Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA1501T

Battery charge level indicator

Objective specification

File under Integrated Circuits, IC11

Philips Semiconductors

December 1994

Page 2

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

FEATURES

• High level of integration to allow assembly in intelligent

battery packs

• Accurate charge and discharge account

• Large dynamic range of charge and discharge currents

• Independent settings of charge and discharge efficiency

• 2 V minimum supply voltage (2 cell operation)

• Temperature protection of batteries during charging

• Temperature controlled self-discharge

• Accurate charge current regulation

• Two charge amount display modes, LCD and LED.

GENERAL DESCRIPTION

The SAA1501T is intended to be used as a battery monitor

and charge current control circuit in rechargeable battery

systems.

The SAA1501T is processed in BiCMOS technology

where the benefits of mixed bipolar and CMOS technology

is fully utilized to achieve high accuracy measurements

and digital signal processing in the same device. The

general function of the integrated circuit is a Coulomb

counter. During battery charging, the charge current and

charge time are registered in a Coulomb counter. During

discharge, the discharge current and time are recorded.

The momentary charge amount of the batteries can be

displayed either on an LCD screen or on an LED bargraph.

Using the SAA1501T, intelligent batteries or intelligent

battery powered systems can be easily designed with only

a few external components.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

I

CC

supply voltage 2.0 3.0 4.3 V

supply current VCC=3V;

− 1.2 1.7 mA

Ic=Id=60µA

I

CCstb

f

osc

V

i(s)

T

amb

supply current in standby mode VCC=3 V;

V

CSI=VDSI

fixed oscillator frequency C

osc

R

ref

= 820 pF;

= 51.5 kΩ

=0V

−− 100 µA

− 4.2 − kHz

input sense voltage (pins 9 and 10) 0 − VCC− 1.6 V

operating ambient temperature 0 − +70 °C

ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

SAA1501T SO24 plastic small outline package; 24 leads; body width 7.5 mm SOT137-1

