Page 1

2-265

Features

• Loop Start Trunk Interface

• 600Ω & 900Ω Input Impedance

• 2-4 Wire Conversion

• Line state Detection Outputs:

• - Forward Loop

• - Reverse Loop

• - Ringing Voltage

• - Switch Hook

• One Relay Driver

• On-Hook Reception

• Small footprint area

• Meets FCC Part 68 Leakage Current

Requirements

Applications

Interface to Central Office for:

• PABX

• Key Telephone Systems

• Channel Bank

• Voice Mail

• Ter minal Equipment

• Digital Loop Carrier

• Optical Multiplexer

Description

The Mitel MH88634-2 Central Office Interface Circuit

trunk provides a complete analogue and signalling

link between audio switching equipment and a

telephone Line. The device is available in a single in

line package for high packing densities or with a lead

frame formed at 90° for low clearance applications.

The device is fabricated as a thick film hybrid

incorporating various technologies for optimum

circuit design and very high reliability.

This part supercedes the MH88634-2 and is pin for pin

compatible.

We advise that the B rev parts are fully tested.

However, we do not expect to see changes between

MH88634-2 and MH88634BV-2.

The component design has been changed to

improve the general performance of the part. It is

also now capable of operating at a 24V battery.

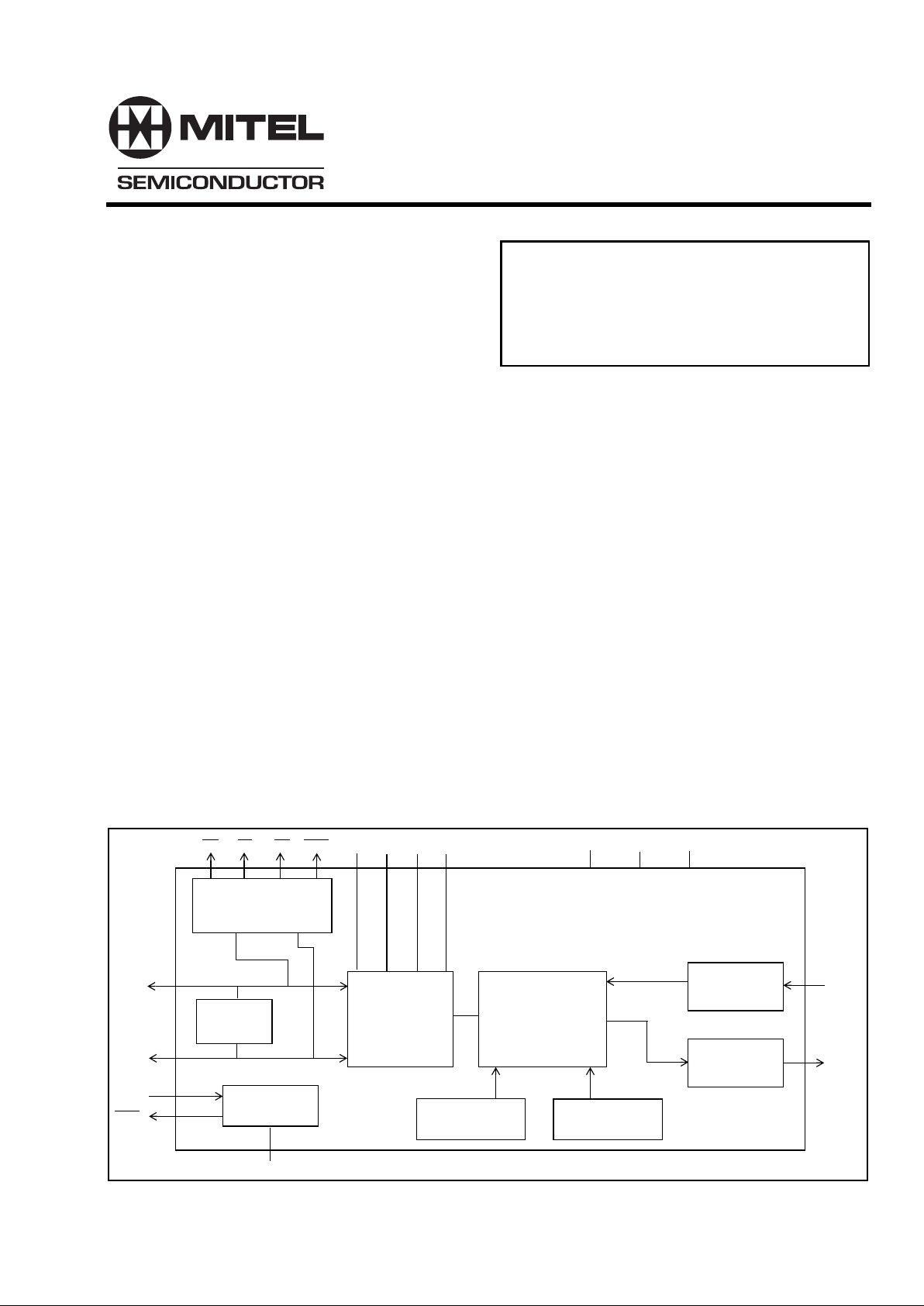

Figure 1 - Functional Block Diagram

Status

Detection

Receive

Gain

Transmit

Gain

