Page 1

OTP CMOS 256K×8-Bit EPROM

Features

•

Operating voltage: +3.3V

•

Programming voltage

–

VPP=12.5V±0.2V

–

VCC=6.0V±0.2V

•

High-reliability CMOS technology

•

Latch-up immunity to 100mA from -1.0V to

V

+1.0V

CC

•

CMOS and TTL compatible I/O

•

Low power consumption

–

Active: 15mA max.

–

Standby: 1µA typ.

•

256K×8-bit organization

General Description

The HT27LC020 chip family is a low-power,

2048K (2,097,152) bit, +3.3V electrically onetime programmable (OTP ) rea d-only me morie s

(EPROM). Organized into 256K words with 8

bits per word, it features a fast singl e address

location programming, typically at 75

byte. Any byte can be accessed in less than

µs per

HT27LC020

•

Fast read access time: -120ns

•

Fast programming algorithm

•

Programming time 75µs typ.

•

Commercial and industrial temperature range

•

Two line controls (OE and CE)

•

Standard product identification code

•

Package type

–

32-pin DIP/SOP

–

32-pin PLCC

•

Commercial temperature ranges

(0

°C to +70°C)

120ns with respect to Spec. This eliminates the

need for WAIT states in high-performance microprocessor systems. The HT27LC020 has

separate Output Enable (

(

CE) controls which eliminate bus contention

issues.

