Page 1

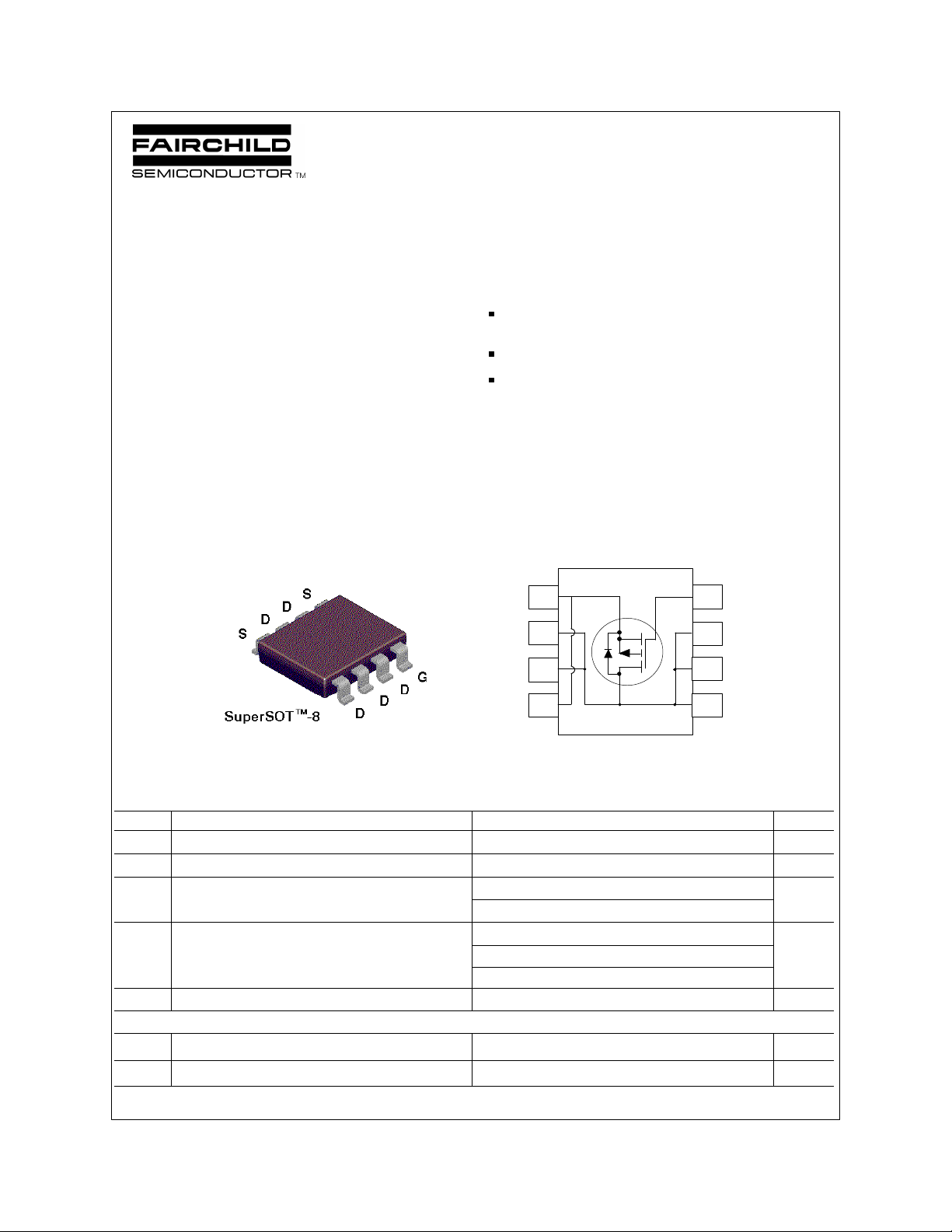

NDH832P

P-Channel Enhancement Mode Field Effect Transistor

General Description Features

June 1996

These P-Channel enhancement mode power field effect

transistors are produced using Fairchild's proprietary, high cell

density, DMOS technology. This very high density process is

especially tailored to minimize on-state resistance and provide

superior switching performance. These devices are particularly

suited for low voltage applications such as notebook computer

-4.2A, -20V. R

R

High density cell design for extremely low R

Enhanced SuperSOTTM-8 small outline surface mount

package with high power and current handling capability.

= 0.06Ω @ VGS = -4.5V

DS(ON)

= 0.08Ω @ VGS = -2.7V.

DS(ON)

DS(ON).

power management and other battery powered circuits where

fast switching, low in-line power loss, and resistance to

transients are needed.

