Page 1

www.fairchildsemi.com

ML4818

Phase Modulation/Soft Switching Controller

Features

• Full bridge phase modulation zero voltage switching

circuit with programmable ZV transition times

• Constant frequency operation to 500kHz

• Current mode operation

• Cycle-by-cycle current limiting with integrating fault

detection and restart delay

• Precision buffered 5V reference (+1%)

• Four 1.5A peak current totem-pole output drivers

• Under-voltage lockout circuit with 6V hysteresis

• Power DIP package

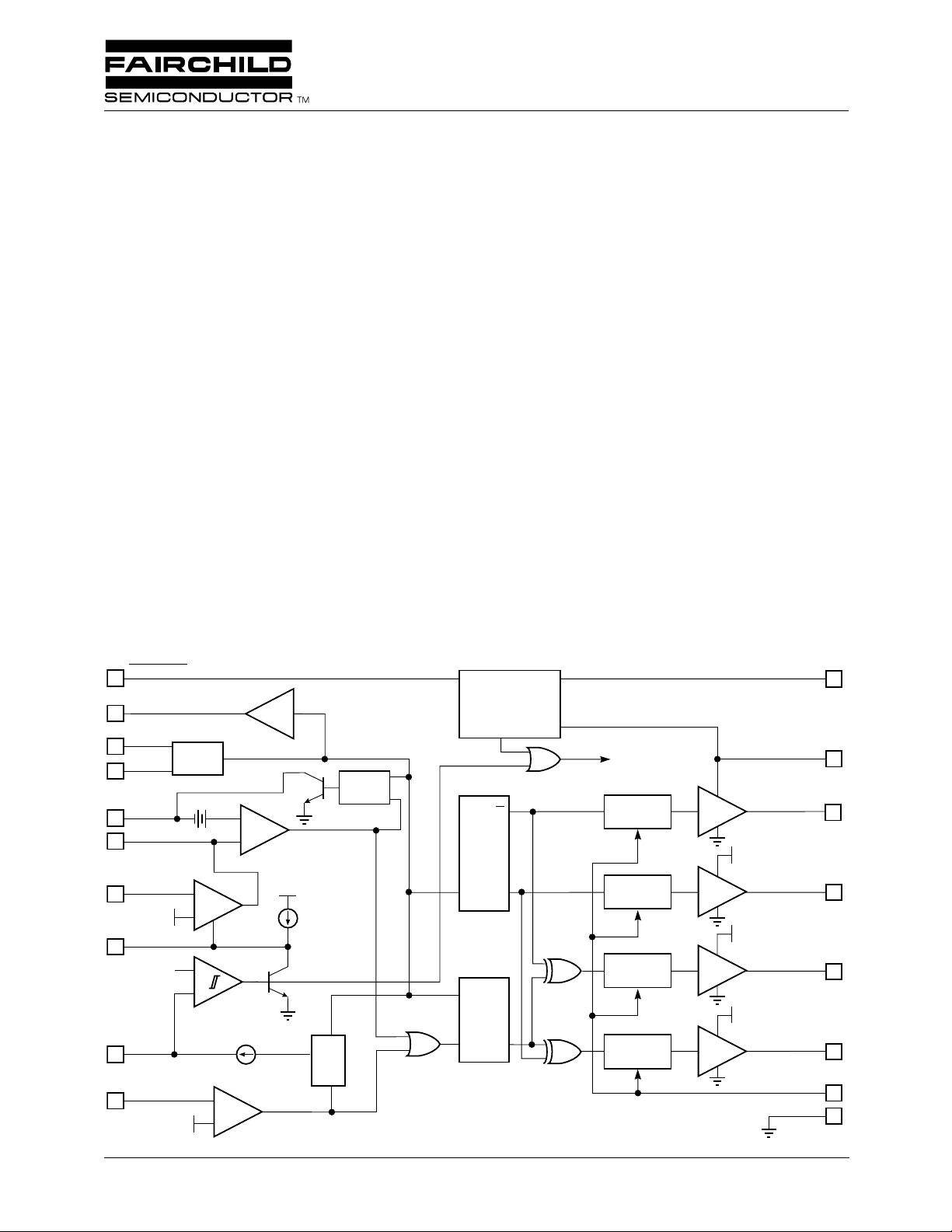

Block Diagram

SHUTDOWN

10

CLOCK

13

R

T

11

2

3

5

C

T

RAMP

E/A OUT

OSC

0.7V

R

Q

+

+

ΦMOD

–

S

General Description

The ML4818 is a complete phase modulation control IC suitable for full bridge soft switching converters. Unlik e conventional PWM circuits, the phase modulation technique allows

for zero-voltage switching transitions and square wave drive

across the transformer. The IC modulates the phases of the

two sides of the bridge to control output power.

