Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA3010

Infrared remote control transmitter

RC-5

Product specification

File under Integrated Circuits, IC01

June 1989

Page 2

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

FEA TURES

• Low voltage requirement

• Biphase transmission technique

• Single pin oscillator

• Test mode facility

The device can generate 2048 different commands and

utilizes a keyboard with a single pole switch for each key.

The commands are arranged so that 32 systems can be

addressed, each system containing 64 different

commands. The keyboard interconnection is illustrated by

Fig.3.

The circuit response to legal (one key pressed at a time)

GENERAL DESCRIPTION

and illegal (more than one key pressed at a time) keyboard

operation is specified in the section “Keyboard operation”.

The SAA3010 is intended as a general purpose (RC-5)

infrared remote control system for use where a low voltage

supply and a large debounce time are expected.

QUICK REFERENCE DATA

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Supply voltage range V

Input voltage range (note 1) V

Input current I

Output voltage range (note 1) V

Output current I

Operating ambient temperature

DD

I

I

O

O

T

amb

2 − 7V

−0.5 − VDD+0.5 V

−−±10 mA

−0.5 − VDD+0.5 V

−−±10 mA

−25 − 85 °C

range

Note

1. V

+0.5 V must not exceed 9 V.

DD

WARNING

The use of this device must conform with the Philips Standard number URT-0421.

PACKAGE OUTLINES

28-lead DIL plastic; (SOT117); SOT117-1; 1996 September 11.

28-lead mini-pack; plastic (SO28; SOT136A); SOT136-1; 1996 September 11.

June 1989 2

Page 3

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

BLOCK DIAGRAM

handbook, full pagewidth

SAA3010

OSC

18

OSC

3 × 2

1

TP1

TP2

SSM

Z3

Z2

Z1

Z0

X7

X6

X5

X4

X3

X2

X1

X0

20

19

2

6

5

4

3

1

27

26

25

24

23

22

21

TEST

MODE

MODE

SELECTION

KEYBOARD

ENCODER

OUTPUT

MASTER

RESET

GENERATOR

CONTROL

UNIT

COMMAND

AND

SYSTEM

ADDRESS

LATCH

PARALLEL

TO SERIAL

CONVERTER

DECODER

13

2

DIVIDER

KEYBOARD

DRIVER

DECODER

17

DR0

16

DR1

15

DR2

13

DR3

12

DR4

11

DR5

10

DR6

9

DR7

8

DATA

7

MDATA

Fig.1 Block diagram.

June 1989 3

14

VSSV

28

MGE347

DD

Page 4

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

PINNING

PIN MNEMONIC

(1)

FUNCTION

1 X7 (IPU) sense input from key matrix

2 SSM (I) system mode selection input

3-6 Z0-Z3 (IPU) sense inputs from key matrix

7 MDATA (OP3) generated output data

modulated with 1/12 the

oscillator frequency at a 25%

duty factor

8 DATA (OP3) generated output information

9-13 DR7-DR3

scan drivers

(ODN)

14 V

SS

15-17 DR2-DR0

ground (0 V)

scan drivers

(ODN)

18 OSC (I) oscillator input

19 TP2 (I) test point 2

20 TP1 (I) test point 1

21-27 X0-X6 (IPU) sense inputs from key matrix

28 V

(I) voltage supply

DD

Note

1. (I) = input

(IPU) = input with p-channel pull-up transistor

(ODN) = output with open drain n-channel transistor

(OP3) = output 3-state

handbook, halfpage

X7

SSM

Z0

Z1

Z2

Z3

MDATA

DATA

DR7

DR6

DR5

DR4

DR3

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

SAA3010

MGE346

V

28

DD

X6

27

X5

26

X4

25

X3

24

23

X2

X1

22

21

X0

TP1

20

TP2

19

OSC

18

DR0

17

DR1

16

1514

DR2

June 1989 4

Fig.2 Pinning diagram.

Page 5

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

handbook, full pagewidth

DR0 DR1 DR2 DR3 DR4 DR5 DR6 DR7

17 16 15 13 12 11 10 9

X0

21

X1

22

X2

23

X3

24

X4

25

X5

26

X6

X7

27

1

SAA3010

Z0

3

Z1

4

Z2

5

Z3

6

8 7 2 20 19 18

DATA MDATA SSM TP1 TP2 OSC

Fig.3 Keyboard interconnection.

