Datasheet SA24C1024LEMF, SA24C1024LEMFF, SA24C1024LEMFFX, SA24C1024LEMFX, SA24C1024LEMW Datasheet (SAIFUN)

...Page 1

This Datasheet states Saifun's current technical specifications regarding the Products descri bed herein. This Datasheet

may be revised by subsequent versions or modifications due to changes in technical specifications.

Publication# 1908 Rev: 1 Amendment: 1

Issue Date: 26 August 2003

SA24C1024

Datasheet

Features

•= Saifun NROM™ NVM Technology

•= Operating voltage: 2.7V to 3.6V

•= Clock frequency: 100/400/1700/3400 kHz

•= Low power consumption

– 0.5µ

µµ

µA standby current typical (L version)

– <0.2µ

µµ

µA standby current typical (LZ version)

•= Write Modes

– Byte Mode

– Page Mode (128 Bytes/Page)

•= Schmitt trigger inputs

•= Hardware and software write protection for entire or partial array

•= Endurance: up to 1 million data changes

•= Data Retention: Greater than 40 years

•= Packages: 8-Pin DIP and 8-Pin SOIC and MLF Leadless

•= Temperature range

– Commercial: 0 °C to +70 °C

– Industrial (E): -40 °C to +85 °C

1024Kb EEPROM

IIC

http://www.saifun.com

Saifun NROMTM is a trademark of Saifun Semiconductors Ltd.

Page 2

SA24C1024 Datasheet

SAIFUN

2

General Description

The SA24C1024 is a 1024Kbit CMOS nonvolatile serial EEPROM organized as 128K

x 8 bit memory. This device conforms to

Extended IIC 2-wire protocol, which

enables accessing of memory in excess of

16 Kbits on an IIC bus. This serial

communication protocol uses a Clock

signal (SCL) and a Data signal (SDA) to

synchronously clock data between a

Master (for example, a microcontroller) and

a Slave (EEPROM).

The SA24C1024 offers hardware write

protection whereby the entire memory

array can be write-protected by pulling the

WP pin to logic HIGH. The entire memory

then becomes unalterable until the WP pin

is switched to logic LOW. The device also

features programmable write protect with

options of full, half or a quadrant of the

array.

The LZ version of the SA24C1024 offers

very low standby current, which makes it

suitable for low power applications. The

SA24C1024 is designed to minimize pin

count and simplify PC board layout

requirements. This device is offered in both

SO and DIP packages. A leadless

microleadframe package and CSP are

under development.

Saifun’s EEPROMs are designed and

tested for applications requiring high

endurance, high reliability and low power

consumption.

Page 3

SA24C1024 Datasheet

SAIFUN

3

Table of Contents

Features......................................................................... 1

