Page 1

LCX009AKB

For the availability of this product, please contact the sales office.

1.8cm (0.7-inch) NTSC/PAL Color LCD Panel

Description

The LCX009AKB is a 1.8cm diagonal active matrix

TFT-LCD panel addressed by the polycrystalline

silicon super thin film transistors with built-in

peripheral driving circuit. This panel provides fullcolor representation in NTSC/PAL mode. RGB dots

are arranged in a delta pattern featuring high picture

quality of no fixed color patterns, which is inherent in

vertical stripes and mosaic pattern arrangements.

Features

• The number of active dots: 180,000 (0.7-inch; 1.8cm in diagonal)

• Horizontal resolution: 400 TV lines

• High optical transmittance: 3.5% (typ.)

• High contrast ratio with normally white mode: 200 (typ.)

• Built-in H and V driving circuit (built-in input level conversion circuit, TTL drive possible)

• High quality picture representation with RGB delta arranged color filters

• Full-color representation

• NTSC/PAL compatible

• Right/left inverse display function

Element Structure

• Dots

Total dots : 827 (H) × 228 (V) = 188,556

Active dots : 800 (H) × 225 (V) = 180,000

• Built-in peripheral driving circuit using the polycrystalline silicon super thin film transistors.

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

– 1 –

E94501C64-ST

Page 2

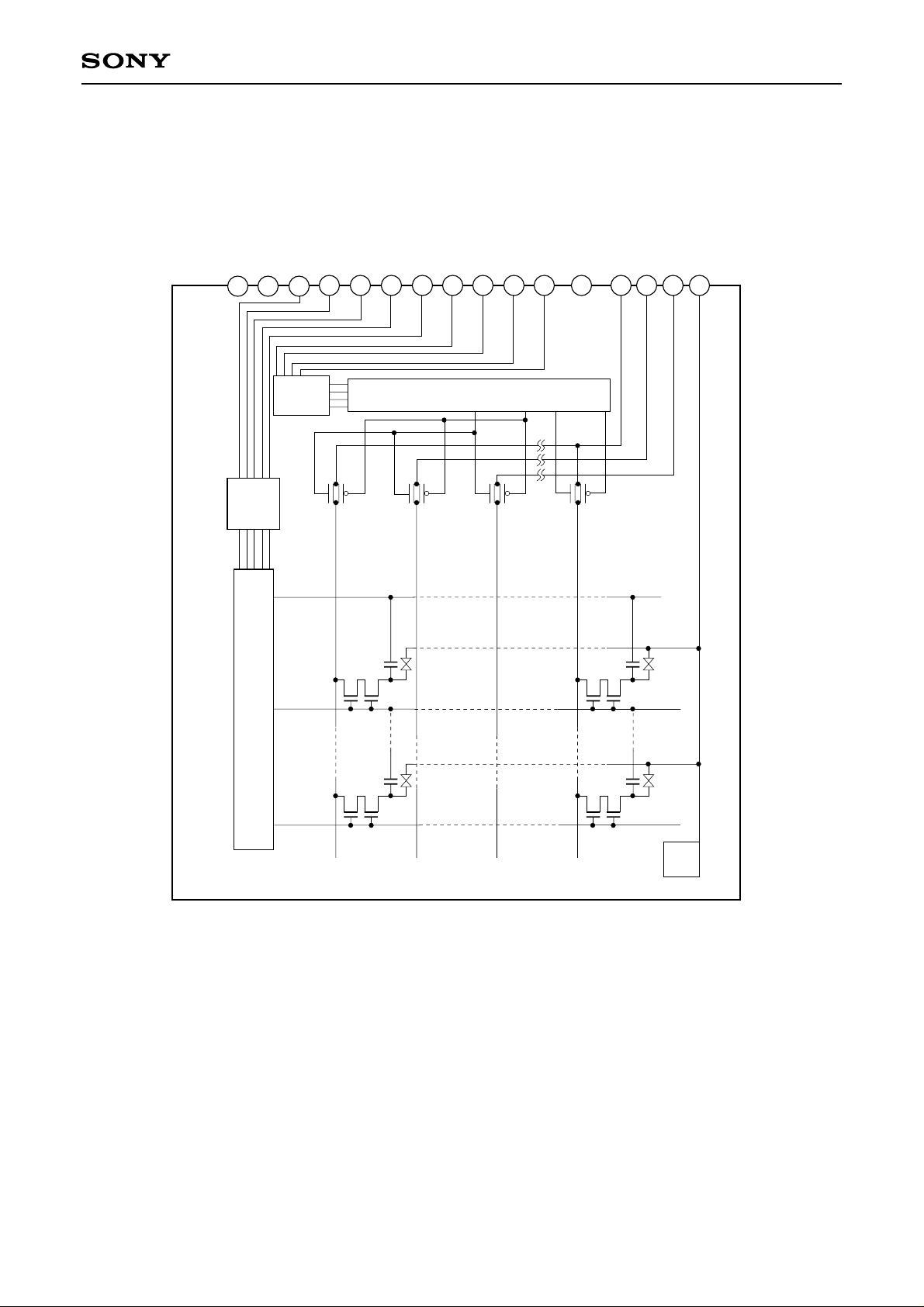

Block Diagram

LCX009AKB

DD

VV

16

V Level

Shifter

15

SS

V

H Level

Shifter

14

VST

VCK1

VCK2

13

12

CS LC

11

EN

CLR

10

HST

RGT

9

8

H Shift Register

HCK2

7

HCK1

6

DD

RED

BLUE

HV

5

4

GREEN

COM

1

2

3

V Shift Register

COM

Pad

– 2 –

Page 3

Absolute Maximum Ratings (Vss = 0V)

• H driver supply voltage HVDD –1.0 to +17 V

• V driver supply voltage VVDD –1.0 to +17 V

• H driver input pin voltage HST, HCK1, HCK2 –1.0 to +17 V

RGT

• V driver input pin voltage VST, VCK1, VCK2 –1.0 to +17 V

CLR, EN

• Video signal input pin voltage GREEN, RED, BLUE –1.0 to +15 V

• Operating temperature Topr –10 to +70 °C

• Storage temperature Tstg –30 to +85 °C

Operating Conditions (Vss = 0V)

• Supply voltage

HVDD 13.5 ± 0.5 V

VVDD 13.5 ± 0.5 V

• Input pulse voltage (Vp-p of all input pins except video signal input pins)

