Page 1

1.8cm (0.7 Type) Black-and-White LCD Panel

Description

The LCX034ALT is a 1.8cm diagonal active matrix

TFT-LCD panel addressed by polycrystalline silicon

super thin film transistors with a built-in peripheral

driving circuit. Use of three LCX034ALT panels

provides a full-color representation. The striped

arrangement suitable for data projectors is capable

of displaying fine text and vertical lines.

The adoption of DMS∗1structure and high light

resistance structure realizes a high luminance

screen. And cross talk free circuit and ghost free

circuit contribute to high picture quality.

This panel has a polysilicon TFT high-speed

scanner and built-in function to display images

up/down and/or right/left inverse. The built-in 5V

interface circuit leads to lower voltage of timing and

control signals.

The panel contains an active area variable circuit

which supports SVGA/VGA/PC98∗2data signals by

changing the active area according to the type of

input signal. In addition, double-speed processed

NTSC/PAL can also be supported.

∗1

Dual Metal Shield

∗2

“PC98” is a treadmark of NEC Corporation.

Features

• Number of active dots: 485,000 (0.7 Type, 1.8cm in diagonal)

• Accepts the computer requirements of SVGA (804 × 604), VGA (644 × 484) and PC98 (644 × 404) platforms

• Supports NTSC (644 × 484) and PAL (762 × 572) by processing the video signal at double speed

• High optical transmittance: 13% (typ.)

• Built-in cross talk free circuit and ghost free circuit

• High contrast ratio with normally white mode

• Built-in H and V drivers (built-in input level conversion circuit, 5V driving possible)

• Up/down and/or right/left inverse display function

• Dust-proof glass used

Element Structure

• Dots: 804 (H) × 604 (V) = 485,616

• Built-in peripheral driver using polycrystalline silicon super thin film transistors

Applications

• Liquid crystal data projectors

• Liquid crystal projectors, etc.

– 1 –

E99665A04

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

LCX034ALT

Page 2

– 2 –

LCX034ALT

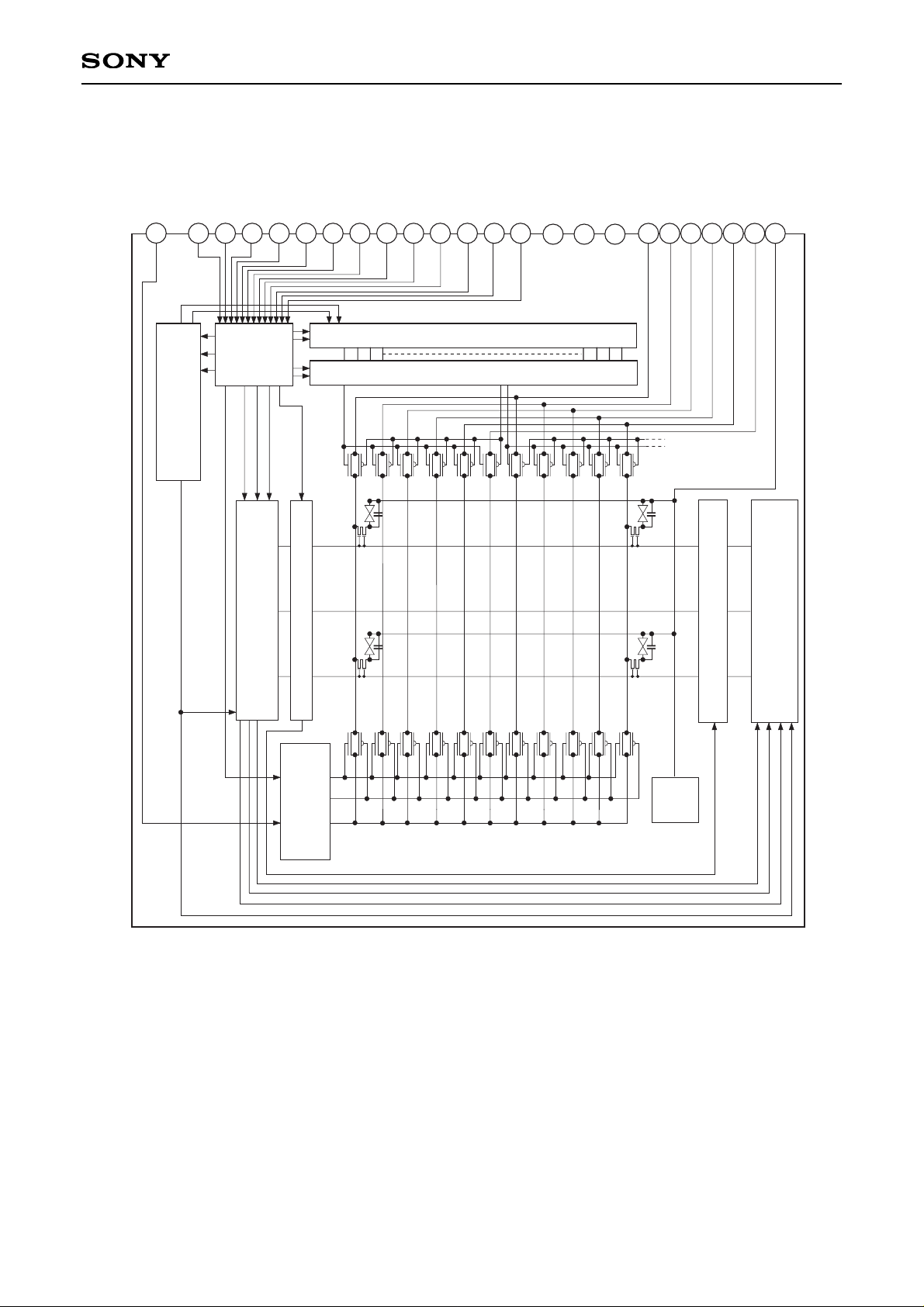

Block Diagram

1

18

H Shift Register (Bidirectional Scanning)

Up/Down and/or Right/Left

Inversion Control Circuit

V Shift Register

(Bidirectional Scanning)

Precharge Control

Circuit

COM

PAD

V Shift Register

(Bidirectional Scanning)

COM

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

Vss

VV

DD

HV

DD

MODE1

ENB

DWN

PCG

VCK

VST

RGT

BLK

HCK2

HCK1

HST

PSIG

14 15

17

9

20

19

21

22

12

11

10

8

23

16

7

6

4

3

5

2

24

Black Frame Control Circuit

Black Frame Control Circuit

13

Black Frame Control Circuit

MODE2

MODE3

Input Signal

Level Shifter

Circuit

Page 3

– 3 –

LCX034ALT

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

PSIG

SIG4

SIG3

SIG5

SIG2

SIG6

SIG1

HVDD

RGT

MODE3

MODE2

MODE1

13

14

15

16

17

18

19

20

21

22

23

24

HST

HCK1

HCK2

Vss

BLK

ENB

VCK

VST

PCG

DWN

VVDD

COM

Start pulse for H shift register

drive

Clock pulse for H shift register

drive

Clock pulse for H shift register

drive

GND (H, V drivers)

Black Frame display pulse

Enable pulse for gate selection

Clock pulse for V shift register

drive

Start pulse for V shift register

drive

Improvement pulse for uniformity

Drive direction pulse for V shift

register (H: normal, L: reverse)

Power supply for V driver

Common voltage of panel

Symbol Description

Pin

No.

