Page 1

®

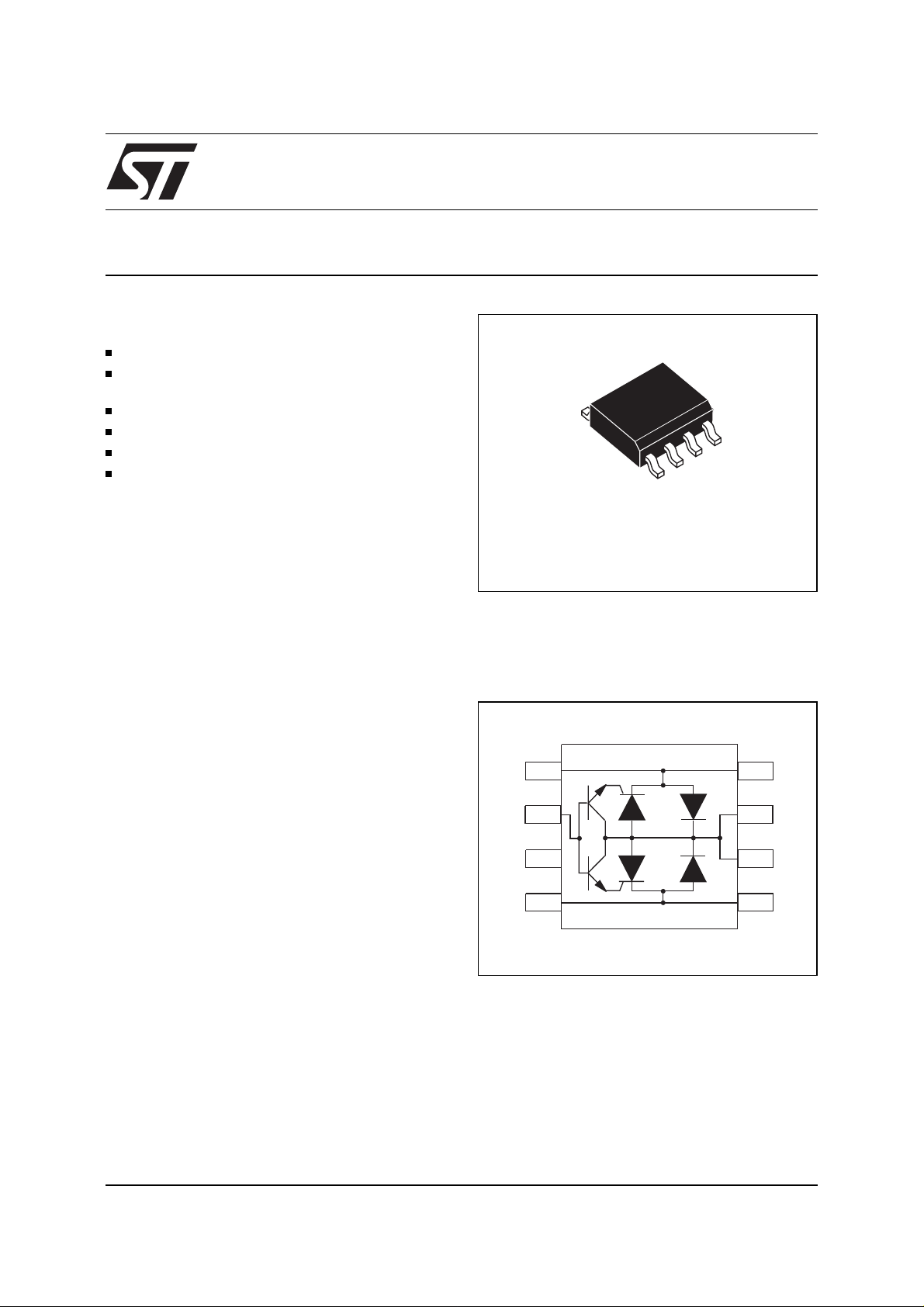

LCP1521

Appl icat ion Sp ecif ic Dis cret es

A.S.D.

FEATURES

Dual programmable transient suppressor

Wide negative firing voltage range:

V

= -150 V max.