Vin 3.0V or more

LCX009AKB

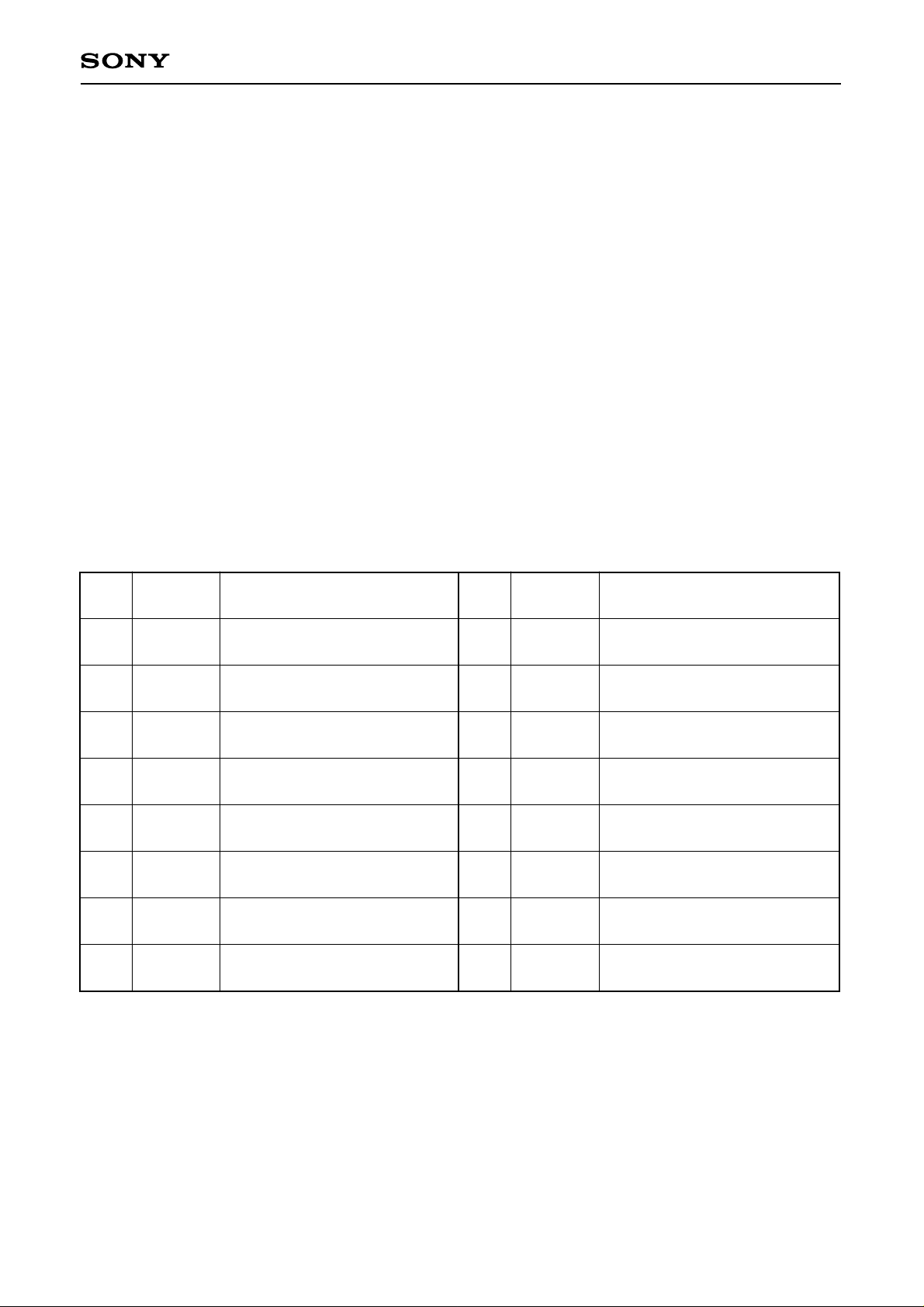

Pin Description

Pin

No.

1

2

3

4

5

6

7

8

Symbol Description

COM

GREEN

RED

BLUE

HVDD

HCK1

HCK2

HST

Common voltage of panel

Video signal (G) to panel

Video signal (R) to panel

Video signal (B) to panel

Power supply for H driver

Clock pulse for

H shift register drive

Clock pulse for

H shift register drive

Start pulse for

H shift register drive

Pin

No.

9

10

11

12

13

14

15

16

Symbol Description

RGT

CLR

EN

VCK1

VCK2

VST

Vss

VVDD

Drive direction pulse for H shift

register (H: normal, L: reverse)

Improvement pulse

for uniformity

Enable pulse for gate selection

Clock pulse for

V shift register drive

Clock pulse for

V shift register drive

Start pulse for

V shift register drive

GND (H, V drivers)