MGE348

June 1989 5

Page 6

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

FUNCTIONAL DESCRIPTION

Keyboard operation

Every connection of one X-input and one DR-output will be recognized as a legal key operation and will cause the device

to generate the corresponding code. The same applies to every connection of one Z-input to one DR-output with the

proviso that SSM must be LOW. When SSM is HIGH a wired connection must exist between a Z-input and a DR-output.

If no connection is present the system number will not be generated. Activating two or more X-inputs, Z-inputs or Z-inputs

and X-inputs at the same time is an illegal action and inhibits further activity (oscillator will not start).

When one X- or Z-input is connected to more than one DR-output, the last scan signal will be considered as legal.

The maximum value of the contact series resistance of the switched keyboard is 7 kΩ.

Inputs

In the quiescent state the command inputs X0 to X7 are held HIGH by an internal pull-up transistor. When the system

mode selection (SSM) input is LOW and the system is quiescent, the system inputs Z0 to Z3 are also held HIGH by an

internal pull-up transistor. When SSM is HIGH the pull-up transistor for the Z-inputs is switched off, in order to prevent

current flow, and a wired connection in the Z-DR matrix provides the system number.

Outputs

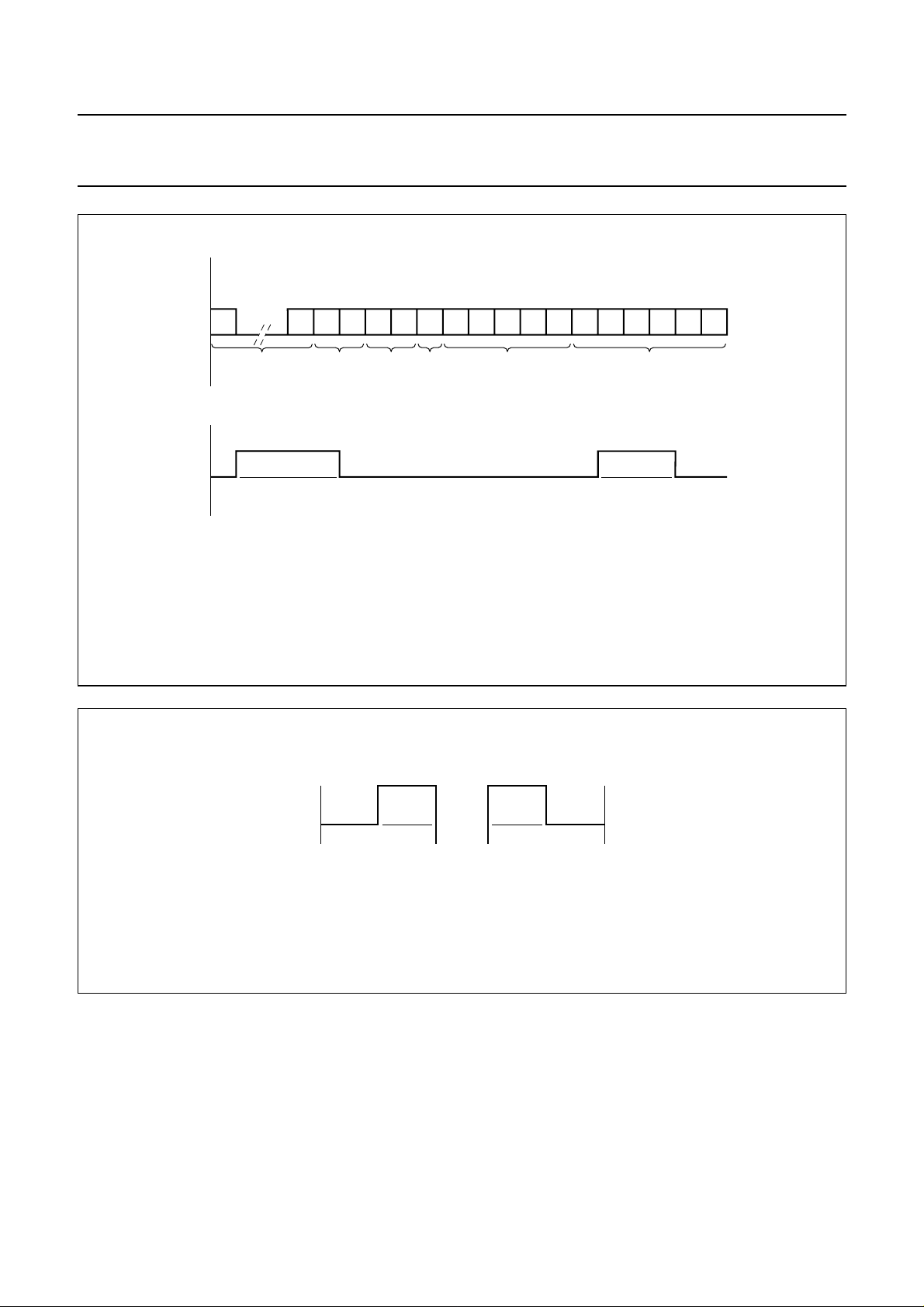

The output signal DATA transmits the generated information in accordance with the format illustrated by Fig.4 and

Tables 1 and 2. The code is transmitted using a biphase technique as illustrated by Fig.5. The code consists of four parts:

• Start part −1.5 bits (2 × logic 1)

• Control part −1 bit

• System part −5 bits

• Command part −6 bits

The output signal MDATA transmits the generated information modulated by 1/12 of the oscillator frequency with a 50%

duty factor.

In the quiescent state both DATA and MDATA are non-conducting (3-state outputs).

The scan driver outputs DR0 to DR7 are open drain n-channel transistors and conduct when the circuit is quiescent.

After a legal key operation the scanning cycle is started and the outputs switched to the conductive state one by one.

The DR-outputs were switched off at the end of the preceding debounce cycle.

June 1989 6

Page 7

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

handbook, full pagewidth

ONE CODE

MSB LSB MSB LSB

start

start

debounce

time

(16 bit-times)

scan

time

control

bits

bit

TWO SUCCESSIVE CODES

system bits command bits

1st. code

start

Where:

debounce time + scan time = 18 bit-times

repetition time = 4 × 16 bit-times

handbook, halfpage

Where:

1 bit-time = 3.28× T

= 1.778 ms (typ.)

OSC

2nd. code

MGE349

Fig.4 Data output format.

logic 1 logic 0

MGE350

Fig.5 Biphase transmission technique.

