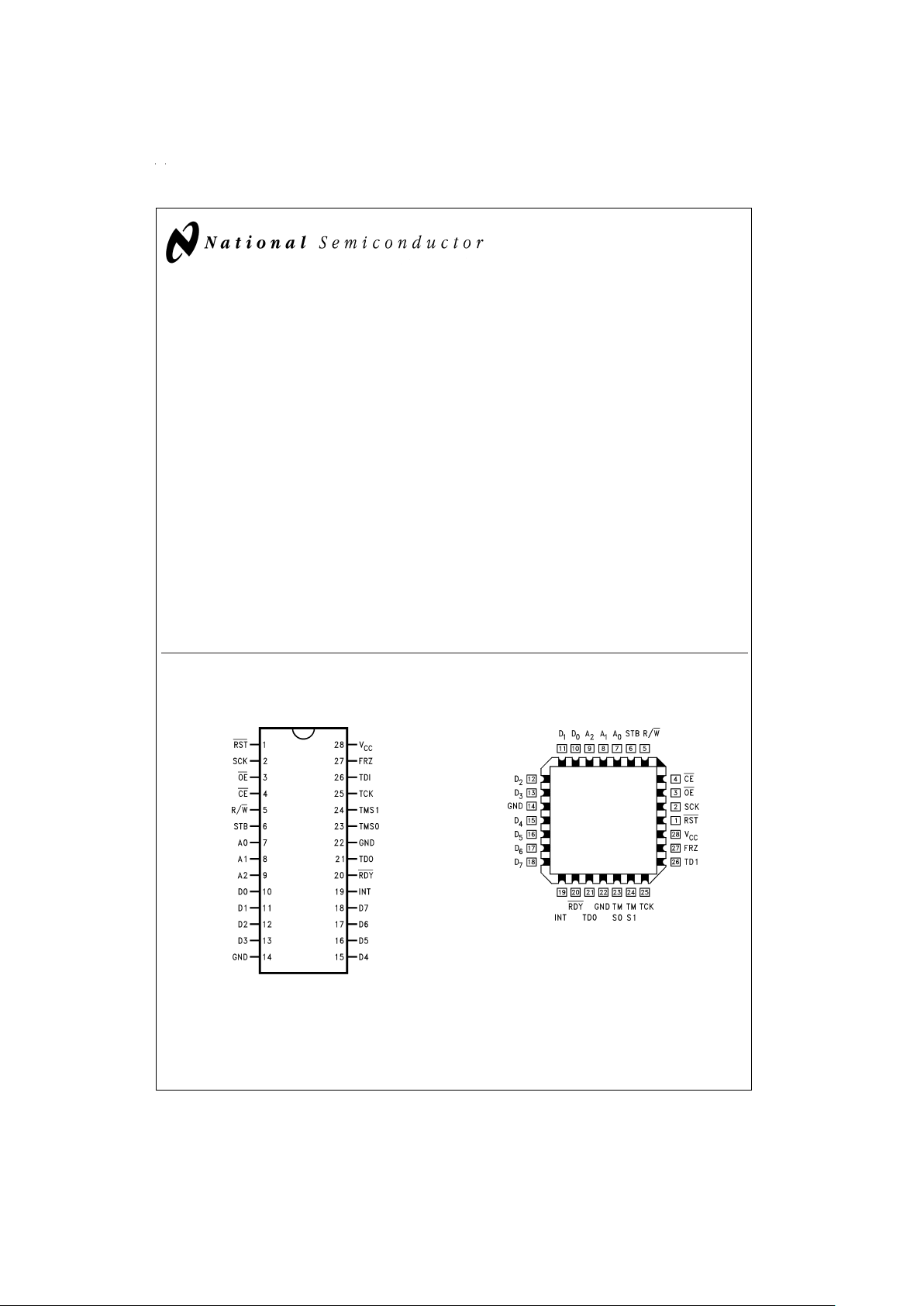

Connection Diagrams

FACT™is a trademark of Fairchild Semiconductor Corporation.

TRI-STATE

®

is a registered trademark of National Semiconductor Corporation.

28-Pin DIP and Flatpak

DS100325-1

Pin Assignment for LCC

DS100325-18

September 1998

SCANPSC100F Embedded Boundary Scan Controller (IEEE 1149.1 Support)

© 1999 National Semiconductor Corporation DS100325 www.national.com

Page 2

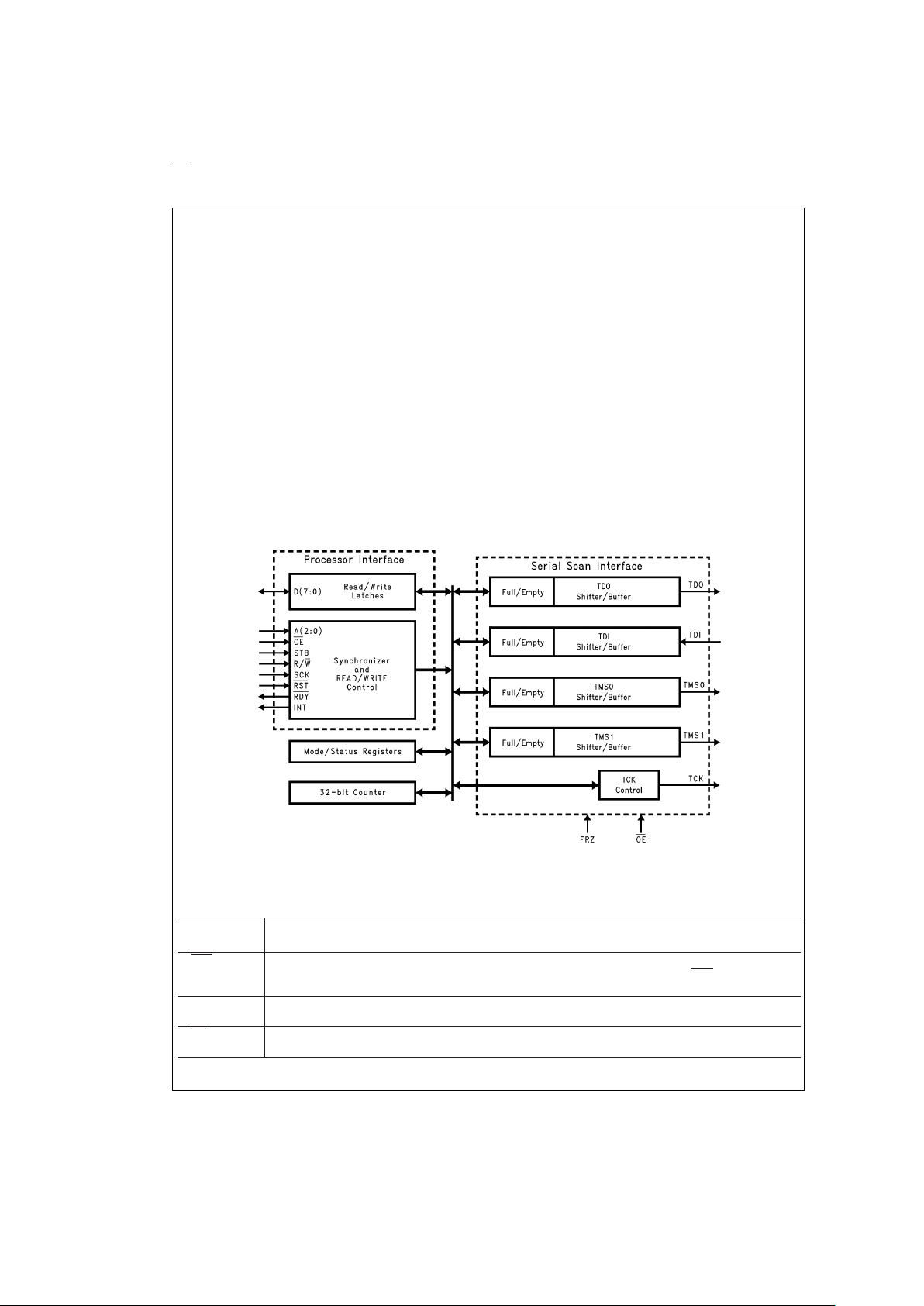

Chip Architecture

The ’PSC100 is designed to act together with a parallel bus

host as a serial test bus master. Parallel data is written by the

host to the ’PSC100, which serializes the data for application

to a serial test bus. Serial data returningfrom thetarget scan

chain(s) is placed on the processor port for parallel reads.

Several features are included in the ’PSC100 which make

scan test communication more convenient and efficient.

Figure 1

shows the major functional blocks of the ’PSC100

design. The Parallel Processor Interface (PPI) is an asynchronous, 8-bit parallel interface which is used by the host

processor to write and read data. The PPI generates the

necessary internal data, address, and control signals to

complete internal write and read operations.

The Serial Scan Interface (SSI) consists of a bank of

double-buffered parallel/serial shift registers (i.e.,a2x8bit

FIFO), or Shifter/Buffers. The double buffering improves efficiency by allowing parallel writes or reads to/from one of the

two 8-bit FIFOs within the shifter/buffer while the other FIFO

is shifting data to/from the scan chain. Three Shifter/Buffers

are provided for outgoing serial data and one for incoming

serial data. TestData Out (TDO) is for scanning out test data

while the two TestMode Select signals (TMS0/1) are used to

provide user specific control data. Test Data In (TDI) receives serial data from the scan chain. A local control block

is associated with each Shifter/Buffer to provide shift and

load control as well as providing full or empty status. The SSI

also provides Test Clock (TCK) Control. TCK is stopped and

started depending on the status of the Shifter/Buffers or the

32-bit Counter. By stopping and starting TCK, scan operations will proceed only when the enabled Shifter/Buffers are

ready to send and/or receive serial data.

The 32-bit Counter (CNT32) is a count-down binary counter

included to assist in controlling the SSI. The initial state of

CNT32 is loaded from the parallel port with four consecutive

writes to its address. When enabled, CNT32 is used to program the number of TCKs applied by the SSI to the boundary scan chain(s). The value of CNT32 can also be used to

generate interrupts (i.e., when CNT32 reaches terminal

count) and to trigger ’PSC100 features, such as, Auto TMS

High (discussed later within this datasheet).