Power supply for V driver

– 3 –

Page 4

LCX009AKB

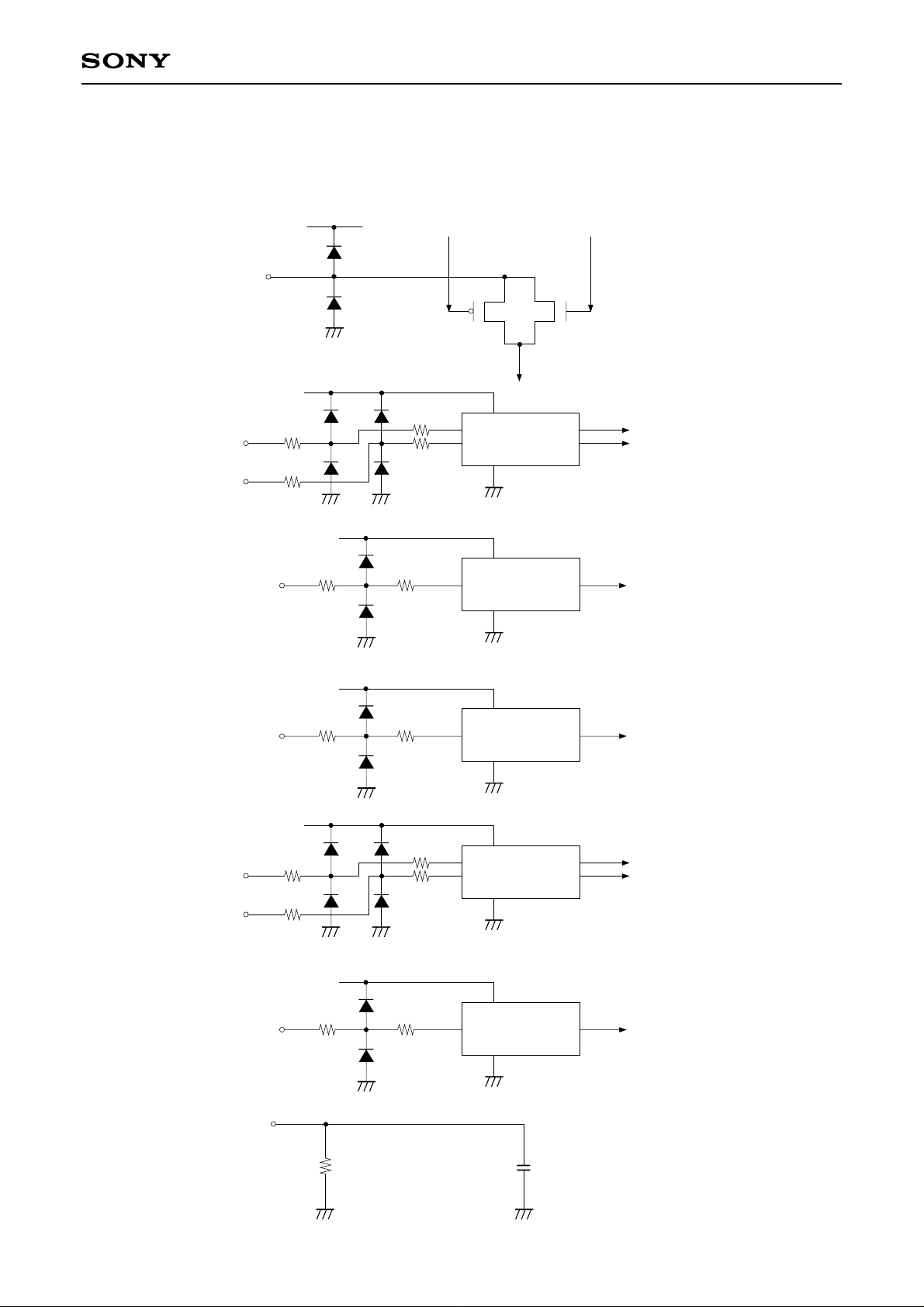

Input Equivalent Circuit

To prevent static charges, protective diodes are provided for each pin except the power supply. In addition,

protective resistors are added to all pins except video signal input. The equivalent circuit of each input pin is

shown below. (The resistor value: typ.)

(1) Video signal input

From H driver

Input

HV

DD

(2) HCK1, HCK2

(3) HST

(4) RGT

(5) VCK1, VCK2

HCK1

HCK2

VCK1

VCK2

Input

Input

HV

250Ω

250Ω

VV

2.5kΩ

DD

DD

1kΩ

HV

HV

DD

DD

250Ω250Ω

2.5kΩ2.5kΩ

250Ω

250Ω

2.5kΩ

1kΩ

Signal line

Level conversion

circuit

(2-phase input)

Level conversion

circuit

(single-phase input)

Level conversion

circuit

(single-phase input)

Level conversion

circuit

(2-phase input)

(6) VST, CLR, EN

(7) COM

Input

Input

VV

DD

1MΩ

2.5kΩ2.5kΩ

Level conversion

circuit

(single-phase input)

LC

– 4 –

Page 5

LCX009AKB

Level Conversion Circuit

The LCX009AKB has a built-in level conversion circuit in the clock input unit located inside the panel. The

circuit voltage is stepped up to 13.5V. This level conversion circuit meets the specifications of a 3.0V to 5.0V

power supply of the externally-driven IC mainly. However, this circuit can operate even with a 12V power

supply of the IC.

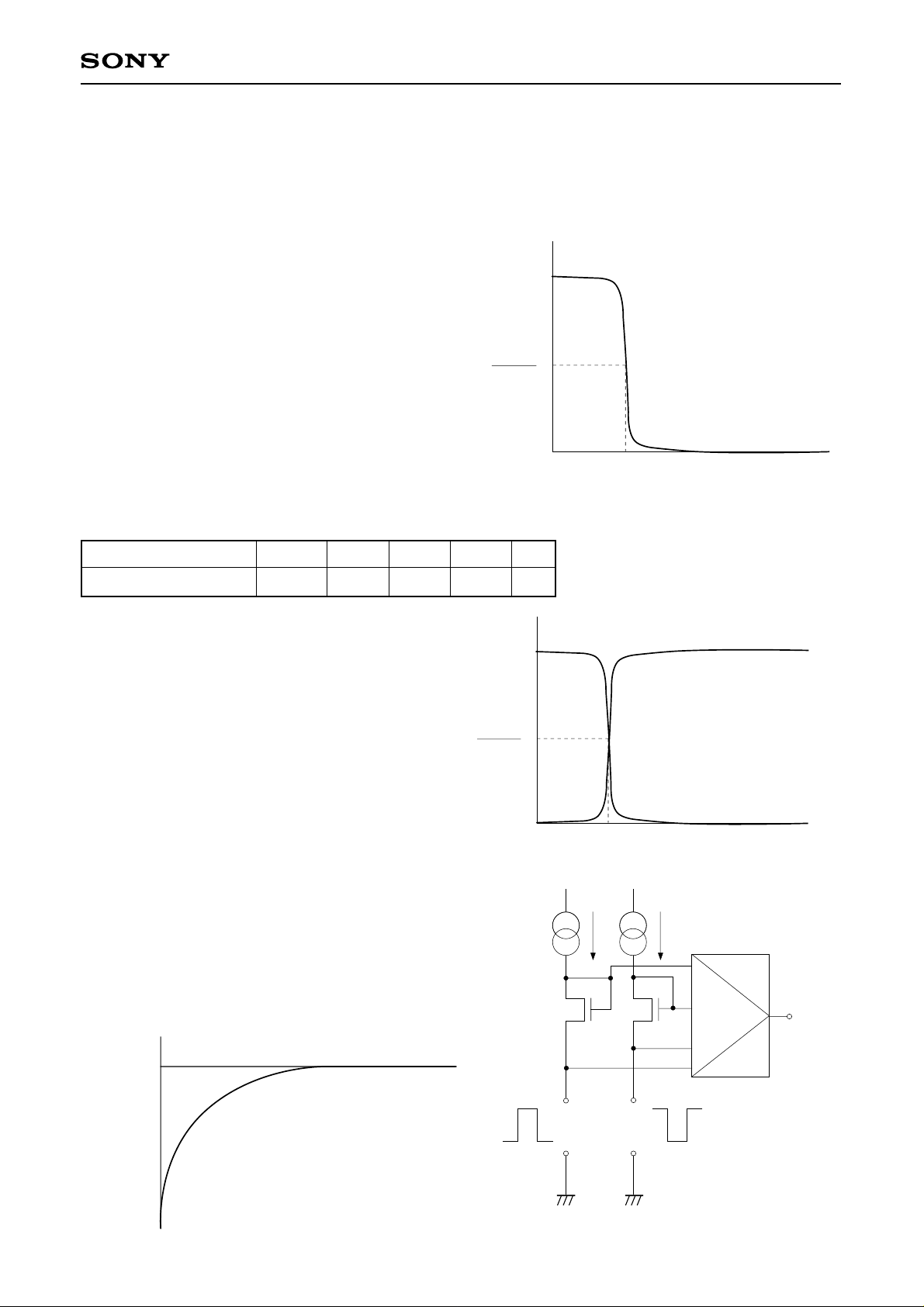

1. I/O characteristics of level conversion circuit

HVDD

(For a single-phase input unit)