December 1994 2

Page 3

Philips Semiconductors Objective specification

B

BBB

B

BBB

BBBB

B

B

B

BBBB

BBB

B

B

B

BBB

B

B

B

BBB

B

B

B

BBB

B

B

B

B

B

B

BBBBBBB

B

B

B

B

B

B

B

B

B

B

B

B

B

B

BBB

B

B

BBB

B

B

B

B

BB

B

B

B

B

B

B

B

B

B

B

B

B

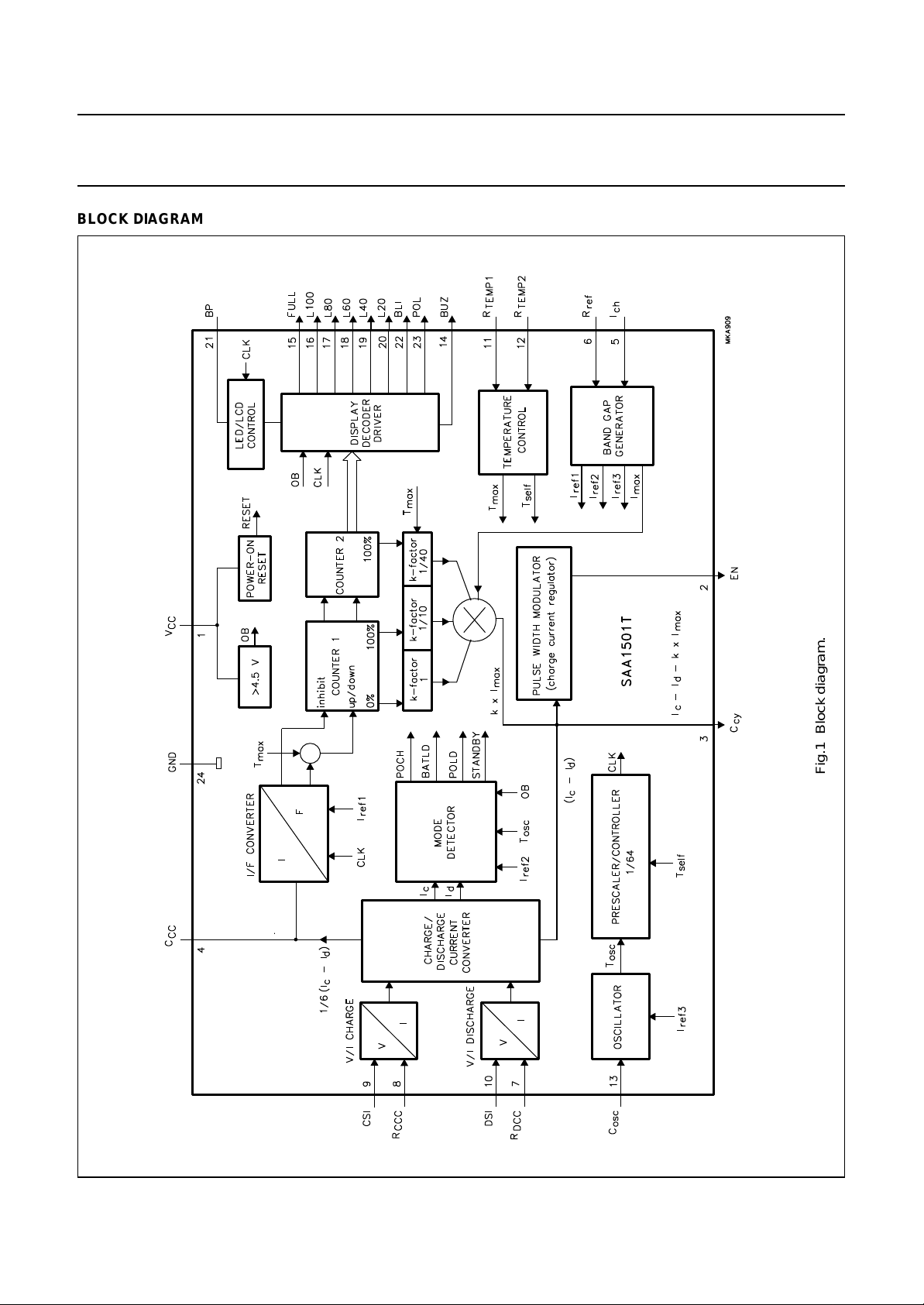

Battery charge level indicator SAA1501T

BLOCK DIAGRAM

B

B

BBBBBB

BB

BB

BB

BB

BB

BB

BB

BB

BB

BB

BBB

BBB

BBB

B

B

B

B

B

B

BB

BB

B

B

B

B

B

B

B

B

B

B

B

B

Fig.1 Block diagram.

December 1994 3

BB

BB

B

B

B

Page 4

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

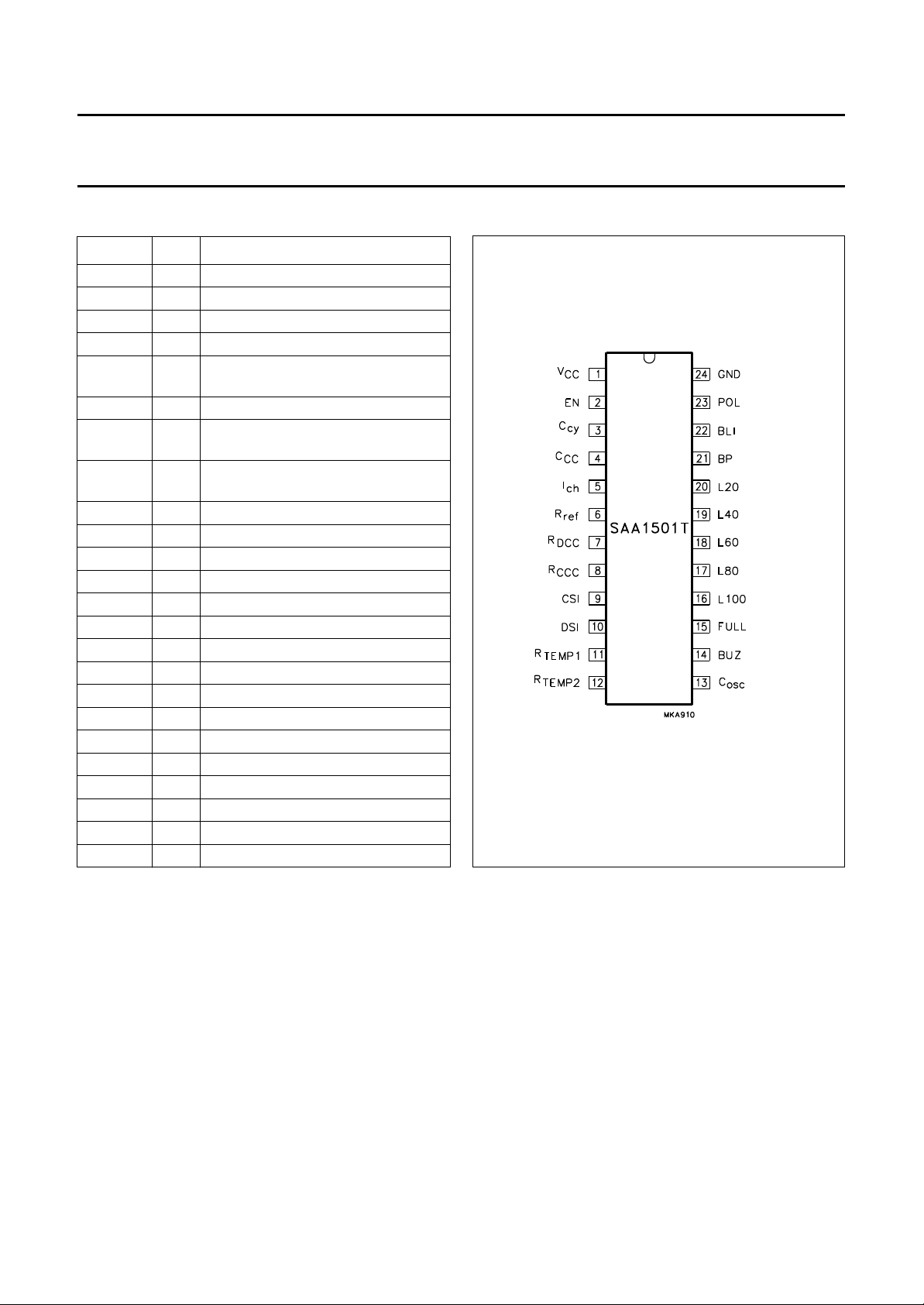

PINNING

SYMBOL PIN DESCRIPTION

V

CC

EN 2 enable output

C

cy

C

CC

I

ch

R

ref

R

DCC

R

CCC

CSI 9 charge sense input

DSI 10 discharge sense input

R

TEMP1

R

TEMP2

C

osc

BUZ 14 buzzer output

FULL 15 battery full indication output

L100 16 100% segment indication output

L80 17 80% segment indication output

L60 18 60% segment indication output

L40 19 40% segment indication output

L20 20 20% segment indication output

BP 21 LCD back plane drive

BLI 22 battery low indicator LED output

POL 23 power-on LED output

GND 24 power ground

1 supply voltage

3 duty cycle capacitor output

4 charge counter capacitor output

5 maximum average charge current

setting input

6 current reference resistor input

7 discharge current conversion resistor

input

8 charge current conversion resistor

input

11 temperature sensing resistor 1 input

12 temperature sensing resistor2 input

13 oscillator capacitor input

Fig.2 Pin configuration.