MGL

Low dynamic switching voltages: VFP and V

Low gate triggering current: IGT = 2 mA max

Peak pulse current: IPP = 30 A (10/1000 µs)

Holding current: IH = 150 mA

DESCRIPTION

This device has been especially designed to protect new high voltage, as well as classical SLICs,

against transient overvoltages.

Positive overvoltages are clipped with 2 diodes.

Negative surges are suppressed by 2 thyristors, their breakdown voltage being referenced

to -V

This component presents a very low gate triggering current (I

sumption on printed circuit board during the firing

phase.

A particular attention has been given to the internal

wire bonding. The K elvin method c onfiguration ensures reliable protection, reducing the overvoltage

introduced by the parasitic inductances of the wiring L x(dI/dt), especially for very fast transients.

through the gate.

BAT

) in order to reduce the current con-

GT

TM

DGL

PROGRAMMABLE TRANSIENT VOLTAGE

SUPPRESSOR FOR SLIC PROTECTION

SO-8

FUNCTIONAL DIAGRAM

TIP

GA TE

NC

RING

TIP

GND

GND

RING

September 1999 - Ed: 2A

1/9

Page 2

LCP1521

COMPLIES WITH THE

FOLLOWING STANDARDS:

ITU-T K20

VDE0433

VDE0878

IEC1000-4-5

FCC Part 68

lightning surge type A

FCC Part 68

Peak Surge

Voltage

(V)

4000

1000

Voltage

Waveform

(µs)

10/700

10/700

Current

Waveform

(µs)

5/310

5/310

Admissible

Ipp

(A)

40

25

2000 10/700 5/310 40 10

2000 1.2/50 1/20 50 2

level 3

level 4

1500

800

10/700

1.2/50

10/160

10/560

5/310

8/20

10/160

10/560

40

100

50

35

1000 9/720 5/320 25 -

Necessary

Resistor

(Ω)

lightning surge type B

BELLCORE:

NWT-001089-CORE

2500

1000

2/10

10/1000

2/10

10/1000

170

30

First level

BELLCORE:

5000 2/10 2/10 170 20

NWT-001089-CORE

Second level

Note 1:

the mentioned value of the series resistance is the minimum value needed to fulfill the standard r equirement.