General Description ...................................................... 2

Block Diagram............................................................... 4

Connection Diagrams................................................... 5

Ordering Information .................................................... 6

Product Specifications ................................................. 7

Absolute Maximum Ratings Operating Conditions... 7

ESD/Latch up Specification (JEDEC 8 Spec) ........... 7

Operating Conditions............................................... 7

VCC (2.7 V to 3.6 V) DC Electrical Characteristics ... 8

Capacitance ............................................................ 8

AC Test Conditions ................................................. 9

AC Testing Input/Output Waveforms....................... 9

AC Characteristics (VCC 2.7 V – 3.6 V).................... 9

Bus Timing............................................................ 10

Write Cycle Timing................................................ 11

Typical System Configuration................................ 11

Background Information (IIC Bus) ............................. 12

Slave Address....................................................... 12

Device Type.......................................................... 13

Device/Page Block Selection................................. 13

Read/Write Bit....................................................... 13

Acknowledge......................................................... 13

Array Address#1.................................................... 13

Array Address#0.................................................... 13

Pin Descriptions.......................................................... 14

Serial Clock (SCL)................................................. 14

Serial Data (SDA).................................................. 14

Write Protect (WP) ................................................ 14

Choice 1: Full Array Write Protect ................. 14

Device Selection Input – A1 (as Appropriate) ........ 14

Choice 2: Programmable W rite Protect ......... 15

Device Operation......................................................... 16

Clock and Data Conventions ................................. 16

START Condition .................................................. 16

STOP Condition .................................................... 16

SA24C1024 Array Addressing............................... 16

Write Operations......................................................... 18

Byte Write ............................................................. 18

Page Write ............................................................ 18

Acknowledge Polling ............................................. 19

Write Protection .................................................... 19

Read Operations ......................................................... 20

Current Address Read........................................... 20

Random Read ....................................................... 20

Sequential Read.................................................... 20

Switching from Standard/Fast Modes to High-speed

Mode and Back....................................................... 22

Physical Dimensions................................................... 24

Contact Information .................................................... 27

Life Support Policy...................................................... 27

List of Figures

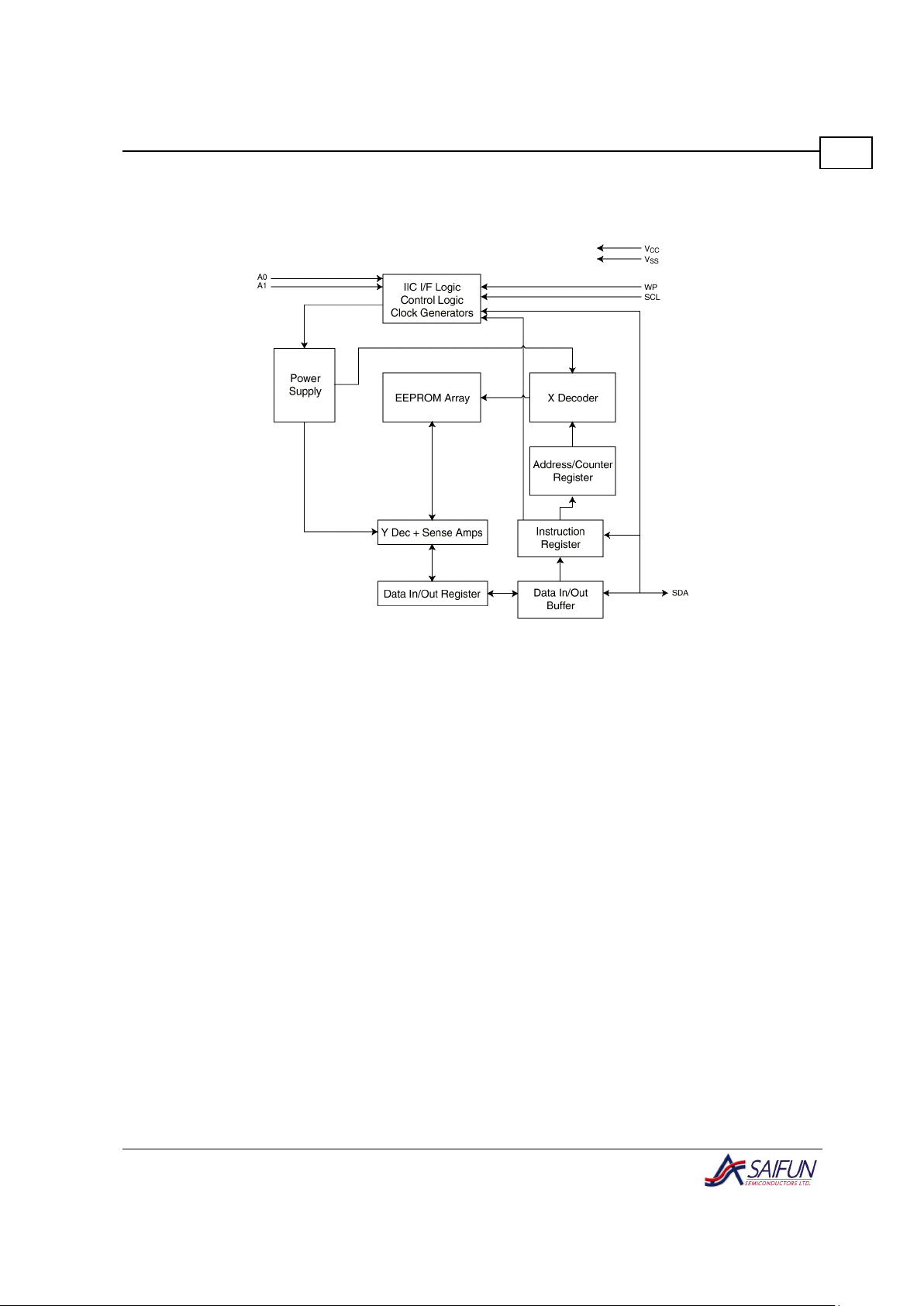

Figure 1. SA24C1024 Block Diagram .............................. 4

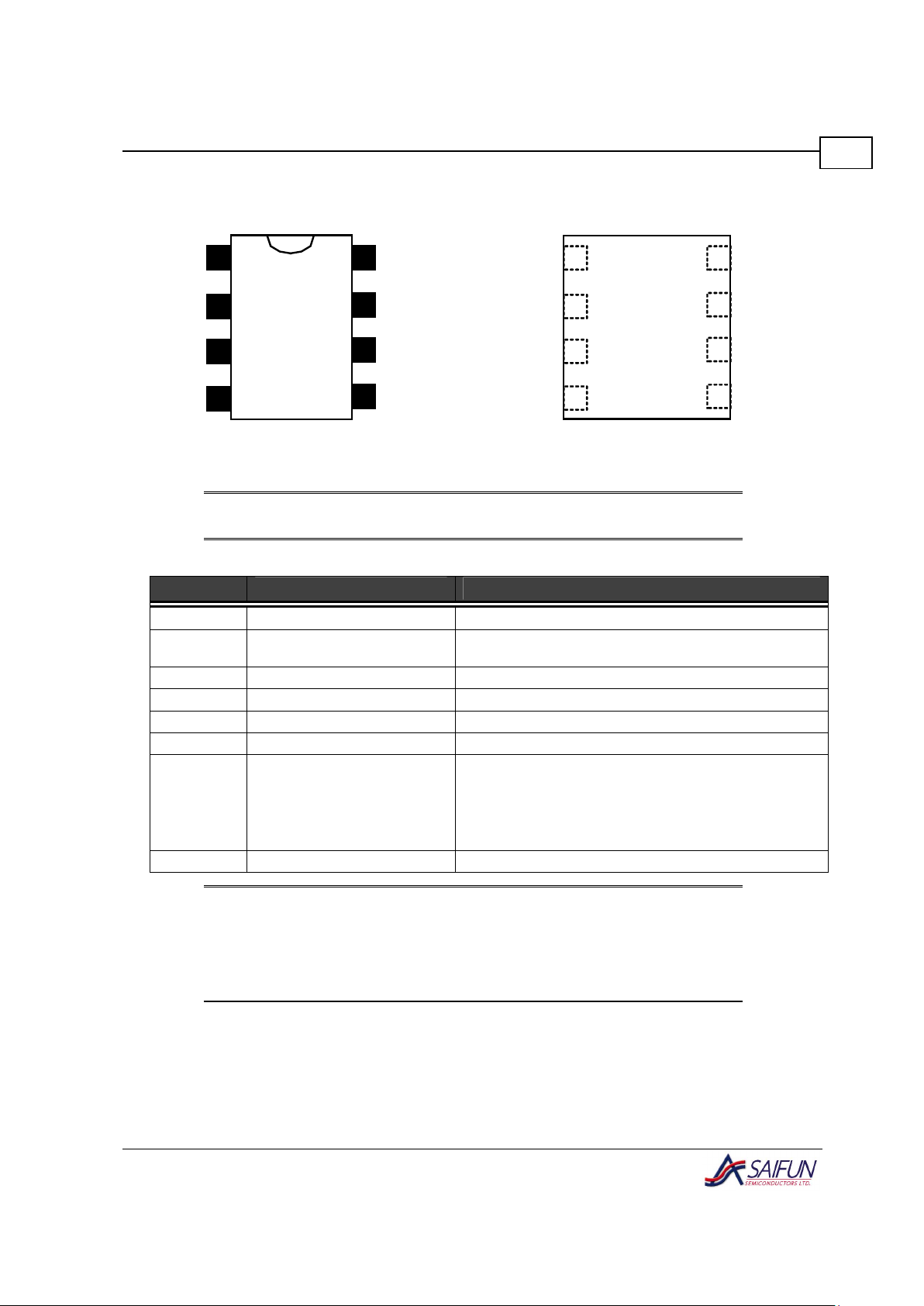

Figure 2. SO Package (MW), Dual Inline (N) – Top View 5

Figure 3. Leadless Package (MLF) – Top View ............... 5

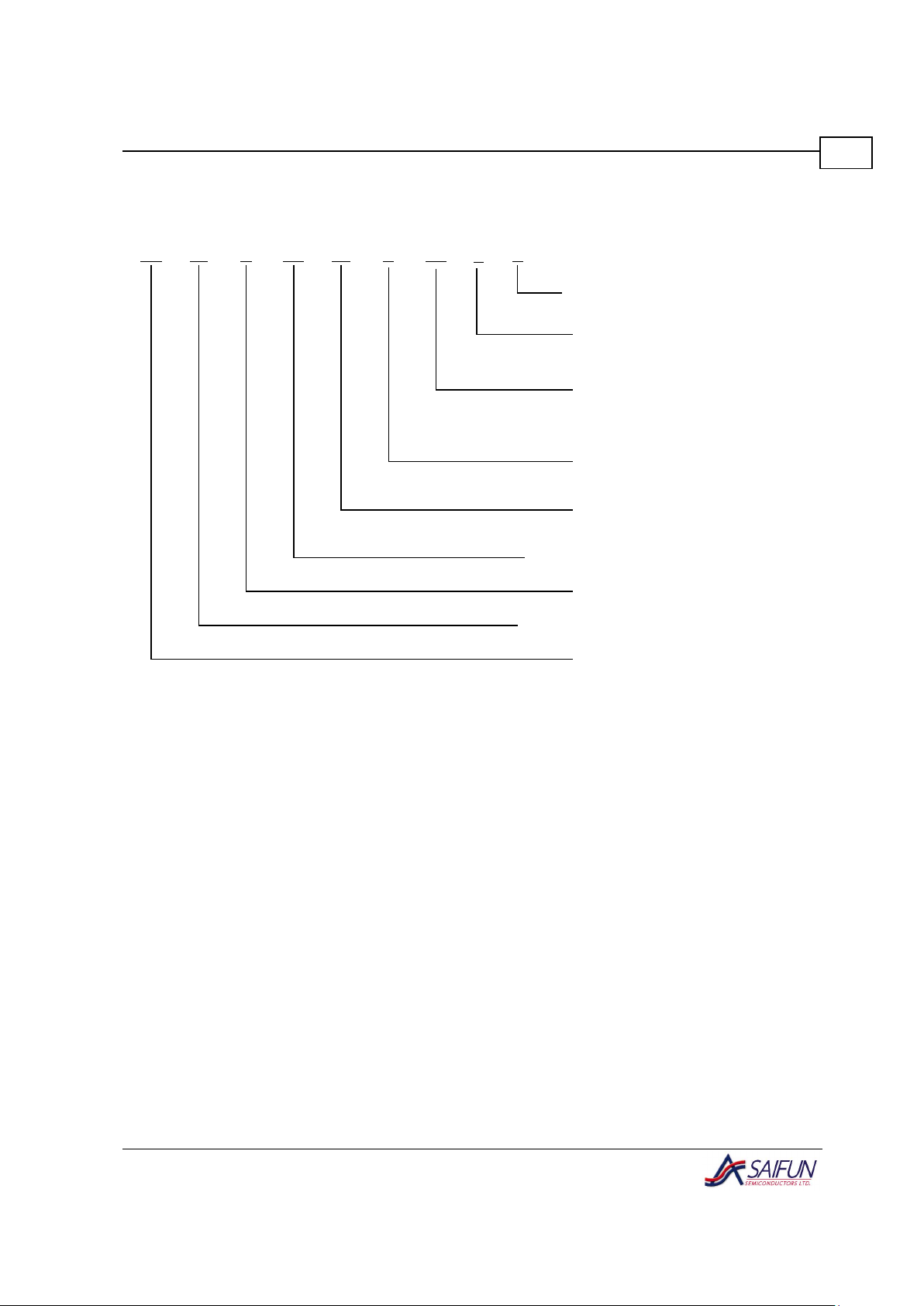