An example of the I/O voltage characteristics of a

level conversion circuit is shown in the figure to the

right. The input voltage value that becomes half the

HVDD

2

Example of single-phase

I/O characteristics

output voltage (after voltage conversion) is defined

as Vth.

Output voltage (inside panel)

The Vth value varies depending on the HVDD and

VVDD voltages.

The Vth values under standard conditions are

Vth

Input voltage [V]

indicated in the table below. (HST, VST, EN, CLR, and RGT in the case of a single-phase input)

HVDD = VVDD = 13.5V

Item

Symbol Min. Typ. Max. Unit

Vth voltage of circuit Vth 0.35 1.50 2.70 V

(For a differential input unit)

An example of I/O voltage characteristics of a

HVDD

level conversion circuit for a differential input is

shown in the figure to the right. Although the

characteristics, including those of the Vth voltage,

are basically the same as those for a singlephased input, the two-phased input phase is

defined. (Refer to clock timing conditions.)

HVDD

2

Output voltage (inside panel)

Example of differential

I/O characteristics

2. Current characteristics at the input pin of level

conversion circuit

A slight pull-in current is generated at the input

pin of the level conversion circuit. (The equivalent

circuit diagram is shown to the right.) The current

volume increases as the voltage at the input pin

decreases, and is maximized when the pin is

grounded.) (Electrical characteristics are defined

by the grounded input.)

0

0

Input pin current

Max. value

Input pin voltage [V]

Pull-in current

characteristics at the

input pin

10

– 5 –

HCK1

input

Vth

Input voltage [V]

VDD

Output

HCK2

input

Level conversion equivalent circuit

Page 6

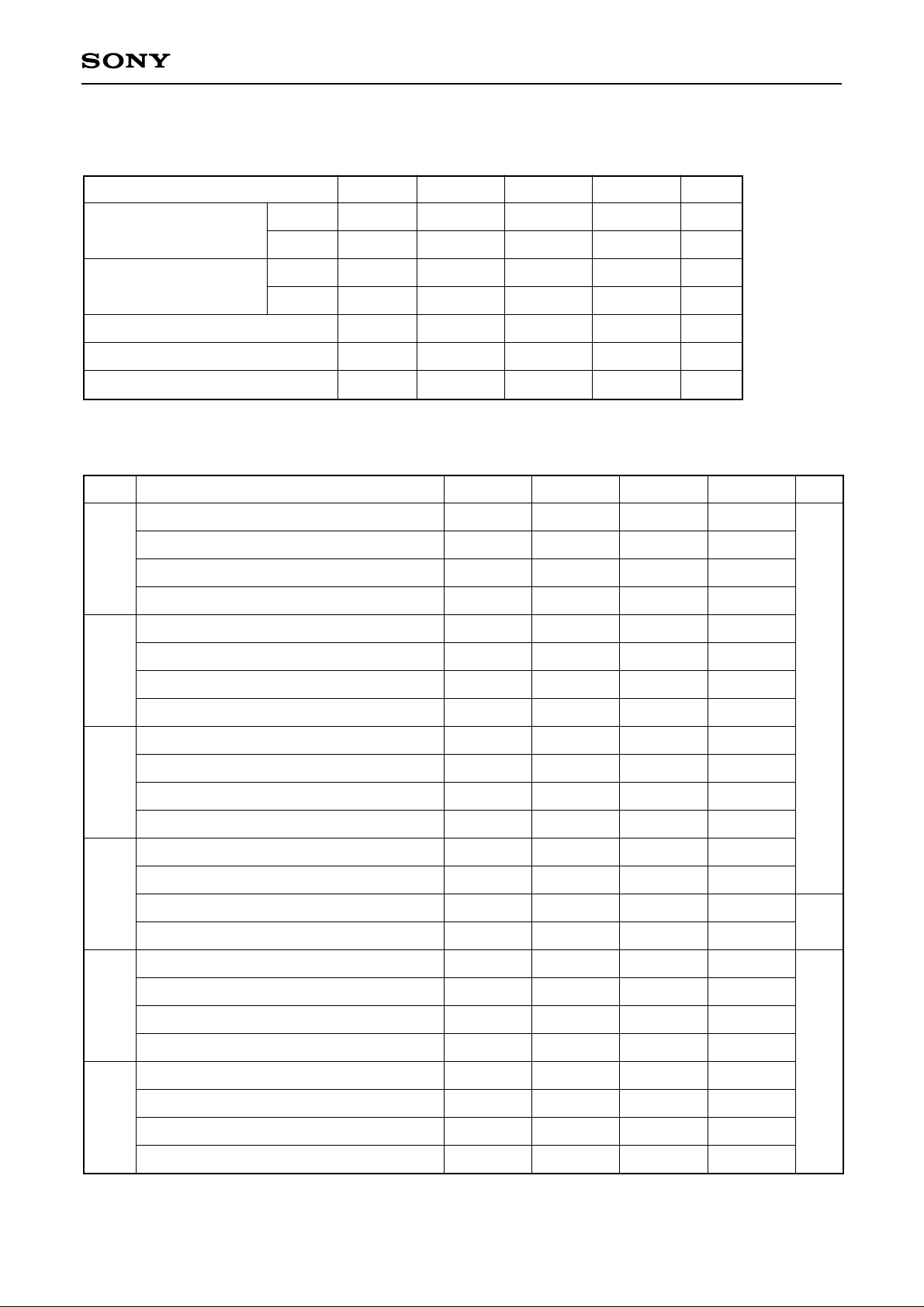

Input Signals

1. Input signal voltage conditions (Vss = 0V)

LCX009AKB

Item

(Low)

Symbol Min. Typ. Max. Unit

VHIL

H driver input voltage

(High)

(Low)

VHIH

VVIL

V driver input voltage

(High)

Video signal center voltage

Video signal input range

∗1

Common voltage of panel

∗1

Video input signal should be symmetrical to VVC.