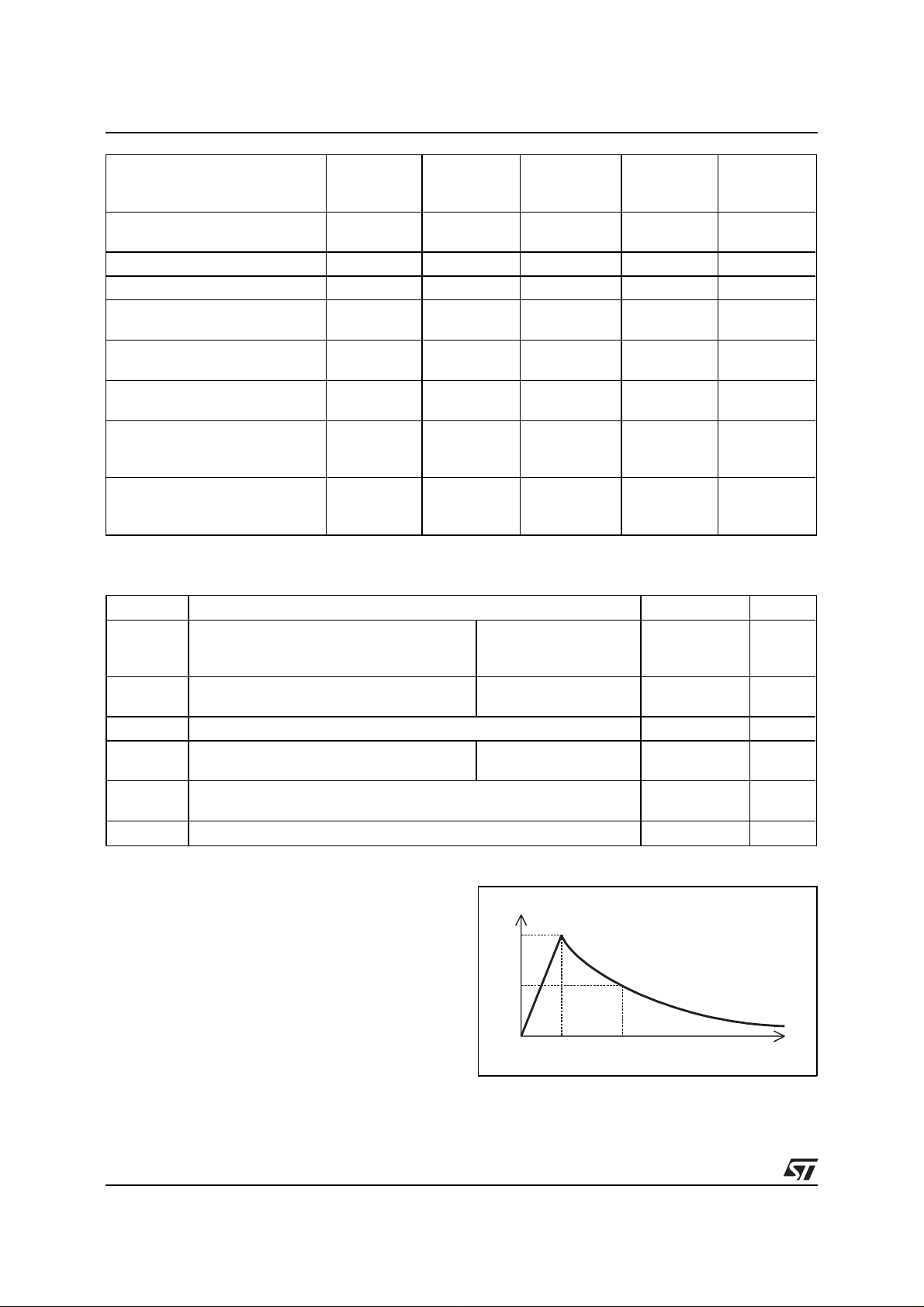

ABSOL UTE M AXIMU M RA TIN GS

= 25°C, unless otherwise specified).

(T

amb

Symbol Parameter Value Unit

I

PP

I

TSM

I

GSM

V

MLG

V

MGL

T

stg

Tj

T

L

Peak pulse current (see note1)

Non repetitive surge peak on-state curr ent

(F = 50Hz)

Maximum gate current (half sine wave tp = 10ms)

Maximum voltage LINE/GND

Maximum voltage GATE/LINE

Storage temperature range

Maximum junction temperature

Maximum lead temperature for soldering d uring 10s

10/1000µs

5/310µs

2/10µs

tp = 10ms

t = 1s

-40° C < Tamb < +85°C

-40° C < Tamb < +85°C

30

40

170

20

5

2A

-150

-150

- 55 to + 150

150

260

60

10

22

15

10

24

-

-

A

A

V

°

C

°

C

Note 1 :

2/9

Pulse waveform

10 / 1000 µs tr = 10 µs tp = 1000 µs

5 / 310 µstr = 5

2 / 10 µstr = 2

µ

s tp = 310 µs

µ

s tp = 10 µs

100

50

%I

0

PP

t

r

t

p

t

Page 3

LCP1521

THERMAL RESISTANCE

Symbol Parameter Value Unit

Rth (j-a)