Symbol Description

Uniformity improvement signal

Video signal 4 to panel

Video signal 3 to panel

Video signal 5 to panel

Video signal 2 to panel

Video signal 6 to panel

Video signal 1 to panel

Power supply for H driver

Drive direction pulse for H shift

register (H: normal, L: reverse)

Display area switching 3

Display area switching 2

Display area switching 1

Absolute Maximum Ratings (VSS = 0V)

• H driver supply voltage HVDD –1.0 to +20 V

• V driver supply voltage VVDD –1.0 to +20 V

• Common pad voltage COM –1.0 to +17 V

• H shift register input pin voltage HST, HCK1, HCK2, –1.0 to +17 V

RGT

• V shift register input pin voltage VST, VCK, PCG, –1.0 to +17 V

BLK, ENB, DWN

MODE1, MODE2, MODE3

• Video signal input pin voltage SIG1, SIG2, SIG3, SIG4, –1.0 to +15 V

SIG5, SIG6, PSIG

• Operating temperature

∗

Topr –10 to +70 °C

• Storage temperature Tstg –30 to +85 °C

∗

Panel temperature inside the antidust glass

Operating Conditions (VSS = 0V)

• Supply voltage

HVDD 15.5 ± 0.5V

VVDD 15.5 ± 0.5V

• Input pulse voltage (Vp-p of all input pins except video signal and uniformity improvement signal input pins)

Vin 5.0 ± 0.5V

Pin Description

Page 4

– 4 –

LCX034ALT

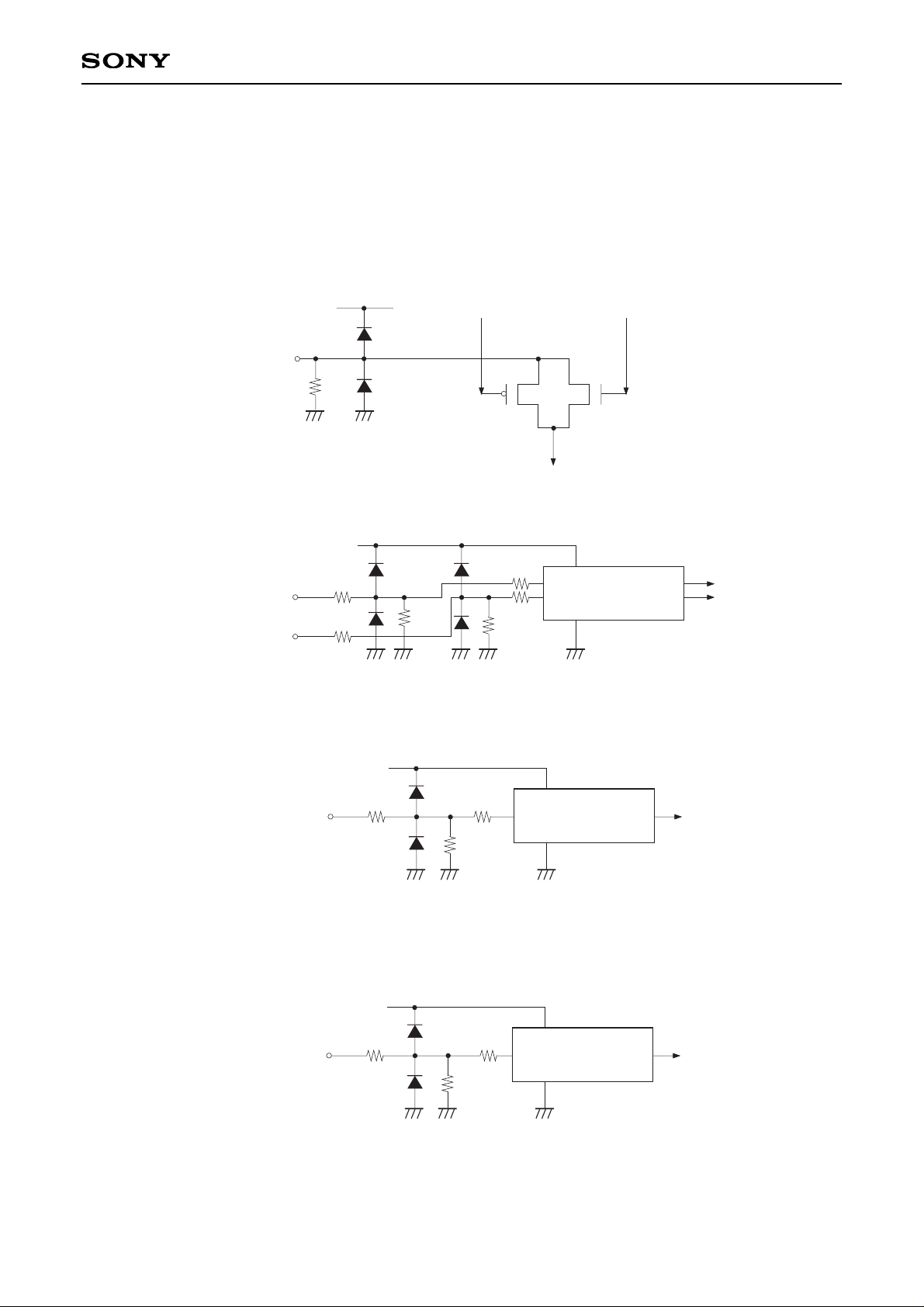

Input Equivalent Circuit

To prevent static charges, protective diodes are provided for each pin except the power supplies. In addition,

protective resistors are added to all pins except the video signal inputs. All pins are connected to VSS with a

high resistor of 1MΩ (typ.). The equivalent circuit of each input pin is shown below: (Resistance value: typ.)

