Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA2022

Tape formatting and error

correction for the DCC system

Product specification

Supersedes data of February 1993

File under Integrated Circuits, Miscellaneous

Philips Semiconductors

February 1994

Page 2

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

FEATURES

• Integrated error correction encoder/decoder function

with Digital Compact Cassette (DCC) optimized

algorithms

• Control of capstan servo during recording and after

recording by microcontroller

• Frequency and phase regulation of capstan servo

during playback

• Choice of two Dynamic Random Access Memory

(DRAM) types operating in page mode

• Scratch pad RAM area available to microcontroller in

system DRAM

• Low power standby mode

• I2S interface

• Microcontroller interface for high-speed transfer burst

rates up to 170 kbytes per second

• SYSINFO and AUXILIARY data flags on microcontroller

interface

• Protection against invalid AUXILIARY data

• +4 V operating voltage capability.

SAA2022

GENERAL DESCRIPTION

Performing the tape formatting and error correction

functions for DCC applications, the SAA2022 can be used

in conjunction with the PASC (SAA2002/SAA2012), tape

equalization (SAA2032), read amplifier (TDA1317 or

TDA1318) and write amplifier (TDA1316 or TDA1319)

circuits to implement a full signal processing system.

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

SAA2022GP 64 QFP

Note

1. When using reflow soldering it is recommended that the Dry Packing instructions in the

Pocketbook”

are followed. The pocketbook can be ordered using the code 9398 510 34011.

PINS PIN POSITION MATERIAL CODE

(1)

PACKAGE

plastic SOT208A

“Quality Reference

February 1994 2

Page 3

February 1994 3

V

DD1VDD2VDD3VDD4

LTCLK

LTEN

LTCNT1

LTCNT0

PINI

SBEF

SBDA

SBCL

SBWS

SBMCLK

TCH0 - 7,

TAUX

RESET

PWRDWN

CLK24

5

6

3

4

49

57

62

61

60

56

33–41

48

47

44

TAPE INPUT

BUFFER

TAPE OUTPUT

BUFFER

CLOCK

GENERATOR

SAA2022

2

SB – I S

INTERFACE

CONTROL

MICROCONTROLLER

INTERFACE

43 8 27 59

ERROR

CORRECTION

CODER

DRAM

INTERFACE

26742

V

SS1VSS2VSS3VSS4

58

17–25

11–14

29

28

32

50

51

15

10

16

64

63

30

31

52

55

2

9

1

LTDATA

WDATA

WCLOCK

PINO1

PINO2

PINO3

RASN

CASN

A0–8

D0–3

WEN

OEN

LTREF

URDA

SBDIR

SPEED

SPDF

AZCHK

MCLK

MEA711 - 2

BLOCK DIAGRAM

correction for the DCC system

SAA2022

Philips Semiconductors Product specification

Tape formatting and error

Fig.1 Block diagram.

Page 4

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

PINNING

SYMBOL PIN DESCRIPTION

LTREF 1 timing reference for microcontroller interface

LTDATA 2 data for microcontroller interface (3-state; CMOS levels)

LTCNT1 3 control for microcontroller interface

LTCNT0 4 control for microcontroller interface

LTCLK 5 bit clock for microcontroller interface

LTEN 6 enable for microcontroller interface

V

SS2

V

DD2

RASN 9 DRAM row address strobe

WEN 10 DRAM write enable

D3 11 DRAM data (MSB); 3-state output; TTL compatible input

D2 12 DRAM data; 3-state output; TTL compatible input

D1 13 DRAM data; 3-state output; TTL compatible input

D0 14 DRAM data (LSB); 3-state output; TTL compatible input

CASN 15 DRAM column address strobe

OEN 16 DRAM output enable

A8 17 DRAM address (MSB)

A7 18 DRAM address

A6 19 DRAM address

A5 20 DRAM address

A4 21 DRAM address

A3 22 DRAM address

A2 23 DRAM address

A1 24 DRAM address

A0 25 DRAM address (LSB)

V

SS3

V

DD3

WCLOCK 28 clock for write amplifier transfers

WDATA 29 write amplifier serial data

SPEED 30 capstan phase information

SPDF 31 capstan frequency information

PINO1 32 Port expander output 1

TAUX 33 AUX channel input from SAA2032

TCH7 34 main data channel 7, input from SAA2032

TCH6 35 main data channel 6, input from SAA2032

TCH5 36 main data channel 5, input from SAA2032

TCH4 37 main data channel 4, input from SAA2032

TCH3 38 main data channel 3, input from SAA2032

TCH2 39 main data channel 2, input from SAA2032

7 supply ground (0 V)

8 supply voltage (+5 V)

26 supply ground (0 V)

27 supply voltage (+5 V)

SAA2022

February 1994 4

Page 5

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SYMBOL PIN DESCRIPTION

TCH1 40 main data channel 1, input from SAA2032

TCH0 41 main data channel 0, input from SAA2032

V

SS1

V

DD1

CLK24 44 24.576 MHz clock from SAA2002

TEST0 45 test select LSB; do not connect

TEST1 46 test select MSB; do not connect

PWRDWN 47 sleep mode selection

RESET 48 reset input with hysteresis and pull-down resistor

PINI 49 Port expander input

PINO2 50 Port expander output 2

PINO3 51 Port expander output 3

AZCHK 52 azimuth check (channels 0 and 7)

TEST2 53 symbol error rate measurement output

TEST3 54 do not connect

MCLK 55 master clock output (6.144 MHz)

SBMCLK 56 master clock for SB-I

SBEF 57 byte error SB-I

V

SS4

V

DD4

SBWS 60 word select SB-I

SBCL 61 bit clock SB-I

SBDA 62 data line SB-I

SBDIR 63 direction SB-I

URDA 64 unusable data SB-I

42 supply ground (0 V)

43 supply voltage (+5 V)

2

S-interface

58 supply ground (0 V)

59 supply voltage (+5 V)

2

S-interface; 3-state output; CMOS levels

2

S-interface; 3-state output; CMOS levels

2

S-interface; 3-state output; CMOS levels

2

S-interface

2

2

S-interface

S-interface

SAA2022

February 1994 5

Page 6

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SBDIR

SBDA

63

62

LTREF

LTDATA

LTCNT1

LTCNT0

LTCLK

LTEN

V

SS2

V

DD2

RASN

WEN

D3

D2

D1

D0

URDA

64

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SBCL

61

V

SBWS

60

SAA2022

DD4

59

V

58

SS4

SBEF

57

MCLK

SBMCLK

56

55

TEST3

54

TEST2

53

AZCHK

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

PINO3

PINO2

PINI

RESET

PWRDWN

TEST1

TEST0

CLK24

V

DD1

V

SS1

TCH0

TCH1

TCH2

TCH3

SAA2022

CASN

15

OEN

16

17

A8

A7

18

A6

19

20

21

A5

A4

22

A3

23

A2

24

A1

25

A0

Fig.2 Pin configuration (SOT208A).

February 1994 6

26

V

SS3

27

DD3

V

28

29

WDATA

WCLOCK

30

SPEED

31

SPDF

37

36

35

34

33

32

PINO1

TCH4

TCH5

TCH6

TCH7

TAUX

MEA693 - 2

Page 7

February 1994 7

FUNCTIONAL DESCRIPTION

correction for the DCC system

Philips Semiconductors Product specification

Tape formatting and error

RECORDING + PLAY BACK

analog

input

analog

output

digital input

digital output

ADC

SAA7360

DAC

SAA7323

DAIO

TDA1315

2

I S

stereo filter

codec

SAA2002

SAA2012

adaptive

allocation and

scale factors

AUDIO INPUT/OUTPUT PASC PROCESSING

MICROCONTROLLER

2

I S

(sub-band)

MEA695 - 2

speed control

TDA1316 or

TDA1319

SAA2022

RAM

256 kbits

SAA2032

digital

equalizer

TAPE DRIVE PROCESSING

write

read

TDA1317 or

TDA1318

capstan

drive

heads

and

tape

Fig.3 DCC data flow diagram.

SAA2022

Page 8

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

The SAA2022 provides the following functions:

In Playback Modes

• Tape channel data and clock recovery

• 10 to 8 demodulation

• Data placement in DRAM

• C1 and C2 error correction decoding

2

S-interfacing to SB-I2S-bus

• I

• Interfacing to microcontroller for SYSINFO and

AUX data

• Capstan control for tape deck.

In Record Modes

2

S-interfacing to SB-I2S-bus

• I

• C1 and C2 error correction encoding

• Formatting for tape transfer

• 8 to 10 modulation

• Interfacing to microcontroller for SYSINFO and

AUX data

• Capstan control for tape deck, programmable by

microcontroller.

SAA2022

PWRDWN

This pin is an active HIGH signal which places the

SAA2022 in a “SLEEP” mode. When the SAA2022 is in

“SLEEP” mode and the CLK24 is either held HIGH or held

LOW, there is no activity in the device, thus resulting in

no EMI and a low power dissipation (typically <10% of

operational dissipation). This pin should be connected to

the DCC power-down signal, which can be driven by the

system microcontroller.