The Mode and Status Registers are used to control and observe the operation of the SSI and CNT32. Each of the

Shifter/Buffers and CNT32 have an associated mode bit

which enables it for participation in on-going operations. Status bits can be used for polling operations.

Pin Descriptions

Pin Description

Name

RST (Input)

The Reset pin is an asynchronous input that, when low, initializes the ’PSC100. Mode bits, Shifter/Buffer

and CNT32 control logic, TCK Control, and the PPI are all initialized to defined states. RST has hysteresis

for improved noise immunity.

SCK (Input) The System Clock drives all internal timing. The test clock, TCK, is a gated and buffered version of SCK.

SCK has hysteresis for improved immunity.

OE (Input)

Output Enable TRI-STATEs all SSI outputs when high. A 20 kΩ pull-up resistor is connected to

automatically TRI-STATE

®

these outputs when this signal is floating.

DS100325-2

FIGURE 1. ’PSC100 Block Diagram

www.national.com 2

Page 3

Pin Descriptions (Continued)

Pin Description

Name

CE (Input)

Chip Enable, when low, enables the PPI for byte transfers. D(7:0) and RDY are TRI-STATEd if CE is high.

CE has hysteresis for improved noise immunity.

R/W (Input) Read/Write defines a PPI cycle —Read when high, Write when low. R/ W has hysteresis for improved

noise immunity.

STB (Input) Strobe is used for timing all PPI byte transfers. D(7:0) are TRI-STATEd when STB is high. All other PPI

inputs must meet specified setup and hold times with respect to this signal. STB has hysteresis for

improved noise immunity.

A(2:0) The Address pins are used to select the register to be written to or read from.

(Input)

D(7:0) (I/O) Bidirectional pins used to transfer parallel data to and from the ’PSC100.

INT Interrupt is used to trigger a host interrupt for any of the defined interrupt events. INT is active high.

(Output)

RDY

Ready is used to synchronize asynchronous byte transfers between the host and the ’PSC100. When low,

(TRI-STATE RDY signals that the addressed register is ready to be accessed RDY is enabled when CE is low.

Output)

TDO Test Data Out is the serial scan output from the ’PSC100. TDO is enabled when OE is low.

(TRI-STATE

Output)

TMS(1:0) The Test Mode Select pins are serial outputs used to supply control logic to the UUT. TMS(1:0) are

(TRI-STATE enabled when OE is low.

Output)

TCK The Test Clock output is a buffered version of SCK for distribution in the UUT. TCK Control logic starts

(TRI-STATE and stops TCK to prevent overflow and underflow conditions. TCK is enabled when OE is low.

Output)

TDI (Input) Test Data In is the serial scan input to the ’PSC100. A 20 kΩ pull-up resistor is connected to force TDI to

a logic 1 when the TDO line from the UUT is floating.

FRZ (Input) The Freeze pin is used to asynchronously generate a user-specific pulse on TCK. If the FRZ Enable Mode

bit is set, TCK will be forced high if FRZ goes high. FRZ has hysteresis for improved noise immunity.

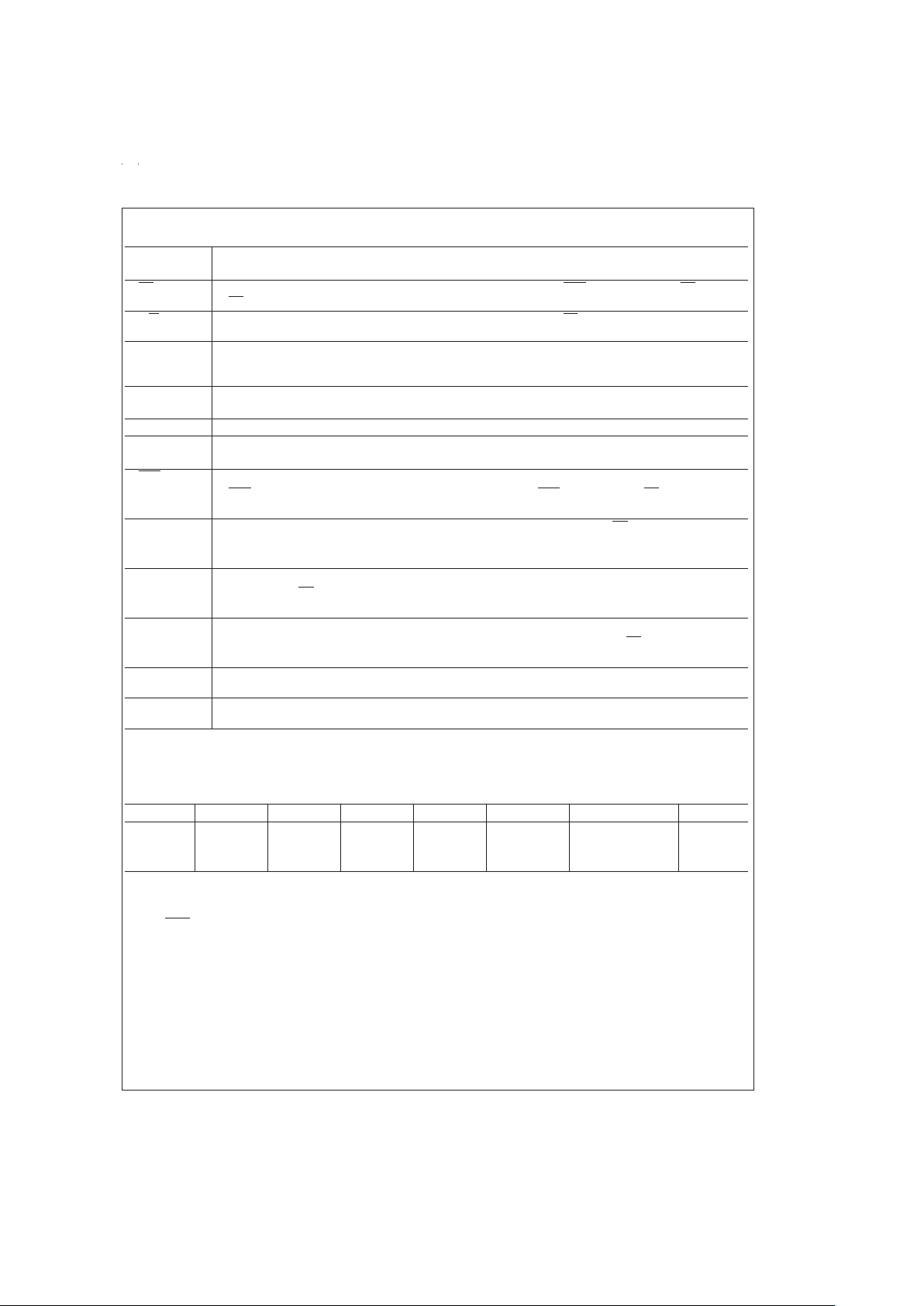

Mode and Status Registers

MODE REGISTER 0 (MODE0)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

TDO TDI CNT32 TMS0 TMS1 Auto TMS High Loop-

Enable Enable Enable Enable Enable Reserved Enable Around

Enable

This register is purely a mode register. All bits are writeable

and readable. The value 00100000 is placed in this register

upon RST low or a synchronous reset operation.

•

Bit 7: This bit enables the TDO shifter/buffer for shift op-

erations. If this bit is set, the TDO shifter/buffer will

cause TCK to stop if it is empty.

•

Bit 6: This bit enables the TDI shifter/buffer for shift op-

erations. If this bit is set, the TDI shifter/buffer will

cause TCK to stop if it is full.

•

Bit 5: This bit enables the 32-bit counter. If this bit is set,

the counter will cause TCK to stop if if has not been

loaded or if it has reached terminal count.

•

Bit 4: This bit enables the TMS0 shifter/bufferfor shift op-

erations. If this bit is set, the TMS0 shifter/bufferwill

cause TCK to stop if it is empty.

•

Bit 3: This bit enables the TMS1 shifter/bufferfor shift op-

erations. If this bit is set, the TMS1 shifter/bufferwill

cause TCK to stop if it is empty.

•

Bit 2: This bit is reserved and should remain as a logic 0

during all ’PSC100 operations.

•

Bit 1: If this bit is set, TMS will be forced high when the

32-bit counter is at state (00000001)h.

•

Bit 0: This bit causes TDI to be connected directly back

through TDO for Loop-Around operations.

www.national.com3

Page 4

Mode and Status Registers (Continued)

MODE REGISTER 1 (MODE1)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

TDO TDI CNT32 PRPG SSC Freeze Test Test

Interrupt Interrrupt Interrupt Enable Enable Pin Loop- Loop-

Enable Enable Enable Enable Back Back

This register is purely a mode register. All bits are writeable

and readable. The value 00000000 is placed in this register

upon RST low or a synchronous reset operation.

•

Bit 7: If this bit is set and the TDO shifter/buffer is

not full (i.e., one or both 8-bit TDO FIFOs

are empty), the INT pin will go high.

•

Bit 6: If this bit is set and the TDI shifter/buffer is

not empty (i.e., one or both 8-bit TDI FIFOs

are full), the INT pin will go high.

•

Bit 5: If this bit is set, and the 32-bit counter is not

loaded or has reached terminal count, the

INT pin will go high.

•

Bit 4: This bit signifies that the TD0 shifter/buffer

is reconfigured as a 32-Bit Pseudo Random

Pattern Generator. If set, and MODE0 Bit 7

is set, the TDO shifter/buffer will stop TCK

until a seed value has been written to all

four of the 8-bit LFSR segments.

•

Bit 3: This bit signifies that the TD1 shifter/buffer

is reconfigured as a 16-Bit Serial Signature

Compactor. If set, and MODE0 Bit 6 is set,

the TDI shifter/buffer will cause TCK to stop

until a seed value has been written to the

two TDI registers.

•

Bit 2: If this bit is set, a high value on FRZ will

force TCK high (see TCK Control Section).

•

Bits 1 and 0: These bits are used to control

Test Loop-Back operations according to the

following table.

