Page 1

RF1K49093

Data Sheet August 1999 File Number

2.5A, 12V, 0.130 Ohm, Logic Level, Dual

P-Channel LittleFET™ Power MOSFET

This Dual P-Channel power MOSFET is manufacturedusing

an advanced MegaFET process. This process, which uses

feature sizes approaching those of LSI integrated circuits,

gives optimum utilization of silicon, resulting in outstanding

performance. It is designed for use in applications such as

switching regulators, switching converters, motor drivers,

relay drivers, and low voltage bus switches. This product

achieves full rated conduction at a gate bias in the 3V - 5V

range, thereby facilitating true on-off power control directly

from logic level (5V) integrated circuits.

Formerly developmental type TA49093.

Ordering Information

PART NUMBER PACKAGE BRAND

RF1K49093 MS-012AA RF1K49093

NOTE: When ordering, use the entire part number. For ordering in

tape andreel, add thesuffix 96 tothe part number,i.e., RF1K4909396.

Features

• 2.5A, 12V

DS(ON)

= 0.130Ω

®

Model

•r

• Temperature Compensating PSPICE

• On-Resistance vs Gate Drive Voltage Curves

• Peak Current vs Pulse Width Curve

• UIS Rating Curve

• Related Literature

- TB334 “Guidelines for Soldering Surface Mount

Components to PC Boards”