To enter the “SLEEP” mode the SAA2022 should reset

and hold reset. After a delay of at least 15 µs the

PWRDWN pin should be brought HIGH after which the

state of the reset pin is “don’t care”. The power dissipation

is reduced further when the CLK24 input signal stops.

When recovering from “SLEEP” mode the PWRDWN pin

should be driven LOW and the chip reset with a pulse of at

least 15 µs duration.

CLK24

This is the 24.576 MHz clock input and should be

connected directly to the SAA2002 CLK24 pin.

Connections to SAA2032

TCH0

TO TCH7 AND TAUX

Operational Modes

The 3 basic modes of operation are:

• DPAP - Main data (audio) and SYSINFO play, AUX play

• DRAR - Main data (audio) and SYSINFO record,

AUX record

• DPAR - Main data (audio) and SYSINFO play,

AUX record.

Hardware Interfacing

RESET

This is an active HIGH input signal which resets the

SAA2022 and brings it into its default mode, DPAP. This

should be connected to the system reset, which can be

driven by the microcontroller. The duration of the reset

pulse should be at least 15 µs. This pin has an internal

pull-down resistor of between 20 kΩ and 125 kΩ.

These lines are the equalized and clipped (to VDD) tape

channel inputs and should be connected to the SAA2032

pins TCH0 to TCH7 and TAUX.

Sub-band I

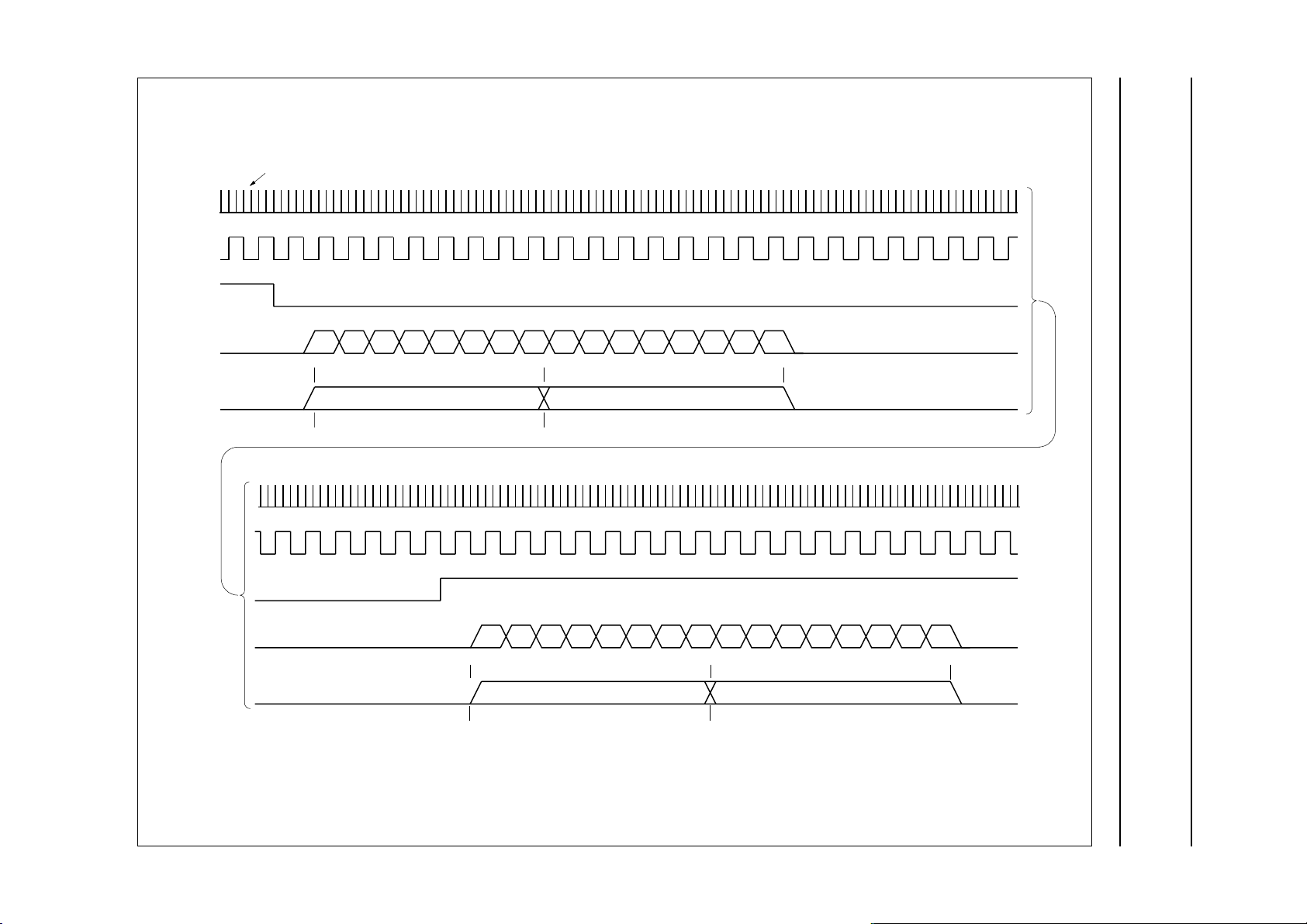

The timing for the SB-I2S-interface is given in Figs 4 to 9.

2

S-bus Connections

February 1994 8

Page 9

February 1994 9

lines show rising edge of SBMCLK

SBMCLK

SBCL

SBWS

SBDA

bit number

byte number

SBEF

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

01

01byte number

correction for the DCC system

Philips Semiconductors Product specification

Tape formatting and error

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

23

23

Fig.4 SB-I2S-interface in playback master mode (1).

MEA697 - 1

SAA2022

Page 10

February 1994 10

SBMCLK

(INPUT)

SBCL

(OUTPUT)

SBWS

(OUTPUT)

SBEF

(OUTPUT)

MCLK

(OUTPUT)

SBDA

(OUTPUT)

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

t

H-1

t

L-1

t

dSR

t

suMR

t

dSR

t

suMR

t

dMR

SBEF

(OUTPUT)

MEA696

SAA2022

Fig.5 SB-I2S-interface in playback master mode (2).

Page 11

February 1994 11

SBCL

SBWS

SBDA

bit number

byte number

SBEF

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

01

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

23

Fig.6 SB-I2S-interface in playback slave mode (1).

MEA699 - 1

SAA2022

Page 12

February 1994 12

MCLK

SBCL

(INPUT)

SBWS

(INPUT)

SBEF

(OUTPUT)

t

hMR

t

suMR

t

hMR

t

suMR

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SBDA

(OUTPUT)

Fig.7 SB-I2S-interface in playback slave mode (2).

t

dMR

MEA698

SAA2022

Page 13

February 1994 13

SBCL

SBWS

SBDA

bit number

byte number

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

01

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

23

Fig.8 SB-I2S-interface in record mode (1).

MSA536

SAA2022

Page 14

February 1994 14

MCLK

(OUTPUT)

SBCL

(INPUT)

SBWS

(INPUT)

SBDA

(INPUT)

t

hMR

t

suMR

MEA700

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Fig.9 SB-I2S-interface in record mode (2).

SAA2022

Page 15

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SBMCLK

This is the sub-band master clock input for the

SB-I2S-interface. The frequency of this signal is nominally

6.144 MHz. This pin should be connected to the SBMCLK

pin of the SAA2002.

SBDIR

2

This output pin is the sub-band I

indicates the direction of transfer on the SB-I2S-bus.

A logic 1 indicates a SAA2022 to SAA2002 transfer

(audio play) whilst a logic 0 is output for a SAA2002 to

SAA2022 transfer (audio record). This pin connects

directly to the SBDIR pin on the SAA2002.

SBCL

This input/output pin is the bit clock line for the

2

S-interface to the SAA2002. Is has a nominal

SB-I

frequency of 768 kHz.

SBWS

This input/output pin is the word select line for the

2

S-interface to the SAA2002. It has a nominal

SB-I

frequency of 12 kHz.

S-bus direction signal, it

SAA2022

SBDA

This input/output pin is the serial data line for the

2

SB-I

S-interface to the SAA2002.

SBEF

This active HIGH output pin is the error per byte line for the

2

S-interface to the SAA2002.

SB-I

URDA

This active HIGH output pin indicates that the main data

(audio), the SYSINFO and the AUXILIARY data are not

usable, regardless of the state of the corresponding

reliability flags. The state of this pin is reflected in the

URDA bit of STATUS byte 0, which can be read by the

microcontroller. This pin should be connected directly to

the URDA pin of the SAA2002. URDA is activated as a

result of a reset, a mode change from DRAR to DPAP, or

if the SAA2022 has had to resynchronize with the incoming

data from tape.

