Page 1

Liquid crystal displays

16 characters2 lines COG module

RCM2090R

The RCM2090R is a reflective TN type liquid crystal module with a built-in controller / driver LSI and a display capacity

of 16 characters2 lines.

Applications

Printers, copiers, facsimiles, etc.

Features

1) Wide viewing angle and high contrast.

2) 57 dot character matrix with cursor.

3) Interfaces with 4-bit MPUs.

4) Displays up to 237 characters and special symbols

5) Custom character patterns are displayed with the

character RAM.

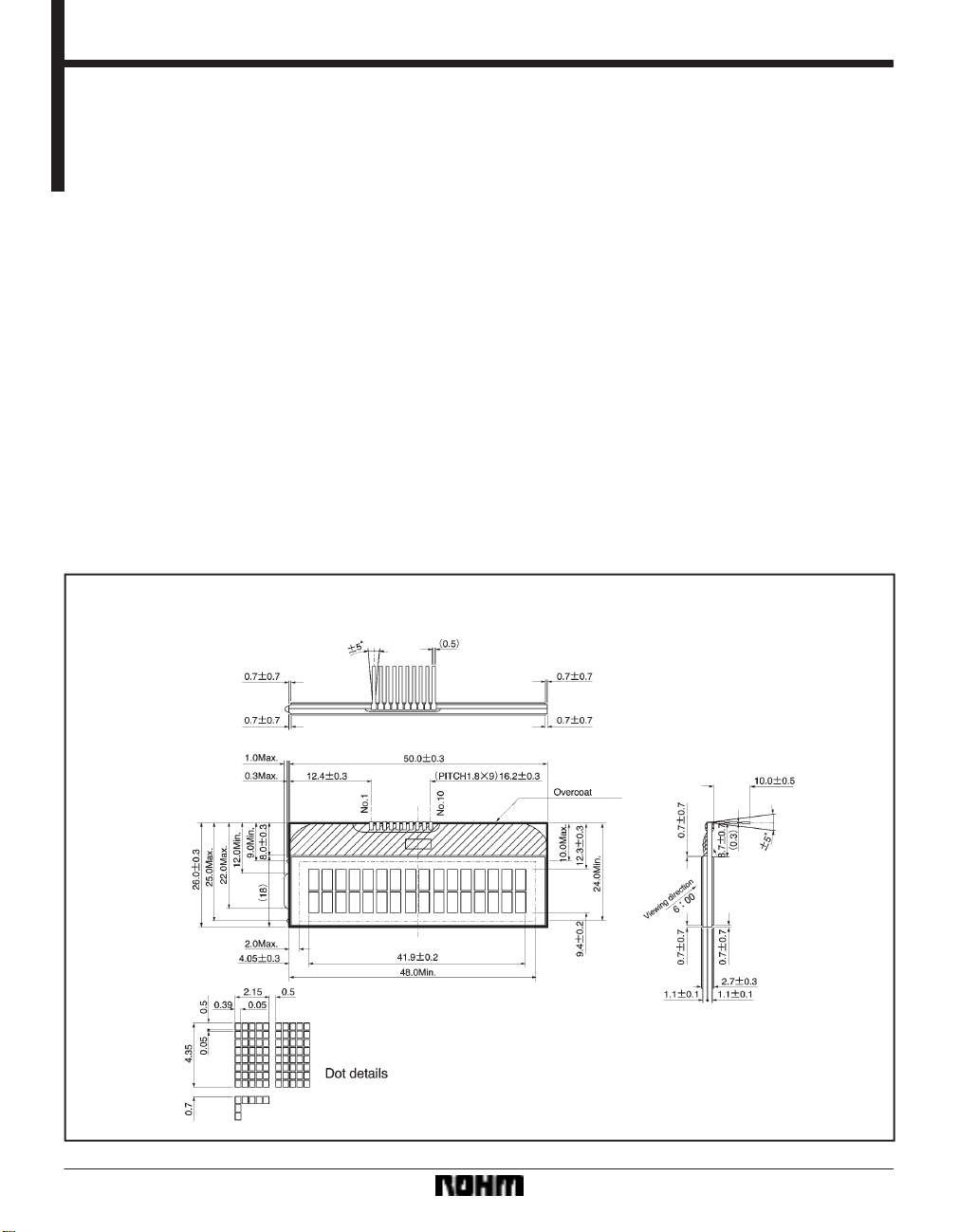

External dimensions (Units: mm)

6) Abundant instruction set including clear display , cursor on / off, and character blinking.