MODE1 MODE1 Function

Bit 1 Bit 0

0 0 Normal Operation

0 1 Loop-Back TDO to TDI

1 0 Loop-Back TMS0 to TDI

1 1 Loop Back TMS1 to TDI

MODE REGISTER 2 (MODE2)

Write:

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Not Not Not Not Continuous Update Single

Used Used Used Used Update Status Reset Step

CNT32

Read:

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

TDO TDI CNT32 TMS0 TMS1 Continuous Single

Status Status Status Status Status Update Reset Step

CNT32

This register contains both mode and status bits. Bits 4–7

are status bits only. Bit 3 is a status bit during read operations and a mode bit during write operations. Bits 0–2 are

mode bits only. Upon RST low, or a synchronous reset, the

value placed in MODE2 is 10111000 (Read mode). Latches

used to update status bits 3–7 retain their last state upon

RST and are in an “unknown” state after power-up. Toinitialize the latches to a known state, they need to be updated using the Update Status bit (bit 2) or continuous update bit (bit

3).

•

Bit 7: Set high if theTDO shifter/buffer is not full, i.e., one

or both 8-bit TDO FIFOs are ready to be written to.

•

Bit 6: Set high if the TDI shifter/buffer is not empty, i.e.,

one or both 8-bit TDI FIFOs are ready to be read

from.

•

Bit 5: Set high if the 32-bit counter has not been loaded,

or has reached terminal count.

•

Bit 4: Set high if the TMS0 shifter/buffer is not full, i.e.,

one or both 8-bit TMS0 FIFOs are ready to be written to.

•

Bit 3 (Read Cycle):

Set high if the TMS1 shifter/buffer is not full, i.e.,

one or both 8-bit TMS1 FIFOs are ready to be written to.

•

Bit 3 (Write Cycle):

If set, will cause all status bits to be continuously

updated.

•

Bit 2 (Read Cycle):

Shows the state of the Continuous Update bit during read operations (Bit 3 during writes).

www.national.com 4

Page 5

Mode and Status Registers (Continued)

•

Bit 2 (Write Cycle):

If set, will cause a pulse to be issued internally that

will update all status bits. This bit will be reset upon

completion of the pulse. The state of this bit is not

readable. It is reset upon RST low.

•

Bit 1: If set, will cause a synchronous reset of all func-

tions except the parallel interface. The value of this

bit will return to zero when the reset operation is

complete.

•

Bit 0: If set, will cause the 32-bit counter to count for one

SCK cycle (no TCK cycle will be generated). The

value of this bit will return to zero when the single

step operation is complete.

PROGRAMMING RESTRICTIONS

Because certain mode bits enable shift operations for certain

functions, these mode bits should

not

be changed when shift

operations are in progress. The alignment of all registers

during shift operations is controlled by a 3-bit counter in the

TCK control block. Enabling or disabling a function in the

middle of a shift operation may disrupt the logicnecessary to

keep all shifter/buffers byte-aligned.

For example, if the TDO shifter/buffer (already loaded) is enabled while the 3-bit counter value is 3, the shifter/buffer will

only shift out only five bits of the first byte loaded.

The following bits should not be changed when shift operations are in progress, i.e., when TCK is enabled (see section

on TCK Control).

•

MODE0(7:3)

•

MODE1(4:3)

•

MODE2(0)

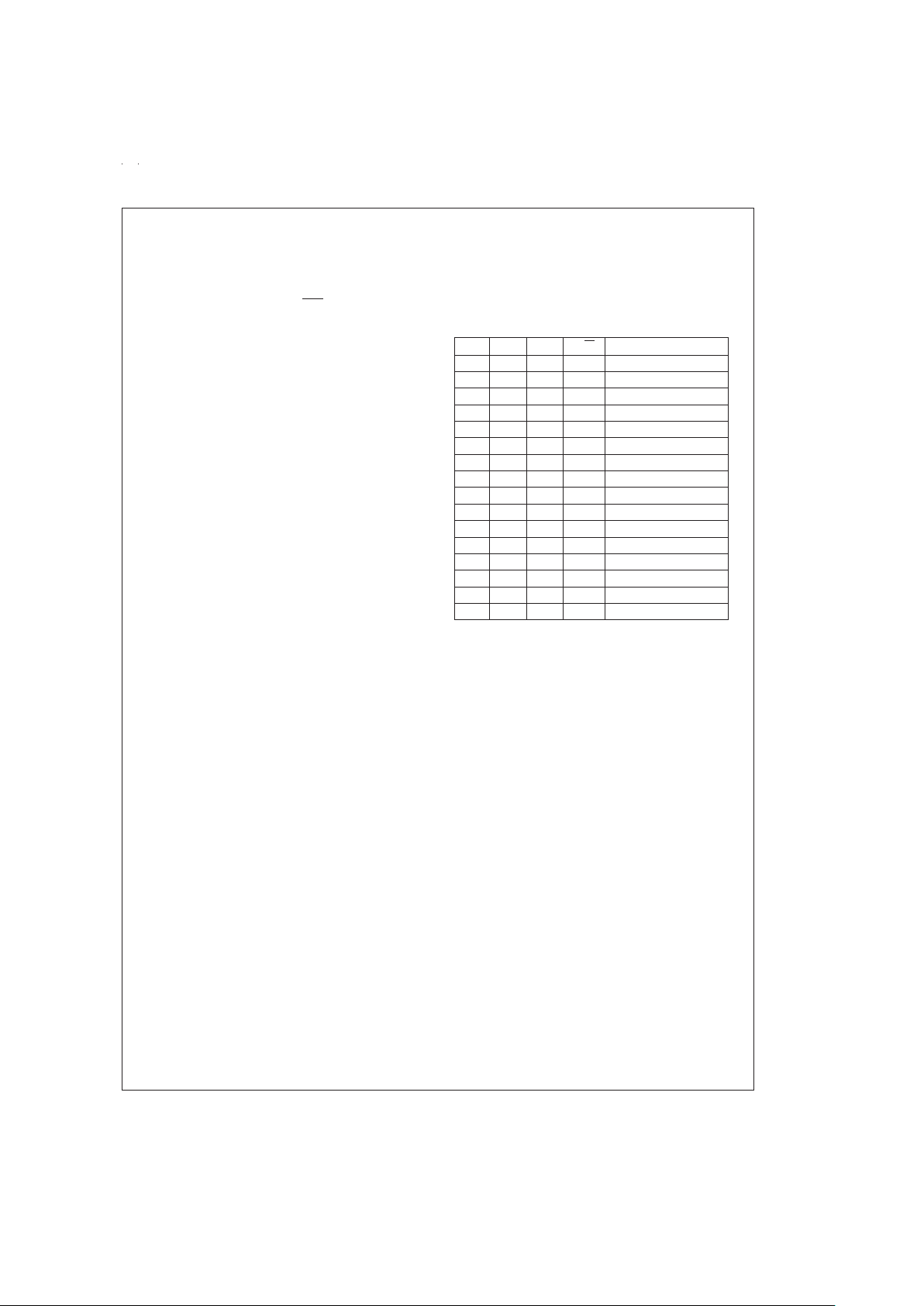

Parallel Processor Interface (PPI)

ADDRESS ASSIGNMENT

The following table defines which register is selected for access with the address lines, A(2:0).

A2 A1 A0 R/W Function

0 0 0 0 TDO Shifter/Buffer

0 0 0 1 Counter Register 1

0 0 1 0 TDI Shifter/Buffer

0 0 1 1 TDI Shifter/Buffer

0 1 0 0 TMS0 Shifter/Buffer

0 1 0 1 Counter Register 2

0 1 1 0 TMS1 Shifter/Buffer

0 1 1 1 Counter Register 3

1 0 0 0 32-Bit Counter

1 0 0 1 Counter Register 0

1 0 1 0 MODE0

1 0 1 1 MODE0

1 1 0 0 MODE1

1 1 0 1 MODE1

1 1 1 0 MODE2

1 1 1 1 MODE2

www.national.com5

Page 6

Parallel Processor Interface (PPI) (Continued)