December 1994 4

Page 5

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

FUNCTIONAL DESCRIPTION

The most important function of the SAA1501T is the

charge account in rechargeable battery systems. Both

NiCd and NiMH batteries in all sizes can be used. The

system can operate alone as a charge monitor with a

charge amount display function or, can operate in

conjunction with a charger. If the SAA1501T operates

together with a charger, it delivers a control signal at output

EN, for charge current regulation or for battery voltage

regulation.

Fast charging systems and charge current regulation

The SAA1501T is especially designed to be used in fast

charging systems. In fast charging systems, the charge

time is lowered by raising the charge current. Signal EN

controls the charger current. The counters register the

state of charge of the batteries and at the 80% level the

charge current is reduced via a smaller duty cycle

regulation of signal EN. The second (slow) level fully

charges the batteries which is not possible with the first

(fast) level. After the slow charge mode the counter

switches over to an even smaller duty cycle of EN and thus

enters the third (trickle) charge mode, to overcome the

self-discharge of the batteries.

Current sensing and charge account

The charge current is sensed by means of a very low

resistance (e.g. 70 mΩ) sense resistor R

(see Fig.8) to

sc

save power at high charge rates. Via the V/I charge

converter and external resistor R

(see Fig.8), the

CCC

sensed voltage is converted into a charge current Ic (the

same is applicable for the discharge current). In the I/F

converter the charge current is converted into a frequency

for up-counting the counter. For the discharge current (Id)

the converted frequency is used for down-counting. The

up and down counting is registered in counters CNT1 and

CNT2, depending on the actual charge and discharge

current levels of the batteries. This is called dynamic

charge account.

Charge display

The charge amount represented by the Coulomb counter

can be displayed via an LCD screen or via an LED

bargraph. If the charge amount is reduced to 0%, the

battery low indicator (BLI) LED is turned on at the end of a

battery discharge session. A flashing BLI, in combination

with a repeating buzzer alarm, informs the user about the

low charge state. A new charge session should then be

started.

Protections

In the temperature control block, the absolute temperature

is used as a protection to end the fast charge cycle. Fast

charging at high temperature is not permitted because of

degradation of the battery cells. If the batteries are

disconnected, an open-battery condition is recognized and

the SAA1501T enters the standby mode.

Mode detection

The mode detector detects whether there are any charge

or discharge currents, whether the system is powered,

whether loads are connected or whether the system is in

the standby mode. If power is connected, the power-on

LED (POL) is on. In the standby mode, the Coulomb

counter will count down in accordance with the

self-discharge speed of the batteries, which is temperature

controlled. The following subsections describe the various

blocks of the block diagram in more detail.

Supply and reference

During the period when VCC rises from 0 V to the internal

reset level, all counters are reset. The internal reset is

released before VCC reaches 1.7 V. The operating supply

voltage ranges from 2 V to the open battery level of

4.3 V (min). The characteristics are guaranteed at

VCC= 3 V. In order to protect the SAA1501T against high

supply voltages during open battery in a flyback converter,

a voltage clamp circuit is made active at 6.35 V (typ). The

clamping current must not exceed 80 mA. A band gap

reference block is included to generate accurate voltages

i.e. for the oscillator. Moreover, together with R

, accurate

ref

currents are generated which are used in the I/F and V/I

converters and the oscillator block. In the standby mode

only the oscillator and the digital parts are active to limit the

discharge current of the batteries to a current level of less

than 100 mA. The circuits that are needed temporarily are

switched on and off during standby (see “Timing

characteristics” t

som

).

Voltage-to-current charge and discharge

In the V/I converter, the input charge current is translated

into acceptable levels for the circuit. The conversion

formula is:

I

ch earg

=

---------------------------------------

c

Rsc×()

R

CCC

; where R

CCC>Rsc

(see Fig.7)I

December 1994 5

Page 6

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

With R

, the charge efficiency can be manipulated

CCC

depending on the charge level. The restriction of the

SAA1501T is a maximum average charge current of 60 µA

and a minimum momentary charge current of 0.6 µA. The

same formula is applicable for the discharge current. The

discharge efficiency can now also be changed by R

DCC

depending on the discharge current levels, but

independent of the charge current. As both sense levels

are referenced to ground, the sensing elements could be

combined into one. The outputs are used combined as

1

⁄6× (Ic− Id) in the I/F converter and combined as (Ic− Id)

in the pulse width modulator block and made separately

available in the mode detector. The conversion is made

lower by a factor of 6 in the I/F converter block, thereby

enabling the use of poor leakage capacitors on pin 4. All

V/I converter pins are sensitive to capacitive loading

(C

out

× R

< 1 ms), the conversion resistors should be

conv

mounted as close as possible to the output pins.

I/F converter

This block produces up-counts while charging and

down-counts while discharging. The I/F converter

translates the charge/discharge currents into a frequency.

This frequency is determined by

I(

C(

CC

cd()Rsense

∆V

oscRCCC RDCC()

f

=

----------------------------------------------------------------------------------- -

6 )××

)××

During the time period ‘t’, the charge current, expressed as

a ‘Charge Parcel’, will be counted in the Coulomb counters

(CNT1 and CNT2). During discharge the ‘Charge Parcel’ is

the product of the discharge current and the ‘t’ from the I/F

converter generated frequency. The momentary contents

of the Coulomb counter is a multiple of the ‘Charge

Parcels’.

