Page 1

MK2059-01

VCXO-Based Frame Clock Frequency Translator

Description

The MK2059-01 is a VCXO (V oltage Controlled Crystal

Oscillator) based clock generator that produces

common telecommunications reference frequencies.

The output clock is phase locked to an 8kHz (frame

rate) input reference clock. The MK2059-01 also

provides jitter attenuation. Included in the selection of

output frequencies are these common system clocks:

1.544 MHz (T1) 2.048 (E1)

19.44 MHz (OC-3) 16.384 MHz (8x E1)

This monolithic IC, combined with an external

inexpensive quartz crystal, can be used to replace a

more costly hybrid VCXO retiming module. Through

selection of external loop filter components, the PLL

loop bandwidth and damping factor can be tailored to

meet input clock jitter attenuation requirements. A loop

bandwidth down to the Hz range is possible.

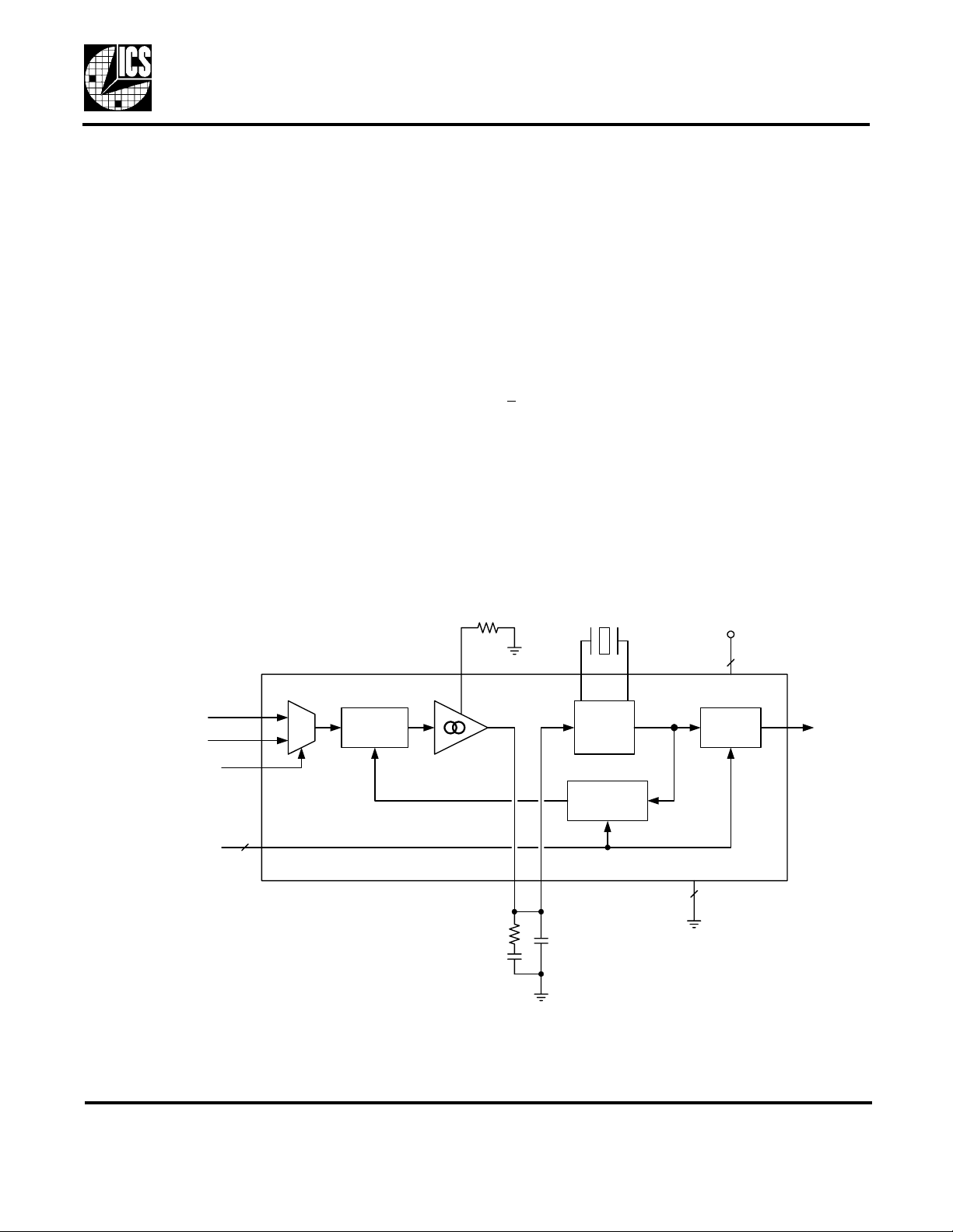

Block Diagram

Features

• Generates T1, E1, OC-3 and other common telecom

clock frequencies from an 8kHz frame clock

• Configurable jitter attenuation characterisitics,

excellent for use as a Stratum source de-jitter circuit

• 2:1 Input MUX for input reference clocks

• VCXO-based clock generation offers very low jitter

and phase noise generation

• Output clock is phase and frequency locked to the

selected input reference clock

• Fixed input to output phase relationship

• +115ppm minimum crystal frequency pullability

range, using recommended crystal

• Industrial temperature range

• Low power CMOS technology

• 20 pin SOIC package

• Single 3.3V power supply

Pullable xtal

VDD

8kHz Ref Input

8kHz Ref Input

ISEL

SEL2:0

ICLK2

ICLK1

ISET

1

0

3

Phase

Detector

Charge

Pump

CHGP

VCXO

Feedback

Divider

VIN

X2X1

GND

VDD

Output

Divider

4

3

CLK

MDS 2059-01 B 1 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race Street, San Jose, C A 95126 ● tel (408) 295-9 800 ● www.icst.com