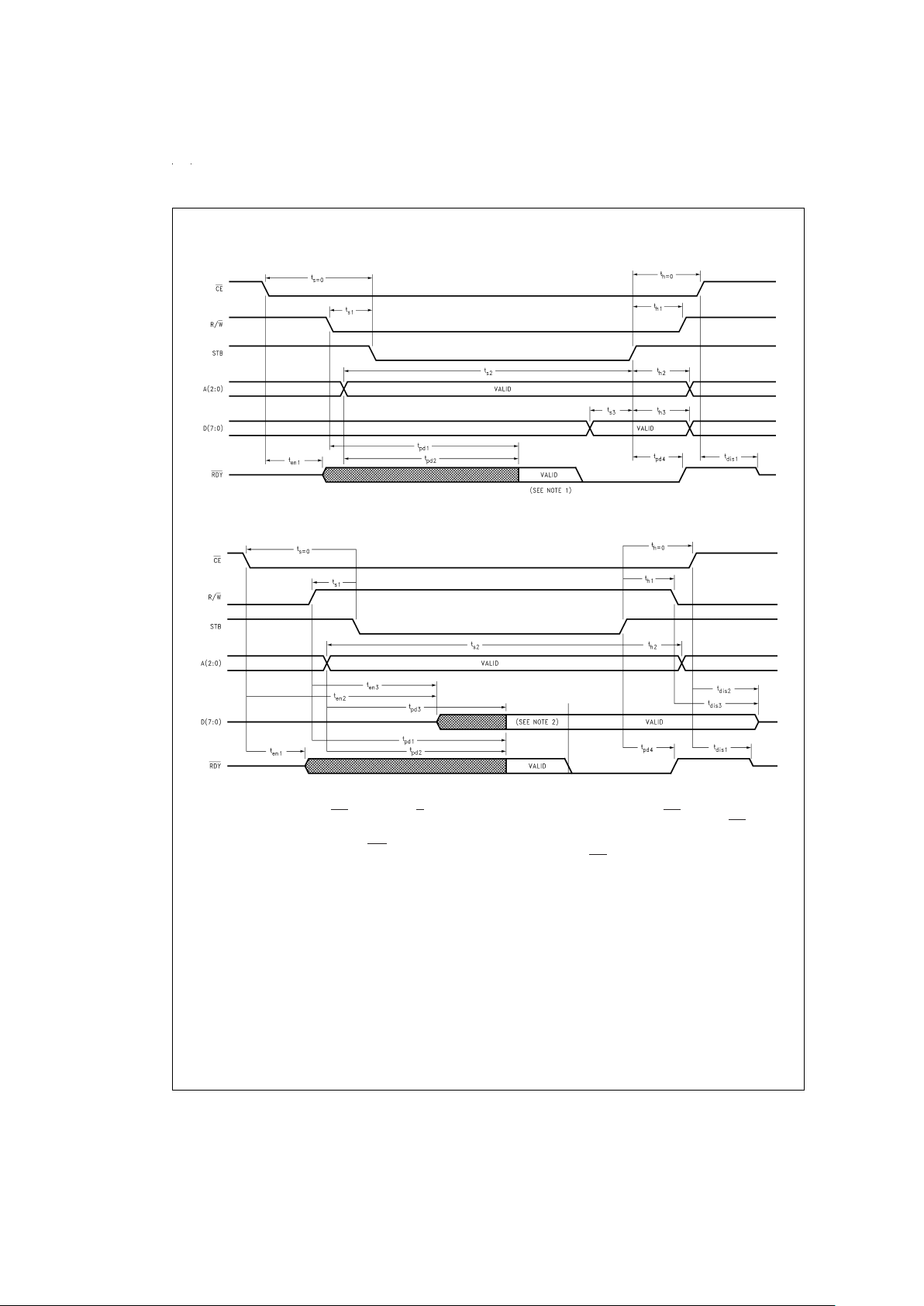

TIMING WAVEFORMS

Note 1: Valid data is provided on the RDY line a t

pd1

after R/W is asserted low or a t

pd2

after valid data is decoded on A2:0. The RDY line will remain high until the

addressed register is ready to participate in the write operation. This condition only applies when writing to a shifter/buffer and is eliminated (i.e., RDY will go low

immediately once valid) when using shifter/buffer status polling (discussed later in this datasheet).

Note 2: Validdata will not appear on D7:0 (and RDY will remain high) until the addressed register is ready to participate in the read operation. When the addressed

register becomes ready (i.e., a byte is available to be read), valid data will be placed on the D7:0 bus and the RDY pin will go low allowing the bus cycle to continue.

This read cycle delay only applies when reading the TDI shifter/buffer and is eliminated when using shifter/buffer status poling.

DS100325-3

FIGURE 2. Write Cycle

DS100325-4

FIGURE 3. Read Cycle

www.national.com 6

Page 7

Parallel Processor Interface (PPI) (Continued)

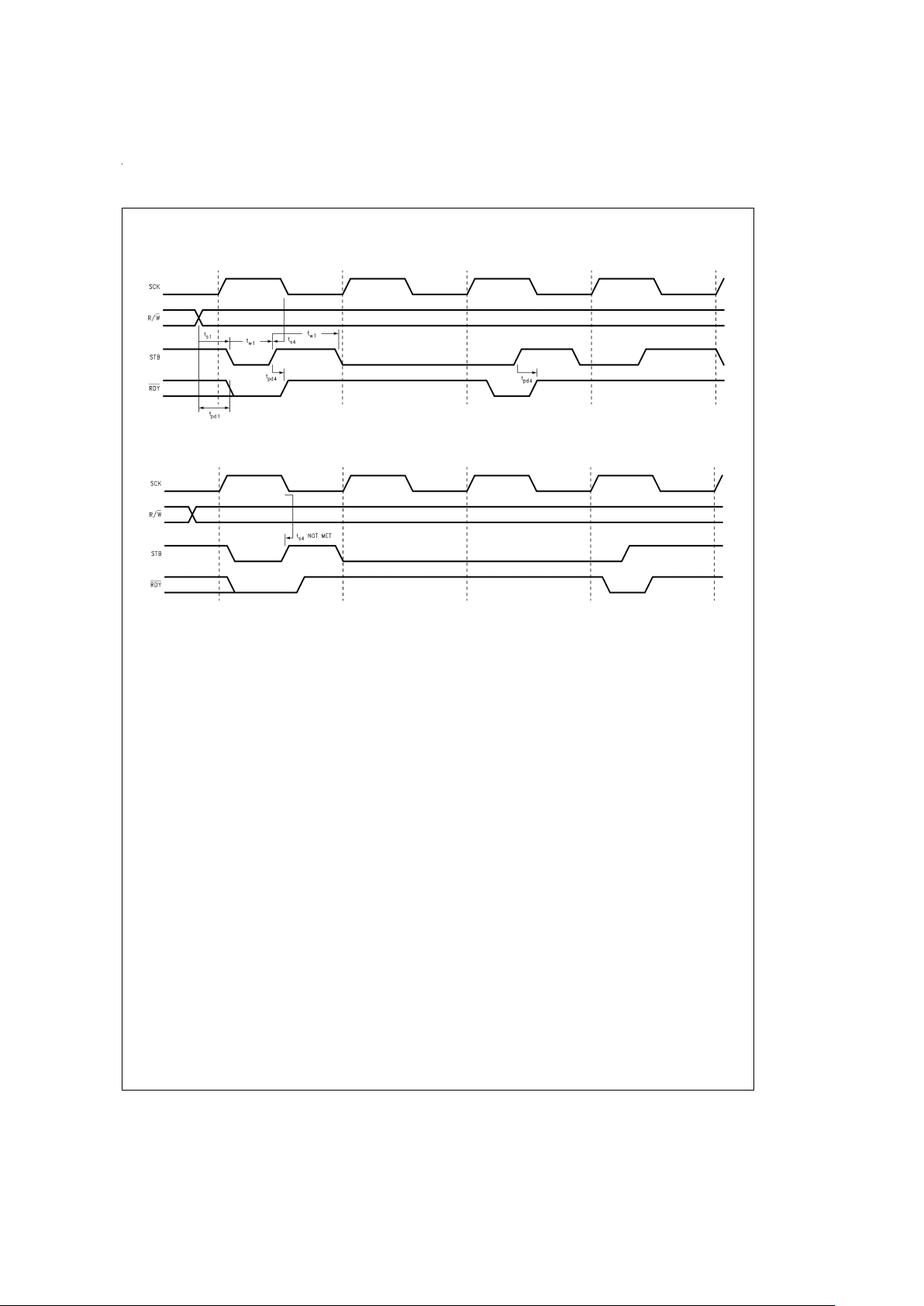

TIMING WAVEFORMS (Continued)

Note 3:

Figures 4, 5:Figure 4

shows the best case bus cycle timing for SCK and STB during consecutive read or write cycles. The rising edge of strobe occurs a

setup time, t

s4

or before the falling edge of SCK. This allows the cycle to be completed within 1.5 clock SCK clock cycles.

Figure 5

shows the worst case bus cycle

timing for SCK and STB during consecutive read or write cycles. The rising edge of strobe does not meet the t

s4

requirement between STB and SCK. Therefore,

the propagation of the internal PSC100 control and reset signals is delayed until the next falling edge of SCK. The bus cycle is then completed 1.5 SCK cycles later

creating a total bus cycle time of 2.5 SCK cycles. If worst case timing is considered for bus cycle timing, t

s4

is not a mandatory timing specification.

DS100325-5

FIGURE 4. Consecutive Read/Writes (best case timing)

DS100325-6

FIGURE 5. Consecutive Read/Writes (worst case timing)

www.national.com7

Page 8

Parallel Processor Interface (PPI) (Continued)

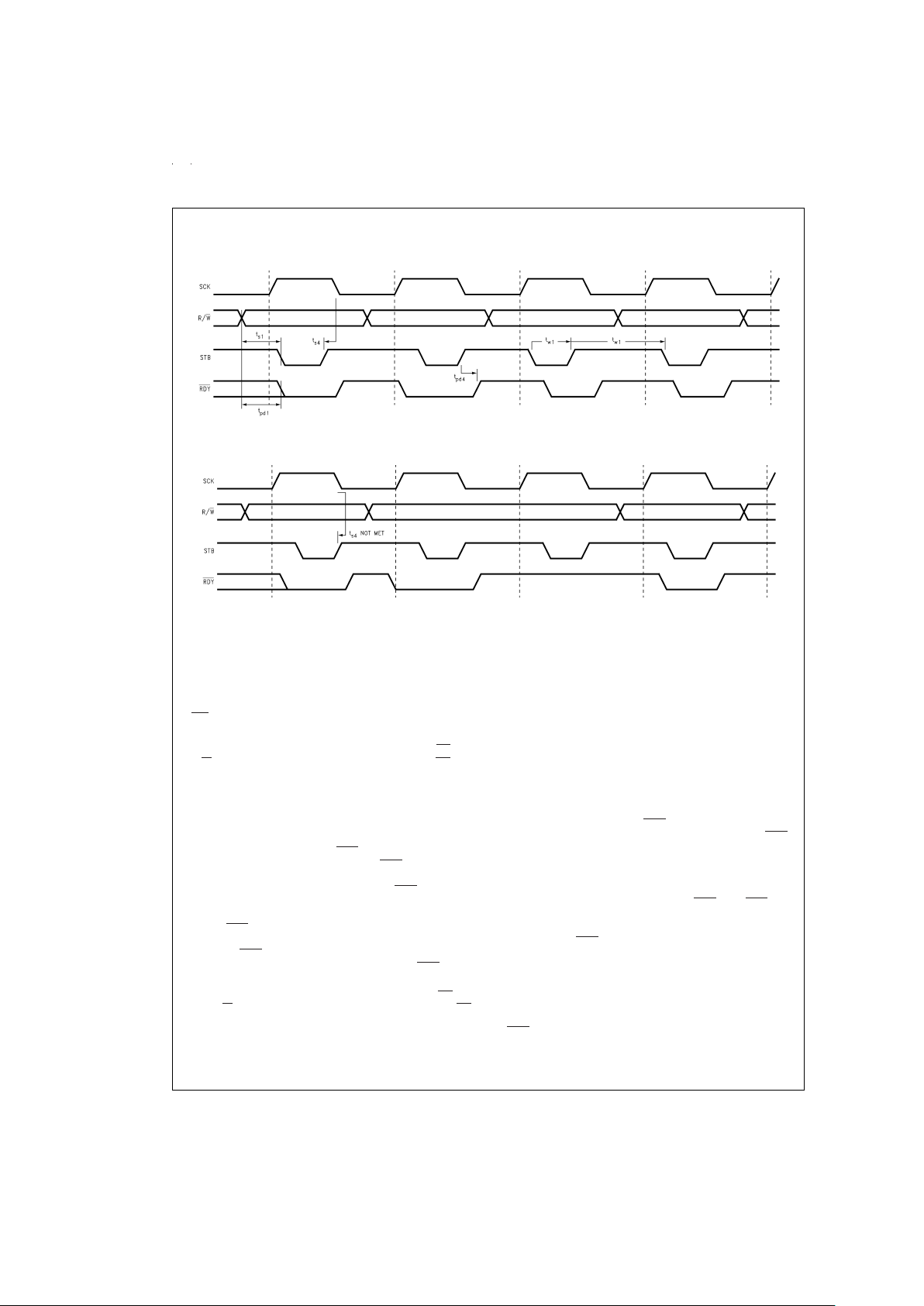

TIMING WAVEFORMS (Continued)

Note 4:

Figures 6, 7

: This diagram shows the timing for a read followed by a write (or write followed by a read). Separate Read and Write data/address latches and

control logic allow consecutive read/write or write/read operations to be overlapped (i.e., do not need to wait 2 or 3 SCK cycles between bus cycles). For the best

case timing scenario (

Figure 6

: rising edge of STB to falling edge of SCK greater than ts4), a new bus cycle can be performed each SCK cycle. For the worst timing

scenario (

Figure 7

: rising edge of STB to falling edge of SCK is less than ts4), a one SCK cycle delay must be included after each back to back read/write or write/

read sequence.

