Page 1

PRELIMINARY DATA SHEET

N-CHANNEL GaAs MESFET

NES1823P-100

100W L-BAND PUSH-PULL POWER GaAs MESFET

DESCRIPTION

The NES1823P-100 is a 100 W push-pull type GaAs MESFET designed for high power transmitter applications for

IMT-2000 and PCS/PCN base station systems. It is capable of delivering 100 watts of output power with high linear

gain, high efficiency and excellent distortion. Its primary band is 1.8 to 2.3 GHz with different maching.

The device employs Tungsten Silicide gates, via holes, plated heat sink, and silicon dioxide and nitride

passivation for superior performance, thermal characteristics, and reliability.

Reliability and performance uniformity are assured by NEC’s stringent quality and control procedures.

FEATURES

• Push-pull type N-channel GaAs MESFET

• High Output Power : 100 W TYP.

• High Linear Gain : 11.0 dB TYP.

• High Drain Efficiency: 50 % TYP. @VDS = 10 V, I

Dset

= 6 A, f = 2.2 GHz

ORDERING INFORMATION (PLAN)

Part Number Package Supplying Form

NES1823P-100 T-92 ESD protective envelope

Remark

To order evaluation samples, please contact your local NEC sales office.

(Part number for sample order: NES1823P-100)

ABSOLUTE MAXIMUM RATINGS (TA = +25°C)

Operation in excess of any one of these parameters may result in permanent damage.

Parameter Symbol Ratings Unit

Drain to Source Voltage V

Gate to Source Voltage V

Drain Current I

Gate Current I

Total Power Dissipat i on P

Channel Temperature T

Storage Temperature T

DS

GSO

D

G

ch

stg

15 V

–7 V

76 A

440 mA

Note

T

220

175 °C

–65 to +175 °C

W

C

= 25°C

T

Note

Caution Please handle this device at static-free workstation, because this is an electrostatic sensitive

device.

Document No. P13839EJ1V0DS00 (1st edition)

Date Published November 1998 N CP(K)

Printed in Japan

The information in this document is subject to change without notice.