Junction to ambient

170

°

C/W

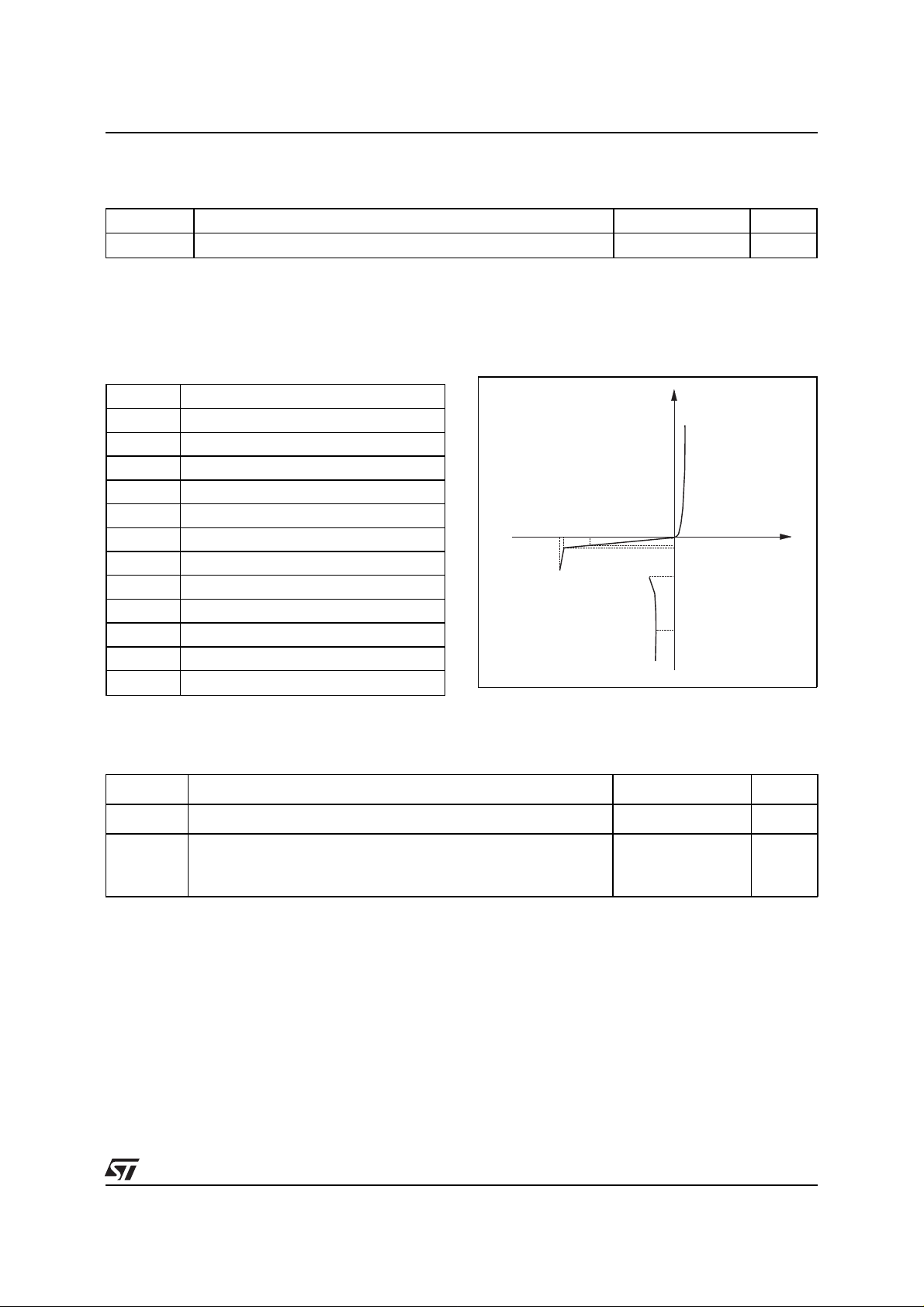

ELECTRICAL CHARACTERISTICS

(T

amb

= 25°C)

Symbol Parameter

I

GT

I

H

I

RM

I

RG

V

RM

V

GT

V

V

FP

V

DGL

V

GATE

V

RG

C

1 - PARAMETERS RELATED TO THE DIODE LINE / GND

Gate triggering current

Holding current

Reverse leakage current LINE / GND

Reverse leakage current GATE / LINE

Reverse voltage LINE / GND

Gate triggering voltage

Forward drop voltage LINE / GND

F

Peak forward voltage LINE / GND

Dynamic switching voltage GATE / LINE

GATE / GND voltage

Reverse voltage GATE / LINE

Capacitance LINE / GND

(T

V

amb

DGL

V

V

R

= 25°C)

RM

V

F

I

RM

I

R

I

H

I

PP

Symbol Test conditions Max Unit

V

F

V

FP

(note 1)

Note 1

: see test circuit for VFP; RP is the protection resistor located on the line card.