2 - 4 Wire

Hybrid

Dummy

Ringer

Line

Termination

Loop Relay

Driver

Impedance

Matching

Network

Balance

XLA XLB XLC

XLD

LRC

LRD

VRLY

RING

TIP

RV

VCC

RX

TX

VEE AGND

FL RL

SHK

DS5061 ISSUE 6 January 1999

Ordering Information

MH88634BV-2 21 Pin SIL Package

MH88634BT-2 21 Pin 90° L/F Package

MH88634BV-4 21 Pin SIL Package

0°C to 70°C

MH88634B

Central Office Interface Circuit

Advance Information

Page 2

MH88634B Advance Information

2-266

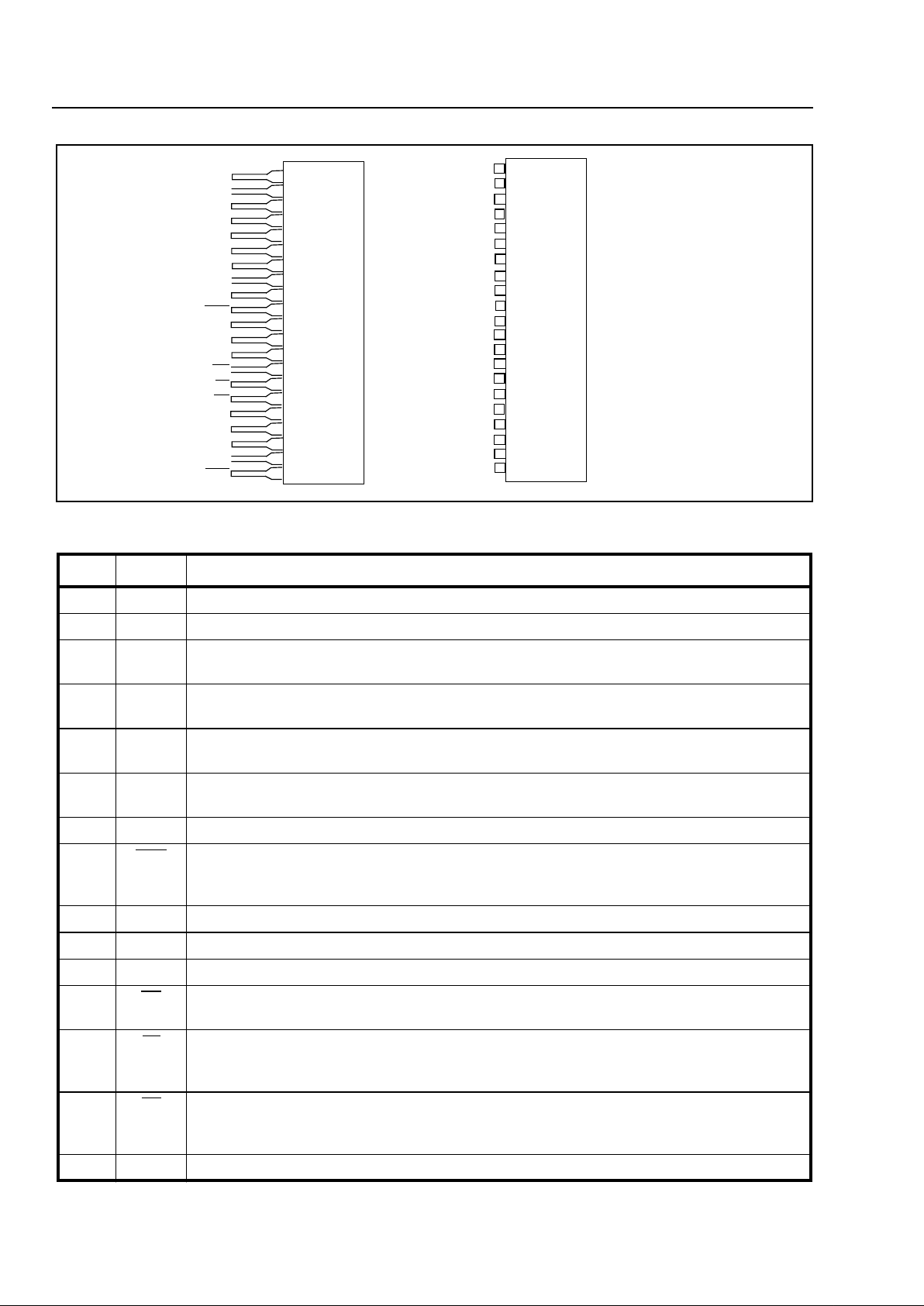

Figure 2 - Pin Connections

Pin Description

Pin # Name Description

1 TIP Tip Lead. Connects to the "Tip" lead of a Telephone Line.

2 RING Ring Lead. Connects to the "Ring" lead of a Telephone Line.

3 XLA Loop Relay Contact A. Connects to XLB through the Loop relay (K1) contacts when the

relay is activated.

4 XLD Loop Relay Contact D. Connects to XLC through the loop relay (K1) contacts, when the

relay is activated.

5 XLB Loop Relay Contact B. Connects to XLA through the loop relay (K1) contacts, when the

relay is activated.

6 XLC Loop Relay Contact C. Connects to XLD through the loop relay (K1) contacts, when the

relay is activated.

7-9 IC Internal Connection. No connection should be made to this pin.

10 SHK Switch Hook (Output). A logic 0 indicates the presence of forward or reverse battery

voltage when LRC is logic 0 and the presence of forward or reverse loop current when LRC

is logic 1.