Figure 4. SA24C1024 Ordering Information..................... 6

Figure 5. AC Testing Input/Output Waveforms ................ 9

Figure 6. Bus Timing..................................................... 10

Figure 7. Write Cycle Timing......................................... 11

Figure 8. Typical System Configuration ......................... 11

Figure 9. Slave Address ................................................ 12

Figure 10. Data Validity ................................................. 17

Figure 11. START and STOP Definition ........................ 17

Figure 12. Acknowledge Response from Receiver ........ 17

Figure 13. Byte Write .................................................... 19

Figure 14. Page Write ................................................... 19

Figure 15. Current Address Read.................................. 21

Figure 16. Random Read .............................................. 21

Figure 17. Sequential Read........................................... 21

Figure 18. Data Transfer ............................................... 22

Figure 19. A Complete HS Mode Transfer..................... 23

Figure 20. 8-pin Molded Small Outline Package (MW8),

Package Number M08D ...................................... 24

Figure 21. Molded Dual-in-Line Package (N), Package

Number N08E...................................................... 25

Figure 22. 8-pin MLF Leadless Package ....................... 26

List of Tables

Table 1. Pin Names......................................................... 5

Table 2. Write Protection Truth Table............................ 14

Page 4

SA24C1024 Datasheet

SAIFUN

4

Block Diagram

Figure 1. SA24C1024 Block Diagram

Page 5

SA24C1024 Datasheet

SAIFUN

5

Connection Diagrams

SA24C1024

1

2

3

4

8

7

6

5

NC

A1

NC

V

SS

V

CC

WP

SCL

SDA

SA24C1024

1

2

3

4

8

7

6

5

NC

A1

NC

V

SS

V

CC

SCL

SDA

Figure 2. SO Package (MW), Dual Inline (N) – Top

View

Figure 3. Leadless Package (MLF) – Top View

Note:

For more details, refer to package number N08E and M08D.

Table 1. Pin Names

Symbol

Pin Name Description

NC Not Connected

A1

Device Select Address Input

Pin

Has an internal "weak" pulldown, and assumes logic LOW

when left unconnected.

NC Not Connected

VSS Device Ground Input Pin

SDA IIC Data Input/Output Pin Open Collector/Drain type.

SCL IIC Clock Input Pin

WP

Write Protect

Has an internal "weak" pulldown, and assumes logic LOW

when left unconnected.

When LOW, writing is allowed to the memory array.

When HIGH, writing is not allowed to the memory array, as

defined in Write Protect (WP), page 14.

VCC Device Power Input Pin 2.7 V to 3.6 V

Note:

No A2 or A0 pins (Pins 2 and 3) are provided, and are instead treated as Not

Connected. Internal address comparison assumes pin A2 to be 0, and so the

command code should have its corresponding A2 bit set to 0 as well. The

command code should also have its corresponding A0 bit set to add16 (MSB

address bit).

Page 6

SA24C1024 Datasheet

SAIFUN

6

Ordering Information

LZXXC24SA Letter

L

LZ

1024

C

24

SA

Interface

Density

Voltage Operating Range

Description

2.7 V to 3.6 V

2.7 V to 3.6 V

< 0.7 µA Standby Current

1 Mb with Write Protect

CMOS EEPROM

Technology

IIC - 2 Wire

Saifun Non-Volatile

Memory

X

Blank

X

Tube

Tape and Reel

PP

Package

N

MW

MF

8-pin DIP

8-pin SOIC (200 mil)

8-lead MLF

F

Blank

F

Non-lead Free

Lead-free Leads

E

Blank

E

Temp. Range

0 to 70 C

-40 to +85 C

o

o

Figure 4. SA24C1024 Ordering Information

Page 7

SA24C1024 Datasheet

SAIFUN

7

Product Specifications

Absolute Maximum Ratings Operating Conditions

Ambient Storage Temperature

–65 °C to +150 °C

All Input or Output Voltages with

Respect to Ground

4.5 V to -0.3 V

Lead Temperature

(Soldering, 10 seconds)

+300 °C

ESD Rating 2000 V min.