2

The position of the first SB-I

shown in Fig.10.

S-bytes in a tape frame is

February 1994 15

Page 16

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SNUM

LTREF

SBWS

SBDA

0

MODE DPAP OR DPAR

MODE DRAR

1

BYTE number

8191

OF PREVIOUS

TAPE FRAME

SAA2022

BYTE number 2

BYTE number 1

BYTE number 0

SNUM

LTREF

SBWS

SBDA

3

BYTE number 8191

OF PREVIOUS

TAPE FRAME

BYTE number 2

BYTE number 1

BYTE number 0

0

Fig.10 Position of first SB-I2S-bytes in tape frame.

MEA701 - 2

February 1994 16

Page 17

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

MCLK

RASN

CASN

D0...D3

A0...A7 (A8)

ROW COLUMN #0 COLUMN #1 COLUMN #2

SAA2022

#1 #2#0

OEN

WEN

1 read cycle = 651 ns

Fig.11 DRAM timing read cycle.

DRAM Interface

The SAA2022 has been designed to operate with

64 k × 4-bit or 256 k × 4-bit DRAMs operating in page

mode, with an access time of 80 to 100 ns. The timing for

read, write and refresh cycles is shown in Figs 11 to 13.

CASN

This output pin is the column address strobe (active LOW)

for the DRAM, it connects directly to the column address

strobe pin of the DRAM.

RASN

This output pin is the row address strobe (active LOW) for

the DRAM, it connects directly to the row address strobe

pin of the DRAM.

MEA702

OEN

This pin provides the output enable (active LOW) for the

DRAM, it connects directly to the output enable pin of the

DRAM.

WEN

This output pin provides the write enable (active LOW) for

the DRAM, it connects directly to the write enable pin of the

DRAM.

TO A8

A0

These output pins are the multiplexed column and row

address lines for the DRAM. When the 64 k × 4-bit DRAM

is used, pins A0 to A7 should be connected to the DRAM

address input pins, and pin A8 should be left unconnected.

When using the 256 k × 4-bit DRAM then address pins

A0 to A8 should be connected to the address input pins of

the DRAM.

February 1994 17

Page 18

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

MCLK

RASN

CASN

D0...D3

A0...A7 (A8)

ROW COLUMN #0 COLUMN #1 COLUMN #2

#0

SAA2022

#1

#2

OEN

WEN

1 write cycle = 651 ns

Fig.12 DRAM write cycle.

D0 TO D3

These input/output pins are the data lines for the DRAM,

they should be connected directly to the DRAM data I/O

pins.

Write amplifier interface

The SAA2022 may be used with either the TDA1316 or

TDA1319 write amplifiers.

WCLOCK

This output pin provides the 3.072 MHz clock output for the

WRITE AMPLIFIER, it should be connected directly to the

WCLOCK pin of the WRITE AMPLIFIER.

MEA703

WDATA

This output pin is the multiplexed data and control line for

the WRITE AMPLIFIER (timing information is shown in

Fig.14). The WDATA pin should be connected directly to

the WDATA pin of the WRITE AMPLIFIER.

February 1994 18

Page 19

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

MCLK

RASN

CASN

D0...D3

A0...A7 (A8)

OEN

SAA2022

ROW

WEN

1 refresh cycle = 651 ns

Fig.13 DRAM refresh cycle.

Tape deck capstan control interface

SPEED

This signal is a pulse width modulated output that may be

used to control the tape deck capstan. The period of the

SPEED signal is 41.66 µs and the nominal duty cycle is

50%.

There are 4 modes of operation for the SPEED signal

which can be selected by the programmed settings of

µCSPD (microcontroller capstan speed), ENFREG

(enable frequency regulation) and ENEFREG (enable

extended frequency regulation) flags.

SPDF

If µCSPD = logic 0 this pin outputs a pulse width

modulated measurement of the main data channel bit

rates and may be used in combination with the SPEED

signal to control the tape deck capstan. The period of the

MEA704 - 1

SPDF signal is 5.2 µs. The duty cycle of SPDF can vary

from 0% at +6.5% deviation to 100% at −6.5% deviation. If

the deviation = 0% then the duty cycle of SPDF is 50%.

Microcontroller Interface

LTREF

The SAA2022 divides time into segments of 42.67 ms

nominal duration which are counted in modulo 4. The

LTREF active LOW output pin can be connected directly to

the interrupt input of the microcontroller and indicates the

start of a time segment. It goes LOW for 5.2 µs once every

42.66 ms and can be used for generating interrupts. Note

if a resync occurs then the time between the occurrences

of LTREF can vary. The function and programming of the

other interface lines LTCNT0, LTCNT1, LTEN, LTCLK and

LTDATA are described in the pinning and programming

sections.

February 1994 19

Page 20

February 1994 20

WCLOCK

WDATA

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SYNC

TDATPLB TAUXPLB TERAUX TCH0 TCH1 TCH2 TCH3 TCH4 TCH5 TCH6 TCHAUX TCH7

Fig.14 WDATA and WCLOCK timing.

SYNC

TDATPLB

MLA643

SAA2022

Page 21

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Duration of the one tape block

andbook, full pagewidth

AZCHK

(8 periods MCLK)

1.3 µs

This is a measure of the azimuth error.

5.3 ms

SAA2022

MEA705

Fig.15 AZCHK timing.

Test Pins

TEST0, TEST1, TEST2

AND TEST 3

These input pins are for test use only and for normal

operation should not be connected.

AZCHK

This output pin indicates the occurrence of a tape channel

sync symbol on tape channels TCH0 and TCH7. The

separation between the pulses for the TCH0 and TCH7

channels gives a measure of the azimuth error between

the tape and head alignment (see Fig.15).

Port Expansion Pins

PINI

This input pin is connected directly to the PINI bit in the

STATUS byte 1, it can be read by the microcontroller, and

may be used for any CMOS level compatible input signals.

PINO1

This output pin is connected directly to the PINO1 bit of the

SETTINGS byte 1 register and can be set or reset by the

microcontroller.

PINO2

This output pin is connected directly to the PINO2 bit of the

SETTINGS byte 1 register and can be set or reset by the

microcontroller.

PINO3

This output pin is connected directly to the PINO3 bit of the

SETTINGS byte 1 register and can be set or reset by the

microcontroller.

Power Supply Pins

V

TO V

DD1

DD4

These are the +5 V power supply pins which must all be

connected. Decoupling of V

TO V

V

SS1

SS4

SS1

to V

is recommended.

SS4

These are the +5 V power supply ground pins, all of which

must be connected.

February 1994 21

Page 22

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

Programming the SAA2022 via the Microcontroller Interface

Table 1 SAA2022 interface connections to the microcontroller.

PIN INPUT/OUTPUT DESCRIPTION

LTEN I enable active HIGH

LTCLK I clock signal

LTCNT0 I control LSB

LTCNT1 I control MSB

LTDATA I/O bi-directional data

LTREF O timing reference 5 µs at start of every segment active LOW

All transfers are in units of 8-bits, registers with less than 8-bits are LSB justified, unless otherwise specified. The four

basic types of transfer are shown in Table 2.

Table 2 Types of transfer.

LTCNT1 LTCNT0 TRANSFER EXPLANATION

0 0 WDAT write DATA to SAA2022

0 1 RDAT read DATA from SAA2022

1 0 WCMD write Command to SAA2022

1 1 RSTAT read Status from SAA2022

Microcontroller Interface Registers

The SAA2022 microcontroller interface has 7 write and 4 read registers, as shown in Table 3.

Table 3 SAA2022 Microcontroller Interface Registers.

REGISTER READ/WRITE NO. OF BITS COMMENTS

SET0 WRITE 7 primary settings

SET1 WRITE 8 secondary settings

CMD WRITE 6 microcontroller command

BYTCNT WRITE 8 byte counter

RACCNT WRITE 7 random access counter

SPDDTY WRITE 8 duty cycle for SPEED

AFLEV WRITE 4 AUXILIARY flag level

STATUS0 READ 8 primary status

STATUS1 READ 7 secondary status

STATUS2 READ 8 SYSINFO/AUX flags

STATUS3 READ 8 channel status flags

February 1994 22

Page 23

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Direct Access

Only one write (CMD) and four read

(STATUS0 to STATUS3) registers can be directly

accessed using the LTCNT lines, all other registers must

be accessed by first programming the command register.

The four Status registers can be read by performing

4 RSTAT transfers within the same LTEN = HIGH period.

transfer of byte from microcontroller (a)

t

LE

LTEN

LTCNT0,1

LTCLK

LTDATA

t

su1

t

h1

t

su4

t

su2

t

su3

t

h3

0 1 2 3 4 5 6 7

t

Lc

t

Hc

SAA2022

Indirect Access

To write to or read from the indirect access registers, a

command must first be sent to the command register. The

transfer of bytes can then occur using WDAT and RDAT

type transfers. It is the responsibility of the microcontroller

to ensure that the transfer type and the last command are

compatible. The same type of transfer can continue until a

new command is sent.

