Page 1

April 1997

ML4813*

Flyback Power Factor Controller

GENERAL DESCRIPTION

The ML4813 is a PWM controller designed for use in a

discontinuous "flyback" or "buck-boost" type power factor

correction (PFC) system for low power, low cost

applications.

The circuit includes a precision reference, oscillator, error

amplifier, over-voltage comparator, over-current

comparator, and an extra op-amp as well as a high

current output. In addition, start-up is simplified by an

under-voltage lockout circuit.

In a typical application, the ML4813 functions as a

voltage mode regulator. By maintaining a constant duty

cycle, the current follows the input voltage, making the

impedance of the entire circuit appear purely resistive.

With the flyback circuit, power factors of 0.99 are easily

achievable with a small output inductor and a minimum

of external components.

BLOCK DIAGRAM

FEATURES

■ Precision buffered 5V reference

■ Extra op-amp for output voltage instrumentation

amplifier

■ Overcurrent comparator for switch protection

■ Soft start and under-voltage lockout for easy low surge

off-line starting

■ 1A peak current Totem-pole output drive

■ Overvoltage comparator eliminates output "runaway"

due to load removal

■ Large oscillator amplitude for better noise immunity

* This Part Is End Of Life As Of August 1, 2000

V

FB

4

SOFT START

2

I

LIMIT

1

OVP

5

COMP

3

C

T

16

R

T

9

SYNC

10

5V

1V

5.6V

ERROR

AMPLIFIER

+

CURRENT LIMIT

COMPARATOR

+

-

COMPARATOR

+

-

-

+

COMPARATOR

OSCILLATOR

OVP

PWM

7V

SRQ

Q

60µA

UNDERVOLTAGE

LOCKOUT

+

-

PWR GND

OA OUT

OA+

OA-

V

REF

V

CC

32V

OUT

GND

6

8

7

14

13

12

11

15

1

Page 2

ML4813

PIN CONFIGURATION

ML4813

16-Pin PDIP (P16)

16-Pin SOIC (S16W)

I

LIMIT

SOFT START

COMP

V

FB

OVP

OA OUT

OA-

OA+

PIN DESCRIPTION

PIN NAME FUNCTION

1I

LIMIT

2 SOFT START Connection for the soft start

3 COMP Output of error amplifier and input

4V

FB

5 OVP Overvoltage comparator input

Current limit sense pin which is

normally connected to the sense

resistor. When I

exceeds 1V,

LIMIT

the PWM cycle is terminated

capacitor

to the PWM comparator

Control loop feedback voltage

1

2

3

4

5

6

7

8

TOP VIEW

16

C

T

15

GND

14

V

REF

13

V

CC

12

OUT

11

PWR GND

10

SYNC

9

R

T

8 OA+ Non-inverting input of the

uncommitted op amp

PIN NAME FUNCTION

9R

T

Connection for the oscillator

timing resistor

10 SYNC Input for synchronizing the

oscillator to an external source

11 PWR GND Return for the high current output

transistors

12 OUT High current driver output

6 OA OUT Output of the uncommitted op

amp

7 OA- Inverting input of the uncommitted

op amp

2

13 V

14 V

CC

REF

Power supply input

Buffered reference output

15 GND Analog signal ground

16 C

T

Connection for the oscillator

timing capacitor

Page 3

ABSOLUTE MAXIMUM RATINGS

ML4813

Absolute maximum ratings are those values beyond

which the device could be permanently damaged.

Absolute maximum ratings are stress ratings only and

functional device operation is not implied.

Lead Temperature (Soldering, 10 sec) .....................260ºC

Thermal Resistance (qJA)

PDIP ................................................................ 88ºC/W

SOIC .............................................................. 105ºC/W

Supply Current .......................................................40mA

OUT Current .............................................................±1A

OUT Energy (capacitive load, per cycle) .................... 5µJ

OPERATING CONDITIONS

COMP Sink Current ............................................... 10mA

CT Charging Current................................................. 5mA

Analog Input Voltage (pins 1, 3-8) ....GND - 0.3V to 5.5V

Junction Temperature..............................................150ºC

Temperature Range

ML4813CX ................................................ 0ºC to 70ºC

ML4813IX ............................................... -40ºC to 85ºC

Storage Temperature Range ..................... –65ºC to 150ºC

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, RT = 14kW, CT = 1nF, TA = Operating Temperature Range (Notes 1, 2)

