Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA4990H

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Preliminary specification

File under Integrated Circuits, IC02

1996 Oct 25

Page 2

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

SAA4990H

reduction IC (PROZONIC)

FEATURES

• Progressive scan conversion

(262.5 to 525 or 312.5 to 625 lines/field)

• Field rate up-conversion (50 to 100 Hz or 60 to 120 Hz)

• Line flicker reduction

• Noise and cross-colour reduction

• Variable vertical sample rate conversion

• Movie phase detection

• Synchronous No parity Eight bit Reception and

Transmission (SNERT) interface.

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. MAX. UNIT

V

T

DDD

amb

digital supply voltage 4.5 5.5 V

operating ambient temperature 0 70 °C

GENERAL DESCRIPTION

The Progressive scan-Zoom and Noise reduction IC,

abbreviated as PROZONIC, is designed for applications

together with:

SAA4951WP Economy Controller (ECO3)

SAA4952H (memory controller)

SAA7158WP Back END IC (BENDIC)

SAA4995WP PANorama IC (PANIC)

SAA4970T ECOnomical video processing Back END IC

(ECOBENDIC)

TMS4C2970/71 (serial field memories)

TDA8755/8753A (A/D converter 4 : 1 : 1 format)

83C652/54 type of microcontroller.

ORDERING INFORMATION

TYPE

NUMBER

SAA4990H QFP80 plastic quad flat package; 80 leads (lead length 1.95 mm); body 14 × 20 × 2.8 mm SOT318-2

NAME DESCRIPTION VERSION

PACKAGE

1996 Oct 25 2

Page 3

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

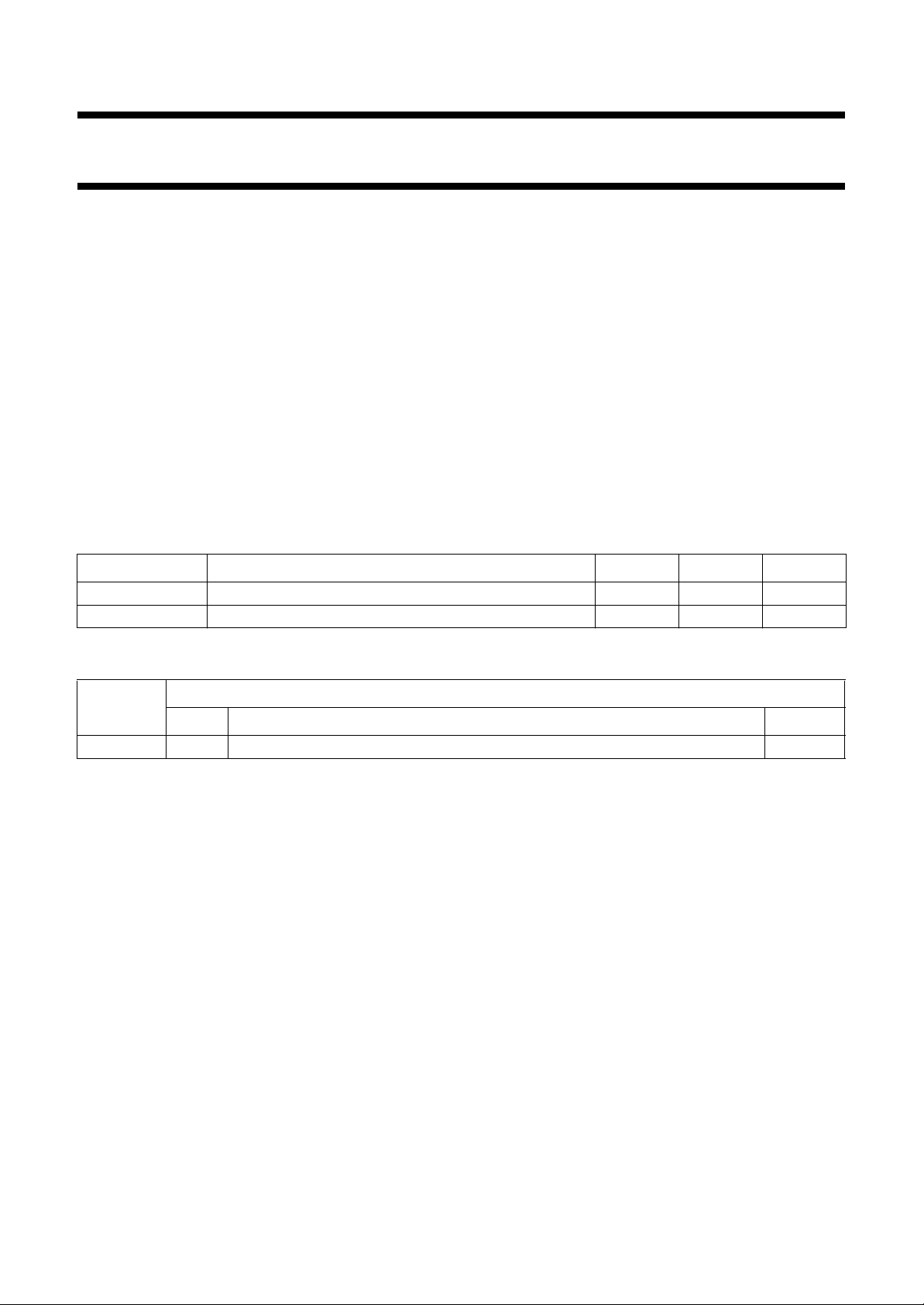

BLOCK DIAGRAM

D

YUV

12

FORMATTER

LINE

MIXER

MEMORY 3

LINE

MIXER

MEMORY 3

SAA4990H

RE1

RE2

WE2

3

CONTROL BLOCK

MGE024

SAA4990H

CK RE, WEVD, HD

book, full pagewidth

LINE

MIXER

MEMORY 2

LINE

MEMORY 1

NOISE

REDUCTION

REFORMATTER

4

UV1

REFORMATTER

4

UV2

LINE

MEDIAN

MEMORY 2

LINE

MEMORY 1

NOISE

REDUCTION

8

8

Y1

Y2

FILTER

84

FORMATTER

3 2 2

(SNERT)

INTERFACE

MICROPROCESSOR

SNRST

SNCL, SNDA,

Fig.1 Block diagram.