Note 5:

Figures 4, 5, 6, 7

assume that the PSC100 register participating in the bus cycle is ready to accept/provide data. For bus cycles involving a PSC100 shifter/

buffer(s), the ready status of a shifter/buffer can be checked using the status bits in Mode Register 2 prior to the start of the bus cycle. Polling is required when the

RDY pin is not used to provide a processor “handshake”.

READ AND WRITE CYCLES

A Write cycle (see

Figure 2

) is initiated by asserting CE and

R/W low followed by a low on STB a set time later. CE and

STB are gated within the PSC100F and may be asserted

concurrently (i.e., zero setup and hold time). The address is

then asserted on A2:0 to indicate which internal address

within the PSC100F will be written to by the processor. An

address decoder within the PSC100F monitors the address

lines for a valid PSC100F register address. Once a valid address has been decoded, the RDY line becomes active (a

propagation delay time later). The active RDY line will go low

immediately if the addressed register is ready to accept data.

If the addressed register is not ready, the RDY pin will remain high preventing the processor from completing the bus

cycle. Once the register is ready to receive date (see

Table

2

), the RDY pin will go low and processor can resume the

write cycle. The processor then forces a high on STB (a wait

time after RDY goes low) which latches the address (A2:0)

and data (D7:0) completing the bus cycle. The RDY line is

forced high a propagation delay later.

A Read cycle (see

Figure 3

) is initiated by asserting CE low

and R/W high followed by a low on STB a set time later. CE

and STB are gated within the PSC100F and may be asserted concurrently (i.e., zero setup and hold time). The address bits (A2:0) are then asserted to indicate which internal

address within the PSC100F will be read by the processor.

An address decoder within the PSC100F monitors the ad-

dress lines for a valid PSC100F register address. Once a

valid address has been decoded and if the addressed

PSC100F register is ready to be read (see

Table 2

), valid

data is placed on the Data lines (D7:0) a propagation delay

later and the ready line isasserted low.If the addressed register is not ready (e.g., the TDI shifter/buffer is empty), the

ready line will remain high and hold the bus cycle until the

register contains valid data. RDY will then go low allowing

the read cycle to continue. With the high to low edge on RDY

line, the processor can successfully read the valid data.

However,the bus cycle is not completed within the PSC100F

until the rising edge on STB which resets the PSC100F read

logic (required prior to the start of the next read cycle).

Important note concerning the use of RDY : The RDY signal provides a useful “handshake” between the PSC100F

and the processor. However,care must betaken whenusing

the PSC100F RDY signal to prevent a large (or indefinite)

number of processor generated wait states. For example, if

the TDO shifter/buffer is not enabled for shift operations and

the processor writes to the TDO shifter/buffer address 3

times, the two registers which make up the TDO shifter/

buffer will accept the first two bytes of data, but since the

data is not shifting out, the 3rd byte will be held off by the

RDY signal indefinitely. An equally severe problem could result with a finite number of wait states if the application uses

DS100325-20

FIGURE 6. Read/Write or Write/Read (best case timing)

DS100325-7

FIGURE 7. Read/Write or Write/Read (worst case timing)

www.national.com 8

Page 9

Parallel Processor Interface (PPI)

(Continued)

dynamic memories. Holding the local bus with the PSC100F

RDY line long enough to violate a DRAM refresh time will result in lost data within the dynamic memory.

Writing and Reading without the use of RDY : With use of

worst case PSC100F timing, Write and Read cycles can be

successfully completed without the use of the RDY signal.All

read and write cycles will complete within 2.5 SCK cycles

(worst case). Therefore, by assuring at least 2.5 cycles occur

after the rising edge of STB, bus cycles can be completed

without using the RDY “handshake”. The critical timing relationship within the PSC100F for write and read operation is

between the rising edge of STB and the falling edge of SCK.

The rising edge of strobe latches the address/data and also

generates the internal signals required to complete read/

write within the PSC100F (including a signal with resets the

read/write logic and releases the RDY line). The propagation

of these internal signals is initiated on the first falling edge of

SCK after the STB pin is asserted high. If the rising edge on

STB occurs an internal setup time (t

s4

) or greater before the

falling edge of SCK, the bus cycle can be completed within

1.5 SCK cycles (see

Figure 4

). However, if the internal setup

time is not met, the propagation of internal control/reset signals is delayed until the next falling edge of SCK (1 SCK

cycle later) which effectively completes the read/write operation and reset the logic for the next bus cycle within 2.5

cycles (see

Figure 5

). Synchronizing the rising edge of STB

with the falling edge of SCK to assure that t

s4

is met provides

the maximum performance for a read/write operation. However,the asynchronous interface can be used effectively with

software delays, hardware delays or programmed wait

states (to assure 2.5 SCK cycles are completed) toavoid the

need for synchronization.

Consecutive Reads and Writes: Separate control logic and

data/address latches are used for a read and write operation

within the PSC100F.This allows a write to occur after a read

(or conversely, a read to occur after a write) prior to the 1.5/

2.5 SCK clock cycle requirements described above. The timing for a read (or write) followed bya write(or read)is shown

in

Figure 5

and

Figure 6

.

SYNCHRONIZATION

Writes and reads can be synchronized by using any of three

methods: polling, interrupts, or wait state generation:

•

Status bits may be polled to see if a register is ready to be

written to or read from. Tostabilize the status bits for read

operations, the Update Status bit must be set in MODE2

to latch the status.

Note: The status bits only provide the state of the shifter/buffers and do not

indicate that an internal write or read is complete. Therefore, for applications not using the RDY signal to monitor the internal write/read status, timing must be controlled to assure that at least 2.5 SCK cycles

are completed between consecutive read or consecutive write cycles.

•

Any of three different events can be used to generate interrupts by forcing the INT pin high, see

Table 1

.

•

The RDY pin can be used to hold offthe host untilthe addressed register is ready to be accessed. As described

above, this pin can also be used to hold off additional

reads/writes until the synchronizer has recovered from

the previous read/write. RDY=0 signifies that the

’PSC100F is ready to complete the current PPI cycle.

The logic that determines the state of RDY is summarized in

Table 2

.

Reading from CNT32 can be synchronized for testing by using the Single Step Counter mode bit.

TABLE 1. Interrupt Logic

MODE1(7)=1 and TDO MODE1(6)=1 and TDI MODE1(5)=1 and

Shifter/Buffer Not Full Shifter/Buffer Not Empty CNT32 Not Loaded, or at INT

Terminal Count

1XX1

X1X1

XX11

0000

Note 6: Interrupts are generated using the INT pin. Three events trigger INT high. Each event has its own mode bit associated with it for masking or enabling these

interrupts.

www.national.com9

Page 10

Parallel Processor Interface (PPI) (Continued)

TABLE 2. Ready State Logic

R/W

Write

Synchronizer

Busy

TDO TMS0 TMS1 Read

Synchronizer

Busy

TDI

RDY

Shifter/Buffer Shifter/Buffer Shifter/Buffer Shifter/Buffer

Full and Full and Full and Empty and

A(2:0)=0 A(2:0)=2 A(2:0)=3 A(2:0)=1

01XXXXX1

0X1XXXX1

0XX1XXX1

0X X X 1 X X1

00000XX0

1XXXX1X1

1XXXXX11

1XXXX000

Serial Scan Interface (SSI)

TCK CONTROL

TCK CONTROL is the central control block that enables or

disables shift operations and provides byte alignment for the

shifter/buffers. The state of all shifter/buffers and the 32-bit

counter (CNT32) is evaluated here and TCK is stopped and

started.A clock enable circuit allows the “TCK enable” signal

to change only when SCK is low; therefore, TCK always

stops low. TCK does not toggle (remains low) under the following conditions:

•

TDO Shifter/Buffer is enabled and empty.

•

TDO Shifter/Buffer is enabled in PRPG mode and is not

fully loaded.

•

TDI Shifter/Buffer is enabled and full.

DS100325-12

FIGURE 8. 1149.1 (JTAG) TAP Controller State Diagram

www.national.com 10

Page 11

Serial Scan Interface (SSI) (Continued)

•

TDI Shifter/Buffer is enabled in SSC mode but is not fully

loaded with an initial value.

•

TMS0 Shifter/Buffer is enabled and empty.

•

TMS1 Shifter/Buffer is enabled and empty.

•

CNT32 is enabled but not loaded.

•

CNT32 is enabled and has reached terminal count.

Also included within the TCK control block in CNT3, a 3-bit

count up counter. CNT3 is included to maintain byte alignment within the shifter/buffers by providing a signal to toggle

between the two 8-bit FIFOs which comprise the shifter/

buffer. The toggling operation occurs, in an enabled shifter/

buffer,each time CNT3 counts 8 TCK cycles or when CNT32

reaches terminal count. The CNT3 is reset to 0when CNT32

reaches terminal count or after a PSC100 reset condition.