PARAMETER CONDITIONS MIN TYP MAX UNITS

OSCILLATOR

Initial Accuracy Tj = 25ºC 90 97 104 kHz

Voltage Stability 12V < VCC < 18V 0.3 %

Temperature Stability 2%

Total Variation Line, temp 88 108 kHz

Ramp Valley 1.0 V

Ramp Peak 4.3 V

RT Voltage 4.8 5.0 5.2 V

Discharge Current Tj = 25ºC, V(CT) = 2V 7.5 8.4 9.3 mA

V(CT) = 2V 7.2 8.4 9.5 mA

SYNC Threshold 0.8 1.4 2.0 V

SYNC Bias Current 350 800 µA

REFERENCE

Output Voltage (V

Line Regulation 12V < VCC < 25V 6 20 mV

Load Regulation 1mA < I

Temperature Stability 0.4 %

Total Variation Line, load, temp 4.9 5.1 V

Output Noise 10Hz to 10kHz 50 µV

Long Term Stability Tj = 125ºC, 1000 hours 5 25 mV

Short Circuit Current V

)T

REF

< 20mA 3 20 mV

REF

= 25ºC, I

j

= GND -30 -85 -180 mA

REF

= 1mA 4.95 5.00 5.05 V

REF

3

Page 4

ML4813

ELECTRICAL CHARACTERISTICS (cont.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

ERROR AMPLIFIER

Input Offset Voltage -15 15 mV

Input Bias Current -0.1 -1.0 µA

Open Loop Gain 1V < COMP < 5V 60 75 dB

PSRR 12V < VCC < 25V 60 70 dB

Output Sink Current COMP = 1.1V, VFB = 6.2V 2 12 mA

Output Source Current COMP = 5V, VFB = 4.8V -0.5 -1.0 mA

Output High Voltage I

Output Low Voltage I

Unity Gain Bandwidth 1.0 MHz

UNCOMMITTED OP AMP

Input Offset Voltage -10 10 mV

Input Bias Current -0.1 -2.0 µA

Input Offset Current -350 350 nA

Open Loop Gain 90 dB

PSRR 80 125 dB

Output High Voltage I

Output Low Voltage RL = 10kW 200 500 mV

I

COMPARATOR

LIMIT

Input Trip Point 0.8 1.0 1.2 V

Input Bias Current -2 -15 µA

Propogation Delay Time 150 ns

OVP COMPARATOR

Input Trip Point 5.4 5.55 5.7 V

= -10mA 6.5 8 V

COMP

= -0.5mA, VFB = 4.8V 5.3 6.4 V

COMP

= 2mA, VFB = 6.2V 0.5 1.0 V

COMP

Hysteresis 100 mV

Input Bias Current -0.3 3 181A

PWM COMPARATOR

Input Common Mode Range -0.2 5.5 V

Input Bias Current -2 -10 µA

Propogation Delay Time 150 ns

SOFT START

Soft Start Current V

SOFT START

= 1V 40 65 90 µA

4

Page 5

ML4813

ELECTRICAL CHARACTERISTICS (cont.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

OUTPUT

Output Low Voltage I

I

= 200mA 1.2 2.2 V

OUT

VCC = 8V, I

Output High Voltage I

I

= -200mA 12 13.4 V

OUT

Rise/Fall Time CL = 1000pF 50 ns

UNDERVOLTAGE LOCKOUT

Start-up Threshold 15 16.3 17.5 V

Shutdown Threshold 9 10.1 11.2 V

V

Good Threshold 4.4 V

REF

SUPPLY

Start-up Current VCC = 14V 0.9 1.5 mA

Operating Current 20 30 mA

Shunt Regulator Voltage ICC = 30mA 25 30 34 V

Note 1: Limits are guaranteed by 100% testing, sampling, or correlation with worst-case test conditions.

Note 2: VCC is raised above the UVLO start-up threshold, then returned to 15V.

= 10mA 0.1 0.4 V

OUT

= 5mA 0.1 0.8 V

OUT

= -20mA 13 13.6 V

OUT

5

Page 6

ML4813

FUNCTIONAL DESCRIPTION

OSCILLATOR

The ML4813 oscillator charges the external capacitor (CT)

with a current (I

) equal to 5/R

SET

. When the capacitor

SET

voltage reaches the upper threshold, the comparator

changes state and the capacitor discharges to the lower

threshold through Q1. While the capacitor is discharging,

Q2 provides a high pulse.

The oscillator period can be described by:

tt t

=+

OSC RAMP DEADTIME

(1)

where:

C

t

RAMP

T

=

I

SET

(2)

and:

C

t

DEADTIME

=

T

mA I

-84.