(1) SIG1, SIG2, SIG3, SIG4, SIG5, SIG6, PSIG

Input

HV

DD

Signal line

1MΩ

(2) HCK1, HCK2

HVDD

250Ω

250Ω

250Ω

250Ω

Level conversion circuit

(2-phase input)

Input

1MΩ

1MΩ

(3) RGT, MODE1, MODE2, MODE3

Level conversion circuit

(single-phase input)

2.5kΩ2.5kΩ

HVDD

Input

1MΩ

(4) HST

Level conversion circuit

(single-phase input)

250Ω250Ω

HV

DD

Input

1MΩ

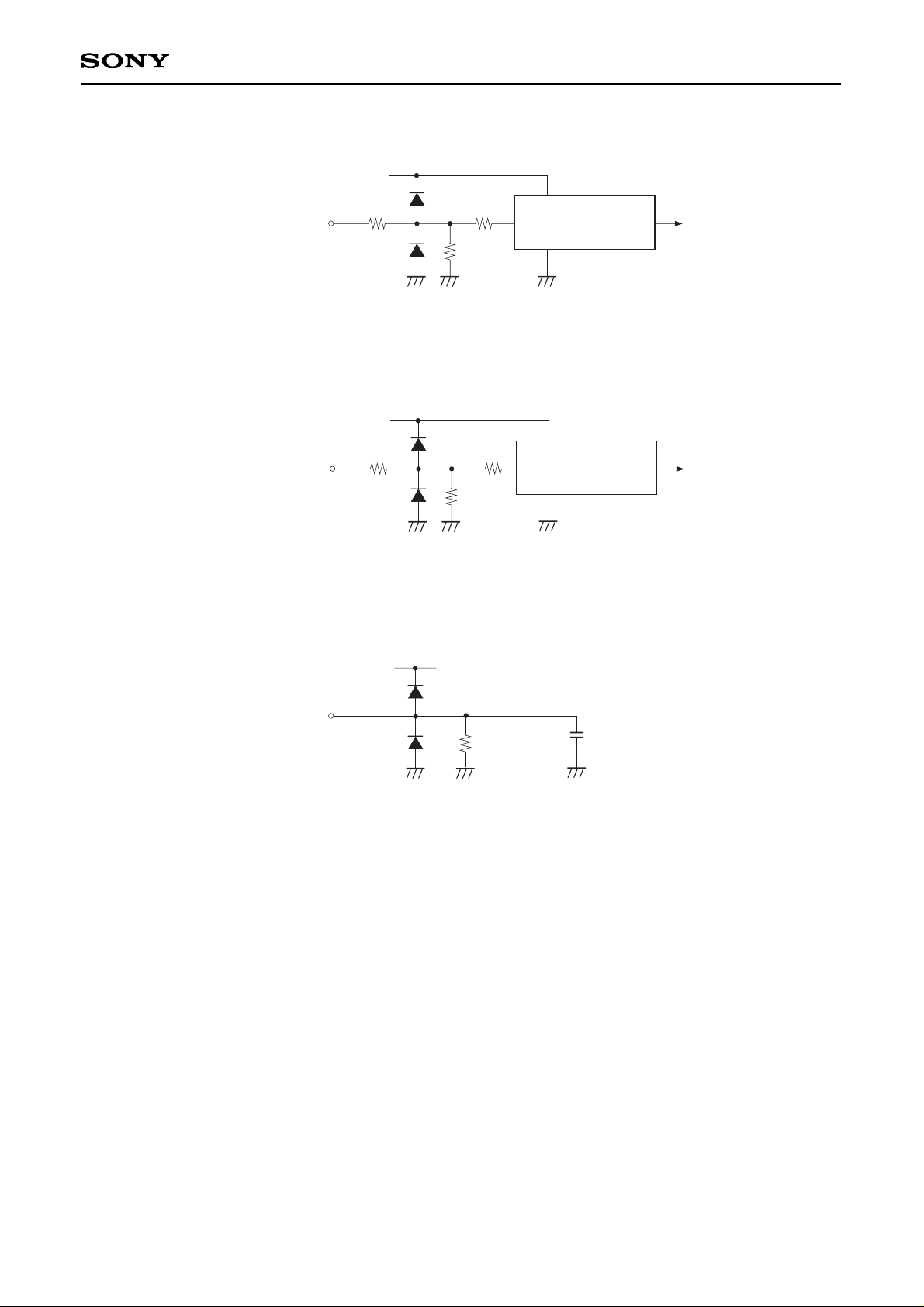

Page 5

– 5 –

LCX034ALT

(5) PCG, VCK

Level conversion circuit

(single-phase input)

250Ω250Ω

VV

DD

Input

1MΩ

(6) VST, BLK, ENB, DWN

Level conversion circuit

(single-phase input)

2.5kΩ2.5kΩ

VV

DD

Input

1MΩ

(7) COM

Input

LC

1MΩ

VVDD

Page 6

– 6 –

LCX034ALT

Input Signals

1. Input signal voltage conditions (VSS = 0V)

Item

H shift register input voltage

HST, HCK1, HCK2, RGT

(Low)

(High)

(Low)

(High)

VHIL

VHIH

VVIL

VVIH

VVC

Vsig

Vcom

VpsigB

VpsigG

–0.5

4.5

–0.5

4.5

6.8

VVC – 4.5

VVC – 0.6

VVC ± 4.4

VVC ± 1.8

0.0

5.0

0.0

5.0

7.0

7.0

VVC – 0.5

VVC ± 4.5

VVC ± 1.9

0.4

5.5

0.4

5.5

7.2

VVC + 4.5

VVC – 0.4

VVC ± 4.6

VVC ± 2.0

V

V

V

V

V

V

V

V

V shift register input voltage

MODE1, MODE2, MODE3,

BLK, VST, VCK, PCG,

ENB, DWN

Video signal center voltage

Video signal input range

∗1

Common voltage of panel

∗2

Uniformity improvement signal

input voltage (PSIG)

∗3

Symbol Min. Typ. Max. Unit

∗1

Input video signal shall be symmetrical to VVC.

∗2

The typical value of the common pad voltage may lower its suitable voltage according to the set

construction to use. In this case, use the voltage of which has maximum contrast as typical value.

When the typical value is lowered, the maximum and minimum values may lower.