ESD/Latch up Specification (JEDEC 8 Spec)

Human Body Model Minimum 2 KV

Machine Model Minimum 500 V

Latch up

100 mA on all pins, +125 °C

Operating Conditions

Ambient Operating Temperature:

•= SA24C1024

•= SA24C1024E

0°C to +70°C

–40°C to +85°C

Positive Power Supply:

•= SA24C1024

•= SA24C1024LZ

2.7 V to 3.6 V

2.7 V to 3.6 V

Page 8

SA24C1024 Datasheet

SAIFUN

8

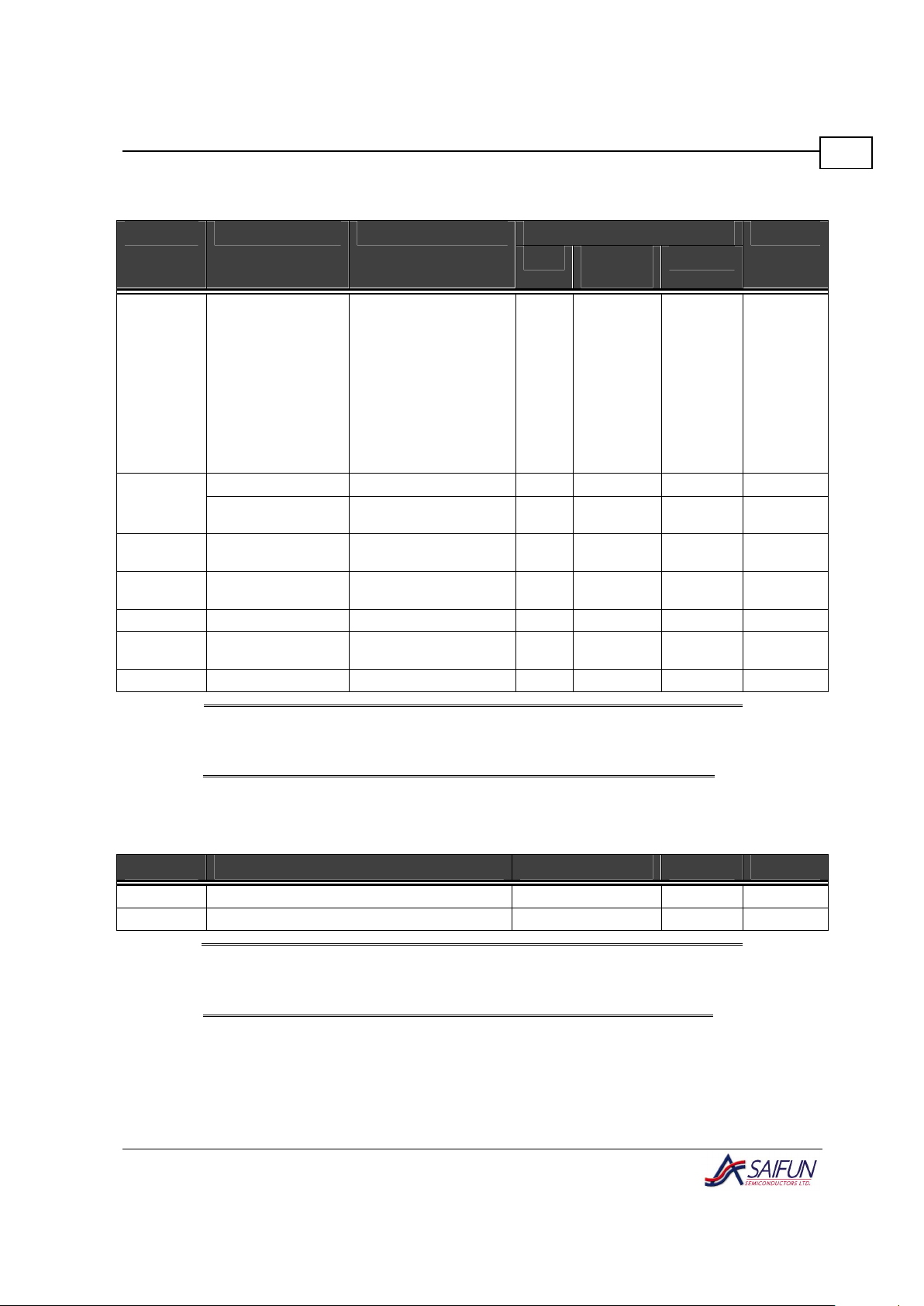

VCC (2.7 V to 3.6 V) DC Electrical Characteristics

Limits Symbol Parameter Test Conditions

Min Typ

(Notes)

Max

Units

f

SCL

= 100 kHz (Read) 2 3 mA

f

SCL

= 100 kHz (Write) 8 11 mA

f

SCL

= 400 KHZ (Read) 2 3 mA

f

SCL

= 400 kHz (Write) 8 11 mA

f

SCL

= 1.7 MHz (Read) 5 7 mA

f

SCL

= 1.7 MHz (Write) 8 11 mA

f

SCL

= 3.4 MHz (Read)

5 7 mA

I

CCA

Active Power Supply

Current

f

SCL

= 3.4 MHz (Write)

8 11 mA

ISB Standby Current (L) VIN = GND or V

CC

0.5 1

µA

Standby Current

(LZ)

VIN = GND or VCC 0.2 0.7

µA=

IIL Input Leakage

Current

VIN = GND to V

CC

0.1 1

µA

IOL Output Leakage

Current

V

OUT

= GND to V

CC

0.1 1

µA

VIL Input Low Voltage

-0.3 VCC x 0.3 V

V

IH

Input High Voltage

VCC *

0.7

V

CC

+ 0.5 V

V

OL

Output Low Voltage I

OL

= 3 mA

0.4 V

Notes:

(1) Typical values are TA = +25 °C and nominal supply voltage of 3 V.

(2) Write frequency is 50 Hz.

Capacitance

T

A

= +25 °C, f = 100/400 kHz/1.7 MHz/3.4 MHz, V

CC

= 3V (see note 2)

Symbol Test Conditions Max Units

C

I/O

Input/Output Capacitance (SDA) V

I/O

= 0 V 8 pF

CIN Input Capacitance (A0, A1, A2, SCL) V

IN

= 0 V 6 pF

Notes:

(1) This parameter is periodically sampled and not 100% tested.

(2) Typical values are T

A

= +25 °C and nominal supply voltage of 3 V.