OE) and Chip Enable

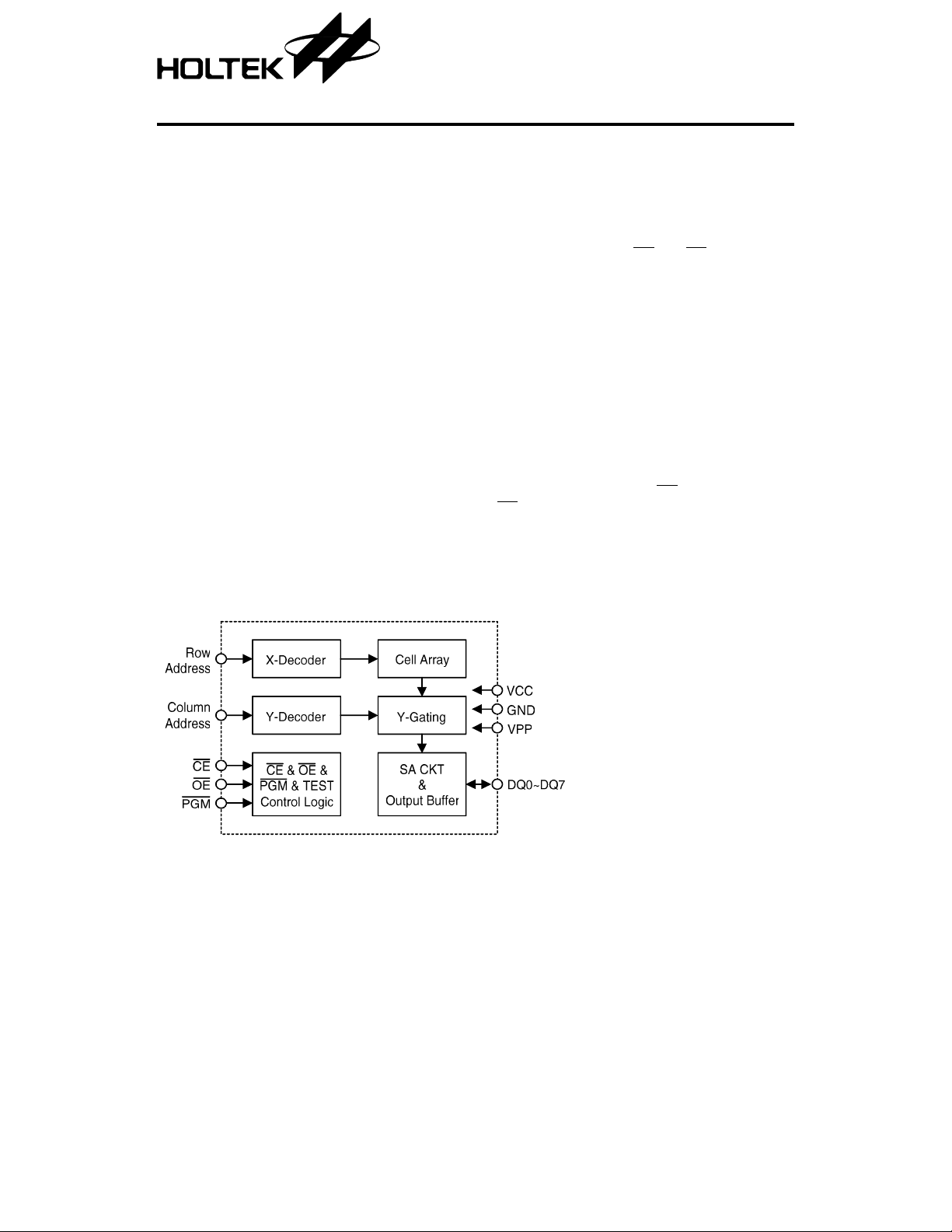

Block Diagram

1 7th May ’99

Page 2

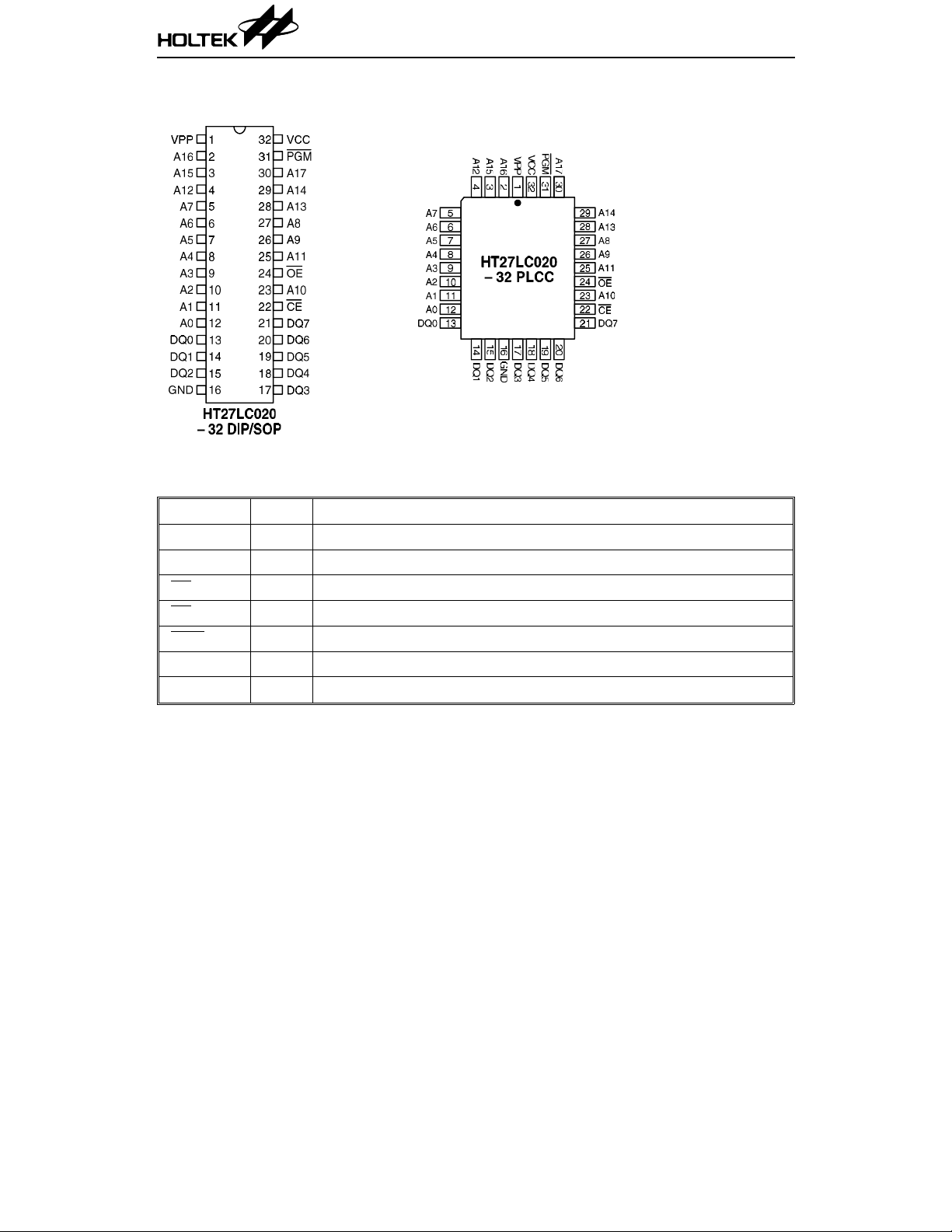

Pin Assignment

Pin Description

HT27LC020

Pin Name I/O/C/P Description

A0~A17 I Address input s

DQ0~DQ7 I/O Data inputs/outputs

CE C Chip enable

OE C Output enable

PGM C Program strobe

NC — No connection

VPP P Program voltage supply

2 7th May ’99

Page 3

HT27LC020

Absolu te Maximum Ra tin g

Operation Temperature Commercial ...................................................................................0°C to +70°C

Storage Temperature.................................... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .–65

Applied VCC Voltage with Respect to GND.................... .. .. .................... .. .. .................... .. . –0.6V to 7.0V

Applied Voltage on Input Pin with Respect to GND ......................................................... –0.6V to 7.0V

Applied Voltage on Output Pin with Respect to GND ............................. .. .. .. .. .. .. .. .. –0.6V to V

Applied Voltage on A9 Pin with Respect to GND..................................................... ...... . –0.6V to 13.5V

Applied VPP Voltage with Respect to GND............................................................ .... .... ..–0.6V to 13.5V

Applied READ V o ltage (Functionality is guaranteed between these limits) .................+3.0V to +3.6V

Note: These are stress ratings only. Stresses exceeding the range specified under “Absolute M axi-

mum Ratings” may cause substantial damage to the device. Functional operation of this device

at other conditions beyond those listed in the specification is not implied and prolonged

exposure to extreme condition s may affect device reliability.