∗3

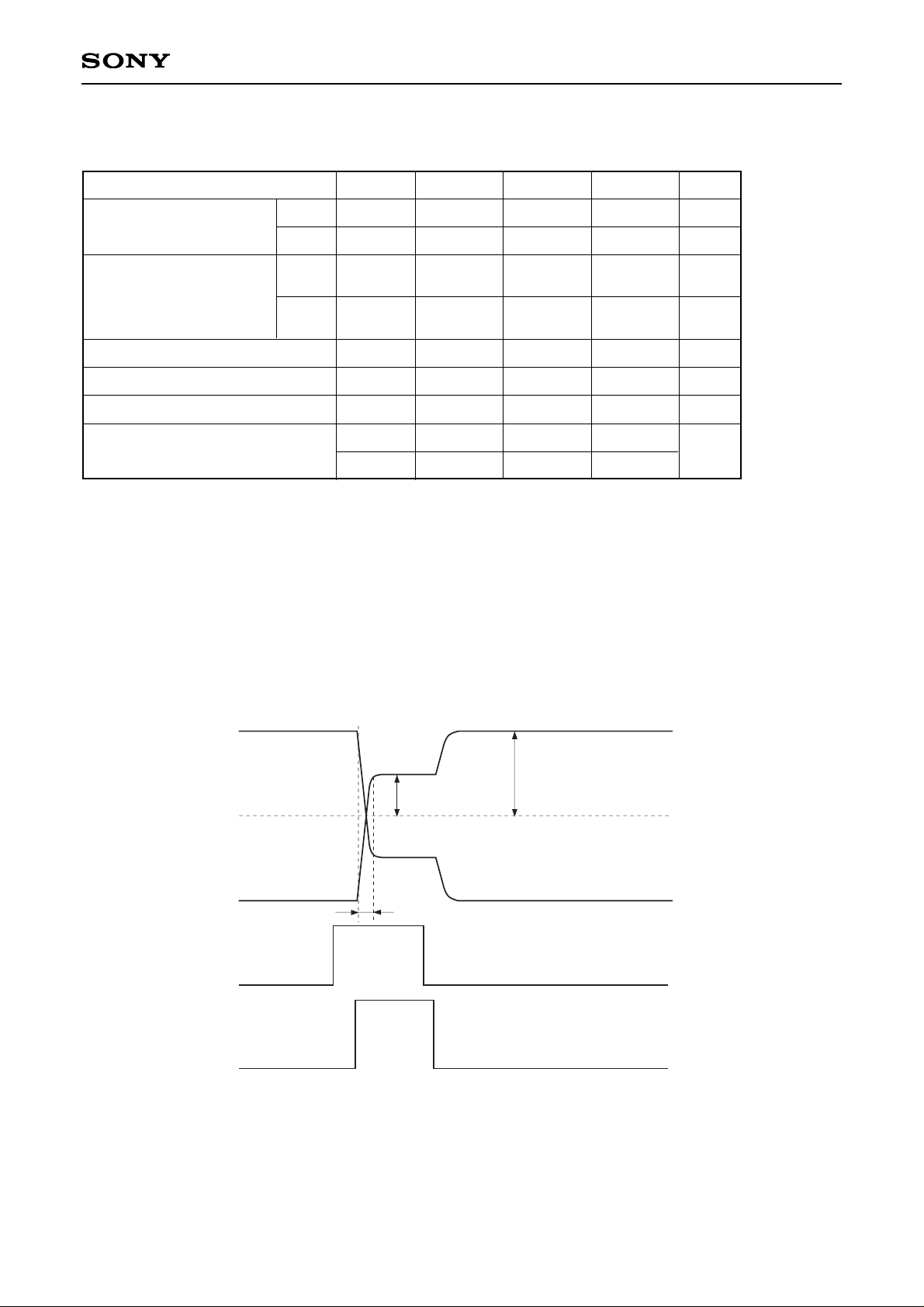

Input a uniformity improvement signal PSIG in the same polarity with video signals VSIG1 to VSIG6 and

which is symmetrical to VVC. PSIG wave form is 2 steps like below, in the upper chart, lower shows signal

level of the 1st step, upper shows signal level of the 2nd step. Also, the rising and falling of PSIG are

synchronized with the rising of PRG pulse, and the rise time trPSIG and fall time tfPSIG are suppressed

within 450ns (as shown in a diagram below).

The optimum input voltage of PSIG may be changed according as drive conditions of the drive side.

∗4

PRG shows the time of the 1st step of PSIG signal, and it is not input to the panel.

Level Conversion Circuit

The LCX034ALT has a built-in level conversion circuit in the clock input unit on the panel. The input signal

level increases to HVDD or VVDD. The VCC of external ICs are applicable to 5 ± 0.5V.

90%

10%

PsigB

PsigG

trPSIG, tfPSIG

PSIG

PCG

PRG

∗

4

VVC

Input waveform of uniformity improvement signal PSIG

Page 7

– 7 –

LCX034ALT

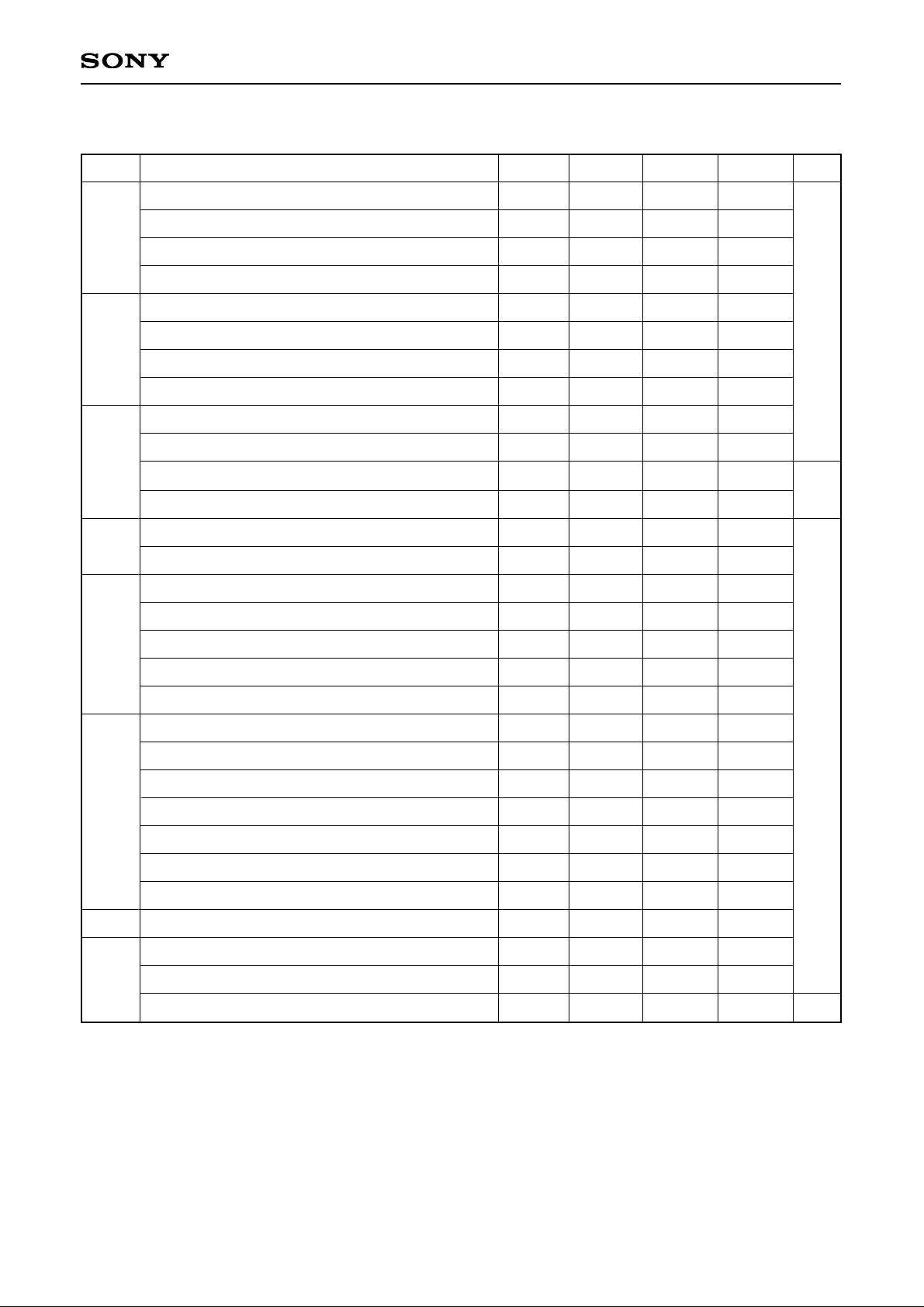

2. Clock timing conditions (Ta = 25°C) (SVGA mode: fHCKn = 4.0MHz, fVCK = 24.0kHz)

∗5

Hckn means Hck1 and Hck2.

