Page 1

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

________________________________________________________________

Maxim Integrated Products

1

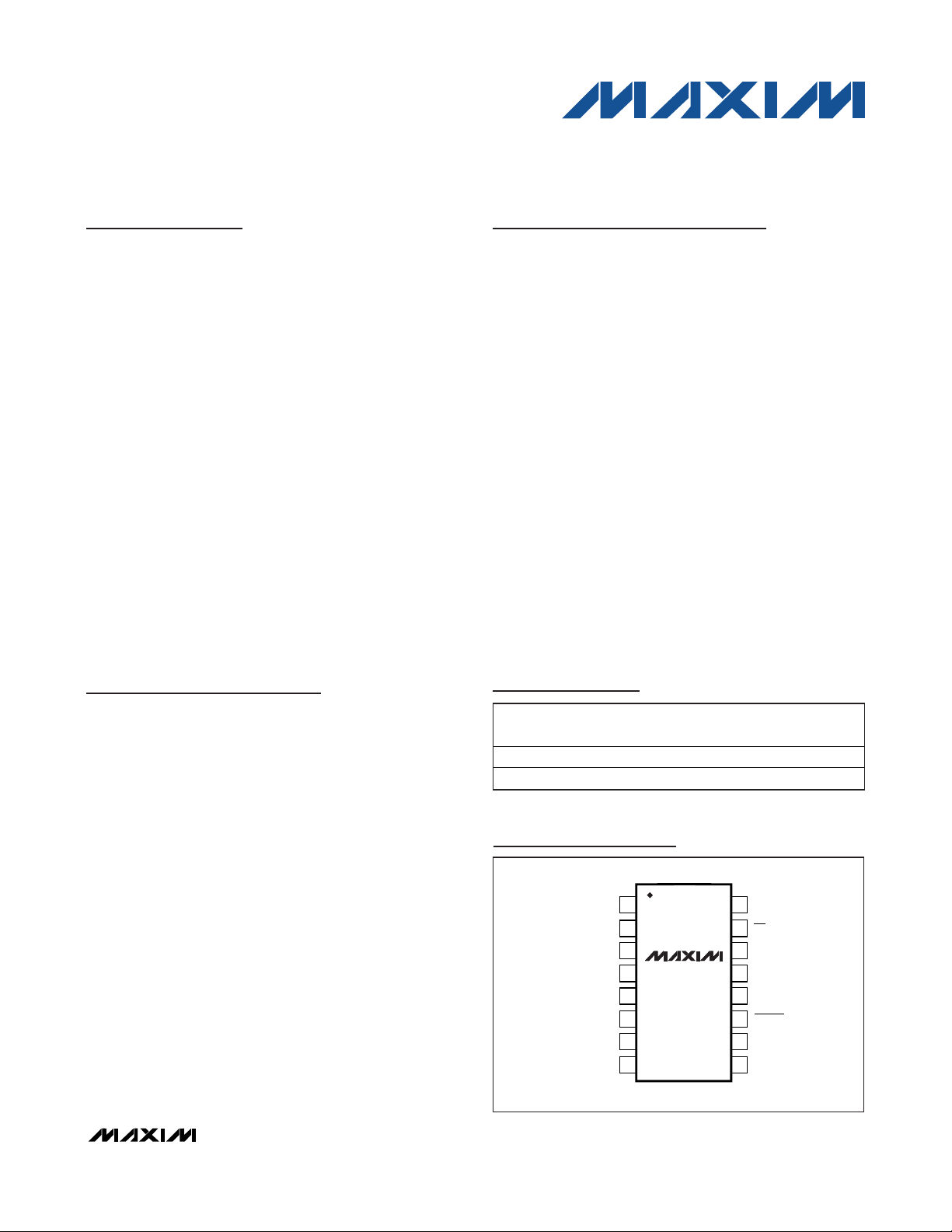

Pin Configuration

19-2436; Rev 2; 1/08

For pricing delivery, and ordering information please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

General Description

The MXB7846 is an industry-standard 4-wire touchscreen controller. It contains a 12-bit sampling analogto-digital converter (ADC) with a synchronous serial

interface and low on-resistance switches for driving

resistive touch screens. The MXB7846 uses an internal

+2.5V reference or an external reference. The

MXB7846 can make absolute or ratiometric measurements. In addition, this device has an on-chip temperature sensor, a battery-monitoring channel, and has the

ability to perform touch-pressure measurements without

external components. The MXB7846 has one auxiliary

ADC input. All analog inputs are fully ESD protected,

eliminating the need for external TransZorb™ devices.

The MXB7846 is guaranteed to operate with a supply

voltage down to +2.375V when used with an external

reference or +2.7V with an internal reference. In shutdown mode, the typical power consumption is reduced

to under 0.5µW, while the typical power consumption at

125ksps throughput and a +2.7V supply is 650µW.

Low-power operation makes the MXB7846 ideal for battery-operated systems, such as personal digital assistants with resistive touch screens and other portable

equipment. The MXB7846 is available in 16-pin QSOP

and TSSOP packages, and is guaranteed over the

-40°C to +85°C temperature range.

Applications

Personal Digital Assistants

Portable Instruments

Point-of-Sales Terminals

Pagers

Touch-Screen Monitors

Cellular Phones

Features

♦ ESD-Protected ADC Inputs

±15kV IEC 61000-4-2 Air-Gap Discharge

±8kV IEC 61000-4-2 Contact Discharge

♦ Pin Compatible with MXB7843

♦ +2.375V to +5.25V Single Supply

♦ Internal +2.5V Reference

♦ Direct Battery Measurement (0 to 6V)

♦ On-Chip Temperature Measurement

♦ Touch-Pressure Measurement

♦ 4-Wire Touch-Screen Interface

♦ Ratiometric Conversion

♦ SPI™/QSPI™, 3-Wire Serial Interface

♦ Programmable 8-/12-Bit Resolution

♦ Auxiliary Analog Input

♦ Automatic Shutdown Between Conversions

♦ Low Power (External Reference)

270µA at 125ksps

115µA at 50ksps

25µA at 10ksps

5µA at 1ksps

2µA Shutdown Current

Ordering Information

TRANSZORB is a trademark of Vishay Intertechnology, Inc.

SPI/QSPI are trademarks of Motorola, Inc.

Typical Application Circuit appears at end of data sheet.

PART TEMP RANGE

MXB7846EEE -40°C to +85°C 16 QSOP E16-6

MXB7846EUE -40°C to +85°C 16 TSSOP U16-1

PINPACKAGE

PKG

CODE

TOP VIEW

V

GND

BAT

AUX

DD

1

X+

2

Y+

3

4

X-

Y-

5

6

7

8

16

DCLK

15

CS

14

DIN

MXB7846

QSOP/TSSOP

13

BUSY

12

DOUT

PENIRQ

11

10

V

DD

REF

9

Page 2

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDD, VBAT, DIN, CS, DCLK to GND ........................-0.3V to +6V

Digital Outputs to GND...............................-0.3V to (V

DD

+ 0.3V)

V

REF

, X+, X-, Y+, Y-, AUX to GND..............-0.3V to (VDD+ 0.3V)

Maximum Current into Any Pin .........................................±50mA

Maximum ESD per IEC-61000-4-2 (per MIL STD-883 HBM)

X+, X-, Y+, Y-, VBAT, AUX ......................................15kV (4kV)

All Other Pins ..........................................................2kV (500V)

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.30mW/°C above +70°C).........667mW

16-Pin TSSOP (derate 5.70mW/°C above +70°C) .......456mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

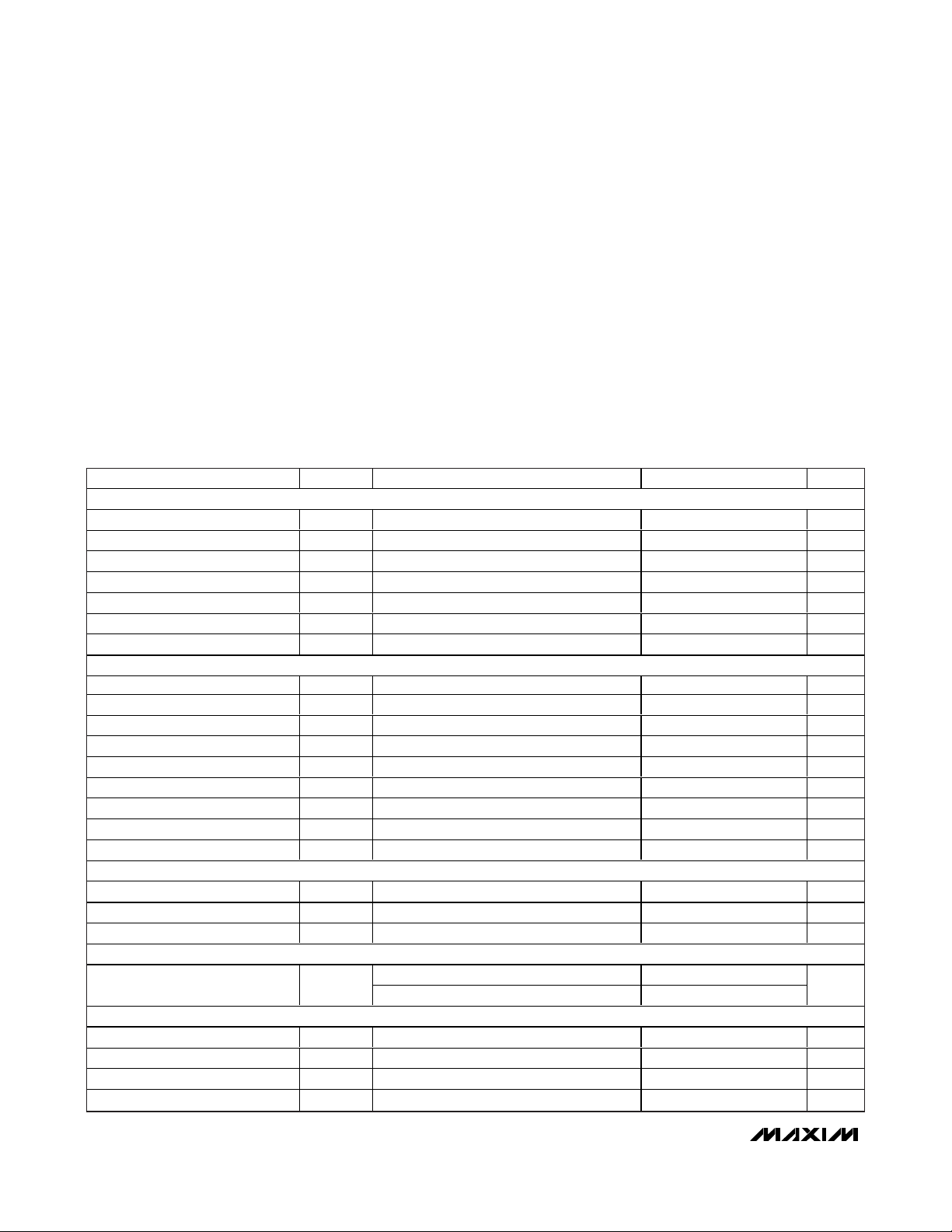

ELECTRICAL CHARACTERISTICS

(VDD= 2.7V to 3.6V, V

REF

= 2.5V, f

DCLK

= 2MHz (50% duty cycle), f

SAMPLE

= 125kHz, 12-bit mode, 0.1µF capacitor at REF, TA=

T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

DC ACCURACY (Note 1)