The ML4818 can be operated in current mode. The delay

times for the outputs are externally programmable to allow

the zero-voltage switching transitions to take place.

Pulse-by-pulse current limit, integrating fault detection, and

soft start reset are provided. The under-voltage lockout circuit features a 6V hysteresis with a low starting current to

allow off-line start up with a low power bleed resistor. A

shutdown function powers down the IC, putting it into a low

quiescent state.

REFERENCE

AND

UNDER-VOLTAGE

LOCKOUT

INHIBIT

OUTPUTS

A2 OUT

CC

T FLIP

FLOP

DELAY

V

V

REF

24

V

CC

20

16

INV

8

SOFT START

9

12

I

LIM

4

+5V

RC

3V

RESET

1V

–

ERROR

AMP

+

–

+

+

–

V+

I

1

R

Q

I

2

S

TQQ

R

SQ

*PINS 1, 6, 7, 15, 18, 19 AND 23 ARE GND

DELAY

V

DELAY

V

DELAY

A1 OUT

17

CC

B1 OUT

22

CC

B2 OUT

21

R

DELAY

14

GND

*

REV. 1.0.3 6/21/01

Page 2

ML4818 PRODUCT SPECIFICATION

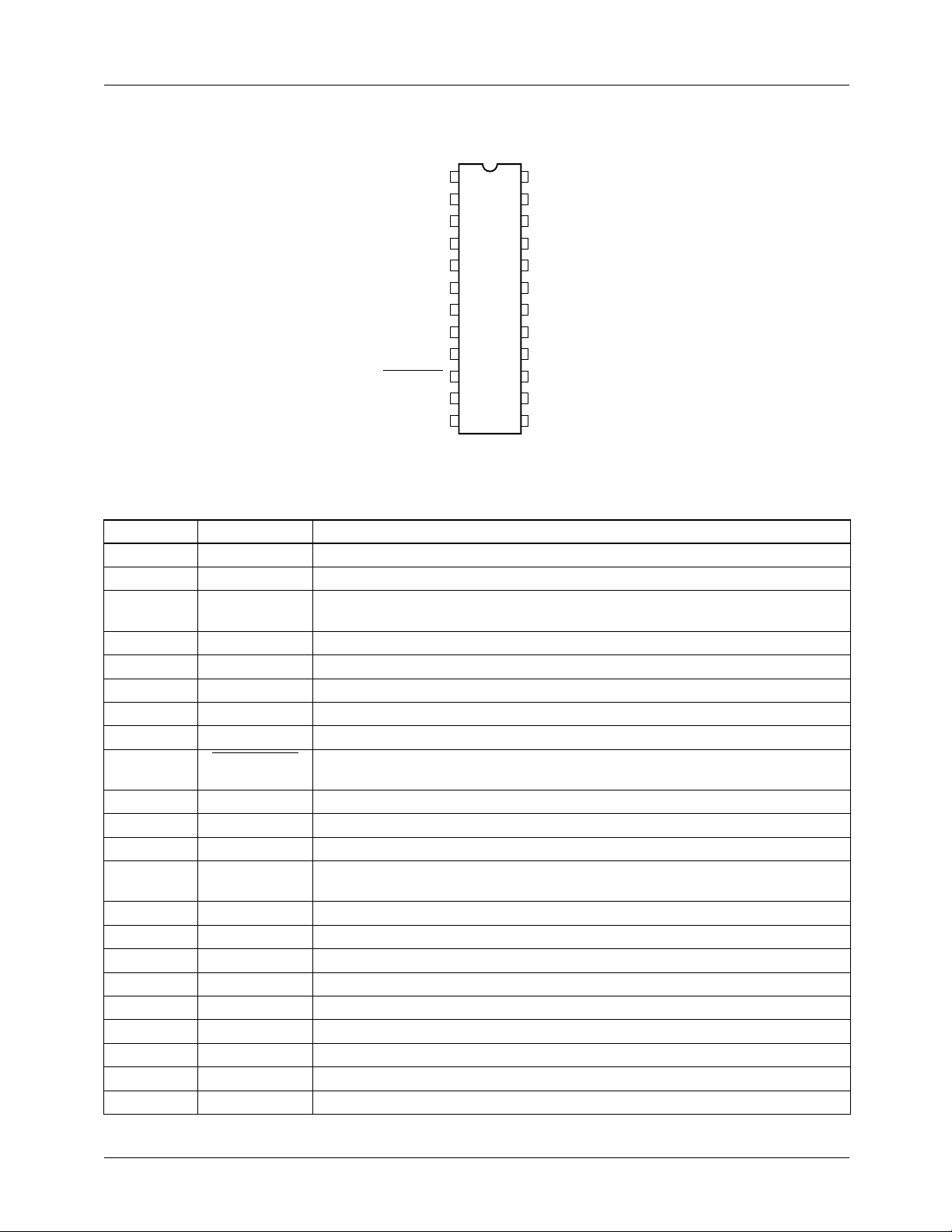

Pin Configuration

24-Pin Power DIP (P24)