Page 2

MK2059-01

VCXO-Based Frame Clock Frequency Translator

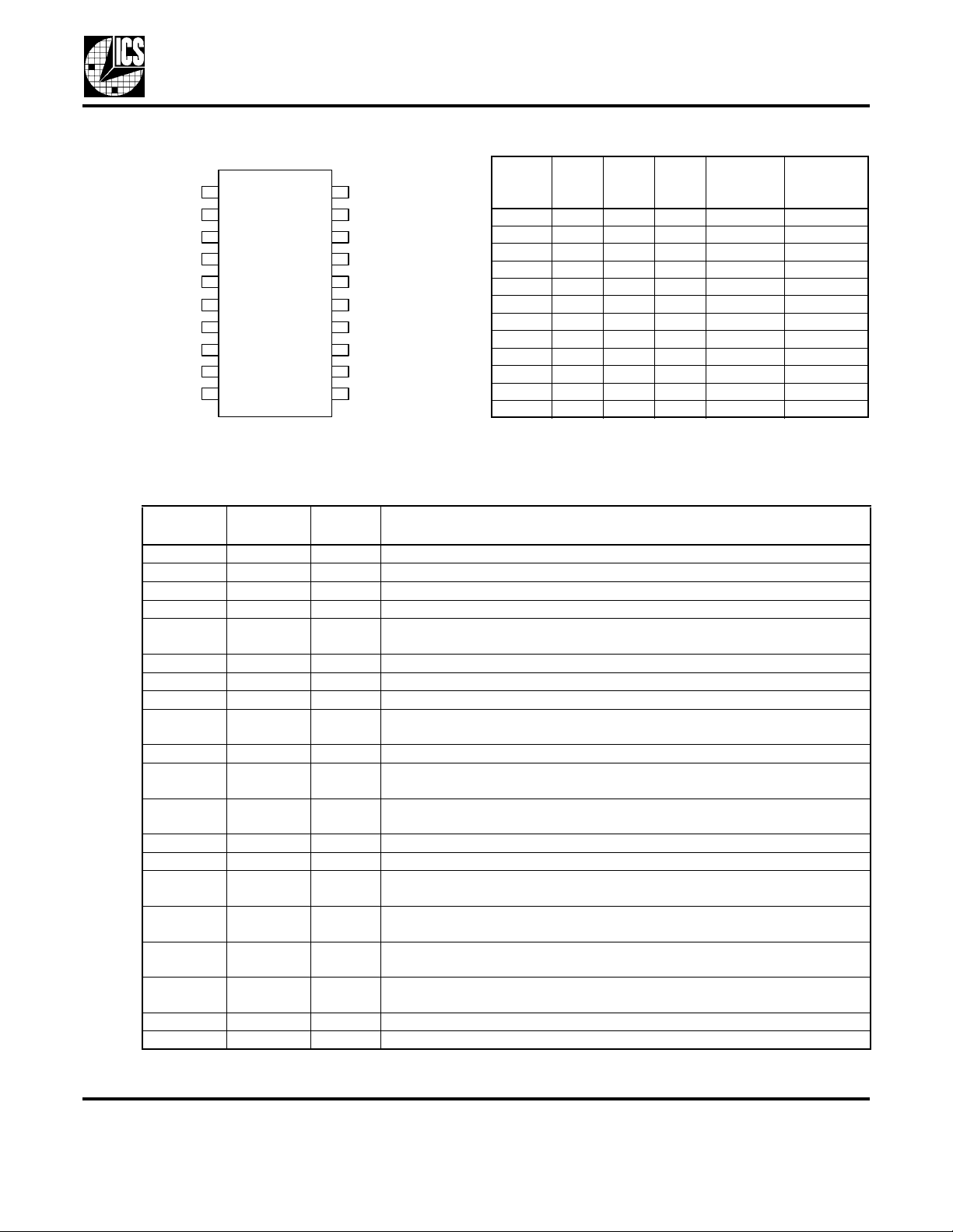

Pin Assignment

X1 X2

VDD

VDD

VDD

VIN

GND

GND

GND

CHGP

ISE T

1

2

3

4

5

6

7

8

9

10

20 pin 300 mil SOIC

Pin Descriptions

Pin

Number

1 X1 - Crystal Input. Connect this pin to the specified crystal.

2 VDD Power Power Supply. Connect to +3.3V.

3 VDD Power Power Supply. Connect to +3.3V.

4 VDD Power Power Supply. Connect to +3.3V.

5 VIN Input VCXO Control Voltage Input. Connect this pin to CHGP pin and the external

6 GND Power Connect to ground

7 GND Power Connect to ground

8 GND Power Connect to ground

9 CHGP Output Charge Pump Output. Connect this pin to the external loop filter and to pin

10 ISET - Charge pump current setting node, connection for setting resistor.

11 SEL2 Input Output Frequency Selection Pin 2. Determines output frequency as per table

12 SEL1 Input Output Frequency Selection Pin 1. Determines output frequency as per table

13 NC Input No Internal Connection.

14 CLK Output Clock Ou tput

15 SEL0 Input Output Frequency Selection Pin 0. Determines output frequency as per table

16 ICLK2 Input Input Clock Connection 2. Connect an input reference clock to this pin. If

17 ICLK1 Input Input Clock Connection 1. Connect an input reference clock to this pin. If

18 ISEL Input Input Selection. Used to select which refere nce input c lock is ac tive. Low inpu t

19 GND Power Connect to ground.

20 X2 - Crystal Output. Connect this pin to the specified crystal.

Pin

Name

20

19

18

17

16

15

14

13

12

11

Pin

Type

Output Clock Selection Table

Output

Input SEL2 SEL1 SEL0

GND

ISEL

IC L K1

IC L K2

SEL0

CLK

NC

SEL1

SEL2

8 kHz 0 0 0 1.544 24.704

8 kHz 0 0 1 2.048 24.576

8 kHz 0 1 0 16.384 16.384

8 kHz 0 1 1 17.664 17.664

8 kHz M 0 0 18.528 18.528

8 kHz M 0 1 20.00 20.00

8 kHz M 1 0 25.00 25.00

8 kHz M 1 1 25.92 25.92

8 kHz 1 0 0 19.44 19.44

8 kHz 1 0 1 20.48 20.48

8 kHz 1 1 0 24.704 24.704

8 kHz 1 1 1 24.576 24.576

