Page 1

High CMR Isolation Amplifiers

Technical Data

H

HCPL-7800

HCPL-7800A

HCPL-7800B

Features

• 15 kV/µs Common-Mode

Rejection at VCM = 1000 V*

• Compact, Auto-Insertable

Standard 8-pin DIP Package

• 4.6 µV/°C Offset Drift vs.

Temperature

• 0.9 mV Input Offset Voltage

• 85 kHz Bandwidth

• 0.1% Nonlinearity

• Worldwide Safety Approval:

UL 1577 (3750 V rms/1 min),

VDE 0884 and CSA

• Advanced Sigma-Delta (Σ∆)

A/D Converter Technology

• Fully Differential Circuit

Topology

• 1 µm CMOS IC Technology

Applications

• Motor Phase Current

Sensing

• General Purpose Current

Sensing

• High-Voltage Power Source

Voltage Monitoring

*The terms common-mode rejection

(CMR) and isolation-mode rejection (IMR)

are used interchangeably throughout this

data sheet.

• Switch-Mode Power Supply

Signal Isolation

• General Purpose Analog

Signal Isolation

• Transducer Isolation

Description

The HCPL-7800 high CMR

isolation amplifier provides a

unique combination of features

ideally suited for motor control

circuit designers. The product

provides the precision and

stability needed to accurately

monitor motor current in highnoise motor control environments, providing for smoother

control (less “torque ripple”) in

various types of motor control

applications.

This product paves the way for a

smaller, lighter, easier to produce,

high noise rejection, low cost

solution to motor current

sensing. The product can also be

used for general analog signal

isolation applications requiring

high accuracy, stability and

linearity under similarly severe

noise conditions. For general

applications, we recommend the

HCPL-7800 which exhibits a

part-to-part gain tolerance of

± 5%. For precision applications,

HP offers the HCPL-7800A and

HCPL-7800B, each with part-topart gain tolerances of ± 1%.

The HCPL-7800 utilizes sigmadelta (Σ∆) analog-to-digital

converter technology, chopper

stabilized amplifiers, and a fully

differential circuit topology

fabricated using HP’s 1 µm

CMOS IC process. The part also

couples our high-efficiency, highspeed AlGaAs LED to a highspeed, noise-shielded detector

Functional Diagram

V

DD1

V

V

GND1

IN+

IN-

I

DD1

1

I

IN

2

3

4

CMR SHIELD

+

I

DD2

8

V

DD2

I

O

7

+

--

V

OUT+

6

V

OUT-

5

GND2

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

1-216

5965-3592E

Page 2

using our patented “light-pipe”

optocoupler packaging

technology.

Together, these features deliver

unequaled isolation-mode noise

rejection, as well as excellent

offset and gain accuracy and

stability over time and temperature. This performance is

delivered in a compact, autoinsertable, industry standard 8-

pin DIP package that meets

worldwide regulatory safety

standards (gull-wing surface

mount option #300 also

available).

Ordering Information:

HCPL-7800x

No Specifier = ± 5% Gain Tol.; Mean Gain Value = 8.00

A = ± 1% Gain Tol.; Mean Gain Value = 7.93

B = ± 1% Gain Tol.; Mean Gain Value = 8.07

Option yyy

300 = Gull Wing Surface Mount Lead Option

500 = Tape/Reel Package Option (1 k min.)

Option datasheets available. Contact your Hewlett-Packard sales representative or authorized distributor for

information.

Package Outline Drawings

Standard DIP Package

9.40 (0.370)

9.90 (0.390)

HP 7800

YYWW

PIN ONE

1.19 (0.047) MAX.

PIN ONE

0.76 (0.030)

1.24 (0.049)

DIMENSIONS IN MILLIMETERS AND (INCHES).

5678

4321

1.78 (0.070) MAX.

2.92 (0.115) MIN.

0.65 (0.025) MAX.

2.28 (0.090)

2.80 (0.110)

TYPE NUMBER*

DATE CODE

4.70 (0.185) MAX.

0.51 (0.020) MIN.

6.10 (0.240)

6.60 (0.260)

7.36 (0.290)

7.88 (0.310)

PIN DIAGRAM

1

V

V

DD1

DD2

2

V

V

IN+

OUT+

V

IN–

GND1

V

OUT–

GND2

3

4

* TYPE NUMBER FOR: HCPL-7800 = 7800

HCPL-7800A = 7800A

HCPL-7800B = 7800B

0.20 (0.008)

0.33 (0.013)

8

7

6

5

5° TYP.