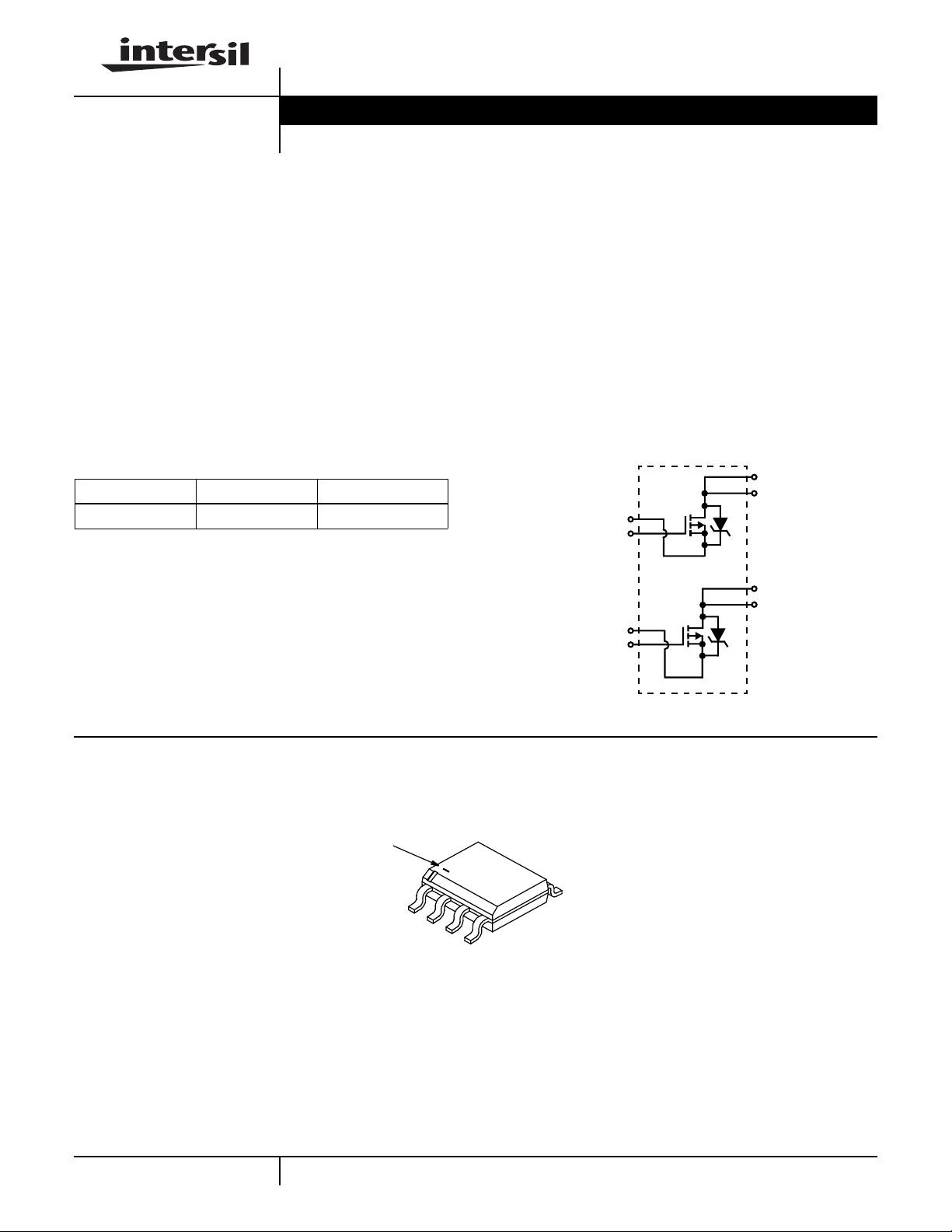

Symbol

D1 (8)

D1 (7)

S1 (1)

G1 (2)

3969.5

Packaging

JEDEC MS-012AA

BRANDING DASH

1

2

D2 (6)

D2 (5)

S2 (3)

G2 (4)

5

3

4

8-152

CAUTION: These devices are sensitive to electrostatic discharge; follow proper ESD Handling Procedures.

LittleFET™ is a trademark of Intersil Corporation. PSPICE® is a registered trademark of MicroSim Corporation.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

Page 2

RF1K49093

Absolute Maximum Ratings T

= 25oC Unless Otherwise Specified

A

RF1K49093 UNITS

Drain to Source Voltage (Note 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Drain to Gate Voltage (RGS= 20kΩ, Note 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Gate to Source Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

DSS

DGR

GS

-12 V

-12 V

±10 V

Drain Current

Continuous (Pulse width = 5s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Pulsed (Figure 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

Pulsed Avalanche Rating (Figure 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E

DM

AS

D

Refer to Peak Current Curve

2.5

Refer to UIS Curve

A

Power Dissipation

TA = 25oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

D

Derate Above 25oC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TJ, T

STG

Maximum Temperature for Soldering

Leads at 0.063in (1.6mm) from Case for 10s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .T

Package Body for 10s, See Techbrief 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

L

pkg

2

0.016

-55 to 150

300

260

W

W/oC

o

C

o

C

o

C

NOTE:

1. TJ = 25oC to 125oC.

Electrical Specifications T

= 25oC, Unless Otherwise Specified

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Drain to Source Breakdown Voltage BV

Gate Threshold Voltage V

GS(TH)VGS

Zero Gate Voltage Drain Current I

Gate to Source Leakage Current I

Drain to Source On Resistance r

DS(ON)ID

Turn-On Time t

Turn-On Delay Time t

d(ON)

Rise Time t

Turn-Off Delay Time t

d(OFF)

Fall Time t

Turn-Off Time t

Total Gate Charge Q

g(TOT)VGS

Gate Charge at -5V Q

Threshold Gate Charge Q

Input Capacitance C

Output Capacitance C

Reverse Transfer Capacitance C

Thermal Resistance Junction-to-Ambient R

DSSID

DSS

GSS

ON

r

f

OFF

g(-5)

g(TH)

ISS

OSS

RSS

JA

θ

= 250µA, VGS = 0V, (Figure 13) -12 - - V

= VDS, ID = 250µA, (Figure 12) -1 - -2 V

VDS = -12V,

VGS = 0V

TA = 25oC---1µA

TA = 150oC - - -50 µA

VGS = ±10V - - ±100 nA

= 2.5A, VGS = -5V, (Figure 9, 11) - - 0.130 Ω

VDD = -6V, ID≈ 2.5A,

RL = 2.40Ω, VGS = -5V,

RGS = 25Ω

(Figure 10)

- - 115 ns

-25-ns

-65-ns

-40-ns

-45-ns

- - 110 ns

= 0V to -10V VDD = -9.6V,

VGS = 0V to -5V - 10 14 nC

VGS = 0V to -1V - 0.8 1.1 nC

ID = 2.5A,

RL = 3.84Ω

(Figure 15)

VDS = -10V, VGS = 0V,

f = 1MHz (Figure 14)