MOVIE

PHASE

DETECTOR

8

12

A

YUV

12

B

YUV

1996 Oct 25 3

12

C

YUV

Page 4

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

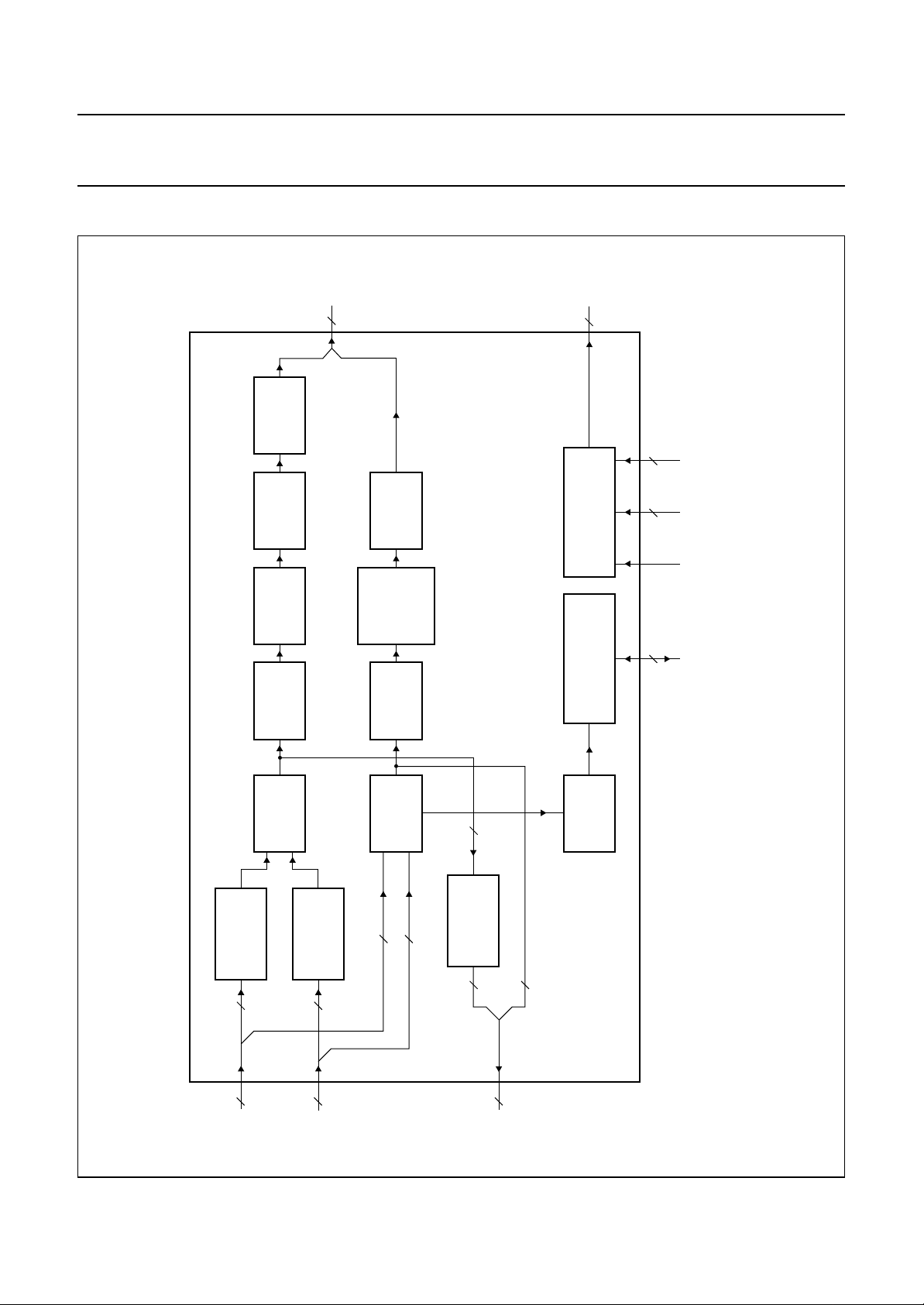

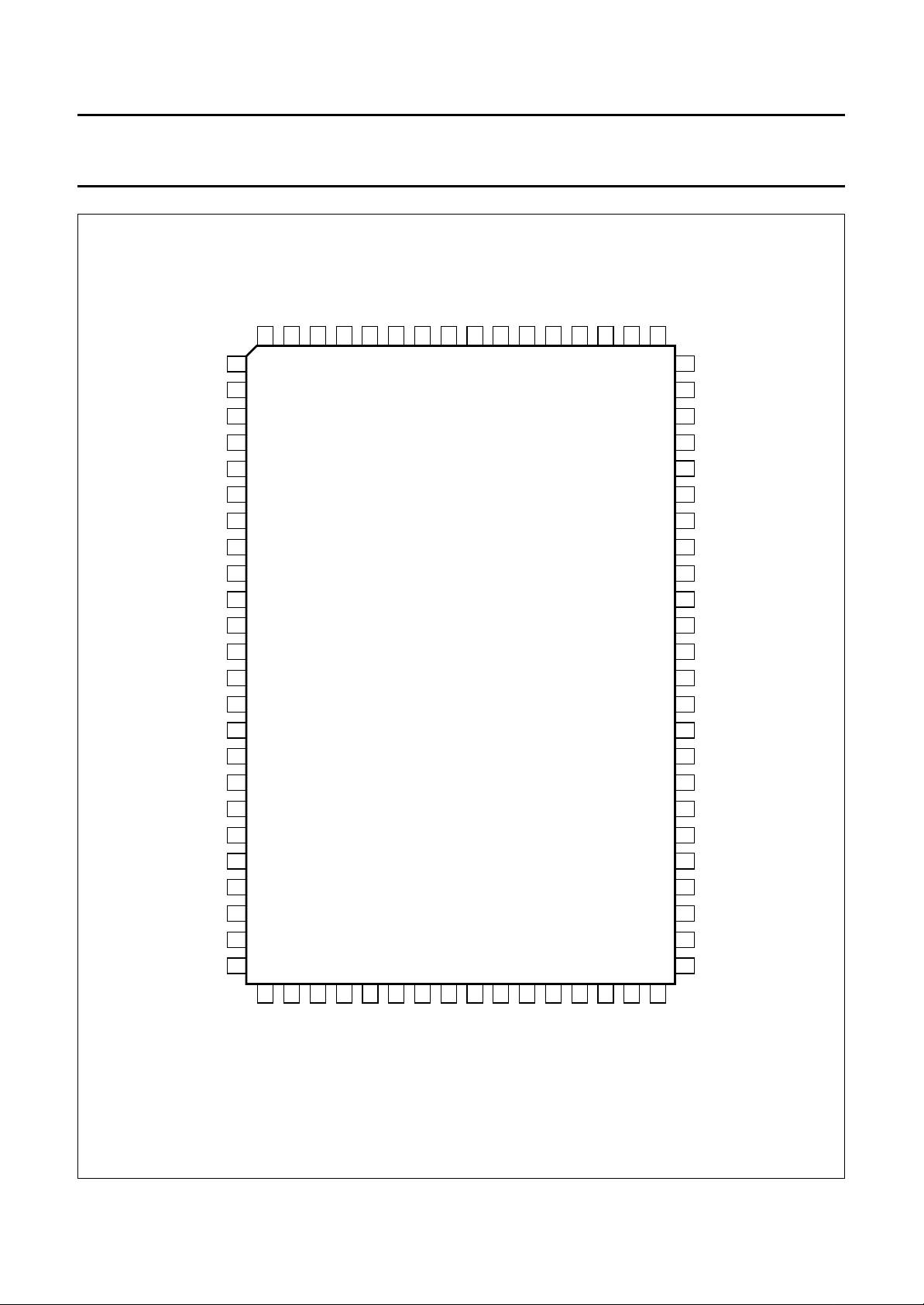

PINNING

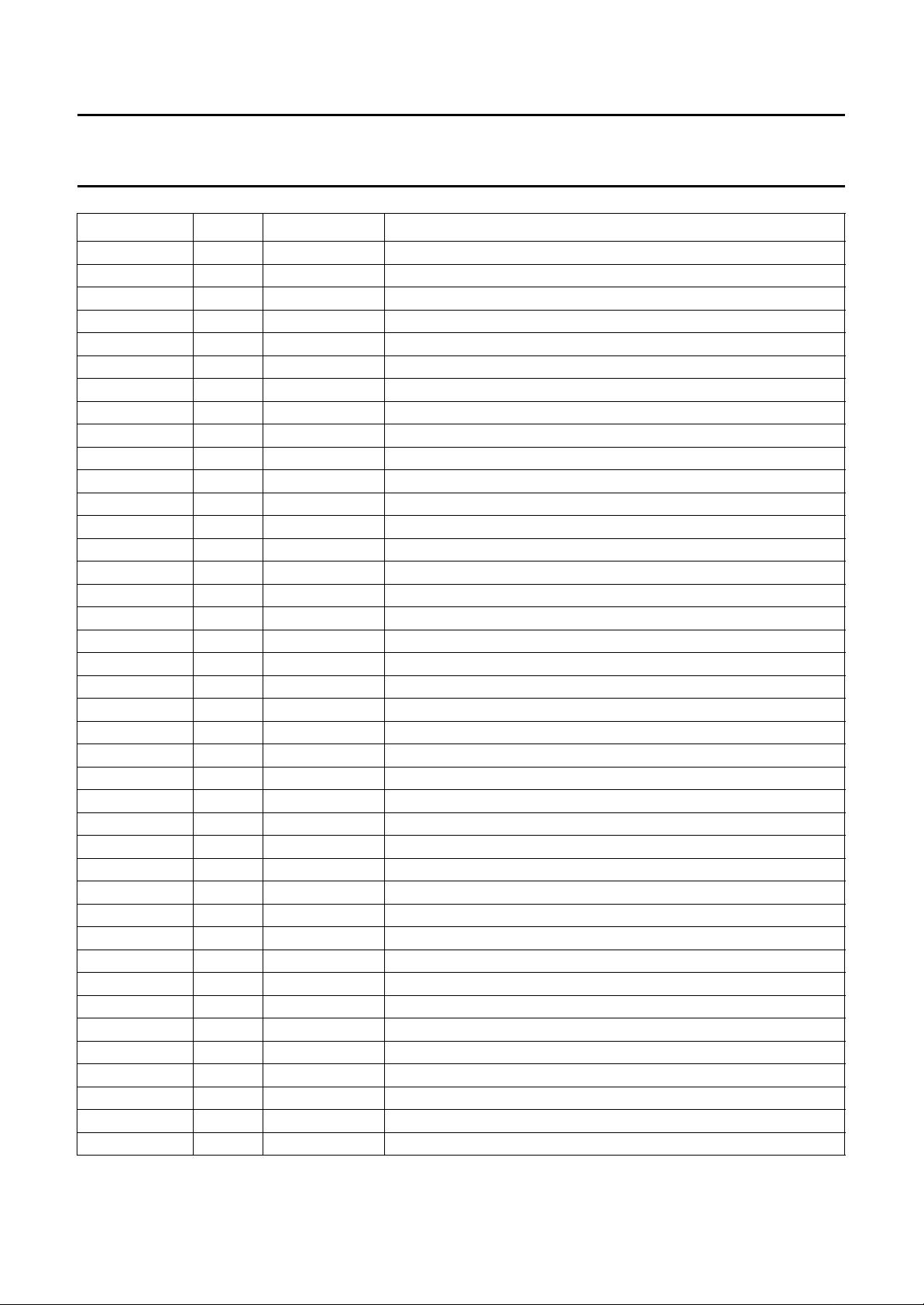

SYMBOL PIN TYPE DESCRIPTION

TEST1/AP 1 input action pin for testing, to be connected to V

TEST2/SP 2 input shift pin for testing, to be connected to V

RE1 3 output read enable to FM1

V

SS1

V

DD1

YUV

C7

YUV

C6

YUV

C5

YUV

C4

YUV

C3

V

SS2

V

DD2

YUV

C2

YUV

C1

YUV

C0

YUV

C11

YUV

C10

YUV

C9

YUV

C8

CK 20 input master clock, nominal 27 or 32 MHz

V

SS3

V

DD3

WE2 23 output write enable to FM2

RE2 24 output read enable to FM2

YUV

B8

YUV

B9

YUV

B10

YUV

B11

YUV

B0

YUV

B1

YUV

B2

YUV

B3

V

DD4

V

SS4

YUV

B4

YUV

B5

YUV

B6

YUV

B7

RE 39 input master read enable

VD 40 input field frequent reset, vertical display

4 ground ground 1

5 supply supply voltage 1

6 output Y bit 7 to FM2

7 output Y bit 6 to FM2

8 output Y bit 5 to FM2

9 output Y bit 4 to FM2

10 output Y bit 3 to FM2

11 ground ground 2

12 supply supply voltage 2

13 output Y bit 2 to FM2

14 output Y bit 1 to FM2

15 output Y bit 0 to FM2

16 output UV bit 3 to FM2

17 output UV bit 2 to FM2

18 output UV bit 1 to FM2

19 output UV bit 0 to FM2

21 ground ground 3

22 supply supply voltage 3

25 input UV bit 0 from FM2

26 input UV bit 1 from FM2

27 input UV bit 2 from FM2

28 input UV bit 3 from FM2

29 input Y bit 0 from FM2

30 input Y bit 1 from FM2

31 input Y bit 2 from FM2

32 input Y bit 3 from FM2

33 supply supply voltage 4

34 ground ground 4

35 input Y bit 4 from FM2

36 input Y bit 5 from FM2

37 input Y bit 6 from FM2

38 input Y bit 7 from FM2

SAA4990H

SS

SS

1996 Oct 25 4

Page 5

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

SAA4990H

reduction IC (PROZONIC)