1-217

Page 3

Gull Wing Surface Mount Option 300*

9.65 ± 0.25

(0.380 ± 0.010)

6

5

3

4

1.780

(0.070)

MAX.

MOLDED

1.19

(0.047)

MAX.

7

8

HP 7800

YYWW

1

2

6.350 ± 0.25

(0.250 ± 0.010)

4.19

MAX.

(0.165)

PIN LOCATION (FOR REFERENCE ONLY)

1.02 (0.040)

1.19 (0.047)

4.83

TYP.

(0.190)

1.19 (0.047)

1.78 (0.070)

9.65 ± 0.25

(0.380 ± 0.010)

7.62 ± 0.25

(0.300 ± 0.010)

0.20 (0.008)

0.33 (0.013)

9.65 ± 0.25

(0.380 ± 0.010)

0.380 (0.015)

0.635 (0.025)

1.080 ± 0.320

(0.043 ± 0.013)

2.540

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

TOLERANCES (UNLESS OTHERWISE SPECIFIED):

* REFER TO OPTION 300 DATA SHEET FOR MORE INFORMATION.

0.51 ± 0.130

(0.020 ± 0.005)

Maximum Solder Reflow Thermal Profile

260

240

220

200

180

160

140

120

100

80

60

TEMPERATURE – °C

40

20

0

∆T = 115°C, 0.3°C/SEC

∆T = 100°C, 1.5°C/SEC

0

123456789101112

TIME – MINUTES

0.635 ± 0.25

(0.025 ± 0.010)

xx.xx = 0.01

xx.xxx = 0.005

∆T = 145°C, 1°C/SEC

12° NOM.

LEAD COPLANARITY

MAXIMUM: 0.102 (0.004)

1-218

(NOTE: USE OF NON-CHLORINE ACTIVATED FLUXES IS RECOMMENDED.)

Page 4

Regulatory Information

The HCPL-7800 has been

approved by the following

organizations:

UL

Recognized under UL 1577,

Component Recognition

Program, File E55361.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

VDE

Approved according to VDE

0884/06.92.

Insulation and Safety Related Specifications

Parameter Symbol Value Units Conditions

Min. External Air Gap L(IO1) 7.4 mm Measured from input terminals to output terminals,

(External Clearance) shortest distance through air

Min. External Tracking L(IO2) 8.0 mm Measured from input terminals to output terminals,

Path (External Creepage) shortest distance path along body

Min. Internal Plastic Gap 0.5 mm Through insulation distance, conductor to conductor,

(Internal Clearance) usually the direct distance between the photoemitter

and photodetector inside the optocoupler cavity

Tracking Resistance CTI 175 V DIN IEC 112/VDE 0303 Part 1

(Comparative Tracking

Index)

Isolation Group III a Material Group (DIN VDE 0110, 1/89, Table 1)

Option 300 – surface mount classification is Class A in accordance with CECC 00802.

VDE 0884 (06.92) Insulation Characteristics

Description Symbol Characteristic Unit

Installation classification per DIN VDE 0110, Table 1

for rated mains voltage ≤ 300 V rms I-IV

for rated mains voltage ≤ 600 V rms I-III

Climatic Classification 40/100/21

Pollution Degree (DIN VDE 0110, Table 1)* 2

Maximum Working Insulation Voltage V

Input to Output Test Voltage, Method b** V

VPR = 1.875 x V

, Production test with tp = 1 sec,

IORM

IORM

PR

Partial discharge < 5 pC

Input to Output Test Voltage, Method a** V

VPR = 1.5 x V

, Type and sample test with tp = 60 sec,

IORM

PR

Partial discharge < 5 pC

Highest Allowable Overvoltage**

(Transient Overvoltage tTR = 10 sec) V

TR

Safety-limiting values (Maximum values allowed in the event

of a failure, also see Figure 27)

Case Temperature T

Input Power P

Output Power P

Insulation Resistance at TS, VIO = 500 V R

*This part may also be used in Pollution Degree 3 environments where the rated mains voltage is ≤ 300 V rms (per DIN VDE 0110).

**Refer to the front of the optocoupler section of the current catalog for a more detailed description of VDE 0884 and other product

safety requirements.

