Datasheet NTE16001-ECG, NTE16003-ECG, NTE16005-ECG, NTE16006-ECG, NTE16010-ECG Datasheet (NTE)

...Page 1

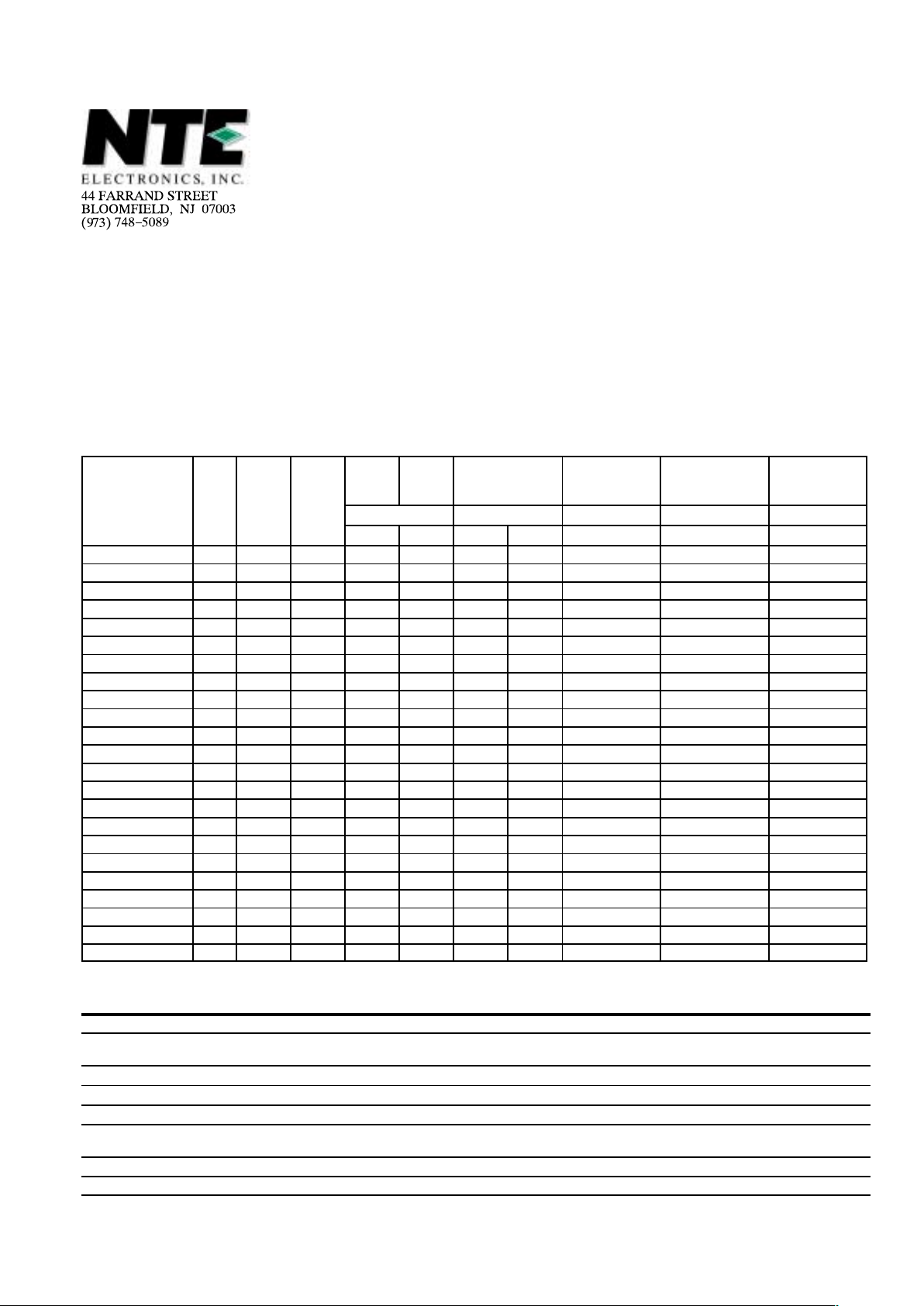

NTE16000–ECG thru NTE16022–ECG

Polymeric Positive Temperature Coefficient (PTC)

Resettable Fuses

ELECTRICAL CHARACTERISTICS

I

Hold

I

Trip

Initial resistance

1 Hour (R1)

Post–Trip

Resistance

Max. Time

To Trip at 5*lh

Tripped Power

Dissipation

Amperes at 235C Ohms at 235C Ohms at 235C Seconds at 235C Watts at 235C

NTE Type No.