SYMBOL PIN TYPE DESCRIPTION

HD 41 input horizontal reference signal

YUV

D8

YUV

D9

YUV

D10

V

DD5

V

SS5

YUV

D11

YUV

D0

YUV

D1

YUV

D2

V

DD6

V

SS6

YUV

D3

YUV

D4

YUV

D5

YUV

D6

YUV

D7

V

DD7

V

SS7

SNRST 60 input field frequent reset from microcontroller; reset for SNERT interface

SNDA 61 I/O data for SNERT interface

SNCL 62 input clock for SNERT interface

AUX 63 output spare output from line-sequencer

H

O

n.c. 65 − not connected

n.c. 66 − not connected

YUV

A7

YUV

A6

YUV

A5

YUV

A4

YUV

A3

YUV

A2

V

SS8

V

DD8

YUV

A1

YUV

A0

YUV

A11

YUV

A10

YUV

A9

YUV

A8

42 output UV bit 0

43 output UV bit 1

44 output UV bit 2

45 supply supply voltage 5

46 ground ground 5

47 output UV bit 3

48 output Y bit 0

49 output Y bit 1

50 output Y bit 2

51 supply supply voltage 6

52 ground ground 6

53 output Y bit 3

54 output Y bit 4

55 output Y bit 5

56 output Y bit 6

57 output Y bit 7

58 supply supply voltage 7

59 ground ground 7

64 output output hold to e.g. LC display

67 input Y bit 7 from FM1

68 input Y bit 6 from FM1

69 input Y bit 5 from FM1

70 input Y bit 4 from FM1

71 input Y bit 3 from FM1

72 input Y bit 2 from FM1

73 ground ground 8

74 supply supply voltage 8

75 input Y bit 1 from FM1

76 input Y bit 0 from FM1

77 input UV bit 3 from FM1

78 input UV bit 2 from FM1

79 input UV bit 1 from FM1

80 input UV bit 0 from FM1

1996 Oct 25 5

Page 6

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

handbook, full pagewidth

TEST1/AP

TEST2/SP

YUV

YUV

YUV

YUV

YUV

YUV

YUV

YUV

YUV

YUV

YUV

YUV

V

V

V

V

V

V

WE2

RE1

SS1

DD1

C7

C6

C5

C4

C3

SS2

DD2

C2

C1

C0

C11

C10

C9

C8

CK

SS3

DD3

RE2

YUVA8YUVA9YUV

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A10

A11

YUV

YUVA0YUVA1V

79

78

77

76

75

DD8VSS8

74

73

SAA4990H

YUVA2YUVA3YUVA4YUVA5YUVA6YUVA7n.c.

71

72

70

69

68

67

66

n.c.

65

SAA4990H

H

64

O

63

AUX

62

SNCL

61

SNDA

60

SNRST

V

59

SS7

V

58

DD7

YUV

57

D7

YUV

56

D6

YUV

55

D5

YUV

54

D4

YUV

53

D3

V

52

SS6

V

51

DD6

YUV

50

D2

YUV

49

D1

YUV

48

D0

YUV

47

D11

V

46

SS5

V

45

DD5

YUV

44

D10

YUV

43

D9

YUV

42

D8

HD

41

25

26

27

28

29

30

31

32

B9

B10

B11

YUVB8YUV

YUV

YUVB0YUVB1YUVB2YUV

YUV

Fig.2 Pin configuration.

1996 Oct 25 6

B3

33

DD4

V

34

35

36

SS4

V

YUVB4YUVB5YUVB6YUV

37

38

39

40

B7

RE

MGE023

VD

Page 7

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

FUNCTIONAL DESCRIPTION

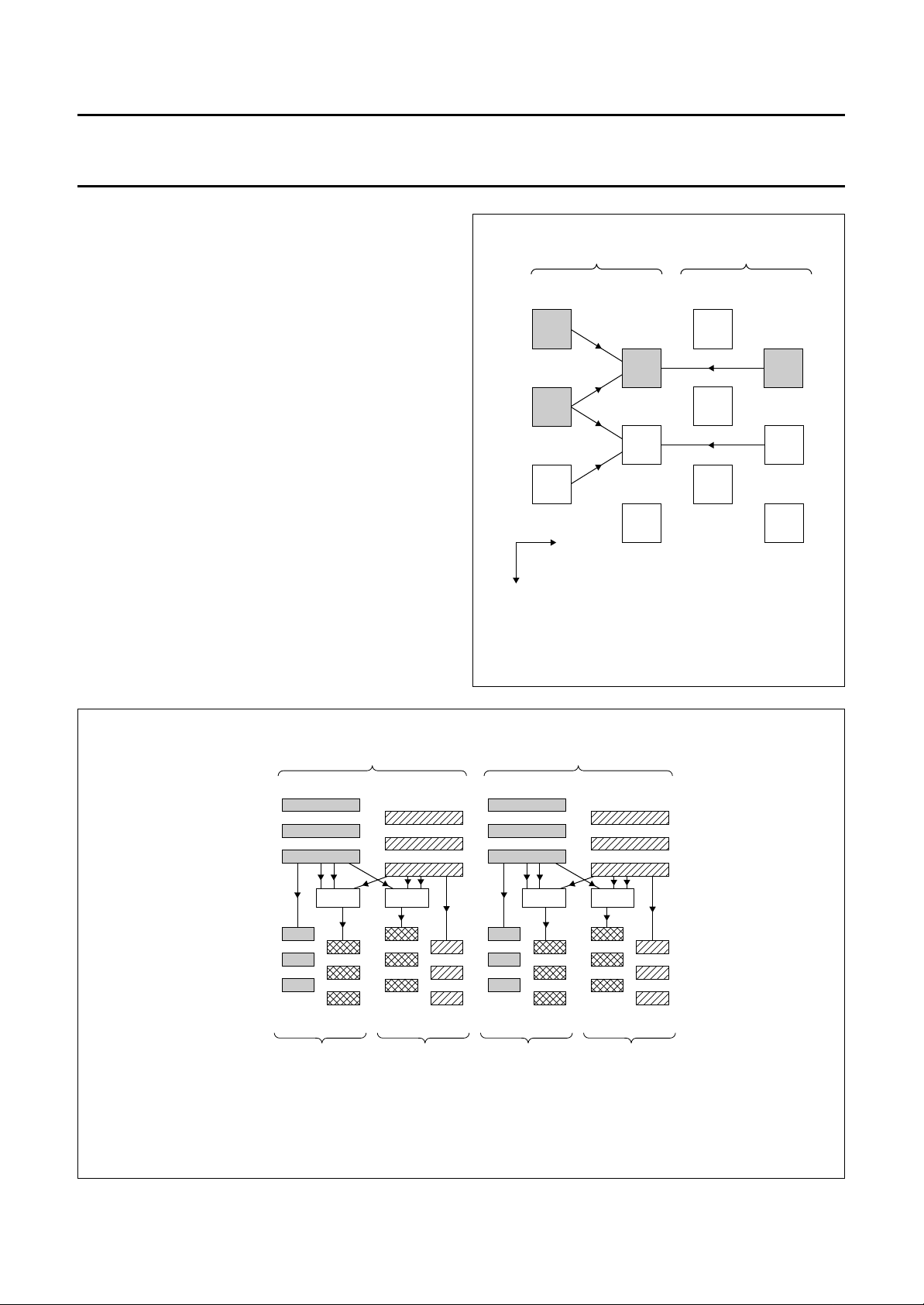

Field rate up-conversion with line flicker reduction

The line flicker reduction in conjunction with field rate

up-conversion is performed by generating a 50 Hz

interlace on the 100 Hz field rate display. Median filtering

supplies the data for the interlaced output fields.

D

EFINITIONS

Framel: l is the number of an input/output frame

temporarily combinating an A and B field.

x

: x is the field raster where A means an odd field and

Field

n

B means an even field.

Frame

combinating an origin/interpolated A and B field;

k indicates the origin input field with

k = 1: odd input field and raster A

k = 2: even input field and raster B within framel.

Field

2 lines of field

(see Fig.3); x is the field raster where A means an odd field

and B means an even field.