-1924nC

- 775 - pF

- 550 - pF

- 150 - pF

Pulse width = 1s

- - 62.5

o

C/W

Device mounted on FR-4 material

Source to Drain Diode Ratings and Specifications

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Source to Drain Diode Voltage V

Reverse Recovery Time t

8-153

SD

ISD = -2.5A - - -1.25 V

ISD = -2.5A, dISD/dt = -100A/µs--55ns

rr

Page 3

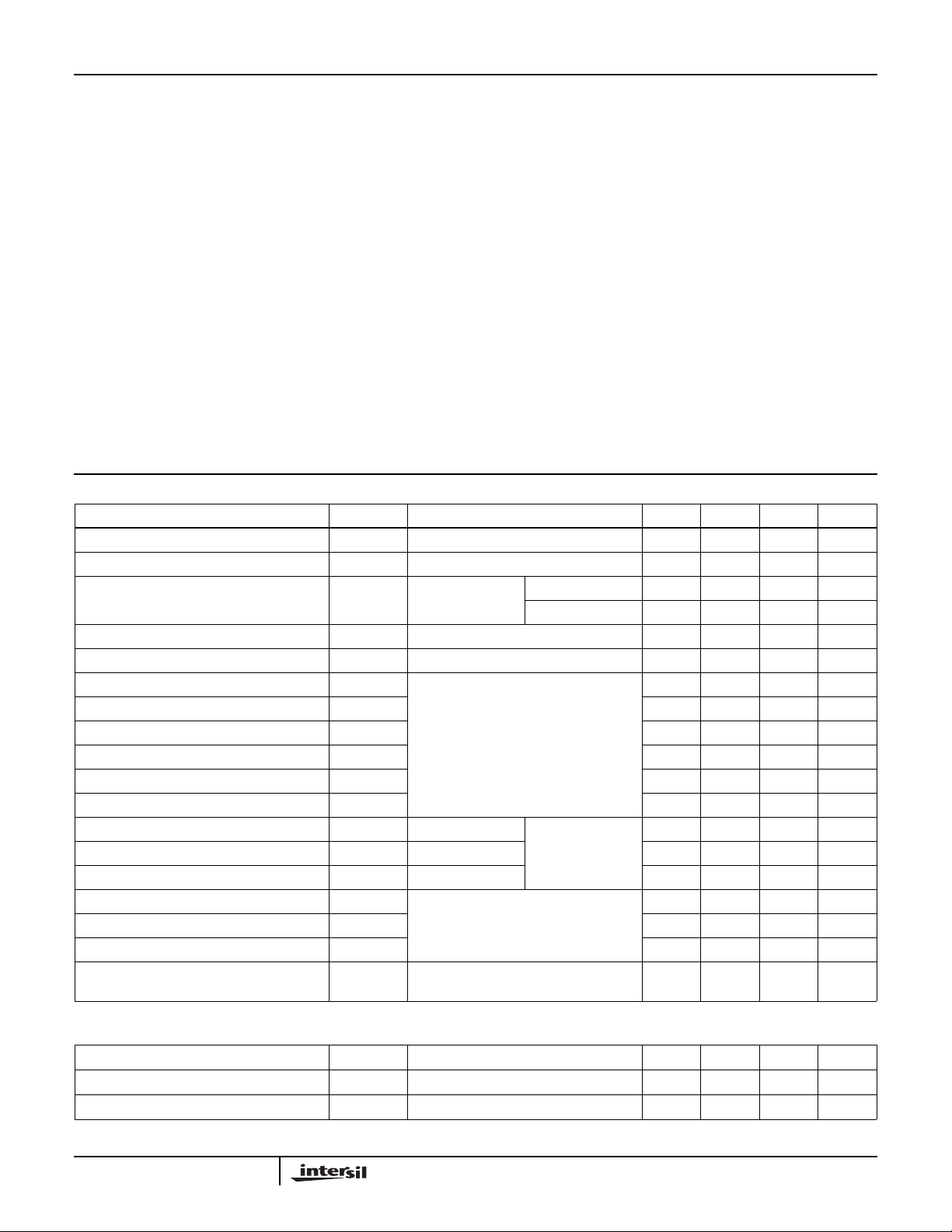

Typical Performance Curves

RF1K49093

1.2

1.0

0.8

0.6

0.4

0.2

POWER DISSIPATION MULTIPLIER

0.0

0 25 50 75 100 150

TA, AMBIENT TEMPERATURE (oC)