Coulomb counters CNT1 and CNT2

The SAA1501T has been designed for average maximum

charge and discharge current levels of 5 C and minimum

charge and discharge current levels of 0.05 C. This means

that counter CNT1 will be full, or empty, after a minimum

time period of 12 minutes at maximum charge and

discharge currents at the recommended oscillator

frequency. Higher charge and discharge rates than 5 C

are possible, but only by changing the oscillator frequency.

It should be noted that the self-discharge time and the

display functions are influenced by a higher oscillator

frequency. The SAA1501T enables top-up charging in

order to account for the decrease of charge efficiency at

high charge rates. The SAA1501T switches to the slow

charge mode at full recognition when CNT1 is at its

maximum. As soon as the batteries are completely full

(when CNT2 is at its maximum), the SAA1501T switches

to the trickle charge mode to overcome the self-discharge

of the batteries. The top-up charge volume of

CNT2 = 0.2 × CNT1 = 0.2 C (where Q is rated as Ampere

hours of the battery). The slow and trickle charge current

levels are dependent on the k-factor. Signal EN controls

the external charger e.g. TEA1400 (see Fig.8). When an

LED bargraph display is used, the LED currents are also

considered as a battery discharge current, and therefore

influence the duty cycle of the charge current regulation

signal EN. The SAA1501T also enables temperature

protection. In the event that the battery temperature

exceeds a certain maximum temperature level

(T

battery>Tmax

), which can be set by an external NTC

resistor, the SAA1501T switches to the slow charge mode.

In the standby mode (self-discharge mode), which is

recognized by the SAA1501T in the mode detector when

both the charge and discharge currents are zero

(Ic=Id= 0), the self-discharge of the batteries is registered

by counting down in 200 days (based on f

T

battery<Tself

T

battery>Tself

or in 100 days (based on f

. T

is also set by means of an external NTC

self

osc

= 4 kHz) if

osc

= 4 kHz) if

resistor.

Band gap generation

From the band gap voltage block, two reference voltages

are derived V

reference currents, I

detector) and I

current I

and V

ref

(oscillator). Voltage V

ref3

which is used in the pulse width modulation

max

. Voltage V

max

(I/F converter); I

ref1

at pin R

ref

ref2

max

ref

(mode

sets the

sets the

block to accurately control the charge current.

Charge current regulation

While charging, the SAA1501T produces a charge current

regulation signal EN in the pulse width modulation block

which is used for controlling an external charger. This

digital signal EN is derived from the signal produced at pin

. The duty cycle is determined by

C

cy

×

kI

max

=

δ

------------------- -

–

I

cId

in which the value of k depends on the state of the

counters CNT1 and CNT2:

CNT1 is not full; k = 1 (fast charging).

CNT1 is full; CNT2 is not full; k = 0.1 (slow charging).

CNT1 and CNT2 are full; k = 0.025 (trickle charging).

December 1994 6

Page 7

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

Mode detector

This block differentiates between the available modes of

operation. The modes are given below:

Charge mode; power charge (POCH).

Discharge mode; battery load (BATLD).

Power load mode (POLD); the batteries are charged

while the load is also active.

Self discharge mode; (STANDBY).

To detect power in a regulated system (see Fig.8) the EN

signal is used for sensing. The POCH mode is recognized

when the converted charge current I

c>Iref2

(when in the

power mode, change of mode can only be recognised if

EN is HIGH). The BATLD mode is recognized when

Id>I

Id>I

and Id<I

; the POLD mode is recognized when Ic>I

ref2

; the standby mode is recognized when Ic<I

ref2

. In the standby mode, if the advised frequency

ref2

ref2

and

ref2

(4 kHz) is applied, it takes 0.5 s to determine another

mode (in all other modes, a change of mode is sensed

continuously). In all other modes an eventual change of

mode is done continuously. To save supply current during

standby, the V/I converters are switched off. With the

specific fixed intervals, the SAA1501T checks whether

power or load is connected again. This checking is

synchronized by the sensing signal of the V/I converters.

The SAA1501T can handle a DC charge current as well as

a discontinuous charge current (SMSP charger). The load

current can also be DC or interrupted, e.g. produced by a

motor. The digital filtering of both signals, to overcome

faulty mode detections, restricts the conditions in which

power and load are recognized. Because of the very

sensitive input detection level of the mode detector for a

charge current (power) in combination with the high

interference levels of motor driving, the detection level for

power (Ic>I

) is raised by a factor of 25 when the

ref2

batteries are loaded.

Prescaler/controller

In the prescaler, a new system clock is created (CLK)

which is used for all timing blocks. Many frequencies are

derived from the basic oscillator at the standard frequency

of 4 kHz (1/T

), such as the self-discharge times and the

osc

modulation frequency for the buzzer, the drive voltage

frequency for the LCD screen and the pulse trains for

temperature measurements and power/load sensing

measurements in the mode detector.

Temperature

In the temperature control block two temperature

measurements are performed. In order to switch off fast

charging when the battery temperature exceeds an

adjustable maximum temperature (T

), a maximum

max

temperature measurement is performed. A second

temperature measurement is performed in the standby

mode. This temperature measurement is input to the

temperature control block to switch over the self-discharge

rate from a count down of 200 days (based on f

if T

battery<Tself

on f

osc

= 4 kHz) if T

, to a count down rate of 100 days (based

battery>Tself

. In all modes the

= 4 kHz)

osc

temperature is measured periodical. The temperature

circuit which controls the above mentioned functions is a

bridge configuration synthesis, as illustrated in Fig.3.