: l is the number of an output frame temporarily

l, k

x

: n, m = lines of field

n, m

and 1 line of fieldm using the median filter

n

are interpolated by

n, m

field

n

frame

A

t

handbook, halfpage

y

Fig.3 Generation of (median filter).field

l, k = 1

field

n,m

SAA4990H

frame

l, k = 2

B

B

n, m

A

field

m,n

B

field

m

MGE026

handbook, full pagewidth

input

1fH, 1f

output

2fH, 2f

v

v

field

1

A

frame

field

1

median

field

1, 2

frame

1

A

1, 1

B

field

2, 1

field

2

median

A

frame

B

field

2

1, 2

B

field

3

Fig.4 Scan rate up-conversion.

A

frame

field

3

median

A

B

field

3, 4

2, 1

frame

2

median

A

field

4, 3

frame

field

4

B

field

4

2, 2

MGE027

B

1996 Oct 25 7

Page 8

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

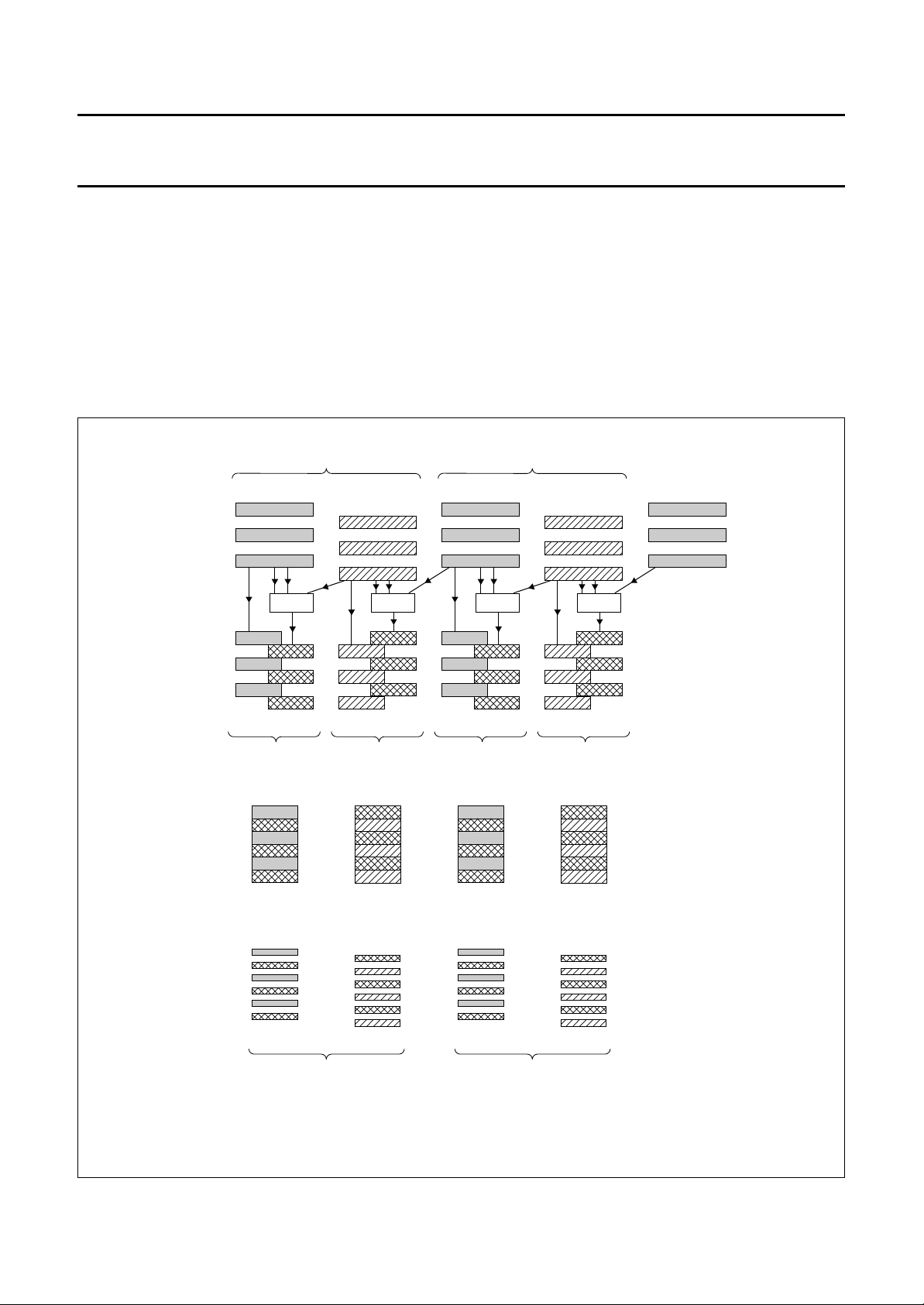

Progressive scan

Progressive scan conversion produces a double number

of lines per field on the output. The field frequency is not

changed, while the line frequency is doubled.

Processing for progressive scan is different for two

successive output fields, e.g. the first output field has a

median operation on the odd lines, while the second has

the median operation on the even lines.

ROGRESSIVE SCAN CONVERSION

P

handbook, full pagewidth

output

1fH, 1f

field

1

v

frame

1

A

field

2

B

SAA4990H

NON-INTERLACE MODE

With non-interlaced progressive scan output, line flicker is

removed because interlace is removed.

I

NTERLACE MODE

With interlaced progressive scan the output line structure

and line flicker is less visible (projection TV).

frame

2

field

3

A

field

4

B

field

5

A

output

2fH, 1f

v

field

1

A

median

frame

B

field

1, 2

1, 1

field

2

B

median

frame

A

field

2,3

1, 2

field

3

A

frame

a. Non-interlaced output; (625/50/1:1) or (525/60/1:1):

frame

1, 1

frame

1, 2

frame

b. Interlaced output; (1250/50/2:1) or (1050/60/2:1):

1

B

field

1,2

field

2,1

A

field

1,1

frame

median

field

3, 4

2, 1

2, 1

A

B

frame

field

4

2

B

frame

frame

field

2,2

median

field

4,5

2, 2

2, 2

B

A

MGE028

Fig.5 Progressive scan conversion.

1996 Oct 25 8

Page 9

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

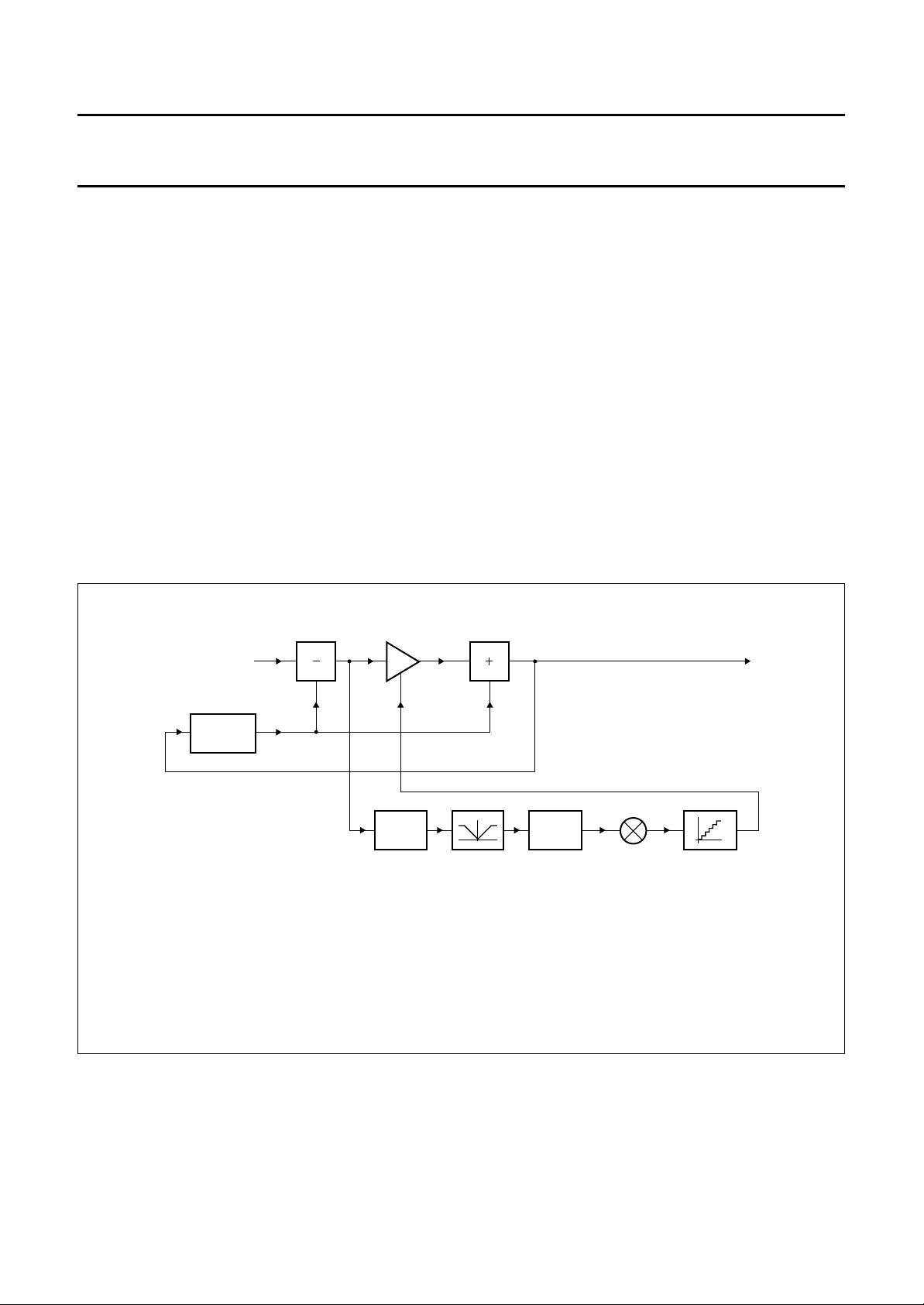

Noise and cross-colour reduction

The noise reduction is field recursive with an average ratio

between fresh and over previous fields averaged

luminance and chrominance.