Note: For SEL input pin programming:

0 = GND, 1 = VDD, M = Floating

Pin Description

loop filter as shown in this data sheet.

VIN.

above. Internally biased to VDD/2.

above. Internal pull-up.

above. Internal pull-up.

unused, connect to ground.

unused, connect to ground.

level selects ICLK1, high input level selects ICLK2. Internal pull-up.

Clock

(MHz)

Crystal

Used (MHz)

MDS 2059-01 B 2 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Page 3

VCXO-Based Frame Clock Frequency Translator

MK2059-01

Functional Description

The MK2059-01 is a clock generator IC that generates

an output clock directly from an internal VCXO circuit

which works in conjunction with an external quartz

crystal. The VCXO is controlled by an internal PLL

(Phase Locked Loop) circuit, enabling the device to

perform clock regeneration from an input reference

clock. The MK2059-01 is configured to provide a MHz

communications reference clock output from an 8kHz

input clock. There are 12 selectable output

frequencies. Please refer to the Output Clock Selection

Table on Page 2.

Most typical PLL clock devices use an internal VCO

(Voltage Controlled Oscillator) for output clock

generation. By using a VCXO with an external crystal,

the MK2059-01 is able to generate a low jitter, low

phase-noise output clock within a low bandwidth PLL.

This serves to provide input clock jitter attenuation and

enables stable operation with a low frequency

reference clock.

The VCXO circuit requires an external pullable crystal

for operation. External loop filter components enable a

PLL configuration with low loop band wid th.

Application Information

Quartz Crystal

It is important that the correct type of quartz crystal is

used with the MK2059-01. Failure to do so may result

in reduced frequency pullability range, inability of the

loop to lock, or excessive output phase jitter.

The MK2059-01 operates by phase-locking the VCXO

circuit to the input signal of the selected ICLK input.