Oscillator

As the oscillator has to operate in all modes, including the

standby mode, the current consumption of the oscillator

must be very low. The same applies for the band gap

generator block, because the band gap delivers accurate

reference voltages and currents to the oscillator block.

Apart from the low current consumption, the accuracy of

the period time is important. The period time of the

oscillator is:

–()

V

t

osc

2C

×

osc

HVL

-------------------------- I

ref3

5.6 C

××=×=

oscRref

December 1994 7

Fig.3 Temperature circuit.

Page 8

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

Display decoder driver

The counters are used to output the battery charge

amount via a decoder and driver stage to the display

outputs L100, L80, L60, L40 and L20 to drive an LCD

screen or an LED bargraph. A 64 Hz (based on

f

= 4 kHz) block signal at output BP (back plane) must

osc

be connected to the back plane of the LCD bar. If pin BP

is connected to ground, the display outputs L20 to L100

will produce signals for an LED bargraph. Output signal

POL (power-on LED) indicates when the batteries are in

the charge mode. When the counter is not at its maximum

state, POL is on and flickers at 2 Hz (based on

= 4 kHz) when the counter is at its maximum. The

f

osc

waveforms illustrated in Fig.4 depict operation of the

monitor display. The outputs BLI (battery low indication),

BUZ (buzzer) and FULL indicate the extreme status

(empty or full) of the counters and the batteries. The

waveforms of the signals BLI and BUZ if one switches over

from BATLD to standby when BLI is active, are given in

Fig.4.

The BLI sequence is as follows. If during discharge the

charge state falls below 0%, the red BLI LED is turned on.

Changing mode from discharge to standby means that the

BLI LED and the buzzer (BUZ) are activated as indicated

in Fig.4. If after a 0% passing recharge is activated, the red

BLI LED is turned on again for as long as the counter

remains below 10%. Switch-over in the 0 to 10% range to

standby will activate BLI and BUZ again.

The LEDs of the LED bargraph are activated as a result of

each operational mode change, starting with a step-up

pattern. Step-up means that LEDs are activated

successively one after the other, in accordance with the

charge status each

⁄8s (based on f

= 4 kHz). After the

osc

1

step-up, the LEDs will be on for 8 s (based on

f

= 4 kHz), except for the POCH mode, where the LEDs

osc

will be on continuously to inform the user about the charge

state of the batteries. The LCD display is, apart from the

LED mode, always visible.

Figure 5 shows the legend for Fig.6. Figure 6 shows the

operation of the monitor display.

BUZ

Fig.4 BLI and buzzer timing.

December 1994 8

Page 9

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

Open battery protection

Open battery protection is active when VCC= 4.5 V (typ.).

The SAA1501T will then react as if the system is in the

standby mode. This means that the LEDs are turned off in

the LED mode, in the LCD mode the flickering is stopped

and the enable pin (EN) is switched to floating.

Testing

A user test facility is built-in for checking if the LCD and/or

LED displays are mounted correctly. Pin R

is used as

CCC

a test pin. Raising the voltage above 1 V during the set-up

time will activate the test. The test mode can only be

started in the standby mode. In the test mode all counters

are reset and will be active successively in the sequence

BLI, L20, L40, L60, L80, L100 and FULL with an interval

period determined by T

the following methods:

Power-on; the Coulomb counter retains the latest data

displayed.

Automatically after the test cycle time; the Coulomb

counter is reset.

. The test mode can be exited via

osc

Fig.5 Legend for Fig.6.

December 1994 9

Page 10

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

Fig.6 Charge state of counter shown by LCD or LED display.

December 1994 10

Page 11

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134). All voltages with respect to GND (pin 24); input

currents are positive; pins 5, 6 and 21 are not allowed to be voltage driven; the voltage ratings are valid provided other

ratings are not being violated.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

V

n1

V

n2

∆V voltage difference between pins 10 and

I

CC

I

GND

I

n

P

tot

T

stg

T

j

T

amb

supply voltage −0.5 +5.5 V

input voltage at pins 9 to 12 −0.5 +1.0 V

input voltage at pins 2 to 4, 13 to 20, 22

−0.5 V

CC

V

and 23

−2.0 +2.0 V

7 and between pins 9 and 8

supply current − 80 mA

power ground supply current −−80 mA

supply current at pins 5 to 8 −−1mA

total power dissipation T

=70°C − 0.75 W

amb

storage temperature −55 +150 °C

junction temperature − +150 °C

operating ambient temperature −10 +75 °C

QUALITY SPECIFICATION

In accordance with SNW-FQ-611 part E. The numbers of the quality specification can be found in the “

Handbook”

. The Handbook can be ordered using the code 9398 510 63011.

Quality Reference

THERMAL CHARACTERISTICS

SYMBOL PARAMETER VALUE UNIT

R

th j-a

thermal resistance from junction to ambient in free air 75 K/W

December 1994 11

Page 12

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

CHARACTERISTICS

VCC=3V; T

(0.1%); I

ref=Vref/Rref

specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

CC

V

CC(ir)

I

CC

I

CCstb

V

ref

I

ref

V

max

TC temperature coefficient of

V

clamp

Voltage-to-current charge/discharge

I

4

I

3

I

4/I3

V

i(s)

I

o(s)