Page 9

SA24C1024 Datasheet

SAIFUN

9

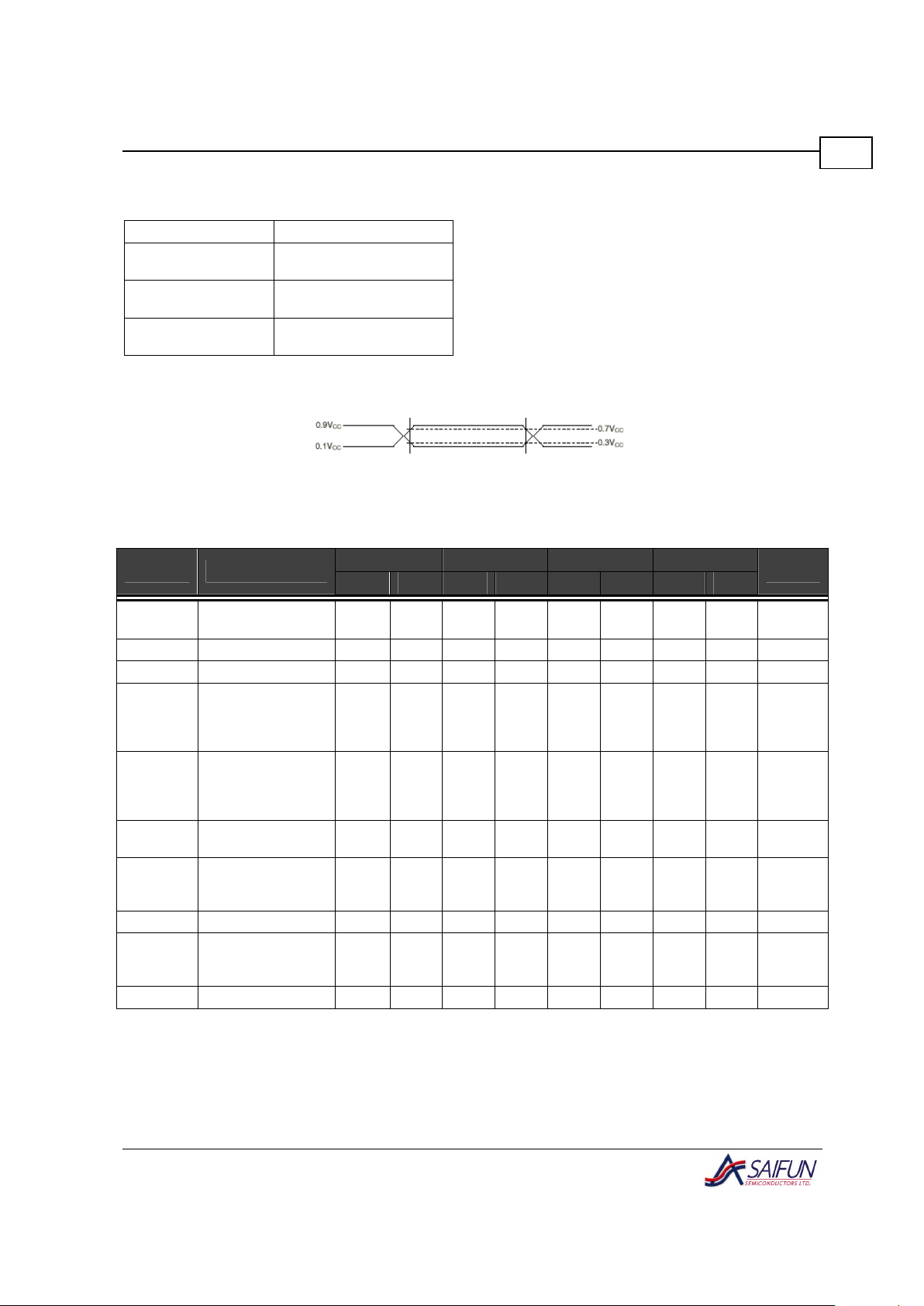

AC Test Conditions

Input Pulse Levels VCC * 0.1 to VCC * 0.9

Input Rise and Fall

Times

10 ns

Input & Output Timing

Levels

VCC * 0.3 to VCC * 0.7

Output Load

1 TTL Gate and CL = 100

pF

AC Testing Input/Output Waveforms

Figure 5. AC Testing Input/Output Waveforms

AC Characteristics (VCC 2.7 V – 3.6 V)

100 kHz 400 kHz 1.7 MHz 3.4 MHz

Symbol Parameter

Min Max Min Max Min Max Min Max

Units

f

SCL

SCL Clock

Frequency

100

400

1700 3400

kHz

t

LOW

Clock Low Period 4700 1300 320 160 ns

t

HIGH

Clock High Period 4000 600 120 60 ns

tSU:STA

Start Condition

Setup Time (for a

repeated START

condition)

4700 600

160 160

ns

t

HD:STA

Start Condition

Hold Time (for a

repeated START

condition)

4000 600

160 160

ns

t

SU:STO

Stop Condition

Setup Time

4000 600

160 160

ns

t

RDA

SDA Rise Time

(depend on

external pullup)

1000 300 20 170 10 85 ns

t

FDA

SDA Fall Time 300 300 20 170 10 85 ns

t

RCL

SCL Rise Time

(depend on

external pullup)

1000 300 20 80 10 40 ns

t

FCL

SCL Fall Time 300 300 20 80 10 40 ns

Page 10

SA24C1024 Datasheet

SAIFUN

10

100 kHz 400 kHz 1.7 MHz 3.4 MHz

Symbol Parameter

Min Max Min Max Min Max Min Max

Units

t

RCL1

SCL Rise Time

(after repeated

START or after

ACK bit)

N/A N/A

N/A

20 160 10 80

ns

t

SU:DAT

Data In Setup Time 250 100 20 20 ns

t

HD:DAT

Data In Hold Time 0 0 0 0 ns

tDH Data Out Hold Time 200 100 0 0 ns

TI

Noise Suppression

Time Constant at

SCL, SDA Inputs

(minimum V

IN

pulse

width)

50 50 10 10 ns

tAA

SCL Low to SDA

Data Out Valid

3001 3500 1001

900

0 170 0 85

ns

t

BUF

Time the Bus Must

Be Free Before a

New Transmission

Can Start

4700 1300

320 160

ns

tWR Write Cycle Time 10 10 10 10 ms

Endurance 1 Million2 Cycles

1

The minimum value is defined in order to bridge the undefined part between VIH and VIL of the falling edge of SCL. The standard

value is 0 ns.

2

This parameter is not tested but ensured by characterization.

Bus Timing

Figure 6. Bus Timing

Page 11

SA24C1024 Datasheet

SAIFUN

11

Write Cycle Timing

Figure 7. Write Cycle Timing

Note:

The write cycle time (tWR) is the time from a valid STOP condition of a Write

sequence to the end of the internal erase/program cycle.

Typical System Configuration

Figure 8. Typical System Configuration

Note:

Due to the open drain configuration of SDA and SCL, a bus-level pullup resistor

is called for (typical value = 4.7 k

Ω).