7) Compact and lightweight for easy assembly to the

host instrument.

8) Operable on single 5V power supply.

9) Low power consumption.

21

Page 2

Liquid crystal displays RCM2090R

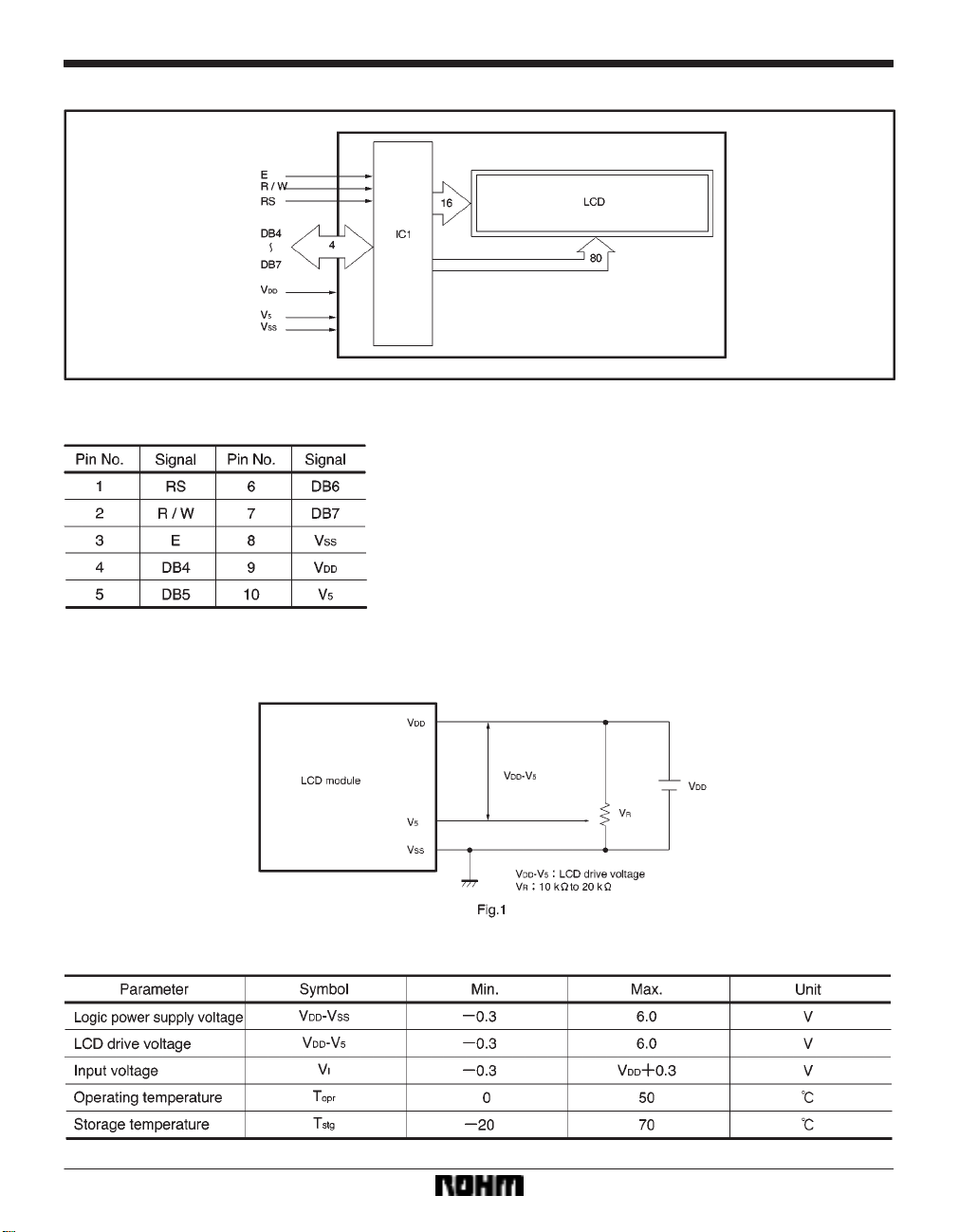

FBlock diagram

FPin assignments

FPower supply example

FAbsolute maximum ratings (Ta = 25_C)

