Page 1

PRELIMINARY DATA SHEET

N-CHANNEL GaAs HJ-FET

NE6510379A

3 W L-BAND POWER GaAs HJ-FET

DESCRIPTION

The NE6510379A is a 3 W GaAs HJ-FET designed for middle power transmitter applications for mobile

communication systems. It is capable of delivering 3 watt of output power (1/3 Duty pulse operation) with high linear

gain, high efficiency and excellent distortion.

Reliability and performance uniformity are assured by NEC’s stringent quality and control procedures.

FEATURES

• GaAs HJ-FET Structure

• High Output Power :

PO = +35 dBm typ. @VDS = 3.5 V, I

PO = +32.5 dBm typ. @VDS = 3.5 V, I

• High Linear Gain : GL = 13 dB typ. @VDS = 3.5 V, I

GL = 8 dB typ. @VDS = 3.5 V, I

• High Power Added Efficiency: 58% typ. @VDS = 3.5 V, I

52% typ. @VDS = 3.5 V, I

Dset

Dset

Dset

= 200 mA, f = 900 MHz, Pin = +24 dBm, 1/3 duty

Dset

= 200 mA, f = 1.9 GHz, Pin = +26 dBm, 1/3 duty

Dset

= 200 mA, f = 900 MHz, Pin = 0 dBm, 1/3 duty

Dset

= 200 mA, f = 1.9 GHz, Pin = 0 dBm, 1/3 duty

= 200 mA, f = 900 MHz, Pin = +24 dBm, 1/3 duty

= 200 mA, f = 1.9 GHz, Pin = +26 dBm, 1/3 duty

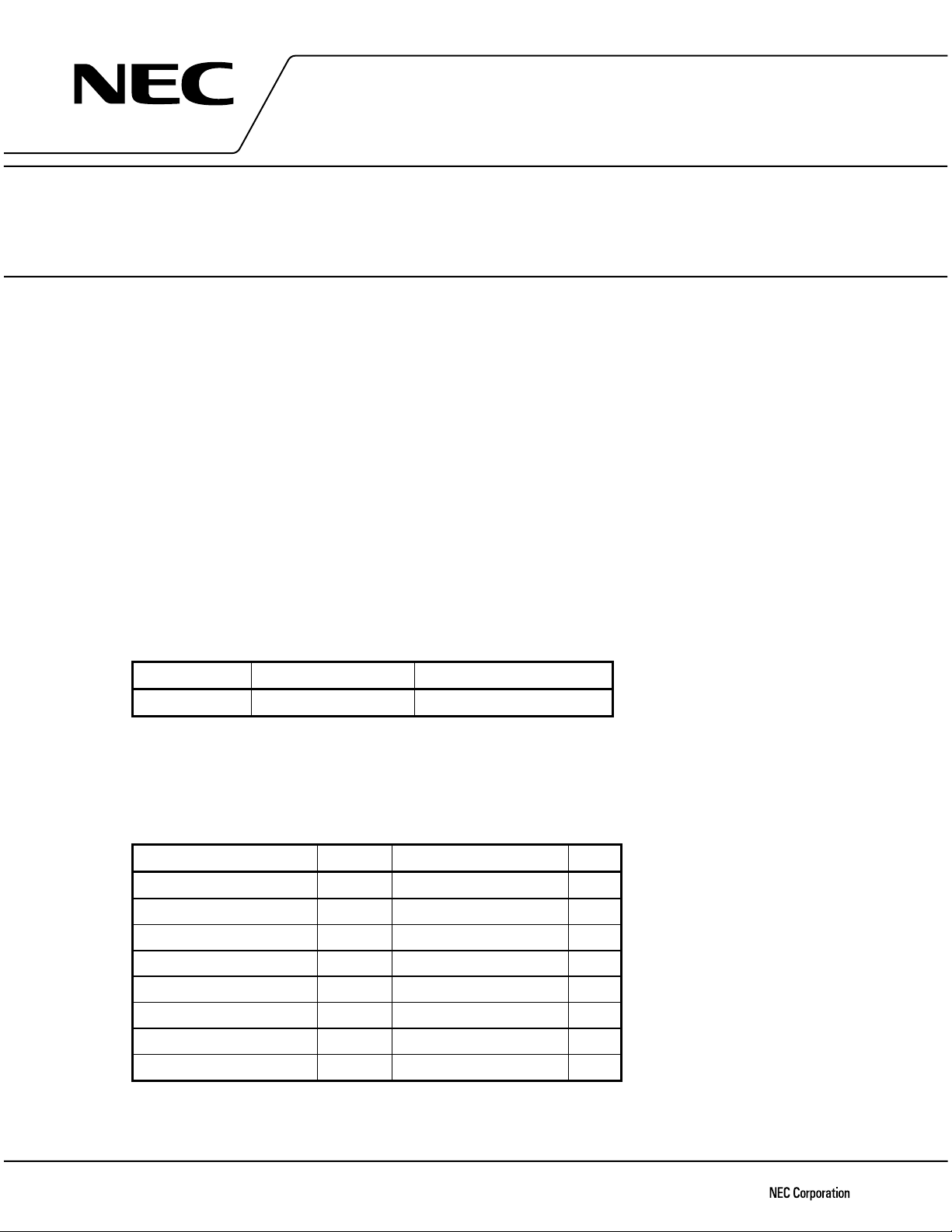

ORDERING INFORMATION (PLAN)

Part Number Package Supplying Form

NE6510379A-T1 79A 12 mm tape width, 1 kpcs / reel

Remark

To order evaluation samples, please contact your local NEC sales office.

(Part number for sample order: NE6510379A)

ABSOLUTE MAXIMUM RATINGS (TA = 25°C)

Operation in excess of any one of these parameters may result in permanent damage.

Parameter Symbol Ratings Unit

Drain to Source Voltage V

Gate to Source Voltage V

Drain Current I

Gate Forward Current I

Gate Reverse Current I

Total Power Dissipat i on P

Channel Temperature T

Storage Temperature T

DS

GSO

D

GF

GR

stg

6V

–4 V

4.2 A

38 mA

38 mA

T

ch

18 W

150 °C

–65 to +150 °C

Caution Please handle this device at static-free workstation, because this is an electrostatic sensitive