The VCXO consists of the external crystal and the

integrated VCXO oscill ator circuit. To achieve the best

performance and reliability, a crystal device with the

recommended parameters (shown bel ow) must be

used, and the layout guidelines discussed in the PCB

Layout Recommendations section must be followed.

The frequency of oscillation of a quartz crystal is

determined by its cut and by the external load

capacitance. The MK2059-01 incorporates variable

load capacitors on-chip which “pull”, or change, the

frequency of the crystal. The crystals specified for use

with the MK2059-01 are designed to have zero

frequency error when the total of on-chip + stray

capacitance is 14pF. To achieve this, the layout should

use short traces between the MK2059-01 and the

crystal.

A complete description of the recommended crystal

parameters is shown below.

Recommended Crystal Parameters:

Output Frequency Configuration

The MK2059-01 is configured to generate a set of

output frequencies from an 8kHz input clock. Please

refer to the Output Clock Selection Table on Page 2.

Input bits SEL2:0 are set according to this table, as is

the external crystal frequency. Please refer to the

Quartz Crystal section on this page regarding external

crystal requirements.

Input Mux

The Input Mux serves to select between two alternate

input reference clocks. Upon reselection of the input

clock, clock glitches on the output clock will not be

generated due to the “fly-wheel” effect of the VCXO

(the quartz crystal is a high-Q tuned circuit). When the

input clocks are not phase aligned, the phase of the

output clock will change to reflect the phase of newly

selected input at a controlled phase slope (rate of

phase change) as influenced by the PLL loop

characteristics.

MDS 2059-01 B 3 Revision 071001

Operating Temperature Range

Commercial Applications 0 to 70

Industrial Applications -40 to 85

Initial Accuracy at 25

Temperature Stability ±30 ppm

Aging ±20 ppm

Load Capacitance Note 1

Shunt Capacitance, C0 7 pF Max

C0/C1 Ratio 250 Max

Equivalent Series Resistance 35 Ω Max

Note 1: For crystal frequencies between 13.5MHz and

27MHz the nominal crystal load capacitance

specification should be 14pF. Contact ICS MicroClock

applications at (408) 297-1201 regarding the use of a

crystal below 13.5MHz.

To obtain a list of qualified crystal devices that meet

these requirements, please contact ICS MicroClock

applications department.

°C ±20 ppm

°C

°C

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Page 4

MK2059-01

VCXO-Based Frame Clock Frequency Translator

PLL Loop Filter Components

All analog PLL circuits use a loop filter to establish

operating stability. The MK2059-01 uses external loop

filter components for the following reasons:

1) Larger loop filter capacitor values can be used,

allowing a lower loop bandwidth. This enables the use

of lower input clock reference frequencies and also

input clock jitter attenuation capabilities. Larger loop

filter capacitors also allow higher loop damping factors

when less passband peaking is desired.

2) The loop filter values can be user selected to

optimize loop response characteristics for a given

application.

Referencing the External Component Schematic on

this page, the external loop filter is made up of

components R

, C1 and C2. R

Z

charge pump current and therefore influences loop

filter characteristics.

establishes PLL

SET

External Compon ent Schematic

C

L

Don’t Stuff

(Re fe r to Optio n a l

Crystal Tuning

section)

C

2

X1 X2

VDD

VDD

VDD

VIN

GND

R

Z

GND

GND

C

1

CHGP

ISET

R

Xtal

1

2

3

4

5

6

7

8

9

10

SET

20

19

18

17

16

15

14

13

12

11

C

L

GND

ISEL

ICLK1

ICLK2

SEL0

CLK

NC

SEL1

SEL2

Recommended Loop Filter Values Vs. Output Frequency Range Selection

Crystal

SEL2 SEL1 SEL0

Multiplier

(N)

0 0 0 3088 120 k

0 0 1 3072 120 k

0 1 0 2048 120 k

0 1 1 2208 120 k

M 0 0 2316 120 k

M 0 1 2500 120 k

M 1 0 3125 120 k

M 1 1 3240 120 k

1 0 0 2430 120 k

1 0 1 2560 120 k

1 1 0 3088 120 k

1 1 1 3072 120 kΩ 1.0 MΩ 0.1 µF 4.7 nF 19 Hz 1.4

Note: For SEL input pin programming: 0 = GND, 1 = VDD, M = Floating

R

SET

R

Z

C1 C2Loop

Bandwidth

(-3dB point)