June 1989 7

Page 8

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

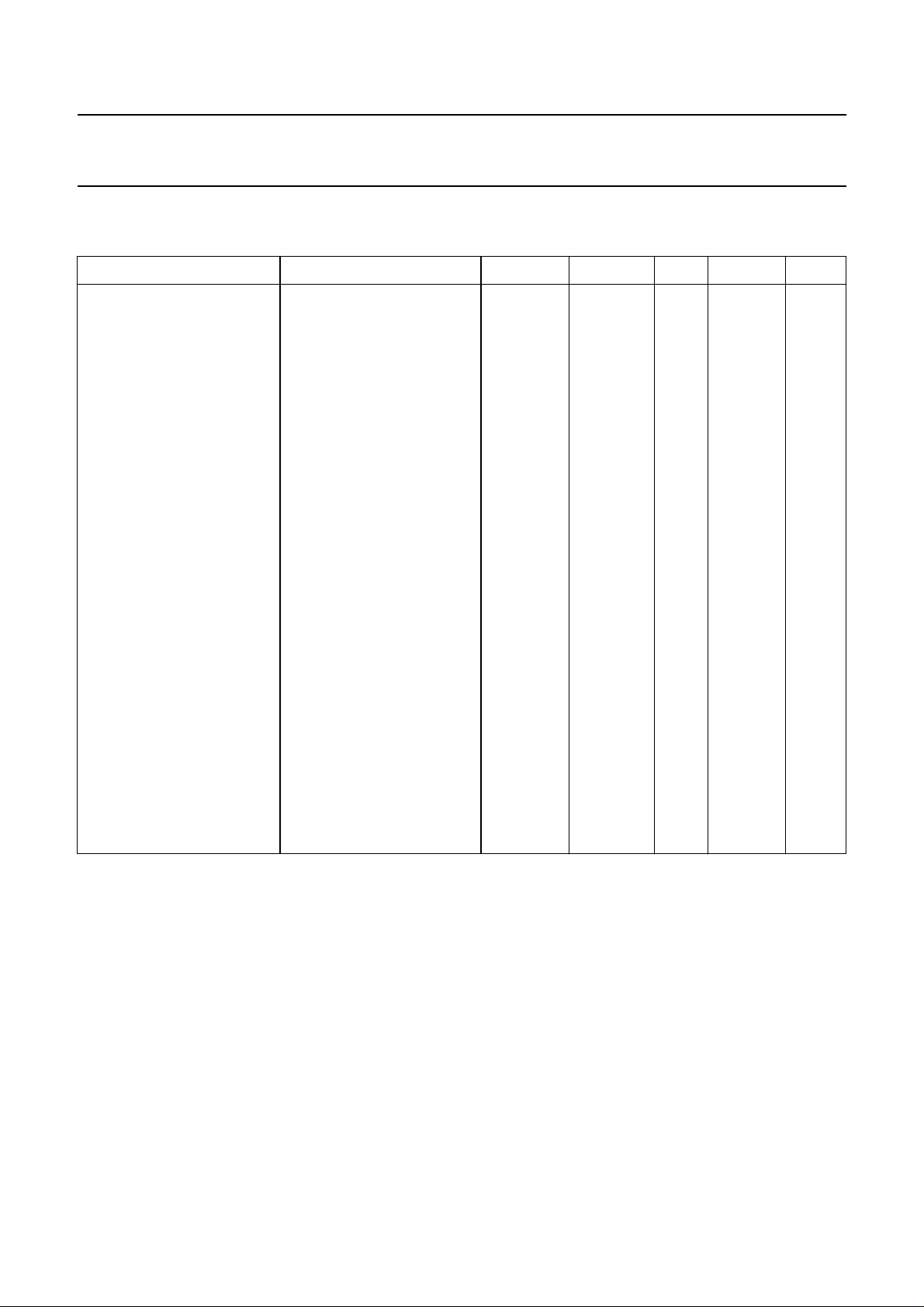

Table 1 Command matrix (X-DR)

CODE

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

X-LINES DR-LINES COMMAND BITS

0123456701234567543210

••000000

0

••000001

1

2

••000010

3

••000011

••000100

4

5

••000101

6

••000110

••000111

7

8

9

•• 001000

••001001

••001010

••001011

••001100

••001101

••001110

••001111

•• 010000

••010001

••010010

••010011

••010100

••010101

••010110

••010111

•• 011000

•• 011001

••011010

••011011

••011100

••011101

••011110

••011111

June 1989 8

Page 9

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

CODE

X-LINES DR-LINES COMMAND BITS

NO.