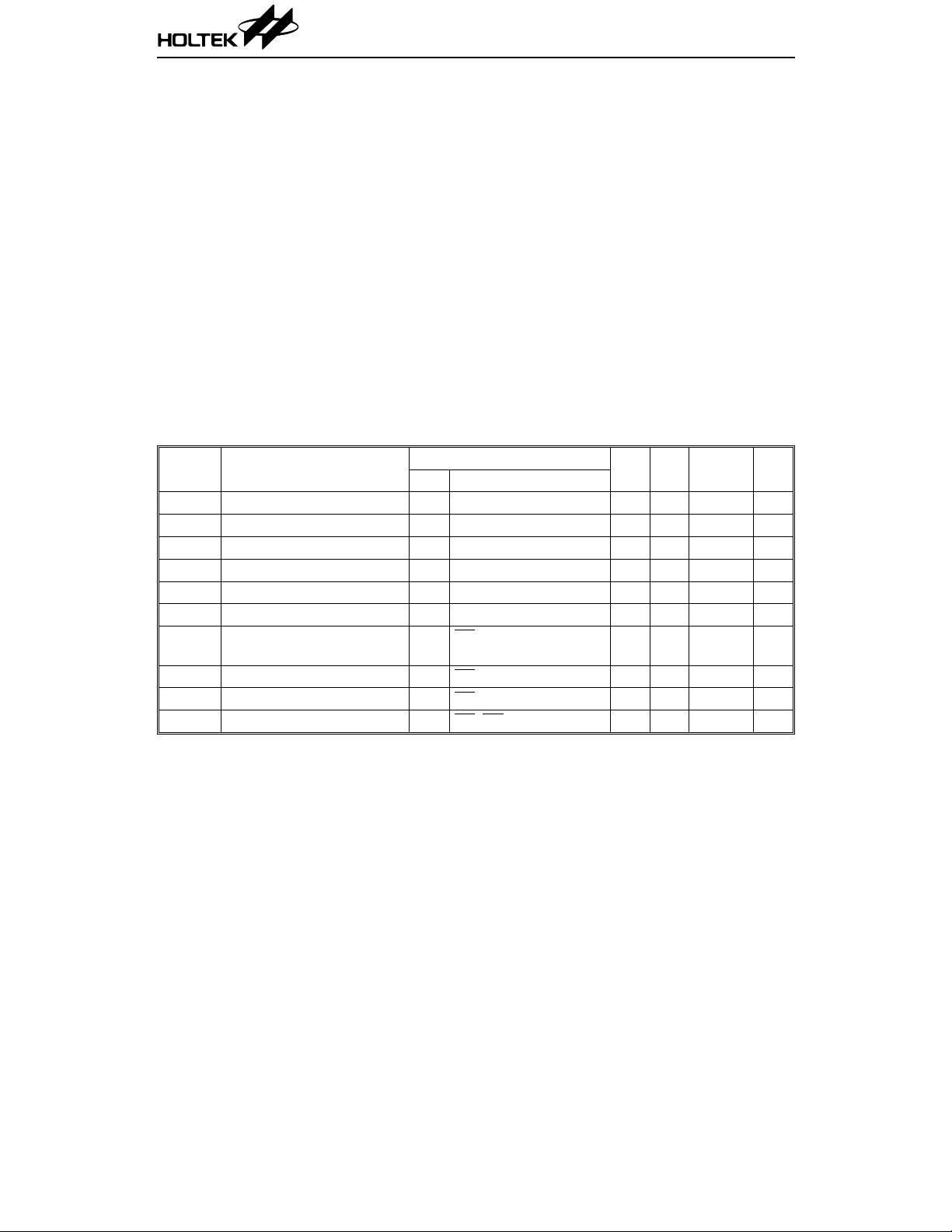

D.C. Characteristics

Read operation

Symbol Parameter

V

V

V

V

I

LI

I

LO

I

CC

I

SB1

I

SB2

I

PP

Output High Level 3.3V IOH=–0.4mA 2.4 — — V

OH

Output Low Level 3.3V IOL=2.0mA — — 0.45 V

OL

Input High Level 3.3V — 2.0 — VCC+0.5 V

IH

Input Low Level 3.3V — –0.3 — 0.8 V

IL

Input Leakage Current 3.3V VIN=0 to 3.6V –5 — 5 µA

Output Leakage Current 3.3V V

VCC Active Current 3.3V

Standby Current (CMOS) 3.3V CE=V

Standby Current (TTL) 3.3V CE=V

VPP Read/Standby Current 3.3V CE=OE=VIL, VPP=V

Test Conditions

V

CC

OUT

CE=VIL, f=5MHz,

I

OUT

Conditions

Min. Typ. Max. Unit

=0 to 3.6V –10 — 10 µA

=0mA

±0.3V — — 10 µA

CC

IH

—— 15 mA

— — 0.6 mA

—— 100 µA

CC

°C to 125°C

+0.5V

CC

3 7th May ’99

Page 4

Programming operation

Symbol Parameter

V

OH

V

OL

V

IH

V

IL

I

LI

V

H

I

CC

I

PP

Output High Level 6V IOH=–0.4mA 2.4 — — V

Output Low Level 6V IOL=2.0mA — — 0.45 V

Input High Level 6V — 0.7V

Input Low Level 6V — –0.5 — 0.8 V

Input Load Current 6V VIN=VIL, V

A9 Product ID Voltage 6V — 11.5 — 12.5 V

VCC Supply Current 6V — — — 40 mA

VPP Supply Current 6V CE=V

Capacitance

Symbol Parameter

C

C

C

IN

OUT

VPP

Input Capacitance 3.3V VIN=0V — 8 12 pF

Output Capacitance 3.3V V

VPP Capacitance 3.3V VPP=0V — 18 25 pF

Test Conditions

V

CC

Conditions

Test Conditions

V

CC

HT27LC020

Min. T yp. Max. Unit

—VCC+0.5 V

CC

IH

IL

Conditions

=0V — 8 12 pF

OUT

— — 5.0 µA

——10mA

Min. Typ. Max. Unit

A.C. Characteristics

Read operation

Symbol Parameter

t

ACC

t

CE

t

OE

t

DF

t

OH

Address to Output Delay 3.3V CE=OE=V

Chip Enable to Output Delay 3.3V OE=V

Output Enable to Outpu t Delay 3.3V CE=V

CE or OE High to Output Float,

Whichever Occurred First

Output Hold from Address, CE or

OE, Whichever Occurred First

Test Conditions –120

V

CC

Conditions Min. Max.