SET

(3)

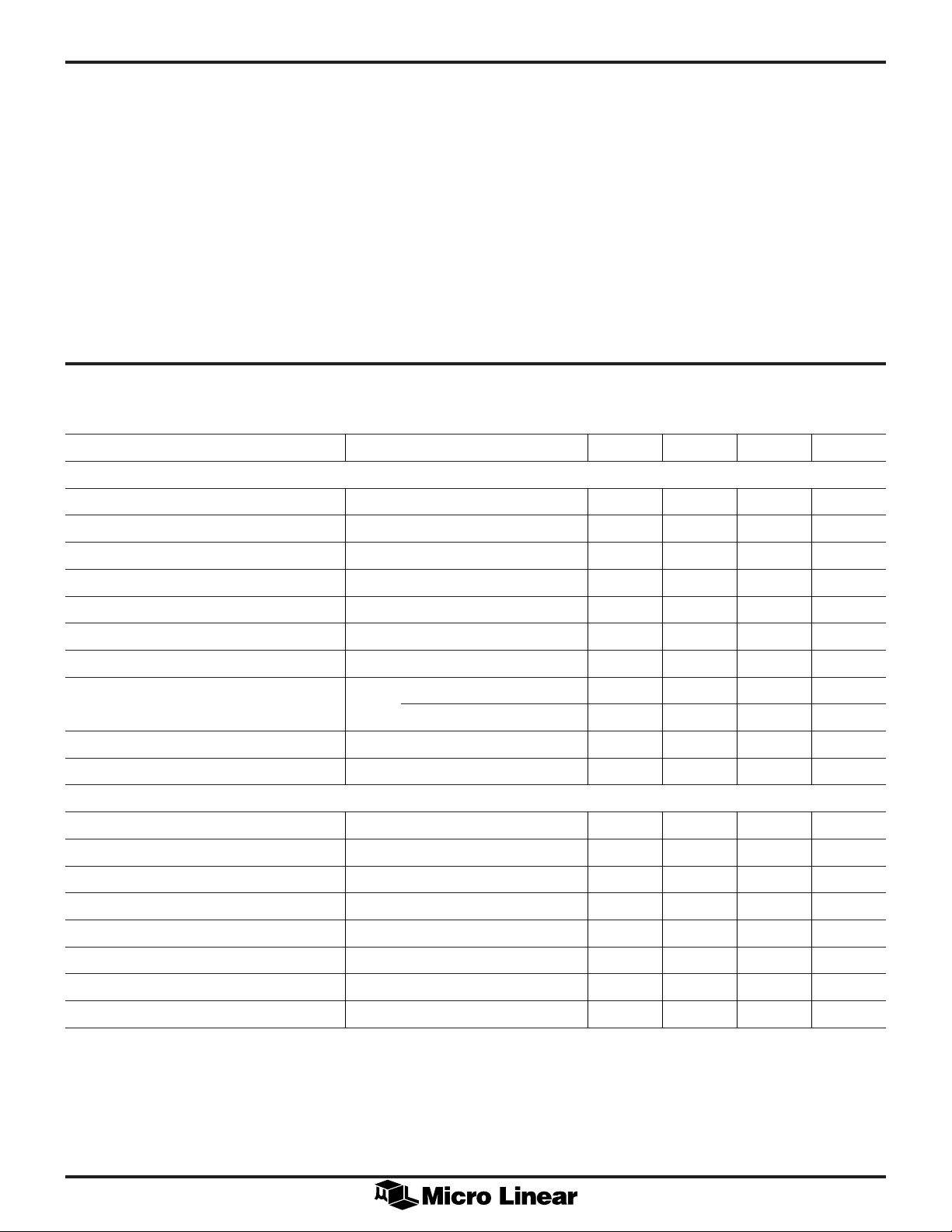

A graph showing the relationship between RT, CT, the

oscillator frequency, and maximum duty cycle is given in

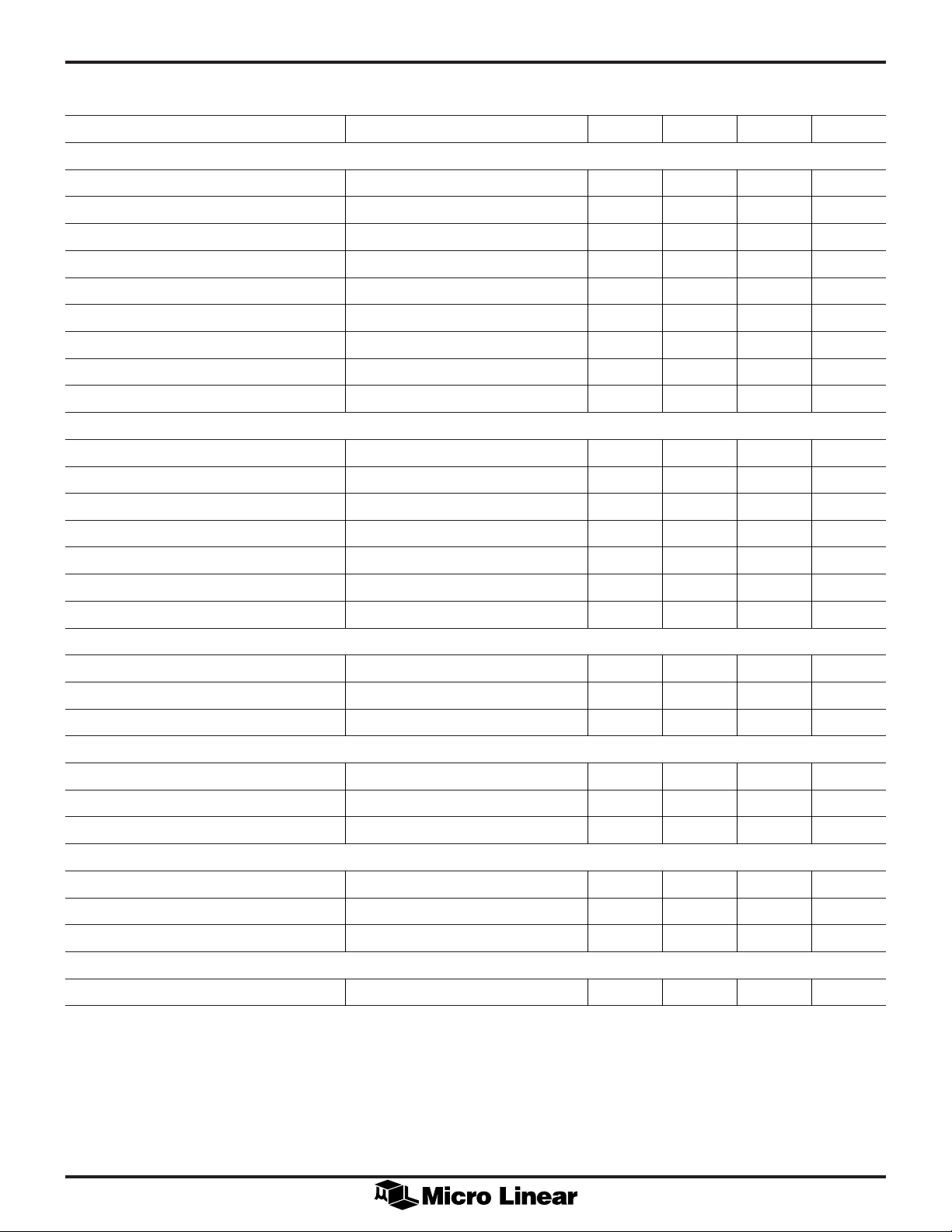

Figure 1. A pulse of a duration shorter than t

DEADTIME

from an external frequency source set to a higher

frequency than f

synchronize the oscillator. R

can be applied to pin SYNC to

OSC

SYNC

and C

SYNC

shorten

longer pulses, as shown in Figure 2.

OUTPUT DRIVER STAGE

The ML4813 output driver is a 1A peak output high speed

totem-pole circuit designed to quickly drive capacitive

loads such as MOSFET gates. See Figure 3 for the output

saturation characteristics for sourcing and sinking current.

10

8

10nF

5

(kΩ)

T

R

3

20nF

2

1

10 100 1000

5nF 2nF

OSCILLATOR FREQUENCY (kHz)

90%

1nF

Figure 1. Oscillator Timing Resistance vs. Frequency

EXTERNAL

CLOCK

C

SYNC

R

SYNC

I

SET

R

C

SYNC

10

R

T

9

T

C

16

T

T

8.4mA

I

SET

5.6V

+

-

85%

MAXIMUM DUTY CYCLE (%)

80%

70%

ERROR AMPLIFIER

The ML4813 error amplifier is a high open loop gain,

wide bandwidth amplifier. See Figure 4 for the gain and

phase plot.

UN-COMMITTED OP-AMP

The ML4813 contains an uncommitted op amp which is

normally configured as a differencing amplifier to sense

the output voltage. The output voltage in the flyback

configuration is not ground referenced. The op amp in the

ML4813 is a PNP input amplifier similar to the LM324

but with an open emitter class A output stage.

REFERENCE

The reference output voltage versus output current

characteristic is shown in Figure 5.

UNDERVOLTAGE LOCKOUT

On power-up, the ML4813 is in the UVLO condition;

6

CLOCK

T

D

RAMP PEAK

V(CT)

RAMP VALLEY

Figure 2. Oscillator Block Diagram

output low and quiescent current low. The ML4813

becomes operational when VCC reaches 16V. When V

drops below 10V, the UVLO condition is re-imposed.

During UVLO, the V

pin is off, making it usable as a

REF

"flag" for starting up a down-stream PWM converter.