0123456701234567543210

32 •• 100000

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

•• 100001

••100010

••100011

••100100

••100101

••100110

••100111

•• 101000

•• 101001

•• 101010

••101011

••101100

••101101

••101110

••101111

•• 110000

•• 110001

•• 110010

••110011

••110100

••110101

••110110

••110111

•• 111000

•• 111001

•• 111010

•• 111011

••111100

••111101

••111110

••111111

June 1989 9

Page 10

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

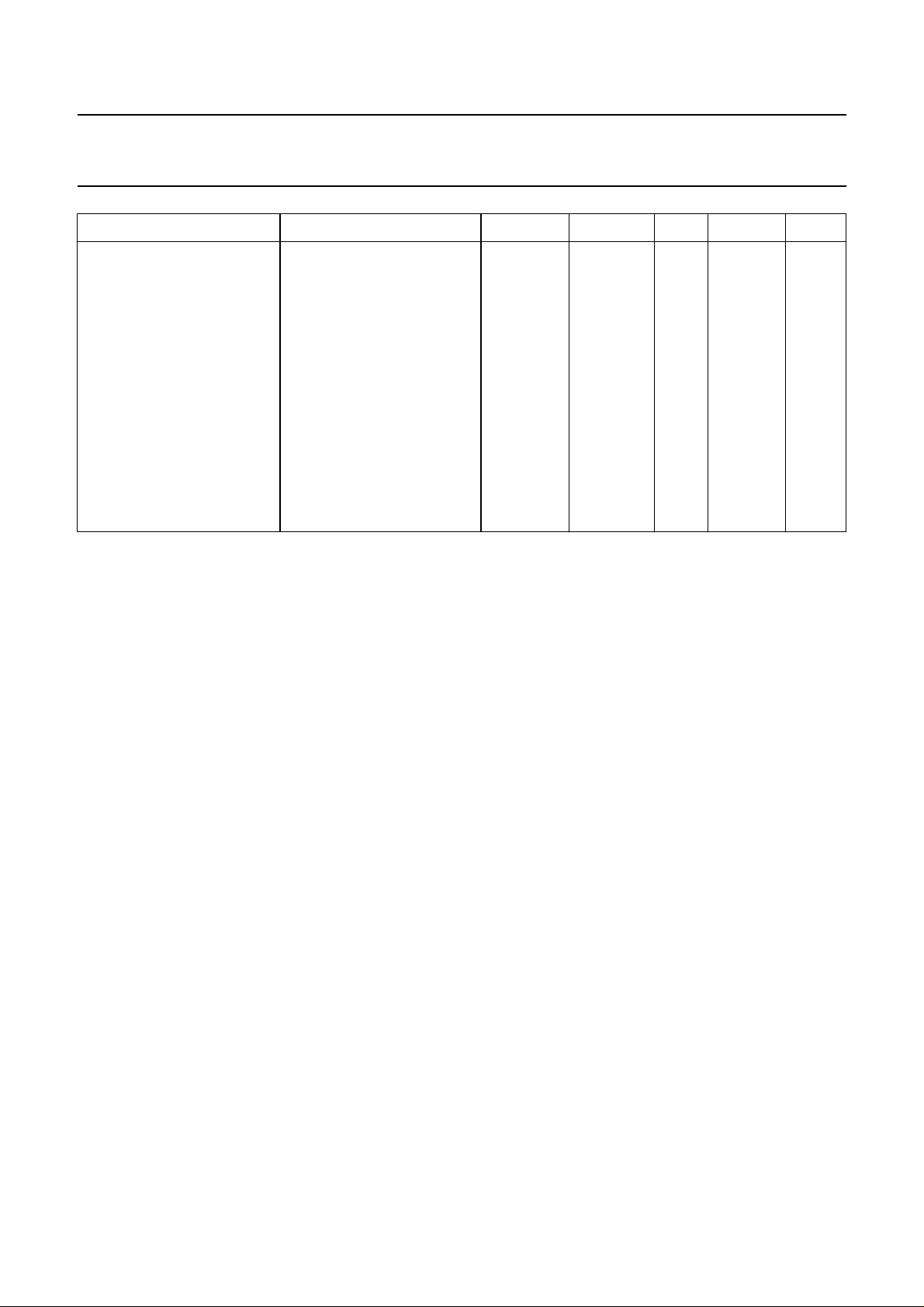

Table 2 System matrix (Z-DR)

SYST.

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Z-LINES DR-LINES SYSTEM BITS

0123456 701234 56 7 43210

•• 00000

0

••00001

1

2

••00010

3

••00011

••00100

4

5

••00101

6

••00110

••00111

7

8

9

•• 01000

••01001

••01010

••01011

••01100

••01101

••01110

••01111

•• 10000

•• 10001

••10010

••10011

••10100

••10101

••10110

••10111

•• 11000

•• 11001

••11010

••11011

••11100

••11101

••11110

••11111

June 1989 10

Page 11

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

Combined system mode (SSM is LOW)

The X and Z sense inputs have p-channel pull-up transistors, so that they are HIGH, until pulled LOW by connecting them

to an output as the result of a key operation. Legal operation of a key in the X-DR or Z-DR matrix will start the debounce

cycle, once key contact has been established for 18 bit-times without interruption, the oscillator enable signal is latched

and the key may be released. An interruption within the 18 bit-time period resets the device.

At the end of the debounce cycle the DR-outputs are switched off and two scan cycles are started, that switch on the

DR-lines one by one. When a Z- or X-input senses a low level, a latch enable signal is fed to the system (Z-input) or

command (X-input) latches.

After latching a system number the device will generate the last command (i.e. all command bits logic 1) in the chosen

system for as long as the key is operated. Latching of a command number causes the chip to generate this command

together with the system number memorized in the system latch. Releasing the key will reset the device if no data is to

be transmitted at the time. Once transmission has started the code will complete to the end.

Single system mode (SSM is HIGH)

In the single system mode, the X-inputs will be HIGH as in the combined system mode. The Z-inputs will be disabled by

having their pull-up transistors switched off; a wired connection in the Z-DR matrix provides the system code. Only legal

key operation in the X-DR matrix will start the debounce cycle, once key contact has been established for 18 bit-times

without interruption the oscillator enable signal is latched and the key may be released. An interruption within the

18 bit-time period resets the internal action.