Page 12

SA24C1024 Datasheet

SAIFUN

12

Background Information

(IIC Bus)

Extended IIC specification is an extension

of the Standard IIC specification, which

enables addressing of EEPROMs with

more than 15 Kbits of memory on an IIC

bus. The difference between the two

specifications is that the Extended IIC

specification defines two bytes of Array

Address information, while the Standard

IIC specification defines only one. All other

aspects are identical between the two

specifications. Using two bytes of the array

address, one Device/Page Block selection

bit (A1) in the Slave address byte and one

address signal (add16) in the Slave

address, it is possible to address up to 2

Mbits (2

8

• 28 • 2 • 2 • 8 = 2 Mbits) of

memory on an IIC bus.

Note that, due to format difference, it is not

possible to have both peripherals that

follow the Standard IIC specification (for

example, 16Kbit EEPROM) and peripherals

that follow the Extended IIC specification

(for example, 1024Kbit EEPROM) on a

common IIC bus.

The IIC bus allows synchronous

bidirectional communication between a

transmitter and a receiver using a Clock

signal (SCL) and a Data signal (SDA).

Additionally, there is one Address signal

(A1) that collectively serves as "chip select

signal" to a device (for example, EEPROM)

on the bus.

All communication on the IIC bus must be

started with a valid START condition (by

the Master), followed by transmittal (also

by the Master) of byte(s) of information

(Address/Data). For every byte of

information received, the addressed

receiver provides a valid acknowledge

(ACK) pulse to further continue the

communication (unless the receiver intends

to discontinue the communication).

Depending on the direction of transfer

(Write or Read), the receiver can either be

a Slave or the Master. A typical IIC

communication concludes with a STOP

condition by the Master.

Addressing an EEPROM memory location

involves sending a command string with

the following information:

[DEVICE TYPE]—[DEVICE/PAGE BLOCK

SELECTION (including ARRAY MSB

ADDRESS BIT (add16)]—[R/WBIT]—

[ARRAY ADDRESS Byte #1]—[ARRAY

ADDRESS Byte #0]

Slave Address

The Slave address is an 8-bit information

consisting of a Device Type field (4 bits), a

Device/Page Block selection field (3 bits)

and one Read/Write bit.

10100A1Add16R/W(LSB)

Device Type

Identifier

Device/ Page

Block Select ion

Figure 9. Slave Address

Page 13

SA24C1024 Datasheet

SAIFUN

13

Device Type

The IIC bus is designed to support a

variety of devices, such as RAMs,

EPROMs, and so on, as well as

EEPROMS. In order to properly identify the

various devices on the IIC bus, a 4-bit

Device Type identifier string is used. For

EEPROMS, this 4-bit string is 1-0-1-0.

Every IIC device on the bus internally

compares this 4-bit string to its own Device

Type string to ensure proper device

selection.

Device/Page Block Selection

When multiple devices of the same type

(for example, multiple EEPROMS) are

present on the IIC bus, the A1 address

information bit is used in device selection.

Every IIC device on the bus internally

compares the first 2 bits of the

Device/Page Block selection string to its

own physical configuration (0, A1pin – for

the SA24C1024, the Device/Page Block

selection MSB is always 0) to ensure

proper device selection. This comparison is

carried out in addition to the Device Type

comparison.

In addition to selecting an EEPROM, the

second and third Device/Page Block

selection bits (A1, add16) can be viewed

as selection controls to a page block within

the selected EEPROM. Each page block is

512 Kbits (64 KBytes) in size.

Read/Write Bit

The last bit of the Slave address indicates

whether the intended access is Read or

Write. If the bit is 1, the access is Read; if it

is 0, the access is Write.

Acknowledge

Acknowledge is an active LOW pulse on

the SDA line that is driven by an addressed

receiver to the addressing transmitter to

indicate receipt of 8 bits of data. The

receiver provides an ACK pulse for every 8

bits of data received. This handshake

mechanism is done as follows:

1. After transmitting 8 bits of data, the

transmitter releases the SDA line

and waits for the ACK pulse.

2. The addressed receiver, if present,

then drives the ACK pulse on the

SDA line during the 9th clock and

releases the SDA line back to the

transmitter.

For more details, see Figure 12.

Array Address#1

This is an 8-bit information that contains

the most significant 8 bits (without the MSB

bit, which is the add16 bit located in the

Slave address byte) of the 17-bit memory

array address.

Array Address#0

This is an 8-bit information that contains

the least significant 8 bits of the 17-bit

memory array address.

Page 14

SA24C1024 Datasheet

SAIFUN

14

Pin Descriptions

Serial Clock (SCL)

The SCL input is used to clock all data into

and out of the device.

Serial Data (SDA)

SDA is a bidirectional pin used to transfer

data into and out of the device. It is an

open drain output and may be wire–ORed

with any number of open drain or open

collector outputs.

Write Protect (WP)

Choice 1: Full Array Write Protect

If pulled HIGH, Write operations are not

executed, and Read operations are

possible. If pulled LOW, normal operation

is enabled, and Read/Write over the entire

memory is possible.

This feature allows the user to assign the

entire memory as ROM, which can then be

protected against accidental programming.

When Write is disabled, the Slave address

and word address are acknowledged but

data is not.

This pin has an internal pulldown circuit.

However, on systems where write

protection is not required, it is

recommended that this pin be tied to V

SS

.

Table 2. Write Protection Truth Table

WP

Pin

"Less Than"

Comparison

T/B Bit

Write

Allowed

1 YES 0 NO

1 NO 0 YES

1 YES 1 YES

1 NO 1 NO

0 Don't Care Don't Care YES

Device Selection Input – A1 (as

Appropriate)

This input serves as a chip select signal to

an EEPROM when multiple EEPROMs are

present on the same IIC bus. These inputs,

if present, should be connected to V

CC

or

V

SS

in a unique manner to enable proper

selection of an EEPROM among multiple

EEPROMs.

During a typical addressing sequence,

every EEPROM on the IIC bus compares

the configuration of these inputs to the

respective two MSBs of the Device/Page

Block selection information (which is part of

the Slave address) to determine a valid

selection. For example, if the two MSB bits

of the Device/Page Block selection are 0-0,

the EEPROM whose Device Selection

input (A1) is connected to the respective

V

SS

is selected.

On the SA24C1024, only A1 is provided,

so the corresponding A2 bit in the

Device/Page Block selection should be set

to 0 during all accesses to the device.

These two pins have a weak internal

pulldown circuit.

Page 15

SA24C1024 Datasheet

SAIFUN

15

Choice 2: Programmable Write Protect

(1)

The Programmable Write protection is available to customers by contacting a Sales

Representative. For this option, use an internal 8-bit wide internal NV-Latch with the following

definition:

T/BA10A11A12A13A14A15A16

Bit 0Bit 1Bit 2Bit 3Bit 4Bit 5Bit 6Bit 7

Address Protection Range - Bit[7:1]

These 7 MSBs of array address determine the

address range that needs to be protected.