11 RX Receive (Input). 4-Wire ground (AGND) referenced analog input.

12 VEE Negative Supply Voltage. -5V DC

13 TX Transmit (Output). 4-Wire ground (AGND) referenced analog output.

14 RV Ringing Voltage Detect (Output). A logic low indicates that ringing voltage is across the Tip

and Ring leads.

15 FL Forward Loop Detect (Output). In the on-hook state, a logic 0 output indicates that

forward loop battery is present. In the off-hook state, a logic 0 indicates that forward loop

current is present.

16 RL Reverse Loop Detect (Output). In the on-hook state, a logic 0 output indicates that

reverse loop battery is present. In the off-hook state, a logic 0 output indicates that reverse

loop current is present.

17 VCC Positive Supply Voltage. +5V DC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

TIP

RING

XLA

XLB

XLC

IC

IC

IC

RX

VEE

TX

RV

FL

RL

VCC

AGND

LRC

VRLY

LRD

21

XLD

SHK

21

20

19

18

17

16

15

14

13

12

11

10

9

8

6

5

4

3

2

1

7

Page 3

Advance Information MH88634B

2-267

18 AGND Analog Ground. 4-wire ground (AGND). Normally connected to system ground.

19 LRC Loop Relay Control (Input). A logic 1 activates the Loop Relay Driver output (LRD).

20 VRLY Relay Positive Supply Voltage. Typically +5V. Connects to the relay supply voltage.

21 LRD Loop Relay Drive (Output). Connects to the Loop Relay Coil. When LRC is at a logic 1 an

open collector output at LRD sinks current and energizes the relay.