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

1.0 M

Ω

0.1 µF 4.7 nF 18 Hz 1.4

Ω

0.1 µF 4.7 nF 19 Hz 1.4

Ω

0.1 µF 4.7 nF 27 Hz 1.7

Ω

0.1 µF 4.7 nF 26 Hz 1.7

Ω

0.1 µF 4.7 nF 24 Hz 1.6

Ω

0.1 µF 4.7 nF 22 Hz 1.6

Ω

0.1 µF 4.7 nF 18 Hz 1.4

Ω

0.1 µF 4.7 nF 17 Hz 1.4

Ω

0.1 µF 4.7 nF 23 Hz 1.6

Ω

0.1 µF 4.7 nF 22 Hz 1.6

Ω

0.1 µF 4.7 nF 18 Hz 1.4

Ω

Damping

Factor

MDS 2059-01 B 4 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Page 5

NBW

R

ZICP

× 575×

N

----------------------------------------=

MK2059-01

VCXO-Based Frame Clock Frequency Translator

A “normalized” PLL loop bandwidth may be calculated

as follows:

The “normalized” bandwidth equation above does not

take into account the effects of damping factor or the

second pole. However, it does provide a useful

approximation of filter performance.

The loop damping factor is calculated as follows:

Damping Factor R

=

625 ICP×

×

-----------------------------------------

Z

C

×

1

N

Where:

= Value of resistor in loop filter (Ohms)

R

Z

= Charge pump current (amps)

I

CP

(refer to Charge Pump Current Table, below)

N = Crystal multiplier shown in the above table

= Value of capacitor C1 in loop filter (Farads)

C

1

As a general rule, the following relationship should be

maintained between components C

and C2 in the loop

1

filter:

C

1

C

----- -

=

2

20

Charge Pump Current Table

Charge Pump Current

R

SET

1.4 MΩ 10 µA

680 kΩ 20 µA

540 kΩ 25 µA

120 kΩ 100 µA

(I

)

CP

1) The loop capacitors should be a low-leakage type to

avoid leakage-induced phase noise. For this reason,

DO NOT use any type of polarized or electrolytic

capacitors.

2) Microphonics (mechanical board vibration) can also

induce output phase noise, especially when the loop

bandwidth is less than 1kHz. For this reason, ceramic

capacitors should have C0G or NP0 dielectric. Avoid

high-K dielectrics like Z5U and X7R. These and some

other ceramics have piezoelectric properties that

convert mechanical vibration into voltage noise that

interferes with VCXO operation.

For larger loop capacitor values such as 0.1 µF or 1 µF,

PPS film types made by Panasonic, or metal poly types

made by Murata or Cornell Dubilier are recommended.

For questions or changes regarding loop filter

characteristics, please contact your sales area FAE, or

ICS MicroClock Applications.

Series Termination Resistor

Clock output traces over one inch should use series

termination. To series terminate a 50Ω trace (a

commonly used trace impedance), place a 33Ω resistor

in series with the clock line, as close to the clock output

pin as possible. The nominal impedance of the clock

output is 20Ω. (The optional series termination resistor

is not shown in the External Component Schematic.)

Decoupling Capacitors

As with any high performance mixed-signal IC, the

MK2059-01 must be isolated from system power

supply noise to perform optimally.

Decoupling capacitors of 0.01µF must be connected

between each VDD and the PCB ground plane. To

further guard against interfering system supply noise,

the MK2059-01 should use one common connection to

the PCB power plane as shown in the diagram on the

next page. The ferrite bead and bulk capacitor help

reduce lower frequency noise in the supply that can

lead to output clock phase modulation.

Special considerations must be made in choosing loop

components C

MDS 2059-01 B 5 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

and C2:

1

Page 6

Connection to 3.3V

Power Plane

Ferrite

Bead

Bulk Decoupling Capacitor

(such as 1

µF Tantalum)

VDD Pin

VDD Pin

VDD Pin

0.01

µF D eco upling Capac itors

MK2059-01

VCXO-Based Frame Clock Frequency Translator

Recommended Power Supply Connection

for Optimal Device Performance

Crystal Load Capacitors

The device crystal connections should include pads for

small capacitors from X1 to ground and from X2 to

ground, shown as C

Schematic. These capacitors are used to adjust the

stray capacitance of the board to match the nominally

required crystal load capacitance. Because load

capacitance can only be increased in this trimming

process, it is important to keep stray capacitance to a

minimum by using very short PCB traces (and no via’s)

been the crystal and device.

In most cases the load capacitors will not be required.

They should not be stuffed on the prototype evaluation

board as the indiscriminate use of these trim capacitors

will typically cause more crystal centering error than

their absence. If the need for the load capacitors is later

determined, the values will fall within the 1-4 pf range.

The need for, and value of, these trim capacitors can

only be determined at prototype evaluation. Please

refer to the Optimization of Crystal Load Capacitors

section for more information.

PCB Layout Recommendations

For optimum device performance and lowest output

phase noise, the following guidelines should be

observed. Pl ease als o refe r to the Re commend ed PCB

Layout drawing on Page 7.