CC

Page 7

ML4813

15

V

CC

14

13

SOURCE SATURATION

LOAD TO GROUND

SINK SATURATION

LOAD TO V

3

2

1

OUTPUT SATURATION VOLTAGE (V)

0

0 200 400 800

CC

OUTPUT CURRENT (mA)

VCC = 15V

80µs PULSED LOAD

120Hz RATE

GND

600

Figure 3. Output Saturation Voltage vs. Output Current

0

-4

100

80

60

40

, Open Loop Gain (dB)

20

VOL

A

0

-20

25

20

100 10k 10M100k

10 1k 1M

Figure 4. Error Amplifier Open Loop

Gain and Phase vs. Frequency

Frequency (Hz)

GAIN

PHASE

0

-30

Excess Phase (degrees)

-60

-90

-120

-150

-180

-8

15

(mV)

-12

REF

∆V

-16

-20

-24

20 60 12080

0 40 100

I

(mA)

REF

(mA)

CC

I

10

5

0

0

VCC (V)

3020 4010

Figure 5. Reference Load Regulation vs. Output Current Figure 6. Supply Current vs. Supply Voltage

7

Page 8

ML4813

APPLICATIONS

The ML4813 is used to implement a discontinuous mode

flyback (buck-boost) power factor regulator as shown in

Figure 7. This topology is particularly well suited for low

power applications such as fluorescent ballasts and low

power switching supplies. It is also a useful topology

when there is a requirement for the output voltage to be

lower than the peak input voltage, or where an isolated

output is required. This is not possible with a boost

topology, where the output voltage must always be higher

than the maximum peak of the input voltage range. The

typical input range for the flyback power factor regulator

is from 90VAC to 260VAC.

The regulator operates in the discontinuous current

conduction mode. The inductor energy stored during the

ON time of the power switch Q is completely delivered

to the output capacitance during the OFF time. Under

steady state conditions, the inductor current at the

beginning of the ON time starts to ramp-up from 0 Amps

to a value that is determined by the instantaneous value

of the input full wave rectified voltage; the ON time as it

is set by the error amplifier and the PWM comparator;

and finally by the inductor itself.

The expression for the inductor peak current is given by:

Vt

q

05

q

=

IN ON

L

(4)

I

05

L

RFI

FILTER

C1

RH2

RL2

V

OUT-

V

OUT+

ML4813

CONTROLLER

RH1RL1

L1

–

V

S

+

D1

Q1

RS

Figure 7. Simplified Application Circuit

waveforms has not been preserved. Normally for 60Hz

input line and 100kHz switching frequency, each half of

the sine wave contains approximately 833 high frequency

triangular waveforms.

Where:

IL(q) = instantaneous peak inductor current

tON = Power MOSFET "ON" time

VIN(q) = VP sin q = Instantaneous input voltage

VP = Input peak voltage

Figure 8 shows the relationship between the low

frequency envelope and the high frequency inductor

current. Note that for clarity the scale between the two

The envelope of the peaks of the switch current, which in

this case represents the current drawn from the input

source, has a sinewave shape. This relationship is shown

as:

II

qq

=sin

0

5

LP

(5)

By combining (4) and (5), the following useful

relationship is obtained:

LI

t

=

ON

P

V

2

RMS

(6)

INDUCTOR CURRENT

SWITCH CURRENT

SINUSOIDAL PEAK ENVELOPE

AVERAGE CURRENT

Figure 8. Switch and Line Currents in the Flyback PFC Circuit

8

Page 9

APPLICATIONS (Continued)

ML4813

Note that VIN(q) = VP x sin(q) and that VP = 1.414 x V

The average value of the input triangular current is:

t

I

AVG

Where I

value of the current at the input of the regulator after

filtering), and T is the period of the switch cycle.

Substitution of (6) into (7) yields:

Equation (8) clearly shows that the average value of the

switch current is sinusoidal and in phase with the input

voltage. The peak value of the average current is:

Also:

Rearranging equations (9) and (10) to solve for P

For optimum performance and the lowest inductor peak

currents, the inductor current should be at the verge of

continuity at the lowest operating voltage point and at full

load. This can be satisfied if:

Finally, (11) and (12) can be combined to derive an upper

bound for the inductor value that will guarantee that the

regulator always stays in the discontinuous mode of

operation. If the regulator were to operate in the

continuous mode the average input current would not be

sinusoidal.

AVG

I

AVG

I

AVG PEAK

I

AVG PEAK

P

=

IN

I

P

L

!

FLYBACK INDUCTOR CALCULATION

Equation (13) gives the upper bound for the inductor

value for any set of specified operating conditions.

Normally, a few iterations may be required for finalizing

the value to correct for second or third order effects. This

means that a good initial value for the inductor is

probably 10 to 20% lower than the value calculated by

the right hand side expression in (13).

ON

qq

=

05

is the average value of the switch current (the

qq

=

05

()

()

LI f

VV

fL V V

+

2

fP V V

+

I

sin

P

T

2

2

LI

P

TV

2828.

LI

TV

.