___________________________________________________________________________________________

5

6

7

8

4

3

2

1

Absolute Maximum Ratings T

Symbol Parameter NDH832P Units

V

DSS

V

GSS

I

D

P

D

TJ,T

THERMAL CHARACTERISTICS

R

θ

R

θ

Drain-Source Voltage -20 V

Gate-Source Voltage -8 V

Drain Current - Continuous (Note 1a) -4.2 A

- Pulsed -15

Maximum Power Dissipation (Note 1a) 1.8 W

(Note 1b)

(Note 1c)

Operating and Storage Temperature Range -55 to 150 °C

STG

Thermal Resistance, Junction-to-Ambient (Note 1a) 70 °C/W

JA

Thermal Resistance, Junction-to-Case (Note 1) 20 °C/W

JC

= 25°C unless otherwise noted

A

1

0.9

NDH832P Rev. B2

Page 2

Electrical Characteristics (T

= 25°C unless otherwise noted)

A

Symbol Parameter Conditions Min Typ Max Units

OFF CHARACTERISTICS

BV

I

DSS

DSS

Drain-Source Breakdown Voltage VGS = 0 V, ID = -250 µA -20 V

Zero Gate Voltage Drain Current

VDS = -16 V, V

GS

= 0 V

-1 µA

TJ = 55oC -10 µA

I

GSSF

I

GSSR

Gate - Body Leakage, Forward

VGS = 8 V, VDS = 0 V

Gate - Body Leakage, Reverse VGS = -8 V, VDS= 0 V -100 nA

100 nA

ON CHARACTERISTICS (Note 2)

V

GS(th)

Gate Threshold Voltage

VDS = VGS, ID = -250 µA

-0.4 -0.7 -1 V

TJ = 125oC -0.3 -0.5 -0.8

R

I

g

D(on)

FS

DS(ON)

Static Drain-Source On-Resistance

On-State Drain Current

Forward Transconductance

VGS = -4.5 V, ID = -4.2 A

TJ = 125oC

VGS = -2.7 V, ID = -3.7 A

VGS = -4.5 V, VDS = -5 V

VGS = -2.7 V, VDS = -5 V

VDS = -10 V, ID = -4.2 A

0.045 0.06

0.063 0.12

0.064 0.08

-15 A

-5

9 S

Ω

DYNAMIC CHARACTERISTICS

C

iss

C

oss

C

rss

Input Capacitance

Output Capacitance 530 pF

VDS = -10 V, VGS = 0 V,

f = 1.0 MHz

Reverse Transfer Capacitance 180 pF

1000 pF

SWITCHING CHARACTERISTICS (Note 2)

t

t

t

t

Q

Q

Q

D(on)

r

D(off)

f

g

gs

gd

Turn - On Delay Time VDD = -5 V, ID = -1 A,

V

= -4.5 V, R

Turn - On Rise Time 53 70 ns

GEN

GEN

= 6 Ω

13 20 ns

Turn - Off Delay Time 60 80 ns

Turn - Off Fall Time 33 40 ns

Total Gate Charge VDS = -10 V,

Gate-Source Charge 1.2 nC

ID = -4.2 A, VGS = -4.5 V

18 30 nC

Gate-Drain Charge 6 nC

NDH832P Rev. B2

Page 3

Electrical Characteristics (T

= 25°C unless otherwise noted)

A

Symbol Parameter Conditions Min Typ Max Units

DRAIN-SOURCE DIODE CHARACTERISTICS AND MAXIMUM RATINGS

I

S

V

SD

Notes:

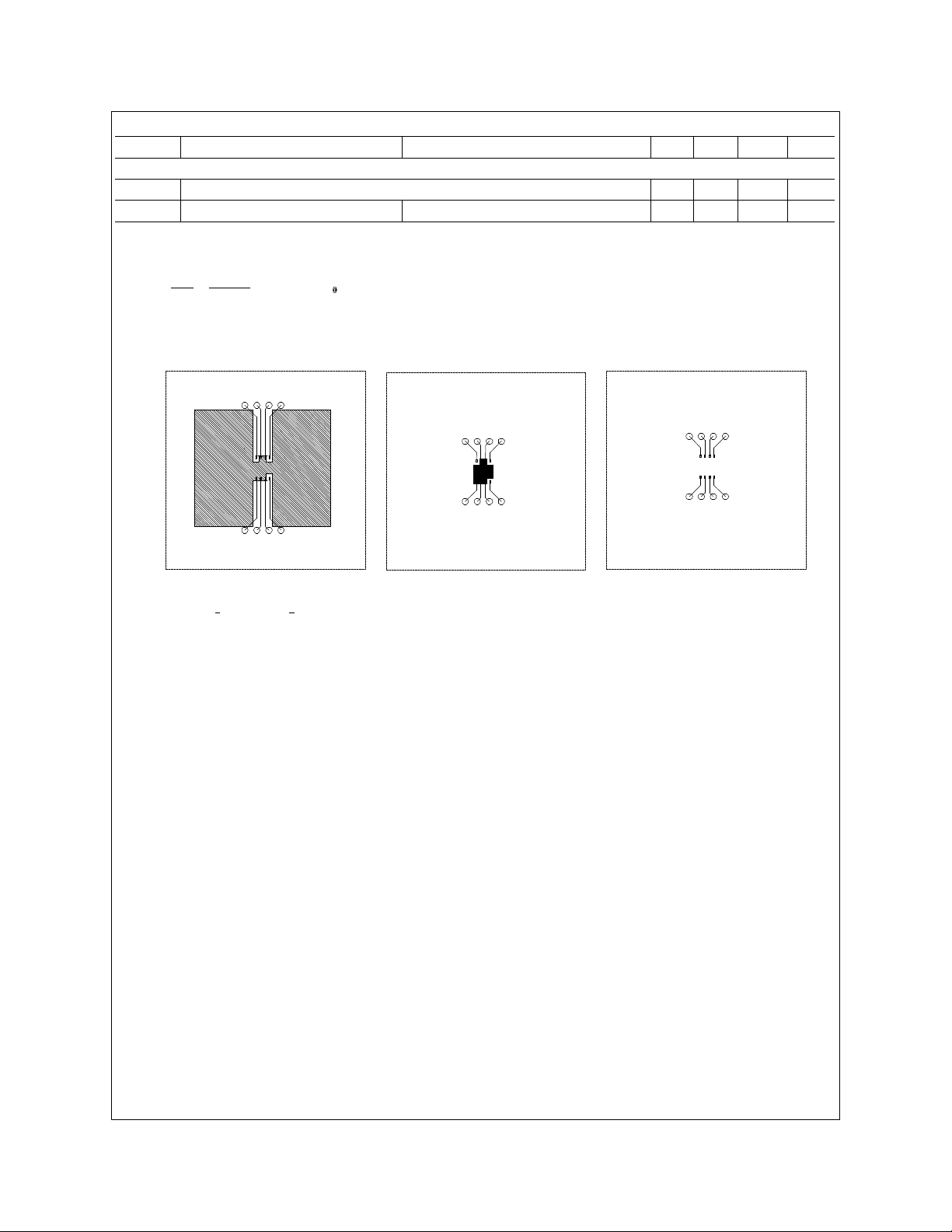

1. R

design while R

P

Typical R

Scale 1 : 1 on letter size paper

Maximum Continuous Drain-Source Diode Forward Current -1.5 A

Drain-Source Diode Forward Voltage

is the sum of the junction-to-case and case-to-ambient thermal resistance where the case thermal reference is defined as the solder mounting surface of the drain pins. R

JA

θ

(t)

D

is determined by the user's board design.

CA

θ

T

=

R

JA

θ

a. 70oC/W when mounted on a 1 in2 pad of 2oz cpper.

b. 125oC/W when mounted on a 0.026 in2 pad of 2oz copper.

c. 135oC/W when mounted on a 0.005 in2 pad of 2oz copper.

T

J−TA

=

(t)

R

θJA

θ

JC

using the board layouts shown below on 4.5"x5" FR-4 PCB in a still air environment:

J−TA

+R

2

= I

(t) ×R

DS(ON ) T

D

(t)

θ

CA

J

1a

VGS = 0 V, IS = -1.5 A

1b

(Note 2)

1c

-0.75 -1.2 V

is guaranteed by

JC

θ

2. Pulse Test: Pulse Width < 300µs, Duty Cycle < 2.0%.

NDH832P Rev. B2

Page 4

Typical Electrical Characteristics

-20

-15

-10

V = -4.5V

GS

-3.5

-3.0

-2.7

-2.5

-2.0

-5

D

I , DRAIN-SOURCE CURRENT (A)

0

V , DRAIN-SOURCE VOLTAGE (V)

DS

Figure 1. On-Region Characteristics.

1.6

I = -4.2A

1.4

1.2

DS(ON)

R , NORMALIZED

0.8

DRAIN-SOURCE ON-RESISTANCE

0.6

D

V = -4.5V

GS

1

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

-1.5

-4-3-2-10

2

1.8

V = -2.5V

1.6

GS

-2.7

1.4

1.2

DS(on)

R , NORMALIZED

1

DRAIN-SOURCE ON-RESISTANCE

0.8

-3.0

-3.5

I , DRAIN CURRENT (A)

D

Figure 2. On-Resistance Variation with Gate

Voltage and Drain Current.

2

V = -4.5V

GS

T = 125°C

1.5

1

DS(on)

R , NORMALIZED

DRAIN-SOURCE ON-RESISTANCE

0.5

I , DRAIN CURRENT (A)

D

J

25°C

-4.0

-55°C

-4.5

-5.0

-20-16-12-8-40

-20-16-12-8-40

Figure 3. On-Resistance Variation with

Temperature.