Diag.

No.

V max.

Volts

I max.

Amps

Hold Trip Min. Max Max.

16000–ECG 629 60 40 0.10 0.20 2.50 4.50 7.50 4.0 0.38

16001–ECG 629 60 40 0.17 0.34 2.00 3.20 8.00 3.0 0.48

16002–ECG 629 60 40 0.20 0.40 1.50 2.84 4.40 2.2 0.40

16003–ECG 629 60 40 0.25 0.50 1.00 1.95 3.00 2.5 0.45

16004–ECG 629 60 40 0.30 0.60 0.76 1.36 2.10 3.0 0.50

16005–ECG 629 60 40 0.40 0.80 0.52 0.86 1.29 3.8 0.55

16006–ECG 629 60 40 0.50 1.00 0.41 0.77 1.17 4.0 0.75

16007–ECG 629 60 40 0.65 1.30 0.27 0.48 0.72 5.3 0.90

16008–ECG 629 60 40 0.75 1.50 0.18 0.40 0.60 6.3 0.90

16009–ECG 629 60 40 0.90 1.80 0.14 0.31 0.47 7.2 1.00

16010–ECG 630 30 40 0.90 1.80 0.07 0.12 0.22 5.9 0.60

16011–ECG 629 30 40 1.10 2.20 0.10 0.18 0.27 6.6 0.70

16012–ECG 629 30 40 1.35 2.70 0.065 0.115 0.17 7.3 0.80

16013–ECG 629 30 40 1.60 3.20 0.055 0.105 0.15 8.0 0.90

16014–ECG 629 30 40 1.85 3.70 0.04 0.07 0.11 8.7 1.00

16015–ECG 630 30 40 2.50 5.00 0.025 0.048 0.07 10.3 1.20

16016–ECG 630 30 40 3.00 6.00 0.02 0.05 0.08 10.8 2.00

16017–ECG 630 30 40 4.00 8.00 0.01 0.03 0.05 12.7 2.50

16018–ECG 630 30 40 5.00 10.00 0.01 0.03 0.05 14.5 3.00

16019–ECG 630 30 40 6.00 12.00 0.005 0.02 0.04 16.0 3.50

16020–ECG 630 30 40 7.00 14.00 0.005 0.02 0.03 17.5 3.80

16021–ECG 630 30 40 8.00 16.00 0.005 0.02 0.03 18.8 4.00

16022–ECG 630 30 40 9.00 18.00 0.005 0.01 0.02 *20.0 4.20

* Tested at 40 Amps.

TECHNICAL DATA

Operating/Storage Temperature –40°C to +85°C

Maximum Device Surface Temperature

in Tripped State

+125°C

Passive Aging +85°C, 1000 Hours ±5% Typical Resistance Change

Humidity Aging +85°C, 85% R.H. 1000 Hours ±5% Typical Resistance Change

Thermal Shock +125°C/–40°C 10 Times ±10% Typical Resistance Change

Mechanical Shock MIL–STD–202, Method 213,

Condition 1 (100g, 6 Seconds)

No Resistance Change

Solvent Resistance MIL–STD–202, Method 215 No Change

Vibration MIL–STD–883C, Method 2007.1, Condition A No Change

Page 2

TEST PROCEDURES AND REQUIREMENTS

Test Test Condition Accept/Reject Criteria

Visual/Mechanical Verify Dimensions and Materials Per PF Physical Description

Resistance In Still Air @ +23°C R

min

≤ R ≤ R

max

Time to Trip 5 Times I

Hold

, V

max

, +23°C T ≤ Max. Time to Trip (Seconds)