At the end of the debounce cycle the pull-up transistors in the X-lines are switched off and those in the Z-lines are

switched on for the first scan cycle. The wired connection in the Z-matrix is then translated into a system number and

memorized in the system latch. At the end of the first scan cycle the pull-up transistors in the Z-lines are switched off and

the inputs are disabled again; the pull-up transistors in the X-lines are switched on. The second scan cycle produces the

command number which, after being latched, is transmitted together with the system number.

Key release detection

An extra control bit is added which will be complemented after key release; this indicates to the decoder that the next

code is a new command. This is important in the case where more digits need to be entered (channel numbers of T eletext

or Viewdata pages). The control bit will only be complemented after the completion of at least one code transmission.

The scan cycles are repeated before every code transmission, so that even with “take over” of key operation during code

transmission the right system and command numbers are generated.

Reset action

The device will be reset immediately a key is released during:

• debounce time

• between two codes.

When a key is released during matrix scanning, a reset will occur if:

• a key is released while one of the driver outputs is in the low ohmic stage (logic 0)

• a key is released before that key has been detected

• there is no wired connection in the Z-DR matrix when SSM is HIGH.

June 1989 11

Page 12

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

Oscillator

The OSC is the input/output for a 1-pin oscillator. The oscillator is formed by a ceramic resonator, TOKO CRK429, order

code, 2422 540 98069 or equivalent. A resistor of 6.8 kΩ must be placed in series with the resonator. The resistor and

resonator are grounded at one side.

Test

Initialization of the circuit is performed when TP1, TP2 and OSC are HIGH. All internal nodes are defined except for the

LATCH. The latch is defined when a scan cycle is started by pulling down an X- or Z-input while the oscillator is running.

If the debounce cycle has been completed, the scan cycle can be completed 3 × 2

If the scan cycle has been completed, the contents of the latch can be read 3 × 27 faster by setting TP2 HIGH.

3

faster, by setting TP1 HIGH.

June 1989 12

Page 13

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

LIMITING VALUES

Limiting values in accordance with the Absolute Maximum Rating System (IEC 134)

PARAMETER SYMBOL MIN. MAX. UNIT

Supply voltage range V

Input voltage range (note 1) V

Output voltage range (note 1) V

Input current I

Output current I

Maximum power dissipation

OSC output P

other outputs P

Total power dissipation P

Operating ambient temperature range T

Storage temperature range T

DD

I

O

I

O

O

O

tot

amb

stg

−0.5 8.5 V

−0.5 VDD+0.5 V

−0.5 VDD+0.5 V

−±10 mA

−±10 mA

− 50 mW

− 100 mW

− 200 mW

−25 +85 °C

−55 +150 °C

Note

1. V

+0.5 V must not exceed 9.0 V.

DD

HANDLING

Inputs and outputs are protected against electrostatic charge in normal handling, however, to be totally safe it is desirable

to take normal precautions appropriate to handling MOS devices (see “Handling MOS Devices”).

June 1989 13

Page 14

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

DC CHARACTERISTICS

= −25 °C to +70 °C; VDD= 2.0 to 7.0 V unless otherwise specified

T

amb

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

Supply voltage V

Quiescent supply current note 1

T

=25°C; IO= 0 mA at all

amb

outputs; X0 to X7 and Z0 to

Z3 at VDD; TP1, TP2, OSC at

VSS SSM at VSS or V

DD

INPUTS

Keyboard inputs X and Z with

p-channel pull-up transistor

Input current at each input V

=0V;

I

TP1 = TP2 = SSM = LOW

Input voltage HIGH note 2 V

Input voltage LOW note 2 V

Input leakage current T

=25°C; VI=7V;

amb

TP1 = TP2 = HIGH

Input leakage current T

=25°C; VI=0V;

amb

TP1 = TP2 = HIGH

OSC

Input leakage current T

=25°C; VI=0V;