V

os

=25°C; R

amb

; I

= 51.5 kΩ (0.1%); C

ref

max=Vmax/Rmax

= 820 pF (0.1%); R

osc

CCC=RDCC

= 3.65 kΩ (0.1%); R

max

; the minimum and maximum values are 4 sigma limits; unless otherwise

supply voltage note 1 2.0 3.0 4.3 V

supply voltage internal

− 1.2 1.7 V

reset

supply current Ic=Id=60µA 0.6 − 1.7 mA

supply current in standby

V

CSI=VDSI

=0V −−100 mA

mode

reference voltage note 2 204 211 217 mV

reference current notes 1 and 2 3.5 − 8 µA

maximum voltage note 2 204 211 217 mV

−6

T=0to100°C 0 25 × 10

100 × 10−6°C

reference voltage

clamping level voltage ICC= 50 mA 5.8 6.3 6.8 V

voltage-to-current

charge/discharge current

accuracy

voltage-to-current

charge/discharge current

accuracy

V9=7mV; V4= 1.5 V −259 −324 −389 nA

= 7 mV; V4= 1.5 V 262 328 394 nA

V

10

= 200 mV; V4= 1.5 V −8.93 −9.13 −9.32 µA

V

9

= 200 mV; V4= 1.5 V 8.93 9.13 9.32 µA

V

10

V9= 7 mV; R

max

= 400 kΩ;

−1.55 −1.94 −2.32 µA

k = 0.025

V

= 7 mV; R

10

= 400 kΩ;

max

1.57 1.97 2.36 µA

k = 0.025

relative current accuracy

= 200 mV;

V

9

R

= 400 kΩ; k = 0.025

max

= 200 mV;

V

10

R

= 400 kΩ; k = 0.025

max

V9= V10= 200 mV − 1.0 2.5 %

−53.5 −54.7 −56 µA

53.5 54.7 56 µA

of voltage-to-current in

charge counter capacitor

input sense voltage at

pins 9 and 10

DC output sense current

V

CC(max)

3.7<V

= 3.7 V; note 1 0 − VCC− 1.6 V

< 4.4 V; note 1 −−2.1 V

CC

0.6 − 60 µA

(pins 8 and 7)

offset voltage −−1.8 mV

= 3.48 kΩ

December 1994 12

Page 13

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I/F converter

I

a multiplication factor for

I

ref1

V

clamp

V

CCC(H)

clamping voltage (pin 4) Ic= 0; Id=60 µA;

HIGH level reference

voltage (pin 4)

V

CCC(L)

LOW level reference

voltage (pin 4)

Pulse width modulator

ACC accuracy for I

I

max

I

d/Imax

V

CCY

maximum DC current I

k factor k = 1; Vd= 1.5 V; idle mode 0.95 0.98 1.01

start up-clamping voltage

max

at C

(pin 3)

V

CCY

V

CCY(H)

clamping voltage (pin 3) open-circuit at pin 3;

HIGH level switching

voltage

V

CCY(L)

LOW level switching

voltage

I

Z

3-state enable current V2= 1.5 V −−1 µA

Mode detector

I

ref2

mode detection level at

pins 7 and 8

I

ref4

mode detection level at

pin 7

=a×I

ref1

ref

(where a is constant);

V4= 1.26 V; idle mode

I4=10µA

15 < I

cy

max=Vmax/Rmax

k = 0.1; V

<60µA −−±3%

max

; note 1 0.6 − 60 mA

= 1.5 V; idle

d

mode

k = 0.025; V

= 1.5 V;

d

idle mode

Id=10µA; Ic= 0 0.7 0.9 1.1 V

pin 5 = VCC;

±(Ic− Id)=60µA

I

≥ e × I

ref2

ref

(where e is constant)

I

≥ I

ref2

;

ref4

in modes POLD and BATLD

2.35 2.5 2.65

0.7 0.9 1.1 V

1.58 1.66 1.74 V

1.26 1.33 1.4 V

0.094 0.099 0.104

0.023 0.025 0.027

−−V

− 0.6 V

CC

1.60 1.77 1.86 V

1.28 1.32 1.37 V

− 0.15I

− 25I

ref2

ref

−

−

Oscillator (pin 13)

Q

c

Q

d

charge amount I

discharge amount I

ref1(sink)

ref1(source)

× T

clk

× T

clk

∆Q difference between

charge and discharge

charge amount

b multiplication factor for

I

ref3

∆V

osc

voltage swing

I

=b×I

ref3

ref

(where b is constant)

HIGH-to-LOW transition

December 1994 13

142 150 158 nC

142 150 158 nC

0.95 1.0 1.05

− 0.75 −

− 440 − mV

Page 14

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

f

osc

Temperature control (pins 11 and 12)

V

i

I

TEMP2/ITEMP1

I

TEMP2/ITEMP1

c multiplication factor for

d multiplication factor for

Open battery protection

V

CC(ob)

Testing

V

test

Display decoder driver

I

OL1

I

OBP

I

LED(CF)

I

OL2

I

OBP(tot)

I

LED(CF)

I

OL

I

OL(14,15)

I

OL(22,23)

I

OL(21)

I

OH

I

OH(21)

oscillator frequency 3.9 4.3 4.7 kHz

input voltage 0 − 900 mV

detection at T

detection at T

I

TEMP1

I

TEMP2

max

self

V11=V12= 300 mV 9.7 10.0 10.3

V11=V12= 300 mV 15 16 17

I

TEMP1

=c×I

ref

0.45 0.54 0.63

(where c is constant);

V

TEMP1=VTEMP2

I

=d×I

TEMP2

ref

= 300 mV

4.5 5.4 6.3

(where d is constant);

V

TEMP1=VTEMP2

= 300 mV

open-battery level voltage 4.3 4.5 4.65 V

test level voltage 1.0 − 2.0 V

LOW level output current

(pin 20 LED),

VOL= 0.6 V; L40 to L100 off;