Typical transfers on the microcontroller interface are

shown in Figs 16 to 19.

t

h2

transfer of byte to microcontroller (b)

t

LE

LTEN

LTCNT0,1

LTCLK

LTDATA

t

su1

t

su4

t

h1

t

su2

t

d1

t

d2

0

1 2 3 4 5 6 7

t

Lc

t

Hc

Fig.16 LT interface timing (1).

February 1994 23

t

h2

t

h5

t

h6

MEA715 - 1

Page 24

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Notes to Fig.16a.

DESCRIPTION TIMING

For the timing figures it is assumed that cycle time T

The set-up time t

The hold time t

of LTEN, LTCNT, LTCLK and LTDATA to MCLK HIGH tsu<40ns

su

of LTEN, LTCNT, LTCLK and LTDATA to MCLK HIGH th = 0 ns

h

LTEN LOW time before start data transfer t

LTCLK LOW time t

LTCLK HIGH time t

LTCNT0/1 set-up time to LTEN HIGH t

LTCNT0/1 hold time to LTEN HIGH t

LTEN set-up time to LTCLK LOW t

LTEN hold time to LTCLK HIGH t

LTDATA set-up time to LTCLK HIGH t

LTDATA hold time to LTCLK HIGH t

LTCLK set-up time to LTEN HIGH t

of MCLK is within the limits 160 ns < Tcy< 165 ns

cy

> 535 ns; note 1

LE

> 205 ns

Lc

> 205 ns

Hc

> 205 ns

su1

> 205 ns

h1

> 0 ns

su2

> 205 ns

h2

> 205 ns

su3

> 40 ns

h3

> 535 ns

su4

SAA2022

Note

1. See interface timing (Fig.16b) for the transfer of a byte to the microcontroller.

February 1994 24

Page 25

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Notes to Fig.16b.

DESCRIPTION TIMING

For the timing figures it is assumed that cycle time Tcy of MCLK is within the limits 160 ns < Tcy< 165 ns

The set-up time t

The hold time t

The delay time t

The delay time t

LTEN LOW time before start data transfer t

LTCLK LOW time t

LTCLK HIGH time t

LTCNT0/1 set-up time to LTEN HIGH t

LTCNT0/1 hold time from LTEN HIGH t

LTEN set-up time to LTCLK LOW t

LTEN hold time from LTCLK HIGH t

LTCLK set-up time to LTEN HIGH t

LTCLK hold time from LTEN LOW t

LTDATA hold time from LTEN LOW t

LTDATA delay time from LTEN HIGH t

LTDATA delay time from LTCLK HIGH t

LTDATA delay time from LTEN (3-state control) t

of LTEN, LTCNT, LTCLK and LTDATA to MCLK HIGH tsu<40ns

su

of LTEN, LTCNT, LTCLK and LTDATA to MCLK HIGH th = 0 ns

h

of LTDATA from MCLK HIGH is within the limits 0 ns < td <30ns

d

of LTEN to the 3-state control of LTDATA 0 ns < td <50ns

d

> 535 ns; note 1

LE

> 205 ns

Lc

> 205 ns

Hc

> 205 ns

su1

> 205 ns

h1

> 0 ns

su2

> 205 ns

h2

> 535 ns

su4

> 160 ns

h5

> 0 ns

h6

< 235 ns

d1

< 400 ns

d2

< 50 ns

d4

SAA2022

Note

is determined by the longest path from LTEN LOW to LTDATA. This path is via the reset of the internal bit counter.

1. t

LE

This reset is only necessary when after the last LTEN = LOW, an exact multiple of 8-bits has not been transferred.

Otherwise tLE can be Tcy = 165 ns less.

February 1994 25

Page 26

February 1994 26

LTEN

transfer of 3 status bytes to microcontroller

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

LTCNT0,1

LTCLK

LTDATA

LTEN

LTCNT0,1

LTCLK

LTDATA

LTEN

LTCNT0,1

LTCLK

LTDATA

3HEX

t

d3

0 1 2 3 4 5 6 07 1 2 3 4 5 6 07 1 2 3 4 5 6 7

transfer of 2 SYSINFO bytes to microcontroller (in fast transfer period)

2HEX

0 1 2 3 4 5 6 7

10010000

transfer of 2 SYSINFO bytes from microcontroller (in fast transfer period)

2HEX

0 1 2 3 4 5 6 7

11010000

1HEX

t

ds1

0 1 2 3 4 5 6 07 1 2 3 4 5 6 7

0HEX

t

dr1

0 1 2 3 4 5 6

t

d3

status byte 2status byte 1status byte 0

t

ds2

t

dr2

07

1 2 3 4 5 6

second SYSINFO bytefirst SYSINFO bytecommand WRSYS

second SYSINFO bytefirst SYSINFO bytecommand RDSYS

7

MEA712 - 1

SAA2022

Fig.17 LT interface timing (2).

Page 27

February 1994 27

LTEN

transfer of two SYSINFO bytes starting at byte # 8 to microcontroller (in fast transfer period)

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

LTCNT0,1

LTCLK

LTDATA

LTEN

LTCNT0,1

LTCLK

LTDATA

2HEX 0HEX 2HEX

Idbyte 08hex rdsys sysinfo (8) sysinfo (9)

transfer of two SYSINFO bytes starting at byte # 8 from microcontroller to SAA2022 (in fast transfer period)

2HEX

0HEX

Idbyte 08hex wrsys

2HEX

0HEX

1HEX

0HEX

sysinfo (8) sysinfo (9)

1HEX

MEA714

SAA2022

Fig.18 LT interface timing (3).

Page 28

February 1994 28

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

LTEN

LTCNT0,1

LTCLK

LTDATA

LTEN

LTCNT0,1

LTCLK

LTDATA

transfer of two scratch pad RAM bytes (SPR) starting at SPR page 3, column 5, row 23 to microcomputer

2HEX 0HEX 2HEX 0HEX 2HEX 1HEX 1HEX

Idbyte 97hex

transfer of two scratch pad RAM bytes (SPR) starting at SPR page 3, column 5, row 23 from microcontroller to SAA2022

2HEX 0HEX 2HEX 0HEX 2HEX

Idbyte 97hex 38hex wrdrac

L

draccnt

L

draccnt

(in fast transfer period)

38hex rddrac spr (3,5,23) spr (3,5,24)

(in fast transfer period)

0HEX 0HEX

spr (3,5,23) spr (3,5,24)

MEA713

Fig.19 LT interface timing (4).

SAA2022

Page 29

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

100 %

91 %

duty

factor

speed

50 %

9 %

0

+ 2 blocks

+ 10.6 ms

+ 1.65 blocks

+ 8.8 ms

SAA2022

MEA717

0

– 1.65 blocks

– 8.8 ms

– 2 blocks

– 10.6 ms

SNUM

AUXBLK

AUX CHN

RECLAB

SYSBLK

DATA CHN

Fig.20 SPEED pulse width as a function of phase error.

01 23 0123012301

23012301230123

012320 0123012301230 2

012301230123012301230123

23

01

01230123

23012301

MEA706

Fig.21 Recording a label.

February 1994 29

Page 30

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Table 4 Microcontroller Interface Commands.

CMD

REGISTER

76543210

XXXX1000 RDAUX read AUXILIARY INFO

XXXX1001 RDSYS read SYSINFO

XXXX1010 WRAUX write AUXILIARY INFO

XXXX1011 WRSYS write SYSINFO

XXXX0000 LDSET0 load new settings register 0

XXXX0001 LDSET1 load new settings register 1

XXXX0010 LDAFLEV load AUX flag threshold level

XXXX0011 LDSPDDTY load record speed duty cycle

XXXX0101 LDBYTCNT load byte counter

XXXX0110 LDRACCNT load random access counter

COMMAND EXPLANATION

SAA2022

XXYZ1100 RDDRAC read data in random access mode from RAM quarter YZ

XXYZ1101 RDFDRAC read flag and data in random access mode from RAM quarter YZ

XXYZ1110 WRDRAC write data in random access mode to RAM quarter YZ

XXYZ1111 WRFDRAC write flag and data in random access mode to RAM quarter YZ

Explanation of settings

SET0 R

µ

An active HIGH, selects microprocessor control for the

SPEED pulse width modulated servo control signal.

EGISTER (TABLE 6)

CSPD

DISRSY

Disable Resyncs active HIGH, is used in after recording.

RECLAB

Record labels active HIGH when in DRAR or DPAR

modes; a label being defined as the bodies of all four AUX

tape blocks in a tape frame which is being written.

This setting has immediate effect and should only be

modified in time segment 1.

ENFREG

In modes DPAP and DPAR Enable Frequency Regulation

active HIGH, allows frequency information from the data

channels to be used with the phase information to

generate the capstan SPEED signal.