22

Page 3

Liquid crystal displays RCM2090R

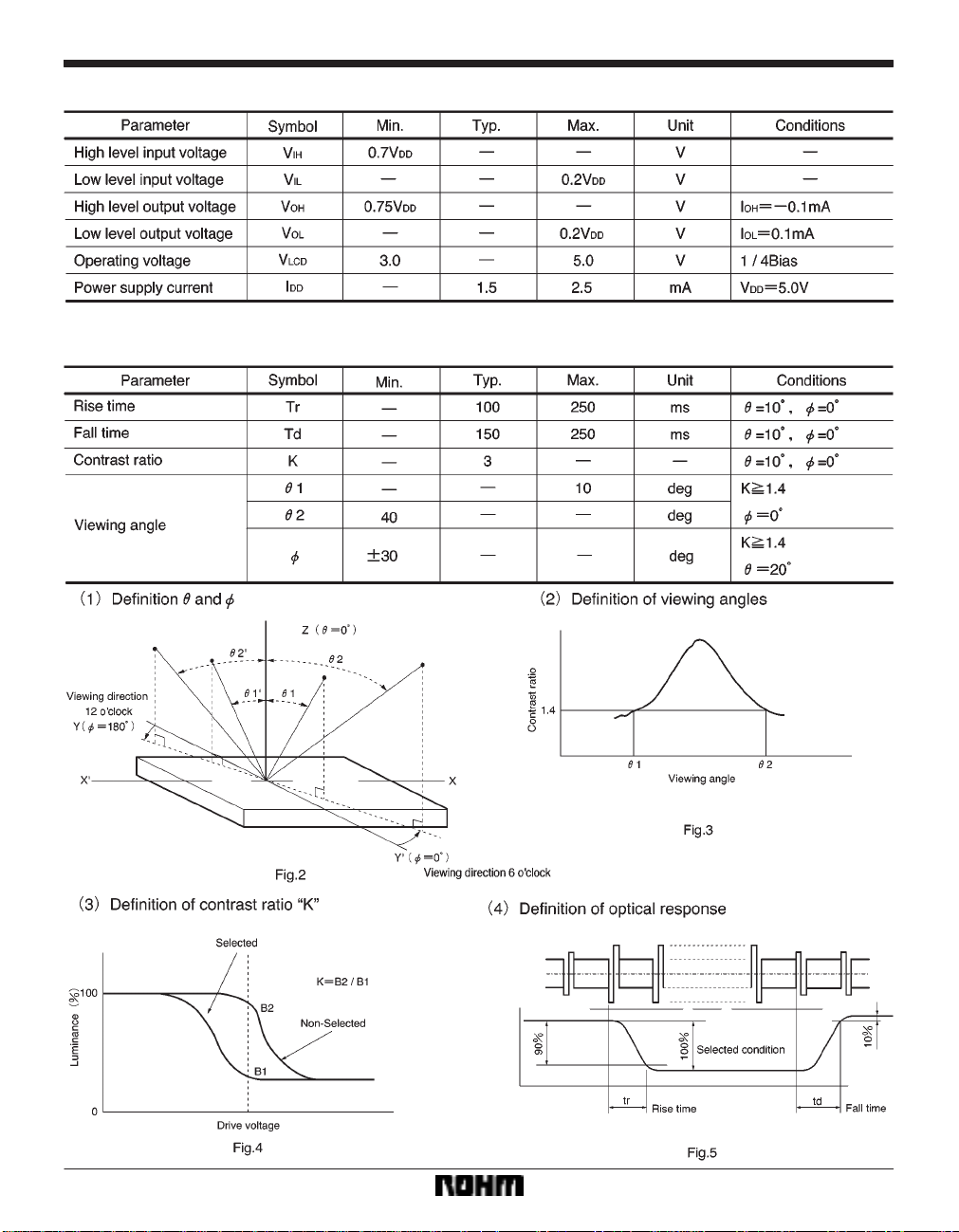

FElectrical characteristics (VDD = 5.0V±0.25 V, Ta = 25_C)

FOptical characteristics (Ta = 25_C)

When viewing from below

23

Page 4

Liquid crystal displays RCM2090R

Pin functions

Timing chart

(1) Writing

24

Page 5

Liquid crystal displays RCM2090R

(2) Reading

25

Page 6

Liquid crystal displays RCM2090R

Instructions

(Example 1) When fosc = 270kHz

250

40µs

270

= 37µs

26

Page 7

Liquid crystal displays RCM2090R

Character code and corresponding character pattern

27

Page 8

Liquid crystal displays RCM2090R

FReset function

When you turn on the power supply, the module automatically returns to its initial (reset) settings. At the initial settings,

the busy flag (BF) becomes

instructions are carried out.

(1) Clear display

(2) Function set

8-bit interface data length (DL = 1)

Two line display (N = 1)

SEG signal transfer direction SEG1SEG50SEG51SEG100 (SD1 = 0, SD2 = 0)

COM signal transfer direction COM1COM16 (CD = 0)

(3) Display on / off control

Display off (D = 0)

Cursor off (C = 0)

Blinking off (B = 0)

(4) Entry mode set

)1 (increment) (I / D = 1)

No shift (S = 0)

∗The internal reset circuit may not operate properly due to conditions with the power supply. If this is the case, use the

appropriate instruction to reset the settings.

FOperation notes

(1) Handling precautions

S Protect the module from strong shocks as they can

cause damage or defective operation.

S The polarizing plate on the surface of the module is

soft and can easily be scratched. Wipe away dirt and

dust using an alcohol-based cleanser.

S If the liquid crystal panel is damaged and liquid crystal

contacts your clothing or body, wash immediately with

soap and water.

S If the module is to be used for long periods subjected