∗6

Blk is set to positive polarity pulse for other than SVGA mode ; Low level for SVGA mode.

Hst rise time

Hst fall time

Hst data set-up time

Hst data hold time

Hckn rise time

∗5

Hckn fall time

∗5

Hck1 fall to Hck2 rise time

Hck1 rise to Hck2 fall time

Vst rise time

Vst fall time

Vst data set-up time

Vst data hold time

Vck rise time

Vck fall time

Enb rise time

Enb fall time

Vck rise/fall to Enb rise time

Horizontal video period completed to Enb fall time

Enb fall to Pcg rise time

Pcg rise time

Pcg fall time

Pcg rise to Prg rise time

Pcg rise to Prg rise time

Prg rise to Pcg fall time

Pcg fall to horizontal video period start time

Pcg pulse width

Prg rise to Vck rise/fall time

Blk rise time

Blk fall time

Blk fall to Vst rise time

trHst

tfHst

tdHst

thHst

trHckn

tfHckn

to1Hck

to2Hck

trVst

tfVst

tdVst

thVst

trVck

tfVck

trEnb

tfEnb

toEnb

tdEnb

toPcg

trPcg

tfPcg

toPrgr

toPrgf

toPcg

toVideo

twPcg

toVck

trBlk

tfBlk

toVst

—

—

50

50

—

—

–15

–15

—

—

5

5

—

—

—

—

300

900

630

—

—

300

200

1050

300

1350

0

—

—

32

—

—

60

60

—

—

0

0

—

—

10

10

—

—

—

—

500

1000

700

—

—

500

250

1100

350

1600

1000

—

—

—

30

30

70

70

30

30

15

15

100

100

15

15

100

100

100

100

—

—

—

30

30

—

—

—

—

—

—

100

100

—

ns

µs

ns

Item Symbol Min. Typ. Max. Unit

HST

HCK

VST

VCK

ENB

PCG

PRG

BLK

∗6

µs

Page 8

– 8 –

LCX034ALT

∗7

Definitions: The right-pointing arrow ( ) means +.

The left-pointing arrow ( ) means –.

The black dot at an arrow ( ) indicates the start of measurement.