FIGURE 1. NORMALIZED POWER DISSIPATION vs

AMBIENT TEMPERATURE

10

DUTY CYCLE - DESCENDING ORDER

0.5

0.2

0.1

0.05

0.02

1

0.01

125

-3.0

-2.5

-2.0

-1.5

-1.0

, DRAIN CURRENT (A)

D

I

-0.5

0

25 50 75 100 125 150

TA, AMBIENT TEMPERATURE (oC)

FIGURE 2. MAXIMUM CONTINUOUS DRAIN CURRENT vs

AMBIENT TEMPERATURE

P

DM

, NORMALIZED

JA

0.1

θ

Z

THERMAL IMPEDANCE

0.01

-3

10

-100

-10

-1

, DRAIN CURRENT (A)

-0.1

D

I

OPERATION IN THIS

AREA MAY BE

LIMITED BY r

-0.01

-0.1

VDS, DRAIN TO SOURCE VOLTAGE (V)

SINGLE PULSE

-2

10

-1

10

FIGURE 3. NORMALIZED MAXIMUM TRANSIENT THERMAL IMPEDANCE

TJ = MAX RATED, TA = 25oC

V

MAX = -12V

DSS

5ms

10ms

100ms

1s

DC

DS(ON)

-1 -10 -100

0

10

t, RECTANGULAR PULSE DURATION (s)

-200

-100

VGS = -10V

-10

TRANSCONDUCTANCE

MAY LIMIT CURRENT

, PEAK CURRENT CAPABILITY (A)

IN THIS REGION

DM

I

-1

-5

10

1

10

VGS = -5V

-4

10

NOTES:

DUTY FACTOR: D = t

PEAK TJ = PDM x Z

2

10

FOR TEMPERATURES

ABOVE 25

CURRENT AS FOLLOWS:

I = I

-3

10

-2

10

t, PULSE WIDTH (s)