VVIH

VVC

Vsig

Vcom

2. Clock timing conditions (Ta = 25°C)

Item Symbol Min. Typ. Max. Unit

Hst rise time

Hst fall time

HST

Hst data set-up time

Hst data hold time

Hckn∗2rise time

–0.3

3.0

–0.3

3.0

5.8

VVC – 4.5

VVC – 0.55

trHst

tfHst

tdHst

thHst

trHckn

0.0

5.0

0.0

5.0

6.0

VVC – 0.40

–100

–200

0.3

5.5

0.3

5.5

6.2

VVC + 4.5

VVC – 0.25

60

–120

V

V

V

V

V

V

V

30

30

100

–50

30

HCK

CLR

VST

VCK

EN

Hckn∗2fall time

Hck1 fall to Hck2 rise time

Hck1 rise to Hck2 fall time

Clr rise time

Clr fall time

Clr pulse width

Clr fall to Hst rise time

Vst rise time

Vst fall time

Vst data set-up time

Vst data hold time

Vckn∗2rise time

Vckn∗2fall time

Vck1 fall to Vck2 rise time

Vck1 rise to Vck2 fall time

En rise time

En fall time

Vck2 rise to En fall time

tfHckn

to1Hck

to2Hck

trClr

tfClr

twClr

toHst

trVst

tfVst

tdVst

thVst

trVckn

tfVckn

to1Vck

to2Vck

trEn

tfEn

tdVck2

–15

–15

3400

1850

–50

–50

–20

–20

–20

0

0

3500

1950

32

–32

0

0

0

30

15

15

100

100

3600

2050

100

100

50

–20

100

100

20

20

100

100

20

ns

µs

ns

Vck1 rise to En rise time

∗2

Hckn and Vckn mean Hck1, Hck2 and Vck1, Vck2. (fHckn = 2.75MHz, fVckn = 7.81kHz)