device.

Document No. P13677EJ1V0DS00 (1st edition)

Date Published August 1998 N CP(K)

Printed in Japan

The information in this document is subject to change without notice.

1998©

Page 2

RECOMMENDED OPERATING LIMITS

Characteristics Symbol Test Conditions MIN. TYP. MAX. Uni t

NE6510379A

Drain to Source Voltage V

DS

3.5 4.2 V

Operating Duty Cycle – Pulse width = 0.577 ms 1/3 –

Gain Compression Gcomp 5.0 dB

Channel Temperature T

ch

+110 °C

ELECTRICAL CHARACTERISTICS

(TA = 25°C, Unless otherwise specified, using NEC standard test fixture.

All RF characteristics is measured at 1/3 duty pulse operation, pulse width = 0.577 ms at 4.616 ms/frame)

Characteristics Symbol Test Conditions MIN. TYP. MAX. Uni t

BV

η

DSS

G

add

VDS = 2.5 V, VGS = 0 V 3.7 A

p

VDS = 2.5 V, ID = 21 mA –2.0 –0.4 V

gd

Igd = 21 mA 11 V

th

Channel to Case 4 7 °C/W

O

f = 1.9 GHz, VDS = 3.5 V

D

Pin = +26 dBm, Rg = 100 Ω

Dset

= 200 mA (RF OFF)

I

Note 2

L

31.5 32.5 dBm

760 mA

44 52 %

8.0 dB

Saturated Drain Current I

Pinch-off Voltage V

Gate to Drain Break Down

Voltage

Thermal Resistance R

Output Power P

Drain Current I

Power Added Efficiency

Linear Gain

Note 1

Notes 1.

Pin = 0 dBm

DC performance is 100% testing. RF performance is testing several samples per wafer.

2.

Wafer rejection criteria for standard devices is 1 reject for several samples.

TYPICAL RF PERFORMANCE FOR REFERENCE (NOT SPECIFIED)

(TA = 25°C, Unless otherwise specified, using NEC standard test fixture.

All RF characteristics is measured at 1/3 duty pulse operation, pulse width = 0.577 ms at 4.616 ms/frame)

Characteristics Symbol Test Conditions MIN. TYP. MAX. Uni t

Output Power P

Drain Current I

Power Added Efficiency

Linear Gain

Note

Note

Pin = 0 dBm

O

f = 900 MHz, VDS = 3.5 V

D

add

η

G

Pin = +24 dBm, Rg = 100 Ω

Dset

= 200 mA (RF OFF)