V

GND

C

RAMP

I

LIM

E/A OUT

GND

GND

INV

SOFT START

SHUTDOWN

R

RC

RESET

T

T

24

1

23

2

22

3

21

4

20

5

19

6

18

7

17

8

16

9

15

10

14

11

13

12

TOP VIEW

REF

GND

B1 OUT

B2 OUT

V

CC

GND

GND

A1 OUT

A2 OUT

GND

R

DELAY

CLOCK

Pin Description

Pin Name Function

1 GND Ground

2CTTiming capacitor for oscillator

3 RAMP Non-inverting input to main comparator. Connected to current sense resistor for

current mode

4I

LIM

Current limit sense pin. Normally connected to current sense resistor

5 E/A OUT Output of error amplifier and input to PWM comparator

6,7 GND Ground and substrate

8 INV Inverting input to error amp

9 SOFT START Normally connected to soft start capacitor

10 SHUTDOWN Pulling this pin low puts the IC into a power down mode and turns off all outputs.

11 R

12 RC

T

RESET

This pin is internally pulled up to V

Resistor which sets discharge current for oscillator timing capacitor

Timing elements for Integrating fault detection and reset delay circuits

REF

.

13 CLOCK Oscillator output

14 R

DELAY

Resistor to ground on this pin programs the amount of delay from the time an

output turns off until its complementary output turns on

15 GND Ground

16 A2 OUT High current totem pole output A1

17 A1 OUT High current totem pole output A2

18,19 GND Ground and substrate

20 V

CC

Positive supply for the IC

21 B2 OUT High current totem pole output B1

22 B1 OUT High current totem pole output B2

23 GND Ground

24 V

REF

Buffered output for the 5V voltage reference

2 REV. 1.0.3 6/21/01

Page 3

PRODUCT SPECIFICATION ML4818

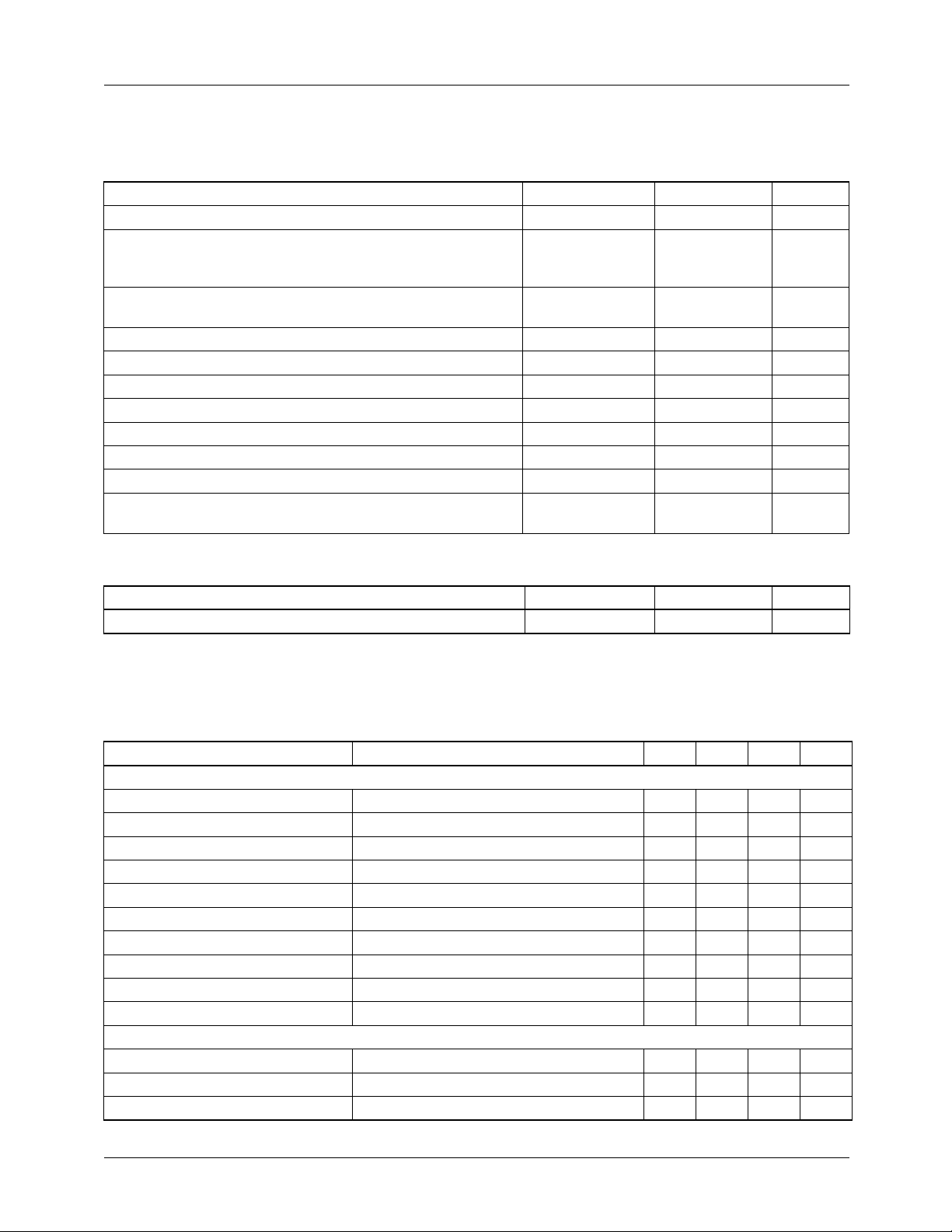

Absolute Maximum Ratings

Absolute Maximum Ratings are those values, beyond which the device could be permanently damaged. Absolute maximum

ratings are stress ratings only and functional device operation is not implied.

Parameter Min. Max. Units

V

CC

Output Driver Current, Source or Sink

DC

Pulse (0.5 µs)

Analog Inputs (CT, RAMP, I

RC

CLOCK Output Current (R

Error Amplifier Output Current (E/A OUT) 5 mA

SOFT START Sink Current 50 mA

Oscillator Charging Current (CT) –5mA

Junction Temperature 150 °C

Storage Temperature Range –65 150 °C

Lead Temperature (Soldering 10 Sec) 260 °C

Thermal Resistance (θJA)

Plastic Power DIP 40 °C/W

) –0.3 6 V

RESET

, E/A OUT, INV, SOFT START,

LIM

) –5mA

T

30 V

0.5

1.5

A

A

Operating Conditions

Parameter Min. Max. Units

Operating Temperature Range 0 70 °C

Electrical Characteristics

Unless otherwise specified, VCC = 15V, RT = 12.7kΩ, CT = 250pF, R

Temperature Range (Note 1).