1998©

Page 2

NES1823P-100

RECOMMENDED OPERATING LIMITS

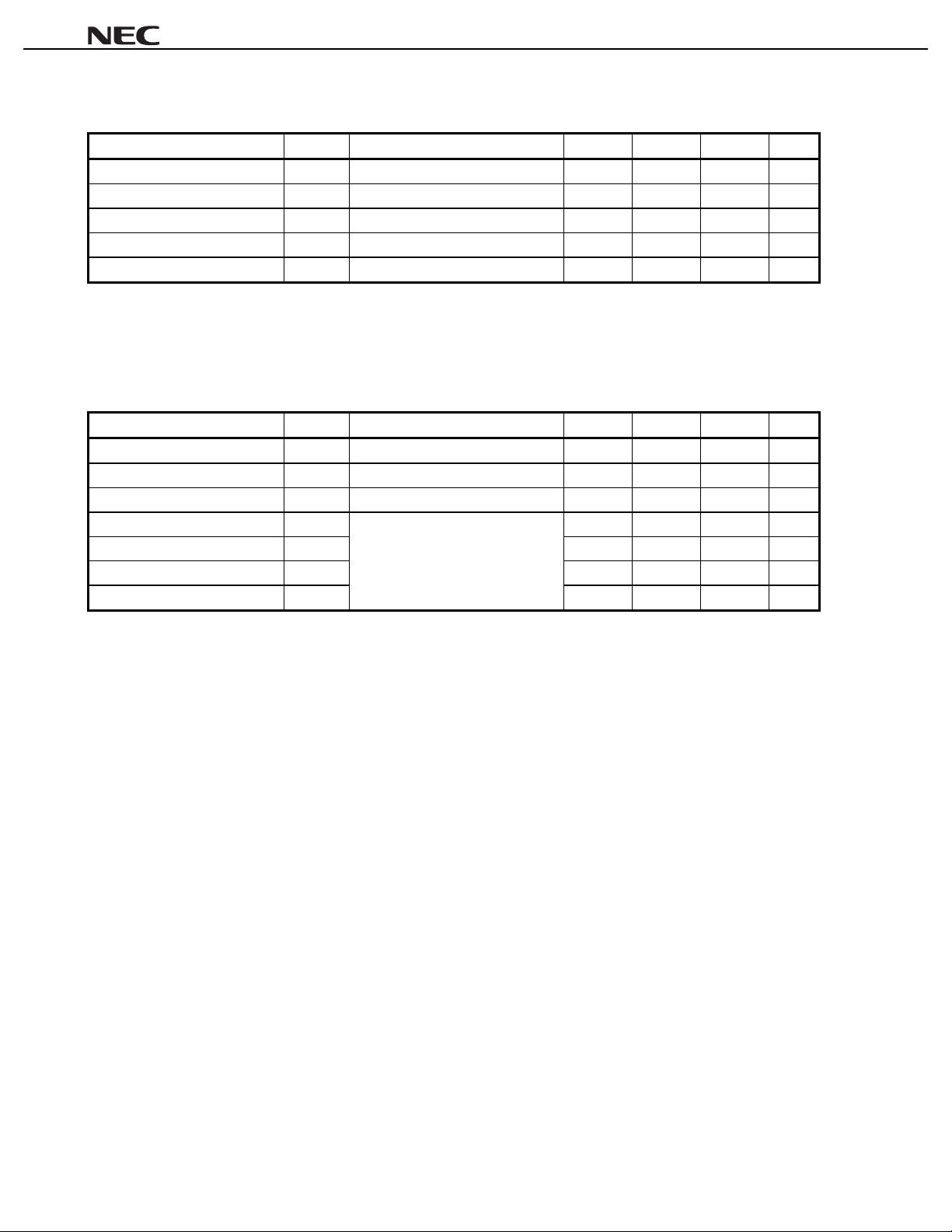

Parameter Symbol Test Condition MIN. TYP. MAX. Unit

I

Dset

R

DSS

η

DS

ch

10.0 10.0 V

6.0 8.0 A

g

10 12.5 Ω

VDS = 2.5 V, VGS = 0 V 76 A

p

VDS = 2.5 V, IDS = 330 mA –4.0 –2.6 V

th

Channel to Case 0.6 0.8 °C/W

out

f = 2.2 GHz, VDS = 10 V

in

= +42.5 dBm, Rg = 12.5 Ω

P

D

Dset

= 6.0 A Total (RF OFF)

I

D

L

Note

49.0 50.0 dBm

20.0 32.5 A

50 %

9.0 11.0 dB

+150 °C

Drain to Source Voltage V

Gain Compression Gcomp 3.0 dB

Channel Temperature T

Set Drain Current

Gate Resistance

Notes 1.

Note 1

Note 2

Dset

I

= 3.0 A each drain, VDS = 10 V, RF OFF.

Rg is the series resistance between the gate supply and FET gate.

2.

ELECTRICAL CHARACTERISTICS (TA = +25°C)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Saturated Drain Current I

Pinch-off Voltage V

Thermal Resistance R

Output Power P

Drain Current I

Drain Efficiency

Linear Gain G

Note

Dset

I

= 3.0 A each drain

Preliminary Data Sheet2

Page 3

TYPICAL CHARACTERISTICS (TA = +25°C)

POWER MATCHING AND IM3 MATCHING

NES1823P-100

NEC produces two type matching circuits, power matching and IM

3

matching. Power matching circuit is used our

production line. And the IM3 matching circuit is useful for the customers to design the special tuning application. The

power matching is designed as this, input impedance is gain-matching, output is matched with power matching

impedance which is calculated with large signal simulation model. The IM3 matching is designed as this, input

impedance is matched to the impedance which has the direction of decreasing S21 phase-shift, output impedance is

matched to the almost same as the efficiency matching impedance. Those typical RF data are shown as this, GL =

10.2 dB P

out

= 50.0 dBm IM3 = –28 dBc at power matching, GL = 10.0 dB P

matching (@2 tone P

out

= 40 dBm).