2828

P

2

=

2

P

4

IN OUT

16

IN

V

RMS

IN OUT

VV

IN OUT

16

IN IN OUT

sin

RMS

2

P

RMS

2

"

#

#

$

sin=

q

yields:

IN

RMS

(7)

(8)

(9)

(10)

(11)

(12)

(13)

.

Several core materials are candidates for the inductor,

such as powder iron, gapped ferrites, moly permalloy, etc.

There are no particular restrictions on the inductor except

that the inductance is the correct value and the losses are

acceptable.

INPUT BYPASS CAPACITANCE

The triangular high frequency current is bypassed by an

input capacitor (CIN). This should be a high quality film

capacitor with low ESR value for minimum losses and

heating. Polyester, polypropylene or x-type (for line side)

are good candidates. Typical values, depending on the

power level, can range anywhere from 330nF to 1.5µF.

The next filtering stage of the RFI filter has an inductor as

an input to isolate CIN from the other capacitors which

may be present at the input circuit. Note that CIN can be

on either side of the bridge rectifier. The preferred

location for low crossover distortion is on the input side.

The ripple voltage across this capacitor is:

V

CP P

-

05

Where V

frequency capacitor voltage, and D is the switch duty

cycle. The RFI filter that follows CIN has to be able to

attenuate V

regulatory specifications.

INPUT TRANSIENT OVERVOLTAGE PROTECTION

Careful examination of the power circuits reveals that

there is no large capacitance at the input of the regulator.

The only capacitance present is that of the RFI filter

capacitors. These capacitors have a combined value in the

range of a few microfarads, and their ability to absorb and

minimize any line induced transients is almost

nonexistent. Transients can also occur under sudden load

removal. If the line impedance is inductive, hazardous

drain-source voltages may be generated leading to the

destruction of the power MOSFET. To keep this from

happening, a transient over-voltage protection device

should be installed such that enough safety margin is

allowed for the power MOSFET. A good rule of thumb is:

Where BV

the MOSFET, V

of the over-voltage transient protector, and V

the maximum output voltage which is set by the OVP

function of the controller.

THE OUTPUT CIRCUIT

The output circuit for this topology, although nonisolated, does not share the same ground with the power

circuit. Therefore connecting the two grounds with the

measuring leads of instruments should be avoided.

C(P-P)

BV V V

DSS CLAMP OUT OVP

D

=

Cf

is the peak to peak worst case high

C(P-P)

>+

is the drain-source breakdown voltage for

DSS

CLAMP

IN

to the levels set by the relevant

is the activation or clamping voltage

P

IN IN

-

LfPCfV

()

2

IN IN

OUT(OVP)

(14)

(15)

is

9

Page 10

ML4813

OUT

V

10nF

R1

330µF

1kV

220kΩ

250V

-

CIRCUIT

START-UP

1%

R13

402kΩ

D6

MUR460

Q2

IRF821

R14

402kΩ

L3

1%

R23

C5

1kV

10nF

D5

1N4148

D9

22V

D8

1N4148

C14

100nF

Q3

2N2222

R22

2kΩ

2kΩ

C10

C11

6.8nF

100nF

C8

C9

D7

MUR460

R2

4.3kΩ

1000µF

1µF

Q1

MTH8N60

CIRCUIT

ENHANCEMENT

R3

10Ω

C7

R10

1nF

R9

1Ω

R8

1Ω

R7

1Ω

R6

1Ω

R5

1Ω

100Ω

R4

1Ω

+

C3

C4

L1

F1

C2

500µH

C1

3A

680nF

680nF

VR1

630V

630V

275V

L2

500µH

R13

SYNC

R11

1.8kΩ

T

C

GND

REF

V

V

CC

OUT

SYNC

T

R

PWR GND

ML4813

LIMIT

I

SOFT START

COMP

VFBOVP

OA OUT

OA-

OA+

1%

R12

4.02kΩ

1%

R17

R25

806kΩ

3.83kΩ

R24

C13

1%

402kΩ

R14

1%

R13

C12

402kΩ

402kΩ

220nF

4.7µF

1%

100kΩ

R14

1%

402kΩ

1%

R18

200Ω

10

LINE

INPUT

Figure 9. 80W Flyback Power Factor Regulator Using the ML4813

Page 11

APPLICATIONS (Continued)

The output voltage "rides" on the input voltage when the

(+) output is measured with respect to PWR GND as

shown in Figure 10.

ML4813

The extra op amp provided in the ML4813 can be used to

sense the output voltage for regulation and overvoltage

conditions. This op amp is connected as a difference

amplifier with its output referenced to PWR GND.

Resistors RH1, RH2, RL1, RL2 are used to scale down the

voltage.