Parameter Conditions Min. Typ. Max. Units

Oscillator

Initial Accuracy TA=25°C 410 450 525 kHz

Voltage Stability 12V<VCC<25V -0.3 %/V

Temperature Stability 0.2 %

Total Variation line, temp. 375 525 kHz

CT Discharge Current VCT=2V 4.7 5.5 6.3 mA

Clock Out High 2.4 3.1 6 V

Clock Out Low 0 0.4 V

Ramp Peak 0 4.1 V

Ramp Valley 1.5 5 V

Ramp Valley to Peak 0 2.6 5 V

Reference

Output Voltage TA=25°C, IO=1mA 4.95 5.0 5.05 V

Line Regulation 12V<VCC<25V -20 2 20 mV

Load Regulation 1mA<IO<10mA -20 3 20 mV

CLK

= 3kΩ, R

= 5kΩ, TA = Operating

DELAY

REV. 1.0.3 6/21/01 3

Page 4

ML4818 PRODUCT SPECIFICATION

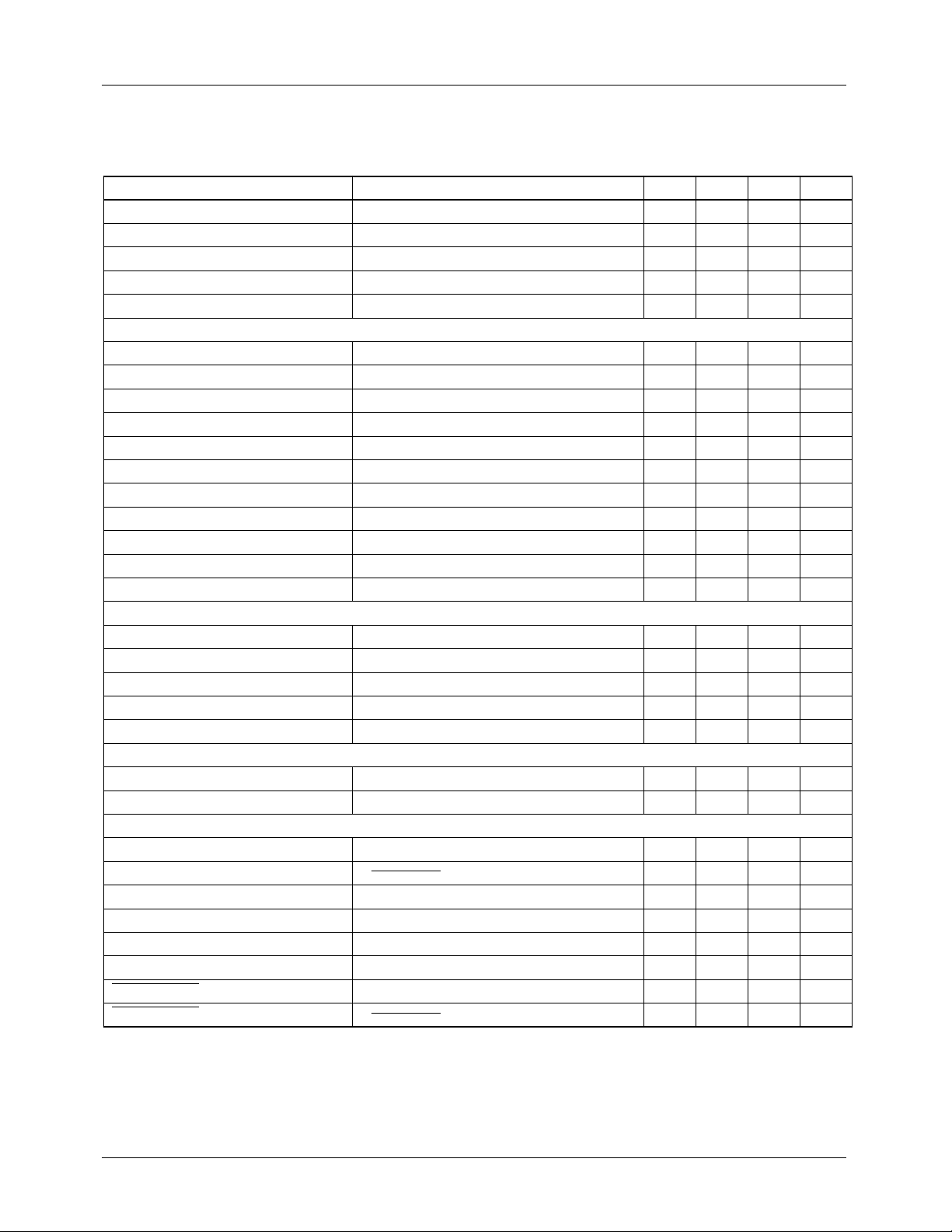

Electrical Characteristics (continued)

Unless otherwise specified, VCC = 15V, RT = 12.7kΩ, CT = 250pF, R

Temperature Range (Note 1).

Parameter Conditions Min. Typ. Max. Units

Temperature Stability 0.2 mV/°C

Total Variation 4.85 5.15 V

Output Noise Voltage 10Hz to 10kHz 50 mV

Long Term Stability T

Short Circuit Current V

=125°C, 1000 hrs 5 25 mV

j

=0V -20 -50 mA

REF

Error Amplifier

Input Offset Voltage -40 30 mV

Input Bias Current -3 0.6 3 µA

Input Offset Current 0.1 1 µA

Open Loop Gain 1 < V

PSRR 12 < V

Output Sink Current V

Output Source Current V