out

= 49.3 dBm IM3 = –31 dBc at IM

3

Preliminary Data Sheet 3

Page 4

NES1823P-100

55

50

45

40

35

(dBm)

out

30

Output Power P

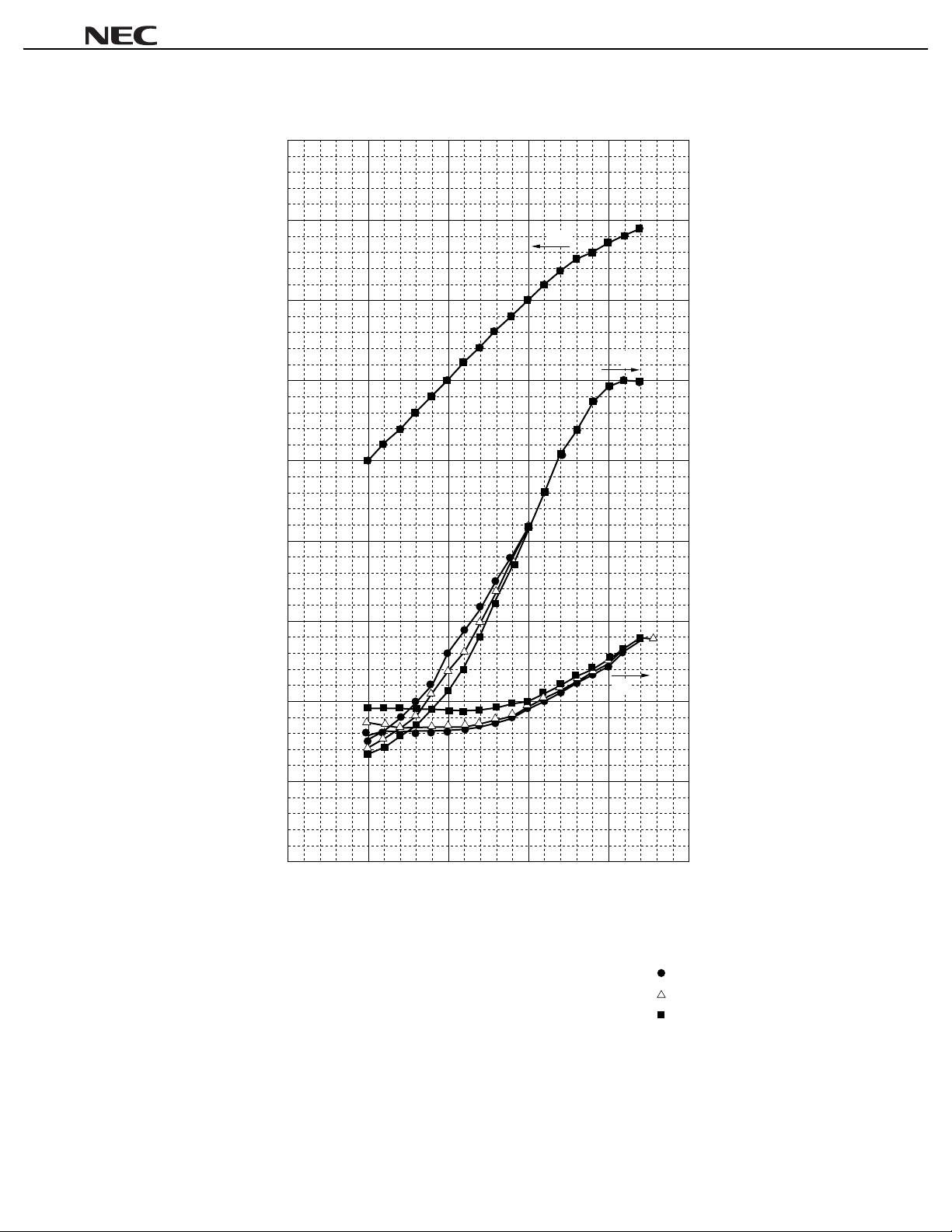

OUTPUT POWER, DRAIN CURRENT AND EFFICIENCY

POWER MATCHING

vs. INPUT POWER

P

out

η

D

I

D

80

70

60

50

(%)

40

D

η

30

Drain Efficiency

(A)

D

Drain Current I

25

20

15

10

20 25 30 35 40 45

Input Power Pin (dBm)

V

DS

f

g

R

20

10

0

–10

= 10 V

= 2.2 GHz

= 12.5 Ω

Dset

= 2 A

I

Dset

= 4 A

I

Dset

= 6 A

I

Preliminary Data Sheet4

Page 5

NES1823P-100

55

50

45

40

35

(dBm)