Pin Description (continued)

Functional Description

The MH88634 is a Central Office Interface Circuit

(COIC). It is used to correctly terminate a Central

Office 2-wire telephone line. The device provides a

signalling link and a 2-4 Wire line interface between

the Telephone Line and subscr iber equipment. The

subscriber equipment can include Private Branch

Exchanges (PBXs), Key Telephone Systems,

Terminal Equipment, Digital Loop Carriers and

Wireless Local Loops.

All descriptions assume that the device is connected

as in the application circuit shown in Figure 3.

Isolation Barrier

The MH88634 provides an isolation barrier which is

designed to meet FCC Part 68 (November 1987)

Leakage Current Requirements.

External Protection Circuit

An external Protection Circuit Device assists in

preventing damage to the device and the

subscriber’s equipment, due to over-voltage

conditions. The type of protection required is

dependant upon the application and regulatorary

standards. Further details should be obtained from

the specific country’s regulatorary body. Typically

you will need lightening protection supplied by

resettable fuses or PTCTM and mains crossover

protection via a foldover diode.

Suitable Markets

The MH88634BV-2/BT-2 has fixed 600Ω line and

network balance impedance for use in North

America and Asia.

The MH88634BV-4 has a fixed 900R impedance and

is also suitable for some applications in North and

South America

Line Termination

When LRC is at a logic 1, LRD will sink current

which energizes the Loop Relay (K1), connecting

XLA to XLB and XLC to XLD. This places a line

termination across Tip and Ring. The device can be

considered to be in an off-hook state and DC loop

current will flow. The line termination consists of a

DC resistance and an AC impedance. When LRC is

at a logic 0, the line termination is removed from

across Tip and Ring.

An internal Dummy Ringer is permanently connected

across Tip and Ring which is a series AC load of

(17kΩ+330nF). This represents a mechanical

telephone ringer and allows ringing voltages to be

sensed. This load can be considered negligible

when the line has been terminated.

Depending on the Network Protocol being used the

Line Termination can terminate an incoming call,

seize the line for an outgoing call, or if applied and

disconnected at the correct rate can be used to

generate dial pulse signals.

The DC line termination circuitry provides the line

with an active DC load termination which is

equivalent to a DC resistance of 280Ω at 20mA

Ringing Equivalent Number

The Ringing Equivalent Number (REN) is application

specific. See the governing regulatory body

specification for details.

Input Impedance

The input impedance (Zin) is the AC impedance that

the MH88634 places across Tip and Ring to

terminate the Telephone line. This is fixed at 600Ω

on the -2 variant and 900R on the -4.

Page 4

MH88634B Advance Information

2-268

Network Balance Impedance

The MH88634BV-2/BT-2’s Network Balance

Impedance is fixed at 600Ω.

The MH88634BV-4 Network Balance Impedance is

fixed at 900R.

2-4 Wire Conversion

The device converts the balanced 2-Wire input,

presented by the line at Tip and Ring, to a ground

referenced signal at TX. This circuit operates with or

without loop current; signal reception with no loop

current is required for on-hook reception enabling the

detection of Caller Line Identification (CLI) signals.

Conversely the device converts the ground

referenced signal input at RX, to a balanced 2-Wire

signal across Tip and Ring.

The 4-Wire side (TX and RX) can be interfaced to a

filter/codec, such as the Mitel MT896X, for use in

digital voice switched systems

During full duplex transmission, the signal at Tip and

Ring consists of both the signal from the device to

the line and the signal from the line to the device.

The signal input at RX, being sent to the line, must

not appear at the output TX. In order to prevent this,

the device has an internal cancellation circuit. The

measure of attenuation is Transhybrid Loss (THL).

Transmit and Receive Gain

The Transmit Gain of the device is the gain from the

balanced signal across Tip and Ring to the ground

referenced signal at TX. It is set at 0dB.