Two operating modes can be used in principal: the fixed

and the adaptive mode (see Table 6).

In the fixed mode, the averaging produces a constant

linear combination of the inputs. Except for k = 1, the fixed

mode should not be used for normal operation, because of

its smearing effects.

In the adaptive mode, the averaging ratio switches softly

on the basis of absolute differences in luminance among

the inputs. When the absolute difference is low, only a

small part of the fresh data will be added. When the

difference is high, much of the fresh data will be taken.

This occurs in either the situation of movement or where a

significant vertical contrast is seen.

SAA4990H

To latter remark, note that recursion is done over a field,

and the pixel positions one field apart always have a

vertical offset of one frame line. So averaging is not only

done in the dimension of time but also in the vertical

direction. Therefore averaging vertically on e.g. a vertical

black to white edge would provide a grey result if this was

not adapted for.

The averaging in chrominance is slaved to the luminance

averaging. This implies that differences in the

chrominance are not taken into account for the k-factor

setting.

The noise reduction scheme effectively decreases both

noise and cross-colour patterns.

The cross-colour pattern does not produce an increase of

the measured luminance difference, therefore this pattern

will be averaged over many fields.

handbook, full pagewidth

(1) Y

(2) see Table 9.

(3) see Fig.11.

out=YA

×k+YB×(1 −k).

FIELD

MEMORY

Y

A

Y

B

k

TF2TF1

FILTER LIMITER FILTER MULTIPLIER

(2)

Y

k-CURVE

(3)

out

(1)

MGE029

Fig.6 Noise reduction scheme.

1996 Oct 25 9

Page 10

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Vertical sample rate conversion

The variable vertical sample rate conversion is performed

on top of the noise reduced and progressively scanned

data.

The vertical sample rate conversion is intended to cope

with the various letter box formats, to be displayed on

displays with e.g. 16:9 aspect ratio. For this sample rate

conversion, which usually has both a vertical and a

horizontal component, the vertical sample rate conversion

is taken care of in the PROZONIC, while the horizontal

compression can be done in e.g. TDA8753A or

SAA4995WP.

The vertical sample rate conversion can also be used to

convert from an NTSC 525 lines source to a 625 line

display, by setting a vertical sample rate conversion factor

6

⁄5 and necessarily some line-time reduction.

of

Conversion from 625 to 525 lines is possible with

progressive scan output, by setting a vertical sample rate

conversion of5⁄6.

The principle of vertical sample rate conversion is based

on linear interpolation from two successive lines of video in

a frame to produce an output line in either a field or a

frame.

The vertical sample rate conversion factor can be switched

to the following settings for increasing the number of

output lines w.r.t. the number of input lines; see Table 1.

Table 1 Vertical sample rate conversion factor

INPUT LINES OUTPUT LINES FACTOR

2 2 1.00

14 16 1.14

12 14 1.16

10 12 1.20

8 10 1.25

6 8 1.33

10 14 1.40

4 6 1.50

10 16 1.60

6 10 1.67

8 14 1.75

2 4 2.00

SAA4990H

Movie phase detection

While processing video, that was originally film

(25 movement phases per second in the case of 50 Hz

field rates), median filtering is not needed when fields are

combined that have the same movement phase. As this

phase is not generally known, the PROZONIC has a

detection circuit to help determine it. The detection is

based on measurement of absolute luminance differences

between successive input fields, pixel by pixel. These

differences are summed over all active video and give a

number every field. In case of video from film with sufficient

movement, the measured number will alternately be HIGH

and LOW. With the controlling microcontroller, this data

can be filtered appropriately to switch to movie processing

in the correct phase.

The PROZONIC has a provision to generate a rectangular

box, which is position and size programmable. This box

can be used to enable the measurement in the movie

phase detection circuit, only within this rectangle.

Otherwise, the active video part in a field is marked with a

derivative of the RE pulse.

Box generation

A rectangular box is defined by the coordinates of the

left-upper edge (hor_start_box, vert_start_box) and the

right-lower edge (hor_stop_box, vert_stop_box). The

reference for the coordinates are the HD positive edge

(with some processing delay) for the horizontal direction

and the VD positive edge for the vertical.

The box can serve the following purposes:

• Switch between adaptive and fixed k in noise reduction.

If k-fixed is set to 0, then the box switches between

adaptive noise reduced and fully still picture areas. This

provides an option for producing multi picture (still)

images. If no noise reduction is desired in the area

where NR is adaptive, the adaptive setting can be

programmed with k steps to all zeros.

• Switch the movie phase detect measurement to a

defined area of the video.

Decreasing the number of lines on the display w.r.t. the

number of input lines is only possible with progressive

scan output.

1996 Oct 25 10

Page 11

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

handbook, halfpage

vert_start_box

vert_stop_box

hor_start_box

Fig.7 Box dimensions and position.

Control and microcontroller (SNERT-) interface

hor_stop_box

MGE033

SAA4990H

RE2

Read enable for FM2, processed from RE by PROZONIC.

WE2

Write enable for FM2, processed from RE by PROZONIC.

H

O

Holds the writing of the LC display when active.

AUX

Spare output from line-sequencer.

VD

Field frequent reset signal, used in PROZONIC to reset

line counting for boxing. The rising edge of VD is taken as

reference. This may be the display related vertical pulse.

SNRST

C

ONTROL SIGNALS

CK

Line-locked clock of nominal 27 or 32 MHz. This is the

system clock, nominally 864 or 1024 × fh, where fh is the

line frequency. Within the PROZONIC, CK is distributed to

different blocks.

HD

Horizontal reference signal. This signal defines with its

rising edge the start phase of the UV 4 :1:1 format. If the

HD signal has a period equal to 4 clock periods, the UV

data will remain in phase without disruptions, once it has

become in phase. For any mismatch between the applied

HD to the UV data phase, an appropriate HD delay can be

set in the PROZONIC. HD is also used to count lines for

boxing.

RE

Master read enable from memory controller or

ECOBENDIC. This signal controls the memory read

enable if only one field memory is present. To control two

field memories, the PROZONIC generates RE1, RE2 and

WE2 from RE. The vertical sample rate conversion

function has a major influence on these signals.

Field frequent asynchronous reset signal, used in

PROZONIC to reset the communication with

microcontroller. After the rising edge of SNRST,

communication is in its defined state. SNRST is also used

to define the initial phase of the line-sequencer.

SNCL

microcontroller interface clock signal. This signal is

transferred asynchronous to CK by a microcontroller

(UART of 8051 family, mode 0) as communication clock

signal at a frequency of 1 MHz.

SNDA

microcontroller interface data signal. This signal is

transferred or received (asynchronous to CK) by a

microcontroller (UART of 8051 family, mode 0) as

communication data signal at 1 MBaud, related to SNCL.

XTERNAL CONTROL

E

The PROZONIC is controlled via the microcontroller

(SNERT) interface, by sending an address byte and a data

byte to it, with the controllable items as in the register

descriptions in Tables 2 and 3.

RE1

Read enable for FM1, processed from RE by PROZONIC.

1996 Oct 25 11

Page 12

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Table 2 Write registers

REGISTER BIT NAME FUNCTION

Register 10H to 13H (Kstep)

1

10H 0 to 3 Kstep0 step in adaptive curve from k =

4 to 7 Kstep1 step in adaptive curve from k =

11H 0 to 3 Kstep2 step in adaptive curve from k =

4 to 7 Kstep3 step in adaptive curve from k =

12H 0 to 3 Kstep4 step in adaptive curve from k =

4 to 7 Kstep5 step in adaptive curve from k =

13H 0 to 3 Kstep6 step in adaptive curve from k =

4 to 7 Kstep7 step in adaptive curve from k =

Register 14H (fixed_k)

14H 0 to 3 fixed_k determines k value in fixed k mode; see Table 8

4 to 5 mult weighting of TF2 output; see Table 9

6 _upbox microcontroller (_upbox = 0) or box controlled (_upbox = 1); see Table 6

7 _adfix adaptive (_adfix = 0) or fixed k (_adfix = 1); see Table 6

⁄16to k =1⁄8; weight of 1

1

⁄8to k =2⁄8; weight of 1

2

⁄8to k =3⁄8; weight of 2

3

⁄8to k =4⁄8; weight of 2

4

⁄8to k =5⁄8; weight of 4

5

⁄8to k =6⁄8; weight of 4

6

⁄8to k =7⁄8; weight of 8

7

⁄8to k =8⁄8; weight of 8

SAA4990H

Register 15H (Tfilter)

15H 0 to 1 Tfilter1_select determines filter1 characteristic; see Table5

2 to 7 Tfilter2_select determines filter2 characteristic; see Table7

Register 16H (hor_start_box)