ENEFREG

Enable Extended Frequency Regulation active HIGH,

allows extended frequency information from the data

channels to be used with the “normal” frequency

information and the phase information to generate the

capstan SPEED signal, if ENFREG is active.

SET1 R

EGISTER (TABLE 7)

TEST1

This setting is for test only. For use in applications this bit

should be always programmed to logic 0.

PINO1

Pin Output 1, Port expander output for the microcontroller.

TFEMAS

This allows the SAA2022 to become master of the

SB-I2S-bus in modes DPAP and DPAR. In mode DRAR

the device always operates as a slave irrespective of the

settings bit.

February 1994 30

Page 31

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

PORTAB

Portable application active HIGH, allows for the data

channels clock extraction to track fast variations in tape bit

rate. For home use set to inactive.

NOCOS

No Corrected Output Symbol active HIGH, disables the

writing of the error corrected output to the DRAM. It is only

used for debugging.

TEST2

This setting is for test only. For use in applications this bit

should always be programmed to logic 0.

PINO2

Pin output 2, Port expander output for the microcontroller.

PINO3

Pin output 3, Port expander output for the microcontroller.

APE PHASE MODE

T

SAA2022

E

XTENDED TAPE FREQUENCY MODE

ENFREG = logic 1, ENEFREG = logic 1 and

µ

CSPD = logic 0

In this mode there are 3 regions. This provides a more

gentle transition from frequency plus phase control to

phase only control. Firstly from 0% to ±4.5% deviation,

where the operation is as for the tape phase mode.

Secondly from ±4.5% to ±6% deviation where the

contribution of the frequency information to the servo

information is half of that in the region beyond ±6%

deviation. Thirdly when the deviation is greater than ±6%,

which is the same as for the tape frequency mode.

ICROCONTROLLER MODE

M

µ

CSPD = logic 1

In this mode the pulse width is determined by the

microcontroller programming of the SPDDTY interface

register.

NMODE0, NMODE1

ENFREG = logic 0, ENEFREG = logic 0 and

µ

CSPD = logic 0

In this mode the SAA2022 performs a new calculation to

determine the pulse width for the SPEED signal

approximately once every 21.33 ms, giving a sampling

rate of approximately 46.9 Hz. This calculation is basically

a phase comparison between the incoming main data tape

frame and an internally generated reference. The pulse

duty cycle increases linearly from approximately 9% when

the incoming main data tape frame is 1.65 tape blocks

(8.8 ms) too early up to 91% when the incoming main data

tape frame is 1.65 tape blocks (8.8 ms) too late, in 256

steps (see Fig.20). Outside ±2 tape blocks range the pulse

width characteristic overflows and repeats itself forming a

saw-tooth pattern. The SAA2022 has an internal buffer of

±8.8 ms inside which the phase information is valid.

T

APE FREQUENCY MODE

ENFREG = logic 1, ENEFREG = logic 0 and

µ

CSPD = logic 0

The above description is overridden with frequency

information. That is if the incoming main data bit rate

deviates by more than approximately ±6% from the

nominal bit rate of 96000 bits per second, frequency

information is mixed with the phase information. In

between the limits ±6% the pulse width is determined as

above.

These two bits control the mode change operation in the

SAA2022.

Table 5 NMODE1, NMODE0.

NMODE1 NMODE0 OPERATING MODE

0 0 DPAP

1 0 DPAR

1 1 DRAR

0 1 invalid state

February 1994 31

Page 32

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SETTINGS REGISTERS

Table 6 SET0.

SETTING BIT DEFAULT

ENEFREG 6 0

ENFREG 5 0

RECLAB 4 0

DISRSY 3 0

µCSPD 2 0

NMODE1 1 0

NMODE0 0 0

Table 7 SET1.

SETTING BIT DEFAULT

PINO3 7 0

PINO2 6 0

SAA2022

Table 8 SPEED Source.

MODE µCSPD SPEED

DPAP 0 tape

DPAP 1 µC

DPAR 0 tape

DPAR 1 µC

DRAR 0 50%

DRAR 1 µC

Notes

1. “Tape” means that the duty cycle has been calculated

from the playback tape signal.

2. “µC” means that the microcontroller programs the

duty cycle via the SPDDTY register in the

microcontroller interface.

3. “50%” defines that the duty cycle is fixed at 50%.

(1)

(2)

(1)

(2)

(3)

(2)

TEST2 5 0

NOCOS 4 0

PORTAB 3 1

TFEMAS 2 1

PINO1 1 0

TEST1 0 0

Table 9 Typical Settings.

SETTING BYTE

WHEN01

7654321076543210

X 1 1 0 0 0 0 0 0 0 0 0 0 1 0 0 play home machine

X 1 1 0 0 0 0 0 0 0 0 0 1 1 0 0 play portable machine

X X X 0 X 0 1 1 0 0 0 0 0 1 0 0 record NO LABEL

X X X 1 X 0 1 1 0 0 0 0 0 1 0 0 record LABEL

X X X 0 1 1 1 0 0 0 0 0 0 1 0 0 after record NO LABEL

X X X 1 1 1 1 0 0 0 0 0 0 1 0 0 after record LABEL

February 1994 32

Page 33

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

STATUS REGISTERS

The SAA2022 has 4 status registers all of which are read only. A circular pointer is used to select which of the status

registers is addressed. This pointer is reset to point to STATUS0 as result of the rising edge of LTEN while the LTCNT0/

1 = RSTAT. Any number of the registers may be read, always starting at STATUS0.

Table 10 STATUS0.

STATUS BIT BIT

RFBT 7

SYSFLC 6

AUXFLC 5

AUXFLO 4

FLAGI 3

URDA 2

SNUM1 1

Table 12 STATUS2.

STATUS BIT BIT

NFLG3 7

NFLG2 6

NFLG1 5

NFLG0 4

FLG3 3

FLG2 2

FLG1 1

SNUM0 0

Table 11 STATUS1.

STATUS BIT BIT

SLOWTFR 7

TEST4 6

− 5

PINI 4

PAG2 3

PAG1 2

MODE1 1

MODE0 0

FLG0 0

Table 13 STATUS3.

STATUS BIT BIT

CHANS7 7

CHANS6 6

CHANS5 5

CHANS4 4

CHANS3 3

CHANS2 2

CHANS1 1

CHANS0 0

February 1994 33

Page 34

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SNUM0, SNUM1

Time segment number.

URDA

Unreliable Data active HIGH, means that regardless of the

other flag information you cannot use the Data,

SYSINFO or AUX, because they are unreliable, this can

occur as result of a RESYNC, a mode change from mode

DRAR to mode DPAP, or a reset of the SAA2022. When a

resync occurs it resynchronizes with the incoming main

data tape channel information, with a result that for a

period of time, the time that URDA is HIGH all output data

is unusable.

FLAGI

Instantaneous flag active HIGH, indicates that the

AUXILIARY byte that is about to be transferred to the

microcontroller has a flag that is ≥ AFLEV, or that the

SYSINFO byte that is about to be transferred is in error.

AUXFLO

Old Aux Flag active HIGH, indicates that AUXILIARY data

due to be transferred to the microcontroller in the current

segment should not be used.

AUXFLC

AUX Flag active HIGH, indicates that at least one of the

AUXILIARY data bytes due to be transferred to the

microcontroller in the current segment is in error. This

information is provided before the transfer occurs.

SYSFLC

SYSINFO flag active HIGH, indicates that at least one of

the SYSINFO bytes in the current segment is in error. This

information is provided before the transfer occurs.

RFBT

Ready for byte transfer of SYSINFO, AUX or Scratch pad

RAM to or from the microcontroller active HIGH.

SAA2022

PINI

Pin input, Port expander input for the microcontroller.

TEST4

This is for test purposes only.

SLOWTFR

Indicates that LT data transfers of SYSINFO, AUX or

Scratch Pad RAM can only occur at low speed rate. This

occurs only during the second half of time segment 0,

therefore the status bit RFBT must be polled to see if a

transfer is possible. This bit will be HIGH only during the

second half of time segment 0.

FLG 0 to 3

Error flag from the next AUXILIARY/SYSINFO byte which

is to be transferred to the microcontroller.

The flags for SYSINFO bytes have only 2 values, logic 0

which implies that the error corrector finds the bytes are

good and logic 1 which implies that the bytes are in error.

The flags for AUXINFO bytes can have any one of 16

values, 0 to 15, depending on the type of correction. All of

the AUX bytes in the same AUX code word will have the

same flag value. The less reliable the data, the higher the

flag value. It is recommended that any byte with a flag

value of 10 or higher is deemed unreliable.

NFLG 0 to 3

Error flag from the byte after the next AUXILIARY/

SYSINFO byte which will be transferred to the

microcontroller.

CHANS 0 to 7

Error Correction Channel status, which indicates if the

even C1 code words in the 5th block of the segment for

each data tape channel were non correctable. Therefore 1

in every 16 C1 code words from each channel is monitored

to see if the C1 error correcting decoding was successful.