Normally, RH1 = RH2 = RH and RL1 = RL2 = RL. The

voltage designated as VS in Figure 7 is given by:

VV

=

SOUT

RL

RH RL

+

(16)

The output capacitance should be calculated such that it

has the required output ripple at the worst case operating

point. In addition, the ESR should be sufficiently low to

prevent excessive dissipation due to RMS currents. The

first criterion can be met by choosing the value of the

output capacitor based on the following:

P

C

OUT

IN

fVV

2pD

LROUT

(17)

Where:

C

= Total output capacitance

OUT

PIN = Total input power

DVR = Peak output capacitor ripple voltage

fL = Line frequency times 2 (120 for 60Hz line)

The second criterion for the selection of the output

capacitor can be satisfied by choosing a component with

adequately low ESR value that can safely bypass the RMS

currents.

OUTPUT DIODE

The output diode can be a "fast" or ultrafast' type

depending on the operating frequency. Reverse recovery

losses are low since under normal operating conditions,

the regulator operates in discontinuous current mode. The

diode should be rated to handle the maximum output

current. The resulting power dissipation will be the

forward drop of the diode times the output current.

POWER SWITCH

If a power MOSFET is used, it should be sized for the

required efficiency. Lower R

devices will yield

DS(ON)

lower losses, but if they are operated at high frequencies

(100kHz), higher charge dumping losses will be

experienced. The RMS current value through the power

FET and the sensing resistor is:

I

RMS

LI f

=

424.

3

PL

V

RMS

Ê

k

r

=

1

sin

k

2

p

r

(15)

200V

V

OUT

V

OUT+

VOLTAGE

V

PWR GND

OUT-

TIME

Figure 10. Output Voltage with Respect to PWR GND

Where:

I

= Total RMS current through the power MOSFET

RMS

fL = Line frequency times 2 (120 for 60Hz line)

r = f

SWITCH/fL

Table 1 is provided to assist in calculating (18). When the

power switch is a bipolar transistor (constant VCE drop),

then the power dissipation produced can be calculated

by:

P

09.

P

=

D

IN

V

V

RMS

CE

(19)

Where:

PD = Power dissipation in the transistor

V

= RMS value of the minimum input voltage

RMS

VCE = Forward drop of the power transistor

r

k

p

f

SWITCH

(kHz) r

Ê

k

2

sin

=

r

1

20 167 9.1

30 250 11.2

40 333 12.9

50 417 14.4

60 500 25.8

70 583 17.1

80 667 18.3

90 750 19.4

100 833 20.4

110 917 21.4

120 1000 22.4

130 1083 23.3

140 1167 24.2

150 1250 25.0

160 1333 25.7

170 1417 26.5

180 1500 27.3

190 1583 28.0

200 1667 28.9

Table 1. Constants for Calculating IRMS (Equation 18)

11

Page 12

ML4813

APPLICATIONS (Continued)

OFF-LINE START-UP AND BIAS SUPPLY GENERATION

A fast starting circuit is included in Figure 9. MOSFET Q2

quickly charges the ML4813 VCC capacitor (C8) when the

supply is initially turned on. This allows the supply to

come on less than 1 second after AC power is applied. A

simpler start-up circuit may be used which replaces the

active circuit with a 39kW, 2W resistor but starts more

slowly (up to 15 seconds under low line conditions).

Systems which do not require quick starting can reduce

cost with the latter start-up method.

POWER FACTOR ENHANCEMENT

Some combinations of line and load may exhibit

distortion of the input current waveform. This distortion is

usually caused by the inductor "ringing" with the CDS of

the power MOSFET, resulting in a non-zero inductor

current at the beginning of the next cycle. This ringing

can be dampened by using R2 and D7 as shown in Figure

9. Applications which can get by with slightly worse

power factor can eliminate these components.

ADJUSTING THE OUTPUT VOLTAGE

The error amplifier creates an error voltage from the

difference between the output voltage presented at OA

OUT and the 5V internal reference. Since the output

voltage is not ground referenced, the ML4813's internal

op amp is connected as an instrumentation amplifier as

shown in Figure 11.

R12

V

OUT+

V

OUT-

Figure 11. Ground Referencing the Op Amp Output

R14'

R15'

Figure 12. Setting OVP at > 1.12 x V

OA+

OA-

OA OUT

+

–

R25

OVP

ML4813

RARB

OA OUT

ERROR AMP

R17

R18

OUT

TO

AND OVP

The output voltage is set by resistors which determine the

relationship between (V

the op amp. For the following discussion, R15' = R15 +

R16 and R14' = R13 + R14. The differencing amplifier

depends on the following relationships:

R14'= R15'

R12 = R25 + (R17 || R18)

Then:

VR

+

518

V

Since R25 is a low value compared to R15', the second

term reduces to approximately 1. The third term is set at

approximately 200. Equation (20) can be reduced to:

V

The overvoltage comparator has a threshold that is set for

1.12 x V

directly. Figure 12 shows the connection for setting an

OVP trip point higher than 1.12 x V

VV

=

OUT

RR

+

17 18

@

1000

OUT

when OVP and OA OUT are connected

OUT

@

112.