Hold Current 30 Min. at I

Hold

No trip

Trip Cycle Life V

max

, I

max

, 100 Cycles No Arcing or Burning

Trip Endurance V

max

, 48 Hours No Arcing or Burning

Solvent Resistance MIL–STD–202, Method 215 No Change

Vibration MIL–STD–883C, Method 2007.1, Condition A No Change

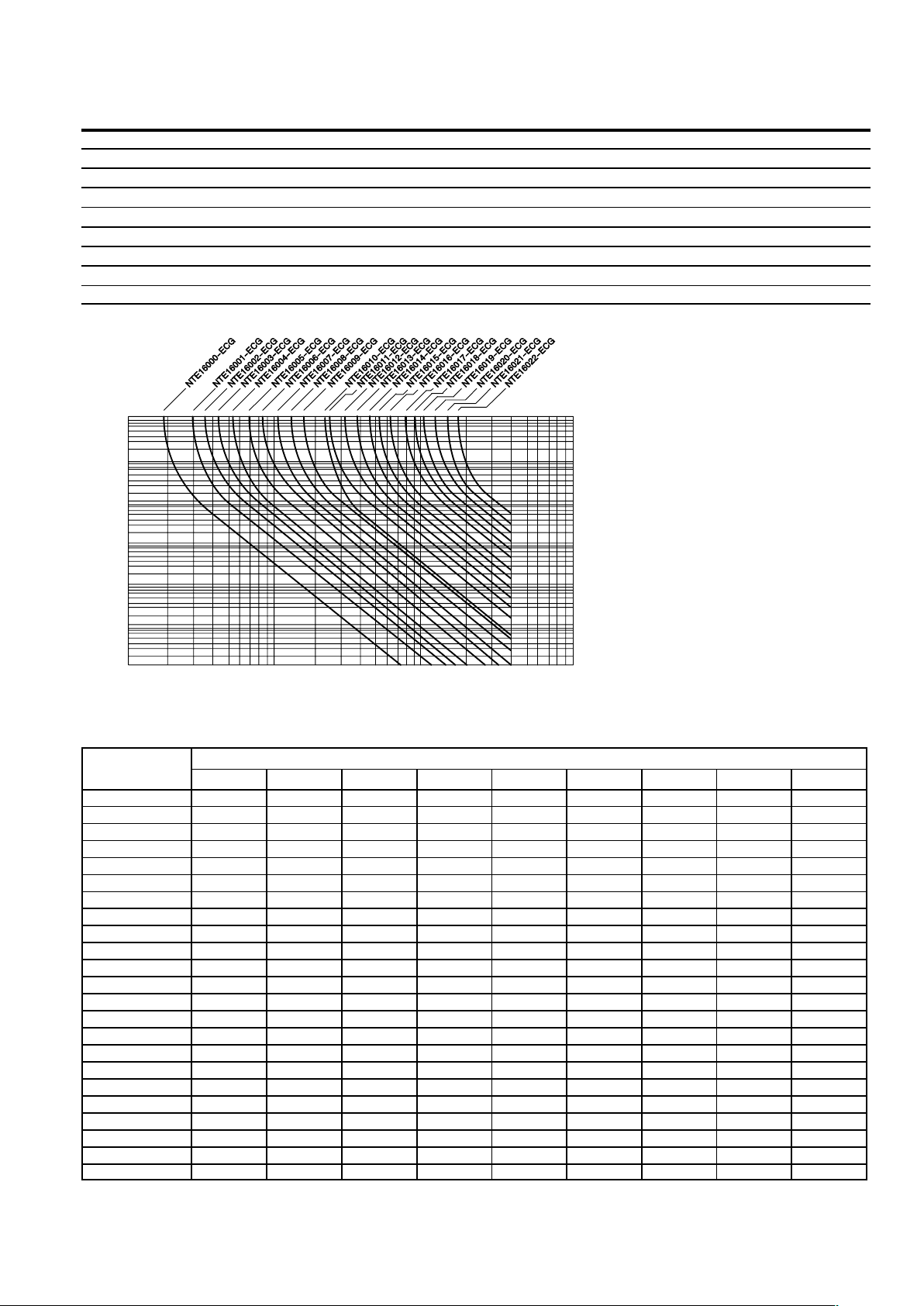

TYPICAL TIME TO TRIP AT +235

0.1 1 10 100

100

10

1

0.1

0.0

1

0.001

Fault Current (Amps)

Time to Trip (Seconds)

THERMAL DERATING CHART – I

HOLD

(Amps) *

Ambient Operating Temperature

NTE Type No.