to direct sunlight, employ a filter to block the ultraviolet

rays.

S Do not use the module in areas of high temperature

or high humidity. Do not use the module in locations

exposed to direct sunlight or fluorescent light.

S A protective film (polyethylene) is pasted over ROHM

liquid crystal modules to protect the panel surfaces.

When peeling this film off, be sure to peel as slow as

possible in order to minimize the generation of static

electricity.

(2) Precautions during operation

S Do not connect or disconnect the module while the

power supply is turned on.

S Input the input signal after the module power supply

is turned on. When turning it off, turn off the input signal first. Otherwise the IC may be damaged by the

latch-up phenomenon.

28

“1.” The busy status last 10 ms from when VDD reaches 4.5V. At the initial settings, following

(3) Precautions during installation

S Be sure to use a grounded soldering iron when per-

forming any installation procedures.

S Be careful to avoid damage from static electricity. A

CMOS-IC is used in the modules circuitry that can be

easily damaged by static electricity .

(4) Precautions during unit assembly

S In order to protect the polarizing plate from dirt or

scratches, it is recommended to use a protective cover on the front surface.

(5) Precautions for COG module

S Do not subject the front and back surfaces of the IC

to light. Doing so may cause defective operation.

S When peeling off the protective film of the panel, use

of an ion blower or other device to reduce the generation of static electricity is recommended.

S No special measures are taken to prevent the genera-

tion of static electricity on the module. Therefore, be

sure to take the appropriate measures to prevent the

generation of electrical charge on the LCD module by

the design of the product itself.

Loading...

Loading...