Output High Voltage I

Output Low Voltage I

< 4V 70 75 dB

O

< 25V 65 80 dB

CC

EA OUT

EA OUT

EA OUT

EA OUT

= 1V 1 3.2 mA

= 5.1V –0.5 –2.2 –20 mA

= –0.5mA 5.0 5.5 6.0 V

= 1mA 0.8 V

Unity Gain Bandwidth 2.0 2.8 MHz

Slew Rate 8.5 V/µs

Phase Modulator

RAMP Bias Current V

EA OUT Zero DC Threshold V

= 2.5V –1 –10 µA

RAMP

= 0V 0.4 0.6 0.9 V

RAMP

tPD, RAMP to Output 50 80 ns

t

DELAY

R

DELAY Voltage

CL = 1nF 99 200 250 ns

Soft Start

Charge Current V

Discharge Current V

SOFT START

SOFT START

= 4V –15 –25 –30 µA

= 1V 10 20 30 mA

Current Limit/Shutdown

I

Bias Current 0V < V

LIM

Current Limit Threshold V

tPD, I

LIM

RC

RC

RC

Shutdown Threshold 3.15 3.4 3.65 V

RESET

Restart Threshold 1.0 1.3 1.6 V

RESET

Charging Current V

RESET

SHUTDOWN

ILIM

< 4V –10 –110µA

ILIM

= 0V 0.92 1.02 1.12 V

=2V, V

RCRESET

SHUTDOWN Threshold 2.0 2.4 2.8 V

SHUTDOWN Input Bias Current V

SHUTDOWN

= 0 –100 –25 10 µA

CLK

= 3kΩ, R

= 5kΩ, TA = Operating

DELAY

4 4.3 5V V

50 ns

= 1.5V –400 –523 –1000 µA

4 REV. 1.0.3 6/21/01

Page 5

ML4818 PRODUCT SPECIFICATION

Electrical Characteristics (continued)

Unless otherwise specified, V

= 15V, RT = 12.7kΩ, CT = 250pF, R

CC

Temperature Range (Note 1).