out

30

Output Power P

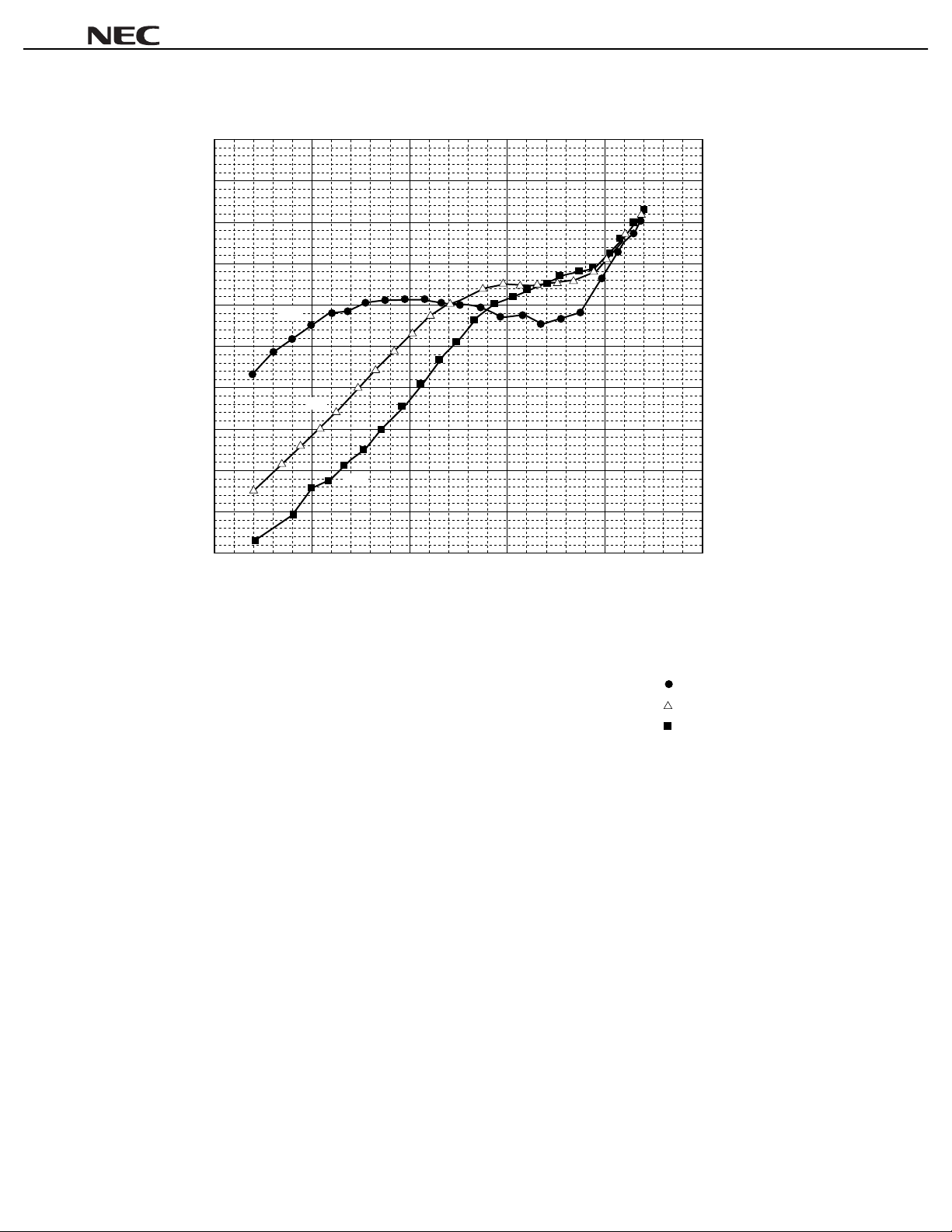

OUTPUT POWER, DRAIN CURRENT AND EFFICIENCY

DISTORTION MATCHING

vs. INPUT POWER

P

out

η

D

80

70

60

50

(%)

40

D

η

30

Drain Efficiency

(A)

D

Drain Current I

25

I

D

20

15

10

20 25 30 35 40 45

Input Power Pin (dBm)

V

DS

= 10 V

f

= 2.12 GHz

g

R

= 12.5 Ω

Dset

I

Dset

I

Dset

I

20

10

0

–10

= 6 A

= 8 A

= 10 A

Preliminary Data Sheet 5

Page 6

NES1823P-100

3rd INTERMODULATION DISTORTION vs.