The Receive Gain of the device is the gain from the

ground referenced signal at RX to the balanced

signal across Tip and Ring. It is set at -2dB.

Supervision Features

Line Status Detection Outputs

The MH88634 supervisory circuitry provides the

signalling status outputs which are monitored by the

system controller. The supervisory circuitry is

capable of detecting: Ringing Voltage; Forward and

Reverse loop battery; Forward and Reverse loop

current; and Switch Hook.

Ringing Voltage Detect Output (RV)

The RV output provides a logic 0 when ringing

voltage is detected across Tip and Ring. This

detector includes a filter which ensures that the

output toggles at the ringing cadence and not at the

ringing frequency. Typically this output switches to a

logic 0 after 50ms of applied ringing voltage and

remains at a logic 0 for 50ms after ringing voltage is

removed.

The threshold is different on the two variants. The

900R part has been designed to meet the ring

sensitivity requirements of TR57, 30 not detecting

ringin below 35Vrms.

Forward Loop and Reverse Loop Detect Outputs

(FL & RL)

The FL output provides a logic 0 when either forward

loop battery or forward loop current is detected, that

is the Ring pin voltage is more negative than the Tip

pin voltage.

The RL output provides a logic 0 when either reverse

loop battery or reverse loop current is detected, that

is the Tip pin voltage is more negative than the Ring

pin voltage.

Switch Hook (SHK)

The SHK output is active if either forward loop or

reverse loop current is detected, or if forward or

reverse battery voltage is detected.

Control Input

The MH88634 accepts a control signal from the

system controller at the Loop Relay Control input

(LRC). This energises the relay drive output Loop

Relay Drive (LRD). The output is active low and has

an internal clamp diode to VRLY.

The intended use of this relay driver is to add and

remove the Line Termination from across Tip and

Ring, as shown in Figure 3.

If this Control input and the Supervisory Features are

used as indicated in Figure 3, Loop-Start Signalling

can be implemented.

Mechanical Data

See Figure 9 for details of the mechanical

specification.