Resolution 12 Bits

No Missing Codes 11 12 Bits

Relative Accuracy INL (Note 2) ±1 ±2 LSB

Differential Nonlinearity DNL ±1 LSB

Offset Error ±6 LSB

Gain Error (Note 3) ±4 LSB

Noise Including internal reference 70 µV

CONVERSION RATE

Conversion Time t

Track/Hold Acquisition Time t

Throughput Rate f

Multiplexer Settling Time 500 ns

Aperture Delay 30 ns

Aperture Jitter 100 p s

Channel-to-Channel Isolation VIN = 2.5V

Serial Clock Frequency f

Duty Cycle 40 60 %

ANALOG INPUT (X+, X-, Y+, Y-, AUX)

Input Voltage Range 0V

Input Capacitance 25 pF

Input Leakage Current On/off leakage, VIN = 0 to V

SWITCH DRIVERS

On-Resistance (Note 5)

INTERNAL REFERENCE

Reference Output Voltage V

REF Output Tempco TCV

REF Short-Circuit Current 18 mA

REF Output Impedance 250 Ω

PARAMETER SYM B O L CONDITIONS MIN TYP MAX UNITS

CONV

ACQ

SAMPLE

DCLK

REF

12 clock cycles (Note 4) 6 µs

3 clock cycles 1.5 µs

16 clock conversion 125 kHz

Y+, X+ 7

Y-, X- 9

VDD = 2.7V to 5.25V, TA = +25°C 2.45 2.50 2.55 V

REF

at 50kHz 100 dB

P-P

DD

0.1 2.0 MHz

REF

±0.1 ±1 µA

50 ppm°/C

RMS

V

Ω

Page 3

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

_______________________________________________________________________________________ 3

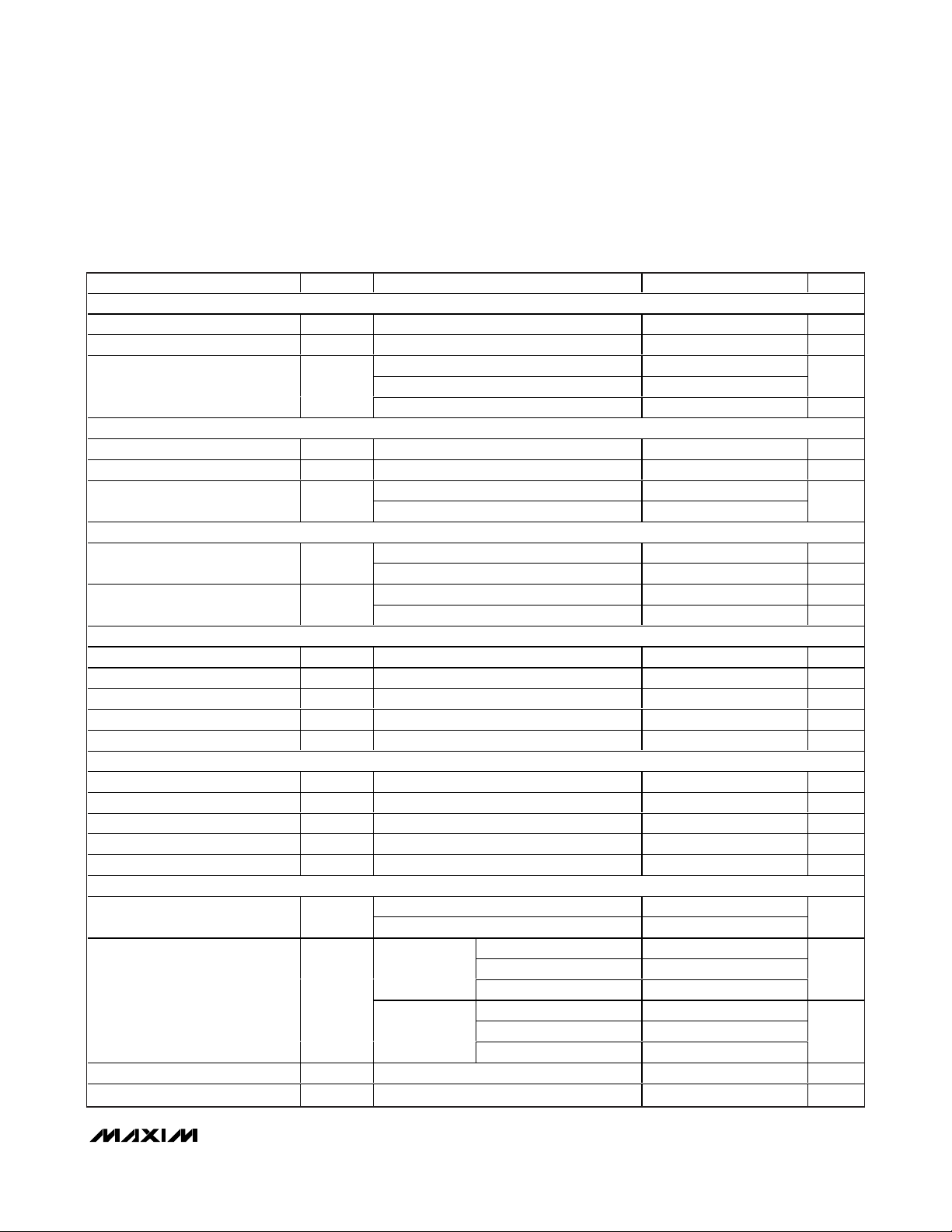

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 2.7V to 3.6V, V

REF

= 2.5V, f

DCLK

= 2MHz (50% duty cycle), f

SAMPLE

= 125kHz, 12-bit mode, 0.1µF capacitor at REF, TA=

T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYM B O L CONDITIONS MIN TYP MAX UNITS

EXTERNAL REFERENCE (Internal reference disabled, reference applied to REF)

Reference Input Voltage Range (Note 7) 1 V

DD

V

Input Resistance 1GΩ

Input Current

f

f

f

= 125kHz 13 40

SAMPLE

= 12.5kHz 2.5

SAMPLE

= 0 ±3

DCLK

µA

BATTERY MONITOR (BAT)

Input Voltage Range 06V

Input Resistance During acquisition 10 kΩ

V

= 2.5V ±2

Accuracy

REF

Internal reference ±3

%

TEMPERATURE MEASUREMENT

Resolution

Accuracy

Differential method (Note 8) 1.6 °C

Single-conversion method 0.3 °C

Differential method (Note 8) ±2°C

Single-conversion method ±3°C

DIGITAL INPUTS (DCLK, CS, DIN)

Input High Voltage V

Input Low Voltage V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

IH

IL

HYST

IN

IN

✕

V

0.7 V

DD

100 mV

15 pF

0.8 V

±1 µA

DIGITAL OUTPUT (DOUT, BUSY)

Output Voltage Low V

Output Voltage High V

PENIRQ Output Low Voltage V

Three-State Leakage Current I

Three-State Output Capacitance C

OUT

OL

OH

OL

L

I

= 250µA 0.4 V

SINK

I

50kΩ pullup to V

CS = V

CS = V

= 250µA V

SOURCE

DD

DD

DD

0.5 V

DD -

1 ±10 µA

15 pF

0.8 V

POWER REQUIREMENTS

Supply Voltage V

Supply Current I

Shutdown Supply Current I

Power-Supply Rejection Ratio P

DD

DD

SHDN

SRR

External reference 2.375 5.250

Internal reference 2.70 5.25

External

reference

Internal

reference

DCLK = CS = V

f

f

f

f

f

f

DD

= 125ksps 270 650

SAMPLE

= 12.5ksps 220

SAMPLE

= 0 150

SAMPLE

= 125ksps 780 950

SAMPLE

= 12.5ksps 720

SAMPLE

= 0 650

SAMPLE

3µA

VDD = 2.7V to 3.6V full scale 70 dB

V

µA

µA

Page 4

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

4 _______________________________________________________________________________________

Note 1: Tested at VDD= 2.7V.

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the full-scale range has

been calibrated.

Note 3: Offset nulled.

Note 4: Conversion time is defined as the number of clock cycles multiplied by the clock period; clock has 50% duty cycle.

Note 5: Resistance measured from the source to drain of the switch.

Note 6: External load should not change during conversion for specified accuracy.

Note 7: ADC performance is limited by the conversion noise floor, typically 300µV

P-P

. An external reference below 2.5V can com-

promise the ADC performance.

Note 8: Difference between Temp0 and Temp1. No calibration necessary.