Parameter Conditions Min. Typ. Max. Units

Output

Output Low Level I

Output High Level I

= 20mA

OUT

= 200mA, TA = 25°C

I

OUT

= –20mA

OUT

= –200mA, TA = 25°C

I

OUT

Rise/Fall Time CL = 1000pF 50 75 ns

Under-Voltage Lockout

Start Threshold 15.5 16.5 17.2 V

Stop Threshold 9.25 10.2 10.7 V

Supply

Start Up Current VCC<15.8V 3 4 mA

I

CC

V

INV

= 4V, V

RAMP

= V

TA = 25°C (Note 2) 60 70 mA

Notes

1. Limits are guaranteed by 100% testing, sampling, or correlation with worst-case test conditions.

2. V

must be brought above the UVLO start voltage (17.2V) before dropping to VCC = 15V to ensure start-up.

CC

= 3kΩ, R

CLK

= 0V, CL = 1nF,

ILIM

= 5kΩ, TA = Operating

DELAY

12.0

11.0

0.1

0.7

13.5

13.0

0.4

2.8

V

V

V

V

5 REV. 1.0.3 6/21/01

Page 6

PRODUCT SPECIFICATION ML4818

Functional Description

Phase Modulator

Power is controlled by modulating the switching phase on

sides A and B of the full H-bridge converter (Figure 1).

Power is delivered to the output through the transformer secondary. The power conversion process is described by the

following sequence and illustrated by the timing diagram of

Figure 2:

1. A2 and B1 are high (Q1 and Q2 are on), beginning the

power conversion cycle.

2. After the Φ MOD comparator trips, B1 goes low turning

off Q2. The parasitic drain-to-source capacitances of Q2

and Q4 charge to +VIN. This forces the drain-to-source

voltage across Q3 to 0V.

T

A2

ML4818

A1

B2

B1

B

B

3. B2 now goes high after t

DELAY

(set by R

DELAY

). Since the

voltage across Q3 is now 0V, B2 turns Q3 on at zero

voltage.

4. The CLOCK now goes high turning A2 off. During this

period, Q1 and Q2 and Q4 are off. The transformer leakage current discharges the drain-to-source capacitance

on Q4 until there is 0V across it.

5. A1 will remain low for a period defined by t

DELAY

, then it

goes high. The voltage across Q4 is now 0V as A1 turns

it on at zero voltage.

6. The previous sequence is now repeated with the opposite polarity on all outputs (see Figure 2).

The above sequence is then repeated but with the opposite

polarity on all outputs.

+VIN

Q3

L

LEAKAGE

TRANSFORMER

Q2 Q4

Q1

A

T

A

I

LIM

R

SENSE

Figure 1. Simplified diagram of Phase Modulated power Outputs

C

T

CLOCK

A2

t

DELAY

A1

t

B1

B2

DELAY

t

PD1

t

DELAY

t

PD1

t

DELAY

B

A

t

PD1

t

DELAY

t

DELAY

Figure 2. Phase Modulation control waveforms (Shaded areas indicate a power cycle)

REV. 1.0.3 6/21/01 6

Page 7

ML4818 PRODUCT SPECIFICATION

The ML4818 can also be used in current mode by sensing

load current on the RAMP input (pin 3).

The four output delay timers are programmed via an external

R

resistor as shown below. This resistor value should be

DELAY

no less than 1kΩ. Expressing R

in kΩ the delay, in ns

DELAY

is:

T

DELAY

33 R

×〈〉= 45+

DELAY

(1)

I

SET

R

11

T

1.7V

2

C

T

5.5mA

Q1

I

SET

5V

5V

+

–

The ML4818 contains special logic circuits to provide for

voltage mode feed-forward and lock out long pulses into the

Figure 5. Ocillator Block Diagram

internal logic. This prevents instability from occuring when

the Φ Comparator trips in voltage mode.

For frequencies of less than 500kHz, oscillator frequency

can be set by using the following formulae:

Φ MOD

OUTPUT

OSC

S

Q

R

RAMP

Q

R

3

f

OSC

-------------------------------------------------- -=

0.52C

TRT

1

500C

+

T

Error Amplifier

Figure 3. Voltage Feed-Forward Circuit

The collector of QR in figure 3 is high only during a power

cycle. When the power cycle terminates, RAMP is pulled

low. In voltage mode operation, a capacitor is connected

from RAMP to GND with a resistor from RAMP to VIN to

provide input voltage feed forward.