–405C –205C 05C +235C +405C +505C +605C +705C +855C

NTE16000–ECG 0.16 0.14 0.12 0.10 0.08 0.07 0.06 0.05 0.04

NTE16001–ECG 0.26 0.23 0.20 0.17 0.14 0.12 0.11 0.09 0.07

NTE16002–ECG 0.31 0.27 0.24 0.20 0.16 0.14 0.13 0.11 0.08

NTE16003–ECG 0.39 0.34 0.30 0.25 0.20 0.18 0.16 0.14 0.10

NTE16004–ECG 0.47 0.41 0.36 0.30 0.24 0.22 0.19 0.16 0.12

NTE16005–ECG 0.62 0.54 0.48 0.40 0.32 0.29 0.25 0.22 0.16

NTE16006–ECG 0.78 0.68 0.60 0.50 0.41 0.36 0.32 0.27 0.20

NTE16007–ECG 1.01 0.88 0.77 0.65 0.53 0.47 0.41 0.35 0.26

NTE16008–ECG 1.16 1.02 0.89 0.75 0.61 0.54 0.47 0.41 0.30

NTE16009–ECG 1.40 1.22 1.07 0.90 0.73 0.65 0.57 0.49 0.36

NTE16010–ECG 1.40 1.22 1.07 0.90 0.73 0.65 0.57 0.49 0.36

NTE16011–ECG 1.60 1.43 1.27 1.10 0.91 0.85 0.75 0.67 0.57

NTE16012–ECG 1.96 1.76 1.55 1.35 1.12 1.04 0.92 0.82 0.70

NTE16013–ECG 2.32 2.08 1.84 1.60 1.33 1.23 1.09 0.98 0.83

NTE16014–ECG 2.68 2.41 2.13 1.85 1.54 1.42 1.26 1.13 0.96

NTE16015–ECG 3.63 3.25 2.88 2.50 2.08 1.93 1.70 1.53 1.30

NTE16016–ECG 4.35 3.90 3.45 3.00 2.49 2.31 2.04 1.83 1.56

NTE16017–ECG 5.80 5.20 4.60 4.00 3.32 3.08 2.72 2.44 2.08

NTE16018–ECG 7.25 6.50 5.75 5.00 4.15 3.85 3.40 3.05 2.60

NTE16019–ECG 8.70 7.80 6.90 6.00 4.98 4.62 4.08 3.66 3.12

NTE16020–ECG 10.15 9.10 8.05 7.00 5.81 5.39 4.76 4.27 3.64

NTE16021–ECG 11.60 10.40 9.20 8.00 6.64 6.16 5.44 4.88 4.16

NTE16022–ECG 13.05 11.70 10.35 9.00 7.47 6.39 6.12 5.49 4.68

*I

Trip

= 2 • I

Hold

Page 3

DIMENSIONAL OUTLINE DRAWINGS

Diagram 629 Diagram 630

NOTE: Shape changes from round to square starting

with NTE16016–ECG.

A

B

C

D

E

E

A

C

B

D

PRODUCT DIMENSIONS (Dimensions are in inches(mm))

A B C D E Physical Characteristice

NTE Type No.

Max. Max. Nom. Tol. + Min. Max. Diag. No. Lead Dia. Material

NTE16000–ECG .290 (7.4) .500 (12.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/NiCu

NTE16001–ECG .290 (7.4) .500 (12.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/CuFe

NTE16002–ECG .290 (7.4) .500 (12.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/CuFe

NTE16003–ECG .290 (7.4) .500 (12.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/CuFe

NTE16004–ECG .290 (7.4) .530 (13.4) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/CuFe

NTE16005–ECG .290 (7.4) .540 (13.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/CuFe

NTE16006–ECG .310 (7.9) .540 (13.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/Cu

NTE16007–ECG .380 (9.7) .600 (15.2) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/Cu

NTE16008–ECG .410 (10.4) .630 (16.0) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/Cu

NTE16009–ECG .460 (11.7) .660 (16.7) .200 (5.1) .027 (0.7) .300 (7.6) .122 (3.1) 629 .020 (0.51) Sn/Cu

NTE16010–ECG .290 (7.4) .480 (12.2) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 630 .020 (0.51) Sn/Cu

NTE16011–ECG .350 (8.9) .550 (14.0) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 629 .020 (0.51) Sn/Cu

NTE16012–ECG .350 (8.9) .750 (18.9) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 629 .020 (0.51) Sn/Cu

NTE16013–ECG .400 (10.2) .660 (16.8) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 629 .020 (0.51) Sn/Cu

NTE16014–ECG .470 (12.0) .720 (18.4) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 629 .020 (0.51) Sn/Cu