1) Each 0.01µF decoupling capacitor should be

mounted on the component side of the board as close

to the VDD pin as possible. No via’s should be used

between decoupling capacitor and VDD pin. The PCB

trace to VDD pin should be kept as short as possible,

MDS 2059-01 B 6 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

in the External Component

L

as should the PCB trace to the ground via. Distance of

the ferrite bead and bulk decoupling from the device is

less critical.

2) The loop filter components must also be placed

close to the CHGP and VIN pins. C

should be closest

2

to the device. Coupling of noise from other system

signal traces should be minimized by keeping traces

short and away from active signal traces. Use of vias

should be avoided.

3) The external crystal should be mounted just next to

the device with short traces. The X1 and X2 traces

should not be routed next to each other with minimum

spaces, instead they should be separated and away

from other traces.

4) T o minimize EMI the 33Ω series termination resistor ,

if needed, should be placed close to the clock output.

5) An optimum layout is one with all components on the

same side of the board, minimizing vias through other

signal layers (the ferrite bead and bulk decoupling

capacitor can be mounted on the back). Other signal

traces should be routed away from the MK2059-01.

This includes signal traces just underneath the device,

or on layers adjacent to the ground plane layer used by

the device.

The ICS Applications Note MAN05 may also be

referenced for additional suggestions on layout of the

crystal section.

Optimization of Crystal Load Capacitors

The concept behind the optional crystal load capacitors

was introduced previously in this data sheet (see

Crystal Load Capacitor section on Page 5). To

determine the need for and value of these capacitors,

you will need a PCB of your final layout, a frequency

counter capable of less than 10 ppm resolution and

accuracy, two power supplies, and some samples of

the crystals which you plan to use in production, along

with measured initial accuracy for each crystal at the

specified crystal load capaci tance, CL.

To determine the value of the crystal capacitors:

1. Connect VDD to 3.3V. Connect pin 5 to the second

power supply. Adjust the voltage on pin 5 to 0V.

Measure and record the frequency of the CLK output.

Page 7

Error 106x

f

3.0Vftetarg

–()f0Vf

tetarg

–()+

f

tetarg

------------------------------------------------------------------------------

error

xtal

–=

MK2059-01

VCXO-Based Frame Clock Frequency Translator

2. Adjust the voltage on pin 5 to 3.3V. Measure and

record the frequency of the same output.

To calculate the centering error:

Where:

= nominal crystal frequency

f

target

error

=actual initial accuracy (in ppm) of the crystal

xtal

being measured

If the centering error is less than ±15 ppm, adjustment

is not needed for most applications. If the cente ring

error is more than 15 ppm negative, the PCB has too

Recommended PCB Layout

much stray capacitance and will need to be redone with

a new layout to reduce stray capacitance. Alternately,

the crystal may be re-specified for a higher lower load

capacitance. Contact ICS MicroClock for details. If the

centering error is more than 15 ppm positive, add

identical fixed centering capacitors from each crystal

pin to ground. The value for each of these caps (in pF)

is given by:

External Capacitor =

2 x (centering error)/(trim sensitivity)

Trim sensitivity is a parameter which can be supplied

by your crystal vendor. If you do not know the value,

assume it is 30 ppm/pF. After any changes, repeat the

measurement to verify that the remaining error is

acceptably low (less than ±15ppm).

For minimum ou tput clock jitter,

device VDD conne ctions should

be made to comm on bulk

decoupling device (see text).

G

G

G

G

1

2

3

4

5

G

6

7

8

G

G

9

G

10

G

20

G

19

18

17

16

15

14

13

12

11

For minimum ou tput clock jitter,

remove ground and power plane

within th is e n tire a rea . A lso ro u te

all other traces away from this area.

NC

Legend:

G

= Ground

Co n n ec tion

MDS 2059-01 B 7 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Page 8

Absolute Maximum Ratings

Stresses above the ratings listed below can cause permanent damage to the MK2059-01. These ratings,

which are standard values for ICS commercially rated parts, are stress ratings only . Functional operation of

the device at these or any other conditions above those indicated in the operational sections of the

specifications is not implied. Exposure to absolute maximum rating conditions for extended periods can

affect product reliability. Electrical parameters are guaranteed only over the recommended operating

temperature range.