IL

IL

IL

—120ns

—120ns

—45ns

Unit

3.3V — — 40 ns

3.3V — 0 — ns

4 7th May ’99

Page 5

HT27LC020

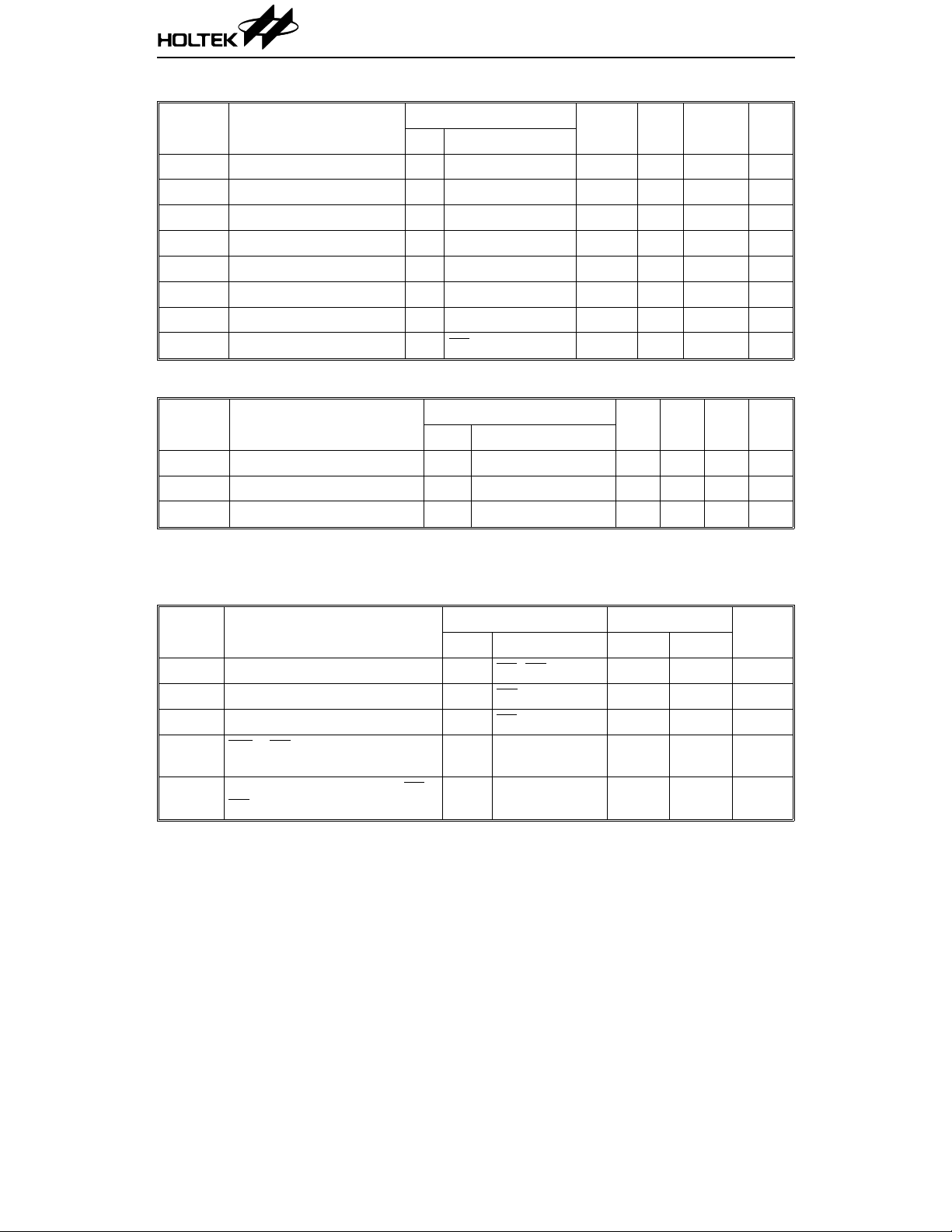

Programming operation Ta=+25°C±5°C

Symbol Parameter

t

AS

t

OES

t

DS

t

AH

t

DH

t

DFP

t

VPS

t

PW

t

VCS

t

CES

t

OE

t

PRT

Address Set up Time 6V — 2 — — µs

OE Setup Time 6V — 2 — — µs

Data Setup Time 6V — 2 — — µs

Address Hold Time 6V — 0 — — µs

Data Hold Time 6V — 2 — — µs

Output Enable to Output Float

Delay

VPP Setup Time 6V — 2 — — µs

PGM Program Pulse Width 6V — 30 75 105 µs

VCC Setup Time 6V — 2 — — µs

CE Setup Time 6V — 2 — — ns

Data Valid from OE 6V — — — 150 µs

VPP Pulse Rise Time Dur ing

Programming

Test waveforms and measurements

Test Conditions

V

CC

Conditions

Min. Typ. Max. Unit

6V — 0 — 130 ns

6V — 2 — —

µs

tR, tF< 20ns (10% to 90%)

Output test loa d

Note: CL=100pF including jig capacitance.