FREEZE MODE. This mode is included in the TCK control

block to support the 1149.1SAMPLE operation. The intent of

the SAMPLE instruction is to allow device input and output

levels to be observed during normal system operation. Data

is latched (or “sampled”) into the boundary scan registers

when the TAP controller (see

Figure 8

on previous page)

transitions from the Capture-DR state to the Shift-DR state (if

SAMPLE/ PRELOAD is the active instruction). Synchronizing this “transition” (rising edge of TCK with TMS at logic low)

with a known system state is imperative to anaccurate pass/

fail assessment. The Freeze Mode provides a means of

asynchronously creating the TCK pulse via an external

PSC100 pin. When the Freeze Pin Enable bit (bit 2 in Mode

Register 1) is set, a logic high on the PSC100 FRZ input pin

will cause TCK to go high. Once the transition is complete,

the Freeze Mode can be removed (i.e. Freeze Pin Enable bit

returned to logic 0 or Freeze pin forced low) and the sampled

data can be shifted out/evaluated using the “standard”

PSC100 protocol.

Figure 9

illustrates the logic implementation of the Freeze feature. It should be noted that Freeze

mode is simply gated with the TCK output and does not disable shift operations within the shifter/buffers or disable

CNT32. Therefore, no shifting or TCK counting using CNT32

should be performed when Freeze mode is enabled.

The “standard” mode of TCK control uses CNT32 in conjunction with the status registers to start and stop TCK. For this

mode, CNT32 is enabled and loaded with the number of

TCK cycles required to shift the desired bits to/from the scan

chain. The shifter/buffer(s) participating in the shift operation

is enabled and provides the necessary full/empty status to

stop TCK for processor writes/reads. This mode of TCK control provides a systematic protocol for managing PSC100

operations (specifically, handling partial bytes). Another option for TCK control relies solely on the status of the shifter/

buffers (i.e., CNT32 is disabled) to start and stop TCK. This

option eliminates the time required to load CNT32, but

makes management of partial bytes (see shifter/buffer description section) more cumbersome.

TMS(1:0) SHIFTER/BUFFERS

The TMS Shifter/Buffer block diagram is shown in

Figure 10

.

These two blocks take parallel data and serialize it for shift

operations through the serial port pins TMS0 and TMS1.

Double-buffering is achieved by configuring the shifter/buffer

asa2x8FIFO. Write and shift operations are controlled by

a local state machine that accepts stimulus from the PPI,

Mode Registers, CNT32 and TCK Control section. The TMS

outputs always change on the falling edge of SCK. The order

of shifting is least significant bit first. TMS(1:0) are forced

high upon RST low. TMS(1:0) are TRI-STATEd when OE is

high.

Write operations are completed if the shifter/buffer is not full

(independent of whether shifter/buffer is enabled or disabled). Otherwise they are ignored. Shifting occurs when the

following conditions are all true:

•

TMS is enabled with its respective mode bit.

•

TMS shifter/buffer is not empty.

DS100325-9

FIGURE 9. TCK Logic

DS100325-10

FIGURE 10. TMS Shifter/Buffer Block Diagram

www.national.com11

Page 12

Serial Scan Interface (SSI) (Continued)

•

TCK is enabled according to the logic in TCK Control.

When shift operations are not enabled, the TMS output retains its last state. During long shift sequences, the TMS

shifter/buffer can be disabled and held static so that shift operations are concentrated only on TDI and TDO. The TMS

output also retains its last state when Test Loop-Back operations are in progress.

Local select circuitry is used to toggle back and forth between the two registers of the “FIFO” when shifting. At any

given time, one register is selected for shift operations. The

other holds its previous state or can accept new parallel

data. Shift register selection changes due to the following

two events:

•

CNT3 in TCK Control signals that 8 bits have been

shifted. This event is used for basic toggling between

each of the two shift registers.

•

CNT32 enabled and at terminal count. This event is used

to account for scan lengths which are not multiples of

eight. When shift register selection changes due to this

signal, any data remaining in the shift register is unused.

AUTO TMS HIGH MODE . This feature is included in the

TMS shifter/buffer block to improve the efficiency of the

PSC100 in supporting shift operations within the 1149.1 devices connected to the SSI. Shifting data and instructions

into 1149.1compliant devices requires that their TAPcontrollers be sequenced to the Shift-DR or Shift-IR states (see

Fig-

ure 8

). Once in this state, shifting occursby holdingTMS low

and clocking TCK. The last bit is shifted when the TAP controller transitions to the EXIT1 state. This transition requires

a logic 1 on TMS. The Auto TMS High feature, enabled by

setting bit 1 of Mode Register 0, automatically creates a logic

1 on the TMS lines of the PSC100 when CNT32=1. Consequently, the last bit is shifted out without having to load specific TMS data into the shifter/buffer.

Note: Auto TMS High mode creates a logic 1 on both TMS lines (i.e., TMS0

and TMS1). Therefore, when using the Auto TMS High feature, all

1149.1 devices connected to the TMS line not participating in the cur-

rent JTAG test operations should be placed in the Test-Logic-Reset

TAP controller state to prevent inadvertent TAP controller transitions.

TDO SHIFTER/BUFFER

The TDO Shifter/Buffer block diagram is shown in

Figure 11

.

This block takes parallel data and serializes it for shift operations through the serial port pin TDO. During normal shift

modes, double-buffering is achieved by configuring the

shifter/buffer asa2x8FIFO. This block can also be configured as a 32-bit Pseudo RandomPattern Generator (PRPG)

with two additional 8-bit parallel-to-serial shift registers. Write

and shift operations are controlled by a local state machine

that accepts stimulus from the PPI,Mode Registers, CNT32,

and the TCK Control section. The TDO output always

changes on the falling edge of SCK. The order of shifting is

least significant bit first. TDO is forced high upon RST low.

TDO is TRI-STATEd when OE is high.

Write operations are completed if the shifter/buffer is not full

(independent of whether shifter/buffer is enabled or disabled). Otherwise they are ignored.

Shifting occurs when the following conditions are all true:

•

TDO is enabled with its respective mode bit.

•

TDO shifter/buffer is not empty.

•

TCK is enabled according to the logic in TCK Control.

When shift operations are not enabled, the TDO output retains its last state. The TDO output also retains its last state

when Test Loop-Back operations are in progress.

Local select circuitry is used to toggle back and forth between the two registers of the “FIFO” when shifting. At any

given time, one register is selected for shift operations. The

other holds its previous state or can accept new parallel

data. Shift register selection changes due to the following

two events:

•

CNT3 in TCK Control signals that 8 bits have been

shifted. This event is used for basic toggling between

each of the two shift registers.

•

CNT32 enabled and at terminal count. This event is used

to account for scan lengths which are not multiples of

eight. When shift register selection changes due to this

signal, any data remaining in the shift register is unused.

PRPG MODE . By setting MODE1(4), the TDO Shifter/Buffer

is reconfigured as a 32-bit PRPG (Pseudo Random Pattern

Generator) using the primitive polynomial:

F(X)=X

32+X22+X2

+X+1

The PSC100 was developed to support both 1149.1 and

non-1149.1 serial test methodologies. Since 1149.1 compliant devices include boundary scan registers on control pins

(i.e. OE), which must remain fixed during boundary scan interconnect testing, generating pseudo-random patterns with

PRPG mode provides limited usefulness for boundary scan

test operations. PRPG mode may provide usefulness in

other serial test or non-test related implementations which

do not require fixed bits in the serial chain.

Figure 12

shows a block diagram of the Linear Feedback

Shift Register hookup.

www.national.com 12

Page 13

Serial Scan Interface (SSI) (Continued)

The PRPG is loaded by four PPI writes to the TDO address.

When the PRPG enable bit is set, apulse isissued internally

that initializes the local parallel load logic such that the

PRPG is loaded sequentially, least significant byte first, most

significant byte last. When in PRPG mode, writes can be

completed at any time; however, shift operations will be disabled until the PRPG is fully loaded.

LOOP AROUND MODE . This mode, enabled by setting bit

0 in Mode Register 0, will cause data appearing at the TDI input to be placed directly back on the TDO output. This fea-

ture can be used for read-only scan operations where data is

shifted into TDI while returning the scan chain to its previous

state when shifting is completed. It can also be used to bypass PSC100 devices connected within a boundary scan

chain (i.e., a PSC100 located within a chain, but not providing the JTAG TAP data). Loop around has limited usefulness

in most boundary scan applications since, typically, data in

the scan chain is shifted out and evaluated as new data is

shifted into the chain for the next test.

DS100325-11

FIGURE 11. TDO Shifter/Buffer Block Diagram Register Hookup

DS100325-14

FIGURE 12. TDO PRPG Block Diagram

www.national.com13

Page 14

Serial Scan Interface (SSI) (Continued)

WRITING A PARTIAL BYTE TO THE TMS0, TMS1 OR

TDO SHIFTER/BUFFER. Since the TMS0, TMS1 and TDO

shifter/buffers shift out least significant bit first, the valid

(meaningful) bits within a partial byte (i.e., byte containing

<

8 valid bits to be shifted to the scan chain) must be stored

and written into the shifter/buffer as the least significant bits.

This will assure that the desired bits will be accurately shifted

to the boundary scan chain. For example, moving the TAP

controllers within the boundary scan chain connected to

TMS0 from the Pause-DR state to the Run-Test/Idlestate requires a 3-bit (110) sequence on TMS0. To provide correct

3-bit sequence on TMS0, the partial byte would be written to

the TMS0 shifter/buffer as:

MSB LSB

xxxxx011→TMS0

A subsequent enable and load of CNT32 with decimal 3 and

enable of theTMS0 shifter/buffer will initialize the shift operation. Terminal count on CNT32 will complete the shift operation. Since terminal count on CNT32 will cause the register

selection to change within the shifter/buffer, the values labeled as “x” will not be used and aretreated as “don’t cares”.

TDI SHIFTER/BUFFER

The TDI Shifter/Buffer block diagram is shown in

Figure 13

.

