Page 1

Also included is a watchdog timer to stop and restart a

microprocessor that is “hung-up”. Three watchdog timeout periods are selectable: 150ms, 610ms and 1,200ms. If the

ST input is not strobed LOW before the time-out period

expires, a reset is issued.

Devices are available in 8-pin DIP, 8-pin SO and compact

8-pin MicroSO packages.

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 1

Key Features

◆

Pin compatible with the Dallas Semiconductor

DS1832

— Over 40% lower supply current

◆

3.3V supply monitor

◆

Push-pull output

◆

Selectable watchdog period

◆

Debounce manual push-button reset input

◆

Precision temperature-compensated voltage

reference and comparator

◆

Power-up, power-down and brownout detection

◆

250ms minimum reset time

◆

Active LOW and HIGH reset signal

◆

Selectable trip point tolerance: 10% or 20%

◆

Low-cost 8-pin DIP/SO and 8-pin MicroSO

packages

◆

Wide operating temperature –40°C to +85°C

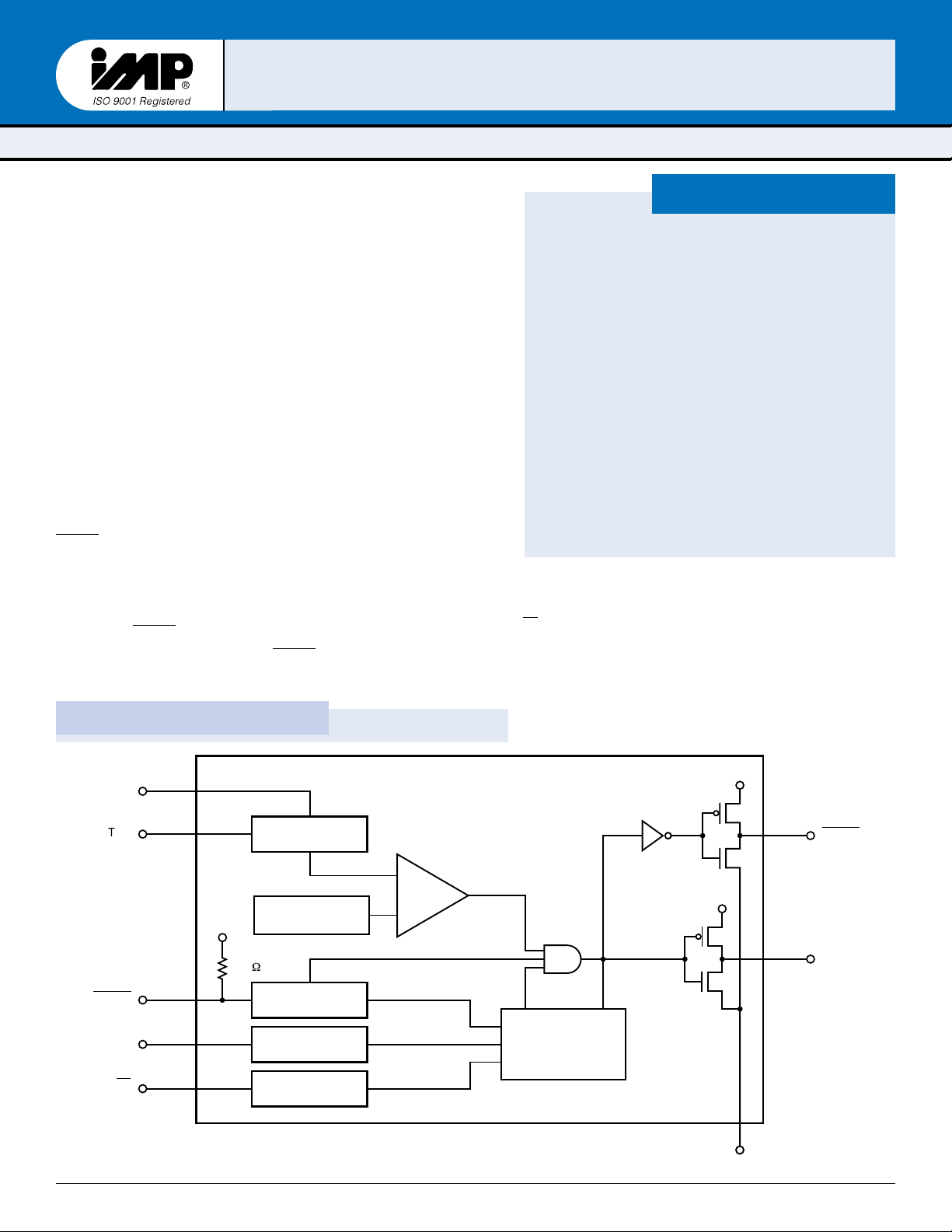

Block Diagram

IMP1

IMP1

832

832

POWER MANAGEMENT

3.3V

3.3V µµ

P P

P Pooww

er Suppl

er Supplyy

Monit

Monit

or and R

or and R

eset Cir

eset Cir

cuit

cuit

– Select

– Select

able T

able Trriipp-P-P

oint T

oint T

oler

oler

ance and

ance and

WWatc

atc

hdog P

hdog Perer

iod

iod

– Push-Butt

– Push-Butt

on R

on R

eset

eset

– Push-Pull R

– Push-Pull R

eset Outputs

eset Outputs

The IMP1832 microprocessor supervisor can halt and restart a “hungup” or “stalled” microprocessor, restart a microprocessor after a power

failure, and debounce a manual push-button microprocessor reset

switch. The IMP1832 features over 40% lower supply current than the

pin compatible Dallas Semiconductor DS1832.

Precision temperature compensated reference and comparator circuits

monitor the 3.3V, V

CC

input voltage. During power-up or when the V

CC

power supply falls outside selectable tolerance limits, both RESET and

RESET become active. When V

CC

rises above the threshold voltage, the

reset signals remain active for an additional 250ms minimum, allowing

the power supply and system microprocessor to stabilize. The trip point

tolerance signal, TOL, selects the trip level tolerance to be either 10- or

20-percent.

RESET and RESET outputs are push-pull.

A debounced manual reset input, PBRST, activates the reset outputs for

a minimum period of 250ms.