t

1

t

2

1/t2

x R

JA

θ

θ

o

C DERATE PEAK

150 - T

25

-1

10

JA

125

+ T

A

3

10

A

TA = 25oC

0

10

1

10

FIGURE 4. FORWARD BIAS SAFE OPERATING AREA FIGURE 5. PEAK CURRENT CAPABILITY

8-154

Page 4

RF1K49093

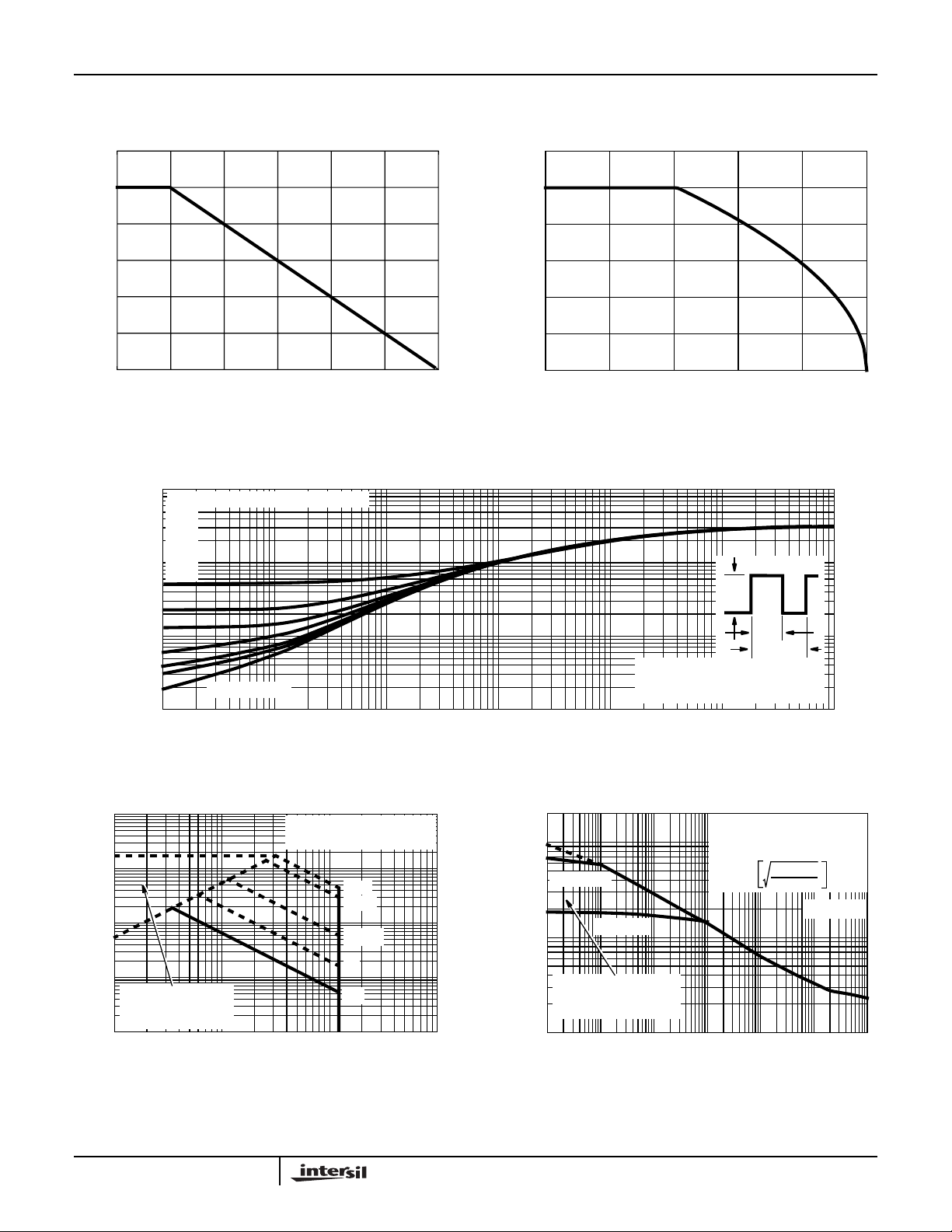

Typical Performance Curves

-20

-10

STARTING TJ = 150oC

If R = 0

, AVALANCHE CURRENT (A)

tAV = (L)(IAS)/(1.3*RATED BV

AS

I

If R ≠ 0

= (L/R)ln[(IAS*R)/(1.3*RATED BV

t

AV

-1

0.1

tAV, TIME IN AVALANCHE (ms)

DSS

1 10 100

(Continued)

STARTING TJ = 25oC

- VDD)

- VDD) +1]

DSS

NOTE: Refer to Intersil Application Notes AN9321 and AN9322.

FIGURE 6. UNCLAMPED INDUCTIVE SWITCHING CAPABILITY

-25

-20

-15

= -6V

V

DD

-55oC

25oC

150oC

-25

= -10V

V

GS

-20

-15

-10

, DRAIN CURRENT (A)

D

I

-5

0

0

-1 -2 -3 -4 -5

VDS, DRAIN TO SOURCE VOLTAGE (V)

FIGURE 7. SATURATION CHARACTERISTICS

500

ID = -1.5A

400

ID = -2.5A

300

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

V

DD

ID = -6.0A

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

TA = 25oC

VGS = -5V

VGS = -4.5V

VGS = -4V

VGS = -3V

= -10V

-10

-5

, ON-STATE DRAIN CURRENT (A)

D(ON)

I

0

0.0

-1.5

VGS, GATE TO SOURCE VOLTAGE (V)

FIGURE 8. TRANSFER CHARACTERISTICS FIGURE 9. DRAIN TO SOURCE ON RESISTANCE vs GATE

120

VDD = -6V, ID = -2.5A, RL= 2.40Ω

100

80

60

40

SWITCHING TIME (ns)

20

0

10

RGS, GATE TO SOURCE RESISTANCE (Ω)

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

-3.0 -4.5 -6.0

20 30 40 500

t

r

t

f

t

D(OFF)

t

D(ON)

-7.5

200

ID = -0.5A

, ON-STATE RESISTANCE (mΩ)

100

DS(ON)

r

0

-2.5 -3.5 -4.0 -4.5 -5.0

-3.0

, GATE TO SOURCE VOLTAGE (V)