Page 5

Advance Information MH88634B

2-269

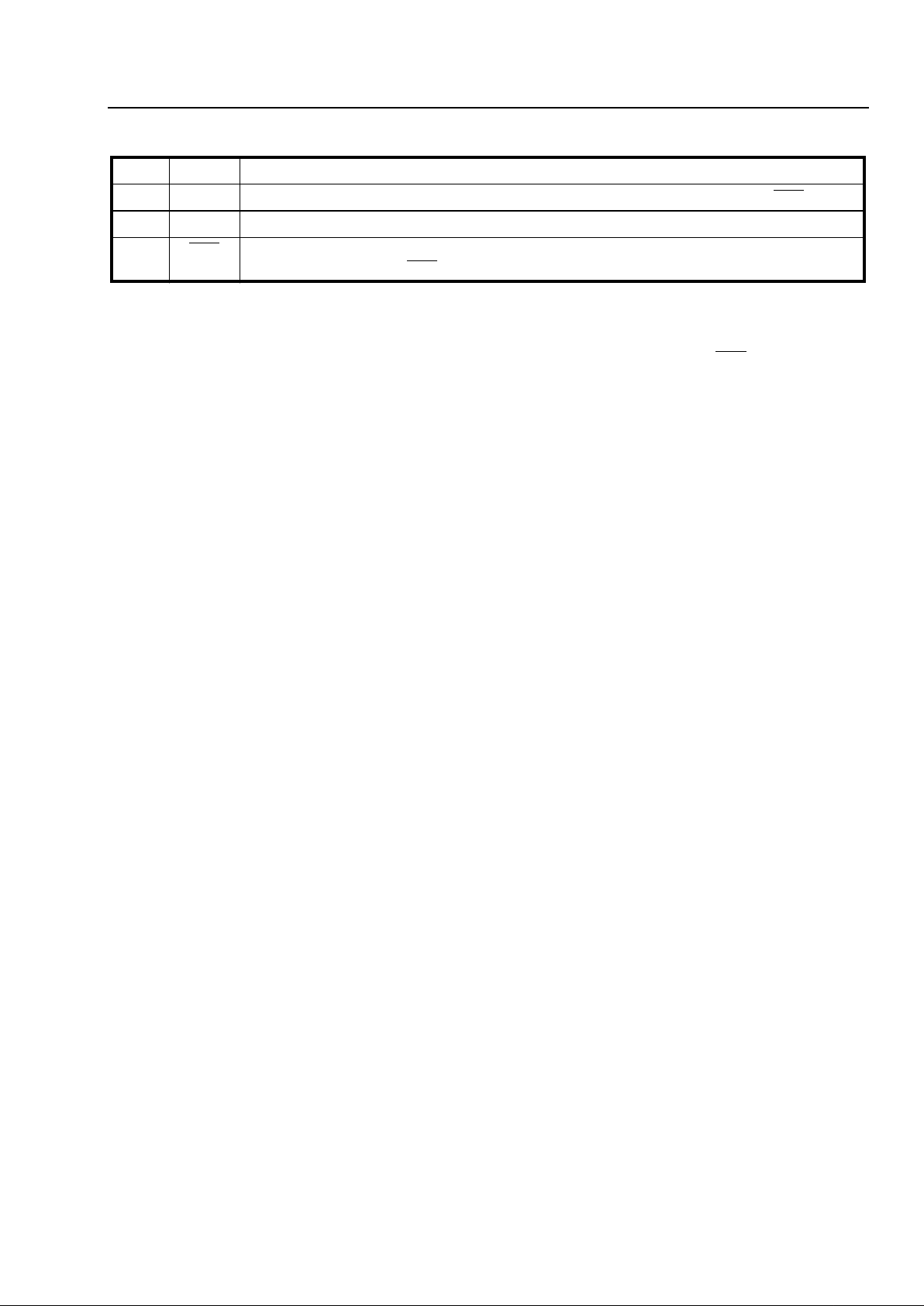

Figure 3 - Typical LS Application Circuit

MH88634

Analog Out

Analog In

Ringing Detect

Forward Loop

Reverse Loop

Switch Hook

-5V

+5V

K1

Protection

Circuit

Tip

Ring

Loop Relay Control

TIP

RING

LRD

VRLY

LRC

XLA

XLB

XLC

XLD

VCC

AGND

VEE

SHK

RL

FL

RV

RX

TX

K1

NOTES:

1) K1 Electro Mechanical 2 Form A

K1

C1

C2

2) C1 and C2 are decoupling capacitors

5

3

15

16

6

10

4

18

12

14

19

21

2

20

11

13

17

1

+5V

Page 6

MH88634B Advance Information

2-270

*Exceeding these values may cause permanent damage. Functional operation under these conditions is not implied.

‡ Typical figures are at 25°C with nominal 5V supplies and are for design aid only.

s

† Electrical Characteristics are over recommended operating conditions unless otherwise stated.

‡ Typical figures are at 25°C with nominal 5V supplies and are for design aid only.