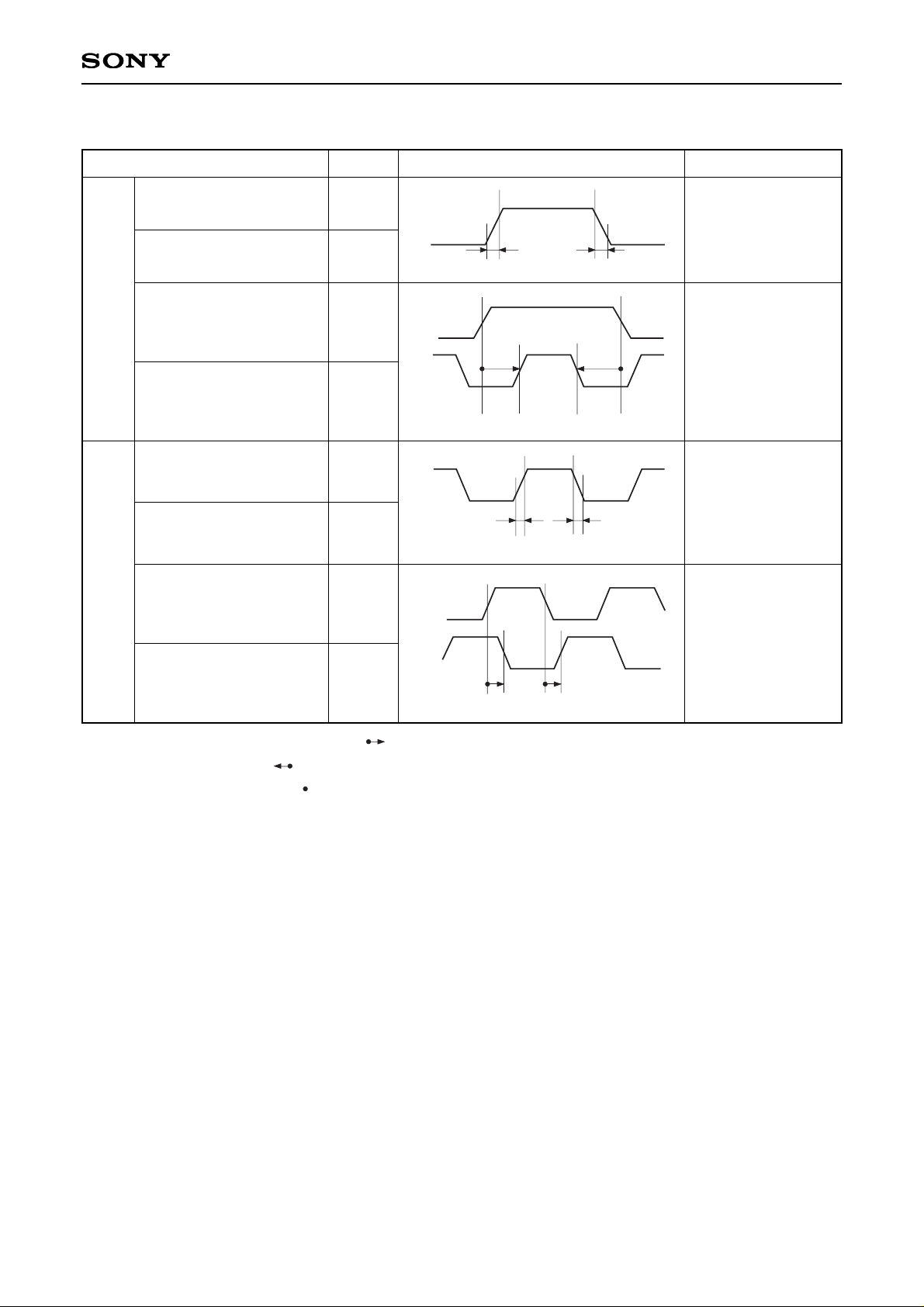

<Horizontal Shift Register Driving Waveform>

Hst rise time

HST

HCK

Hst fall time

Hst data set-up time

Hst data hold time

Hckn rise time

∗3

Hckn fall time

∗3

Hck1 fall to Hck2 rise time

Hck1 rise to Hck2 fall time

• Hckn

∗5

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

• Hckn

∗5

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

• Hckn

∗5

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

trHst

tfHst

tdHst

thHst

trHckn

tfHckn

to1Hck

to2Hck

Item Symbol Waveform Conditions

90%

10%

10%

90%

Hst

trHst tfHst

50%

50%

∗

7

Hst

Hck1

tdHst thHst

50%

50%

∗

5

Hckn

10%

10%

90%

90%

trHckn tfHckn

50%

50%

∗

7

Hck1

to2Hck to1Hck

50%

50%

Hck2

Page 9

– 9 –

LCX034ALT

<Vertical Shift Register Driving Waveform>

VCK

ENB

Vck rise time

Vck fall time

Enb rise time

Enb fall time

trVck

tfVck

trEnb

tfEnb

Vck rise/fall to

Enb rise time

toEnb

Horizontal video period

completed to Enb fall time

tdEnb

Enb fall to Pcg rise time toPcg

Item Symbol Waveform Conditions

Vck

10%

10%

90%

90%

trVckn tfVckn

Vst rise time

VST

Vst fall time

Vst data set-up time

Vst data hold time

trVst

tfVst

tdVst

thVst

90%

10%

10%

90%

Vst

trVst tfVst

50%

50%

∗

7

Vst

Vck

tdVst thVst

50%

50%

90%

10%

10%

90%

Enb

tfEnb trEnb

50%

50%

toEnb

Vck

H. blanking periodH. video period

tdEnb

toPcg

50% 50%

Enb

Pcg

∗

7

Page 10

– 10 –

LCX034ALT

tfBlk

toVst

BLK

Blk rise time

Blk fall time

Blk fall to Vst rise time

trBlk

Blk

50%

50%

toVst

Vst

∗

7

50%

∗8

Input the pulse obtained by taking the OR of the above pulse (PCG) and BLK to the PCG input pin.

Item Symbol Waveform Conditions

Pcg rise time

PCG

∗8

PRG

trPcg

Pcg fall time tfPcg

Pcg rise to Prg rise time

toPrgr

Pcg fall to Prg fall time

toPrgf

Prg rise to Pcg fall time

toPcg

Pcg fall to horizontal

video period start time

toVideo

Pcg pulse width

twPcg

Prg rise to

Vck rise/fall time

toVck

90%

10%

10%

90%

Pcg

tfEnb trEnb

50%

H. video period startH. blanking period

toPcg

toVideo

50%

Pcg

50%

toPrgr

toPrgf

50%

Prg

twPcg

∗

7

50%

50%

toVck

Prg

Vck

∗

7

Page 11

– 11 –

LCX034ALT

Electrical Characteristics (Ta = 25°C, HVDD = 15.5V, VVDD = 15.5V)

1. Horizontal drivers

Item

Input pin capacitance HCKn

HST

Input pin current HCK1

HCK2

HST

RGT

Video signal input pin capacitance

Current consumption

CHckn

CHst

Csig

IH

HCK1 = GND

HCK2 = GND

HST = GND

RGT = GND

HCKn: HCK1, HCK2 (4.0MHz)

—

—

–500

–1000

–500

–150

—

—

7

7

–250

–300

–150

–30

130

10.0

12

12

—

—

—

—

200

15.0

pF

pF

µA

µA

µA

µA

pF

mA

Symbol Min. Typ. Max. Unit Condition

2. Vertical drivers

Item

Input pin capacitance VCK

VST

Input pin current VCK

PCG, VST, ENB, DWN, BLK, MODE1,

MODE2, MODE3

Current consumption

CVck

CVst

IV

—

—

–1000

–150

—

7

7

–150

–30

3.0

12

12

—

—

6.0

pF

pF

µA

µA

mA

Symbol Min. Typ. Max. Unit Condition

3. Total power consumption of the panel

Item

Total power consumption of the

panel

PWR — 200 300 mW

Symbol Min. Typ. Max. Unit

4. Pin input resistance

Item

Pin – VSS input resistance Rpin 0.4 1 — MΩ

Symbol Min. Typ. Max. Unit

VCK = GND

PCG, VST, ENB, DWN,

BLK, MODE1, MODE2,

MODE3 = GND

VCK: (24.0kHz)

5. Uniformity improvement signal

Item

Input pin capacitance for uniformity

improvement signal

CPSIGo 8 nF

Symbol Min. Typ. Max. Unit

—

12

Page 12

– 12 –

LCX034ALT

Reflection Preventive Processing

When a retardation film which rotates the polarization axis is used to adjust to the polarization direction of a

polarization screen or prism, use a retardation film with reflection preventive processing on the surface. This

prevents characteristic deterioration caused by luminous reflection.

Electro-optical Characteristics (SVGA mode)

Item

Contrast ratio

25°C

25°C

25°C

60°C

25°C

60°C

25°C

60°C

0°C

25°C

0°C

25°C

60°C

25°C

25°C

CR

T

RV90-25

GV90-25

BV90-25

RV90-60

GV90-60

BV90-60

RV50-25

GV50-25

BV50-25

RV50-60

GV50-60

BV50-60

RV10-25

GV10-25

BV10-25

RV10-60

GV10-60

BV10-60

ton0

ton25

toff0

toff25

F

YT60

CTK

120

11

1.0

1.1

1.2

1.0

1.0

1.1

1.4

1.5

1.6

1.4

1.4

1.5

1.9

2.0

2.1

1.9

1.9

1.9

—

—

—

—

—

—

—

150

13

1.3

1.5

1.6

1.3

1.4

1.5

1.7

1.8

1.9

1.6

1.7

1.8

2.2

2.3

2.4

2.1

2.2

2.3

30

12

100

30

–65

—

—

—

—

1.7

1.9

2.0

1.6

1.7

1.9

2.0

2.1

2.2

1.9

2.0

2.1

2.5

2.6

2.7

2.4

2.5

2.6

80

40

200

70

–40

0

5

1

2

3

4

5

6

7

—

%

V

ms

dB

s

%

Optical transmittance

V-T

characteristics

V90

V50

ON time

OFF time

V10

Response time

Flicker

Image retention time

Cross talk

Symbol Measurement method Min. Typ. Max. Unit

Page 13

– 13 –

LCX034ALT

<Electro-optical Characteristics Measurement>

• Measurement system I

• Measurement system II

Luminance

Meter

Measurement

Equipment

Light Detector

Measurement

Equipment

Screen: Made by Sony (VPS-120FH: Gain 2.8, Glass Beaded Type) or equivalent

Projection lens: Focal distance 80mm, F1.9

Light source: 155W metal Haloid arc lamp (Color temperature 7500K ± 500)

(× 24, Sensor area: 7mmφ)

Polarizer: Side of incidence – Nitto Denko’s EG-1224DU or Polatechno’s SKN-1824ZT or equivalent

Side of output light – Polatechno's SHC-128 or equivalent

Optical fiber

LCD panel

Light receptor lens

Drive Circuit

Light

Source

Basic measurement conditions

(1) Driving voltage

HVDD = 15.5V, VVDD = 15.5V

VVC = 7.0V, Vcom = 6.5V

(2) Measurement temperature

25°C unless otherwise specified.