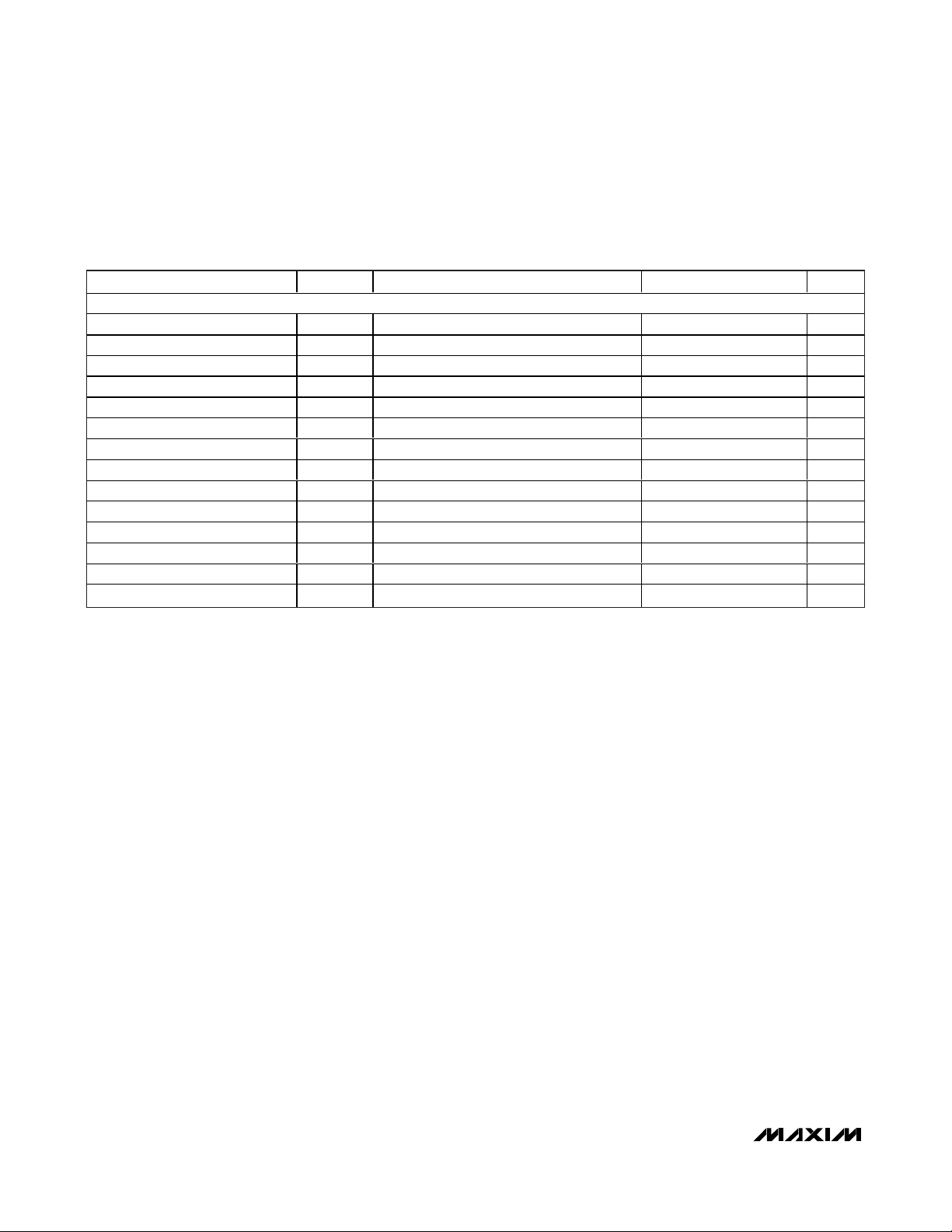

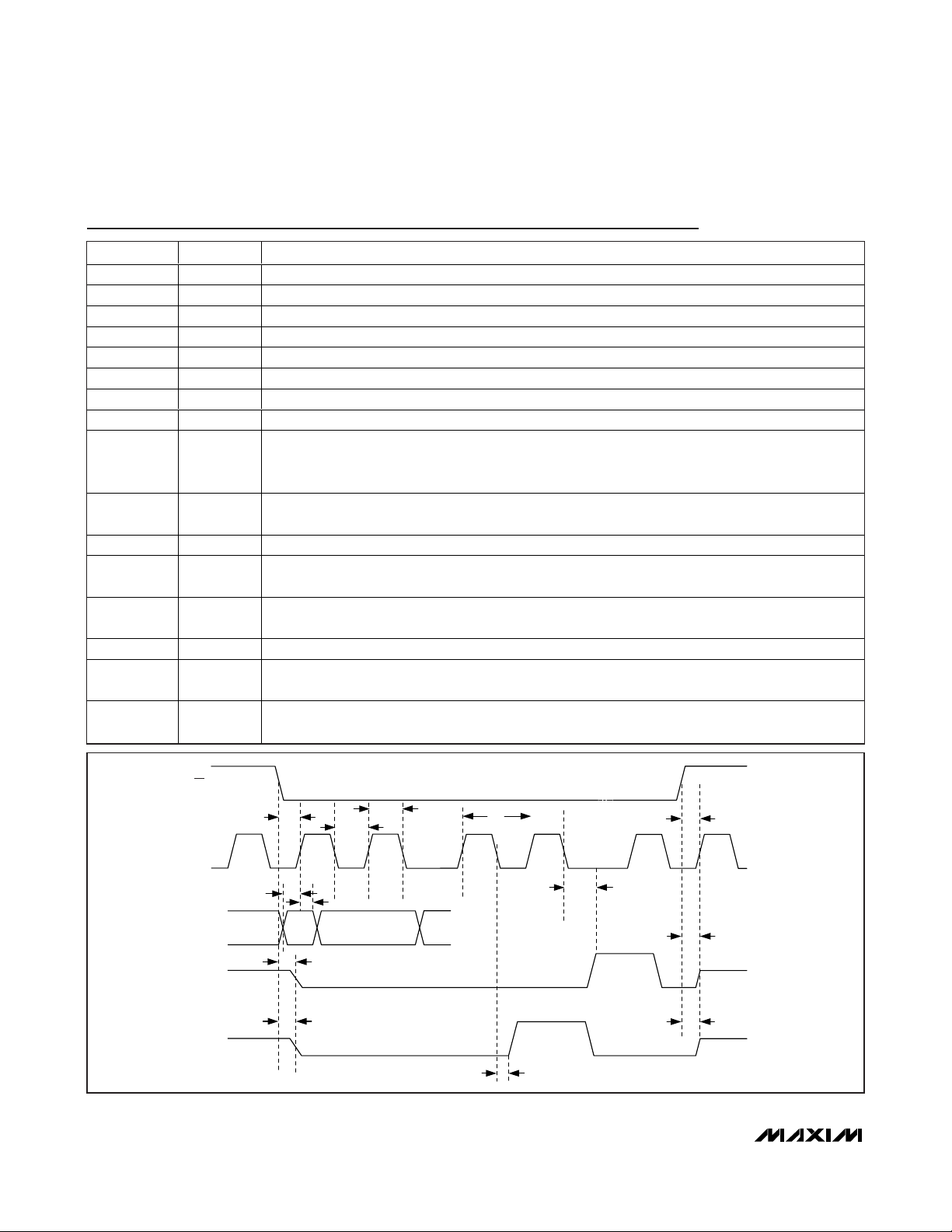

TIMING CHARACTERISTICS (Figure 1)

(VDD= 2.7V to 3.6V, V

REF

= 2.5V, f

DCLK

= 2MHz (50% duty cycle), f

SAMPLE

= 125kHz, 12-bit mode, 0.1µF capacitor at REF, TA=

T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

TIMING CHARACTERISTICS (Figure 1)

Acquisition Time t

DCLK Clock Period t

DCLK Pulse Width High t

DCLK Pulse Width Low t

DIN-to-DCLK Setup Time t

DIN-to-DCLK Hold Time t

CS Fall-to-DCLK Rise Setup Time t

CS Rise-to-DCLK Rise Ignore t

DCLK Falling-to-DOUT Valid t

CS Rise-to-DOUT Disable t

CS Fall-to-DOUT Enable t

DCLK Falling-to-BUSY Rising t

CS Falling-to-BUSY Enable t

CS Rise-to-BUSY Disable t

PARAMETER SYM B O L CONDITIONS MIN TYP MAX UNITS

ACQ

CP

CH

CL

DS

DH

CSS

CSH

DO

TR

DV

BD

BDV

BTR

C

C

C

LOAD

LOAD

LOAD

= 50pF 200 ns

= 50pF 200 ns

= 50pF 200 ns

1.5 µs

500 ns

200 ns

200 ns

100 ns

0ns

100 ns

0ns

200 ns

200 ns

200 ns

Page 5

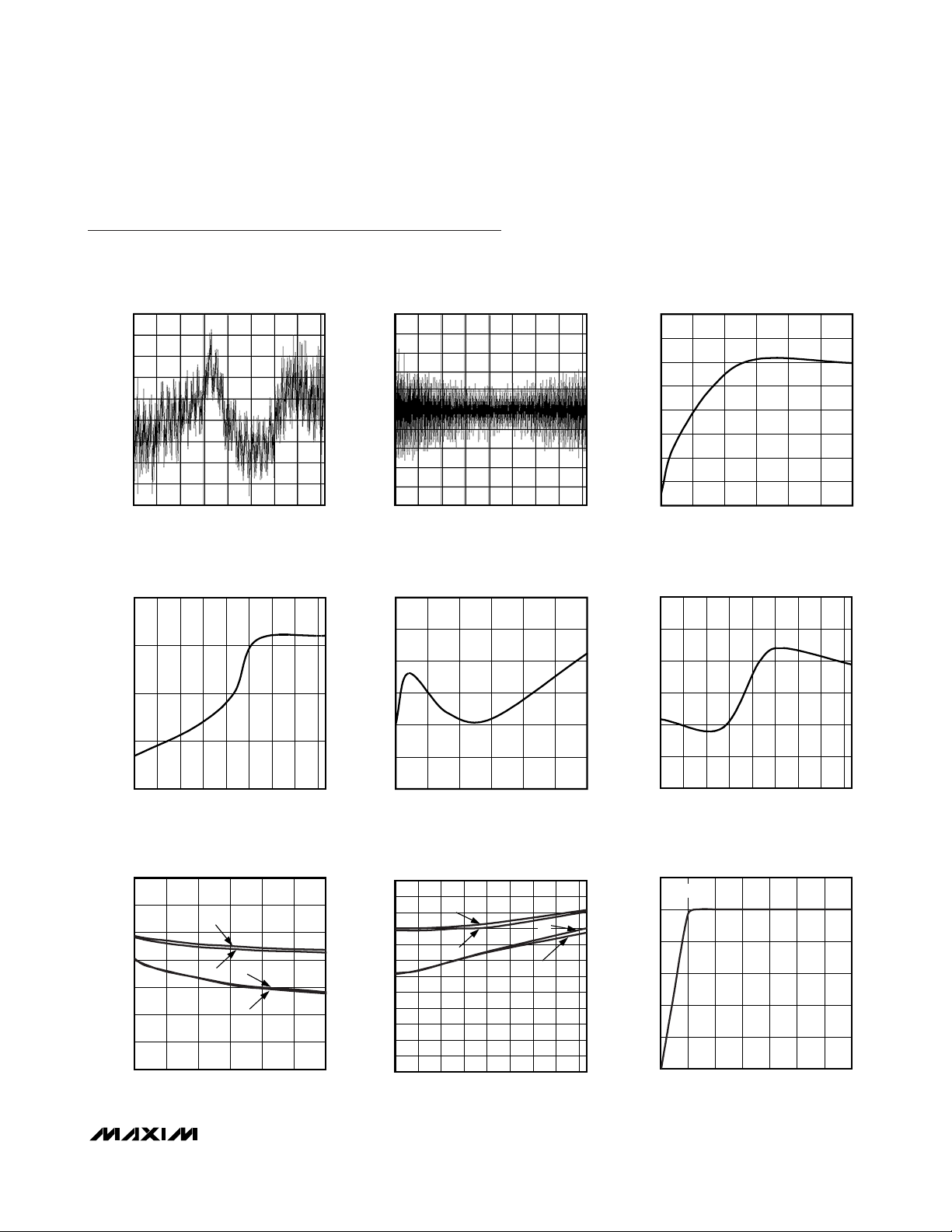

Typical Operating Characteristics

(VDD= 2.7V, V

REF

= 2.5V

EXTERNAL

, f

DCLK

= 2MHz, f

SAMPLE

= 125kHz, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless

otherwise noted.)