V

GS

VOLTAGE AND DRAIN CURRENT

2.0

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

VGS = -5V, ID = -2.5A

1.5

1.0

ON RESISTANCE

0.5

NORMALIZED DRAIN TO SOURCE

0

-80 -40 0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

FIGURE 10. SWITCHING TIME AS A FUNCTION OF

GATE RESISTANCE

8-155

FIGURE 11. NORMALIZED DRAIN TO SOURCE ON

RESISTANCE vs JUNCTION TEMPERATURE

Page 5

RF1K49093

Typical Performance Curves

2.0

VGS = VDS, ID = -250µA

1.5

1.0

NORMALIZED GATE

0.5

THRESHOLD VOLTAGE

0.0

-80 -40 0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

(Continued)

FIGURE 12. NORMALIZED GATE THRESHOLD VOLTAGE vs

JUNCTION TEMPERATURE

1200

900

600

C, CAPACITANCE (pF)

300

0

0 -2 -4 -6 -8 -10

VDS, DRAIN TO SOURCE VOLTAGE (V)

C

C

C

ISS

OSS

RSS

VGS = 0V, f = 1MHz

= CGS + C

C

ISS

C

= C

RSS

OSS

GD

= CDS + C

C

FIGURE 14. CAPACITANCE vs DRAIN TO SOURCE VOLTAGE

GD

GD

2.0

ID = -250µA

1.5

1.0

0.5

BREAKDOWN VOLTAGE

NORMALIZED DRAIN TO SOURCE

0.0

-80

-40 0 40 80 120

, JUNCTION TEMPERATURE (oC)

T

J

FIGURE 13. NORMALIZED DRAIN TO SOURCE BREAKDOWN

VOLTAGE vs JUNCTION TEMPERATURE

-12

-9

-6

-3

, DRAIN-SOURCE VOLTAGE (V)

DS

V

0

V

= BV

DD

I

G REF()

--------------------- -

20

I

G ACT()

DSS

0.75 BV

0.50 BV

0.25 BV

RL = 3.84Ω

I

= -0.5mA

G(REF)

V

= -5V

GS

t, TIME (µs)

DSS

DSS

DSS

VDD = BV

I

GREF()

--------------------- -

80

I

GACT()

DSS

-5.00

-3.75

-2.50

-1.25

0.00

NOTE: Refer to Intersil Application Notes AN7254 and AN7260.

FIGURE 15. NORMALIZED SWITCHING WAVEFORMS FOR

CONSTANT GATE CURRENT

160

, GATE-SOURCE VOLTAGE (V)

GS

V

Test Circuits and Waveforms

V

DS

VARY t

TO OBTAIN

P

REQUIRED PEAK I

0V

V

GS

t

P

AS

L

R

G

DUT

I

AS

0.01Ω

-

V

DD

+

0

V

DD

I

AS

t

P

FIGURE 16. UNCLAMPED ENERGY TEST CIRCUIT FIGURE 17. UNCLAMPED ENERGY WAVEFORMS

8-156

BV

t

AV

DSS

V

DS

Page 6

RF1K49093

Test Circuits and Waveforms

DUT

R

V

GS

FIGURE 18. SWITCHING TIME TEST CIRCUIT

12V

BATTERY

0.2µF

G

50kΩ

CURRENT

REGULATOR

0.3µF

(Continued)

R

L

-

V

DD

+

-V

DS

(ISOLATED

SUPPLY)

DUT

t

ON

t

d(ON)

t

0

V

DS

V

GS

0

10%

r

10%

90%

50%

PULSE WIDTH

t

d(OFF)

FIGURE 19. RESISTIVE SWITCHING WAVEFORMS

V

0

VGS= -1V

Q

g(TH)

90%

DS

t

OFF

90%

50%

t

f

10%

D

S

CURRENT

I

D

SAMPLING

DUT

+V

DS

G

0

I

g(REF)

IG CURRENT

SAMPLING

RESISTOR RESISTOR

FIGURE 20. GATE CHARGE TEST CIRCUIT FIGURE 21. GATE CHARGE WAVEFORMS

Soldering Precautions

The soldering process creates a considerable thermal stress

on any semiconductor component. The melting temperature

of solder is higher than the maximum rated temperature of

the device. The amount of time the device is heated to a high

temperature should be minimized to assure device reliability.

Therefore, the following precautions should always be

observed in order to minimize the thermal stress to which

the devices are subjected.

