Page 1

sames

CMOS 256 X 256 DIGITAL SWITCHING MATRIX

FEATURES

■

Hardware (pin-to-pin) and software

compatible with M088 and M3488

■ 256 input and 256 output channel digital

switching matrix

■ Building block designed for large

capacity electronic exchanges, subsystems and PABX

■ Non-blocking single stage and higher

capacity blocks (512 or 1024 channels)

■ European and U.S. standard

compatible (32/24 serial channels per

frame)

■ PCM inputs and outputs mutually

compatible

SA3488

SA3488

■ Actual input-output channel

connections stored and modified via

an on chip 8-bit parallel microprocessor

interface

■ 6 main “Functions” or “Instructions”

available

■ Typical Bit Rate : 2Mbit/s

■ Typical Synchronization Rate : 8KHz

(time frame is 125µs)

■ 5V power supply with internally

generated bias voltage

■ MOS & TTL input/output levels

compatible

DESCRIPTION

The SA3488 is a non-blocking digital

switching matrix that is capable of routing

256 input channels to any of 256 output

channels. Data is fed into and out of the

device via eight serial PCM input and

output channels at 2MBits/sec. The device

can connect or disconnect each input

channel with any output channel, as well as

carry out other functions which are user

programmable via an eight bit parallel

microprocessor interface. The SA3488

sees its primary use as a building block in

high volume electronic exchanges, voice

data PABX and other standard data

communications applications. It can be

easily configured for operation in PCM 24

or PCM 30 formats.

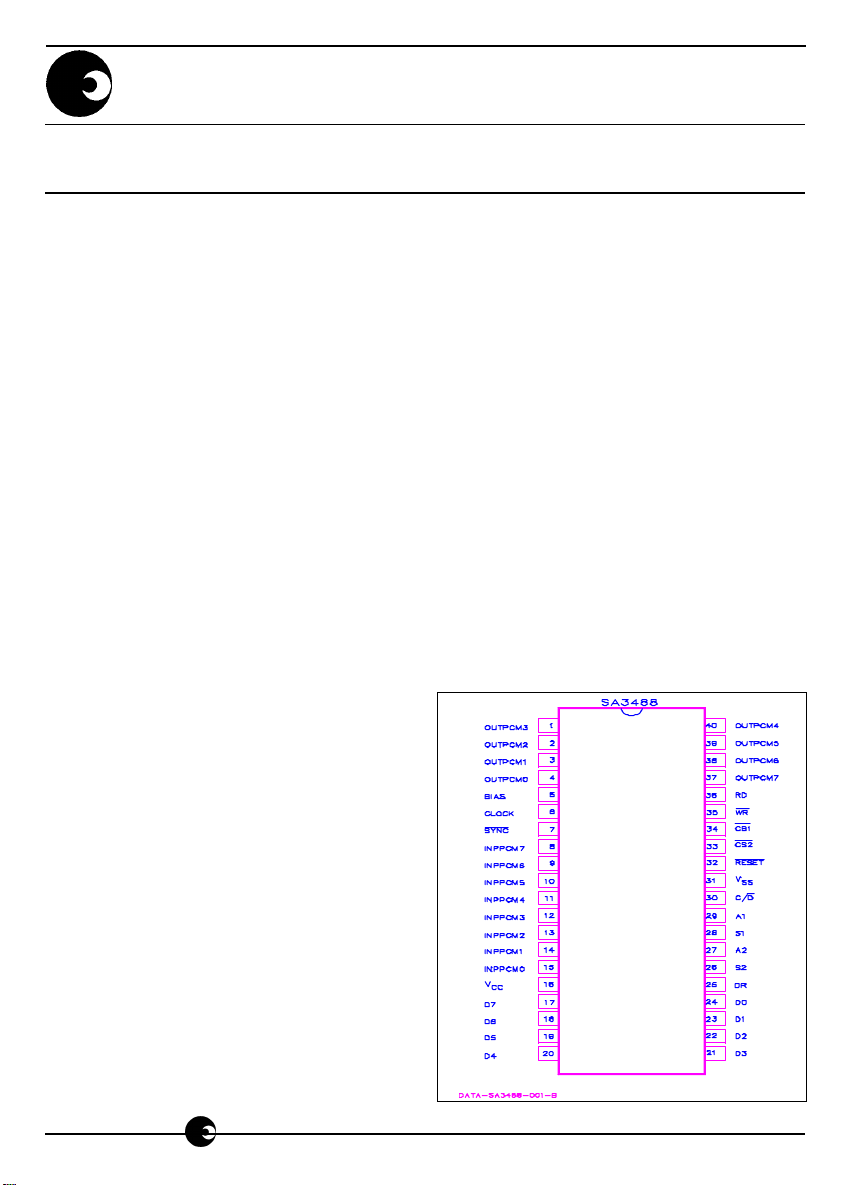

SA3488

sames

PIN CONNECTIONS:

1

Page 2

SA3488

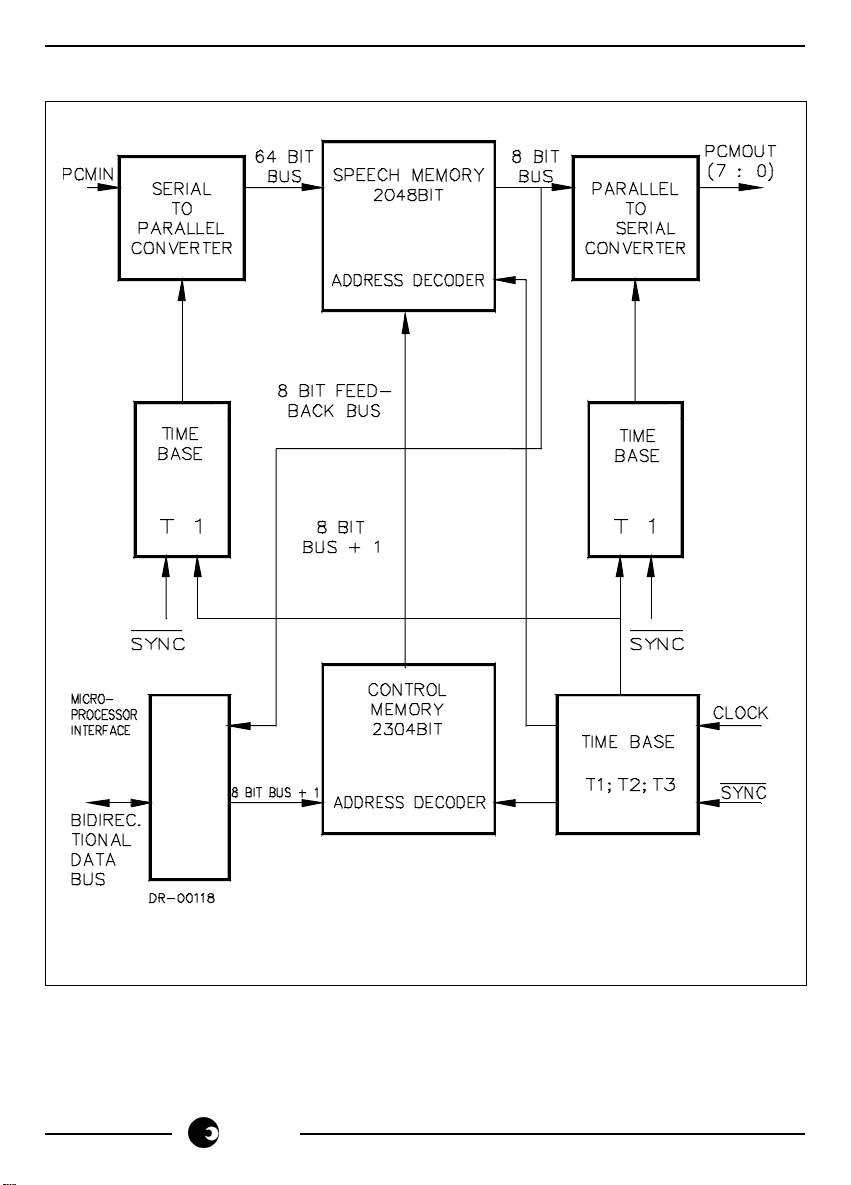

BLOCK DIAGRAM

sames

2

Page 3

SA3488

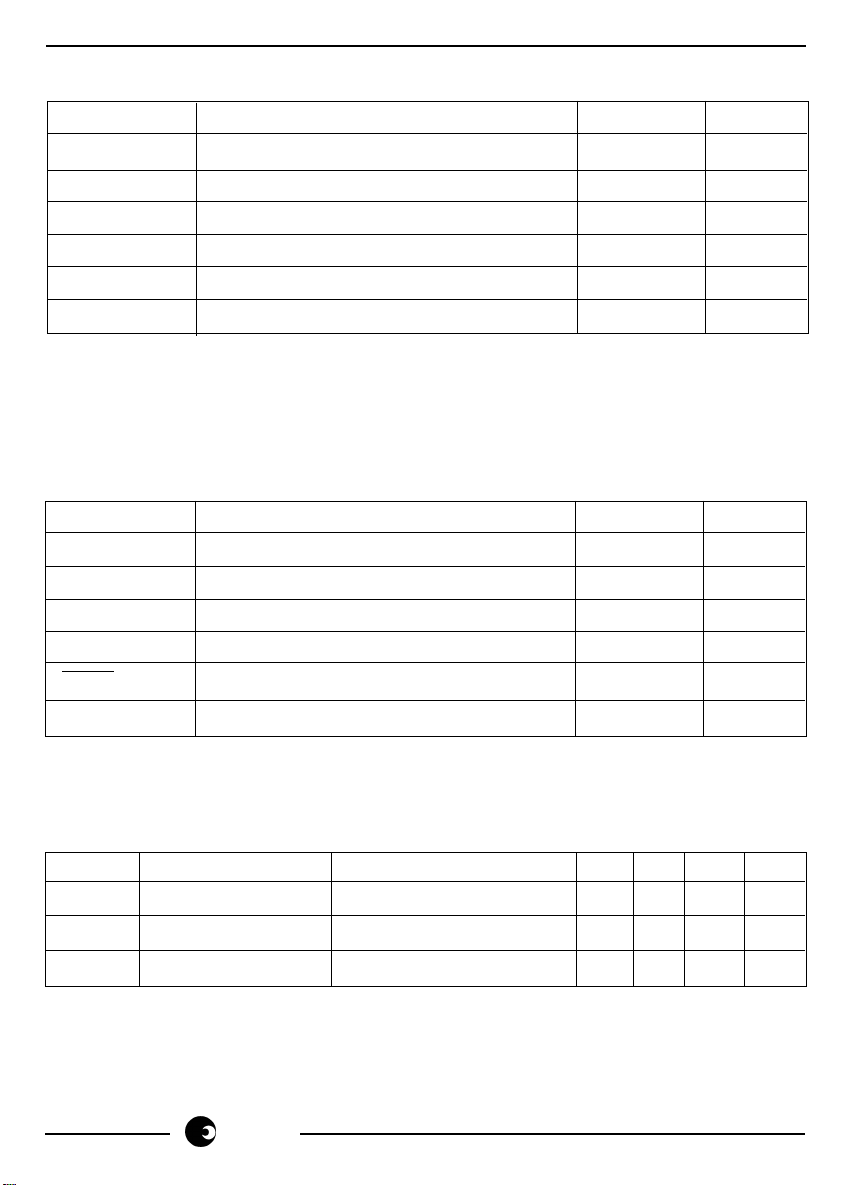

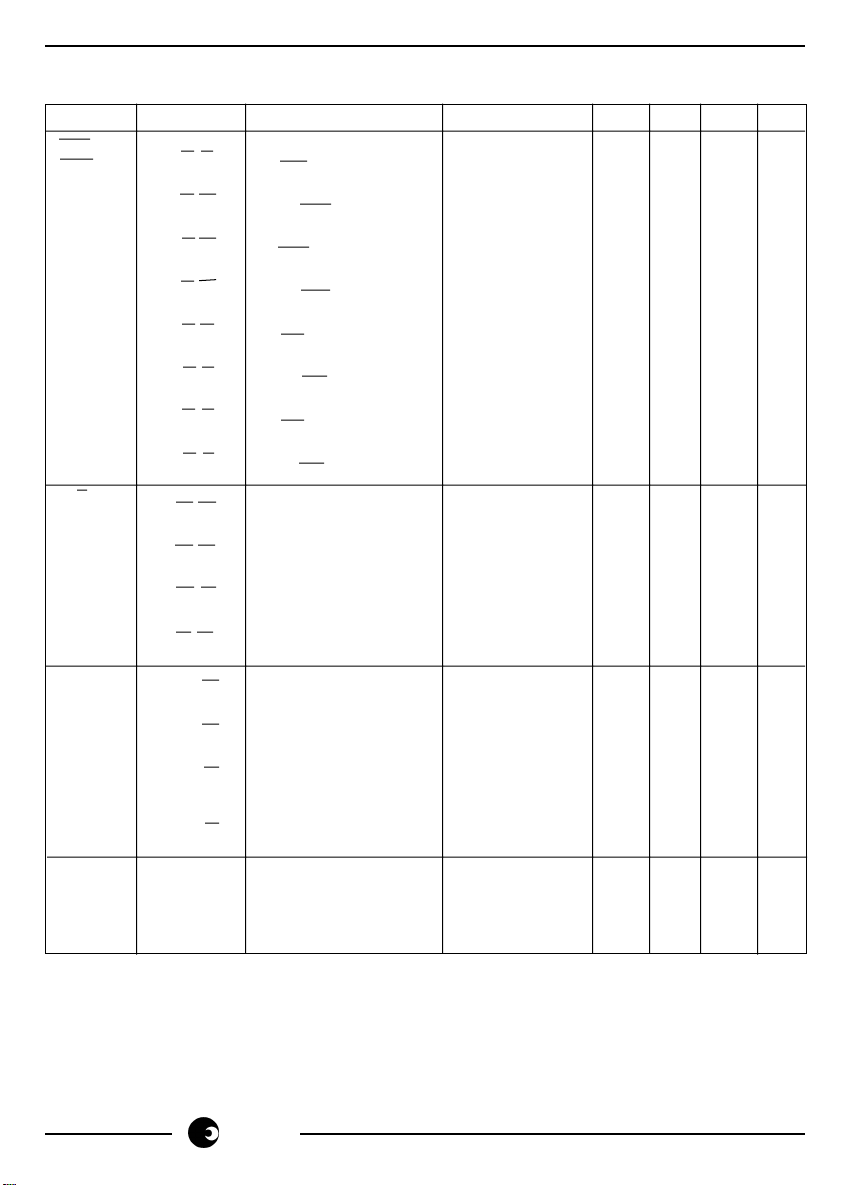

ABSOLUTE MAXIMUM RATINGS *

Symbol Parameter Value Unit

V

CC

V

I

V

O

P

tot

T

stg

T

op

Supply Voltage -0.3 to 7 V

Input Voltage -0.3 to 7 V

Off State Output 7 V

Total Package Power Dissipation 1.5 W

Storage Temperature Range -40 to +125 °C

Operating Temperature Range 0 to +70 °C

* Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage

to the device. This is a stress rating only. Functional operation of the device at these or any other

condition above those indicated in the operation sections of this specification, is not implied.

Exposure to Absolute Maximum Ratings for extended periods may affect device reliability.

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Value Unit

V

CC

V

I

V

O

Supply Voltage 4.75 to 5.25 V

Input Voltage 0 to 5.25 V

Off State Input Voltage 0 to 5.25 V

CLOCK Freq. Input Clock Frequency 4.096 MHz

SYNC Freq. Input Synchronization 8 KHz

T

op

Operating Temperature 0 to 70 °C

CAPACITANCES (Measuring freq. = 1MHz; T

= 0 to 70°C; unused pins tied to VSS)