Square pulse : tp = 500µs IF = 5A

10/700µs

1.2/50µs

2/10µs

1.5kV

1.5kV

2.5kV

RP = 10Ω

R

= 10Ω

P

R

= 62Ω

P

2V

5

V

7

12

3/9

Page 4

LCP1521

2 - PARAMETERS RELATED TO THE PROTECTION THYRISTOR

(T

amb

= 25°C)

Symbol Test conditions Min Max Unit

V

GND / LINE

V

GATE

at I

Tc=25°C VRG = -150V

Tc=85°C V

V

GATE

V

V

I

I

GT

I

H

GT

RG

DGL

10/700µs

1.2/50µs

2/10µs

Note 2:

see functional holding current (IH) test cir cu i t

Note 3:

see test circuit for V

The oscillations with a time duration lo wer than 50ns are not taken into account

3 - PARAMETERS RELATED TO DIODE AND PROTECTION THYRISTOR

= -48V

= -48V (see note 2)

GT

= -150V

RG

= -48V (see note 3)

1kV

1.5kV

2.5kV

DGL

R

R

R

= 10Ω

P

= 10Ω

P

= 62Ω

P

I

PP

I

PP

I

PP

= 30A

= 30A

= 38A

0.1 2 mA

150 mA

1.5 V

5

50

7

10

25

(T

= 25°C)

amb

Symbol Test conditions Max Unit

I

RM

Tc=25°C V

Tc=85°C V

GATE / LINE

GATE / LINE

= -1V VRM = -150V

= -1V VRM = -150V

5

50

µ

A

V

µ

A

C

VR = -3V F = 1MHz

= -48V F = 1MHz

V

R

100

50

pF

4/9

Page 5

FUNCTIONAL HOLDING CURRENT (IH) TEST CIRCUIT : GO-NO GO TEST

R

LCP1521

-V

P

V

BAT

=

- 100V

D.U.T.

This is a GO-NO GO test which allows to confirm the holding current (I

TEST PROCEDURE :

- Adjust the current level at the I

- Fire the D.U.T. with a surge current : I

value by short circuiting the D.U.T.

H

= 10A, 10/1000µs.

PP

- The D.U.T. will come back to the off-state within a duration of 50ms max.

TEST CIRCUIT FOR VFP AND V

(V is defined in unload condition )

P

PARAMETERS

DGL

L

R

2

Surge generator

) level in a functional test circ uit.

H

R

4

TIP

RING

R

3

V

CC

P

1

R

1

2

GND

Pulse (µs) V

t

r

t

p

p

(V) (µF) (nF) (µH) (Ω)(

10 700 1500 20 200 0 50 15 25 25 30 10

1.2 50 1500 1 33 0 76 13 25 25 30 10

2 10 2500 10 0 1.1 1.3 0 3 3 38 62

C

1

C

2

LR

1

R

2

Ω

)(

R

3

Ω

)(

R

4

Ω

IPPR

)(A)(

Ω

p

)

5/9

Page 6

LCP1521

TECHNICAL INFORMATION

Fig. A1:

LCP1521 concept behavior.

L 1

GND

L 2

-Vbat

Rs1

Rs2

TIP

IG

Gate

C

T1

Th1

RING

ID1

D1

VTip

GND

V Ring

Figur e A1 shows the class ic al pr otecti on c irc uit us ing th e L CP152 1 crowb ar c onc ept. This to polog y

has been developed to protect the new high voltage SLIC’s, it allows to program the negative firing

threshold whil e the positive clamping va lue is fixed at GND.

When a negative surge occurs on one wire (L1 for example) a current Ign flows through the base of the

transistor T1 and then injects a current in the gate of the thyristor Th1. Th1 fires and all the surge current

flows through the ground. After the surge when the current flowing through Th1 becomes less negative

than the holding current I

, then Th1 switches off.

H

When a positive surge occurs on one wire (L1 for example) the diode D1 conducts and the surge current

flows through the ground.

Fig. A2:

Example of PCB layout based on LCP1521 protection.