16H 0 to 7 hor_start_box horizontal start position of box w.r.t. picture

Register 17H (hor_stop_box)

17H 0 to 7 hor_stop_box horizontal stop position of box w.r.t. picture

Register 18H and 19H (vert_start_box)

18H (bit 8 = 0) 0 to 7 vert_start_box vertical start position of box w.r.t. picture; bit 8 (MSB) is encoded in the

19H (bit 8 = 1)

address

Register 1AH and 1BH (vert_stop_box)

1AH (bit 8 = 0) 0to7 vert_stop_box vertical stop position of box w.r.t. picture; bit 8 (MSB) is encoded in the

1BH (bit 8 = 1)

address

Register 1CH (box generation and UV processing)

1CH 0 UV8bit U/V signals are taken from input as 8-bit values instead of 7-bit

1 UVbin U/V signals are taken from input as binary signals instead of

twos complement

2 inv_box inversion of box signal (inv_box = 1)

3 en_box overall enable box signal

4 en_box_mpd enable box signal to define movie phase detection area

5 boxPSC box generation for progressive scan with more than 511 lines

6, 7 reserved

Register 1DH (reserved)

1996 Oct 25 12

Page 13

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

SAA4990H

reduction IC (PROZONIC)

REGISTER BIT NAME FUNCTION

Register 1EH (horizontal delay)

1EH 0 to 2 in_del programmable horizontal delay (0 to 7 clock periods) of the luminance data

input in comparison to the U/V data input (from FM1)

3, 4 HD_del determines 1 to 4 clock pulse shift for horizontal reference HD

5, 6 WE2_del determines 1to4 clock pulse shift for WE2 output

7 reserved

Register 1FH (sequence data)

1

1FH 0 to 2 mix setting of mixer to 0,

of line sequencer

3 post_zoom setting of multiplexer pre or post LM_zoom to MIX; setting per line in

1 to 16 lines of line sequencer

4 post_lfr setting of multiplexer pre or post LM_lfr to MIX; setting per line in

1 to 16 lines of line sequencer

5 mem_hold setting of field and line memory hold; setting per line in 1 to 16 lines of line

sequencer

6 o_hold setting of output hold, may stop e.g. LC display; setting per line in

1 to 16 lines of line sequencer

7 aux setting of auxiliary sequencer output signal; setting per line in 1 to 16 lines

of line sequencer

⁄4,1⁄4,1⁄2,1⁄2,3⁄4,3⁄4, 1; setting per line in 1 to 16 lines

Register 20H (sequence length)

20H 0 to 3 seq_length setting of sequence length to 1, 2, 3 to 16 lines

4 to 7 reserved

Register 21H (field control 1); note 1

21H 0 FCM4 see Fig.12 and Table 10

1 FCM23

2 FCM1

3, 4 fixselUV defines UV data output; see Fig.12 and Table 11

5, 6 fixselY defines Y data output; see Fig.12 and Table 11

7 RAM1wr selects RAM1 for write operation; note 2; see Fig.13

Register 22H (field control 2); note 1

22H 0 WE2act activates field controlled write enable 2 for FM2

1, 2 RE1del line delay for read enable 1 (FM1) w.r.t. RE input (pin 39)

3, 4 RE2del line delay for read enable 2 (FM2) w.r.t. RE input (pin 39)

5, 6 WE2del line delay for write enable 2 (FM2) w.r.t. RE input (pin 39)

7 UV_av UV averaged while luminance signal is median filtered

Notes

1. Data will be active after next VD pulse (pin 40).

2. In normal conditions control bit should be toggled field by field.

1996 Oct 25 13

Page 14

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Table 3 Read registers

REGISTER BIT NAME

Register 26H (MPD_LSB)

26H 0 to 7 MPD_LSB

Register 27H (MPD_MSB)

27H 0 to 7 MPD_MSB

Table 4 Output multiplex control

output_mux[2:0] THROUGHPUT

000 video

011 grey

111 sawtooth

Table 5 Filter1 characteristic

Tfilter1_select[1:0] Tfilter1-TRANSFER (z)

00 1

1

01

10

11

⁄2× z+1+1⁄2×z

1

⁄

2

1

⁄2× z+1⁄2+1⁄2×z

−1

−1

SAA4990H

Table 6 Adaptive/fixed_k selection

Dynamic box signal, active in user defined rectangular

part of the picture, enable with en_box, may be inverted

with inv_box.

_upbox _adfix box k

00X

00X

01X

01X

1X

1X

1X

1X

(1)

(1)

(1)

(1)

Note

1. X = don’t care bits.

(1)

(1)

(1)

(1)

adapt

adapt

fixed

fixed

0 fixed

1 adapt

0 fixed

1 adapt

TF1(z) =1⁄2z+a+1⁄2z−1.

(1) a = 1.

(2) a =1⁄2.

15

handbook, halfpage

10

IH_TF1I

5

(dB)

0

−5

−10

−15

−20

−25

MGE035

(1)

(2)

1/4 f

s

Fig.8 Characteristic pre-filter TF1.

1/2 f

s

1996 Oct 25 14

Page 15

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Table 7 Filter2 characteristic

Tfilter2_select[5:0]

HEX DECIMAL

00 00

01 01 1 × z2+1⁄2× z+1+1⁄2×z−1+1×z

02 02 0 × z2+1⁄2× z+1+1⁄2×z−1+0×z

04 04

05 05 1 × z2+1×z+1+1×z−1+1×z

06 06 0 × z2+1×z+1+1×z−1+0×z

08 08

09 09 1 × z2+0×z+1+0×z−1+1×z

0A 10 0 × z2+0×z+1+0×z−1+0×z

10 16

11 17 1 × z2+1⁄2× z+2+1⁄2×z−1+1×z

12 18 0 × z2+1⁄2× z+2+1⁄2×z−1+0×z

14 20

15 21 1 × z2+1×z+2+1×z−1+1×z

16 22 0 × z2+1×z+2+1×z−1+0×z

18 24

19 25 1 × z2+0×z+2+0×z−1+1×z

1A 26 0 × z2+0×z+2+0×z−1+0×z

20 32

21 33 1 × z2+1⁄2× z+0+1⁄2×z−1+1×z

22 34 0 × z2+1⁄2× z+0+1⁄2×z−1+0×z

24 36

25 37 1 × z2+1×z+0+1×z−1+1×z

26 38 0 × z2+1×z+0+1×z−1+0×z

28 40

29 41 1 × z2+0×z+0+0×z−1+1×z

2A 42 0 × z2+0×z+0+0×z−1+0×z

1

1

1

1

1

1

1

1

1

Tfilter2-TRANSFER (z)

⁄2× z2+1⁄2× z+1+1⁄2×z−1+1⁄2×z

−2

−2

⁄2× z2+1×z+1+1×z−1+1⁄2×z

⁄2× z2+0×z+1+0×z−1+1⁄2×z

−2

−2

−2

−2

−2

−2

⁄2× z2+1⁄2× z+2+1⁄2×z−1+1⁄2×z

−2

−2

⁄2× z2+1×z+2+1×z−1+1⁄2×z

⁄2× z2+0×z+2+0×z−1+1⁄2×z

−2

−2

−2

−2

−2

−2

⁄2× z2+1⁄2× z+0+1⁄2×z−1+1⁄2×z

−2

−2

⁄2× z2+1×z+0+1×z−1+1⁄2×z

⁄2× z2+0×z+0+0×z−1+1⁄2×z

−2

−2

−2

−2

−2

−2

SAA4990H

−2

−2

−2

1996 Oct 25 15

Page 16

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

15

handbook, halfpage

10

IH_TF2I

5

(dB)

0

−5

−10

−15

−20

−25

(1)

(2)

1/4 f

s

MGE036

1/2 f

s

15

handbook, halfpage

10

IH_TF2I

5

(dB)

0

−5

−10

−15

−20

−25

(2)

(1)

1/4 f

SAA4990H

s

MGE037

1/2 f

s

TF2(z) = a z2+bz+2c+bz−1+az−2.

(1) c = 0.

(2) c = 1.

Fig.9 Characteristic pre-filter TF2 (a = 0; b = 1).

Table 8 Fixed_k setting

Fixed_k SETTING [3:0]

HEX DECIMAL

00 00 0

01 01

02 02

03 03

04 04

05 05

06 06

07 07

08 08

09 09

0A 10

0B 11

0C 12

0D 13

0E 14

0F 15

TF2(z) = a z2+bz+2c+bz−1+az−2.

(1) b = 1.

(2) b = 0.

Fig.10 Characteristic pre-filter TF2 (a = 1; c = 1).

Table 9 Mult setting

MULT SETTING [1:0]

k

FACTOR

HEX DECIMAL

00 00 1

1

⁄

16

2

⁄

16

3

⁄

16

4

⁄

16

5

⁄

16

6

⁄

16

7

⁄

16

8

⁄

16

9

⁄

16

10

⁄

16

11

⁄

16

12

⁄

16

13

⁄

16

14

⁄

16

16

⁄

16

01 01 2

02 02 4

03 03 8

1996 Oct 25 16

Page 17

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

handbook, full pagewidth

1

14/16

k

12/16

10/16

8/16

6/16

4/16

2/16

0

SAA4990H

MGE034

9080706050403020101

input amplitude

128120110100

Fig.11 k factor curve (example) from filter TF2 and multiplier (see Fig.6).

handbook, full pagewidth

FM1

a

MUX1 LM1

b

FM2

FCM1

FM1 and FM2: field memories (external).