VCC= 2.4 V

71012mA

(LED 20 is on)

output LED sense current

(pin 21 LED),

V

= 0.1 V; L40 to L100

OBP

off; VCC= 2.4 V

63 82 100 µA

(LED 20 is on)

LED current

I

OL1/IOBP

; VCC= 2.4 V 110 121 132

compensation factor

LOW level output current

(pins 20 to 16 LED),

all LEDs on; VOL= 0.7 V;

VCC= 2.8 V

7.5 11 14 mA

(all LEDs are on)

total output sense current

(pins 21)

LED current

V

= 0.1 V; VCC= 2.8 V;

OBP

L20 to L100 on

5I

OL2/IOBP(tot)

350 452 560 µA

115 125 135

compensation factor

output current

VOL= 0.5 V; VCC= 2.8 V 350 480 640 µA

(pins 20 to 16 LCD)

LOW level output current

VOL= 0.4 V; VCC= 2.4 V 0.9 1.2 1.7 mA

(pins 14 and 15)

LOW level output current

VOL= 0.4 V; VCC= 2.1 V 7 10 12 mA

(pins 22 and 23 LED)

LOW level output current

VOL= 0.4 V; VCC= 2.8 V 572 849 1214 µA

(pin 21 LCD)

HIGH level output current

VOH= 2.4 V; VCC= 2.8 V 261 378 526 µA

(pins 20 to 16 LED)

HIGH level output current

VOH= 2.4 V; VCC= 2.8 V 239 378 565 µA

(pin 21 LED)

December 1994 14

Page 15

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

OH(14)

I

OH(15)

I

OH(22,23)

I

LO

Notes

1. Not measured by the industrial measuring program, but guaranteed by design.

2. Internally detected from band gap generator.

HIGH level output current

(pin 14)

HIGH level output current

(pin 15)

HIGH level output current

(pins 22 and 23)

output leakage current

(pin 21)

VOH=2V; VCC= 2.4 V 0.7 1.6 2.5 µA

VOH= 2 V; VCC= 2.4 V 0.99 1.67 2.69 mA

VOH= 2.4 V; VCC= 2.4 V 260 450 708 µA

VOH= 0 to V

CC

−−±1µA

December 1994 15

Page 16

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

TIMING CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE

T

osc

T

clk

t

som

t

som(p)

t

rec

t

self

t

battery(s)

t

battery(p)

t

su

t

id

t

pd

t

su:LED

t

LED(ON)

f

BP

f

BUZ

oscillator cycle time note 1 T

clock cycle time 64t

sense operation mode time note 2 1.5 × 27T

sense operation mode period

note 2 212T

time

recognition time power; note 3 >32t

load; note 4 >20t

self discharge counter time T

battery>Tself

(100 days at f

T

battery>Tself

(200 days at f

osc

osc

= 4 kHz)

= 4 kHz)

battery temperature

measurement sense time

battery temperature

measurement period time

display test set-up time 211T

interval display test time 210T

period display test time 1.5 × 218T

LED set-up time 29T

LEDs-on time after change of mode

(except POCH mode)

drive voltage frequency for back

plane

modulation frequency for auto

buzzer

osc

235T

236T

27T

216T

215T

2−4T

1

⁄2T

=2C

osc

osc

osc

osc

osc

osc

osc

osc

osc

osc

<t<1.5×218T

osc

osc

osc

osc

osc

osc

osc

× V

osc/Iref3

osc

Notes

1. ; where V

t

osc

2C

osc

×=

----------I

ref3

= 440 mV and I

osc

ref3

= 0.75.

V

osc

2. Applies to all converters and enable signal.

3. For charge current AC or DC: f >1⁄2f

4. For discharge current AC: f >1⁄4f

osc

.

osc

.

December 1994 16

Page 17

Philips Semiconductors Objective specification

B

B

B

B

BBBBBBBBBBBB

BBBBBBBBBB

B

B

BBBBBBBBBB

B

B

Battery charge level indicator SAA1501T

APPLICATION INFORMATION

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

Fig.7 Battery pack application diagram; with camcorder.

BBBB

BBBB

BBBBBBBBB

BBBBBBBBB

Fig.8 State-of-charge indicator and charge current regulation.

December 1994 17

Page 18

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

PACKAGE OUTLINE

handbook, full pagewidth

S

pin 1

index

112

0.9

0.4

(4x)

15.6

15.2

1.27

0.49

0.36

0.1 S

1324

0.25 M

(24x)

2.45

2.25

0.3

0.1

10.65

10.00

detail A

7.6

7.4

1.1

0.5

1.1

1.0

0.32

0.23

0 to 8

MBC235 - 1

A

2.65

2.35

o

Dimensions in mm.

Fig.9 Plastic small outline package; 24 leads; body width 7.5 mm (SO24; SOT137-1).

December 1994 18

Page 19

Philips Semiconductors Objective specification

Battery charge level indicator SAA1501T

SOLDERING

Plastic small-outline packages

YWAVE

B

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two solder waves (dual-wave), in which a turbulent

wave with high upward pressure is followed by a smooth

laminar wave. Using a mildly-activated flux eliminates the

need for removal of corrosive residues in most

applications.

Y SOLDER PASTE REFLOW

B

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

R

IRON OR PULSE

-HEATED SOLDER TOOL)

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between 270

and 320 °C. (Pulse-heated soldering is not recommended

for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

December 1994 19

Page 20

Philips Semiconductors – a worldwide company

Argentina: IEROD, Av. Juramento 1992 - 14.b, (1428)

BUENOS AIRES, Tel. (541)786 7633, Fax. (541)786 9367

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. (02)805 4455, Fax. (02)805 4466

Austria: Triester Str. 64, A-1101 WIEN, P.O. Box 213,

Tel. (01)60 101-1236, Fax. (01)60 101-1211

Belgium: Postbus 90050, 5600 PB EINDHOVEN, The Netherlands,

Tel. (31)40 783 749, Fax. (31)40 788 399

Brazil: Rua do Rocio 220 - 5

CEP: 04552-903-SÃO PAULO-SP, Brazil.