amb

TP1 = TP2 = HIGH

Input current T

=25°C; VI=V

amb

DD

SSM, TP1, TP2

Input voltage HIGH V

Input voltage LOW V

Input leakage current T

Input leakage current T

=25°C; VI= 7.0 V I

amb

=25°C; VI=0V −I

amb

I

DD

−I

I

LI

−I

−I

I

OSC

LI

DD

I

IH

IL

LI

LI

IH

IL

LI

2.0 − 7.0 V

−−10 µA

10 − 600 µA

0.7V

DD

0 − 0.3V

− V

DD

DD

V

V

−−1µA

−−1µA

−−2µA

4.5 − 30 µA

0.7V

DD

0 − 0.3V

− V

DD

DD

V

V

−−1µA

−−1µA

June 1989 14

Page 15

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

OUTPUTS

DATA, MDATA

Output voltage HIGH IOH= −0.4 mA V

Output voltage LOW I

Output leakage current V

= 0.6 mA V

OL

= 7.0 V +I

O

V

= 7.0 V; T

O

V

=0V −I

O

=0V; T

V

O

=25°C+I

amb

=25°C −I

amb

OH

OL

LO

LO

LO

LO

DR0 TO DR7

Output voltage low I

Output leakage current V

= 0.3 mA V

OL

= 7.0 V +I

O

= 7.0 V; T

V

O

=25°C+I

amb

OL

LO

LO

Notes to the DC characteristics

1. Quiescent supply current measurement must be preceded by the initialization procedure described in the “Test”

section.

2. This DC test condition protects the AC performance of the output. The DC current requirements in the actual

applications are lower.

VDD−0.3 −− V

−−0.3 V

−−10 µA

−−1µA

−−20 µA

−−2µA

−−0.3 V

−−10 µA

−−1µA

June 1989 15

Page 16

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

AC CHARACTERISTICS

= −25 to +85 °C; VDD= 2.0 to 7.0 V unless otherwise stated.

T

amb

PARAMETER CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

Oscillator frequency C

operational f

free-running f

= 160 pF;

L

Figs 6 and 7

OSC

OSC

−−450 kHz

10 − 120 kHz

handbook, halfpage

V

28

18

21

SAA3010

3

17

20

TP1 TP2 V

160 pF

OSC

DR0

C

L

X0

Z0

Fig.6 Test set-up for maximum f

DD

MGE352

CL (pF)

(kHz)

2

1

0

0

80 400

160 240 320

V

DD

SSM

2

19

DATA

8

14

SS

V

SS

MGE351

handbook, halfpage

normalized

frequency

Fig.7 Typical normalized frequency as a function of

measurement.

OSC

keyboard load capacitance.