op

Symbol Parameter Pins Min. Typ. Max. Unit

C

I

C

I/0

C

0

Input Capacitance 6 to 15; 26 to 30; 32 to 36 5 pf

I/O Capacitance 20 to 24 15 pf

Output Capacitance 1 to 4; 17 to 19; 37 to 40 10 pf

sames

3

Page 4

SA3488

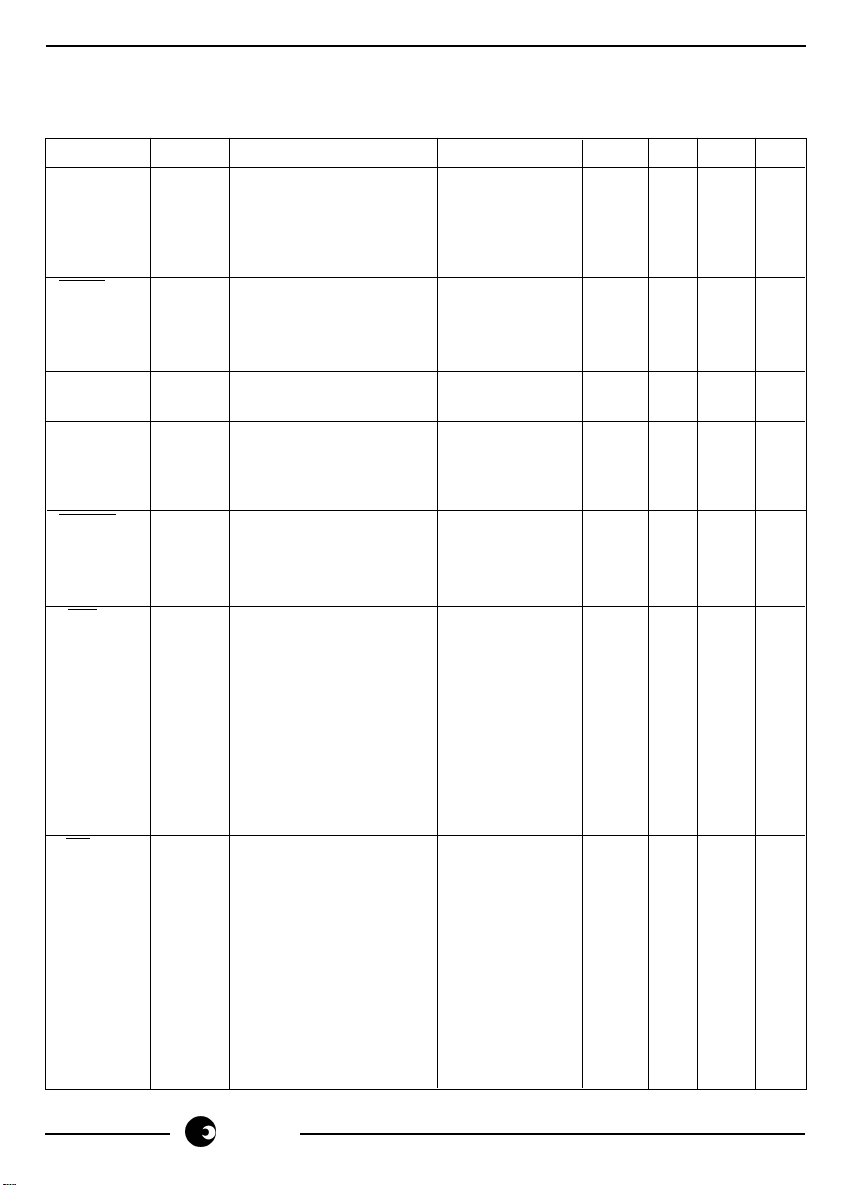

D.C. ELECTRICAL CHARACTERISTICS (T

All D.C. characteristics are valid 250µs after V

= 0 to 70°C, V

amb

and clock have been applied.

CC

= 5V 5%)

CC

Symbol Parameter Pins Test Condition Min. Typ. Max. Unit

V

V

V

Clock Input Low Level 6 -0.3 0. 8 V

ILC

Clock Input High Level 6 2.4 V

IHC

Input Low Level 7 to 15 -0.3 0. 8

IL

20 to 24 V

CC

26 to 30

32 to 36

V

Input High Level 7 to 15 2.0 V

IH

CC

20 to 24 V

26 to 30

32 to 36

V

V

V

I

IL

Output Low Level 17 to 25 IOL = 1.8mA 0.4 V

OL

Output High Level 17 to 25 IOH = 250µA 2.4 V

OH

PCM Output Low Level 1 to 4 IOL = 2.0mA 0.4 V

OL

Input Leakage Current 6 to 15 V

37 to 40

26 to 30

= 0 to V

IN

CC

10 µA

32 to 36

I

DL

Data Bus Leakage 17 to 24 V

Current V

= 0 to V

IN

CC

and 36 tied to V

Device Initialization

CC

applied; Pins 35

CC

±10 µA

, after

V

I

CC

Supply Current 16 Clock Freq.= 4.096MHz 180 mA

sames

4

Page 5

SA3488

A.C. ELECTRICAL CHARACTERISTICS (T

All A.C. characteristics are valid 250µs after V

capacitive load and R

the test pull up resistor.

L

= 0 to 70°C, VCC = 5V ±5%)

amb

and clock have been applied. CL is the max.