V

CC

TOL

PBRST

TD

ST

8

3

1

2

7

10%/20% Tolerance

V

CC

40k

W

Timebase Selection

Transition Detector

Selection

Reference

Push Button

Debounce

Watchdog

Watchdog

+

–

IMP1832

Reset &

Watchdog Timer

V

CC

6

V

CC

5

4

GND

RESET

RESET

1832_02.eps

Page 2

2

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

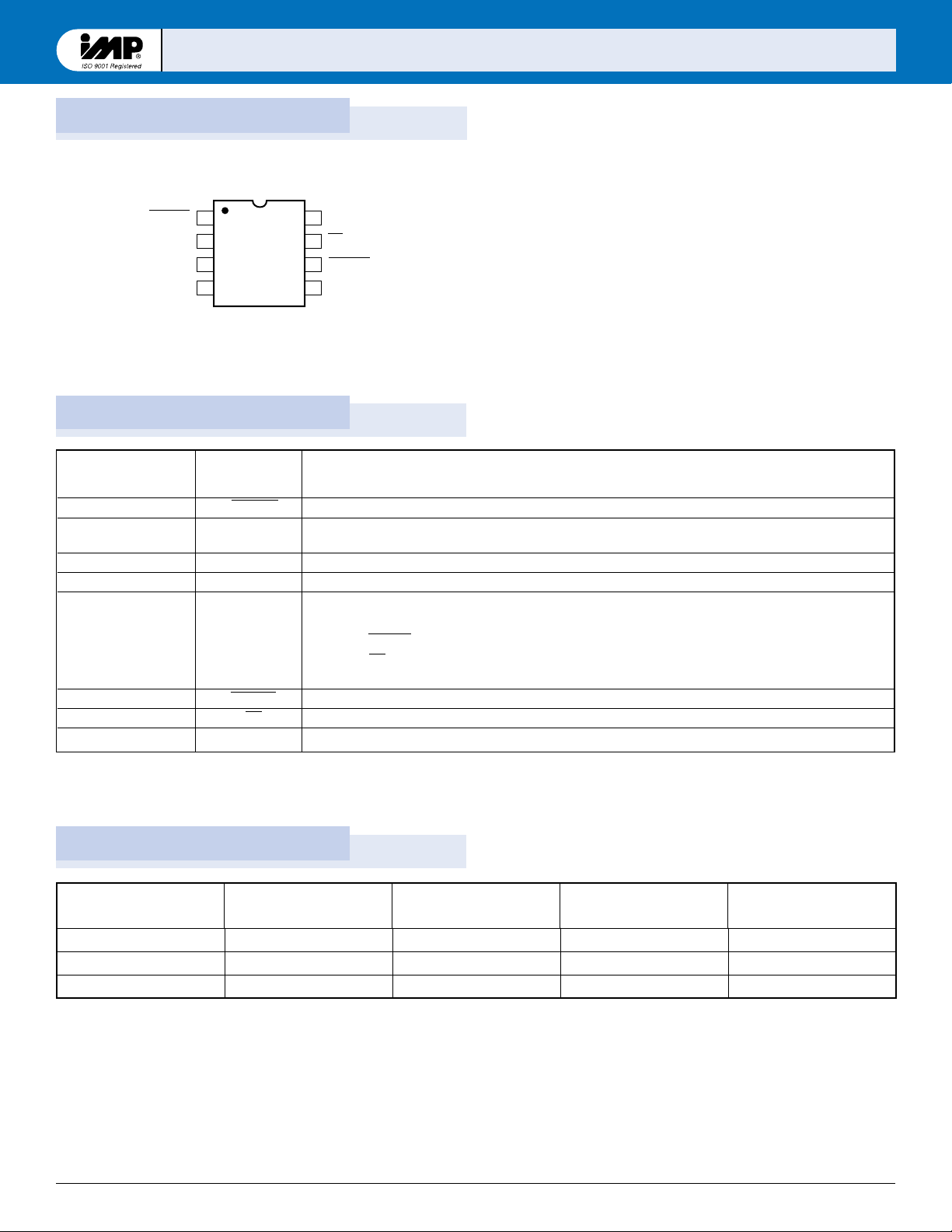

Pin Configuration

IMP1

IMP1

832

832

Pin Descriptions

Ordering Information

DIP/SO/MicroSO

rebmuNtraPegakcaP

erutarepmeTgnitarepO

egnaR

ylppuSmumixaM

(tnerruC µ )A

gnirotinoMegatloV

noitacilppA

2381PMIPID-8 – 04C° 58otC° 02V3.3

S2381PMIOS-8 – 04C° 58otC° 02V3.3

AMES2381PMIOSorciM-8 – 04C° 58otC° 02V3.3

spe.10t_2381

Pin Number

8-Pin Package Name Function

1 PBRST Debounced manual pushbutton reset input

2 TD Watchdog time delay selection. (t

TD

= 150ms for TD = GND, tTD= 610ms for TD = Open,

and tTD=1200ms for TD = VCC)