2 TONES OUTPUT POWER

–10

–15

–20

(dBc)

3

–25

–30

2A

–35

–40

4A

3rd Intermodulation Distortion IM

–45

–50

–55

POWER MATCHING

6A

–60

25 30 35 40 45 50

2 tones Output Power P

out

(2 tones) (dBm)

V

f

∆

f

R

DS

g

= 10 V

= 1 MHz

= 2.2 GHz

= 12.5 Ω

Dset

= 2 A

I

Dset

= 4 A

I

Dset

= 6 A

I

Preliminary Data Sheet6

Page 7

NES1823P-100

3rd INTER MODULATION DISTORTION vs.

DISTORTION MATCHING

2TONES OUTPUT POWER

–10

–15

–20

–25

–30

–35

–40

–45

3rd Intermodulation Distortion IM3 (dBc)

–50

–55

–60

25 30 35 40 45 50

2 tones Output Power Pout (2 tones) (dBm)

V

DS

= 10 V

f

= 1 MHz

∆

f

= 2.12 GHz

g

R

= 12.5 V

Dset = 6 A

I

Dset = 8 A

I

Dset = 10 A

I

Preliminary Data Sheet 7

Page 8

NES1823P-100

3rd INTER MODULATION DISTORTION vs.

DISTORTION MATCHING

2TONES OUTPUT POWER

–10

–15

–20

–25

–30

–35

–40

–45

3rd Intermodulation Distortion IM3 (dBc)

–50

–55

–60

25 30 35 40 45 50

2 tones Output Power Pout (2 tones) (dBm)

DS

= 10 V

V

f

= 20 MHz

∆

f

= 2.12 GHz

g

R

= 12.5 Ω

Dset = 6 A

I

Dset = 8 A

I

Dset = 10 A

I

Preliminary Data Sheet8

Page 9

NES1823P-100

S-Parameters

DS

V

= 10 V, I

START 1 GHz, STOP 3 GHz, STEP 40 MHz Marker 2.2 GHz

Dset

= 3 A each drain

S

11

S

12

1.0

0.5

0

–0.5

+135° +45°

120.5

–1.0

S

21

+90°

–2.0

R

2.0

max

. = 1

+90°

+135° +45°

∞

±180° 0°

–135°

0.5

–90°

S

1.0

22

–45°

max

. = 0.1

R

2.0

±180° 0°

–135°

–90°

–45°

max

. = 5

R

Preliminary Data Sheet 9

0

0.5

–0.5

1

–1.0

2

–2.0

R

max

. = 1

∞

Page 10

S-Parameters

VDS = 10 V, I

Dset

= 3 A each drain

NES1823P-100

FREQUENCY S

11

21

S

12

S

GHz MAG. ANG. MAG. ANG. MAG. ANG. MAG. ANG.