This block shifts in serial datafrom theTDI portand puts it in

parallel form for read operations at the PPI. During normal

shift modes, double-buffering is achieved by configuring the

shifter/buffer asa2x8FIFO. This block can also be configured as a 16-bit Serial Signature Compactor (SSC). Write,

read, and shift operations are controlled by a local state machine that accepts stimulus from the PPI, Mode Registers,

CNT32 and the TCK Control section. The TDI input always

shifts in data on the rising edge of SCK. The order of shifting

is least significant bit first. The TDI input includes a pull-up

resistor to force a logic 1 when the test data signal returning

from the scan chain is floating.

Read operations are completed if the shifter/buffer is not

empty and SSC mode is not enabled. Otherwise they are ignored. Write operations are only possible while in SSC

mode. Otherwise they are ignored.

Shifting occurs when the following conditions are all true:

•

TDI is enabled with its respective mode bit.

•

TDI shifter/buffer is not full.

•

TCK is enabled according to the logic in TCK Control.

Local select circuitry is used to toggle back and forth between the two registers of the “FIFO” when shifting. At any

given time, one register is selected for shift operations. The

other holds its previous state or can accept new serial data.

Shift register selection changes due to the following two

events:

•

CNT3 in TCK Control signals that 8 bits have been

shifted in. This event is used for basic toggling between

each of the two shift registers.

•

CNT32 enabled and at terminal count. This event is used

to account for scan lengths which are not multiples of

eight. When shift register selection changes due to this

signal, a partial byte (i.e., byte with

<

eight valid data bits

shifted from the scan chain) will exist in the corresponding shift register. The embedded test software functions

written to support the evaluation of data read from the

TDI shifter/buffer must consider bit placement when

reading and evaluating a partial byte.

READING A PARTIAL BYTE FROM THE TDI SHIFTER/

BUFFER. Data is shifted from the scan chain into each TDI

register from most significant bit to least significant bit. Consequently, the valid (i.e., meaningful) bits in a partial byte

shifted into a TDI register will reside in the upper significant

bit locations. For example, if a scan operation involves shifting and evaluating 53 bits returning to TDI, TDI shifter/buffer

must be read 7 times (i.e., 6 full bytes plus apartial byte containing 5 meaningful bits). If the last 5 bits shifted back to the

TDI shifter/buffer are 11010, then upon completion of the

shift operation (i.e., terminal count on CNT32), the shift register within the TDI shifter/buffer will contain the following

partial byte:

MSB LSB

TDI

→

01011xxx

Following a read of a partial byte, the embedded test software must adjust the position of the valid bits read from the

TDI shifter/buffer or the position of the expected data to assure that an accurate comparison is made (and the

non-meaningful bits are masked).

www.national.com 14

Page 15

Serial Scan Interface (SSI) (Continued)

SSC MODE. By setting MODE1(3), the TDI Shifter/Buffer is

reconfigured as a 16-bit SSC (Serial Signature Compactor)

using the primitive polynomial:

F(X)=X

16+X12+X3

+X+1

Within a chain of 1149.1 compliant devices, there are typically one or more input pins which are drivenby uncontrolled

signals (i.e., signals which are not driven to known logic levels during a boundary scan CAPTURE operation). These

signals are masked during the evaluation of data returning

from the scan chain. The SSC within the PSC100 does not

provide masking capabilities and, therefore, provides limited

usefulness for boundary scan test operations. SSC mode

may provide usefulness in other serial test or non-test related implementations which contain predictable data returning into the TDI shifter/buffer.

Figure 14

shows a block diagram of the Linear Feedback

Shift Register hookup.

The SSC is loaded by two PPI writes to the TDI address.

When the SSC enable bit is set, a pulse is issued internally

that initializes the local parallel load logic such that the SSC

DS100325-8

FIGURE 13. TDI Shifter/Buffer Block Diagram

DS100325-13

FIGURE 14. TDI SSC Block Diagram

www.national.com15

Page 16

Serial Scan Interface (SSI) (Continued)

is loaded sequentially,most significant byte first, leastsignificant byte last. When in SSC mode, writes can be completed

at any time; however, shift operations will be disabled until

the SSC is fully loaded. PPI reads from TDI are ignored while

in SSC mode.

Upon leaving SSC mode an internal pulse causes the TDI

shifter/buffer to be full. Also, local read select logic is initialized such that the signature is read most-significant byte

first.

TEST LOOP-BACK MODES. This feature provides a means

for testing ’PSC100 functionality by looping data appearing

at the output of an outgoing shifter/buffer (i.e., TMS0, TMS1

or TDO) back to the input of the TDI shifter/buffer. The loop

back function is accomplished with a simple multiplexer (see

Figure 13

) whose path selection is determined by setting the

mode bits in MODE1(1:0). Loop back does not disable TCK

or prevent shifting of data in the shifter/buffers to the scan

chain(s) connected to the PSC100. Therefore, the state and

operation of the TAP controllers within the scan chain(s)

must be considered when developing Loop-Back test vectors to prevent undesired shifting of data or TAP controller

transitions within the scan chain.

32-BIT COUNTER (CNT32)

CNT32 is a 32-bit, count-down binary counter arranged in

four 8-bit segments. CNT32 can be loaded independent of

its enable/disable status. Loading requires four consecutive

writes to its address (least significant byte first). These four

writes must

not

be interleaved with writes to any other ad-

dress or the CNT32 write control logic will be re-initialized.

This re-initialization will result in a partially filled counter with

an undesired

value

. CNT32 is reset each time the counter

hits terminal count or by asserting the RST pin. A synchronous reset condition (setting Mode2(1)) does not reset the

counter and a new value must be written to CNT32 to provide the desired number of TCK cycles.

SINGLE STEP MODE: All four 8-bit registers are readable

for testability; however,there are no update latches similar to

the ones used for the status bits. To stabilize the counter for

read operations during on-board test, the Single Step Mode

has been added. This allows the user to place CNT32 in any

state and then count for one SCK cycle (TCK will not toggle

when in singled step mode). The result can then be read

from the PPI. The counter can be tested by loading it with

values at its boundary conditions, and then clocking for one

cycle to see the results. For example, the counter could be

loaded with the value:

00000001 00000000 00000000 00000000

The next step is to set the Single Step Mode bit so that the

counter counts down to the next state and stops. The next

value is:

00000000 11111111 11111111 11111111

Four read cycles using the PPI will reveal the results of the

test.

Note: CNT32 will not wrap from terminal count (i.e., 00000000h decremented

by 1 will remain unchanged and will not wrap to FFFFFFFFh). Therefore, CNT32 should be loaded with a non-zero value prior to a Single

Step Mode Operation.

TIMING WAVEFORMS

DS100325-15

FIGURE 15. Serial Scan Interface Timing

www.national.com 16

Page 17

Embedded Test Software Support

A SCANPSC100 device driver is provided by National to

supply functions for performing write, read and shift operations. National also offers a suite of software tools (called

SCAN EASE) which enablesATPG or custom generated test

vectors to be embedded, applied and evaluated within an

IEEE 1149.1 compatible system. SCAN EASE is written to

run on a wide range of processor and memory architectures.

SCAN EASE includes the source code (ANSI C) and is

modular to allow user modification based on application specific needs.

www.national.com17

Page 18

Absolute Maximum Ratings (Note 7)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

CC

) −0.5V to +7.0V

DC Input Diode Current (I

IK

)

V

I

=

−0.5V −20 mA

V

I

=

V

CC

+ 0.5V +20 mA

DC Input Voltage (V

I

) −0.5V to VCC+0.5V

DC Output Diode Current (I

OK

)

V

O

=

−0.5V −20 mA

V

O

=

V

CC

+ 0.5V +20 mA

DC Output Voltage (V

O

) −0.5V to VCC+ 0.5V

DC Output Source/Sink Current (I

O

)

±

50 mA

DC V

CC

or Ground Current

±

50 mA

per Output Pin

DC Latchup Source or Sink Current

±

300 mA

Junction Temperature

Ceramic +175˚C

Storage Temperature −65˚C to +150˚C

ESD Last Passing Voltage (Min) 4000V

Recommended Operating

Conditions

Supply Voltage (VCC)

’PSC100F 4.5V to 5.5V

Input Voltage (V

I

) 0VtoV

CC

Output Voltage (VO) 0VtoV

CC

Operating Temperature (TA)

Military −55˚C to +125˚C

Minimum Input Edge Rate dV/dt

SCAN “F” Series Devices 125 mV/ns

V

IN

from 0.8V to 2.0V

V

CC

@

4.5V, 5.5V

Note 7: Absolute maximum ratings are those values beyond which damage

to the device may occur. The databook specifications should be met, without

exception, to ensure that the system design is reliable over its power supply,

temperature, and output/input loading variables. National does not recommend operation of SCAN outside of recommended operation conditions.

DC Electrical Characteristics

Military

Symbol Parameter V

CC

T

A

=

−55˚C to Units Conditions

(V) +125˚C

Guaranteed Limits

V

IH

Minimum High 4.5 2.0 V V

OUT

=

0.1V or

Input Voltage 5.5 2.0 V

CC

− 0.1V

V

IL

Maximum Low 4.5 0.8 V V

OUT

=

0.1V or

Input Voltage 5.5 0.8 V

CC

− 0.1V

V

OH

Minimum High 4.5 4.4 V I

OUT

=

−50 µA

Output Voltage 5.5 5.4

4.5 3.70 V

IN

=

V

IL

or V

IH

5.5 4.70 V I

OH

=

−24 mA

All Outputs Loaded

V

OL

Maximum Low 4.5 0.1 V I

OUT

=

−50 µA

Output Voltage 5.5 0.1

4.5 0.50 V

IN

=

V

IL

or V

IH

5.5 0.50 V I

OL

=

24 mA

All Outputs Loaded

I

IN

Maximum Input 5.5

±

1.0 µA V

IN

=

V

CC

for TDI, OE

Leakage Current V

IN

=

V

CC

, GND for

All Others

I

ILR

Maximum Input 5.5 −385 µA V

IN

=

GND for

Leakage Current TDI, OE Only

I

OLD

Minimum V

OLD

=

1.65V Max

Dynamic 5.5 50 mA Maximum Test Duration

=

Output Current 2.0 ms, One Output

Loaded at a Time

I

OHD

Minimum V

OHD

=

3.85V Min

Dynamic 5.5 −50 mA Maximum Test Duration=2.0 ms,

Output Current One Output Loaded at a Time

www.national.com 18

Page 19

DC Electrical Characteristics (Continued)

Military

Symbol Parameter V

CC

T

A

=

−55˚C to Units Conditions

(V) +125˚C

Guaranteed Limits

I

OZ

Maximum

±

10.0 µA V

IN

=

V

CC

, GND

TRI-STATE V

IN

(OE , R/W , CE , STB)

=

Leakage Current VIL,V

IH

I

OZT

Maximum I/O

±

11.0 µA V

IN

=

V

CC

, GND

Leakage Current V

O

=

V

CC

, GND

V

IN

(R/W , CE , STB)=VIL,V

IH

I

CC

Maximum

Quiescent

5.5 160 µA TDI, OE Float

Supply Current

I

CCmax

Maximum

Quiescent

5.5 920 µA TDI, OE low

Supply Current

I

CCT

Maximum 5.5 1.60 mA V

IN

=

V

CC

− 2.1V

I

CC

/Input Float: TDI, OE

I

CCTR

Maximum V

IN

=

V

CC

−2.1V

I

CC

/Input 5.5 1.65 mA TDI and OE Only

Float Untested Pin

Note 8: This parameter is not directly testable, but is derived for use in Total Power Supply calculations.