3 TOL Selects 10% (TOL connected to GND) or 20% (TOL connected to VCC) trip point tolerance

4 GND Ground

5 RESET Active HIGH reset output. RESET is active:

1. If VCCfalls below the reset voltage trip point.

2. IfPBRST is LOW.

3. If ST is not strobed LOW before the timeout period set by TD expires.

4. During power-up.

6 RESET Active LOW reset output. (See RESET)

7 ST Strobe Input

8V

CC

5V power

PBRST

TD

TOL

GND

1V

2

IMP1832

3

4

8

CC

7ST

6 RESET

5

RESET

1832_01.eps

Page 3

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 3

IMP1

IMP1

832

832

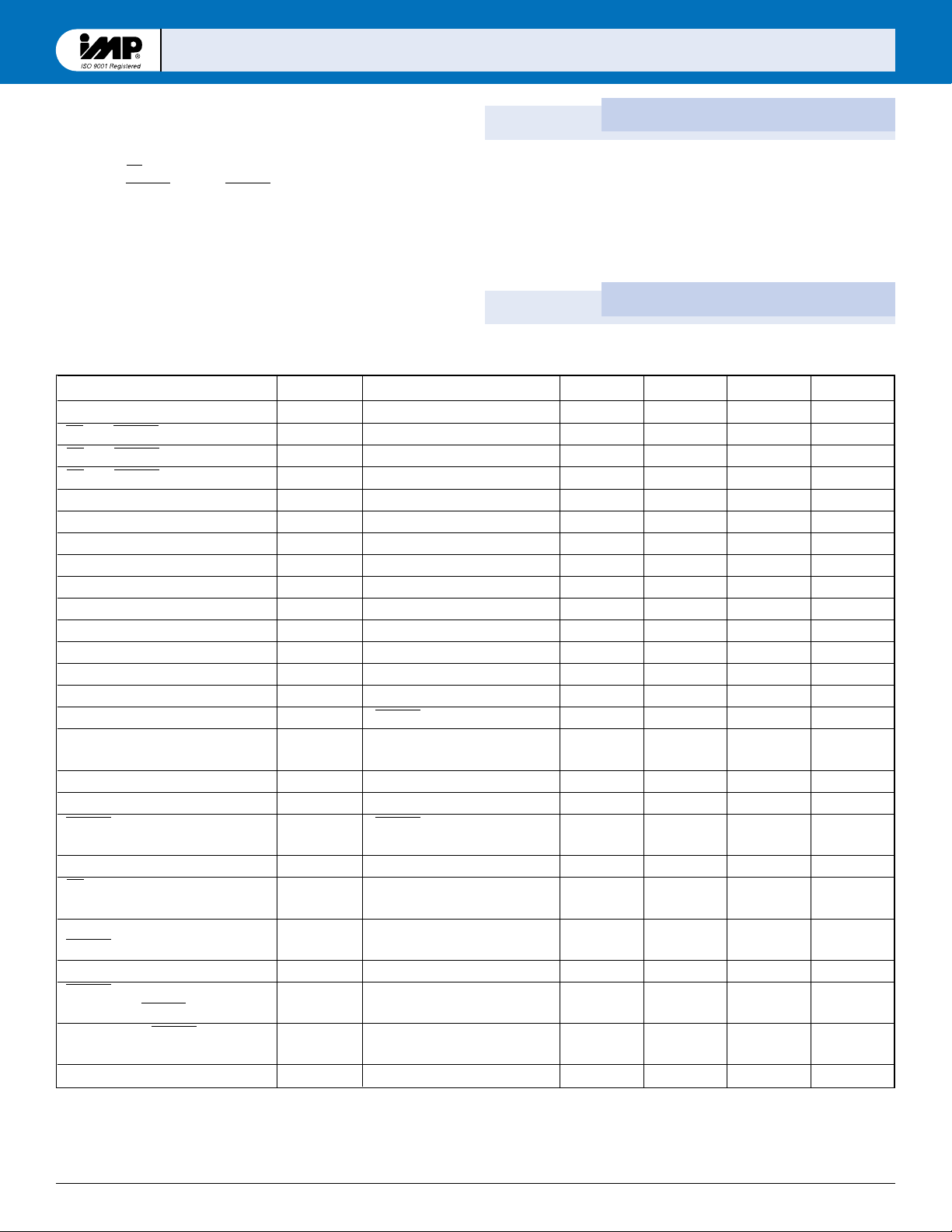

Absolute Maximum Ratings

Electrical Characteristics

Voltage on VCC . . . . . . . . . . . . . . . . . . . . . . . . –0.5V to 7V

Voltage on ST, TD . . . . . . . . . . . . . . . . . . . . . – 0.5V to V

CC

+ 0.5V

Voltage on PBRST, RESET, RESET . . . . . . . . – 0.5V to V

CC

+ 0.5V

Operating Temperature Range . . . . . . . . . . . –40°C to 85°C

Soldering Temperature . . . . . . . . . . . . . . . . . . 260°C for 10 seconds

Storage Temperature . . . . . . . . . . . . . . . . . . . –55°C to 125°C

Voltages measured with respect to ground.

These are stress ratings only and functional operation is not implied.