LM1 and LM2: line memories.

a

MUX2

b

a

MUX3

b

CONTROL LOGIC

FCM23

a

MUX4

b

FCM4

LM2

MEDIAN (Y)

or

MULTIPLEXER (UV)

fixselY

fixselUV

data

output

MGE030

Fig.12 Extract of the Progressive scan-Zoom and Noise reduction IC (PROZONIC) data path.

1996 Oct 25 17

Page 18

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

SAA4990H

reduction IC (PROZONIC)

Table 10 Field controlled output

FCM23

(1)

FCM1

(2)

FCM4

0 X 0 X FM1 FM2 FM1

0 X 1 X FM1 FM2 FM2

1 0 0 FM2 FM1 FM2/1H delay FM1

1 0 1 FM2 FM1 FM2/1H delay FM2/1H delay

1 1 0 FM1 FM1/1H delay FM2 FM1/1H delay

1 1 1 FM1 FM1/1H delay FM2 FM2

Notes

1. FCM23 is the field controlled MUX2, MUX3.

2. FCM1 is the field controlled MUX1.

3. FCM4 is the field controlled MUX4.

Table 11 Data output

fixselY/fixselUV

HEX DECIMAL

00 00 MUX2

01 01 MUX4/1H delay

02 02 MUX3

03 03 MEDIAN (Y)/median controlled MULTIPLEXER (UV)

FIELD CONTROLLED OUTPUT TO MEDIAN (Y) OR MUL TIPLEXER (UV)

(3)

MUX1 MUX2 MUX3 MUX4

DATA OUTPUT FROM

handbook, full pagewidth

from SNERT

register

R/W control

(RAM1wr)

(1) n = sequence length + 1

RAM1

sequence data 1

sequence data 2

sequence data n

RAM2

sequence data 1

sequence data 2

sequence data n

Fig.13 Internal RAM control.

1996 Oct 25 18

to

to

(1)

to internal

processing

(1)

MGE031

Page 19

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Microcontroller interface (SNERT)

In the microcontroller interface the external signals SNDA

and SNCL are processed to address and data. Data

enable pulses are derived from the received addresses.

The data enable pulses are used elsewhere for input

enabling the delivered data into various control registers.

The microcontroller interface operates in a few stages:

1. SNCL positive and negative edges are sampled

2. on each negative edge of SNCL and SNDA data is

shifted in a shift register

3. starting from phase 0, a counter counts positive edges

of SNCL

4. during phase 7, but waited for a negative edge of

SNCL, so after the 8th negative edge of SNCL, an

address latch enable pulse is made, whereby the shift

register contents are taken over in the address register

5. in the address range 10H to 27H, the addresses are

decoded in two steps

6. during phase 15, but waited for a negative edge of

SNCL, so after the 16th negative edge of SNCL, the

address has been decoded and will be passed to any

of the data enable pulses.

SAA4990H

For each of the functions vert_start_box and

vert_stop_box, two addresses are used, in which the LSB

from the address is taken as an extra MSB for the data.

This is done because vert_start_box and vert_stop_box

must be supplied with 9-bit data. All other data from the

SNERT-bus has only relevance in the 7:0 range.

During the data phases (phase 8 to 15), each negative

edge produces a shift pulse for the movie phase detect

circuit that produces output data on the SNDA signal. The

data enables for the movie phase detect circuit are active

in all of the data phases, when an address 26 or 27 has

been decoded.

After an MPD read transmission it is necessary to send a

second (dummy) transmission to the PROZONIC.

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

V

V

T

T

I

DDD

DDA

stg

amb

input voltage −0.5 +7 V

digital supply voltage −0.5 +7 V

analog supply voltage −0.5 +7 V

storage temperature −65 +150 °C

operating ambient temperature 0 70 °C

1996 Oct 25 19

Page 20

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

SAA4990H

reduction IC (PROZONIC)

CHARACTERISTICS

V

= 4.5 to 5.5 V; T

DDD

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

Supply

V

I

DDD

DDD

supply voltage 4.5 5.5 V

supply current − 180 mA

Digital inputs

V

IL

LOW level input voltage except CK −0.5 +0.8 V

LOW level input voltage for CK −0.5 +0.6 V

V

IH

HIGH level input voltage except CK 2.0 V

HIGH level input voltage for CK 2.4 V

I

LI

C

I

input leakage current − 10 µA

input capacitance − 10 pF

Digital outputs

V

OH

V

OL

HIGH level output voltage note 1 2.4 V

LOW level output voltage note 1 0 0.6 V

Timing

T

cyCK

δ

CK

t

r

t

f

t

SU

t

HD

t

OH

t

OD

CK cycle time 27 − ns

CK duty factor t

CK rise time − 5ns

CK fall time − 6ns

input data set-up time − 3ns

input data hold time − 3ns

output data hold time note 1 3 − ns

output data delay time note 1 − 23 ns

Data output loads (3-state outputs)

C

L

output load capacitance 10 20 pF

output load capacitance for RE1, RE2, WE2

and SNDA

= 0 to 70 °C; unless otherwise specified.

amb

CKH/tCKL

+ 0.5 V

DDD

+ 0.5 V

DDD

DDD

V

40 60 %

10 35 pF

Note

1. Timings and levels have to be measured with load circuits 1.2 kΩ connected to 3.0 V (TTL load) and C

1996 Oct 25 20

=20pF.

L

Page 21

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

Input/output timing

handbook, full pagewidth

CLOCK

CK1, CK2

INPUT

DATA

t

r

t

HD

t

SU

T

cyCKH

T

cyCK

SAA4990H

t

f

2.4 V

1.5 V

0.6 V

2.0 V

0.8 V

OUTPUT

DATA

t

OD

t

OH

Fig.14 Timing diagram.

2.4 V

0.6 V

MGE032

1996 Oct 25 21

Page 22

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

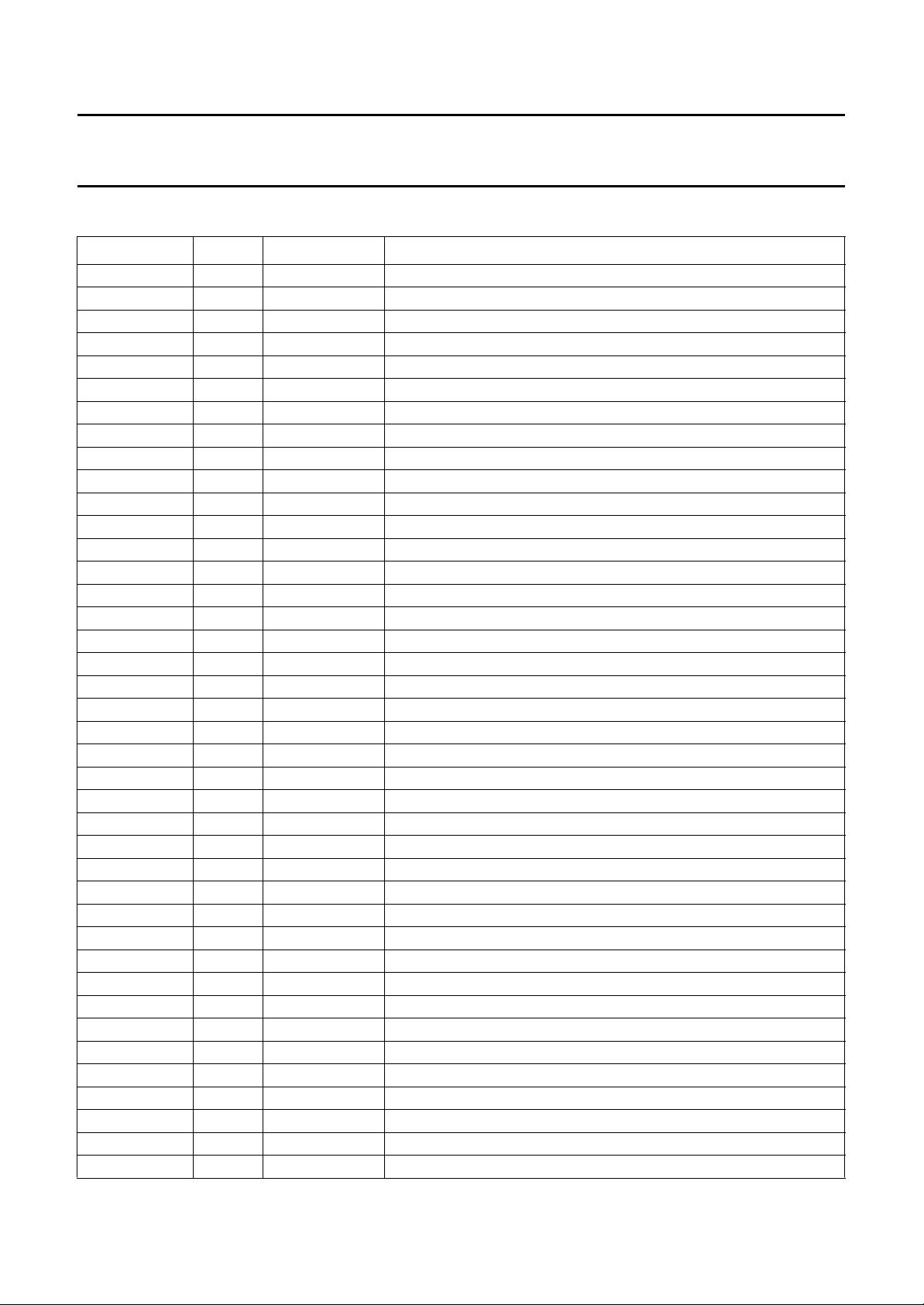

APPLICATION INFORMATION

The basic application of PROZONIC in a feature box is

shown in Fig.15. Here, apart from the data streams, the

‘timed control data’ streams indicate that some memory

control signals have to be processed by the PROZONIC,

in order to let the vertical sample rate conversion function

correctly.