MODE0, MODE1

Current mode of operation of the SAA2022.

PAG1, PAG2

Two most significant bits of the modulo 6 internal page

counter, the least significant bit is equal to SNUM0.

February 1994 34

Page 35

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

Loadable registers

Table 14 AFLev.

3210 BIT

1 0 1 0 default value

AUX Flag threshold level. FLAGI goes HIGH for the AUX bytes whose flags are ≥ AFLev. AUXFLC will go HIGH if the

flags from either code word in the current segment are ≥ AFLev. The default value is 10.

Table 15 SPDDTY.

76543210 BIT

10000000default value

SPEED duty cycle register. If µCSPD is active, this register determines the duty cycle of the speed signal.

The duty cycle is given by:

Duty cycle

SPDDTY 100

------------------------------------------=

256

×

%

• 0 for 0% duty cycle

• 128 for 50% duty cycle

• 255 for 99.6% duty cycle.

The default value is 128.

Table 16 BYTCNT.

76543210 BIT

00000000default value

Byte counter for SYSINFO, AUX and Scratch Pad RAM

transfers. For SYSINFO:

values 0 to 31 access SYSINFO from the current segment.

values 32 to 63 access SYSINFO from the current +1 segment.

values 64 to 95 access SYSINFO from the current +2 segments.

values 96 to 127 access SYSINFO from the current +3 segments.

In Random access mode the SYSTEM ADDRESS is mapped on to BYTCNT as follows:

Table 17 SYSTEM ADDRES in Random access mode.

76543210 BYTCNT

76543210ROW

Table 18 RAACNT.

6543210 BIT

0000000default value

February 1994 35

Page 36

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

Random Access counter is used for generating addresses in the Random access mode, the SYSTEM ADDRESS is

mapped on to RACCNT as shown in Table 19.

Table 19 SYSTEM address.

6543210 RACCNT

−−−−−−8 ROW

−−−210−COL

210−−−−PAG

SYSINFO AND AUX DATA OFFSETS

AUX data consists of 4 blocks of 36 bytes, one block being

transferred in each time segment.

Each tape frame contains 128 bytes of SYSINFO, the

SYSINFO bytes can for convenience, be considered as

being grouped into 4 SYSINFO blocks, with:

SYSBlk0 ==> SI0 to SI31,

SYSBlk1 ==> SI32 to SI63, etc.

In modes DPAP and DPAR SYSINFO transfers may occur

in two ways:

1. 4 blocks of 32 bytes, one block being transferred from

the SAA2022 in each time segment.

2. 1 block of 128 bytes being transferred in time

segment 1.

In mode DRAR SYSINFO must be transferred to the

SAA2022 as 4 blocks of 32 bytes, one block in each

segment.

Figures 26 to 29 show the offsets between the SYSINFO

and AUX and the time segment counter, for the various

modes of operation of the SAA2022.

February 1994 36

Page 37

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

BLOCK OFFSETS WITH RESPECT TO TIME SEGMENT

Mode DPAP

SYSBlk = (SNUM + 3) MOD 4;

or read all 4 SYSINFO blocks when SNUM = 1.

If AUX and MAIN were recorded simultaneously then

AUXBlk = (SNUM + 1) MOD 4; else read and interpret

1 AUX block in each time segment.

Mode DRAR

SYSBlk = SNUM;

AUXBlk = (SNUM + 1) MOD 4.

Mode DPAR

SYSBlk = (SNUM + 3) MOD 4;

or read all 4 SYSINFO blocks when SNUM = 1;

AUXBlk = (SNUM + 1) MOD 4.

T

HE SCRATCH PAD RAM

The SAA2022 provides the microcontroller with a scratch

pad RAM, which it can use for any purpose. The size of the

scratch pad depends upon the size of the DRAM used and

the locations may be written and read in 8-bit or 12-bit

units.

For a 64 k × 4-bit DRAM, the scratch pad is arranged as

6 pages, where each page consists of

7 columns × 64 rows. The pages are numbered 0 to 5,

columns 1 to 7 and rows 0 to 63. This gives a total of

(6 × 7 × 64) = 2688 locations.

For a 256 k × 4-bit DRAM, the scratch pad is the same as

for the 64 k × 4 bit DRAM, plus an additional 3 RAM

SAA2022

quarters, each of 6 pages where each page consists of

8 columns × 448 rows. The pages are numbered 0 to 5,

columns 0 to 7 and rows 0 to 431. This gives then a total

of (2688 + (3 × 6 × 8 × 448)) = 67200 locations. The RAM

quarter is chosen by the YZ bits of the microcontroller

interface commands.

Use of the scratch pad RAM outside the above ranges will

upset the operation of the device.

As with SYSINFO, AUX transfers can occur at high-speed

at all times except the second half of time segment 0, that

is when the status bit SLOWTFR is HIGH. During this

period the microcontroller must poll the status bit RFBT to

determine when a transfer can occur.

There are two possible methods for addressing the scratch

pad RAM. For random access of the scratch pad the

address of each location is sent by the microcontroller to

the SAA2022 before each location transfer. Alternatively,

the address of the first location can be sent by the

microcontroller before the first location transfer. This will

automatically increment the row for all subsequent

transfers until the end of the column. The RACCNT and

BYTCNT registers are used for addressing the scratch

pad. For the 64 k × 4-bit DRAM, and first quarter of

256 k × 4 DRAM the mapping of the scratch pad RAM

address onto the RACCNT and BYTCNT registers is

shown in Tables 20 and 21. For the other three-quarters of

the 256 k × 4 DRAM the mapping of the scratch pad RAM

address onto the RACCNT and BYTCNT registers is

shown in Tables 22 and 23.

Table 20 RACCNT bit.

RACCNT BIT

6543210

P2 P1 P0 C2 C1 C0 1

Table 21 BYTCNT bit.

BYTCNT BIT

76543210

1 0 R5 R4 R3 R2 R1 R0

February 1994 37

Table 22 RACCNT bit.

RACCNT BIT

6543210

P2 P1 P0 C2 C1 C0 R8

Table 23 BYTCNT bit.

BYTCNT BIT

76543210

R7 R6 R5 R4 R3 R2 R1 R0

Page 38

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

Mode changes

Table 24 Possible mode changes for the SAA2022.

CURRENT MODE

DPAP DRAR DPAR

DPAP − YES YES

DRAR YES −−

DPAR YES −−

TIMING FOR MODE CHANGES

Mode change DPAP to DRAR

This mode change occurs at the end of the time segment

in which the SAA2022 receives the new settings. Writing

of the first MAIN and AUX data commences at the start of

the time segment 1 which follows two subsequent end of

time segment 3 intervals. The delay to writing to tape is

approximately 222 ms, as shown in Fig.22. If “seamless

appending” is required the new settings should be sent to

the SAA2022 during time segment 2.

Mode change DPAP to DPAR

This mode change occurs at the first end of time segment

2 after the SAA2022 receives the new settings. Output of

AUX to tape begins at the start of the following time

segment 1, (i.e. ≈85.3 ms after the mode change), as

shown in Fig.23.

SAA2022

NEW MODE

Mode change DRAR to DPAP

This mode change occurs at the first end of time

segment 0 after the SAA2022 receives the new setting.

Writing of MAIN and AUX data stops immediately after the

mode change. The time segment jumps back to 0, URDA

goes HIGH and stays HIGH for 5 time segments

(≈213.3 ms) after which it goes LOW, as shown in Fig.24.

Mode change DPAR to DPAP

This mode change occurs at the first end of time

segment 0 after the SAA2022 receives the new setting.

The writing of AUX data to tape stops immediately after the

mode change. The first AUX read from tape can be

expected during the following time segment 0 or 1 (i.e.

128 to 170.67 ms after the mode change), as shown in

Fig.25.

February 1994 38

Page 39

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

handbook, halfpage

AUXILIARY, MAIN

NEW MODE

TAPE OUT

SNUM

MODE

01 230123012

DPAP DRAR

DRAR

≈

222 ms

MEA707 - 2

handbook, halfpage

SNUM

MODE

NEW MODE

AUXILIARY

TAPE OUT

SAA2022

1230123012

DPAP

≈

85.3 ms

DPAR

DPAR

MEA708 - 2

Fig.22 Mode change DPAP to DRAR (AUX

and MAIN simultaneously recording).

handbook, halfpage

SNUM

MODE

NEW MODE

URDA

1230 12301

DRAR

DPAP

0

DPAP

≈

213.3 ms

MEA709 - 1

Fig.23 Mode change DPAP to DPAR

handbook, halfpage

NEW MODE

AUXILIARY

TAPE OUT

AUXILIARY

MICROCONTROLLER

(AUX after recording).

SNUM

MODE

1230123012

DPAR DPAP

DPAP

≈

128 ms

TO

≈

170.66 ms

MEA710 - 2

Fig.24 Mode change DRAR to DPAP.

February 1994 39

Fig.25 Mode change DPAR to DPAP.