I

L

35.0 dBm

1.40 A

58 %

13.0 dB

Preliminary Data Sheet2

Page 3

NE6510379A

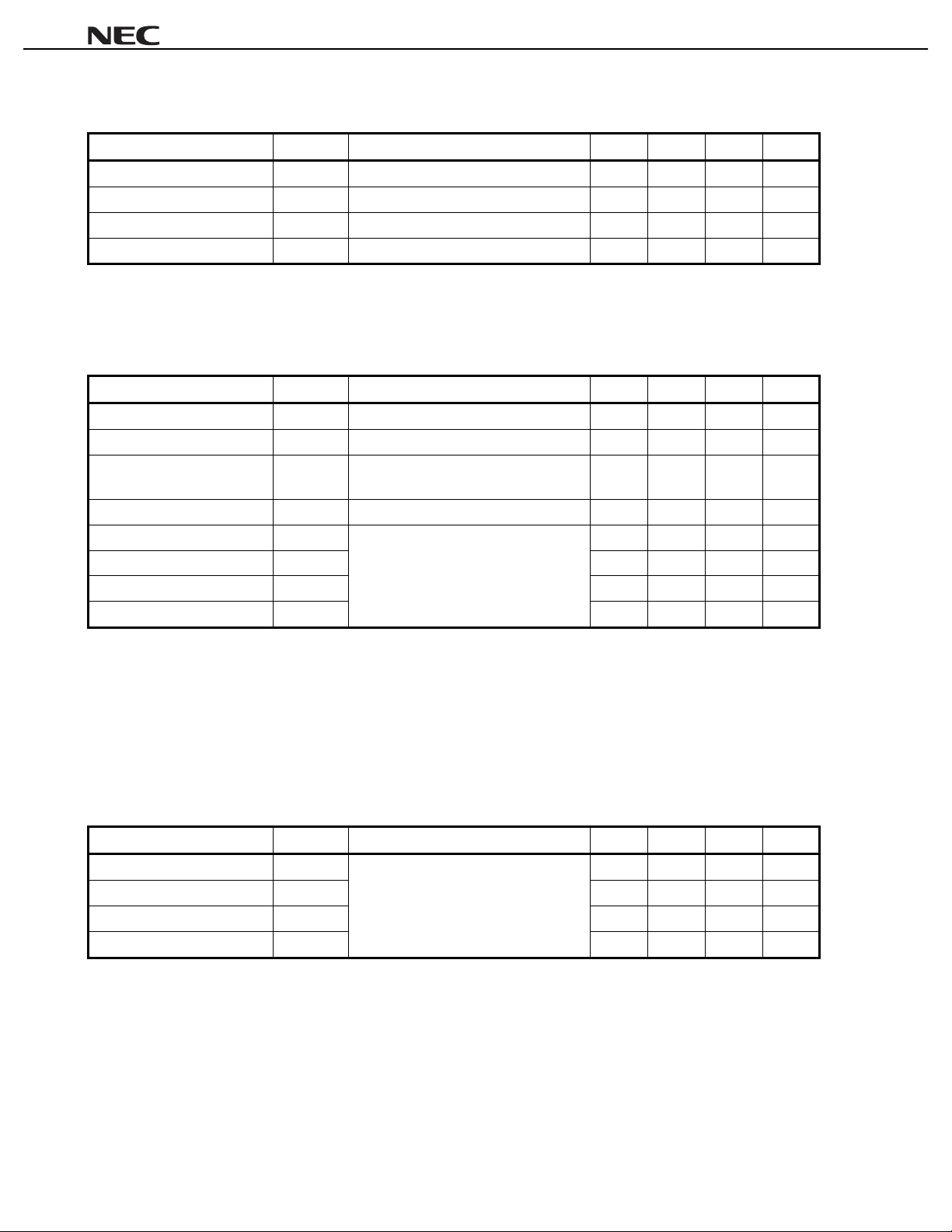

NE6510379A S-PARAMETERS TEST CONDITIONS: VDS = 3.5 V, I

11

S

21

S

Dset

= 200 mA (Preliminary Data)

12

S

22

S

freq. (MHz) MAG. ANG. (deg.) MAG. ANG. (deg.) MAG. ANG. (deg.) MAG. ANG. (deg.)