tdVck1

–20

– 6 –

0

20

Page 7

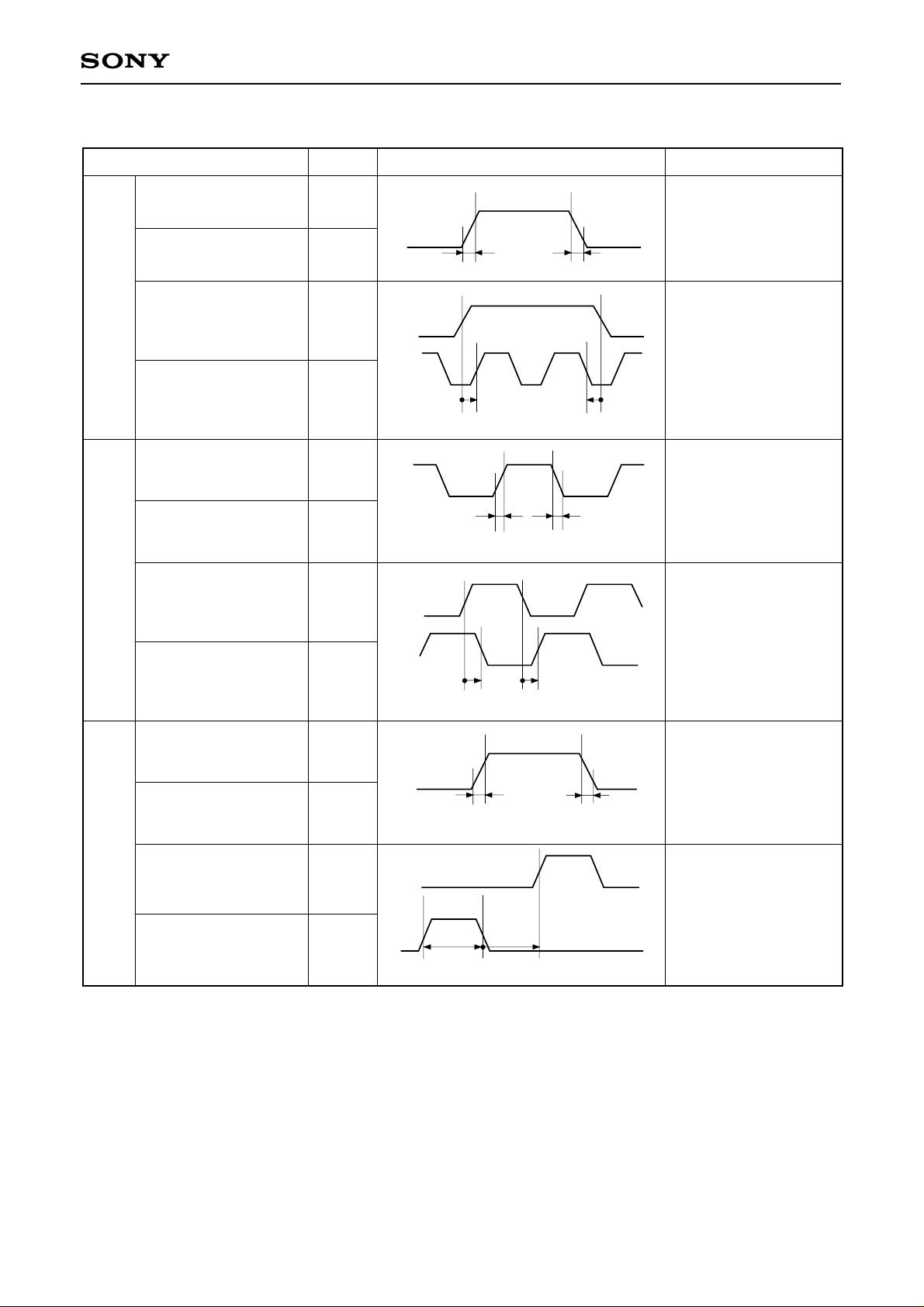

<Horizontal Shift Register Driving Waveform>

Item Symbol Waveform Conditions

LCX009AKB

HST

HCK

Hst rise time

Hst fall time

Hst data set-up time

Hst data hold time

Hckn∗2rise time

Hckn∗2fall time

Hck1 fall to

Hck2 rise time

Hck1 rise to

Hck2 fall time

trHst

tfHst

tdHst

thHst

trHckn

tfHckn

to1Hck

to2Hck

Hst

∗3

Hst

Hck1

Hckn

∗3

Hck1

Hck2

90%

10%

trHst tfHst

50%

50%

tdHst thHst

90%

∗2

10%

trHckn tfHckn

50%

50%

to2Hck to1Hck

90%

50%

50%

50%

90%

10%

10%

50%

∗2

• Hckn

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

∗2

• Hckn

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

• Hckn

∗2

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

tdHst = 60ns

thHst = –120ns

• tdHst = 60ns

thHst = –120ns

CLR

Clr rise time

Clr fall time

Clr pulse width

Clr fall to

Hst rise time

trClr

tfClr

twClr

toHst

Clr

Hst

Clr

90%

10%

trClr tfClr

50%

50% 50%

twClr toHst

90%

10%

∗2

• Hckn

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

∗2

• Hckn

duty cycle 50%

to1Hck = 0ns

to2Hck = 0ns

– 7 –

Page 8

<Vertical Shift Register Driving Waveform>

Item Symbol Waveform Conditions

LCX009AKB

VST

VCK

Vst rise time

Vst fall time

Vst data set-up time

Vst data hold time

Vckn∗2rise time

Vckn∗2fall time

Vck1 fall to

Vck2 rise time

Vck1 rise to

Vck2 fall time

trVst

tfVst

tdVst

thVst

trVckn

tfVckn

to1Vck

to2Vck

Vst

∗3

Vst

Vck1

Vckn

∗3

Vck1

Vck2

90%

10%

trVst tfVst

50%

50%

tdVst thVst

90%

10%

trVckn tfVckn

50%

50%

to2Vck to1Vck

90%

50%

50%

50%

90%

10%

10%

50%

∗2

• Vckn

duty cycle 50%

to1Vck = 0ns

to2Vck = 0ns

∗2

• Vckn

duty cycle 50%

to1Vck = 0ns

to2Vck = 0ns

∗2

• Vckn

duty cycle 50%

to1Vck = 0ns

to2Vck = 0ns

tdVst = 32µs

thVst = –32µs

• tdVst = 32µs

thVst = –32µs

En rise time

En fall time

EN

Vck2 rise to

En fall time

Vck1 rise to

En rise time

∗3

Definitions: The right-pointing arrow ( ) means +.

trEn

tfEn

tdVck2

tdVck1

∗3

Vck2

En

The left-pointing arrow ( ) means –.

The black dot at an arrow ( ) indicates the start of measurement.

90%

En

tfEn trEn

50%

50%

tdVck2 tdVck1

10%

10%

50%

50%

90%

∗2

• Vckn

duty cycle 50%

to1Vck = 0ns

to2Vck = 0ns

∗2

• Vckn

duty cycle 50%

to1Vck = 0ns

to2Vck = 0ns

– 8 –

Page 9

Electrical Characteristics (Ta = 25°C, HVDD = 13.5V, VVDD = 13.5V)

1. Horizontal drivers

LCX009AKB

Item

Input pin capacitance Hckn

Hst

Input pin current Hck1

Hck2

Hst

Rgt

Video signal input pin capacitance

Current consumption

2. Vertical drivers

Item

Input pin capacitance Vckn

Vst

Input pin current Vck1

Vck2

Symbol Min. Typ. Max. Unit Condition

CHckn

CHst

IHck1

IHck2

IHst

IRgt

Csig

IH

–200

–500

–300

–100

5

5

–60

–260

–100

–15

45

3

10

10

60

4

pF

pF

µA

µA

µA

µA

pF

mA

Hck1 = GND

Hck2 = GND

Hst = GND

Rgt = GND

Hckn: Hck1, Hck2 (2.75MHz)

Symbol Min. Typ. Max. Unit Condition

CVckn

CVst

IVck1

IVck2

–100

–400

5

5

–30

–200

10

10

pF

pF

µA

µA

Vck1 = GND

Vck2 = GND

Vst

En

Clr

Current consumption

IVst,

IEn,

IClr

IV

–100

–15

400

1000

µA

Vst, En, Clr = GND

µA

Vckn: V ck1 , V ck2 (7.87kHz)

3. Total power consumption of the panel

Item

Total power consumption of the panel (NTSC)

Symbol Min. Typ. Max. Unit

PWR 45 70 mW

4. COM input resistance

Item

Symbol Min. Typ. Max. Unit

COM – Vss input resistance Rcom 0.5 1 MΩ

– 9 –

Page 10

LCX009AKB

Electro-optical Characteristics (Ta = 25°C, NTSC mode)

Item

Contrast ratio

Optical transmittance

Chromaticity

V90

V – T

characteristics

V50

V10

Half tone color

reproduction range

ON time

Response time

OFF time

Flicker

Image retention time

Optimum Vcom voltage

Symbol

25°C

60°C

CR25

CR60

T

R

X

Y

G

X

Y

B

X

Y

25°C

60°C

25°C

60°C

25°C

60°C

R vs. G

B vs. G

0°C

25°C

0°C

25°C

60°C

60min.

Rx

Ry

Gx

Gy

Bx

By

V90-25

V90-60

V50-25

V50-60

V10-25

V10-60

V50RG

V50BG

ton0

ton25

toff0

toff25

F

YT60

Vcomopt

Measurement

method

1

2

3

4

5

6

7

8

9

Min. Typ.

80

80

2.7

0.560

0.300

0.275

0.541

0.120

0.040

1.1

1.0

1.5

1.4

2.2

2.1

—

—

—

200

200

3.5

0.630

0.345

0.310

0.595

0.148

0.088

1.6

1.3

2.0

1.8

2.7

2.5

–0.10

0.10

25

—

—

—

—

—

5.45

65

20

—

—

5.60

8

Max. Unit

—

—

—

—

%

0.670

0.390

0.347

0.650

CIE

standards

0.187

0.122

2.2

2.1

2.5

V

2.4

3.2

3.1

–0.25

V

0.45

100

40

ms

150

60

–40

20

5.75

dB

s

V

– 10 –

Page 11

<Electro-optical Characteristics Measurement>

Basic measurement conditions

(1) Driving voltage

HVDD = 13.5V, VVDD = 13.5V

VVC = 6.0V, Vcom = 5.6V

(2) Measurement temperature

25°C unless otherwise specified.

(3) Measurement point

One point in the center of screen unless otherwise specified.

(4) Measurement systems

Two types of measurement system are used as shown below.

(5) RGB input signal voltage (Vsig)

Vsig = 6 ± VAC [V] (VAC: signal amplitude)

∗ Measurement system I

LCX009AKB

Back Light

3.5mm

LCD panel

Luminance

Meter

∗ Measurement system II

Optical fiber

Light receptor lens

Drive Circuit

Light

Source

LCD panel

1. Contrast Ratio

Contrast Ratio (CR) is given by the following formula (1).