P.O. Box 7383 (01064-970).

Tel. (011)821-2333, Fax. (011)829-1849

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS:

Tel. (800) 234-7381, Fax. (708) 296-8556

Chile: Av. Santa Maria 0760, SANTIAGO,

Tel. (02)773 816, Fax. (02)777 6730

Colombia: IPRELENSO LTDA, Carrera 21 No. 56-17,

77621 BOGOTA, Tel. (571)249 7624/(571)217 4609,

Fax. (571)217 4549

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. (032)88 2636, Fax. (031)57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. (9)0-50261, Fax. (9)0-520971

France: 4 Rue du Port-aux-Vins, BP317,

92156 SURESNES Cedex,

Tel. (01)4099 6161, Fax. (01)4099 6427

Germany: P.O. Box 10 63 23, 20043 HAMBURG,

Tel. (040)3296-0, Fax. (040)3296 213.

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. (01)4894 339/4894 911, Fax. (01)4814 240

Hong Kong: PHILIPS HONG KONG Ltd., 6/F Philips Ind. Bldg.,

24-28 Kung Yip St., KWAI CHUNG, N.T.,

Tel. (852)424 5121, Fax. (852)428 6729

India: Philips INDIA Ltd, Shivsagar Estate, A Block ,

Dr. Annie Besant Rd. Worli, Bombay 400 018

Tel. (022)4938 541, Fax. (022)4938 722

Indonesia: Philips House, Jalan H.R. Rasuna Said Kav. 3-4,

P.O. Box 4252, JAKARTA 12950,

Tel. (021)5201 122, Fax. (021)5205 189

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. (01)640 000, Fax. (01)640 200

Italy: PHILIPS SEMICONDUCTORS S.r.l.,

Piazza IV Novembre 3, 20124 MILANO,

Tel. (0039)2 6752 2531, Fax. (0039)2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. (03)3740 5028, Fax. (03)3740 0580

Korea: (Republic of) Philips House, 260-199 Itaewon-dong,

Yongsan-ku, SEOUL, Tel. (02)794-5011, Fax. (02)798-8022

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA,

SELANGOR, Tel. (03)750 5214, Fax. (03)757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TX 79905,

Tel. 9-5(800)234-7381, Fax. (708)296-8556

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB

Tel. (040)783749, Fax. (040)788399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. (09)849-4160, Fax. (09)849-7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. (022)74 8000, Fax. (022)74 8341

th

floor, Suite 51,

Pakistan: Philips Electrical Industries of Pakistan Ltd.,

Exchange Bldg. ST-2/A, Block 9, KDA Scheme 5, Clifton,

KARACHI 75600, Tel. (021)587 4641-49,

Fax. (021)577035/5874546.

Philippines: PHILIPS SEMICONDUCTORS PHILIPPINES Inc,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. (02)810 0161, Fax. (02)817 3474

Portugal: PHILIPS PORTUGUESA, S.A.,

Rua dr. António Loureiro Borges 5, Arquiparque - Miraflores,

Apartado 300, 2795 LINDA-A-VELHA,

Tel. (01)4163160/4163333, Fax. (01)4163174/4163366.

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. (65)350 2000, Fax. (65)251 6500

South Africa: S.A. PHILIPS Pty Ltd.,

195-215 Main Road Martindale, 2092 JOHANNESBURG,

P.O. Box 7430 Johannesburg 2000,

Tel. (011)470-5911, Fax. (011)470-5494.

Spain: Balmes 22, 08007 BARCELONA,

Tel. (03)301 6312, Fax. (03)301 42 43

Sweden: Kottbygatan 7, Akalla. S-164 85 STOCKHOLM,

Tel. (0)8-632 2000, Fax. (0)8-632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. (01)488 2211, Fax. (01)481 77 30

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66, Chung Hsiao West

Road, Sec. 1. Taipeh, Taiwan ROC, P.O. Box 22978,

TAIPEI 100, Tel. (02)388 7666, Fax. (02)382 4382.

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong,

Bangkok 10260, THAILAND,

Tel. (662)398-0141, Fax. (662)398-3319.

Turkey:Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. (0212)279 2770, Fax. (0212)269 3094

United Kingdom: Philips Semiconductors LTD.,

276 Bath road, Hayes, MIDDLESEX UB3 5BX,

Tel. (081)73050000, Fax. (081)7548421

United States:811 East Arques Avenue, SUNNYVALE,

CA 94088-3409, Tel. (800)234-7381, Fax. (708)296-8556

Uruguay: Coronel Mora 433, MONTEVIDEO,

Tel. (02)70-4044, Fax. (02)92 0601

For all other countries apply to: Philips Semiconductors,

International Marketing and Sales, Building BE-p,

P.O. Box 218, 5600 MD, EINDHOVEN, The Netherlands,

Telex 35000 phtcnl, Fax. +31-40-724825

SCD35 © Philips Electronics N.V. 1994

All rights are reserved. Reproduction in whole or in part is prohibited without the

prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation

or contract, is believed to be accurate and reliable and may be changed without

notice. No liability will be accepted by the publisher for any consequence of its

use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Printed in The Netherlands

373061/1500/01/pp20 Date of release: December 1994

Document order number: 9397 743 50011

Philips Semiconductors

Loading...

Loading...