To the

line side

nF

0

GND

To the

SLIC side

22

In order to minimize the remaining voltage across the S LIC inputs during the surge, the TIP and RING pins

of the LCP1521 are doubled (Pins 1 and 8 for TIP / Pins 4 and 5 for RING).

This fact allows the board designer to connect the track like designed in figure A2. With such a PCB design,

the extra voltages caused by track stray inductance (LdI / dt) remain located on the line side of the LCP and

do not affects its SLIC side.

The capacitor C is used to speed up the crowbar structure firing during the fast surge edges.

This allows to minimize the dynamical breakover voltage at the SLIC Tip and Ring inputs during fast strikes.

Please note that this capacitor is generally present around the SLIC - Vbat pin.

So to be efficient it has be as close as possible from the LCP1521 Gate pin and from the reference ground

track (or plan) (see Fig. A2). The optimized value for C is 220nF.

6/9

Page 7

LCP1521

The series resitors Rs1 and Rs2 designed in figure 1 represent the fuse resistors or the PTC which are mandatory to withstand the power contact or the power inductance tests imposed by the different country standards. Ta ki ng i nt o ac co unt thi s f ac t t he a ctu al li ghtni n g s urg e c urre n t fl owi ng t hro ug h th e L CP is eq ua l to :

I surge = V surge / (Rg + Rs)

With V surge = peak surge voltage imposed by the standard.

Rg = series resistor of the surge generator

Rs = series resistor of the line card (e.g. PTC)

e.g. For a line card with 30Ω of series resistors which has to be qualified under Bellcore 1000V 10/1000µs

surge, the actual current through the LCP1521 is equal to:

I surge = 1000 / (10 + 30) =

25A

The LCP1521 is particularly optimized for the new telecom applications such as the fiber in the loop, the

WLL, the decentralized central office for example. These short line applications need smaller operating

voltages than the long line applications and then allow the use of high voltage SLIC’s operating without ring

relay. The schematics of figure A3 gives the most frequent topology used for these emergent applications.

Fig. A3:

Protection of high voltage SLIC.

GND

Line

Rs (*)

Rs (*)

220nF

Gate

GND

TIP

RING

-Vbat

TIP

GND

SLIC

RING

LCP1521

Line card

Rs (*) = PTC or Res ito r fu se

7/9

Page 8

LCP1521

Surge peak current versus overload duration.

ITSM (A)

20

18

16

14

12

10

8

6

4

2

0

0.01 0.1 1 10 100 1000

t(s)

ORDER CODE

LCP 1 5 2 1 RL

Relative variation of holding current versus junction temperature

IH [Tj] / IH [Tj=25°C ]

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

-40 -20 0 20 40 60 80 100

Tj(°C)

LINE CARD

PRO TECTION

I = 150 mA

H

VERSION

PACKAGE

1 : SO-8

RL :Tape & Reel

:Tube

8/9

Page 9

PACKAGE ME CHANICAL D AT A

SO-8 (Plas tic )

L

A

a2

b

8

1

e

e3

D

M

5

4

S

F

LCP1521

DIMENSIONS

REF.

c1

C

a3

b

a

1

E

1

A 1.75 0.069

a1 0.1 0.25 0.004 0.010

a2 1.65 0.065

a3 0.65 0.85 0.025 0.033

b 0.35 0.48 0.014 0.019

b1 0.19 0.25 0.007 0.010

C 0.25 0.50 0.50 0.010 0.020

c1 45° (typ )

D 4.8 5.0 0.189 0.197

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 3.81 0.150

F 3.8 4.0 0.15 0.157

L 0.4 1.27 0.016 0.050

M 0.6 0.024

S8

Millimetre s Inche s

Min. Typ. Max. Min. Typ. Max.

°

(max)

Order code Marking Package Weight Base qty Delivery mode

LCP1521 151DH V SO-8 0.08 g 2500 Tube

LCP1521RL 151DHV SO-8 0.08 g 2000 Tape & Reel

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express writte n a pproval of STMicroelectronics.

The ST logo is a registered trademark of STMicro electroni cs

© 1999 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

9/9

Loading...

Loading...