CC

Signal Symbol Parameter Test Condition Min. Typ. Max. Unit

CK t

(clock) t

SYNC t

PCM input t

Busses t

PCM t

Output referred to CK low level

Busses t

PDmin

PDmax

RESET t

WR t

t

RD t

t

Clock Period 230 ns

CK

Clock Low Level Width 100 ns

WL

t

Clock High Level Width 100 ns

WH

Rise Time 25 ns

t

R

t

Fall Time 25 ns

F

Low Level Setup Time 80 ns

SL

t

Low Level Hold Time 40 ns

HL

High Level Setup Time 80 ns

t

SH

t

High Level Width t

WH

Setup Time -5 ns

S

Hold Time 45 ns

H

CK

Propagation time CL = 50pf,RL=2K 45 ns

Propagation time CL = 50pf,RL=2K 200 ns

referred to CK high level

Low Level Setup Time 100 ns

SL

Low Level Hold Time 50 ns

t

HL

t

High Level Setup Time 90 ns

SH

t

High Level Width t

WH

Low Level Width 150 ns

WL

t

High Level Width t

WH

Repetition Interval t

REP

between Active Pulses + t

t

High Level Setup Time + t

SH

to Active Read Strobe

High Level Hold Time 20 ns

t

HH

from Active Read Strobe

Rise Time 60 ns

t

R

t

Fall Time 60 ns

F

Low Level Width 180 ns

WL

t

High Level Width t

WH

Repetition Interval t

REP

between Active Pulses + t

t

High Level Setup Time 0 ns

SH

to Active Read Strobe

High Level Hold Time 20 ns

t

HH

= 40+2 t

REP

WL(CK) +

R(CK)

= 40+2 t

REP

WL

+ t

CK +

CK

R

CK

CK

see

formula

0ns

CK

see

formula

from Active Write Strobe

t

Rise Time 60 ns

R

t

Fall Time 60 ns

F

ns

ns

ns

ns

sames

5

Page 6

SA3488

A.C. ELECTRICAL CHARACTERISTICS (Cont.)

Signal Symbol Parameter Test Conditions Min. Typ. Max. Unit

CS1, t

CS2 to WR falling edge

C/D t

A1,S1, t

A2,S2 strobe end

(match t

inputs) strobe end

DR t

(data t

ready) from write strobe end Instructions 5, 5.t

SL(CS-WR)

t

HL(CS-WR)

t

SH(CS-WR)

t

HH(CS-WR)

t

SL(CS-RD)

t

HL(CS-RD)

t

SH(CS-RD)

t

HH(CS-RD)

S(C/D-WR)

t

H(C/D-WR)

t

S(C/D-WR)

t

H(C/D-WR)

S(match-WR)

H(match-WR)

t

S(match-RD)

t

H(match-RD)

W

PD

Low level setup time Active Case 0 ns

Low level hold time Active Case 0 ns

from WR rising edge

High level setup time Inactive Case 0 ns

to WR falling edge

High level hold time Inactive Case 0 ns

from WR rising edge

Low level setup time Active Case 0 ns

to RD falling edge

Low level hold time Active Case 0 ns

from RD rising edge

High level setup time Inactive Case 0 ns

to RD falling edge

High level hold time Inactive Case 0 ns

from RD rising edge

Setup time to write

strobe end 130 ns

Hold time from

write strobe end 25 ns

Setup time to read

strobe start 20 ns

Hold time from read

strobe end 25 ns

Setup time to write 130 ns

Hold time from 25 ns

Setup time to read 20 ns

strobe start

Hold time from read 25 ns

strobe end

Low state width Instructions 5,6 2 t

DR output delay

(active command) CL= 50pf ns

CK

14 t

CK

CK

ns

sames

6

Page 7

SA3488

A.C. ELECTRICAL CHARACTERISTICS (Cont.)

Signal Symbol Parameter Test Conditions Min. Typ. Max. Unit

D0 to D7 t

(Interface write strobe end

bus) t

S(BUS-WR)

H(BUS-WR)

t

PD(BUS)

Input setup time to 130 ns

Input hold time 25 ns

from write strobe end

Propagation time CL= 200pf 120 ns

from (active) falling

edge of read strobe

t

HZ(BUS)

Propagation time 80 ns

from (active)rising

edge of read strobe

to high impedance

state

sames

7

Page 8

SA3488

PIN DESCRIPTION

Pin Designation Description

17 D7 Bidirectional data bus used to transfer data and instructions

18 D6 to and from the microprocessor. The output bus is 8 bits

19 D5 wide and the input 5 bits wide. D0 is the least significant

20 D4 digit. The bus is tristate and is not available for use while

21 D3 RESET is held low.

22 D2

23 D1

24 D0

30 C/D In a write operation C/D = 0 qualifies bus content as data,

while C/D = 1 qualifies it as a opcode. In a read operation

C/D = 0 selects OR1 whereas C/D = 1 selects OR2.

33 CS2 Chip select pins. Enable the device to perform valid read

34 CS1 and write operations (active low). The two pins allow for

row column selection for different types of microprocessors;

normally though one is tied low.

26 S 2 Address select or match pins. With S1 and S2 hardwired

27 A 2 to ground or VCC, signals on A1 and A2 give rise to a 28S1

matched or unmatched condition i.e. S1=A1, S2=A2 =>a

29 A 1 matched condition. Since in a matrix structure, devices in

the same row share the same PCM output bus, instructions

pertaining to channel connections (matched condition),

must be processed as channel disconnections in the other

devices (unmatched condition). Two channels can

therefore never collide.

35 WR When CS1 and CS2 are low, WR enables data transfer

from the microprocessor to the device. Data, opcode and

control signals are latched on the rising edge of WR. To

ensure simultaneous instruction execution in a multichip

configuration the WR rising edge must be 20 to 20 + t

nsec late relative to the clock falling edge.

WL(CK)

36 RD When CS1 and CS2 are low and a matched condition

exists, a low level on RD enables OR1 or OR2 for a read

operation. In addition the rising edge of RD latches C/D

and the matched condition pins in order to direct the

internal flow of operations. In a multichip configuration

the sametiming requirement must be met as in the WR

case.

sames

8

Page 9

SA3488

Pin Description (Cont.)