June 1989 16

Page 17

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

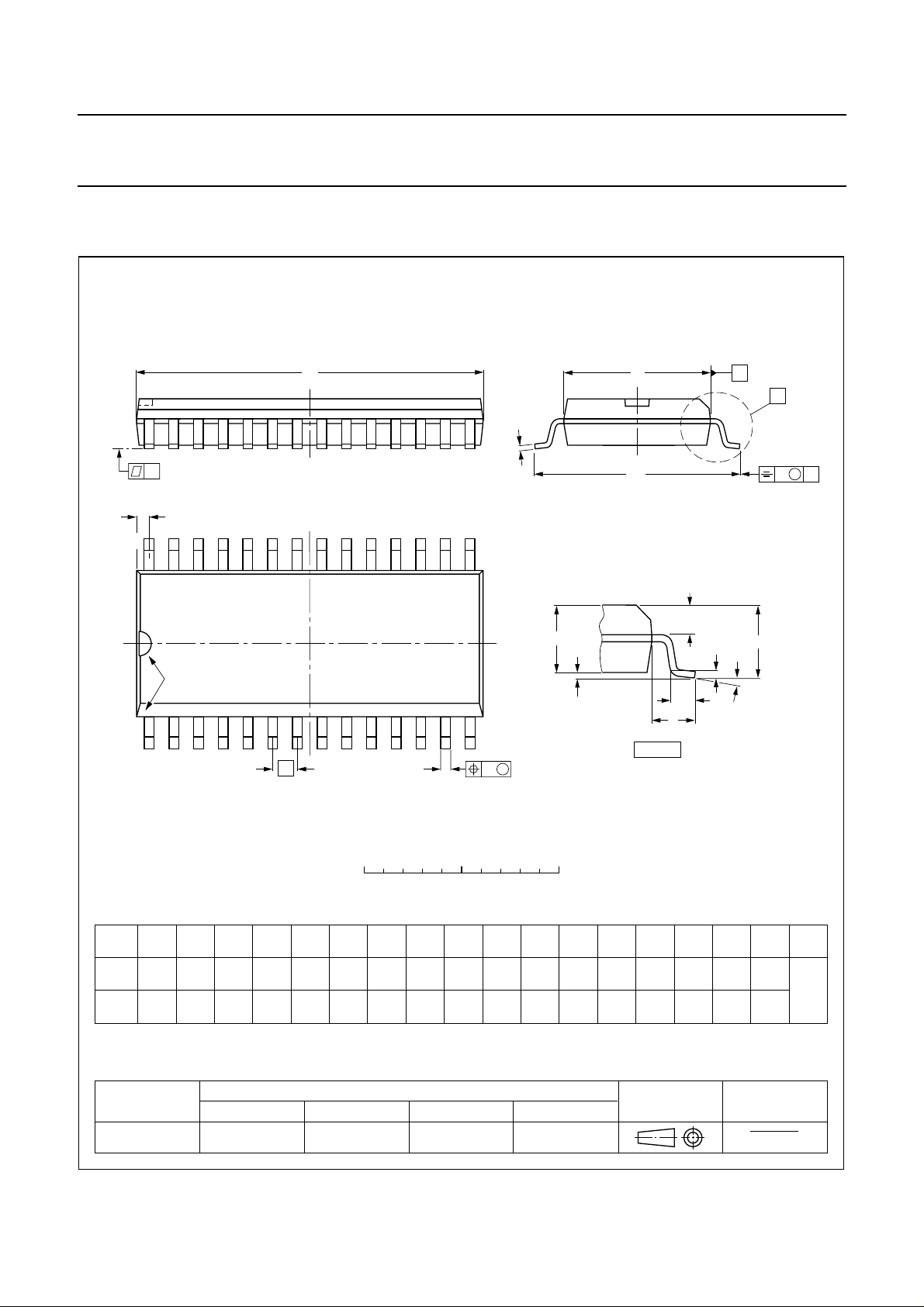

PACKAGE OUTLINES

handbook, full pagewidth

DIP28: plastic dual in-line package; 28 leads (600 mil)

SOT117-1

seating plane

L

Z

28

1

pin 1 index

D

A

2

A

A

1

e

b

w M

b

1

15

E

14

c

M

(e )

M

E

1

H

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

OUTLINE

VERSION

SOT117-1

1 2

min.

max.

1.7

1.3

0.066

0.051

IEC JEDEC EIAJ

051G05 MO-015AH

b

b

1

0.53

0.38

0.020

0.014

0.32

0.23

0.013

0.009

REFERENCES

cD E weM

(1) (1)

36.0

35.0

1.41

1.34

June 1989 17

14.1

13.7

0.56

0.54

(1)

92-11-17

95-01-14

Z

max.

1.75.1 0.51 4.0

0.0670.20 0.020 0.16

L

3.9

15.80

3.4

15.24

EUROPEAN

PROJECTION

M

0.62

0.60

H

E

17.15

15.90

0.68

0.63

0.252.54 15.24

0.010.10 0.60

ISSUE DATE

e

1

0.15

0.13

Page 18

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

SO28: plastic small outline package; 28 leads; body width 7.5 mm

D

c

y

Z

28

pin 1 index

1

e

15

14

w M

b

p

SOT136-1

E

H

E

Q

A

2

A

1

L

p

L

detail X

(A )

A

X

v M

A

A

3

θ

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT136-1

A

max.

2.65

0.10

A

1

0.30

0.10

0.012

0.004

A

A3b

2

2.45

0.25

2.25

0.096

0.01

0.089

IEC JEDEC EIAJ

075E06 MS-013AE

p

0.49

0.36

0.019

0.014

0.32

0.23

0.013

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1) (1)

cD

18.1

7.6

7.4

0.30

0.29

1.27

0.050

17.7

0.71

0.69

REFERENCES

June 1989 18

eHELLpQ

10.65

10.00

0.419

0.394

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

PROJECTION

0.25

0.25 0.1

0.01

0.01

EUROPEAN

ywv θ

Z

0.9

0.4

0.035

0.004

0.016

ISSUE DATE

95-01-24

97-05-22

o

8

o

0

Page 19

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

(order code 9398 652 90011).

DIP

SOLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO

packages.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

AVE SOLDERING

W

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

EPAIRING SOLDERED JOINTS

R

Fix the component by first soldering two diagonally-

opposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

June 1989 19

Page 20

Philips Semiconductors Product specification

Infrared remote control transmitter RC-5 SAA3010

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

June 1989 20

Loading...

Loading...