Page 40

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SNUM

AUX BLK

SYS BLK

SYS BLK

AUX, MAIN

DATA INPUT

FROM TAPE

01 23 0123012

123012301230123

3012301230122301

*

0

1

2

3

01 23 01230123012

0

1

2

3

0

1

2

3

SAA2022

3012

0

1

2

3

MLB413

Fig.26 SYSINFO and AUX block delays in DPAP (Audio and AUX simultaneously recorded).

SNUM

AUX BLK

SYS BLK

SYS BLK

AUX, MAIN

DATA INPUT

FROM TAPE

01 23 0123012

DEPENDS ON PHASE OF AUX WRT MAIN DATA CHANNELS

3012301230122301

*

0

1

2

3

01 23 01230123012

0

1

2

3

0

1

2

3

3012

0

1

2

3

MLB414

Fig.27 SYSINFO and AUX block delays in mode DPAP (Audio and AUX recorded separately).

February 1994 40

Page 41

Philips Semiconductors Product specification

,

,

,

,

,

Tape formatting and error

correction for the DCC system

SNUM

AUX BLK

SYS BLK

AUX, MAIN

DATA OUTPUT

FROM TAPE

01 23 0123012

123012301230123

01 23 01230123012

3012301230122301

SAA2022

3012

MLB415

Fig.28 SYSINFO and AUX block delays in mode DRAR.

SNUM

AUX BLK

SYS BLK

SYS BLK

MAIN DATA

INPUT

FROM TAPE

AUX OUTPUT

TO TAPE

01 23 0123012

123012301230123

,,,

3012301230122301

*

0

1

2

,

3

0

1

2

3

,

0

1

2

3

,

01 23 01230123012

012301230122301

1

,,,,

3012

0

1

2

3

MLB416

Fig.29 SYSINFO and AUX block delays in mode DPAR.

February 1994 41

Page 42

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DD

V

I

I

SS

I

DD

I

I

I

O

P

tot

T

stg

T

amb

V

es1

V

es2

supply voltage −0.5 +6.5 V

input voltage note 1 −0.5 VDD + 0.5 V

supply current in V

supply current in V

SS

DD

−−100 mA

− 100 mA

input current −10 +10 mA

output current −20 +20 mA

total power dissipation − 500 mW

storage temperature −55 +150 °C

operating ambient temperature −40 +85 °C

electrostatic handling note 2 −1500 +1500 V

electrostatic handling note 3 −70 +70 V

Notes

1. Input voltage should not exceed 6.5 V unless otherwise specified.

2. Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

3. Equivalent to discharging a 200 pF capacitor through a 0 Ω series resistor.

DC CHARACTERISTICS

= 3.8 to 5.5 V; T

V

DD

= −40 to +85 °C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

DD

I

DD

supply voltage note 1 3.8 5.0 5.5 V

supply current VDD= 5 V − 21 30 mA

= 3.8 V − 16 25 mA

V

DD

Inputs CLK24, TCH0 to TCH7, TAUX, PWRDWN, LTCLK, LTCNT0, LTCNT1, LTEN, PINI and SBMCLK

V

IL

V

IH

I

I

LOW level input voltage −−0.3V

HIGH level input voltage 0.7V

input current VI = 0 V; T

= 5.5 V; T

V

I

= 25 °C −−−10 µA

amb

= 25 °C −−10 µA

amb

−−V

DD

DD

V

February 1994 42

Page 43

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Input RESET

V

tLH

threshold voltage

LOW-HIGH

V

tHL

threshold voltage

HIGH-LOW

V

hys

I

I

hysteresis V

input current VI = V

tLH

− V

tHL

DD

Outputs RASN, CASN, WCLOCK and WDATA

V

OL

V

OH

LOW level output voltage IO = −3mA −−0.4 V

HIGH level output voltage IO = 3 mA VDD − 0.5 −−V

Outputs LTREF, WEN, OEN, A0 to A8, SPEED, SPDF, PINO1, PINO3, AZCHK, TEST2, TEST3, MCLK, SBEF,

SBDIR and URDA

V

OL

V

OH

LOW level output voltage IO = −2mA −−0.4 V

HIGH level output voltage IO = 2 mA VDD − 0.5 −−V

Inputs/outputs D0 to D3; with outputs in 3-state

0.8V

−−0.2V

−−V

DD

DD

V

− 1.5 − V

25 − 400 µA

V

IL

V

IH

I

I

LOW level input voltage TTL-level −−0.8 V

HIGH level input voltage TTL-level 2 −−V

input leakage current VI = 0 V; T

= 5.5 V; T

V

I

= 25 °C −−−10 µA

amb

= 25 °C −−10 µA

amb

Inputs/outputs D0 to D3

V

OL

V

OH

LOW level output voltage IO = −3mA −−0.4 V

HIGH level output voltage IO = 3 mA VDD − 0.5 −−V

Inputs/outputs LTDATA, SBCL, SBDA and SBWS; with outputs in 3-state

V

IL

V

IH

I

I

LOW level input voltage TTL-level −−0.3V

HIGH level input voltage TTL-level 0.7V

input leakage current VI = 0 V; T

= 5.5 V; T

V

I

= 25 °C −−−10 µA

amb

= 25 °C −−10 µA

amb

Inputs/outputs LTDATA, SBCL, SBDA and SBWS

V

OL

V

OH

LOW level output voltage IO = − 3mA −−0.4 V

HIGH level output voltage IO = 3 mA VDD − 0.5 −−V

Note

DD

−−V

DD

V

1. For applications requiring minimum power dissipation the device may be operated from a nominal +4 V supply.

February 1994 43

Page 44

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

AC CHARACTERISTICS

= 3.8 to 5.5 V; T

V

DD

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Clock inputs

C

i

input capacitance −−10 pF

CLK24

f pulse frequency 23 24.576 26 MHz

t

L-i

t

H-i

pulse width LOW 10 −−ns

pulse width HIGH 10 −−ns

SBMCLK

f pulse frequency − 6.144 12.5 MHz

t

L-i

t

H-i

pulse width LOW 30 −−ns

pulse width HIGH 30 −−ns

Clock outputs

= −40 to +85 °C; unless otherwise specified.

amb

C

L

load capacitance −−50 pF

MCLK

f pulse frequency − 6.144 − MHz

t

L-i

t

H-i

t

dMFR

t

d

pulse width LOW 50 −−ns

pulse width HIGH 50 −−ns

delay time from CLK24 note 1 −−45 ns

delay time from PWRDWN − 15 − ns

Clock inputs

C

i

input capacitance −−10 pF

Inputs LTCLK, LTCNT0, LTCNT1, LTEN, RESET, TCH0 to TCH7 and TAUX

t

suMR

t

hMR

set-up time to MCLK note 2 40 −−ns

hold time from MCLK note 2 0 −−ns

Input PINI

t

suMR

t

hMR

set-up time to MCLK note 1 70 −−ns

hold time from MCLK note 1 0 −−ns

Outputs

C

L

load capacitance −−50 pF

February 1994 44

Page 45

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Outputs A0 to A8, AZCHK, TEST2, LTREF, SBDIR, SBEF, SPDF, SPEED, PINO1 to PINO3, URDA, WCLOCK,

WDATA, OEN and WEN

t

dMR

Outputs OEN and WEN

t

d

Output RASN

t

dFR

t

d

Output CASN

t

dFR

t

d

Inputs/outputs

C

i

C

L

Inputs/outputs D0 to D3

delay time from MCLK note 2 −−30 ns

delay time from PWRDWN − 15 − ns

delay time from CLK24 note 1 −−30 ns

delay time from PWRDWN − 15 − ns

delay time from CLK24 note 1 −−30 ns

delay time from PWRDWN − 15 − ns

input capacitance −−10 pF

load capacitance −−50 pF

t

suCR

t

hCR

t

dMR

t

d

set-up time to CASN note 3 10 −−ns

hold time from CASN note 3 0 −−ns

delay time from MCLK note 2 −−25 ns

delay time from PWRDWN − 15 − ns

Input/output LTDATA

t

suMR

t

hMR

t

dMR

t

d

t

d

set-up time to MCLK note 2 40 −−ns

hold time from MCLK note 2 0 −−ns

delay time from MCLK note 2 −−30 ns

delay time from PWRDWN − 15 − ns

delay time from LTEN − 15 − ns

Inputs/outputs SBCL and SBWS

t

suMR

t

hMR

t

dSR

t

dMR

t

d

set-up time to MCLK note 2 40 −−ns

hold time from MCLK note 2 0 −−ns

delay time from SBMCLK note 3 −−40 ns

delay time from MCLK notes 2 and 5 −−30 ns

delay time from PWRDWN − 15 − ns

February 1994 45

Page 46

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Input/output SBDA

t

suMR

t

hMR

t

dMR

t

d

Notes

1. LOW-to-HIGH transition of CLK24.

2. LOW-to-HIGH transition of MCLK.

3. LOW-to-HIGH transition of CASN.

4. LOW-to-HIGH transition of SBMCLK.

5. 3-state control.

set-up time to MCLK note 2 40 −−ns

hold time from MCLK note 2 0 −−ns

delay time from MCLK note 2 −−30 ns

delay time from PWRDWN − 15 − ns

CLK24

OUT1

MCLK

IN1

OUT2

CASN

IN2

SBMCLK

OUT3

t

dMFR

t

dFR

t

suCR

t

L– i

t

suMR

t

hCR

t

dFR

t

dFR

t

t

dSR

hMR

t

t

H– i

t

L–i

t

dMR

H–O

t

H–i

t

L–O

t

dMFR

MEA716 - 1

Fig.30 Timing for AC characteristics.