Pin Designation Description

32 RESET This pin is used to initialise the device. The initialisation

routine takes one time frame whatever the RESET pulse

width (one clock cycle minimum). All internal registers are

set 'high' and the control memory is set to all 'ones' i.e.

channel disconnection. The data bus is pulled to a high

impedance state as well as the PCM output channels.

25 DR DR is the data ready pin which is normally high. If DR goes

low the following information is available via this pin.

1. Invalid instruction code (The pin is held low until a valid

instruction is loaded).

2. An active output channel was found in a matrix of

devices with the same CS pins during the execution of

instruction 5. DR is low for two clock cycles.

3. Status register 2 was loaded with the total number of

messages in time slot 0 during the execution of

instruction 6. DR is active low for two clock cycles.

6 CLOCK Input clock frequency is typically 4.096Mhz. This signal

will set the internal input/ output channel bit rate to 2.048

Mbits/sec. The bit rate is set by division of the master

clock frequency.

7 SYNC The input synchronisation signal frequency is 8kHz and is

active low. Internally generated time bases that maintain

sequential addressing are synchonised via the SYNC

signal.

8 INP PCM7 The input PCM bus accepts a standard data rate of 2MBits/

sec.

9 INP PCM6

10 INP PCM5

11 INP PCM4

12 INP PCM3

13 INP PCM2

14 INP PCM1

15 INP PCM0

sames

9

Page 10

SA3488

Pin Description (Cont.)

Pin Designation Description

37 OUT PCM7 Output PCM channel bit rate is also 2MBits/sec. The

output 38 OUT PCM6 buffers are open drain simulating a wired

OR connection. 39 OUT PCM5 This minimises current spike problems in

multichip 40 OUT PCM4 configurations. Input and output channels

are driven in 1 OUT PCM3 such a manner as to reduce any analogue

delay time up to:

2 OUT PCM2 Time delay max = 1 bit time-(clock high prop. time - Clock

3 OUT PCM1 low prop. time).

4 OUT PCM0

5 BIAS Internally generated bias voltage (-2.5 to -3.0V for VCC in

the operating range). A maximum of 220pf capacitor

connected to pin 5 provides improved filtering.

sames

10

Page 11

SA3488

FUNCTIONAL OVERVIEW

The SA3488 is intended for large telephone switching systems, mainly central exchanges,

digital line concentrators and private branch exchanges where a distributed microcomputer

control approach is extensively used. It consists of a speech memory (SM), a control

memory (CM), a serial/parallel and a parallel/serial converter, an internal parallel bus,

an interface (8 data lines, 11 control signals) and dedicated logic. By means of repeated

clock division two time bases are generated. These are preset from an external

synchronization signal to two specific count numbers so that sequential scanning of the

bases give synchronous addresses to the memories and I/O channel controls. Different

preset count numbers are needed because of processing delays and data path direction.

The time-base for output channels is advanced with respect to the actual time. Each

serial PCM input channel is converted to parallel data and stored in the speech memory

at the beginning of any new time slot (according to first timebase) in the location

determined by input pin number and time slot number. The control memory CM

maintains the correspondences between input and output channels. More exactly, for

any output pin/output channel combination the control memory gives either the full

address of the speech memory location involved in the PCM transfer or an 8-bit word to

be supplied to the parallel/serial output converter. A 9th bit at each CM location defines

the data source for output links; low for SM, high for CM.

The late timebase is used to scan the output channels and to determine the pins to be

serviced within each channel. Enough idle cycles are left to the microprocessor for

synchronous instruction processing. Two 8-bit registers OR1 and OR2 supply feedback

data for control or diagnostic purposes; OR1 comes from the internal bus i.e. from

memories, while OR2 gives an opcode copy and additional data to the microcomputer.

A four byte, 5-bit stack register and an instruction register, under microcomputer control,

store input data available at the interface.

Dedicated logic, under control of the microprocessor interface, extracts the 0 channel

content of any selected PCM input bus, using spare cycles of SM.

sames

11

Page 12

SA3488

FUNCTIONAL DESCRIPTION OF SPECIFIC MICROPROCESSOR OPERATIONS

The device, under microprocessor control, performs the following instructions:

1 CHANNEL CONNECTION/DISCONNECTION

2 CHANNEL DISCONNECTION

3 INSERTION OF A BYTE ON A PCM OUTPUT CHANNEL/CHANNEL

DISCONNECTION)

4 TRANSFER OF A SINGLE OUTPUT CHANNEL SAMPLE

5 TRANSFER OF A SINGLE OUTPUT CHANNEL CONTROL WORD

6 TRANSFER OF SELECTED 0 CHANNEL PCM INPUT DATA ACCORDING TO AN

8-BIT MASK PREVIOUSLY STORED IN THE “EXPECTED MESSAGES”

REGISTER.

The instruction flow is as follows:

Any input protocol is started by the microprocessor interface loading the internal stack

register with 2 bytes (4 bytes for instructions 1 and 3) qualified as data bytes by C/D =

0 and a specific opcode qualified by C/D = 1 (match condition is normally needed).

After the code is loaded, the instruction register is immediately checked to see whether

it is acceptable; if not, it is rejected. If accepted the instruction is also processed as

regards match condition and is appended for execution during the memories’ space

cycles.

Four cases are possible:

a) the code is not valid; execution cannot take place, the DR output pin is reset to

indicate the error and all registers are saved;

b) the code is valid for types 2, 4 and 6 but it is unmatched; execution cannot take place,

and DR is not affected.

c) the code is valid for types 1 and 3 and it is unmatched; the instruction is interpreted

as a channel disconnection.

d) the code is valid and it either matches or is of type 5; the instruction is processed as

received.