Absolute Maximum Ratings*

Parameters Sym Min Max Units Comments

1 DC Supply Voltages V

CC

V

EE

-0.3

0.3

7

-7

V

V

2 DC Ring Relay Voltage V

RLY

-0.3 18 V

3 Storage Temperature

T

S

-55 +125 ˚C

4 Ring Trip Current I

TRIP

180 mArms 250ms 10% duty cycle or 500ms single shot

Recommended Operating Conditions

Parameters Sym Min Typ

‡

Max Units

1 DC Supply Voltages V

CC

V

EE

4.75

-4.75

5.0

-5.0

5.25

-5.25

V

V

2 DC Ring Relay Voltage V

RLY

5.0 15 V

3 Operating Temperature T

OP

02570˚C

DC Electrical Characteristics

†

Characteristics Sym Min Typ

‡

Max Units Test Conditions

1 Supply Current I

CC

I

EE

5

2.5

13

13

mA

mA

2 Power Consumption PC 37.5 137 mW V

BAT

not connected

3 FL

RL

SHK

RV

Low Level Output Voltage

High Level Output Voltage

V

OL

V

OH

2.4

0.5 V

V

IOL = 4mA

IOH= 0.4mA

4 LRD Sink Current, Relay to

V

CC

Clamp Diode Current

I

OL

I

CD

100

150

mAmAVOL = 0.35V not

continuous, LRC=5V

5 LRC Low Level Input Voltage

High Level Input Voltage

V

IL

V

IH

2.0

0.8 V

V

6 LRC High Level Input Current

Low Level Input Current

I

IH

I

IL

40

40

µAµAVIH = 5.0V

Page 7

Advance Information MH88634B

2-271

† Electrical Characteristics are over recommended operating conditions unless otherwise stated.

‡ Typical figures are at 25°C with nominal 5V supplies and are for design aid only.

Note 1: Maximum figure of 282Ω at 0°C

DC Electrical Characteristics

†

Characteristics Symbol Min Typ

‡

Max Units Test Conditions

1 Ringing Voltage VR 40 90 150 V

rms

-2 Variant only

17 to 68Hz

2 Detect

No Detect

VR 60 106

35

V

rms

-4 Variant only

-4 Variant only

16-33Hz

(TR57 compliant)

3 Operating Loop Current 16 70 mA

4 Off-Hook DC Resistance 270 280 Ω @ 20mA Note 1

5 Leakage Current

(Tip-Ring to AGND)

7 mArms @ 1000VAC

6 SHK & FL Threshold

Tip-Ring (On-hook)

Tip-Ring Current (Off-Hook)

12

5

21

15

VdcmALRC = 0V

LRC = 5V

7 SHK & RL Threshold

Tip-Ring (On-Hook)

Tip-Ring Current (Off-Hook)

12

-5

21

-15

VdcmALRC = 0V

LRC = 5V

Page 8

MH88634B Advance Information

2-272

† Electrical Characteristics are over recommended operating conditions unless otherwise stated.

‡ Typical figures are at 25°C with nominal 5V supplies and are for design aid only.

AC Electrical Characteristics

†

Characteristics Symbol Min Typ

‡

Max Units Test Conditions

1 2-wire Input Impedance Zin 600

900

Ω -2 Variant

-4 Variant

2 Return Loss at 2-wire RL

20 29 dB

Test Circuit as Fig 6

200-3400 Hz

3 Longitudinal to Metallic

Balance 58

55

53

60

60

58

dB

dB

dB

Test Circuit as Fig 7

200Hz

1000Hz

3400Hz

4 Transhybrid Loss THL 20 27 dB 200-3400Hz

5 Gain, 2 wire to TX

Relative Gain

-0.25

-0.3

0

0

0.25

0.3

dB

dB

Test Circuit as Fig 4

1000Hz

200-3400Hz

6 Gain, Rx to 2 wire

Relative Gain

-2.25

-0.3

-2

0

-1.75

0.3

dB

dB

Test Circuit as Fig 5

1000Hz

200-3400Hz

7 Input impedance at RX 10 kΩ

8 Output impedance at TX 5 Ω

9 Signal Overload Level

at 2-wire

at TX

4.0

1.7

dBm

dBm

% THD < 5% @ 20mA

10 Total Harmonic Distortion

at 2-wire

at TX

THD

1.0

1.0

%

%

Input 0.5V, 1kHz @

RX

Input 0.5V, 1kHz @

Tip-Ring

11 Idle Channel Noise

at 2-Wire

at TX

NC

15

15

16.5

16.5

dBrnC

dBrnC

12 Power Supply Rejection Ratio

at 2-wire and TX

V

CC

V

EE

PSRR

25

25

48

47

dB

dB

Ripple 0.1V, 1kHz

13 On-Hook Gain, 2-Wire to TX

Relative to Off-Hook Gain

-1 0 1 dB Input 1000Hz @ 0.5V

14 Met. to Long. Balance

-2 Variant

-4 Variant

60

40

55

40

62

48

62

48

Test Circuit as Fig. 8

200-1000Hz

1000-3400Hz

200-1000Hz

1000-3400Hz

15 Common Mode Rejection

Ratio

CMRR 48 55 dB Test Circuit as Fig. 7

1000Hz, FL = 0V,

I

Loop

= 25mA

Page 9

Advance Information MH88634B

2-273

Figure 4 - 2-4 Wire Gain Test Circuit

Figure 5 - 4-2 Wire Gain Test Circuit

~

100uF

RING

TIP

XLA

XLB

XLC

XLD

Vs = 0.5V

600

Ω

AGND

VCC

VEE

RX

TX

100uF

+5V

-5V

I = 25mA

10H 300Ω

10H 300Ω

+

+

Gain = 20 * Log (Vtx/Vs)