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

_______________________________________________________________________________________

5

INTEGRAL NONLINEARITY

vs. DIGITAL OUTPUT CODE

0.5

0.4

0.3

0.2

0.1

0

INL (LSB)

-0.1

-0.2

-0.3

-0.4

0 4000

CHANGE IN OFFSET ERROR

1.0

0.5

OUTPUT CODE

vs. TEMPERATURE

350030002000 25001000 1500500

1.0

0.8

MXB7846 toc01

0.6

0.4

0.2

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

MXB7846 toc05

DIFFERENTIAL NONLINEARITY

vs. DIGITAL OUTPUT CODE

0

0 4000

OUTPUT CODE

CHANGE IN GAIN ERROR

vs. SUPPLY VOLTAGE

3

2

1

350030002000 25001000 1500500

MXB7846 toc02

OFFSET ERROR (LSB)

MXB7846 toc07

CHANGE IN OFFSET ERROR

vs. SUPPLY VOLTAGE

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

-2.0

2.5 5.5

SUPPLY VOLTAGE (V)

CHANGE IN GAIN ERROR

vs. TEMPERATURE

1.0

0.5

0

MXB7846 toc04

5.04.53.0 3.5 4.0

MXB7846 toc08

0

-0.5

OFFSET ERROR FROM +25°C (LSB)

-1.0

-40 80

655035205-10-25

°

SWITCH ON-RESISTANCE vs. SUPPLY VOLTAGE

(X+, Y+ : +V

14

12

10

8

(Ω)

ON

R

6

4

2

0

2.5 5.5

TO PIN; X-, Y- : TO GND)

DD

X-

Y-

X+

Y+

SUPPLY VOLTAGE (V)

5.04.54.03.53.0

GAIN ERROR (LSB)

MXB7846 toc03

(Ω)

ON

R

0

-1

-2

-3

2.5 5.5

SUPPLY VOLTAGE (V)

5.04.54.03.53.0

SWITCH ON-RESISTANCE vs. TEMPERATURE

(X+, Y+ : +V

12

11

10

9

8

7

6

5

4

3

2

1

0

-40 50 65 80

TO PIN; X-, Y- : PIN TO GND)

DD

X-

X+

Y-

Y+

35205-10-25

TEMPERATURE (°C)

-0.5

-1.0

GAIN ERROR FROM +25°C (LSB)

-1.5

-2.0

2.6

2.5

MXB7846 toc06

2.4

2.3

2.2

INTERNAL REFERENCE (V)

2.1

2.0

-40 80

655035205-10-25

°

INTERNAL REFERENCE

vs. SUPPLY VOLTAGE

CL = 0.1μf

2.0 5.5

SUPPLY VOLTAGE (V)

5.04.54.03.53.02.5

MXB7846 toc09

Page 6

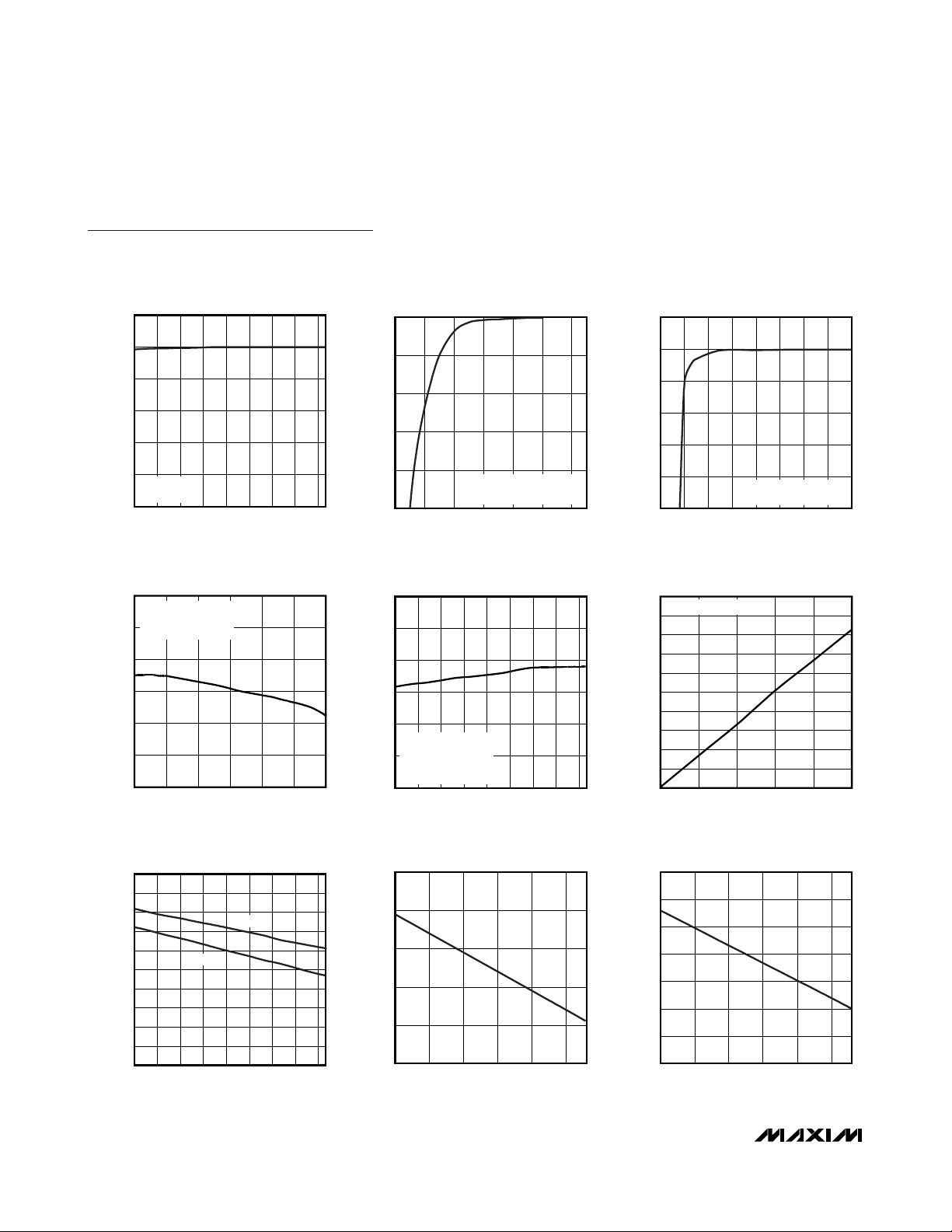

Typical Operating Characteristics (continued)

(VDD= 2.7V, V

REF

= 2.5V

EXTERNAL

, f

DCLK

= 2MHz, f

SAMPLE

= 125kHz, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless

otherwise noted.)

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

6 _______________________________________________________________________________________

2.6

INTERNAL REFERENCE VOLTAGE

vs. TEMPERATURE

2.5

INTERNAL VOLTAGE REFERENCE

vs. TURN-ON TIME

INTERNAL VOLTAGE REFERENCE

vs. TURN-ON TIME

3.0

2.5

2.4

2.3

2.2

INTERNAL REFERENCE VOLTAGE (V)

2.1

VDD = 2.7V

= 0.1μF

C

L

2.0

-40

TEMPERATURE (°C)

REFERENCE CURRENT

vs. SUPPLY VOLTAGE

8.3

CL = 0.1μF

= 125kHz

f

SAMPLE

8.2

EXTERNAL REFERENCE

8.1

8.0

7.9

REFERENCE CURRENT (μA)

7.8

7.7

2.5 5.5

SUPPLY VOLTAGE (V)

TEMP DIODE VOLTAGE

vs. TEMPERATURE

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

TEMP DIODE VOLTAGE (V)

0.2

0.1

0

-40

TEMP2

TEMPERATURE (°C)

TEMP1

MXB7846 toc10

2.0

1.5

1.0

0.5

INTERNAL VOLTAGE REFERENCE (V)

80655035205-10-25

0

0

(1060μs) 12-BIT SETTLING

TURN-ON TIME (μs)

CL = 1μF

12001000800600400200

REFERENCE CURRENT vs. TEMPERATURE

8.3

8.2

MXB7846 toc12

8.1

8.0

7.9

REFERENCE CURRENT (μA)

VDD = 2.7V

= 0.1μF

C

L

7.8

5.04.54.03.53.0

7.7

= 125kHz

f

SAMPLE

EXTERNAL REFERENCE

-40 80

TEMPERATURE (°C)

655035205-10-25

TEMP0 DIODE VOLTAGE

vs. SUPPLY VOLTAGE

590

MXB7846 toc15

589

TEMP0

588

587

TEMP0 DIODE VOLTAGE (mV)

586

585

806535 50-10 5 20-25

2.7

SUPPLY VOLTAGE (V)

5.24.74.23.73.2

2.5

MXB7846 toc11a

2.0

1.5

1.0

INTERNAL VOLTAGE REFERENCE (V)

0.5

0

040

REFERENCE CURRENT vs. SAMPLE RATE

10

EXTERNAL REFERENCE

9

MXB7846 toc13

MXB7846 toc16

8

7

6

5

4

3

REFERENCE CURRENT (μA)

2

1

0

0 125

705

704

703

702

701

700

TEMP1 DIODE VOLTAGE (mV)

699

698

2.7

NO CAPACITOR

(30μs) 12-BIT SETTLING

TURN-ON TIME (μs)