Validation control takes only two cycles out of a total execution time of 5 to 13 cycles;

the last operation is the updating of the contents of registers OR1 and OR2.

sames

12

Page 13

SA3488

During a very long internal operation (device initialization after RESET going high or

execution of instruction 6) a new set of data bytes with a valid opcode is accepted while

a wrong code is rejected. At the end of the current routine execution takes place in the

same way as described before.

At the end of an instruction it is normally recommended to read one or both registers. To

enable instruction 6, however, it is necessary to read register OR2. This is because

instruction 6, used between other short instructions of type 1 to 5, must have a lower

priority and can be enabled only after the short instructions have been completed.

Instruction 6 normally has a long process and a special flow which is described below.

First a not-all-zero mask is stored in the “expected messages” register and in another

“background” register. This operation starts the second phase of instruction 6 which is

called “channel 0 extraction” and is repeated at the beginning of any new time frame. At

the beginning of the time frame a new copy of activated channels to be extracted is made

from the “background register” and put in the “expected messages” register. In addition

the latter register is modified to indicate the exact number of messages that have arrived.

The term messages covers any input 0 channel data with starting sequence different

from the label 01. So using this label the number of expected messages can be reduced

to correspond to the number of effective messages. If and only if the residual number

is different from zero will the device start the extraction protocol at the end of the current

routine.

The procedure is as follows: the DR output is pulsed low as a two cycle interrupt request

and OR2 is loaded with the total number of active channels to be extracted.

The transfer of OR2 contents to the microprocessor continues the extraction which

consists of repeated steps of OR1 and OR2 loading, indicating respectively the message

and the incoming bus number. Reading the registers in the order OR1, OR2 must be

continued until completion or until the time frame runs out.

With a new time frame a new extraction process begins, resuming the copy operation

from the background register.

During extraction the active channels are scanned from the highest to the lowest number

(from 7 to 0). While extraction is being carried out the time interval requirements between

active rising edges of RD are a minimum of 5 to 13 tCK for sequence OR2 - OR1 and a

minimum of 3 times tCK for sequence OR1 - OR2. More details are given in the following

tables.

sames

13

Page 14

SA3488

INSTRUCTION TABLES

The most significant digits of OR2 A7, A6, A5 are a copy of the PCM selected output bus;

the least significant digits or OR2 are the opcode while C8 is the control bit. In all cases

parentheses () define actual register contents.

INSTRUCTION 1: CHANNEL CONNECTION/DISCONNECTION

Control Signals Data Bus

Match C/D CS WR RD D7 D6 D5 D4 D3 D2 D1 D0 Notes

X 0 0 0 1 X X X X X Bi2 Bi1 Bi0 1st Data Byte:selected input bus

X 0 0 0 1 X X X Ci4 Ci3 Ci2 Ci1 Ci0 2nd Data Byte: selected input

X 0 0 0 1 X X X X X Bo2 Bo1 Bo0 3rd Data Byte: selected output

X 0 0 0 1 X X X Co4 Co3 Co2 Co1 Co0 4

Yes/No 1 0 0 1 X X X X 0 0 0 1 Instruction Opcode

Yes 0 0 1 0 C7 C6 C5 C4 C3 C2 C1 C0 0R1 : CM content copy,

(11111111)that is for mismatch

(Bi2 Bi1 Bi0 Ci4 Ci3 Ci2 Ci1 Ci0) condition or match

Yes1 010 A7A6A5C8000 1OR2

(Bo2 B01 Bo0 10001)

(Bo2 Bo1 Bo0 00001)

channel

bus

th

Data Byte: selected output

channel

condition

INSTRUCTION 2: OUTPUT CHANNEL DISCONNECTION

Control Signals Data Bus

Match C/D CS WR RD D7 D6 D5 D4 D3 D2 D1 D0 Notes

X 0 0 0 1 X X X X X Bo2 Bo1 Bo0 1

X 0 0 0 1 X X X Co4 Co3 Co2 Co1 Co0 2nd Data Byte: selected

Yes 1 0 0 1 X X X X 0 0 1 0 Instruction Opcode

Yes001011111111OR1 : CM Content Copy

Yes1010A7A6A510010OR2

(Bo2 Bo1 Bo0 10010)

st

Data Byte: selected output

bus

output channel

(output channel is inactive)

sames

14

Page 15

SA3488

INSTRUCTION 3: LOADING A MICROPROCESSOR BYTE

Control Signals Data Bus

Match C/D CS WR RD D7 D6 D5 D4 D3 D2 D1 D0 Notes

X 0 0 0 1 X X X X X Ci7 Ci6 Ci5 1

st

Data Byte: most significant

digits to be inserted

X 0 0 0 1 X X X Ci4 Ci3 Ci2 Ci1 Ci0 2nd Data Byte: least significant

digits to be inserted

X 0001XXXXXBo2Bo0Bo13

rd

Data Byte: selected output

bus

X 0 0 0 1 X X X Co4 Co3 Co2 Co1 Co0 4

th

Data Byte: selected output

channel

Yes/no 1 0 0 1 X X X X 0 1 0 0 Instruction Opcode

Yes 0 0 1 0 C7 C6 C5 C4 C3 C2 C1 C0 OR1 : CM

(1 1 1 1 1 1 1 1) content copy, that

(Ci7 Ci6 Ci5 Ci4 Ci3 Ci2 Ci1 Ci0) is for mismatch condition or

match condition

Yes1010A7A6A510100OR2

(Bo2 Bo1 Bo0 1 0 1 0 0)