(3) Measurement point

One point in the center of the screen unless otherwise specified.

(4) Measurement systems

Two types of measurement systems are used as shown below.

(5) Video input signal voltage (Vsig)

Vsig = 7.0 ± VAC [V] (VAC = signal amplitude)

Screen

LCD Projector

Approx. 2000mm

1. Contrast Ratio

Contrast Ratio (CR) is given by the following formula (1).

L (White)

CR = ... (1)

L (Black)

L (White): Surface luminance of the center of the screen at the input signal amplitude VAC = 0.5V.

L (Black): Surface luminance of the center of the screen at VAC = 4.5V.

Both luminosities are measured by System I.

Page 14

– 14 –

LCX034ALT

2. Optical Transmittance

Optical Transmittance (T) is given by the following formula (2).

White luminance

T = × 100 [%] ... (2)

Luminance of light source

"White luminance" means the maximum luminance on the screen at the input signal amplitude VAC = 0.5V

on Measurement System I.

3. V-T Characteristics

V-T characteristics, or the relationship between signal

amplitude and the transmittance of the panels, are

measured by System II by inputting the same signal

amplitude VAC to each input pin. V90, V50, and V10

correspond to the voltages which define 90%, 50%,

and 10% of transmittance respectively.

4. Response Time

Response time ton and toff are defined by

formulas (5) and (6) respectively.

ton = t1 – tON ...(5)

toff = t2 – tOFF ...(6)

t1: time which gives 10% transmittance of

the panel.

t2: time which gives 90% transmittance of

the panel.

The relationships between t1, t2, tON and

tOFF are shown in the right figure.

90

50

10

V

90 V50 V10

VAC – Signal amplitude [V]

Transmittance [%]

Input signal voltage (Waveform applied to the measured pixels)

4.5V

0.5V

7.0V

0V

Optical transmittance output waveform

100%

90%

10%

0%

tON t1

ton

tOFF t2

toff

Page 15

– 15 –

LCX034ALT

5. Flicker

Flicker (F) is given by formula (7). DC and AC (SVGA/VGA/PC98/NTSC: 30Hz, rms, PAL: 25Hz, rms)

components of the panel output signal for gray raster∗mode are measured by a DC voltmeter and a spectrum

analyzer in System II.

F [dB] = 20log

{

AC component

}

...(7)

DC component

6. Image Retention Time

Apply the monoscope signal to the LCD panel for 60 minutes and then change this signal to the gray scale

of Vsig = 7.0 ± VAC (VAC: 3 to 4V). Judging by sight at the VAC that holds the maximum image retention,

measure the time till the residual image becomes indistinct.

∗

Monoscope signal conditions:

Vsig = 7.0 ± 4.5 or ±2.0 [V]

(shown in the right figure)

Vcom = 6.6V

7. Cross Talk

Cross talk is determined by the luminance differences between adjacent areas represented by Wi' and

Wi (i = 1 to 4) around a black window (Vsig = 4.5 V/1V).

Cross talk value CTK = × 100 [%]

∗

Each input signal voltage for gray raster mode

is given by Vsig = 7.0 ± V50 [V]

where: V50 is the signal amplitude which gives

50% of transmittance in V-T characteristics.

Black level

White level

Vsig waveform

7.0V

0V

4.5V

2.0V

4.5V

2.0V

W1

W1

'

W3

W3

'

W2

W2

' W4'

W4

Wi' – Wi

Wi

Page 16

– 16 –

LCX034ALT

Viewing angle characteristics (Reference Value)

90

270

180

0

Theta

Phi

30 70

θ

φ

φ180°

X

φ270°

Y

φ0°

φ90°

Z

θ0°

Measurement method

5010

Page 17

– 17 –

LCX034ALT

Optical transmittance of LCD panel (Reference Value)

20

10

0

400 500 600 700

Wavelength [nm]

Trans. [%]

Measurement method: Measurement system ΙΙ

Page 18

– 18 –

LCX034ALT

1. Dot Arrangement

The dots are arranged in a stripe. The shaded area is used for the dark border around the display.

612 dots

4 dots

604 dots (Effective 10.87mm)

Active area

Photo-Shielding

Gate SW Gate SW Gate SW

6 dots

816 dots

6 dots

4 dots

804 dots (Effective 14.47mm)

Page 19

– 19 –

LCX034ALT

2. LCD Panel Operations

[Description of basic operations]

• A vertical driver, which consists of vertical shift registers, enable-gates and buffers, applies a selected pulse

to every 604 gate lines sequentially in a single horizontal scanning period. (in SVGA mode)

• A horizontal driver, which consists of horizontal shift registers, gates and CMOS sample-and-hold circuits,

applies selected pulses to every 804 signal electrodes sequentially in a single horizontal scanning period.

These pulses are used to supply the sampled video signal to the row signal lines.

• Vertical and horizontal shift registers address one pixel, and then Thin Film Transistors (TFTs; two TFTs) turn

on to apply a video signal to the dot. The same procedures lead to the entire 604 × 804 dots to display a

picture in a single vertical scanning period.

• The data and video signals shall be input with the 1H-inverted system.

[Description of operating mode]

This LCD panel can change the active area by displaying a black frame to support various computer or video

signals. The active area is switched by MODE1, 2 and 3. However, the center of the screen is not changed.

The active area setting modes are shown below.

MODE1 MODE2 MODE3 Display mode

L

H

H

L

H

L

H

L

SVGA

804 × 604

PAL

762 × 572

VGA/NTSC

644 × 484

PC98

644 × 404

L

L

L

H

This LCD panel has the following functions to easily apply to various uses, as well as various broadcasting

systems.

• Right/left inverse mode

• Up/down inverse mode

These modes are controlled by two signals (RGT and DWN). The right/left and/or up/down setting modes are

shown below.

Right/left and/or up/down mean the direction when the Pin 1 marking is located at the right side with the pin

block upside.

To locate the active area in the center of the panel in each mode, polarity of the start pulse and clock phase for

both the H and V systems nust be varied. The phase relationship between the start pulse and the clock for

each mode is shown on the following pages.