Parameter Symbol Conditions Min Typ Max Units

Supply Voltage (VCC)V

CC

1.0 5.5 V

ST and PBRST Input High Level V

IH

VCC≥ 2.7V 2 VCC+ 0.3V V

ST and PBRST Input High Level V

IH

VCC< 2.7V VCC- 0.4V V

ST and PBRST Input Low Level V

IL

–0.3 0.5 V

VCCTrip Point (TOL = GND) V

CCTP

2.80 2.88 2.97 V

VCCTrip Point (TOL = VCC)V

CCTP

2.47 2.55 2.64 V

Watchdog Time-Out Period t

TD

TD = GND 62.5 150 250 ms

Watchdog Time-Out Period t

TD

TD = V

CC

500 1200 2000 ms

Watchdog Time-Out Period t

TD

TD floating 250 610 1000 ms

Output Voltage V

OH

I = –500µA, VCC< 2.7V VCC- 0.3V VCC- 0.1V V

Output Current I

OH

Output = 2.4V, VCC≥ 2.7V 350 µA

Output Current I

OL

Output = 0.4V, VCC≥ 2.7V 10 mA

Input Leakage I

IL

–1.0 1.0 µA

RESET Low Level V

OL

0.4 V

Internal Pull-Up Resistor PBRST pin 40 kΩ

Operating Current I

CC1

Outputs open. VCC≤ 3.6V 20 µA

and all inputs at VCCor GND

Input Capacitance C

IN

5pF

Output Capacitance C

OUT

7pF

PBRST Manual Reset t

PB

PBRST = V

IL

20 ms

Minimum Low Time

Reset Active Time t

RST

250 610 1000 ms

ST Pulse Width t

ST

Must not exceed tRDminimum. 20 ns

Watchdog cannot be disabled.

VCCFail Detect to t

RPD

Pulses < 2µs at V

CCTP

58µs

RESET or RESET minimum will not cause reset.

VCCSlew Rate t

F

20 µs

PBRST Stable LOW to t

PDLY

20 ms

RESET and RESET Active

VCCDetect to RESET or t

RPU

t

rise

= 5µs 250 610 1000 ms

RESET Inactive

VCCSlew Rate t

R

0ns

Unless otherwise stated, 1.2V ≤ VCC≤ 5.5V and over the operating temperature range of –40°C to +85°C . All voltages are referenced

to ground.

Page 4

On power-down, once VCCfalls below the reset threshold RESET

stays LOW and is guaranteed to be 0.4V or less until V

CC

drops

below 1.2V. The active HIGH reset signal is valid down to a V

CC

level of 1.2V also.

Manual Reset Operation

Push-button switch input, PBRST, allows the user to override the

internal trip point detection circuits and issue reset signals. The

pushbutton input is debounced and is pulled HIGH through an

internal 40kΩ resistor.

When PBRST is held LOW for the minimum time t

PB

, both resets

become active and remain active for a minimum time period of

250ms after PBRST returns HIGH.

The debounced input is guaranteed to recognize pulses greater

than 20ms. No external pull-up resistor is required, since PBRST

is pulled HIGH by an internal 40kΩ resistor.

The PBRST can be driven from a TTL or CMOS logic line or shorted to ground with a mechanical switch.

ecnareloT

tceleSecnareloT

)V(egatloVtnioPPIRT

niMlanimoNxaM

V=LOT

CC

%0274.255.246.2

DNG=LOT%0108.288.279.2

spe.20t2381

4

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

IMP1

IMP1

832

832

Application Information

Supply Voltage Monitor

The IMP1832 monitors the microprocessor or microcontroller

power supply and issues reset signals, both active HIGH and

active LOW, that halt processor operation whenever the power

supply voltage levels are outside a predetermined tolerance.

Tolerance levels are set with the TOL pin.

RESET and RESET signals are generated at the last moment of a

valid V

CC

signal. On power-up, both reset signals are active for a

minimum of 250ms after the supply has returned to intolerance

level. This allows the power supply and monitored processor to

stabilize before instruction execution is allowed to begin.

Trip Point Tolerance Selection

With TOL connected to V

CC

, RESET and RESET become active

whenever V

CC

falls below 2.64V. RESET and RESET become active

when V

CC

falls below 2.98V if TOL is connected to ground.

After V

CC

has risen above the trip point set by TOL, RESET and

RESET remain active for a minimum time period of 250ms.

Figure 1. Timing Diagram: Power Up

Figure 2. Timing Diagram: Power Down

1832_04.eps

V

CCTP(MAX)

V

CCTP

V

CCTP(MIN)

V

CC

RESET

RESET

t

R

t

RPU

V

OH

V

OL

Figure 3. Timing Diagram: Pushbutton Reset

V

IH

V

IL

V

OH

V

OL

RESET

RESET

PBRST

t

PDLY

t

PB

t

RST

1832_07.eps

Figure 4. Application Circuit: Pushbutton Reset

1832_05.eps

PBRST

Supply

Voltage

1

V

CC

TD

2

ST

TOL

IMP1832

µP

3

4

RESET

GND

8

7

6

5

RESET

RESET

V

CCTP(MAX)

V

CCTP

V

CCTP(MIN)

V

CC

RESET

RESET

t

F

V

OH

V

OL

t

RPD

1832_03.eps

Page 5

Watchdog Timer and ST Input

A watchdog timer stops and restarts a microprocessor that is

“hung-up”. Through the time delay input, TD, three watchdog

time-out periods are selectable: 150ms, 610ms and 1,200ms. If the

strobe input, ST , is not str obed LOW prior to timeout, r eset signals

become active. On power-up or after the supply voltage returns to

an in-tolerance condition, the reset signal remains active for

250ms minimum, allowing the power supply and system microprocessor to stabilize.