Oscillator

The ML4818 oscillator charges the external capacitor, CT,

with a current (I

reaches the upper threshold (Ramp Peak), the comparator

changes state, turning on the current sink which discharges

CT to the lower threshold (Ramp Valley). The CT pin is

clamped to Ramp Valley by Q1 (Figure 5) to prevent inaccuracy due to undershoot on CT.

) equal to 5/RT. When the CT voltage

SET

The ML4818 error amplifier is a 2.5MHz bandwidth, 8.5V/

µs slew rate op-amp with provision for limiting the positive

output voltage swing (output inhibit line) to implement the

soft start function. The error amplifier output source current

is limited to 4.5mA.

120

100

80

60

GAIN

40

20

0

0 100 1k 10k 100k 1M 10M

GAIN

PHASE

FREQUENCY

CLOCK

OUT

250Ω

13

(2)

180

PHASE (Degrees)

135

90

45

0

To use the CLOCK output for driving external synchronization circuitry, a pull-down resistor is required from CLOCK

to GND.

CLOCK

RAMP PEAK

C

T

RAMP VALLEY

T

C

T

D

Figure 4. Ocillator Timing Diagram

Figure 6. Error Amplifier Open-Loop Gain and Phase vs.

Frequency

V

CC

V

Q2

Q1

CC

OUT

POWER

GND

Figure 7. Power Driver Simplified Schematic

7 REV. 1.0.3 6/21/01

Page 8

ML4818 PRODUCT SPECIFICATION

Output Driver Stage

7

6

5

4

3

2

SATURATION DROP (V)

1

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

SOURCE

SINK

OUTPUT CURRENT (A)

Figure 8. Output Drive Saturation Voltage vs.

Output Current

15

The ML4818 has four high current high speed totem pole

output drivers each capable of 1.5A peak output, designed to

quickly switch the gates of capacitive loads, such as power

MOSFET transistors. Figure 8 illustrates the saturation characteristics of the ouput drive transistors shown in Figure 7.

Typical rise and fall time characteristics of the output drivers

are illustrated with capacitive loads of 1nF and 10nF in

Figure 9.

Current Limit, Fault Detection and Soft Start

Current limit is implemented when the current sensed on I

reaches the 1V limit. At this point, the PWM cycle is terminated. The flip flop (Figure 10) turns on the current source to

charge C

period. When C

and remains on for the duration of the clock

RST

has charged to 3.4V, a soft start reset

RST

occurs. The number of times the PWM cycle is terminated

due to over-current is “remembered” on C

C

is discharged by R

RST

providing a measure of “forget-

RST

. Over time,

RST

ting” when the over-current condition no longer occurs. This

integrating fault detection is useful in differentiation between

short circuit and load surge conditions.

LIM

10

1nF

5

OUTPUT VOLTAGE (V)

10nF

1nF

~

~

100 200 100 200

t

F

(ns)

t

R

10nF

Figure 9. Output Rise/Fall Time

V+

I

SWITCH

R

SENSE

R1

SOFT START

9

C

SS

I

LIM

4

C1

V+

1V

+

–

I

1

TERMINATE

PWM CYCLE

S

Q

I2

12

RC

R

RST

C

RST

RESET

3.4V

1.3V

R

CLOCK

+

–

UNDER-VOLTAGE

INHIBIT

OUTPUT

LOCKOUT

Figure 10. Over-Current, Soft-Start, and Integrating Fault Detect Circuits

8 REV. 1.0.3 6/21/01

Page 9

PRODUCT SPECIFICATION ML4818

V

Since the per cycle charge on RC

is proportional to how

RESET

early in the power cycle the over-current occurs, a reset will

occur more quickly under output short circuit conditions

(Figures 11a and 11b) than during a load surge (Figures 11c

and 11d).

When the soft start reset occurs, the output is inhibited and

the soft start capacitor is discharged. The output will remain

off until C

discharges to 1.3V through R

RST

, providing a

RST

reset delay. When the IC restarts, the error amplifier output

voltage is limited to the voltage at SOFT START, thus limiting the duty cycle.

1V

V(PIN 4)

3.4V

V(PIN 12)

Figure 11a, 11b. I

Waveforms During Short Circuit

and Resulting RC

LIMIT

RESET

Under-Voltage Lockout

On power up, when VCC is below 16V, the IC draws very little current (1.1mA typ.) and V

above 16V, the IC becomes active and V

will stay in that condition until V

Figure 12).