600 0.958 178.7 1.601 91.9 0.017 23.4 0.848 177.3

700 0.956 178.1 1.374 91.8 0.017 26.2 0.847 176.6

800 0.954 177.1 1.210 90.7 0.017 29.7 0.845 176.1

900 0.956 176.0 1.087 90.8 0.017 33.6 0.846 175.3

1000 0.953 175.3 0.966 89.9 0.018 36.6 0.847 174.6

1100 0.952 174.4 0.869 89.7 0.018 41.0 0.848 173.8

1200 0.951 173.9 0.818 89.5 0.018 43.9 0.849 172.9

1300 0.949 173.2 0.747 88.9 0.019 45.9 0.848 172.1

1400 0.949 172.2 0.694 89.7 0.020 47.4 0.846 171.3

1500 0.952 170.6 0.656 90.0 0.020 50.2 0.846 170.4

1600 0.954 169.4 0.625 88.9 0.020 53.1 0.844 169.6

1700 0.945 168.3 0.584 90.7 0.021 56.1 0.844 168.5

1800 0.947 166.9 0.595 89.0 0.022 57.9 0.844 167.4

1900 0.949 165.0 0.570 86.1 0.022 60.3 0.846 166.1

2000 0.946 163.5 0.515 86.3 0.022 61.6 0.846 164.9

2100 0.947 161.2 0.505 85.2 0.022 64.2 0.846 163.7

2200 0.949 160.1 0.479 92.7 0.023 67.0 0.842 162.1

Preliminary Data Sheet 3

Page 4

APPLICATION CIRCUIT EXAMPLE

f = 1.9 GHz (Unit: mm)

NE6510379A

VGS VDS

Rg

Tantalum Condenser

µ

47 F

λ

/4 OPEN STUB

5

3

5

3

10.5

3

4

3

4.5 30 2

f = 1.9 GH

VDS = 3.5 V

I

Z

Dset

= 200 mA (RF OFF)

2

INPUT

C1

APPLICATION CIRCUIT EXAMPLE

f = 900 MHz (Unit: mm)

1000 p

/4 LINE

λ

5

5

16

C1 = 30 pF

C2 = 30 pF

VGS VDS

18

2

Rg = 100 Ω

30.9

Tantalum Condenser

µ

100 F

/4 OPEN STUB

λ

50 Ω LINE

52

5 5

3

10

GND

Substrate: Teflon glass ( r = 2.6)

t = 0.8 mm

OUTPUT

C2

10

3

3

3

ε

Tantalum Condenser

2

INPUT

535

C1

f = 900 MHZ

VDS = 3.5 V

I

Dset = 200 mA (RF OFF)

µ

47 F

λ

/4 OPEN STUB

Rg

7

4.5

C4 C5 C6 C7

3

3

3 2.5 526

C1 = 30 pF C6 = 2 pF

C2 = 30 pF

C3 = 1000 pF

C4 = 2 pF

C5 = 3 pF

3

C7 = 8 pF

C8 = 8 pF

C9 = 3 pF

1000 p

λ

/4 LINE

1

R1

C3

7

2

C8 C9

R1 = 270 Ω

Rg = 100 Ω

Tantalum Condenser

µ

100 F

/4 OPEN STUB

λ

50 Ω LINE

3

3

2.5

2033

7

GND

Substrate: Teflon glass ( r = 2.6)

t = 0.8 mm

5 5

3

3

C2

OUTPUT

ε

Preliminary Data Sheet4

Page 5

79A Package Dimensions (Unit: mm)

NE6510379A

4.2 max.

Source

Gate Gate

5.7 max.

0.6 ±0.15

0.4 ±0.15

5.7 max.

0.9 ±0.2

Drain Drain

4.4 max.

0.8 ±0.15

0.2 ±0.1

79A Package Recommended P.C.B. Layout (Unit: mm)

1.0 max.

1.5 ±0.2

Source

1.2 max.

0.8 max.

3.6 ±0.2

Bottom View

5.9

1.2

4.0

1.7

Stop up the hole with a rosin

or something to avoid solder

flow.

Drain Gate

0.5

Source

through hole 0.2 × 33

0.5 0.5

1.0

φ

6.1

Preliminary Data Sheet 5

Page 6

NE6510379A

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered under the following recommended conditions. For soldering methods and

conditions other than those recommended below, contact your NEC sales representative.

Soldering Method Soldering Conditions

Infrared Reflow Package peak temperature: 235°C or below

Time: 30 seconds or less (at 210°C)

Count: 2, Exposure limi t

Partial Heating Pin tem perature: 260°C

Time: 5 seconds or less (per pi n row)

Exposure limit

After opening the dry pack, keep it in a place below 25°C and 65% RH for the allowable storage period.

Note

Note

: None

Note

: None

Caution Do not use different soldering methods together (except for partial heating).

Recommended

Condition Symbol

IR35-00-2

–

Preliminary Data Sheet6

Page 7

[MEMO]

NE6510379A

Preliminary Data Sheet 7

Page 8

NE6510379A

Caution

The Great Care must be taken in dealing with the devices in this guide.

The reason is that the material of the devices is GaAs (Gallium Arsenide), which is

designated as harmful substance according to the law concerned.

Keep the law concerned and so on, especially in case of removal.

The application circuits and their parameters are for reference only and are not intended for use in actual design-ins.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...