SAMPLE RATE (kHz)

TEMP1 DIODE VOLTAGE

vs. SUPPLY VOLTAGE

TEMP1

SUPPLY VOLTAGE (V)

MXB7846 toc11b

3530252015105

MXB7846 toc14

100755025

MXB7846 toc17

5.24.74.23.73.2

Page 7

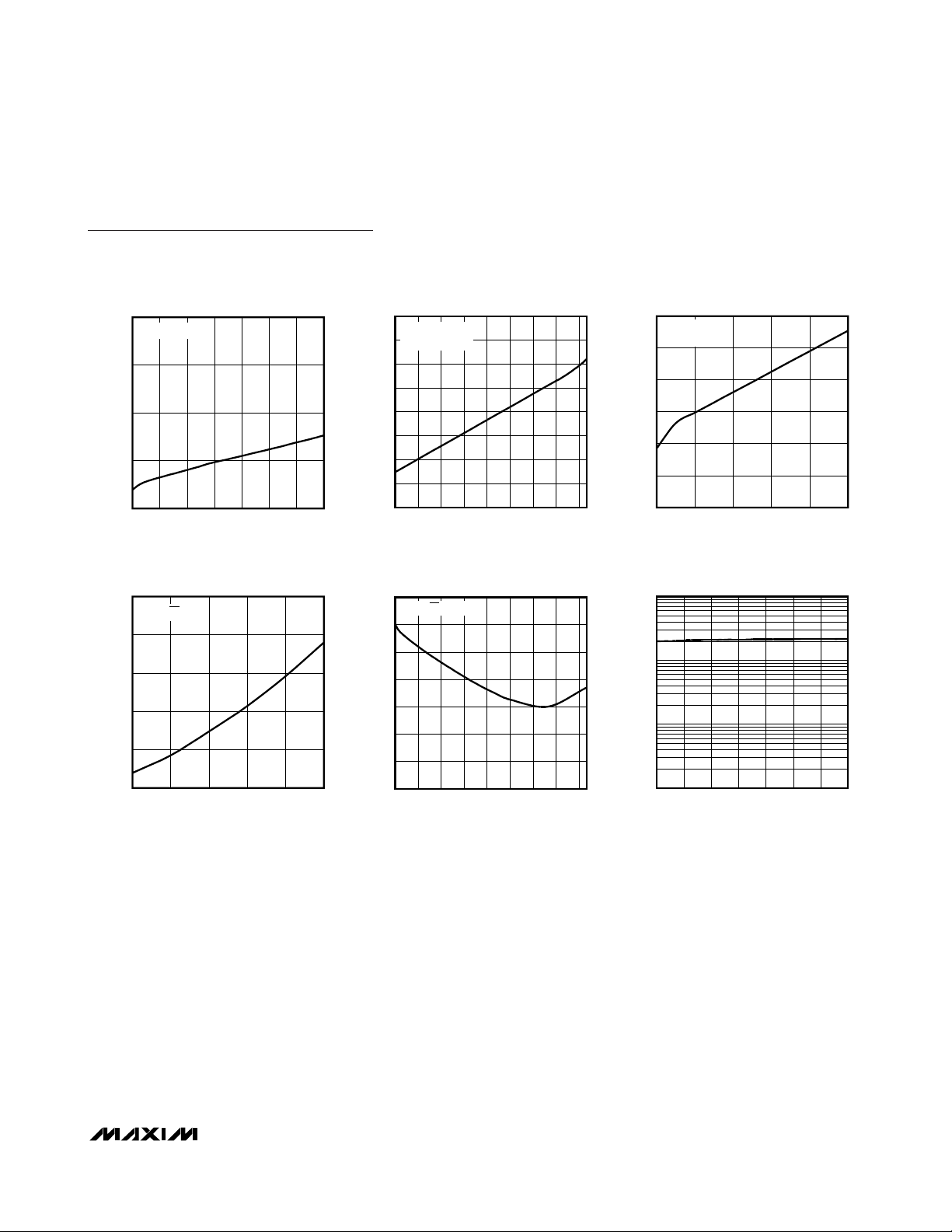

Typical Operating Characteristics (continued)

(VDD= 2.7V, V

REF

= 2.5V

EXTERNAL

, f

DCLK

= 2MHz, f

SAMPLE

= 125kHz, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless

otherwise noted.)

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

_______________________________________________________________________________________

7

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

250

f

= 12.5kHz

SAMPLE

225

200

SUPPLY CURRENT (μA)

175

150

2.0 5.5

SUPPLY VOLTAGE (V)

SHUTDOWN CURRENT

vs. SUPPLY VOLTAGE

300

DCLK = CS = V

250

200

DD

5.04.54.03.53.02.5

MXB7846 toc18

SUPPLY CURRENT (μA)

MXB7846 toc21

290

285

280

275

270

265

260

255

250

-40 80

SHUTDOWN CURRENT vs. TEMPERATURE

120

110

100

90

SUPPLY CURRENT vs. TEMPERATURE

f

= 125kHz

SAMPLE

= 2.7V

V

DD

6550-25 -10 5 20 35

TEMPERATURE (°C)

DCLK = CS = VDD = 3V

MXB7846 toc19

MXB7846 toc22

SUPPLY CURRENT vs. SAMPLE RATE

250

VDD = 2.7V

= 2.5V

V

REF

225

200

175

150

SUPPLY CURRENT (μA)

125

100

0 125

SAMPLE RATE (kHz)

MAXIMUM SAMPLE RATE

vs. SUPPLY VOLTAGE

1000

100

MXB7846 toc20

100755025

MXB7846 toc23

150

SHUTDOWN CURRENT (nA)

100

50

2.7 5.2

SUPPLY VOLTAGE (V)

80

SAMPLE RATE (kHz)

70

SHUTDOWN CURRENT (nA)

60

4.74.23.73.2

50

-40 80

TEMPERATURE (°C)

655035205-10-25

10

1

2.0 5.5

SUPPLY VOLTAGE (V)

5.04.54.03.53.02.5

Page 8

Pin Description

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

8 _______________________________________________________________________________________

Figure 1. Detailed Serial Interface Timing

PIN NAME FUNCTION

1VDDPositive Supply Voltage. Connect to pin 10.

2 X+ X+ Position Input, ADC Input Channel 1

3 Y+ Y+ Position Input, ADC Input Channel 2

4 X- X- Position Input

5 Y- Y- Position Input

6 GND Ground

7 BAT Battery Monitoring Inputs; ADC Input Channel 3

8 AUX Auxiliary Input to ADC; ADC Input Channel 4

Voltage Reference Output/Input. Reference voltage for analog-to-digital conversion. In internal

9 REF

10 V

DD

reference mode, the reference buffer provides a 2.50V nominal output. In external reference mode,

apply a reference voltage between 1V and V

. Bypass REF to GND with a 0.1µF capacitor.

DD

Positive Supply Voltage, +2.375V (2.70V) to +5.25V. External (internal) reference. Bypass with a 1µF

capacitor. Connect to pin 1.

11 PENIRQ Pen Interrupt Output. Open anode output. 10kΩ to 100kΩ pullup resistor required to VDD.

12 DOUT

13 BUSY

Serial Data Output. Data changes state on the falling edge of DCLK. High impedance when CS is

HIGH.

Busy Output. BUSY pulses high for one clock period before the MSB decision. High impedance when

CS is HIGH.

14 DIN Serial Data Input. Data clocked in on the rising edge of DCLK.

15 CS

16 DCLK

Active-Low Chip Select. Data is only clocked into DIN when CS is low. When CS is HIGH, DOUT and

BUSY are high impedance.

Serial Clock Input. Clocks data in and out of the serial interface and sets the conversion speed (duty

cycle must be 40% to 60%).

CS

t

DCLK

DIN

DOUT

BUSY

t

CSS

t

DS

t

DH

t

DV

t

BDV

CH

t

CL

t

CP

t

DO

t

BD

t

CSH

t

TR

t

BTR

Page 9

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

_______________________________________________________________________________________ 9

Detailed Description

The MXB7846 uses a successive-approximation conversion technique to convert analog signals to a 12-bit digital output. An SPI/QSPI/MICROWIRE™-compatible serial

interface provides easy communication to a microprocessor (µP). It features an internal 2.5V reference, an

on-chip temperature sensor, a battery monitor, and a

4-wire touch-screen interface (

Functional Diagram

).

Analog Inputs

Figure 2 shows a block diagram of the analog input section that includes the input multiplexer of the MXB7846,

the differential signal inputs of the ADC, and the differential reference inputs of the ADC. The input multiplexer

switches between X+, X-, Y+, Y-, AUX, BAT, and the

internal temperature sensor.

In single-ended mode, conversions are performed using

REF as the reference. In differential mode, ratiometric

conversions are performed with REF+ connected to X+ or

Y+, and REF- connected to X- or Y-. Configure the reference and switching matrix according to Tables 1 and 2.

During the acquisition interval, the selected channel

charges the sampling capacitance. The acquisition

interval starts on the fifth falling clock edge and ends

on the eighth falling clock edge.

The time required for the T/H to acquire an input signal

is a function of how quickly its input capacitance is

charged. If the input signal’s source impedance is high,

the acquisition time lengthens, and more time must be

allowed between conversions. The acquisition time

(t

ACQ

) is the maximum time the device takes to acquire

the input signal to 12-bit accuracy. Calculate t

ACQ

with

the following equation:

where RIN= 2kΩ and RSis the source impedance of

the input signal.

Source impedances below 1kΩ do not significantly affect

the ADC’s performance. Accommodate higher source

impedances by either slowing down DCLK or by placing

a 1µF capacitor between the analog input and GND.

tRRpF

ACQ S IN

. =× +

()

×84 25

MICROWIRE is a trademark of National Semiconductor Corp.