1.000

1.040

1.080

1.120

1.160

1.200

1.240

1.280

1.320

1.360

1.400

1.440

1.480

1.520

1.560

1.600

1.640

1.680

1.720

1.760

1.800

1.840

1.880

1.920

1.960

2.000

2.040

2.080

2.120

2.160

2.200

2.240

2.280

2.320

2.360

2.400

2.440

2.480

2.520

2.560

2.600

2.640

2.680

2.720

2.760

2.800

2.840

2.880

2.920

2.960

3.000

0.959

0.959

0.956

0.956

0.956

0.950

0.946

0.941

0.941

0.935

0.927

0.920

0.912

0.903

0.890

0.876

0.858

0.839

0.815

0.789

0.756

0.719

0.674

0.616

0.548

0.474

0.405

0.371

0.403

0.477

0.553

0.622

0.664

0.693

0.712

0.719

0.723

0.721

0.713

0.701

0.684

0.661

0.632

0.594

0.542

0.483

0.499

0.530

0.555

0.587

0.625

173.5

172.7

171.7

170.8

170.8

168.7

167.5

166.2

164.8

163.3

161.7

159.9

158.1

156.0

153.9

151.5

149.1

146.6

143.8

141.2

138.1

135.1

132.1

129.1

127.3

127.6

132.9

144.4

156.0

160.5

159.4

155.8

150.3

144.6

138.7

132.7

127.3

120.8

114.1

106.5

98.3

88.7

78.0

65.6

51.8

40.7

29.6

10.9

–9.1

–28.3

–46.2

0.857

0.537

0.478

0.429

0.419

0.408

0.424

0.416

0.475

0.540

0.577

0.728

0.780

0.956

1.001

1.183

1.262

1.364

1.542

1.585

1.823

1.968

2.157

2.379

2.757

2.806

3.193

3.181

3.141

3.069

2.740

2.545

2.246

2.008

1.732

1.576

1.333

1.181

1.131

0.887

0.965

0.751

0.851

0.727

0.735

0.650

0.714

0.636

0.689

0.654

0.625

65.1

58.8

57.7

58.5

59.5

62.7

60.9

66.8

68.3

68.3

67.2

66.4

59.2

55.2

46.2

41.6

30.6

24.7

16.7

6.3

3.4

–11.4

–16.4

–28.8

–40.5

–54.6

–70.0

–85.4

–103.6

–118.7

–133.2

–150.0

–157.0

–175.7

–178.2

165.7

161.8

156.5

149.7

145.0

142.0

135.7

134.8

125.7

119.7

119.2

109.0

106.7

94.9

88.7

72.9

0.006

0.006

0.006

0.007

0.007

0.008

0.008

0.009

0.009

0.010

0.012

0.012

0.014

0.015

0.017

0.018

0.021

0.022

0.025

0.028

0.030

0.036

0.038

0.044

0.045

0.054

0.055

0.059

0.058

0.054

0.051

0.048

0.042

0.036

0.038

0.031

0.033

0.029

0.028

0.028

0.028

0.026

0.027

0.026

0.023

0.022

0.020

0.023

0.023

0.022

0.024

62.5

57.4

53.7

51.0

48.3

47.1

43.5

43.8

37.8

34.8

32.1

28.6

20.2

18.9

9.6

7.7

–1.8

–8.4

–18.3

–25.1

–36.7

–45.7

–58.5

–74.2

–85.5

–103.2

–120.7

–140.4

–159.5

–179.6

168.1

147.2

135.8

123.9

114.5

100.7

94.9

80.3

74.3

65.5

46.9

44.9

27.6

18.4

3.4

–5.7

–7.0

–15.0

–24.8

–36.4

–47.5

0.943

0.924

0.922

0.914

0.904

0.898

0.880

0.866

0.851

0.832

0.814

0.794

0.776

0.758

0.739

0.720

0.701

0.683

0.663

0.644

0.625

0.606

0.583

0.563

0.535

0.499

0.461

0.436

0.443

0.483

0.543

0.605

0.660

0.708

0.749

0.783

0.804

0.823

0.848

0.860

0.875

0.882

0.894

0.900

0.907

0.915

0.917

0.923

0.928

0.931

0.932

22

S

171.2

166.7

165.7

164.2

162.7

161.5

159.8

158.2

156.4

154.7

152.8

150.9

148.9

146.8

144.5

142.0

139.5

136.7

133.6

130.0

125.8

120.5

113.6

104.6

91.7

74.1

50.3

19.8

–14.0

–44.9

–69.8

–89.0

–103.5

–115.0

–124.2

–131.9

–136.9

–142.7

–147.4

–151.8

–155.2

–158.4

–161.5

–163.8

–166.2

–168.7

–170.4

–172.2

–174.0

–175.7

–177.1

Preliminary Data Sheet10

Page 11

NES1823P-100

CIRCUIT DESIGN

The matching circuit of package inside consists of bond-wire, chip-capacitor and microstrip line on the alumina

substrate. The package-lead impedance is designed as 25 Ω connecting to the external matching circuit, in the

external circuit design, the microstrip line impedance is 25 Ω, conjugate with package impedance, then the

impedance is connected to balun, it is 1:2 balun structure, finally connected to 50 Ω. Balun technology has some

advantage over single-ended device, minimize matching-loss with decrease of impedance change ratio and cancel

the even mode harmonic frequency for IM

BALUN DESIGN

The balun design is the key for these high power push-pull structure device. NEC designed low insertion loss

microstrip balun for this product. What is the reason of our choice? One is the repeatability of assembly, and the

other is its performance. Microstrip balun performance tolerance is small because of its simple structure. So the

balun performance is stable and repeatable between NEC and customers. And its insertion loss is 0.2 dB less than

coaxial balun 0.3 dB, also Its band width is better than coaxial balun. The microstrip balun is consists of microstrip

pattern and cavity, therefore its insertion loss and band width due to its parameter design. Those parameters are

optimized with simuration. : (substrate duroid ε r = 2.2 t = 0.8 mm)

Then the phase difference between two ports is 180° ±4, insertion loss is 0.2 dB from 1 to 3 GHz.

3

performance. The balun circuit is employed for this product.