Item Rating

Supply Voltage, VDD 7V

All Inputs and Outputs -0.5V to VDD+0.5V

Ambient Operating Temperature -40 to +85°C

Storage Temperature -65 to +150°C

Junction Temperature 175°C

Soldering Te mpe ra ture 260°C

MK2059-01

VCXO-Based Frame Clock Frequency Translator

Recommended Operation Conditions

Parameter Min. Typ. Max. Units

Ambient Operating Temperature -40 – +85

Power Supply Voltage (measured in respect to GND) +3.15 +3.3 +3.45 V

DC Electrical Characteristics

Unless stated otherwise, VDD = 3.3V ±5%, Ambient Temperature -40 to +85°C

Parameter Symbol Conditions Min. Typ. Max. Units

Operating Voltage VDD 3.15 3.3 3.45 V

Supply Current IDD Clock outputs

unloaded, VDD = 3.3V

Input High Voltage, SEL2 V

Input Low Voltage, SEL2 V

Input High Voltage, ISEL,

SEL1:0

Input Low Voltage, ISEL,

SEL1:0

Input High Voltage, ICLK1, 2 V

Input Low Voltage, ICLK1, 2 V

Input High Current I

Input Low Current I

Input Capacitance, except X1 C

IH

IL

V

IH

V

IL

IH

IL

IH

IL

V

IH

V

IL

IN

C

°

10 15 mA

–VDD-0.5––V

–––0.5V

–2––V

–––0.8V

–

–––

VDD/2+1

––V

VDD/2-1

V

= VDD -10 – +10 µA

= 0 -10 – +10 µA

––7–pF

MDS 2059-01 B 8 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Page 9

Parameter Symbol Conditions Min. Typ. Max. Units

Output High Voltage (CMOS

Level)

Output High Voltage V

Output Low Voltage V

Short Circuit Current I

VIN, VCXO Control Voltage V

Nominal Output Impedance Z

AC Electrical Characteristics

Unless stated otherwise, VDD = 3.3V ±5%, Ambient Temperature -40 to +85° C

Parameter Symbol Conditions Min. Typ. Max. Units

VCXO Crystal Pull Range f

VCXO Crystal Nominal

Frequency

Input Jitter Tolerance t

Input pulse width (1) t

Output Frequency Error F

Output Duty Cycle (% high

time)

Output Rise Time t

Output Fall Time t

Skew, Input to Output Clock t

Cycle Jitter (short term jitter) t

Timing Jitter, Filtered

500Hz-1.3MHz (OC-3)

Timing Jitter, Filtered

65kHz-1.3MHz (OC-3)

V

OUT

OH

OH

OL

OS

XC

VCXO-Based Frame Clock Frequency Translator

I

= -4 mA VDD-0.4 V

OH

I

= -8 mA 2.4 V

OH

IOL = 8 mA – – 0.4 V

±50 mA

0VDDV

20

XP

Using Recommended

-115 +115 ppm

Crystal

f

X

ji

In reference to input

13.5 27 MHz

clock period

pi

OUT

t

OD

OR

OF

IO

ja

t

ICLK = 0 ppm error 0 0 0 ppm

Measured at VDD/2,

=15pF

C

L

0.8 to 2.0V, CL=15pF 1.5 ns

2.0 to 0.8V, CL=15pF 1.5 ns

Rising edges, CL=15pF -5 +5 ns

150 ps p-p

jf

Referenced to

10 ns

40 – 60 %

227 ps p-p

Mitel/Zarlink MT9045,

Note 2

t

jf

Referenced to

170 ps p-p

Mitel/Zarlink MT9045,

Note 2

MK2059-01

Ω

0.4 UI

Note 1: Minimum high or low time of input clock.

Note 2: Input reference is the 8 kHz output from a Mitel/Zarlink MT9045 device in freerun mode

(SEL2:0 = 100, 19.44 MHz external crystal).