AC Electrical Characteristics/Operating Requirements

Symbol Parameter V

CC

(V)

(Note 9)

Military Units Fig.

No.

T

A

=

−55˚C to +125˚C

C

L

=

50 pF

Min Max

PARALLEL PROCESSOR INTERFACE (PPI)

t

pd1

Prop Delay 5.0 5.5 19.5 ns 2, 3, 4

R/W to RDY

t

pd2

Prop Delay 5.0 5.5 21.0 ns 2, 3

AtoRDY

t

pd3

Prop Delay 5.0 6.5 24.0 ns 3

AtoD

t

pd4

Prop Delay 5.0 7.0 24.0 ns 2–4, 6

STB to RDY

t

pd10

Prop Delay 5.0 7.5 39.0 ns 2–4, 6

SCK to D

t

pd11

Prop Delay 5.0 9.0 34.0 ns 2–4, 6

SCK to INT

t

pd12

Prop Delay 5.0 10.0 36.0 ns 2–4, 6

SCK to RDY

t

en1

Enable Time 5.0 2.0 13.0 ns 2, 3

CE to RDY

t

dis1

Disable Time 5.0 1.5 10.0 ns 2, 3

CE to RDY

t

en2

Enable Time 5.0 1.5 16.5 ns 3

CE to D

www.national.com19

Page 20

AC Electrical Characteristics/Operating Requirements (Continued)

Symbol Parameter V

CC

(V)

(Note 9)

Military Units Fig.

No.

T

A

=

−55˚C to +125˚C

C

L

=

50 pF

Min Max

PARALLEL PROCESSOR INTERFACE (PPI)

t

dis2

Disable Time 5.0 2.5 14.5 ns 3

CE to D

t

en3

Enable Time 5.0 3.0 17.5 ns 3

R/W to D

t

dis3

Disable Time 5.0 3.0 16.0 ns 3

R/W to D

t

en

Enable Time 5.0 3.0 16.0 ns 3

STB to D

t

dis

Disable Time 5.0 2.5 14.5 ns 3

STB to D

t

h1

Hold Time, 5.0 0.5 ns 2–4, 6

R/W to STB

t

s1

Setup Time 5.0 1.0 ns 2–4, 6

R/W to STB

t

h2

Hold Time, 5.0 4.5 ns 2, 3

AtoSTB

↑

t

s2

Setup Time, 5.0 5.0 ns 2, 3

AtoSTB

↑

t

h3

Hold Time, 5.0 4.5 ns 2

DtoSTB

↑

t

s3

Setup Time, 5.0 0.0 ns 2

DtoSTB

↑

t

h

Hold Time, 5.0 1.0 ns 2–4, 6

CE to STB

t

s

Setup Time, 5.0 0.5 ns 2–4, 6

CE to STB

t

s4

Setup Time, 5.0 7.5 ns 4–7

STB

↑

to

SCK

↓

t

h4

Hold Time, 5.0 0.0 ns 4–7

STB

↑

to

SCK

↓

t

h

Hold Time, 5.0 0.0 ns 4–7

STB to RDY

t

W

Clock Pulse

Width, SCK, H

or L

5.0 20.0

ns 4, 6

t

W1

Pulse Width 5.0 6.0 ns 4, 6

STB (H or L)

f

max

Maximum 5.0 25 MHz

Frequency

Clock

www.national.com 20

Page 21

AC Electrical Characteristics/Operating Requirements (Continued)

Symbol Parameter V

CC

(V)

(Note 9)

Military Units Fig.

No.

T

A

=

−55˚C to +125˚C

C

L

=

50 pF

Min Max

SERIAL SCAN INTERFACE (SSI)

t

pd5

Prop Delay 5.0 3.0 14.0 ns 15

SCK to TCK

t

pd6

Prop Delay 5.0 5.5 19.5 ns 15

SCK to TDO

t

pd7

Prop Delay 5.0 4.5 18.5 ns 15

SCK to TMS

t

pd8

Prop Delay 5.0 3.0 13.5 ns 15

FRZ to TCK

t

pd9

Prop Delay 5.0 1.5 10.0 ns 15

TDI to TDO

t

en4

Enable Time 5.0 2.0 13.0 ns 14

OE to JTAG

t

dis4

Disable Time 5.0 1.5 11.0 ns 14

OE to JTAG

t

h5

Setup Time, H

or L, TDI to

SDK (Note

10)

5.0 0.5

ns

15

t

s5

Hold Time, H

or L, TDI to

SDK (Note

10)

5.0 7.5

ns

15

RST RELATED TIMING

t

pd

Prop Delay 5.0 8.0 29.5 ns

RST to D

t

pd

Prop Delay 5.0 8.0 31.0 ns

RST to RDY

t

phl

Prop Delay 5.0 7.0 28.0 ns

RST to INT

t

plh

Prop Delay 5.0 5.5 21.0 ns

RST to TDO

t

plh

Prop Delay 5.0 5.5 20.0 ns

RST to TMS

t

WR

Pulse Width 5.0 6.5 ns

RST (L)

t

REC

Recovery

Time

5.0 1.0 ns

SCK from

RST

Note 9: Voltage Range 5.0 is 5.0V±0.5V.

Note 10: SSC Mode

www.national.com21

Page 22

Application Note

SCK MINIMUM PULSE WIDTH CALCULATION

The SCANPSC100 Parallel to Serial Converter is intended

to act as the interface between a processor and an IEEE

1149.1 boundary scan chain. When used in this configuration, there is a critical timing situation that is not obvious.

This timing involves the system clock rate at whichdata from

the scan ring is being read into the ’PSC100’s TDI pin(target

TAP controllers in SHIFT-DR or SHIFT-IR states).

To fully understand the events which are taking place during

this critical period, it is useful to view the waveforms of interest as they relate in time. See

Figure 16

. The TCK is derived

internally to the ’PSC100 based on the system clock (SCK)

and clock gating control. The result is that when TCK is running, it is at the same frequency as SCK but delayed in time

by the SCK-TCK propagation delay.

The TCK signal from the ’PSC100 drives all of the IEEE

1149.1 target devices. On the rising edge of TCK, data

present at each scan cell is clocked into it. On the falling

edge, this data is presented at the output of the same scan

cell for the next adjacent cell toread. With regards to the last

cell in a particular target, the falling edge of TCK presents

the data in the last scan cell to the TDO pin, a TCK-TDO

propagation delay later.

At the ’PSC100, data shifted in through the TDI pin is

clocked in on the rising edge of SCK, not TCK. The reason

for this is that TCK is generated internal to the ’PSC100 and

intended to control the boundary scan targets. The ’PSC100

is controlled by SCK, therefore the signal to be shifted into

the TDI pin needs to be referenced to SCK not TCK. New

TDI data must be present a TDI-SCK set-up time prior to the

rising edge of SCK in order to guarantee validity. Although

SCK is usually continuous, the TDI buffer is controlled by a

SHIFT-ENABLE signal which is generated internal to the

’PSC100, based on the status of the TDI buffer and the

Mode Registers.

We now see the three major timing components which limit

the duration of the SCK pulse width low. There are two minor

additional delays which should be noted. The TCK signal

from the ’PSC100 needs to arrive at the target device to be

recognized, and this takes a finite amount of time depending

on the signal trace length and impedance. Similarly, the TDO

signal of the last target in the chain needs to reach the TDI

pin of the ’PSC100, taking a finite amount of time as well.

These two trace delays can be minimized by making the target device closest to the ’PSC100 the last device in the

chain. See

Figure 17

.

PROGRAMMING RESTRICTIONS

Because certain mode bits enable shift operations for certain

functions, these mode bits should not be changed when shift

operations are in progress. The alignment of all registers

during shift operations is controlled by a three bit counter in

the TCK control block. Enabling or disabling a function in the

middle of a shift operation may disrupt the logicnecessary to

keep all shifter/buffers byte-aligned. For example, if the TDO

shifter/buffer (already loaded) is enabled while the three bit

counter value is three, the shifter/buffer will only shift out 5

bits of the first byte loaded.

The following bits should not be changed when shift operations are in progress, i.e., when TCK is enabled (see TCK

control section):

•

MODE0(7:3)

•

MODE1(4:3)

•

MODE2(0)

DS100325-16

Pw(L) minimum=Tpd1 + Td1 + Tpd2 + Td2 + Tsu

FIGURE 16. System Clock Timing for Accurate TDI Data

www.national.com 22

Page 23

Application Note (Continued)

DS100325-17

Note:-----Minimize the lengths of these two traces.

FIGURE 17. SCANPSC100 Location Relative to Targets

www.national.com23

Page 24

Physical Dimensions inches (millimeters) unless otherwise noted

28-Pin Leadless Chip Carrier (LCC)

NS Package Number E28A

28-Pin Ceramic DIP

NS Package Number J28A

28-Lead Cerpack

NS Package Number WA28D

www.national.com 24

Page 25

Notes

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

SCANPSC100F Embedded Boundary Scan Controller (IEEE 1149.1 Support)

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...