Note: Optocouplers providing safe electrical separation per VDE 0884 do so only within the safety-limiting values to which they are

qualified. Protective cut-out switches must be used to ensure that the safety limits are not exceeded.

S

S,Input

S,Output

S

848 V peak

1591 V peak

1273 V peak

6000 V peak

175 °C

80 mW

250 mW

≥ 1x10

12

Ω

1-219

Page 5

Absolute Maximum Ratings

Parameter Symbol Min. Max. Unit Note

Storage Temperature T

Ambient Operating Temperature T

Supply Voltages V

Steady-State Input Voltage V

DD1

IN+

A

, V

, V

S

DD2

IN-

-55 125 °C

- 40 100 °C

0.0 5.5 V

-2.0 V

+0.5 V

DD1

Two Second Transient Input Voltage -6.0

Output Voltages V

Lead Solder Temperature T

OUT+

, V

LS

OUT-

-0.5 V

+0.5 V

DD2

260 °C1

(1.6 mm below seating plane, 10 sec.)

Reflow Temperature Profile See Package Outline Drawings Section

Recommended Operating Conditions

Parameter Symbol Min. Max. Unit Note

Ambient Operating Temperature T

Supply Voltages V

Input Voltage V

DD1

IN+

A

, V

, V

DD2

IN-

Output Current |IO|1mA5

-40 85 °C2

4.5 5.5 V 3

-200 200 mV 4

1-220

Page 6

DC Electrical Specifications

All specifications and figures are at the nominal operating condition of V

5.0 V, and V

Parameter Symbol Min. Typ. Max. Unit Test Conditions Fig. Note

Input Offset Voltage V

Input Offset Drift vs. dVOS/dT -2.1 µV/°C 1, 2 6

Temperature

Abs. Value of Input |dV

Offset Drift vs. Temperature

Input Offset Drift vs. V

Input Offset Drift vs. V

Gain (± 5% Tol.) G 7.61 8.00 8.40 -200 mV < V

Gain - A Version (± 1% Tol.) G

Gain - B Version (± 1% Tol.) G

Gain Drift vs. Temperature dG/dT 0.001 %/°C 5, 6 11

Abs. Value of Gain Drift vs. |dG/dT| 0.001 %/°C512

Temperature

Gain Drift vs. V

Gain Drift vs. V

200 mV Nonlinearity NL

200 mV Nonlinearity Drift dNL

vs. Temperature

200 mV Nonlinearity Drift dNL

vs. V

DD1

200 mV Nonlinearity Drift dNL

vs. V

DD2

100 mV Nonlinearity NL

Maximum Input Voltage |V

Before Output Clipping

Average Input Bias Current I

Input Bias Current dIIN/dT 3 nA/°C

Temperature Coefficient

Average Input Resistance R

Input Resistance dRIN/dT 0.38 %/°C

Temperature Coefficient

Input DC Common-Mode CMRR

Rejection Ratio

Output Resistance R

Output Resistance dR

Temperature Coefficient

Output Low Voltage V

Output High Voltage V

Output Common-Mode V

Voltage 4.5 V < V

Input Supply Current I

Output Supply Current I

Output Short-Circuit |I

Current

= 5.0 V, unless otherwise noted.