DC STABILITY (AVOID OSCILLATION)

The function of DC-cut capacitor arranged between transformer and microstrip balun is avoid DC oscillation.

When the gate is pinch-off, a few pinch-off voltage (VP) difference of each port occur the loop current, then start DC

oscillation in the area of pinch-off. Because of this reasons, the DC-cut capacitor is need to this microstrip balun

assemble. Additionally, the ground of transformer substate is effective to DC oscillation, so that five screws are

arranged at the middle of substrate.

Preliminary Data Sheet 11

Page 12

RF TEST FIXTURE

Input MS Balun Output MS Balundevice

NES1823P-100

180˚

50 Ω

IN OUT

0˚

Input MS Balun Output MS Balun

DC CUT

25 Ω

25 Ω 25 Ω

1 000 pF

µ

4.7 F

transformer transformer

Rg=5 Ω

25 Ω

0˚

180˚

µ

4.7 F

DC CUT 20 pF × 2

50 Ω

OUT

IN

cavity (depth = 1.2 mm)

Series R = 510 Ω

39 pF

1 000 pF

4.7 F

µ

g

= 10 Ω

R

device

chip C 2.2 F

VGS

µ

VDS

1 000 pF

4.7 F

cavity (depth = 1.2 mm)

µ

Preliminary Data Sheet12

Page 13

FIGURES OF SUBSTRATE (UNIT: mm)

BALUN (FACE)

10.75

8.25

2.78

0

35.25

33.25

38.75

39.75

37.75

41.75

59.25

+0

72.22

NES1823P-100

–0.1

75

0

18

20.5

C2.5

φ

6 – 3

BALUN (BACK)

0

3.08

5 adjusting patterns at a 0.5 mm pitch

17

19

20

2-C5.5

2-C1.5

0

22.75

28.25

33.75

41.25

49.5

46.75

5.3

0.5

52.25

0.5

0.5

61.01

20.5

23

28.5

41

43.13

46.92

+0

50

–0.1

22.5

46.5

65.517

10

7.5

13.5

21.5

34.5

49.5

19.520.5

9

6.5

3

1.5

61

Preliminary Data Sheet 13

Page 14

TRANSFORMER

75

70

65

30

+0

–0.1

NES1823P-100

92 –

18.8

2

1

7.8

5 – 3.5

φ

4 – 3

φ

3.5555

3

1

+0

–0.1

30

15

1

10

2.5 5

4 1 4.5 2 4 4

15.5

1.8 6.5

1

16 – 1

φ

through hole

2

1

10

7

3

2

35

61

61.5

t = 0.8 mm

ε

r

= 2.2

Preliminary Data Sheet14

Page 15

PACKAGE DIMENSIONS (UNIT: mm)

NES1823P-100

35.2 ± 0.3

9.7 ± 0.3

2.4 ± 0.3

R1.2 ± 0.3

2.4 ± 0.2

G1, G2: Gate

D2: Drain

D1,

S

: Source

45˚

S

G1 G2

D1 D2

4.0 ± 0.3

31.6 ± 0.3

S

8.0

17.4 ± 0.3

4.75 MAX.

1.8 ± 0.2

Preliminary Data Sheet 15

Page 16

NES1823P-100

RECOMMENDED MOUNTING CONDITION FOR CORRECT USE

(1) Fix to a heatsink or mount surface completely with screw at the four holes of the flange.

(2) Recommended torque strength of the screw is 3 kgF typical using M2.3 type screw.

(3) Recommended flatness of the mount surface is less than ±10 µm. (roughness of surface is )

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered under the following recommended conditions. For soldering methods and

conditions other than those recommended below, contact your NEC sales representative.

Soldering Method Soldering Conditions Recommended Condition Symbol

Partial Heating Pin temperature: 260°C

Time: 5 seconds or less (per pi n row)

For details of recommended soldering conditions, please contact your local NEC sales office.

–

Preliminary Data Sheet16

Page 17

[MEMO]

NES1823P-100

Preliminary Data Sheet 17

Page 18

[MEMO]

NES1823P-100

Preliminary Data Sheet18

Page 19

[MEMO]

NES1823P-100

Preliminary Data Sheet 19

Page 20

NES1823P-100

Caution

The Great Care must be taken in dealing with the devices in this guide.

The reason is that the material of the devices is GaAs (Gallium Arsenide), which is

designated as harmful substance according to the law concerned.

Keep the law concerned and so on, especially in case of removal.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...