Horizontal scaling factors are performed by the memory

controller SAA4951WP/SAA4952H.

All basic clock signals in the feature box are provided by

the memory controller, nominal frequencies on the double

scan parts of the system are 27, 32 or 36 MHz. In any case

the display frequency is decoupled from the acquisition

clock.

The memory controller supplies the deflection processor

with clock, horizontal and vertical pulses.

The SNERT-bus is used to control the PROZONIC at a

data rate of typically 1 Mbits/s.

SAA4990H

Table 12 Abbreviations used in Fig.15

BLND horizontal blanking signal, display related

HDFL horizontal synchronization signal, deflection

related

HA horizontal synchronization signal, acquisition

related

HRA horizontal reference signal, acquisition related

HRD horizontal reference signal, display related

HRDFL horizontal reference signal, deflection related

IE input enable signal

LLA line locked clock signal, acquisition related

LLD line locked clock signal, display related

LLDFL line locked clock signal, deflection related

RE read enable signal

RSTR reset read signal

RSTW reset write signal

2

SCL serial clock signal (I

SDA serial data signal (I

SNERT synchronous no parity eight bit reception and

transmission (serial control bus)

SRC serial read clock signal

SWC serial write clock signal

VA vertical synchronization signal,

acquisition related

VDFL vertical synchronization signal,

deflection related

C-bus)

2

C-bus)

1996 Oct 25 22

Page 23

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

handbook, full pagewidth

10nF220

Y

in

3

−(R−Y)

in

9

−(B−Y)

in

7

18 nF

5

33 nF

11

33 nF

6,23,

12

32

+5 V

1.5

220

µF

nF

nF

41328

ADC

TDA8755

10,

18

1615 17

24

25

26

27

28

29

30

31

19

20

21

22

C0

6

C1

7

C2

8

C3

9

C4

10

C5

11

C6

12

C7

13

C8

2

C9

3

C10

4

C11

5

0

9

1

8

2

7

3

6

4

5

5

4

6

3

7

2

8

13

9

12

10

11

11

10

+5 V

18,19,201,36 16,17

FM 2

TMS4C2970

15,22 14,23

+5 V

18,19,201,36 22 23 21

FM 1

TMS4C2970

14

15 17 16

SWC RSTW WE IE

SAA4990H

WE2

RE2

B0

B10

B11

SRC

RE1

A10

A11

24

29

B1

30

B2

31

B3

32

B4

35

B5

36

B6

37

B7

38

B8

25

B9

26

27

28

40,60

20

3

A0

76

A1

75

A2

72

A3

71

A4

70

A5

69

A6

68

A7

67

A8

80

A9

79

78

77

39

RE

21

31

30

29

28

27

26

25

24

35

34

33

32

RSTR

28

29

30

31

32

33

34

35

24

25

26

27

n.c.

63,64,

23

65,66

PROZONIC

SAA4990H

5,12,22,33,45

1,2,4,11,21,34

46,52,59,73

41 62 61

12 12

51,58,74

C0

15

C1

14

C2

13

C3

10

C4

9

C5

8

C6

7

C7

6

C8

19

C9

18

C10

17

C11

16

+5 V

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

9,25,

45

40,62,

65,66

46

47

48

49

50

51

52

41

42

43

44

26 19 23 24

48

49

50

53

54

55

56

57

42

43

44

47

SNERT

+5 V

60,63,

68

BENDIC

SAA7158

0

10 kΩ

598,27,

Y

out

61

−(R−Y)

out

67

−(B−Y)

out

64

100 nF

54

100 nF

57

20,21,

22

BLND

2

10

6

18

3428 7 4

12,24,34,44

2,10,23,36

+5 V

VA

HA

39

137 11 35 33 13 43 38

HDFL HRD HRA HRDFL LLDFL LLA LLD

ECO 3

SAA4951

DEFLECTION PLL

ACQUISITION PLL

DISPLAY PLL

20

0

25

1

26

2

27

3

28

4

29

5

30

6

31

7

32

8

21

9

22

21311

43

42

41

40

39

38

37

36

33

18,19

µC

S87C654

15 14 20 21

22 pF 22 pF

35,44

22

10

8

9

12 MHz

MGE025

+5 V

2.2 µF

SCL

SDA

VDFL

LLDFL

HDFL

Fig.15 Application circuit.

1996 Oct 25 23

Page 24

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

PACKAGE OUTLINE

QFP80: plastic quad flat package; 80 leads (lead length 1.95 mm); body 14 x 20 x 2.8 mm

c

y

X

64 41

65

40

A

Z

E

SAA4990H

SOT318-2

pin 1 index

80

1

w M

b

0.25

p

D

H

D

cE

0.25

0.14

D

20.1

19.9

p

0.45

0.30

0 5 10 mm

(1)

(1) (1)(1)

14.1

13.9

e

DIMENSIONS (mm are the original dimensions)

mm

A

max.

3.2

0.25

0.05

2.90

2.65

UNIT A1A2A3b

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

24

Z

D

scale

eH

H

24.2

0.8 1.95

23.6

25

D

e

H

E

E

w M

b

p

v M

A

B

v M

B

LLpQZywv θ

E

18.2

17.6

1.0

0.6

1.4

1.2

A

2

A

A

1

detail X

0.20.2 0.1

Q

(A )

3

θ

L

p

L

Z

E

D

1.2

0.8

o

7

o

0

1.0

0.6

OUTLINE

VERSION

SOT318-2

IEC JEDEC EIAJ

REFERENCES

1996 Oct 25 24

EUROPEAN

PROJECTION

ISSUE DATE

92-12-15

95-02-04

Page 25

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

Reflow soldering

Reflow soldering techniques are suitable for all QFP

packages.

The choice of heating method may be influenced by larger

plastic QFP packages (44 leads, or more). If infrared or

vapour phase heating is used and the large packages are

not absolutely dry (less than 0.1% moisture content by

weight), vaporization of the small amount of moisture in

them can cause cracking of the plastic body. For more

information, refer to the Drypack chapter in our

Reference Handbook”

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

(order code 9398 652 90011).

“Quality

(order code 9397 750 00192).

SAA4990H

If wave soldering cannot be avoided, the following

conditions must be observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave)

soldering technique should be used.

• The footprint must be at an angle of 45° to the board

direction and must incorporate solder thieves

downstream and at the side corners.

Even with these conditions, do not consider wave

soldering the following packages: QFP52 (SOT379-1),

QFP100 (SOT317-1), QFP100 (SOT317-2),

QFP100 (SOT382-1) or QFP160 (SOT322-1).

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

Wave soldering

Wave soldering is not recommended for QFP packages.

This is because of the likelihood of solder bridging due to

closely-spaced leads and the possibility of incomplete

solder penetration in multi-lead devices.

1996 Oct 25 25

Page 26

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

SAA4990H

reduction IC (PROZONIC)

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1996 Oct 25 26

Page 27

Philips Semiconductors Preliminary specification

Progressive scan-Zoom and Noise

reduction IC (PROZONIC)

SAA4990H

NOTES

1996 Oct 25 27

Page 28

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 200 733, Fax. +375 172 200 773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 689 211, Fax. +359 2 689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. +45 32 88 2636, Fax. +45 31 57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615800, Fax. +358 9 61580/xxx

France: 4 Rue du Port-aux-Vins, BP317, 92156 SURESNES Cedex,

Tel. +33 1 40 99 6161, Fax. +33 1 40 99 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 23 53 60, Fax. +49 40 23 536 300

Greece: No. 15, 25th March Street, GR 17778 TAVROS/ATHENS,

Tel. +30 1 4894 339/239, Fax. +30 1 4814 240

Hungary: see Austria

India: Philips INDIA Ltd, Shivsagar Estate, A Block, Dr. Annie Besant Rd.

Worli, MUMBAI 400 018, Tel. +91 22 4938 541, Fax. +91 22 4938 722

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, TEL AVIV 61180,

Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. +81 3 3740 5130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 247 9145, Fax. +7 095 247 9144

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 7430 Johannesburg 2000,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

South America: Rua do Rocio 220, 5th floor, Suite 51,

04552-903 São Paulo, SÃO PAULO - SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 829 1849

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 3 301 6312, Fax. +34 3 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 632 2000, Fax. +46 8 632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2686, Fax. +41 1 481 7730

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66,

Chung Hsiao West Road, Sec. 1, P.O. Box 22978,

TAIPEI 100, Tel. +886 2 382 4443, Fax. +886 2 382 4444

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 625 344, Fax.+381 11 635 777

For all other countries apply to: Philips Semiconductors, Marketing & Sales Communications,

Building BE-p, P.O. Box 218, 5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. 1996 SCA52

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

Printed in The Netherlands 537021/1200/01/pp28 Date of release: 1996 Oct 25 Document order number: 9397 750 01435

Loading...

Loading...