Figure 2. Equivalent Input Circuit

PENIRQ

TEMP0

TEMP1

+V

V

DD

REF

X+

X-

Y+

Y-

V

AUX

GND

BAT

7.5kΩ

2.5kΩ

BATTERY

MXB7846

A2–A0

)

(SHOWN 001

B

2.5V

REFERENCE

ON

SER/DFR

(SHOWN HIGH)

REF ON/OFF

+IN

12-BIT ADC

-IN

REF+

REF-

Page 10

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

10 ______________________________________________________________________________________

Functional Diagram

Table 1. Input Configuration, Single-Ended Reference Mode (SER/DFR HIGH)

Table 2. Input Configuration, Differential Reference Mode (SER/DFR LOW)

V

DD

PENIRQ

X+

X-

TEMPERATURE

SENSOR

DOUT

BUSY

PENIRQ

DCLK

DIN

CS

BAT

AUX

REF

Y+

Y-

BATTERY

MONITOR

6-TO-1

MUX

12-BIT ADC

SERIAL

DATA

INTERFACE

2.5V

REFERENCE

A2 A1 A0 MEASUREMENT ADC INPUT CONNECTION DRIVERS ON

0 0 0 Temp0 Temp0 —

0 0 1 Y position X+ Y+, Y-

0 1 0 BAT BAT —

0 1 1 Z1 X+ X-, Y+

1 0 0 Z2 Y- X-, Y+

1 0 1 X- position Y+ X-, X+

1 1 0 AUX AUX —

1 1 1 Temp1 Temp1 —

A2 A1 A0

ADC +REF

CONNECTION TO

0 0 1 Y+ Y- X+ Y position Y+, Y-

0 1 1 Y+ X- X+ Z1 position Y+, X-

1 0 0 Y+ X- Y- Z2 position Y+, X-

1 0 1 X+ X- Y+ X position X+, X-

ADC -REF

CONNECTION TO

ADC INPUT

CONNECTION TO

MEASUREMENT

PERFORMED

DRIVER ON

Page 11

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 11

Input Bandwidth and Anti-Aliasing

The ADCs input tracking circuitry has a 25MHz smallsignal bandwidth, so it is possible to digitize highspeed transient events. To avoid high-frequency signals being aliased into the frequency band of interest,

anti-alias filtering is recommended.

Analog Input Protection

Internal protection diodes, which clamp the analog input

to VDDand GND, allow the analog input pins to swing

from GND - 0.3V to V

DD

+ 0.3V without damage. Analog

inputs must not exceed VDDby more than 50mV or be

lower than GND by more than 50mV for accurate conversion. If an off-channel analog input voltage exceeds

the supplies, limit the input current to 50mA. The analog

input pins are ESD protected to ±8kV using the Contact

Discharge method and ±15kV using the Air-Gap

method specified in IEC 61000-4-2.

Touch-Screen Conversion

The MXB7846 provides two conversion methods—differential and single ended. The SER/DFR bit in the control

word selects either mode. A logic 1 selects a singleended conversion, while a logic 0 selects a differential

conversion.

Differential vs. Single Ended

Changes in operating conditions can degrade the accuracy and repeatability of touch-screen measurements.

Therefore, the conversion results representing X and Y

coordinates may be incorrect. For example, in singleended measurement mode, variation in the touch-screen

driver voltage drops results in incorrect input reading.

Differential mode minimizes these errors.

Single-Ended Mode

Figure 3 shows the switching matrix configuration for

Y-coordinate measurement in single-ended mode. The

MXB7846 measures the position of the pointing device

by connecting X+ to IN+ of the ADC, enabling Y+ and

Y- drivers, and digitizing the voltage on X+. The ADC

performs a conversion with REF+ = REF and REF- =

GND. In single-ended measurement mode, the bias to

the touch screen can be turned off after the acquisition

to save power. The on-resistance of the X and Y drivers

results in a gain error in single-ended measurement

mode. Touch-screen resistance ranges from 200Ω to

900Ω (depending on the manufacturer), whereas the

on-resistance of the X and Y drivers is 8Ω (typ). Limit

the touch-screen current to less than 50mA by using a

touch screen with a resistance higher than 100Ω. The

resistive-divider created by the touch screen and the

on-resistance of the X and Y drivers result in both an

offset and a gain shift. Also, the on-resistance of the X

and Y drivers does not track the resistance of the touch

screen over temperature and supply. This results in further measurement errors.

Differential Measurement Mode

Figure 4 shows the switching matrix configuration for

Y-coordinate measurement. The REF+ and REF- inputs

are connected directly to the Y+ and Y- pins, respectively. Differential mode uses the voltage at the Y+ pin

as the REF+ voltage and voltage at the Y- pin as REFvoltage. This conversion is ratiometric and independent

of the voltage drop across the drivers and variation in

the touch-screen resistance. In differential mode, the

touch screen remains biased during the acquisition and

conversion process. This results in additional supply

current and power dissipation during conversion when

compared to the absolute measurement mode.

PEN Interrupt Request (PENIRQ)

Figure 5 shows the block diagram for the PENIRQ function. When used, PENIRQ requires a 10kΩ to 100kΩ

pullup to +VDD. If enabled, PENIRQ goes low whenever

the touch screen is touched. The PENIRQ output can

be used to initiate an interrupt to the microprocessor,

which can write a control word to the MXB7846 to start

a conversion.

Figure 6 shows the timing diagram for the PENIRQ pin

function. The diagram shows that once the screen is

touched while CS is high, the PENIRQ output goes low

after a time period indicated by t

TOUCH

. The t

TOUCH

value changes for different touch-screen parasitic

capacitance and resistance. The microprocessor

receives this interrupt and pulls CS low to initiate a conversion. At this instant, the PENIRQ pin should be

masked, as transitions can occur due to a selected

input channel or the conversion mode. The PENIRQ pin

functionality becomes valid when either the last data bit

is clocked out, or CS is pulled high.

Touch-Pressure Measurement

The MXB7846 provides two methods for measuring the

pressure applied to the touch screen (Figure 7). By

measuring R

TOUCH

, it is possible to differentiate

between a finger or stylus in contact with the touch

screen. Although 8-bit resolution is typically sufficient,

the following calculations use 12-bit resolution demonstrating the maximum precision of the MXB7846.

Page 12

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

12 ______________________________________________________________________________________

Figure 3. Single-Ended Y-Coordinate Measurement

Figure 4. Ratiometric Y-Coordinate Measurement

Figure 5. PENIRQ Functional Block Diagram

V

DD

V

DD

Y+

X+

Y-

GND

+IN

-IN

REF

REF+

12-BIT ADC

REF-

Y+

REF+

X+

Y-

GND

+IN

12-BIT ADC

-IN

REF-

+V

DD

100kΩ

PENIRQ

TOUCH SCREEN

OPEN CIRCUIT

Y+

X+

Y-

ON

PENIRQ

ENABLE

Page 13

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 13

The first method performs pressure measurements

using a known X-plate resistance. After completing

three conversions (X-position, Z1, and Z2), use the following equation to calculate R

TOUCH

:

The second method requires knowing both the X-plate

and Y-plate resistance. Three conversions are required in

this method: the X-position, Y-position, and Z1-position.

Use the following equation to calculate R

TOUCH:

Internal Temperature Sensor

The MXB7846 provides two temperature measurement

options: single-ended conversion and differential conversion. Both temperature measurement techniques rely

on the semiconductor junction’s temperature characteristics. The forward diode voltage (VBE) vs. temperature

is a well-defined characteristic. The ambient temperature can be calculated by knowing the value of VBEat a

fixed temperature and then monitoring the change in

that voltage as the temperature changes. The single

conversion method requires calibration at a known temperature, but only needs a single reading to calculate

R

R

Z

X

Z

R

Y

TOUCH

XPLATE POSITION

YPLATE

POSITION

=

⎛

⎝

⎜

⎞

⎠

⎟

×

⎛

⎝

⎜

⎞

⎠

⎟

×

⎛

⎝

⎜

⎞

⎠

⎟

⎡

⎣

⎢

⎢

⎧

⎨

⎪

⎩

⎪

×

⎛

⎝

⎜

⎞

⎠

⎟

⎧

⎨

⎩

⎫

⎬

⎭

−

−

11

4096

4096

1

4096

RR

XZ

Z

TOUCH XPLATE

POSITION

=

()

×

⎛

⎝

⎜

⎞

⎠

⎟

×

⎛

⎝

⎜

⎞

⎠

⎟

⎡

⎣

⎢

⎢

⎤

⎦

⎥

⎥

−

4096

1

2

1

Figure 7. Pressure Measurement Block Diagram

Figure 6. PENIRQ Timing Diagram

SCREEN TOUCHED HERE

PENIRQ

CS

DCLK

DIN

+

V

-

MEASURE Z1

1 2 3 4 5 6 7 8 1 2 3 1213141516

S A2 A1 A0 M S/D PD1 PD0

INTERRUPT PROCESSOR

t

TOUCH

X+

R

TOUCH

FORCED LINE

X- POSITION

X-

X+

OPEN CIRCUIT

Y+

NO RESPONSE TO TOUCH⎯MASK PENIRQ

MEASURE X- POSITION

Y+

SENSE LINE

Y-

PENIRQ ENABLED

R

SENSE LINE

X-

OPEN CIRCUIT

X+

TOUCH

OPEN CIRCUIT

Y-

Y+

+

V

-

FORCED LINE

R

TOUCH

+

V

-

X-

FORCED LINE

Y-

SENSE LINE

MEASURE Z2

Page 14

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

14 ______________________________________________________________________________________

the ambient temperature. First, the PENIRQ diode forward bias voltage is measured by the ADC with an

address of A2 = 0, A1 = 0, and A0 = 0 at a known temperature. Subsequent diode measurements provide an

estimate of the ambient temperature through extrapolation. This assumes a temperature coefficient of

-2.1mV/°C. The single conversion method results in a

resolution of 0.3°C/LSB and a typical accuracy of ±3°C.

The differential conversion method uses two measurement points. The first measurement (Temp0) is performed with a fixed bias current into the PENIRQ diode.

The second measurement (Temp1) is performed with a

fixed multiple of the original bias current with an

address of A2 = 1, A1 = 1, and A0 = 1. The voltage difference between the first and second conversion is

proportional to the absolute temperature and is

expressed by the following formula:

where T0 (Temp0) and T1 (Temp1) are the conversion

results.

This differential conversion method can provide much

improved absolute temperature measurement; however,

the resolution is reduced to 1.6°C/LSB.

Battery Voltage Monitor

A dedicated analog input (BAT) allows the MXB7846 to

monitor the system battery voltage. Figure 8 shows the

battery voltage monitoring circuitry. The MXB7846 monitors battery voltages from 0 to 6V. An internal resistor

network divides down V

BAT

by 4 so that a 6.0V battery

voltage results in 1.5V at the ADC input. To minimize

power consumption, the divider is only enabled during

the sampling of V

BAT

.