INHIBIT

OUTPUTS

POWER

DOWN

+

–

Figure 12. Under-Voltage Lockout and Reference Circuits

is disabled. When VCC rises

REF

falls below 10.2V. (see

CC

9V

REF

–

+

INTERNAL

BIAS

is enabled and

4V

TO LOGIC

CIRCUITS

5V

V

V

REF

24

CC

20

1V

V(PIN 4)

3.4V

(PIN 12)

Figure 11c, 11d. I

and Resulting RC

Waveforms During Load Surge

LIMIT

RESET

70

68

66

64

62

60

58

56

SUPPLY CURRENT (mA)

54

52

50

–75 –25 25 75 125 175

TEMPERATURE

Figure 13. Supply Current vs. Temperature (°C)

REV. 1.0.3 6/21/01 9

Page 10

ML4818 PRODUCT SPECIFICATION

Thermal Information

The ML4818 is offered in a Power DIP package. This package features improved thermal conduction through the leadframe. Much of the heat is conducted through the center 4

grounded leads. Thermal dissipation can be improved with

this package by using copper area on the board to function as

a heat sink. Increasing this area can reduce the θ

ures 14 and 15), increasing the power handling capability of

the package. Additional impro vement may be obtained by

using an external heat sink (available from Staver).

0.555"

24

1

23

2

22

3

21

4

20

5

19

I

I

Figure 14. PC Board Copper Area Used as a Heat Sink

6

18

7

17

8

16

9

15

10

14

11

13

12

JA

I

(see fig-

Applications

The application circuit shown in Figure 16 features the

ML4818 in a primary-side controlled voltage mode

application with voltage feed-forward. Input voltage is

rectified 120VAC (nominal). Feed-forward is provided by

the RAMP pin via the resistor connected to the high voltage

input. Current is sensed through sense transformer T4.

50

40

I

30

20

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8

02

I : HEAT SINK DIMENSION (INCHES)

Figure 15. θ

as a Function of I (see figure 15)

JA

10 REV. 1.0.3 6/21/01

Page 11

PRODUCT SPECIFICATION ML4818

,

–

+

OUT

15V, 13A

V

4 x 1N5406,

+HV

82kΩ, 1W

5A, 250V

3A, 600V

1/4W

240kΩ

+

200V

680µF,

MUR150

200µH

CC

V

AC IN

FUSE

+

T1

4T

+

100µF

1/4W

240kΩ

200V

680µF,

4T

MUR150

25V

1µF

120VAC–220VAC JUMPER

J1

T3

IRF840B

0.01µF

IRF840B

5.1Ω, 1/4W 5.1Ω, 1/4W

T2

1µF

1kV

1N5818

10T 10T

10T

10T

2 x IN5248

SCHOTTKY

MBR1535CT

T1

45T

80T

T4

39Ω

2 x IN5248

15µH

DIODE

0.33µF

1T

1/4W

1N5818

1µF

+

25V

100µF

4T 4T

630V

1N4148

1N5818

IC2

CC

V

1kΩ,1/4W

5.1Ω, 1/4W

5.1Ω, 1/4W

T2

MOC8102

1kΩ

T3

10T

IRF840B

IRF840B

10T

POT

1N5818

510

1/4W

1µF

330kΩ

1/4W

0.1µF

2423222120191817161514

ML4818

1234567891011

470pF

680pF

100kΩ

220pF

120pF

5.1kΩ 1/4W

1000pF

470pF

7.5kΩ, 1/4W

13

12

1µF

100kΩ

1/4W

4.3kΩ, 1/4W

1µF

240kΩ, 1/4W

Figure 16. Offline Full Bridge Converter

REV. 1.0.3 6/21/01 11

Page 12

ML4818 PRODUCT SPECIFICATION

Mechanical Dimensions inches (millimeters)

Package: P24N

24-Pin Narrow PDIP

1.240 - 1.260

(31.49 - 32.01)

24

0.070 MIN

(1.77 MIN)

(4 PLACES)

0.170 MAX

(4.32 MAX)

0.125 MIN

(3.18 MIN)

PIN 1 ID

1

0.050 - 0.065

(1.27 - 1.65)

0.016 - 0.022

(0.40 - 0.56)

0.240 - 0.270

(6.09 - 6.86)

0.100 BSC

(2.54 BSC)

0.015 MIN

(0.38 MIN)

SEATING PLANE

0.295 - 0.325

(7.49 - 8.26)

0º - 15º

0.008 - 0.012

(0.20 - 0.31)

12 REV. 1.0.3 6/21/01

Page 13

ML4818 PRODUCT SPECIFICATION

Ordering Information

Part Number Temperature Range Package

ML4818CP 0°C to 70°C Power DIP (P24)

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO

ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME

ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN;

NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

www.fairchildsemi.com

6/21/01 0.0m 003

© 2001 Fairchild Semiconductor Corporation

Stock#DS30004841

Loading...

Loading...