INSTRUCTION 4: TRANSFER OF A SINGLE PCM SAMPLE

Control Signals Data Bus

Match C/D CS WR RD D7 D6 D5 D4 D3 D2 D1 D0 Notes

X 0001XXXXXBo2Bo1Bo01

X 0 0 0 1 X X X Co4 Co3 Co2 Co1 Co0 2

Yes 1 0 0 1 X X X X 1 0 1 1 Instruction Opcode

Yes 0 0 1 0 C7 C6 C5 C4 C3 C2 C1 C0 OR1 : CM Content

S7 S6 S5 S4 S3 S2 S1 S0 Copy if C8= 1; or

Yes1010A7A6A5C81011OR2

(Bo2 Bo1 Bo0 C 8 1 0 1 1)

Note: S7..S0 is a parallel copy of the PCM data; S7 is the most significant digit and the first of the sequence.

st

Data Byte: selected output

bus

nd

Data Byte: selected output

channel

SM Content Sample if C8=0

sames

15

Page 16

SA3488

INSTRUCTION 5: TRANSFER OF AN OUTPUT CHANNEL CONTROL WORD

Control Signals Data Bus

Match C/D CS WR RD D7 D6 D5 D4 D3 D2 D1 D0 Notes

X 0001XXXXXBo2Bo1Bo01st Data Byte: selected output

X 0 0 0 1 X X X Co4 Co3 Co2 Co1 Co0 2nd Data Byte: selected output

X 1 0 0 1 X X X X 1 0 0 0 Instruction Opcode

Yes 0 0 1 0 C7 C6 C5 C4 C3 C2 C1 C0 OR1 : CM selected CM word

Yes1010A7A6A5C81000OR2

(Bo2 Bo1 Bo0 C 8 1 0 0 0)

bus

channel

copy

INSTRUCTION 6: CHANNEL 0 SELECTION MASK STORE/DATA TRANSFER

Control Signals Data Bus

Match C/D CS WR RD D7 D6 D5 D4 D3 D2 D1 D0 Notes

X 0 0 0 1 X X X X X Mi7 Mi6 Mi5 1st Data Byte: most significant

X 0 0 0 1 X X X Mi4 Mi3 Mi2 Mi1 Mi0 2nd Data Byte: most significant

Yes 1 0 0 1 X X X X 1 1 1 0 Instruction Opcode

Mask store control

Yes 0 0 1 0 (previous content) OR1 : register is not affected

Yes 1 0 1 0 N2 N1 N0 Tn 1 1 1 0 OR2 : see below

First Data Transfer (after DR going low)

Yes 0 0 1 0 (previous content) OR1 : register is not affected

Yes 1 0 1 0 N2 N1 N0 Tn 1 1 1 0 OR2 : see below

Repeated Data Transfer (after first OR2 transfer)

Yes 0 0 1 0 S7 S6 S5 S4 S3 S2 S1 S0 OR1 : expected message stored

Yes1010P2P1P0Fn1110OR2

Notes: 1. Regarding mask bits Mi0 to Mi7 a logic “0” level means disabling condition, a logic “1” level means

enabling condition.

2. A null mask or a RESET pulse clears the mask and the deep background mask registers and disable

channel 0 extraction function.

3. Reading of OR2 is optional after mask store or redefinition, because function is activated only by notnull mask writing.

4. After mask store (N2 N1 N0) is the sum of activated channels, after DR is the sum of active channels;

Tn=1/0 means activation/suppression of the function after store while after DR only Tn = 1 can appear

indicating non-null configuration extraction.

5. Reading of OR2 is imperative after DR in order to step the data transfer; reading of OR1 is also needed

to scan in descending order the priority register. Relevant messages only are considered, i.e. only

messages with a MSD label different from 0 1.

6. (P2 P1 P0) is the PCM bus on which the message copied in OR1 was found; Fn is a continuation bit

telling respectively on level 1/0 for any more/no more extraction to be performed.

digits of selection mask

digits of selection mask

in SM

sames

16

Page 17

PCM TIMING, RESET

WRITE OPERATION TIMING

SA3488

sames

17

Page 18

SA3488

READ OPERATION TIMING

sames

18

Page 19

Notes:

SA3488

sames

19

Page 20

SA3488

Disclaimer: The information contained in this document is confidential and proprietary to South African Micro-

Electronic Systems (Pty) Ltd ("SAMES") and may not be copied or disclosed to a third party, in whole or in part,

without the express written consent of SAMES. The information contained herein is current as of the date of

publication; however, delivery of this document shall not under any circumstances create any implication that the

information contained herein is correct as of any time subsequent to such date. SAMES does not undertake to

inform any recipient of this document of any changes in the information contained herein, and SAMES expressly

reserves the right to make changes in such information, without notification,even if such changes would render

information contained herein inaccurate or incomplete. SAMES makes no representation or warranty that any

circuit designed by reference to the information contained herein, will function without errors and as intended by

the designer.

Any Sales or technical questions may be posted to our e-mail address below:

energy@sames.co.za

For the latest updates on datasheets, please visit out web site:

http://www.sames.co.za

South African Micro-Electronic Systems (Pty) Ltd

P O Box 15888, 33 Eland Street,

Lynn East, 0039 Koedoespoort Industrial Area,

Republic of South Africa, Pretoria,

Republic of South Africa

Tel: 012 333-6021 Tel: Int +27 12 333-6021

Fax: 012 333-8071 Fax: Int +27 12 333-8071

sames

20

Loading...

Loading...