ST Pulses as short as 20ns can be detected.

Figure 5. Timing Diagram: Strobe Input

ST

Valid

Strobe

Valid

Strobe

Invalid

Strobe

t

RST

t

ST

Note: ST is ignored whenever a reset is active.

t

TD

(Min)

t

TD

(Max)

1832_08.eps

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 5

IMP1

IMP1

832

832

Application Information

Figure 6. Application Circuit: Watchdog Timer

A HIGH-to-LOW ST signal transition must be regularly issued

no later than the minimum time-out period defined by the state of

the TD signal. This guarantees the watchdog timer does not

time-out.

Timeouts periods of approximately 150ms, 610ms or 1,200ms are

selected through the TD pin.

1832_06.eps

PBRST

Supply

Voltage

1

V

CC

TD

2

ST

TOL

IMP1832

m

P Decoder

3

4

RESET

GND

8

7

6

5

RESET

MREQ

Address

Bus

RESET

leveLegatloVDT

)sm(doirePtuO-emiTgodhctaW

niMlanimoNxaM

DNG5.26051052

gnitaolF0520160001

V

CC

00500210002

spe.30t_2381

The watchdog timer can not be disabled. It must be strobed with

a high-to-low transition to avoid a watchdog timeout and reset.

Page 6

IMP1

IMP1

832

832

Package Dimensions

6

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

Plastic DIP (8-Pin)

L

0°– 8°

C

H

E

e

D

B

A1

A

SO (8-Pin).eps

SO (8-Pin)

MicroSO (8-Pin)

e

b

D

E1 E

a

L

+

C

D

0.10mm

0.004in

A1

A2

A

MicroSO (8-Pin).eps

sehcnIsretemilliM

niMxaMniMxaM

*)niP-8(OSorciM

A ––––– 3340.0 –––– 01.1

1A0200.09500.0050.051.0

2A5920.04730.057.059.0

b8900.07510.052.004.0

C1500.01900.031.032.0

D2411.00221.009.201.3

eCSB6520.0CSB56.0

ECSB391.0CSB09.4

1E2411.00221.009.201.3

L7510.06720.004.007.0

a °0 °6 °0 °6

**)niP-8(OS

A350.0960.053.157.1

1A400.0010.001.052.0

B310.0020.033.015.0

C700.0010.091.052.0

e050.072.1

E051.0751.008.300.4

H822.0442.008.502.6

L610.0050.004.072.1

D981.0791.008.400.2

***)niP-8(PIDcitsalP

A ––––– 012.0 –––– 33.5

1A510.0 ––––– 83.0 –––––

2A511.0591.029.259.4

b410.0220.063.065.0

2b540.0070.041.187.1

3b030.0540.008.041.1

D553.0004.020.961.01

1D500.0 ––––– 31.0 –––––

E003.0523.026.762.8

1E042.0082.001.611.7

e001.0 ––––– 45.2

Ae003.0 ––––– 26.7

Be ––––– 034.0 ––––– 29.01

Ce ––––– 060.0

L511.0051.029.218.3

** AA781-OMgniwarDCEDEJ*

* AA211-SMgniwarDCEDEJ**

AB100-SMgniwarDCEDEJ***

3ta.40t_2381

A2

A

L

A1

D1

D

e

b

b2

0°–15°

E

E1

C

eA

eB

Plastic DIP (8-Pin)a.eps

Page 7

IMP1

IMP1

832

832

IMP, Inc.

Corporate Headquarters

2830 N. First Street

San Jose, CA 95134-2071

Tel: 408-432-9100

Tel: 800-438-3722

Fax: 408-434-0335

e-mail: info@impinc.com

http://www.impweb.com

The IMP logo is a registered trademark of IMP, Inc.

All other company and product names are trademarks of their respective owners.

© 1999 IMP, Inc.

Printed in USA

Publication #: 1015

Revision: B

Issue Date: 11/08/99

Type: Preliminary

Loading...

Loading...