Internal Reference

Enable the internal 2.5V reference by setting PD1 in the

control byte to a logic 1 (see Tables 3 and 4). The

MXB7846 uses the internal reference for single-ended

measurement mode, battery monitoring, temperature

measurement, and for measurement on the auxiliary

input. To minimize power consumption, disable the internal reference by setting PD1 to a logic 0 when performing

ratiometric position measurements. The internal 2.5V reference typically requires 10ms to settle (with no external

load). For optimum performance, connect a 0.1µF capacitor from REF to GND. This internal reference can be overdriven with an external reference. For best performance,

the internal reference should be disabled when the external reference is applied. The internal reference of the

MXB7846 must also be disabled to maintain compatibility

with the MXB7843. To disable the internal reference of the

MXB7846 after power-up, a control byte with PD1 = 0 is

required. (See

Typical Operating Characteristics

for

power-up time of the reference from power down.)

External Reference

Although the internal reference may be overdriven with

an external reference, the internal reference should be

disabled (PD1 = 0) for best performance when using

an external reference. During conversion, an external

reference at REF must deliver up to 40µA DC load current. If the reference has a higher output impedance or

is noisy, bypass it close to the REF pin with a 0.1µF and

a 4.7µF capacitor. Temperature measurements are

always performed using the internal reference.

Digital Interface

Initialization After Power-Up and Starting a

Conversion

The digital interface consists of three inputs, DIN, DCLK,

CS, and one output, DOUT. A logic-high on CS disables

the MXB7846 digital interface and places DOUT in a

high-impedance state. Pulling CS low enables the

MXB7846 digital interface.

TC T T

VREF

() . ( )°= ×

⎛

⎝

⎜

⎞

⎠

⎟

×

⎡

⎣

⎢

⎤

⎦

⎥

−−260 1 0

4096

1000 273

Figure 8. Battery Measurement Functional Block Diagram

BATTERY

0 TO 6.0V

7.5kΩ

BAT

2.5kΩ

DC/DC

CONVERTER

0 TO 1.5V

+2.375V TO +5.25V

V

DD

12-BIT ADC

BATTERY

MEASUREMENT ON

Page 15

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 15

Start a conversion by clocking a control byte into DIN

(Table 3) with CS low. Each rising edge on DCLK

clocks a bit from DIN into the MXB7846’s internal shift

register. After CS falls, the first arriving logic 1 bit

defines the control byte’s START bit. Until the START bit

arrives, any number of logic 0 bits can be clocked into

DIN with no effect.

The MXB7846 is compatible with SPI/QSPI/MICROWIRE

devices. For SPI, select the correct clock polarity and

sampling edge in the SPI control registers of the microcontroller: set CPOL = 0 and CPHA = 0. MICROWIRE,

SPI, and QSPI all transmit a byte and receive a byte at

the same time. The simplest software interface requires

only three 8-bit transfers to perform a conversion (one 8bit transfer to configure the ADC, and two more 8-bit

transfers to read the conversion result; Figure 9).

Simple Software Interface

Make sure the CPU’s serial interface runs in master

mode so the CPU generates the serial clock. Choose a

clock frequency from 500kHz to 2MHz:

1) Set up the control byte and call it TB. TB should be

in the format: 1XXXXXXX binary, where X denotes

the particular channel, selected conversion mode,

and power mode (Tables 3, 4).

2) Use a general-purpose I/O line on the CPU to pull

CS low.

3) Transmit TB and simultaneously receive a byte; call

it RB1.

4) Transmit a byte of all zeros ($00 hex) and simultaneously receive byte RB2.

5) Transmit a byte of all zeros ($00 hex) and simultaneously receive byte RB3.

6) Pull CS high.

Figure 9 shows the timing for this sequence. Byte RB2

and RB3 contain the result of the conversion, padded

with four trailing zeros. The total conversion time is a

function of the serial-clock frequency and the amount of

idle timing between 8-bit transfers.

Digital Output

The MXB7846 outputs data in straight binary format. Data

is clocked out on the falling edge of the DCLK MSB first.

Serial Clock

The external clock not only shifts data in and out, but it

also drives the analog-to-digital conversion steps.

BUSY pulses high for one clock period after the last bit

of the control byte. Successive-approximation bit decisions are made and appear at DOUT on each of the

next 12 DCLK falling edges. BUSY and DOUT go into a

high-impedance state when CS goes high.

The conversion must complete in 500µs or less; if not,

droop on the sample-and-hold capacitors can degrade

conversion results.

Data Framing

The falling edge of CS does not start a conversion. The

first logic high clocked into DIN is interpreted as a start

bit and defines the first bit of the control byte. A conversion starts on DCLK’s falling edge, after the eighth bit of

the control byte is clocked into DIN.

The first logic 1 clocked into DIN after bit 6 of a conversion in progress is clocked onto the DOUT pin and is

treated as a START bit (Figure 10).

Once a start bit has been recognized, the current conversion must be completed.

Table 3. Control Byte Format

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

START A2 A1 A0 MODE SER/DFR PD1 PD0

BIT NAME DESCRIPTION

7 START Start bit

6A2

5A1

4A0

3 MODE Conversion resolution: 1 = 8 bits, 0 = 12 bits

2 SER/DFR Conversion mode: 1 = single ended, 0 = differential

1 PD1

0 PD0

Address (Tables 1 and 2)

Power-down mode (Table 4)

Page 16

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

16 ______________________________________________________________________________________

The fastest the MXB7846 can run with CS held continuously low is 15 clock conversions. Figure 10 shows the

serial-interface timing necessary to perform a conversion every 15 DCLK cycles. If CS is connected low and

DCLK is continuous, guarantee a start bit by first clocking in 16 zeros.

Most microcontrollers (µCs) require that data transfers

occur in multiples of eight DCLK cycles; 16 clocks per

conversion is typically the fastest that a µC can drive the

MXB7846. Figure 11 shows the serial interface timing necessary to perform a conversion every 16 DCLK cycles.

8-Bit Conversion

The MXB7846 provides an 8-bit conversion mode

selected by setting the MODE bit in the control byte

high. In the 8-bit mode, conversions complete four

clock cycles earlier than in the 12-bit output mode,

resulting in 25% faster throughput. This can be used in

conjunction with serial interfaces that provide 12-bit

transfers, or two conversions could be accomplished

with three 8-bit transfers. Not only does this shorten each

conversion by 4 bits, but each conversion can also

occur at a faster clock rate since settling to better than 8

bits is all that is required. The clock rate can be as much

as 25% faster. The faster clock rate and fewer clock

cycles combine to increase the conversion rate.

Table 4. Power-Mode Selection

Figure 9. Conversion Timing, 24-Clock per Conversion, 8-Bit Bus Interface

SUPPLY CURRENT (typ) (µA)

PD1 PD0 PENIRQ STATUS

0 0 Enabled ADC is ON during conversion, OFF between conversion 200 1

0 1 Disabled ADC is always ON, reference is always OFF 200 200

1 0 Disabled ADC is always OFF, reference is always ON 400 400

1 1 Disabled ADC is always ON, reference is always ON 600 600

CS

T

B

t

ACQ

R

B2

DURING

CONVERSION

R

B3

AFTER

CONVERSION

DCLK

DIN

BUSY

DOUT

A/D STATE

1891216

SA2A1A0

(START)

DRIVERS 1 AND 2

(SER/DFR HIGH)

DRIVERS 1 AND 2

(SER/DFR LOW)

IDLE

SER/

MODE

PD1 PD0

DFR

ACQUIRE CONVERSION IDLE

RB1

(MSB) (LSB)

ACQUIRE

OFF

OFF OFFON

ON OFF

4567891011 3210

CONVERSION

20 244

IDLEIDLE

Page 17

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 17

Data Format

The MXB7846 output data is in straight binary format as

shown in Figure 12. This figure shows the ideal output

code for the given input voltage and does not include

the effects of offset, gain, or noise.

Applications Information

Basic Operation of the MXB7846

The 4-wire touch-screen controller works by creating a

voltage gradient across the vertical or horizontal resistive network connected to the MXB7846, as shown in

the

Typical Application Circuit

. The touch screen is

biased through internal MOSFET switches that connect

each resistive layer to VDDand ground on an alternate

basis. For example, to measure the Y position when a

pointing device presses on the touch screen, the Y+

and Y- drivers are turned on, connecting one side of

the vertical resistive layer to V

DD

and the other side to

ground. In this case, the horizontal resistive layer functions as a sense line. One side of this resistive layer

gets connected to the X+ input, while the other side is

left open or floating. The point where the touch screen

is pressed brings the two resistive layers in contact and

forms a voltage-divider at that point. The data converter

senses the voltage at the point of contact through the

X+ input and digitizes it. The horizontal layer resistance

does not introduce any error in the conversion because

no DC current is drawn.

The conversion process of the analog input voltage to

digital output is controlled through the serial interface

between the A/D converter and the µP. The processor

controls the MXB7846 configuration through a control

Figure 11. 16-Clock/Conversion Timing

Figure 10. 15-Clock/Conversion Timing

CS

1 8 15 1 8 15 1

DCLK

DIN

S CONTROL BYTE 0 CONTROL BYTE 1 CONTROL BYTE 2SS

DOUT

BUSY

CS

1 8 16 1 8 16

DCLK

DIN

DOUT

BUSY

CONTROL BYTE 0 CONTROL BYTE 1SS

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

CONVERSION RESULT 0 CONVERSION RESULT 1

CONVERSION RESULT 0 CONVERSION RESULT 1

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

B11 B10 B9 B8 B7 B6B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

. . .

. . .

. . .

. . .

. . .

Page 18

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

18 ______________________________________________________________________________________

byte (see Tables 3 and 4). Once the processor instructs

the MXB7846 to initiate a conversion, the MXB7846

biases the touch screen through the internal switches at

the beginning of the acquisition period. The voltage

transient at the touch screen needs to settle down to a

stable voltage before the acquisition period is over.

After the acquisition period is over, the A/D converter

goes into a conversion period with all internal switches

turned off if the device is in single-ended mode. If the

device is in differential mode, the internal switches

remain on from the start of the acquisition period to the

end of the conversion period.

Power-On Reset

When power is first applied, internal power-on circuitry

resets the MXB7846. Allow 10µs for the first conversion

after the power supplies stabilize. If CS is low, the first

logic 1 on DIN is interpreted as a start bit. Until a conversion takes place, DOUT shifts out zeros. On powerup, allow time for the reference to stabilize.

Power Modes

Save power by placing the converter in one of two lowcurrent operating modes or in full power down between

conversions. Select the power-down mode through

PD1 and PD0 of the control byte (Tables 3 and 4).