OVP OUT

RR

- V

OUT+

RR25

R

18

+

17 18

RR

AB

) and the output of

OUT-

R

15

’

+

+

15

’

OUT

+

R

B

R

14

’

R

, where:

1

12

(20)

(21)

(22)

+

RD

COMP

V

FB

ML4813

OVP

OA OUT

OUT

(23)

C13

R24RD

Figure 13. Setting OVP at < 1.12 x V

Figure 15 shows OVP set for a voltage lower than 1.12 x

V

where:

OUT

RD R24

VV

@

112.

OVP OUT

12

Page 13

APPLICATIONS (Continued)

INDUCTOR INFORMATION

L3 is the flyback inductor and also provides the operating

power for the control circuitry. A gapped ferrite pot core

was chosen for this application for it's modest high

frequency losses with high ripple current operation. Some

possible choices are:

ML4813

SHORTED TURN

(COPPER FOIL)

Manufadurer Part # Total Gap N

Magnetics Inc. F43019 0.05" 32

Phillips 3019 PL00-3F3 0.05" 32

Phillips 3019 PA125-3C8 0.07" 38

The first 2 cores are sold ungapped and require the use of

a .025. spacer to gap the center leg to yield a total gap

length of 0.05". If an ungapped core is used, a "shorted

turn" should be employed as shown in Figure 14 to

prevent radiated EMI. The third core listed is sold with its

center ieg pre-gapped (0.07" total) so that the outside of

the core closes completely, providing shielding without a

shorted turn. NS should be 3 turns. All windings are

#24AWG wire.

Inductors L1 and L2 are constructed using a powdered

iron. This is a suitable material for these inductors since

the high frequency ripple currents (and resulting flux

excursions) are much less severe than for L3. The core

selected is a MicroMetals T68-26D with 80 turns or

#24AWG wire.

P

0.25" SPACER

Figure 14. EMI Shielding for Ungapped Cores

WINDINGS

13

Page 14

ML4813

PHYSICAL DIMENSIONS inches (millimeters)

Package: P16

16-Pin PDIP

0.740 - 0.760

(18.79 - 19.31)

16

0.02 MIN

(0.50 MIN)

(4 PLACES)

0.170 MAX

(4.32 MAX)

0.125 MIN

(3.18 MIN)

16

PIN 1 ID

1

0.055 - 0.065

(1.40 - 1.65)

0.016 - 0.022

(0.40 - 0.56)

0.400 - 0.414

(10.16 - 10.52)

0.240 - 0.260

(6.09 - 6.61)

0.100 BSC

(2.54 BSC)

0.015 MIN

(0.38 MIN)

SEATING PLANE

Package: S16W

16-Pin Wide SOIC

0.295 - 0.325

(7.49 - 8.26)

0º - 15º

0.008 - 0.012

(0.20 - 0.31)

14

0.024 - 0.034

(0.61 - 0.86)

(4 PLACES)

0.090 - 0.094

(2.28 - 2.39)

1

PIN 1 ID

0.050 BSC

(1.27 BSC)

0.012 - 0.020

(0.30 - 0.51)

0.291 - 0.301

0.095 - 0.107

(2.41 - 2.72)

SEATING PLANE

(7.39 - 7.65)

0.005 - 0.013

(0.13 - 0.33)

0.398 - 0.412

(10.11 - 10.47)

0º - 8º

0.022 - 0.042

(0.56 - 1.07)

0.009 - 0.013

(0.22 - 0.33)

Page 15

ML4813

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4813CP (EOL) 0°C to 70°C 16-Pin PDIP (P16)

ML4813CS (Obsolete) 0°C to 70°C 16-Pin SOIC (S16W)

ML4813IP (Obsolete) -40°C to 85°C 16-Pin PDIP (P16)

ML4813IS (Obsolete) -40°C to 85°C 16-Pin SOIC (S16W)

© Micro Linear 1996 is a registered trademark of Micro Linear Corporation.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570;

5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565761; 5,592,128; 5,594,376. Japan: 2,598,946; 2,619,299. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design. Micro Linear does not assume any liability arising out of

the application or use of any product described herein, neither does it convey any license under its patent right nor the rights of others. The circuits contained in this data

sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to whether the illustrated circuits infringe any intellectual property

rights of others, and will accept no responsibility or liability for use of any application herein. The customer is urged to consult with appropriate legal counsel before

deciding on a particular application.

DS4813-01

2092 Concourse Drive

San Jose, CA 95131

Tel: 408/433-5200

Fax: 408/432-0295

15

Loading...

Loading...