RGT

Mode

Right scan

Left scan

H

L

DWN Mode

Down scan

Up scan

H

L

Page 20

– 20 –

LCX034ALT

VST (DWN = H)

VST (DWN = L)

(1.2) PAL

VD

1

2

VCK

569 570 571 572

VST (DWN = H)

VST (DWN = L)

(1.1) SVGA

VD

1 2

VCK

601 602 603 604

VD

1 2

VCK

482 483 484

(1.3) VGA/NTSC

VD

1 2

VCK

401 402 403 404

(1.4) PC98

VST (DWN = H)

VST (DWN = L)

VST (DWN = H)

VST (DWN = L)

481

Vertical display cycle 572H

Vertical display cycle 604H

Vertical display cycle 484H

Vertical display cycle 404H

(1) Vertical direction display cycle

Page 21

– 21 –

LCX034ALT

(2.1.1) SVGA, RGT = H

Horizontal display cycle

HST

HCK1

1 2 3 4 131 132 133 134

HCK2

HD

(2.1.2) SVGA, RGT = L

Horizontal display cycle

HST

HCK1

HCK2

HD

1

2

3 4 131

132 133

134

1 2 3 4

Horizontal display cycle

HST

HCK1

125 126 127 128

(2.2.1) PAL, RGT = H

HCK2

Horizontal display cycle

HST

HCK1

1 2 3 4 125 126 127 128

(2.2.2) PAL, RGT = L

HCK2

HD

HD

(2) Horizontal direction display cycle

Page 22

– 22 –

LCX034ALT

Horizontal display cycle

HST

HCK1

105 106 107 108

(2.3.1) VGA/NTSC/PC98, RGT = H

HCK2

Horizontal display cycle

HST

HCK1

1 2 3 4

105 106

107 108

(2.3.2) VGA/NTSC/PC98, RGT = L

HCK2

HD

HD

1 2 3 4

Page 23

– 23 –

LCX034ALT

3. 6-dot Simultaneous Sampling

The horizontal shift register samples signals SIG1 to SIG6 simultaneously. This requires phase matching

between signals SIG1 to SIG6 to prevent the horizontal resolution from deteriorating. Thus, phase matching

between each signal is required using an external signal delaying circuit before applying the video signal to

the LCD panel.

The block diagram of the delaying procedure using the sample-and-hold method is as follows. The following

phase relationship diagram indicates the phase setting for right scan (RGT = High level). For left scan (RGT =

Low level), the phase settings for signals SIG1 to SIG6 are exactly reversed.

S/H

CK1

CK2

SIG3

SIG6

SIG1

LCX034ALT

SIG3

SIG6

SIG1

SIG2

SIG2

SIG4

SIG4

SIG5

SIG5

CK3

CK4

CK5

S/H

S/H

S/H

S/H

S/H

CK6

S/H

S/H

S/H

S/H

S/H

5

3

2

4

6

7

HCKn

CK1

CK3

CK5

CK2

CK4

CK6

<Phase relationship of delaying sample-and-hold pulses> (right scan)

Page 24

– 24 –

LCX034ALT

Display System Block Diagram

An example of display system is shown below.

R-IN

G-IN

B-IN

Vsync

Hsync

CLP, PRG

MCK1

FRP, S/H Control

6

HST, HCK, VST, VCK, PCG, ENB

Pre Driver

CXA2111R

Timing

Generator

CXD3500R

PLL

CXA3106Q

S/H Driver

CXA2112R

S/H Driver

CXA2112R

S/H Driver

CXA2112R

LCX034

R

LCX034

G

LCX034

B

6

6

Page 25

– 25 –

LCX034ALT

Notes on Handling

(1) Static charge prevention

Be sure to take the following protective measures. TFT-LCD panels are easily damaged by static charges.

a) Use non-chargeable gloves, or simply use bare hands.

b) Use an earth-band when handling.

c) Do not touch any electrodes of a panel.

d) Wear non-chargeable clothes and conductive shoes.

e) Install conductive mats on the working floor and working table.

f) Keep panels away from any charged materials.

g) Use ionized air to discharge the panels.

(2) Protection from dust and dirt

a) Operate in a clean environment.

b) When delivered, the panel surface (glass panel) is covered by a protective sheet. Peel off the protective

sheet carefully so as not to damage the glass panel.

c) Do not touch the glass panel surface. The surface is easily scratched. When cleaning, use a clean-

room wiper with isopropyl alcohol. Be careful not to leave a stain on the surface.

d) Use ionized air to blow dust off the glass panel.

(3) Light resistance

Orientation film and organic matter such as liquid crystal used inside of the LCD panel deteriorate by the

light chemical reaction. As a result, its indication characteristic may irreversible change. The progress of its

chemical reaction is influenced by short wavelength side's light (characteristics of UV cut filter) and

temperature when quantitiy of light is constant. To control its progress, attach suitable UV cut filter between

light source and LCD panel. (Sharp characteristic's filter of λ > 425nm is recommended.) Also, use suitable

IR cut filter to lower the temperature of LCD panel and cool the panel carefully.

(4) Other handling precautions

a) Do not twist or bend the flexible PC board especially at the connecting region because the board is

easily deformed.

b) Do not drop the panel.

c) Do not twist or bend the panel or panel frame.

d) Keep the panel away from heat sources.

e) Do not dampen the panel with water or other solvents.

f) Avoid storing or using the panel at a high temperature or high humidity, which may result in panel

damages.

g) Minimum radius of bending curvature for a flexible substrate must be 1mm.

h) Torque required to tighten screws on a panel must be 0.098N · m (measurement screw : JCIS Type 1,

M1.7 flat head screw) or less.

i) Do not pressure the portion other than mounting hole (cover).

Page 26

– 26 –

LCX034ALT

Package Outline Unit: mm

Active Area

1

2

3

4

5

7

8

9

Output light

Polarizing Axis

25.0 ± 0.15

(14.47)

(10.87)

12.0 ± 0.15

(75.5)

101.5 ± 1.4

23.0 ± 0.1

26.0 ± 0.15

8-R1.0

12.5 ± 0.05

4.9 ± 0.2

Thickness of the connector

0.3 ± 0.05

2.2 ± 0.1

1.5 ± 0.1

12.5 ± 0.15

2.0 ± 0.1

21.0 ± 0.1

Incident

light

5-φ1.8 ± 0.05

electrode (enlarged)

PIN24

PIN1

P 0.5 ± 0.02 × 23 = 11.5 ± 0.03

0.5 ± 0.1

0.5 ± 0.15

4.0 ± 0.4

0.35 ± 0.03

The rotation angle of the active area relative to H and V is ± 1°.

Incident light

Polarizing Axis

6

weight 5.6g

Description

Molding material

Outside frame

Reinforcing board

Reinforcing material

F P C

No

1

2

3

4

5

6

Cover 1

7

8

Cover 2

9

Glass 1

Glass 2

Sony Corporation

Loading...

Loading...