5 7th May ’99

Page 6

Product Identification Code

HT27LC020

Code

Pins

A0 A1 DQ7 DQ6 DQ5 DQ4 DQ3 DQ2 DQ1 DQ0

Hex

Data

Manufacturer 0 1 000111001C

Device Type 1 1 0000001002

Continuation

00011111117F

10011111117F

Functional Description

Operation mode

All the operation mo des are shown in the table following.

Mode CE OE PGM A0 A1 A9 VPP Output

Read V

Output Disable V

Standby (TTL) V

Standby (CMOS) V

CC

Program V

Program Verify V

Product Inhi bi t V

Manufacturer Code (3) V

Device Code (3) V

IL

IL

IH

± 0.3V X X X X X V

IL

IL

IH

IL

IL

V

V

X (2) X X X V

IL

IH

XXXXVCCHigh Z

CC

Dout

XXXX XVCCHigh Z

High Z

CC

V

V

IH

IL

V

IL

V

IH

XXXVPPD

XXXVPPD

OUT

XXXX XVPPHigh Z

V

IL

V

IL

XVILV

XVIHV

IH

IH

VH (1) V

VH (1) V

CC

CC

1C

02

IN

Notes: (1) V

= 12.0V ± 0.5V

H

(2) X=Either V

IH

or V

IL

(3) For Manufacturer Code and Device Code, A1=VIH, When A1=VIL, both codes will read 7F

6 7th May ’99

Page 7

HT27LC020

Programming of t he HT27LC0 20

When the HT27LC020 is delivered, the chip has

all 2048K bits in the “ONE”, or HIGH state.

“ZEROs” are loaded into the HT27LC020

through programming.

The programming mode is entered when

12.5

±0.2V is applied to the VPP pin, OE is at V

and

CE and PGM are VIL. For programming, the

IH

data to be programmed is applied with 8 bits in

parallel to the data pins.

The programming flowchart in Figure 3

shows the fast interactive programming algorithm. The interacti ve al gor i th m reduces programming time by using 30

µs to 105µs

programming pulses and giving each address

only as many pulses as is necessary in order to

reliably program the data. After each pulse is

applied to a given address, the data in that

address is verified. If the data is not verified,

additional pulses are given until it is verified or

until the maximum number of pulses is

reached while sequencing through each address of the HT27LC020. This process is repeated while sequencing through each address

of the HT27LC020. This part of the programming algorithm is done at V

=6.0V to assure

CC

that each EPROM bit is programmed to a sufficiently high threshold voltage. This ensures

that all bits have sufficient margin. After the

final address is completed, the entire EPROM

memory is read at V

CC=VPP

=5.25±0.25V to ver-

ify the entire memory.

Program inhibi t mode

Programming of multiple HT27LC020 in parallel

with different data is also easily accomplished by

using the Program Inhibit Mode. Except for

CE,

all like inputs of the parallel HT27LC020 may be

common. A TTL low-level program pulse applied to

an HT27LC020

CE input with Vpp=12.5±0.2V,

PGM LOW, and OE HIGH will program that

HT27LC020. A high-level

CE input inhibits the

HT27LC020 from being programmed.

Program verify mode

Verification should be performed on the programmed bits to determi ne whether the y were

correctly programmed. T he verification should

be performed with

V

, and VPP at its programming voltage.

IH

,

Auto product identification

OE and CE at VIL, PGM at

The Auto Product Identification mode allows

the reading out of a binary code from an

EPROM that will identify its manufacturer and

the type. This mode is intended for programming to automatically match the device to be

programmed with its corresponding programming algorithm. This mod e is functional in the

25

°C±5°C ambient temperature range that is

required when programming the HT27LC020.

To activate this mode, the programming equip-

ment must force 12.0

±0.5V on the address line A9

of the HT27LC020. T wo identifier by tes may then

be sequenced from the device outputs by toggling

address line A0 from V

to VIH, when A1=VIH. All

IL

other address lines must be held at V

Auto Product Identification mode.