MDS 2059-01 B 9 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Page 10

MK2059-01

VCXO-Based Frame Clock Frequency Translator

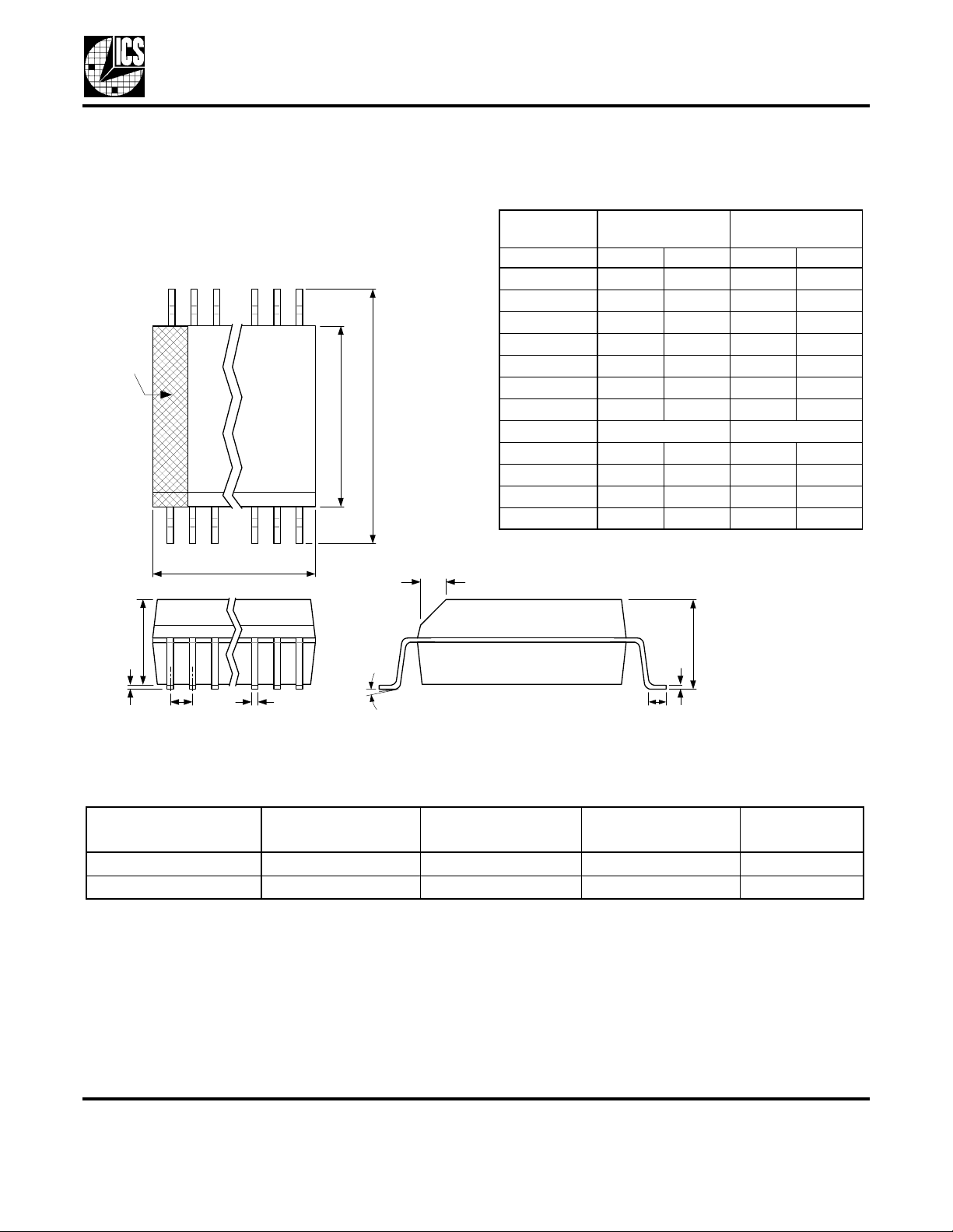

Package Outline and Package Dimensions (20 pin SOIC, 300 Mil. Wide Body)

Package dimensions are kept current with JEDEC Publication No. 95

Millimeters Inches

Symbol Min Max Min Max

A -- 2.65 -- 0.104

A1 1.10 -- 0.0040 -A2 2.05 2.55 0.081 0.100

Ind ex

Area

E

H

B 0.33 0.51 0.013 0.020

C 0.18 0.32 0.007 0.013

D 12.60 13.00 0.496 0.512

E 7.40 7.60 0.291 0.299

e 1.27 Basic 0.050 Basic

H 10.00 10.65 0.394 0.419

h 0.25 0.75 0.010 0.029

L 0.40 1.27 0.016 0.050

α

0

°

8

°

0

°

8

°

A2

A1

12

D

α

Be

h x 45

o

A

C

L

Ordering Information

Part / Order Number Marking Shipping

packaging

MK2059-01SI MK2059-01SI Tubes 20 pin SOIC -40 to +85° C

MK2059-01SITR MK2059-01SI Tape and Reel 20 pin SOIC -40 to +85° C

While the information presented herein has been checked for both accuracy and reliability, Integrated Circuit Systems (ICS)

assumes no responsibility for either its use or for the infringement of any patent s or other rights of third parties, which would

result from its use. No other circuits, patents, or licenses are implied. This product is intended for use in normal commercial

applications. Any oth er ap pl ic ations such as those req uiri ng extended temperat ure ran ge, high reliability, or other extraordina ry

environmental requirements are not recommended without additional processing by ICS. ICS reserves the right to change any

circuitry or specifications without notice. ICS does not authorize or warrant any ICS product for use in life support devices or

critical medical instruments.

Package Temperature

MDS 2059-01 B 10 Revision 071001

Integrated Circuit Systems, Inc. ● 525 Race St reet, San Jose, CA 9512 6 ● tel (408) 295-9800 ● www.icst.com

Loading...

Loading...