-20

V = -10V

DS

-16

-12

-8

D

I , DRAIN CURRENT (A)

-4

0

V , GATE TO SOURCE VOLTAGE (V)

GS

T = -55°C

J

Figure 5. Transfer Characteristics.

25°C

125°C

-4-3.5-3-2.5-2-1.5-1-0.50

Figure 4. On-Resistance Variation with Drain

Current and Temperature.

1.2

V = V

1.1

1

0.9

th

0.8

V , NORMALIZED

0.7

GATE-SOURCE THRESHOLD VOLTAGE

0.6

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

DS

I = -250µA

D

Figure 6. Gate Threshold Variation with

GS

Temperature.

NDH832P Rev. B2

Page 5

Typical Electrical Characteristics

1.1

I = -250µA

D

1.08

1.06

1.04

1.02

1

DSS

BV , NORMALIZED

0.98

0.96

DRAIN-SOURCE BREAKDOWN VOLTAGE

0.94

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

Figure 7. Breakdown Voltage Variation with

Temperature.

2500

2000

1000

500

300

CAPACITANCE (pF)

200

100

f = 1 MHz

V = 0V

GS

0.1 0.2 0.5 1 2 5 10 20

-V , DRAIN TO SOURCE VOLTAGE (V)

DS

C

C

iss

oss

C

rss

20

10

V = 0V

GS

2

1

T = 125°C

J

0.1

0.01

0.001

S

-I , REVERSE DRAIN CURRENT (A)

0.0001

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

-V , BODY DIODE FORWARD VOLTAGE (V)

25°C

-55°C

SD

Figure 8. Body Diode Forward Voltage Variation

with Current and Temperature.

5

I = -4.2A

D

4

3

2

1

GS

-V , GATE-SOURCE VOLTAGE (V)

0

0 5 10 15 20 25

V = -5.0V

DS

Q , GATE CHARGE (nC)

g

-10V

-15V

Figure 9. Capacitance Characteristics.

20

V = -10V

DS

15

T = -55°C

J

25°C

Figure 10. Gate Charge Characteristics.

125°C

10

5

FS

g , TRANSCONDUCTANCE (SIEMENS)

0

I , DRAIN CURRENT (A)

D

-20-16-12-8-40

Figure 11. Transconductance Variation with Drain

Current and Temperature.

NDH832P Rev. B2

Page 6

Typical Thermal Characteristics

2.5

2

1.5

1b

1

1c

0.5

STEADY-STATE POWER DISSIPATION (W)

0

0 0.2 0.4 0.6 0.8 1

2oz COPPER MOUNTING PAD AREA (in )

4.5"x5" FR-4 Board

o

T = 25 C

A

Still Air

2

Figure 12. SOT-8 Maximum Steady-State Power

Dissipation versus Copper Mounting Pad

Area.

30

10s

100ms

10ms

1s

100us

1ms

10

RDS(ON) LIMIT

3

1

0.3

0.1

D

-I , DRAIN CURRENT (A)

0.03

0.01

0.1 0.2 0.5 1 2 5 10 20 30

V = -4.5V

GS

SINGLE PULSE

R = See Note 1c

JA

θ

T = 25°C

A

- V , DRAIN-SOURCE VOLTAGE (V)

DS

DC

5

1a

4.5

4

3.5

1b

1c

3

2.5

D

-I , STEADY-STATE DRAIN CURRENT (A)

2

0 0.2 0.4 0.6 0.8 1

2oz COPPER MOUNTING PAD AREA (in )

4.5"x5" FR-4 Board

T = 25 C

A

Still Air

V = -4.5V

GS

2

1a

o

Figure 13. Maximum Steady-State Drain

Current versus Copper Mounting Pad

Area.

Figure 14. Maximum Safe Operating Area.

1

D = 0.5

0.5

0.3

0.2

0.2

0.1

0.05

0.03

r(t), NORMALIZED EFFECTIVE

0.02

TRANSIENT THERMAL RESISTANCE

0.01

0.1

0.05

0.02

0.01

Single Pulse

0.0001 0.001 0.01 0.1 1 10 100 300

Figure 15. Transient Thermal Response Curve.

Note: Thermal characterization performed using the conditions described in note 1c. Transient thermal response will change

depending on the circuit board design.

t , TIME (sec)

1

R (t) = r(t) * R

JA

θ

R = See Note 1c

JA

θ

P(pk)

t

1

t

2

T - T = P * R (t)

J

A

Duty Cycle, D = t / t

JA

θ

JA

θ

2

1

NDH832P Rev. B2

Page 7

NDH832P Rev. B2

Page 8

NDH832P Rev. B2

Loading...

Loading...