Top or Bottom Selection - Bit[0]

0 = Protects from address 0x0000 up to the

address set in Bits[7:1].

1 = Protects from address 1xFFFF up to the

address set in Bits[7:1].

1

Predefined on Sort. Not a user command.

Example

(1024K )

Write Protection

Area

NV-Latch Bit

Setting - Bits [7:0]

Result

1

Full Array

(0x0000 – 0x1FFFF)

0-0-0-0-0-0-0-1

Address bits (A16:A10) issued during the Write

command are compared against bits[7:1] of this

NV-Latch. As bit[0] of this NV-Latch is set to 1, Write

is not allowed as long as the comparison results in a

greater than or equal to status.

2

Bottom Half

(0x0000 – 0x0FFFF)

1-0-0-0-0-0-0-0

As in example 1.

3

Bottom Quadrant

(0x0000 – 0x07FFF)

0-1-0-0-0-0-0-0

As in example 1.

4

Top Quadrant

(0x18000 – 0x1FFFF)

1-1-0-0-0-0-0-1

Address bits (A16:A10) issued during the Write

command are compared against bits[7:1] of this

NV-Latch. As bit[0] of this NV-Latch is set to 1, Write

is allowed as long as the comparison results in a

greater than or equal to status.

5

Top Half

(0x10000 – 0x1FFFF)

1-0-0-0-0-0-0-1

As in example 4.

6 No Write Protection 0-0-0-0-0-0-0-0 As in example 4.

Page 16

SA24C1024 Datasheet

SAIFUN

16

Device Operation

The SA24C1024 supports a bidirectional

bus-oriented protocol, which defines any

device that sends data onto the bus as a

transmitter and the receiving device as the

receiver. The device controlling the transfer

is defined as the Master and the device

that is controlled is the Slave. The Master

always initiates data transfers and provides

the clock for both transmit and receive

operations. The SA24C1024 is therefore

considered to be the Slave in all

applications.

Clock and Data Conventions

Data states on the SDA line can change

only during SCL LOW. SDA state changes

during SCL HIGH are reserved for

indicating START and STOP conditions.

For more details, see Figure 10.

START Condition

All commands are preceded by the START

condition, which is a HIGH-to-LOW

transition of SDA when SCL is HIGH. The

SA24C1024 continuously monitors the

SDA and SCL lines for the START

condition and does not respond to any

command until this condition has been met.

For more details, see Figure 11.

STOP Condition

All communications are terminated by a

STOP condition, which is a LOW-to-HIGH

transition of SDA when SCL is HIGH. The

STOP condition is also used by the

SA24C1024 to place the device in the

standby power mode. For more details, see

Figure 11.

SA24C1024 Array Addressing

During Read/Write operations, addressing

the EEPROM memory array involves

providing the Slave address with the Most

Significant Address bit (add16), as well as

two address bytes, Word Address 1 and

Word Address 0. The Word Address 1 byte

contains the 8 MSBs of the array address,

while the Word Address 0 byte contains

the 8 LSBs of the array address.

Page 17

SA24C1024 Datasheet

SAIFUN

17

Figure 10. Data Validity

Figure 11. START and STOP Definition

Figure 12. Acknowledge Response from Receiver

Page 18

SA24C1024 Datasheet

SAIFUN

18

Write Operations

Byte Write

Two address bytes are required after the

Slave address, which contains the Most

Significant Address bit (add16), for a byte

Write operation. These 17 address bits

select one out of the 128K locations in the

memory. The Master provides these

address bytes, and for each address byte

received, the SA24C1024 responds with an

ACK pulse. The Master then provides a

byte of data to be written into the memory.

Upon receipt of this data, the SA24C1024

again responds with an ACK pulse. The

Master then terminates the transfer by

generating a STOP condition, at which

time the SA24C1024 begins the internal

write cycle to the memory. While the

internal write cycle is in progress, the

SA24C1024 inputs are disabled, and the

device does not respond to any requests

from the Master for the duration of t

WR

. For

more details regarding the address,

acknowledge and data transfer sequence,

see Figure 13.

Page Write

To minimize write cycle time, the

SA24C1024 offers a Page Write feature,

which allows simultaneous programming of

up to 128 contiguous bytes. To facilitate

this feature, the memory array is organized

in terms of “pages.” A page consists of 128

contiguous byte locations starting at every

128-byte address boundary (for example,

starting at array address 0x00000,

0x00080, 0x00100, and so on).

The Page Write operation is confined to a

single page, which means that it does not

cross over to locations on the next page

but rolls over to the beginning of the page

whenever the end of the page is reached

and additional data bytes continue to be

provided. A Page Write operation can be

initiated to begin at any location within a

page (the starting address of the Page

Write operation does not have to be the

starting address of a page).

Page Write is initiated in the same manner

as the Byte Write operation; however,

rather than terminate the cycle after

transmitting the first data byte, the Master

can further transmit up to 127 more bytes.

After the receipt of each byte, the

SA24C1024 responds with an ACK pulse,

increments the internal address counter to

the next address, and is ready to accept

the next data. If the Master transmits more

than 128 bytes prior to generating the

STOP condition, the address counter rolls

over and previously loaded data is

re-loaded. As with the Byte Write

operation, all inputs are disabled until

completion of the internal write cycle. For

more details regarding the address,

acknowledge, and data transfer sequence,

see Figure 14.

Page 19

SA24C1024 Datasheet

SAIFUN

19

Acknowledge Polling

Once the STOP condition is issued to

indicate the end of the host’s Write

operation, the SA24C1024 initiates the

internal write cycle. ACK polling can be

initiated immediately, which involves

issuing the START condition followed by

the Slave address for a Write operation.

If the SA24C1024 is still busy with the

Write operation, no ACK is returned. If the

SA24C1024 has completed the Write

operation, an ACK is returned and the host

can then proceed with the next Read or

Write operation.

Write Protection

Programming of the memory does not take

place if the SA24C1024's WP pin is pulled

HIGH. The SA24C1024 responds to Slave

and byte addresses but does not generate

an ACK after the first byte of data has been

received. This means that the program

cycle is not started when the STOP

condition is asserted.

1010 0100

A

1

A

d

d

16

A

C

K

A

C

K

A

C

K

S

T

A

R

T

S

T

O

P

SLAVE

ADDRESS

WORD

ADDRESS

DATA

Bus Activity:

Master

SDA Line

Bus Activity:

EEPROM

Figure 13. Byte Write

1010 0100

A1A

d

d

16

A

C

K

A

C

K

A

C

K

S

T

A

R

T

S

T

O

P

SLAVE

ADDRESS

WORD

ADDRESS (n)

DATA n

Bus Activity:

Master

SDA Line

Bus Activity:

EEPROM

A

C

K

DATA n + 1

A

C

K

DATA n + 15

Figure 14. Page Write

Page 20

SA24C1024 Datasheet

SAIFUN

20

Read Operations

Read operations are initiated in the same

manner as Write operations, with the

exception that the R/

W bit of the Slave

address is set to 1. There are three basic

Read operations: current address Read,

random Read, and sequential Read.