Byte 0 (A0=V

code, and byte 1 (A0=V

) represents the manufacture r

IL

), the device code. For

IH

HT27LC020, these two identifier bytes are given

in the Mode Select Table. All identifiers for the

manufacturer and device codes will possess odd

parity, with the MSB (DQ7) defined as the parity

bit. When A1=V

, the HT27LC020 will read out

IL

the binary code of 7F, continuation code, to signify

the unavailability of manufacturer ID codes.

Read mode

The HT27LC020 has two control functions, both

of which must be logically satisfie d in order to

obtain data at outputs. Chip Enable (

power control and should be used for device

selection. Output Enable (

OE) is the output control and should be used to gate data to the

output pins, independent of device selection.

Assuming that addresses are stable, address

access time (t

to output (t

(t

) after the falling edge of OE, assuming the

OE

) is equal to t he del ay fr om CE

ACC

). Data is available at the outputs

CE

CE has been LOW and addresses have been

stable for at least t

ACC–tOE

.

during

IH

CE) is the

7 7th May ’99

Page 8

HT27LC020

Standby mode

The HT27LC020 has CMOS standby mode

which reduces the maximum VCC current to

10

µA. It is placed in CMOS standby when CE is

at V

±0.3V. The HT27LC020 also has a TTL-

CC

standby mode which reduces the maximum

VCC current to 0.6mA. It is placed in TTLstandby when

CE is at VIH. When in standby

mode, the outputs are in a high-impedance

state, independent of the

Two-line output control function

OE input.

To accommodate multiple memory connections,

a two-line control functi on is provi ded to allow

for:

•

Low memory power dissipation

•

Assurance that output bus contention will not

occur

It is recommended that

CE be decoded an d used

as the primary device-selecti on functio n, while

OE be made a common connection to the READ

line from the system control bus. Th is assures

that all deselected me mo ry de vices are in the ir

low-power standby mode and that the output

pins are only active when data is desired from a

particular memory device.

System considerations

During the switch betwe en active and standby

conditions, transient current peaks are produced on th e rising and fall ing edges of Chip

Enable. T he magn itude o f these tra nsient current peaks is dependent on the output capacitance loading of the device. At a minimum, a

0.1

µF ceramic capacitor (high frequency, low

inherent inductance) should be used on each

device between VCC and VPP to minimize transient effects. In addition, to overco me the voltage drop cause d by the inductive effects of the

printed circuit board traces on EPR OM arrays,

a 4.7

µF bulk electrolytic capacitor should be

used between VCC and VPP for each eight devices. The location of the capacitor should be

close to where the power supply is connected to

the array.

8 7th May ’99

Page 9

Figure 1. A.C. waveforms for read operation

HT27LC020

Figure 2. Programming waveforms

9 7th May ’99

Page 10

HT27LC020

Figure 3. Fast programming flowchart

10 7th May ’99

Page 11

HT27LC020

Holtek Semiconductor Inc. (Headquarters)

No.3 Creation Rd. II, Science-based Industrial Park, Hsinchu, Taiwan, R.O.C.

Tel: 886-3-563-1999

Fax: 886-3-563-1189

Holtek Semiconductor Inc. (Taipei Office)

5F, No.576, Sec.7 Chung Hsiao E. Rd., Taipei, Taiwan, R.O.C.

Tel: 886-2-2782-9635

Fax: 886-2-2782-9636

Fax: 886-2-2782-7128 (International sales hotline)

Holtek Microelectronics Enterprises Ltd.

RM.711, Tower 2, Cheung Sha Wan Plaza, 833 Cheung Sha Wan Rd., Kowloon, Hong Kong

Tel: 852-2-745-8288

Fax: 852-2-742-8657

Copyright © 1999 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek

assumes no responsibility arising from the use of the specif ications descri bed. The applications mentioned herein are

used solely for the purpose of illustration and Holtek makes no warranty or representation that such applications

will be suitable without further modification, nor recommends the use of its products for appli cation that may present

a risk to human life due to malfunction or otherwise. Holtek reserves the right to alter its products without prior

notification. For the most up-to-date information, please visit our web site at http://www.holtek.com.tw.

11 7th May ’99

Loading...

Loading...