February 1994 46

Page 47

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

PACKAGE OUTLINE

seating plane

64 52

1

pin 1 index

0.15

19.2

18.2

SAA2022

S

S

B

51

1.2

(4x)

0.8

1.0

20.1

19.9

25.2

24.2

1.55

0.85

X

1.45

1.15

0.25

0.14

o

0 to 7

MBC658 - 1

3.2

2.7

B

0.15 M

0.50

0.35

3220

0.30

0.05

33

1.2

(4x)

0.8

A

detail X

19

1.0

0.50

0.35

14.1

13.9

0.15 M A

2.85

2.65

Dimensions in mm.

Fig.31 64-lead quad flat-pack; plastic (SOT208).

February 1994 47

Page 48

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SOLDERING

Quad flat-packs

B

YWAVE

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two waves (dual-wave), in which, in a turbulent wave

with high upward pressure is followed by a smooth laminar

wave. Using a mildly-activated flux eliminates the need for

removal of corrosive residues in most applications.

B

Y SOLDER PASTE REFLOW

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

SAA2022

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

R

IRON OR PULSE-HEATED SOLDER TOOL

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between 270

and 320 °C. (Pulse-heated soldering is not recommended

for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

)

February 1994 48

Page 49

Philips Semiconductors Product specification

Tape formatting and error

SAA2022

correction for the DCC system

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress rating only and operation of

the device at these or at any other conditions above those given in the Characteristics sections of the specification is

not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

The Digital Compact Cassette logo is a registered trade mark of Philips Electronics N.V.

February 1994 49

Page 50

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SAA2022

NOTES

February 1994 50

Page 51

Philips Semiconductors Product specification

Tape formatting and error

correction for the DCC system

SAA2022

NOTES

February 1994 51

Page 52

Philips Semiconductors – a worldwide company

Argentina: IEROD, Av. Juramento 1992 - 14.b, (1428)

BUENOS AIRES, Tel. (541)786 7633, Fax. (541)786 9367

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. (02)805 4455, Fax. (02)805 4466

Austria: Triester Str. 64, A-1101 WIEN, P.O. Box 213,

Tel. (01)60 101-1236, Fax. (01)60 101-1211

Belgium: Postbus 90050, 5600 PB EINDHOVEN, The Netherlands,

Tel. (31)40 783 749, Fax. (31)40 788 399

Brazil: Rua do Rocio 220 - 5

CEP: 04552-903-SÃO PAULO-SP, Brazil.

P.O. Box 7383 (01064-970).

Tel. (011)829-1166, Fax. (011)829-1849

Canada: INTEGRATED CIRCUITS:

Tel. (800)234-7381, Fax. (708)296-8556

DISCRETE SEMICONDUCTORS: 601 Milner Ave,

SCARBOROUGH, ONTARIO, M1B 1M8,

Tel. (0416)292 5161 ext. 2336, Fax. (0416)292 4477

Chile: Av. Santa Maria 0760, SANTIAGO,

Tel. (02)773 816, Fax. (02)777 6730

Colombia: Carrera 21 No. 56-17, BOGOTA, D.E., P.O. Box 77621,

Tel. (571)217 4609, Fax. (01)217 4549

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. (032)88 2636, Fax. (031)57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. (9)0-50261, Fax. (9)0-520971

France: 4 Rue du Port-aux-Vins, BP317,

92156 SURESNES Cedex,

Tel. (01)4099 6161, Fax. (01)4099 6427

Germany: P.O. Box 10 63 23, 20095 HAMBURG ,

Tel. (040)3296-0, Fax. (040)3296 213

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. (01)4894 339/4894 911, Fax. (01)4814 240

Hong Kong: 15/F Philips Ind. Bldg., 24-28 Kung Yip St.,

KWAI CHUNG, Tel. (0)4245 121, Fax. (0)4806 960

India: PEICO ELECTRONICS & ELECTRICALS Ltd.,

Components Dept., Shivsagar Estate, Block 'A',

Dr. Annie Besant Rd., Worli, BOMBAY 400 018,

Tel. (022)4938 541, Fax. (022)4938 722

Indonesia: Philips House, Jalan H.R. Rasuna Said Kav. 3-4,

P.O. Box 4252, JAKARTA 12950,

Tel. (021)5201 122, Fax. (021)5205 189

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. (01)640 000, Fax. (01)640 200

Italy: Viale F. Testi, 327, 20162 MILANO,

Tel. (02)6752.1, Fax. (02)6752.3350

Japan: Philips Bldg13-37 , Kohnan 2-chome, Minato-ku, KOKIO 108,

Tel. (03)3740 5101, Fax. (03)3740 0570

Korea: (Republic of) Philips House, 260-199 Itaewon-dong,

Yongsan-ku, SEOUL, Tel. (02)794-5011, Fax. (02)798-8022

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA,

SELANGOR, Tel. (03)757 5511, Fax. (03)757 4880

Mexico: Philips Components, 5900 Gateway East, Suite 200,

EL PASO, TX 79905, Tel. 9-5(800)234-7381, Fax. (708)296-8556

Netherlands: Postbus 90050, 5600 PB EINDHOVEN,

Tel. (040)78 37 49, Fax. (040)78 83 99

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. (09)849-4160, Fax. (09)849-7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. (22)74 8000, Fax. (22)74 8341

th

floor, Suite 51,

Pakistan: Philips Markaz, M.A. Jinnah Rd., KARACHI 3,

Tel. (021)577 039, Fax. (021)569 1832

Philippines: PHILIPS SEMICONDUCTORS PHILIPPINES Inc,

106 Valero St. Salcedo Village, P.O. Box 911, MAKATI,

Metro MANILA, Tel. (02)810 0161, Fax. (02)817 3474

Portugal: Av. Eng. Duarte Pacheco 6, 1009 LISBOA Codex,

Tel. (01)683 121, Fax. (01)658 013

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. (65)350 2000, Fax. (65)251 6500

South Africa: 195-215 Main Road, Martindale,

P.O. Box 7430,JOHANNESBURG 2000,

Tel. (011)470-5433, Fax. (011)470-5494

Spain: Balmes 22, 08007 BARCELONA,

Tel. (03)301 6312, Fax. (03)301 42 43

Sweden: Kottbygatan 7, Akalla. S-164 85 STOCKHOLM,

Tel. (0)8-632 2000, Fax. (0)8-632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. (01)488 2211, Fax. (01)481 7730

Taiwan: 69, Min Sheng East Road, Sec 3, P.O. Box 22978,

TAIPEI 10446, Tel. (2)509 7666, Fax. (2)500 5899

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

60/14 MOO 11, Bangna - Trad Road Km. 3

Prakanong, BANGKOK 10260,

Tel. (2)399-3280 to 9, (2)398-2083, Fax. (2)398-2080

Turkey: Talatpasa Cad. No. 5, 80640 LEVENT/ISTANBUL,

Tel. (0212)279 2770, Fax. (0212)269 3094

United Kingdom: Philips Semiconductors Limited, P.O. Box 65,

Philips House, Torrington Place, LONDON, WC1E 7HD,

Tel. (071)436 41 44, Fax. (071)323 03 42

United States:INTEGRATED CIRCUITS:

811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. (800)234-7381, Fax. (708)296-8556

DISCRETE SEMICONDUCTORS: 2001 West Blue Heron Blvd.,

P.O. Box 10330, RIVIERA BEACH, FLORIDA 33404,

Tel. (800)447-3762 and (407)881-3200, Fax. (407)881-3300

Uruguay: Coronel Mora 433, MONTEVIDEO,

Tel. (02)70-4044, Fax. (02)92 0601

For all other countries apply to: Philips Semiconductors,

International Marketing and Sales, Building BAF-1,

P.O. Box 218, 5600 MD, EINDHOVEN, The Netherlands,

Telex 35000 phtcnl, Fax. +31-40-724825

SCD28 © Philips Electronics N.V. 1994

All rights are reserved. Reproduction in whole or in part is prohibited without the

prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation

or contract, is believed to be accurate and reliable and may be changed without

notice. No liability will be accepted by the publisher for any consequence of its

use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Philips Semiconductors

Loading...

Loading...