Measurement

Equipment

Back light: color temperature 6500K, +0.004uV (25°C)

∗

Back light spectrum (reference) is listed on another page.

Light Detector

Measurement

Equipment

L (White)

CR=

L (Black)

... (1)

L (White): Surface luminance of the TFT-LCD panel at the RGB signal amplitude VAC = 0.5V.

L (Black): Surface luminance of the panel at VAC = 4.5V

Both luminosities are measured by System I.

– 11 –

Page 12

2. Optical Transmittance

Optical Transmittance (T) is given by the following formula (2).

LCX009AKB

T = × 100 [%] ... (2)

Luminance of Back Light

L (White)

L (White) is the same expression as defined in the "Contrast Ratio" section.

3. Chromaticity

Chromaticity of the panels are measured by System I. Raster modes of each color are defined by the

representations at the input signal amplitude conditions shown in the table below. System I uses

Chromaticity of x and y on the CIE standards here.

Signal amplitudes (VAC) supplied to each input

R input G input B input

R

G

0.5

4.5

4.5

0.5

4.5

4.5

Raster

B

4.5

4.5

0.5

(Unit: V)

4. V-T Characteristics

V-T characteristics, the relationship between signal

amplitude and the transmittance of the panels, are

measured by System II. V90, V50 and V10 correspond

90

to the each voltage which defines 90%, 50% and 10%

of transmittance respectively.

50

5. Half Tone Color Reproduction Range

Half tone color reproduction range of the LCD panels is

characterized by the differences between the V-T

characteristics of R, G and B. The differences of these

V-T characteristics are measured by System II. System

II defines signal voltages of each R, G, B raster modes

which correspond to 50% of transmittance, V50R, V50G

and V50B respectively. V50RG and V50BG, the voltage

differences between V50R and V50G, V50B and V50G, are

simply given by the following formula (3) and (4)

respectively.

V50RG = V50R – V50G ... (3)

V50BG = V50B – V50G ... (4)

Transmittance [%]

10

100

50

R raster

Transmittance [%]

0

V90 V50 V10

VAC – Signal amplitude [V]

V50RG

V50BG

G raster

50R V50B

V

V50G

VAC – Signal amplitude [V]

B raster

– 12 –

Page 13

LCX009AKB

6. Response Time

Input signal

Response time ton and toff are defined by

the formula (5) and (6) respectively.

ton = t1 – tON ... (5)

toff = t2 – tOFF ... (6)

4.5V

6V

0.5V

t1: time which gives 10% transmittance of

the panel.

t2: time which gives 90% transmittance of

the panel.

The relationships between t1, t2, tON and

tOFF are shown in the right figure.

0V

Light transmission

output waveform

100%

90%

10%

0%

tON t1

ton

tOFF t2

toff

7. Flicker

Flicker (F) is given by the formula (7). DC and AC (NTSC: 30Hz, rms, PAL: 25Hz, rms) components of the

panel output signal for gray raster∗mode are measured by a DC voltmeter and a spectrum analyzer in

System II.

component

AC

F [dB] = 20 log

{}

DC component

(7)

...

∗

R, G, B input signal condition for gray raster mode is given by

Vsig = 6 ± V50 [V]

where: V50 is the signal amplitude which gives 50% of

transmittance in V-T curve.

8. Image Retention Time

Image retention time is given by the following procedures:

Apply monoscope signal to the LCD panel for 60 minutes and then change monoscope signal∗to gray scale

signal (Vsig = 6 ± VAC (V); VAC = 3 to 4V) so as to give the maximum image retention. Hold input signal VAC.

The time of the residual image to disappear gives the image retention time.

∗

Monoscope signal conditions:

Black level

Vsig = 6 ± 4.5 or 6 ±2.0 [V]

(shown in the right figure)

Vcom = 5.6V

4.5V

2.0V

6V

White level

2.0V

4.5V

0V

– 13 –

Vsig waveform

Page 14

9. Method of Measuring the Optimum Vcom

There are two methods of measuring the optimum Vcom using the photoelectric element.

9-1. Method of Measuring Flicker

In the field invert drive mode, adjust the flicker level of the half tone (Vsig = 1.5 to 2.5V) using the

photoelectric element and oscilloscope so that its 30Hz component becomes minimum. The Vcom value

at this time is taken to be the optimum Vcom.

9-2. Method of Measuring Contrast

In the normal 1H invert drive mode, adjust the optical output voltage of the half tone (Vsig = 1.5 to 2.5V) so

that it becomes minimum. The Vcom value at this time is taken to be the optimum Vcom.

Example of Back Light Spectrum (Reference)

LCX009AKB

0.4

0.3

0.2

0.1

0

400 500 600 700

Wavelength 380 – 780 [nm]

– 14 –

Page 15

Description of Operation

1. Color Coding

Color filters are coded in a delta arrangement.

The shaded area is used for the dark border around the display.

LCX009AKB

Gate SW

dummy 1 to 4

B R G B R G B R G B R G B R G B R

B R G B R G B R G B R G B R G B R

B R G B R G B R G B R G B R G B R

B R G B R G B R G B R G B R G B R

Gate SW Gate SW Gate SW Gate SW

Active area

Gate SW

dummy 5 to 8

2

GRBGRBGRBGRBGRBGR

GRBGRBGRBGRBGRBGR

GRBGRBGRBGRBGRBGR

GRBGRBGRBGRBGRBGR

225

228

Photo-shielding

B R G B R G B R G B R G B R G B R

RBGRBGRBGRBGRBGR

827

14 800 13

G

1

– 15 –

Page 16

LCX009AKB

2. LCD Panel Operations

• A vertical driver, which consists of vertical shift registers, enable-gates and buffers, applies a selected pulse

to every 225 gate lines sequentially in every single horizontal scanning period. A vertical shift register scans

the gate lines from the top to bottom of the panel.

• The selected pulse is delivered when the enable pin turns to High level. PAL mode images are displayed by

controlling the enable and VCK1, VCK2 pins. The enable pin should be High when not in use.

• A horizontal driver, which consists of horizontal shift registers, gates and CMOS sample-and-hold circuit,

applies selected pulses to every 800 signal electrodes sequentially in a single horizontal scanning period.

• Scanning direction of horizontal shift register can be switched with RGT pin.Scanning direction is left to right

for RGT pin at High level; and right to left for RGT pin at Low level.(These scanning directions are from a

front view.) Normally, set to High level.