Current Address Read

Internally the SA24C1024 contains an

address counter that maintains the address

of the last byte accessed, incremented by

1. Therefore, if the last access (either a

Read or Write) was to address n, the next

Read operation would access data from

address n + 1. Upon receipt of the Slave

address with R/

W set to 1, the SA24C1024

issues an ACK pulse and transmits the 8bit word. The Master does not

acknowledge the transfer but does

generate a STOP condition, which causes

the SA24C1024 to discontinue

transmission. For more details regarding

the sequence of address, acknowledge

and data transfer, see Figure 15.

Random Read

Random Read operations enable the

Master to access any memory location in a

random manner. Prior to issuing the Slave

address with the R/

W bit set to 1, the

Master must first perform a “dummy” Write

operation. The Master issues the START

condition, the Slave address's R/

W bit is

set to 0 and the byte address is read. After

the byte address is acknowledged, the

Master immediately issues another START

condition and the Slave address's R/

W bit

is set to 1. This is followed by an ACK from

the SA24C1024 and then by the 8-bit word.

The Master does not acknowledge the

transfer but does generate the STOP

condition, which causes the SA24C1024 to

discontinue transmission. For more details

regarding address, acknowledge, and data

transfer sequence, see Figure 16.

Sequential Read

Sequential Reads can be initiated as either

a current address Read or random access

Read. The first word is transmitted in the

same manner as the other Read modes;

however, the Master responds with an ACK

pulse, indicating it requires additional data.

The SA24C1024 continues to output data

for each ACK received. The Read

operation is terminated either by the

Master not responding with an ACK pulse

or by generating a STOP condition.

Page 21

SA24C1024 Datasheet

SAIFUN

21

The data output is sequential, with the data

from address n followed by the data from

n + 1. The address counter for Read

operations increments all word address

bits, enabling the entire memory contents

to be serially read during one operation.

After the entire memory has been read, the

counter rolls over to the beginning of the

memory. The SA24C1024 continues to

output data for each ACK received. For

details regarding the address,

acknowledge, and data transfer sequence,

see Figure 17.

1010 00 1

A1A

d

d

16

A

C

K

S

T

A

R

T

S

T

O

P

SLAVE

ADDRESS

DATA

Bus Activity:

Master

SDA Line

Bus Activity:

EEPROM

NO

A

C

K

Figure 15. Current Address Read

1010 0 0

A1A

d

d

16

A

C

K

A

C

K

A

C

K

S

T

A

R

T

S

T

O

P

SLAVE

ADDRESS

WORD

ADDRESS

Bus Activity:

Master

SDA Line

Bus Activity:

EEPROM

NO

A

C

K

S

T

A

R

T

SLAVE

ADDRESS

DATA n

Figure 16. Random Read

1

A

1

A

d

d

16

A

C

K

A

C

K

S

T

O

P

SLAVE

ADDRESS

DATA n + 1

Bus Activity:

Master

SDA Line

Bus Activity:

EEPROM

NO

A

C

K

DATA n + 1

A

C

K

DATA n + 2

A

C

K

DATA n + x

Figure 17. Sequential Read

Page 22

SA24C1024 Datasheet

SAIFUN

22

Switching from

Standard/Fast Modes to

High-speed Mode and

Back

The Standard (S), Fast (F) and High-speed

(HS) modes are defined according to the

IIC Bus specifications as follows:

•= S mode: Maximum bit transfer

rates of 100 Kbps.

•= F mode: Maximum bit transfer

rates of 400 Kbps.

•= HS mode: Maximum bit transfer

rates of 3.4 Mbps.

After reset and initialization, the device

must be put in F mode. The Master on the

bus can then choose to switch the

connected Slave devices to HS mode. The

Slave device must recognize the

"S 00001XXX A" sequence and then must

switch its internal circuit from F mode to

HS mode. Each device must also

recognize the STOP condition and switch

back to F mode.

Timings and flow can be seen in Figure 18

and Figure 19.

Figure 18. Data Transfer

Page 23

SA24C1024 Datasheet

SAIFUN

23

Figure 19. A Complete HS Mode Transfer

Page 24

SA24C1024 Datasheet

SAIFUN

24

Physical Dimensions

All measurements are in inches (millimeters), unless otherwise specified.

Figure 20. 8-pin Molded Small Outline Package (MW8), Package Number M08D

Page 25

SA24C1024 Datasheet

SAIFUN

25

Figure 21. Molded Dual-in-Line Package (N), Package Number N08E

Page 26

SA24C1024 Datasheet

SAIFUN

26

Figure 22. 8-pin MLF Leadless Package

Page 27

SA24C1024 Datasheet

SAIFUN

27

Contact Information

International Headquarters United States

Saifun Semiconductors Ltd.

ELROD Building

45 Hamelach St.

Sappir Industrial Park

Netanya 42504

Israel

Tel.: +972-9-892-8444

Fax: +972-9-892-8445

Saifun Semiconductors Inc.

2350 Mission College Blvd.

Suite 1070

Santa Clara, CA 95054

U.S.A.

Tel: +1-408-982-5888

Fax: +1-408-982-5890

Email: tech_support@saifun.com

http://www.saifun.com

Revision History

Rev Date Description of Change

0.0 05-Sep-02 Initial release

1.0 05-Dec-02 Editing and review

1.1 26-Aug-03 Endurance, MLF Package and tDH

© Saifun Semiconductors Ltd. 2003

Saifun reserves the right, without notice, to change any of the products described in this guide, in order to improve functionality,

reliability or design. Saifun assumes no liability arising from the application or use of any product described in this guide; and

under its patent rights, gives no authorization for the use of this product or associated products. Saifun makes no warranty for use

of its products, other than expressly provided by Saifun in any applicable warranty. The Buyer will not hold Saifun responsible for

direct or indirect damages and expenses, as well as any claim of injury or death, associated with the unauthorized use, including

claims of manufacture or design negligence.

Saifun and Saifun NROM are trademarks or registered trademarks of Saifun Semiconductors Ltd. Other company and brand

products and service names are trademarks or registered trademarks of their respective holders.

Life Support Policy

Saifun's products are not authorized for use as critical components in life support devices or systems without the express written

approval of the President of Saifun Semiconductors Ltd. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical

implant into the body, or (b) support or sustain

life, and whose failure to perform, when properly

used in accordance with instructions for use

provided in the labeling, can be reasonably

expected to result in a significant injury to the

user.

2. A critical component is any component of a life

support device or system whose failure to

perform can be reasonably expected to cause the

failure of the life support device or system, or to

affect its safety or effectiveness.

Loading...

Loading...