1. Always preheat the device.

2. Thedeltatemperaturebetweenthepreheatandsoldering

should alwaysbe less than 100

device can result in excessive thermal stress which can

damage the device.

o

C.Failure to preheat the

-V

GS

Q

g(-5)

V

DD

Q

0

I

g(REF)

3. The maximum temperature gradient should be less than

o

5

C per second when changing from preheating to solder-

VGS= -5V

VGS= -10V

g(TOT)

ing.

4. The peaktemperature in the soldering process should be

at least 30oC higher than the melting point of the solder

chosen.

5. The maximum soldering temperature and time must not

exceed 260oC for 10 seconds on the leads and case of

the device.

6. After soldering is complete, the deviceshould be allowed

to cool naturally for at least three minutes, as forced cooling will increase the temperature gradient and may result

in latent failure due to mechanical stress.

7. During cooling, mechanical stress or shock should be

avoided.

8-157

Page 7

PSPICE Electrical Model

SUBCKT RF1K49093 2 1 3; rev 10/24/94

CA 12 8 8.75e-10

CB 15 14 8.65e-10

CIN 6 8 7.65e-10

RF1K49093

10

DPLCAP

5

LDRAIN

2

DRAIN

DBODY 5 7 DBDMOD

DBREAK 7 11 DBKMOD

DPLCAP 10 5 DPLCAPMOD

EBREAK 5 11 17 18 -23.75

EDS 14 8 5 8 1

EGS 13 8 6 8 1

ESG 6 10 8 6 1

EVTO 20 6 8 18 1

IT 8 17 1

LDRAIN 2 5 1e-9

LGATE 1 9 1.233e-9

LSOURCE 3 7 0.452e-9

MOS1 16 6 8 8 MOSMOD M = 0.99

MOS2 16 21 8 8 MOSMOD M = 0.01

RBREAK 17 18 RBKMOD 1

RDRAIN 5 16 RDSMOD 7.36e-3

RGATE 9 20 6.1

RIN 6 8 1e9

RSOURCE 8 7 RDSMOD 4.56e-2

RVTO 18 19 RVTOMOD 1

S1A 6 12 13 8 S1AMOD

S1B 13 12 13 8 S1BMOD

S2A 6 15 14 13 S2AMOD

S2B 13 15 14 13 S2BMOD

GATE

1

LGATE RGATE

9

CA

RDRAIN

6

ESG

8

+

EVTO

+

-

13814

EGS

6

RIN

S2A

13

S2B

13

+

6

8

18

8

20

S1A

12

S1B

-

VTO

15

EDS

CIN

CB

16

+

21

MOS1

14

+

5

8

--

8

EBREAK

MOS2

DBREAK

RSOURCE

17

18

17

+

-

11

7

RBREAK

IT

DBODY

LSOURCE

SOURCE

18

RVTO

19

VBAT

+

3

VBAT 8 19 DC 1

VTO 21 6 -0.558

.MODEL DBDMOD D (IS = 3.0e-13 RS = 4.4e-2 TRS1 = 1.0e-3 TRS2 = -7.37e-6 CJO = 1.27e-9 TT = 2.2e-8)

.MODEL DBKMOD D (RS = 7.84e-2 TRS1 = -4.27e-3 TRS2 = 5.77e-5)

.MODEL DPLCAPMOD D (CJO = 2.85e-10 IS = 1e-30 N = 10)

.MODEL MOSMOD PMOS (VTO = -2.1423 KP = 9.206 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u)

.MODEL RBKMOD RES (TC1 = 9.61e-4 TC2 = -1.09e-6)

.MODEL RDSMOD RES (TC1 = 2.10e-3 TC2 = 6.99e-6)

.MODEL RVTOMOD RES (TC1 = -1.82e-3 TC2 = 1.47e-7)

.MODEL S1AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = 5.47 VOFF= 3.47)

.MODEL S1BMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = 3.47 VOFF= 5.47)

.MODEL S2AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = 1.05 VOFF= -3.95)

.MODEL S2BMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = -3.95 VOFF= 1.05)

.ENDS

NOTE: For further discussion of the PSPICE model, consult A New PSPICE Sub-circuit for the Power MOSFET Featuring Global

Temperature Options; IEEE Power Electronics Specialist Conference Records, 1991.

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only.Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

8-158

Loading...

Loading...