• Vertical and horizontal drivers address one pixel, and then dot Thin Film Transistors (TFTs; two TFTs for one

dot) turn on to apply a video signal to the dot. The same procedures lead to the entire 225 × 800 dots to

display a picture in a single vertical scanning period.

• Pixels are arranged in a delta pattern, where sets of RGB pixels are positioned with 1.5-dot offset against

juxtaposed horizontal line. For this reason, 1.5-dot offset of a horizontal driver output pulse against horizontal

synchronized pulse is required to apply a video signal to each dot properly. 1 H reversed displaying mode is

required to apply video signal to the panel.

• The CLR pin is provided to eliminate the shading effect caused by the coupling of selected pulses. While

maintaining the CLR at High level, the VVDD potential drops to approximately 8.5V. This pin should be

grounded when not in use.

• The video signal must be input with polarity-inverted system in every horizontal cycle.

• Timing diagrams of the vertical and the horizontal right-direction scanning (RGT = High level) display cycle

are shown below.

Hck1 and Hck2 should be exchanged to display the left-direction horizontal scanning (RGT = Low level). This

exchange enables the center of the image to be fixed by eliminating offsets.

(1) Vertical display cycle

VD

Vst

Vck1

1 2 224 225

Vck2

(2) Horizontal display cycle (right-direction scanning)

BLK

Hst

Hck1

Hck2

The horizontal display cycle consists of 800/3 = 267 clock pulses because of RGB simultaneous sampling∗.

∗

Refer to Description of Operation "3. RGB Simultaneous Sampling''

123456

Vertical display 225H (14.3ms)

270

271

Horizontal display cycle (48.4µs)

– 16 –

Page 17

LCX009AKB

3. RGB Simultaneous Sampling

Horizontal driver performs R, G and B signal sampling simultaneously, which requires the phase matching

between R, G, B signals to prevent horizontal resolution from deteriorating. The phase matching by an

external signal delaying circuit is needed before applying video signal to the LCD panel.

Two methods are applied for the delaying procedure: Sample-and-hold and Delay circuit. These two block

diagrams are as follows.

The LCX009AKB has a right/left inverse function. The following phase relationship diagram indicates the

phase setting for the right-direction scanning (RGT = High level). For the left-direction scanning (RGT = Low

level), the phase setting should be inverted for B and G signals.

(1) Sample-and-hold (right-direction scanning)

B

R

G

S/H S/H AC Amp

CKB

S/H

CKR

CKG

S/H AC Amp

CKG

S/H AC Amp

CKG

4

3

2

<Phase relationship of delaying sample-and-hold pulses> (right-direction scanning)

HCKn

CKB

CKR

BLUE

RED

LCX009AKB

GREEN

CKG

(2) Delay circuit (right-direction scanning)

B

R

G

Delay Delay AC Amp

Delay AC Amp

AC Amp

– 17 –

4

3

2

BLUE

RED

LCX009AKB

GREEN

Page 18

Example of Color Filter Spectrum (Reference)

100

80

LCX009AKB

Color Filter Spectrum

R

G

60

Transmittance [%]

40

20

B

0

400 500 600 700

Wavelength [nm]

– 18 –

Page 19

Color Display System Block Diagram (1)

An example of single-chip display system is shown below.

+12V +5V +13.5V

LCX009AKB

Composite video

Y/C

Y/color difference

CXA1854R

RED

GREEN

BLUE

HST

HCK1

HCK2

VST

VCK1

VCK2

EN

VCOM

LCD panel

NTSC/PAL

LCX009AKB

(Refer to CXD1845R data sheet.)

CLR

RGT

– 19 –

Page 20

Color Display System Block Diagram (2)

An example of dual-chip display system is shown below.

+12V +5V +13.5V

LCX009AKB

Composite video

Y/C

Y/color difference

Decoder/Driver

CXA1785AR

FRPSYNC

TG

CXD2411R

+5V

RED

GREEN

BLUE

Hst

Hck1

Hck2

Vst

Vck1

Vck2

En

Clr

Vcom

LCD Panel

NTSC/PAL

LCX009AKB

(Refer to CXD2411R data sheet.)

RGT

– 20 –

Page 21

Notes on Handling

(1) Static charge prevention

Be sure to take following protective measures. TFT-LCD panels are easily damaged by static charge.

a) Use non-chargeable gloves, or simply use bare hands.

b) Use an earth-band when handling.

c) Do not touch any electrodes of a panel.

d) Wear non-chargeable clothes and conductive shoes.

e) Install conductive mat on the working floor and working table.

f) Keep panels away from any charged materials.

g) Use ionized air to discharge the panels.

(2) Protection from dust and dirt

a) Operate in clean environment.

b) When delivered, a surface of a panel (Polarizer) is covered by a protective sheet. Peel off the protective

sheet carefully not to damage the panel.

c) Do not touch the surface of a panel. The surface is easily scratched. When cleaning, use a clean-room

wiper with isopropyl alcohol. Be careful not to leave stain on the surface.

d) Use ionized air to blow off dust at a panel.

LCX009AKB

(3) Other handling precautions

a) Do not twist or bend the flexible PC board especially at the connecting region because the board is easily

deformed.

b) Do not drop a panel.

c) Do not twist or bend a panel or a panel frame.

d) Keep a panel away from heat source.

e) Do not dampen a panel with water or other solvents.

f) Avoid to store or to use a panel in high temperature or in high humidity, which results in panel damages.

– 21 –

Page 22

Package Outline Unit: mm

LCX009AKB

18.4 ± 0.3

sc

Active Area

CK1

Thickness of the connector 0.3 ± 0.05

8.5 ± 0.05

1.3 ± 0.3

4

(29.0)

(40.2)

1

61.2 ± 0.9

2

4-R1.0

21.0 ± 0.15

32.2 ± 0.8

Incident

4.0 ± 0.5

3

Reinforcing board

5

6

light

6

Active Area

22.0 ± 0.15

P 0.5 ± 0.02 × 15 = 7.5 ± 0.03

electrode (enlarged)

(10.7)

9.5 ± 0.25

(14.4)

11.0 ± 0.25

0.35

0.5 ± 0.1

PIN16PIN1

2.9 ± 0.15

+ 0.04

– 0.03

0.5 ± 0.15

3.0 ± 0.3

No

1

2

3

4

5

6

Description

F P C

Molding material

Outside frame

Reinforcing board

Reinforcing material

Polarizing film

weight 2g

– 22 –

Loading...

Loading...