-V

V

tx

V

~

Vs = 0.5V

Z = 600Ω

Gain = 20 * Log (Vz/Vs)

100uF

-V

RING

TIP

XLA

XLB

XLC

XLD

AGND

VCC

VEE

RX

TX

100uF

+5V

-5V

I = 25mA

10H 300Ω

10H 300Ω

+

+

VZ

Page 10

MH88634B Advance Information

2-274

Figure 6 - Return Loss Test Circuit

Figure 7 - Longitudinal to Metallic Balance and CMRR Test Circuit

600Ω

368Ω

V1

Return Loss = 20 * Log (V1\Vs)

~

100uF

-V

RING

TIP

XLA

XLB

XLC

XLD

Vs = 0.5V

AGND

VCC

VEE

RX

TX

100uF

+5V

-5V

I = 25mA

10H 300Ω

10H 300Ω

+

+

368Ω

368Ω

V1

Long to Met Bal. = 20 * Log (V1\Vs)

~

100uF

-V

RING

TIP

XLA

XLB

XLC

XLD

Vs = 0.5V

AGND

VCC

VEE

RX

TX

100uF

+5V

-5V

I = 25mA

10H 300

Ω

10H 300Ω

+

+

368Ω

CMRR = 20 * Log (Vtx\Vs) - ( 2-4W Gain)

VEX

V

V

tx

Page 11

Advance Information MH88634B

2-275

Figure 8 - Metallic to Longitudinal Balance Test Circuit

Figure 9 - Mechanical Data

368Ω

V1

Met to Long Bal. = 20 * Log (V1\Vs)

~

100uF

-V

RING

TIP

XLA

XLB

XLC

XLD

Vs = 0.5V

AGND

VCC

VEE

RX

TX

100uF

+5V

-5V

I = 25mA

10H 300

Ω

10H 300Ω

+

+

368Ω

510Ω

1

0.625 Max

(15.9 Max)

0.020 +0.005

(0.5

+0.13)

0.100 + 0.010

(6.35+0.51)

0.250

+0.020

0.180 + 0.020

(4.57 + 0.51)

(2.54 + 0.25)

*

*

0.14 Max

(3.6 Max)

0.010 + 0.002

(0.25

+ 0.05)

0.13 Max

(3.3 Max)

Notes:

1) Not to scale

2) Dimensions in inches.

(Dimensions in millimetres)

* Dimensions to centre of pin.

3) Pin tolerances are non-accumulative.

4) Recommended soldering conditions: Wave soldering tempetature 260˚C for 10 secs.

2.120 Max

(53.85 Max)

Page 12

MH88634B Advance Information

2-276

Figure 10 - MH88634T-2 Mechanical Information

1

2.12 Max

(53.85 Max)

0.260 +0.015

(6.60 +0.38)

0.080

+0.020

(2.03 +0.51)

0.080 Max

(2.03 Max)

0.170 Max

(4.32 Max)

0.100 0.010

0.020 +0.005

(0.51

+0.13)

(2.54 0.25)

*

(15.75 Max)

0.62 Max

Notes:

1) Not to scale

2) Dimensions in inches.

(Dimensions in millimetres)

* Dimensions to centre of pin.

3) Pin tolerances are non-accumulative.

4) Recommended soldering conditions:

Wave Soldering Max temp at pins 260˚ for 10 secs.

0.250 0.020

(6.35 0.51)

Page 13

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

http://www.mitelsemi.com

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or service or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form part of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

Loading...

Loading...