The software power-down modes take effect after the

conversion is completed. The serial interface remains

active while waiting for a new control byte to start a conversion and switches to full-power mode. After complet-

ing its conversion, the MXB7846 enters the programmed

power mode until a new control byte is received.

The power-up wait before conversion period is dependent on the power-down state. When exiting software

low-power modes, conversion can start immediately

when running at decreased clock rates. Upon poweron reset, the MXB7846 is in power-down mode with

PD1 = 0 and PD0 = 0. When exiting software shutdown,

the MXB7846 is ready to perform a conversion in 10µs

with an external reference. When using the internal reference, allow enough time for reference to settle to 12bit accuracy when exiting full power-down mode, as

shown in the

Typical Operating Characteristics

.

PD1 = 1, PD0 = 1

In this mode, the MXB7846 is always powered up and

both the reference and the ADC are always on. The

device remains fully powered after the current conversion completes.

PD1 = 0, PD0 = 0

In this mode, the MXB7846 powers down after the current conversion completes or on the next rising edge of

CS, whichever occurs first. The next control byte

received on DIN powers up the MXB7846. At the start

of a new conversion, it instantly powers up. When each

conversion is finished, the part enters power-down

mode, unless otherwise indicated. The first conversion

after the ADC returns to full power is valid for differential conversions and single-ended measurement conversions when using an external reference.

When operating at full speed and 16 clocks per conversion, the difference in power consumption between

PD1 = 0, PD0 = 1, and PD1 = 0, PD0 = 0 is negligible.

Also, in the case where the conversion rate is

decreased by slowing the frequency of the DCLK input,

the power consumption between these two modes is

not very different. When the DCLK frequency is kept at

the maximum rate during a conversion, conversions are

done less often. There is a significant difference in

power consumption between these two modes.

PD1 = 1, PD0 = 0

In this mode, the MXB7846 is powered down. This

mode becomes active after the current conversion

completes or on the next rising edge of CS, whichever

occurs first. The next command byte received on the

DIN returns the MXB7846 to full power. The first conversion after the ADC returns to full power is valid.

PD1 = 0, PD0 = 1

This mode turns the internal reference off and leaves

the ADC on to perform conversions using an external

reference.

Figure 12. Ideal Input Voltages and Output Codes

OUTPUT CODE

11…111

11…110

11…101

00…011

00…010

00…001

00…000

123 FS0

INPUT VOLTAGE (LSB) = [(V

FULL-SCALE

TRANSITION

+IN

) - (V

FS-3/2LSB

)]

-IN

FS = (V

1LSB =

REF+

(V

REF+

4096

- V

)

REF-

- V

)

REF-

Page 19

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 19

Hardware Power-Down

CS also places the MXB7846 into power-down. When

CS goes HIGH, the MXB7846 immediately powers

down and aborts the current conversion. The internal

reference does not turn off when CS goes high. To disable the internal reference, an additional command

byte is required before CS goes high (PD1 = 0). Set

PD1 = 0 before CS goes high.

Touch-Screen Settling

There are two key touch-screen characteristics that can

degrade accuracy. First, the parasitic capacitance

between the top and bottom layers of the touch screen

can result in electrical ringing. Second, vibration of the

top layer of the touch screen can cause mechanical

contact bouncing.

External filter capacitors may be required across the

touch screen to filter noise induced by the LCD panel

or backlight circuitry, etc. These capacitors lengthen

the settling time required when the panel is touched

and can result in a gain error, as the input signal may

not settle to its final steady-state value before the ADC

samples the inputs. Two methods to minimize or eliminate this issue are described below.

One option is to lengthen the acquisition time by stopping

or slowing down DCLK, allowing for the required touchscreen settling time. This method solves the settling time

problem for both single-ended and differential modes.

The second option is to operate the MXB7846 in the differential mode only for the touch screen, and perform

additional conversions with the same address until the

input signal settles. The MXB7846 can then be placed

in the power-down state on the last measurement.

Connection to Standard Interface

MICROWIRE Interface

When using the MICROWIRE- (Figure 13) or SPI-compatible interface (Figure 14), set the CPOL = CPHA = 0.

Two consecutive 8-bit readings are necessary to obtain

the entire 12-bit result from the ADC. DOUT data transitions occur on the serial clock’s falling edge and are

clocked into the µP on the DCLK’s rising edge. The first

8-bit data stream contains the first 8 bits of the current

conversion, starting with the MSB. The second 8-bit

data stream contains the remaining 4 result bits followed by 4 trailing zeros. DOUT then goes high impedance when CS goes high.

QSPI/SPI Interface

The MXB7846 can be used with the QSPI/SPI interface

using the circuit in Figure 14 with CPOL = 0 and CPHA

= 0. This interface can be programmed to do a conversion on any analog input of the MXB7846.

TMS320LC3x Interface

Figure 15 shows an example circuit to interface the

MXB7846 to the TMS320. The timing diagram for this

interface circuit is shown in Figure 16.

Use the following steps to initiate a conversion in the

MXB7846 and to read the results:

1) The TMS320 should be configured with CLKX (trans-

mit clock) as an active-high output clock and CLKR

(TMS320 receive clock) as an active-high input

clock. CLKX and CLKR on the TMS320 are connected to the MXB7846 DCLK input.

Figure 13. MICROWIRE Interface

Figure 14. QSPI/SPI Interface

Figure 15. TMS320 Serial Interface

I/O

SCK

MISO

MICROWIRE

MOSI

MASKABLE

INTERRUPT

I/O

SCK

MISO

QSPI/SPI

MOSI

MASKABLE

INTERRUPT

XF

CLKX

CLKR

TMS320LC3x

DX

DR

FSR

CS

DCLK

DOUT

MXB7846

DIN

BUSY

CS

DCLK

DOUT

MXB7846

DIN

BUSY

CS

SCLK

MXB7846

DIN

DOUT

BUSY

Page 20

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

20 ______________________________________________________________________________________

2) The MXB7846’s CS pin is driven low by the TMS320’s

XF I/O port to enable data to be clocked into the

MXB7846’s DIN pin.

3) An 8-bit word (1XXXXXXX) should be written to the

MXB7846 to initiate a conversion and place the

device into normal operating mode. See Table 3 to

select the proper XXXXXXX bit values for your specific applications.

4) The MXB7846’s BUSY output is monitored through

the TMS320’s FSR input. A falling edge on the BUSY

output indicates that the conversion is in progress

and data is ready to be received from the device.

5) The TMS320 reads in 1 data bit on each of the next

16 rising edges of DCLK. These bits represent the

12-bit conversion result followed by 4 trailing bits.

6) Pull CS high to disable the MXB7846 until the next

conversion is initiated.

Layout, Grounding, and Bypassing

For best performance, use printed circuit (PC) boards

with good layouts; wire-wrap boards are not recommended. Board layout should ensure that digital and analog

signal lines are separated from each other. Do not run

analog and digital (especially clock) lines parallel to one

another, or digital lines underneath the ADC package.

Establish a single-point analog ground (star ground

point) at GND. Connect all analog grounds to the star

ground. Connect the digital system ground to the star

ground at this point only. For lowest noise operation,

minimize the length of the ground return to the star

ground’s power supply.

Power-supply decoupling is also crucial for optimal

device performance. A good way to decouple analog

supplies is to place a 10µF tantalum capacitor in parallel with a 0.1µF capacitor bypassed to GND. To maximize performance, place these capacitors as close as

possible to the supply pin of the device. Minimize

capacitor lead length for best supply-noise rejection. If

the supply is very noisy, a 10Ω resistor can be connected in series as a lowpass filter.

While using the MXB7846, the interconnection between

the converter and the touch screen should be as short

as possible. Since touch screens have low resistance,

longer or loose connections may introduce error. Noise

can also be a major source of error in touch-screen

applications (e.g., applications that require a backlight

LCD panel). EMI noise coupled through the LCD panel

to the touch screen may cause flickering of the converted data. Utilizing a touch screen with a bottom-side

metal layer connected to ground decouples the noise

to ground. In addition, the filter capacitors from Y+, Y-,

X+, and X- inputs to ground also help further reduce

the noise. Caution should be observed for settling time

of the touch screen, especially operating in the singleended measurement mode and at high data rates.

Definitions

Integral Nonlinearity

Integral nonlinearity (INL) is the deviation of the values

on an actual transfer function from a straight line. This

straight line can be either a best-straight-line fit or a line

drawn between the endpoints of the transfer function,

once offset and gain errors have been nullified. The

static linearity parameters for the MXB7846 are measured using the end-point method.

MXB7846

Figure 16. MXB7846-to-TMS320 Serial Interface Timing Diagram

CS

DCLK

DIN

START A2 A1 A0 MODE SER/DEF PD1 PD0

BUSY

DOUT

HIGH IMPEDANCE

MSB B10 B1 B0

HIGH IMPEDANCE

Page 21

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 21

Differential Nonlinearity

Differential nonlinearity (DNL) is the difference between

an actual step width and the ideal value of 1LSB. A

DNL error specification of less than 1LSB guarantees

no missing codes and a monotonic transfer function.

Aperture Jitter

Aperture jitter (tAJ) is the sample-to-sample variation in

the time between the samples.

Aperture Delay

Aperture delay (tAD) is the time defined between the

falling edge of the sampling clock and the instant when

an actual sample is taken.

Chip Information

TRANSISTOR COUNT: 12,000

PROCESS: 0.6µm BiCMOS

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

+V

DD

SERIAL/CONVERSION CLOCK

CHIP SELECT

SERIAL DATA IN

CONVERTER STATUS

SERIAL DATA OUT

PEN INTERRUPT

50kΩ

X+

Y+

X-

Y-

GND

BAT

AUX

VOLTAGE

REGULATOR

AUXILIARY

INPUT

TO BATTERY

TOUCH

SCREEN

2.375V TO 5.5V

1μF TO 10μF

OPTIONAL

0.1μF

0.1μF

MXB7846

DCLK

CS

DIN

PENIRQ

BUSY

DOUT

+V

DD

REF

Typical Application Circuit

Page 22

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

22 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QSOP.EPS

Page 23

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

______________________________________________________________________________________ 23

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

TSSOP4.40mm.EPS

PACKAGE OUTLINE, TSSOP 4.40mm BODY

21-0066

1

I

1

Page 24

MXB7846

2.375V to 5.25V, 4-Wire Touch-Screen Controller

with Internal Reference and Temperature Sensor

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

2 1/08 Changed input configuration, differential reference mode 10

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Loading...

Loading...