NTE16015–ECG .470 (12.0) .720 (18.3) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16016–ECG .470 (12.0) .720 (18.3) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16017–ECG .570 (14.4) .970 (24.8) .200 (5.1) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16018–ECG .690 (17.4) .980 (24.9) .400 (10.2) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16019–ECG .760 (19.3) 1.260 (31.9) .400 (10.2) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16020–ECG .870 (22.1) 1.170 (29.8) .400 (10.2) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16021–ECG .960 (24.2) 1.300 (32.9) .400 (10.2) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

NTE16022–ECG .960 (24.2) 1.300 (32.9) .400 (10.2) .027 (0.7) .300 (7.6) .120 (3.0) 630 .030 (0.81) Sn/Cu

Page 4

RESETTABLE CIRCUIT PROTECTION

When it comes to Polymeric Positive Temperature

Coefficient (PPTC) circuit protection, you now have a

choice.

Polymeric fuses are made from a conductive plastic

formed into thin sheets, with electrodes attached to either

side. The conductive plastic is manufactured from a non–

conductive crystalline polymer and a highly conductive

carbon balck. The electrodes ensure even distribution of

power through the device, and provide a surface for leads

to be attached or for custom mounting.

The phenomenon that allows conductive plastic materials to be used for resettable overcurrent protection devices is that they exhibit a very large non–linear Positive

Temperature Coefficient (PTC) effect when heated. PTC

is a characteristic that many materials exhibit whereby resistance increases with temperature. What makes the

polymeric conductive plastic material unique is the magnitude of its resistance increase. At a specific transition temperature, the increase is resistance is so great that it is typically expressed on a log scale.

HOW POLYMERIC RESETTABLE

OVERCURRENT PROTECTORS WORK

The conductive carbon black filler material in the polymeric device is dispersed in a polymer that has a crystalline structure. The crystalline structure densely packs the

carbon particles into its crystalline boundry so they are

close enough together to allow current to flow through the

polymer insulator via these carbon “chains”.

When the conductive plastic material is at normal room

temperature, there are numerous carbon chains forming

conductive paths through the material.

Under fault conditions, excessive current flows through

the polymeric device. I

2

R heating causes the conductive

plastic material’s temperature to rise. As this self heating

continues, the material’s temperature continues to rise

until it exceeds its phase transformation temperature. As

the material passes through this phase transformation

temperature, the densely packed crystalline polymer matrix changes to an amorphous structure. This phase

change is accompanied by a small expansion. As the conductive particles move apart from each other, most of

them no longer conduct current and the resistance of the

device increases sharply.

0 20 40 60 80 100 120 140

TEMPERATURE °C

10

1

10

0

10

2

10

3

10

4

10

5

10

6

10

7

LOG R OHMS

The material will stay “hot”, remaining in this high resistance state as long as the power is applied. The device will

remain latched, providing continuous protection, until the

fault is cleared and the power is removed. Reversing the

phase transformation allows the carbon chains to re–form

as the polymer re–crystallizes. The resistance quickly re-

turns to its original value.

PRODUCT SELECTION

To select the correct polymeric circuit protection device,

complete the imformation listed below for application, and

then refer to thwe resettable overcurrent protector data

sheets.

1. Determine the nromal operating current:

__________ amps

2. Determine the maximum circuit voltage (V

max

):

__________ volts

3. Determine the fault current (I

max

):

__________ amps

4. Determine the operating temperature range:

Minimum Temperature: __________ °C

Maximum Temperature: __________ °C

5. Select a product family so that the maximum rating for

V

max

and I

max

is higher than the maximum circuit volt-

age and fault current in the application.

6. Using the I

Hold

vs. Temperature Table on the product

family data sheet, select the polymeric device at the

maximum operating temperature with an I

Hold

greater

than or equal to the normal operating current.

7. Verify that the selected device will trip under fault conditions by checking in the I

Trip

table that the fault cur-

rent is greater than I

Trip

for the selected device, at the

lowest operating temperature.

8. Order samples and test in application.

APPLICATIONS

The benefits of polymeric Resettable Overcurrent Protectors are being recognized by more and more design

engineers, and new applications are being discovered every day.

The use of polymeric types of devices have been widely

accepted in the following applications and industries:

D Personal computers

D Laptop computers

D Personal digital assistants

D Transformers

D Small and medium electric motors

D Audio equipment and speakers

D Test and measurement equipment

D Security and fire alarm systems

D Personal care products

D Point–of–sale equipment

D Industrial controls

D Automotive electronics and harness protection

D Marine electronics

D Battery–operated toys

Loading...

Loading...