DD2

OS

/dT| 4.6 µV/°C17

OS

DD1

DD2

DD1

DD2

dVOS/dV

DD1

dVOS/dV

DD2

A

B

dG/dV

DD1

dG/dV

DD2

200

/dT -0.001 % pts/°C5, 1016

200

/dV

200

DD1

/dV

200

DD2

100

IN+|max

IN

IN

IN

O

/dT 0.6 %/°C

O

OL

OH

OCM

DD1

DD2

| 9.3 mA V

OSC

-1.8 -0.9 0.0 mV 1

30 µV/V 1, 3 8

-40 µV/V 1, 4 9

7.85 7.93 8.01

7.99 8.07 8.15

0.21 %/V 5, 7 13

-0.06 %/V 5, 8 14

0.2 0.35 % 5, 9 15

-0.005 % pts/V 5, 11 17

-0.007 % pts/V 5, 12 18

0.1 0.25 % -100 mV< V

300 mV 14

-670 nA 15, 16 20

530 kΩ 15 20

72 dB 21

11 Ω 5

1.18 V |V

3.61 V I

2.20 2.39 2.60 V -40°C < TA < 85°C14

10.7 15.5 mA 17 23

11.6 14.5 mA V

= 0 V, V

IN+

IN+

OUT+

= 200 mV, 18 24

IN+

-40° C < T

4.5 V < V

OUT

= 0 V, TA = 25°C, V

IN-

< 200 mV 1, 5 10

IN+

< 100 mV 5, 13 19

IN+

| = 500 mV 14 22

= 0 A, I

DD1

A

DD2

= 0 V or V

OUT–

< 5.5 V

< 85°C

< 5.5 V

DD2

= 0 A

DD1

=

25

1-221

Page 7

AC Electrical Specifications

All specifications and figures are at the nominal operating condition of V

V

= 5.0 V, and V

DD1

Parameter Symbol Min. Typ. Max. Unit Test Conditions Fig. Note

= 5.0 V, unless otherwise noted.

DD2

= 0 V, V

IN+

= 0 V, TA = 25°C,

IN-

Rising Edge Isolation IMR

10 25 kV/µsVIM = 1 kV 19, 20 26

R

Mode Rejection

Falling Edge Isolation IMR

10 15 kV/µs

F

Mode Rejection

Isolation Mode Rejection IMRR >140 dB 19 27

Ratio at 60 Hz

Propagation Delay to 10% t

Propagation Delay to 50% t

Propagation Delay to 90% t

Rise/Fall Time (10%-90%) t

Bandwidth (-3 dB) f

Bandwidth (-45°)f

RMS Input-Referred V

PD10

PD50

PD90

R/F

-3dB

-45°

N

50 85 kHz 23, 24

2.0 3.3 µs -40°C < TA < 85°C 21, 22

3.4 5.6 µs

6.3 9.9 µs

4.3 6.6 µs

35 kHz

300 µV rms Bandwidth = 100 kHz 25, 26 28

Noise

Power Supply Rejection PSR 5 mV

p-p

Package Characteristics

All specifications and figures are at the nominal operating condition of V

= 5.0 V, and V

Parameter Symbol Min. Typ. Max. Unit Test Conditions Fig. Note

= 5.0 V, unless otherwise noted.

DD2

= 0 V, V

IN+

= 0 V, TA = 25°C, V

IN-

29

DD1

Input-Output Momentary V

ISO

3750 V rms t = 1 min., RH ≤ 50% 30, 31

Withstand Voltage*

Input-Output Resistance R

Input-Output Capacitance C

Input IC Junction-to- θ

I-O

I-O

jci

10

10

12

11

13

10

Ω TA = 25° CV

= 500 Vdc 30

I-O

TA = 100°C

0.7 pF f = 1 MHz 30

96 °C/W 32

Case Thermal Resistance

Output IC Junction-to-Case θ

jco

114 °C/W

Thermal Resistance

*The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to the VDE 0884 Insulation Characteristics Table (if applicable), your

equipment level safety specification, or HP Application Note 1074, “Optocoupler Input-Output Endurance Voltage.”

1-222

Page 8

Notes:

General Note: Typical values represent the

mean value of all characterization units at

the nominal operating conditions. Typical

drift specifications are determined by

calculating the rate of change of the specified parameter versus the drift parameter

(at nominal operating conditions) for each

characterization unit, and then averaging

the individual unit rates. The corresponding drift figures are normalized to the

nominal operating conditions and show

how much drift occurs as the particular

drift parameter is varied from its nominal

value, with all other parameters held at

their nominal operating values. Figures

show the mean drift of all characterization

units as a group, as well as the ± 2-sigma

statistical limits. Note that the typical drift

specifications in the tables below may

differ from the slopes of the mean curves

shown in the corresponding figures.

1. HP recommends the use of nonchlorine activated fluxes.

2. The HCPL-7800 will operate properly

at ambient temperatures up to 100°C

but may not meet published specifications under these conditions.

3. DC performance can be best

maintained by keeping V

DD1

and V

DD2

as close as possible to 5 V. See

application section for circuit

recommendations.

4. HP recommends operation with V

= 0 V (tied to GND1). Limiting V

IN-

IN+

to 100 mV will improve DC

nonlinearity and nonlinearity drift. If

V

is brought above 800 mV with

IN-

respect to GND1, an internal test

mode may be activated. This test mode

is not intended for customer use.

5. Although, statistically, the average

difference in the output resistance of

pins 6 and 7 is near zero, the standard

deviation of the difference is 1.3 Ω

due to normal process variations.

Consequently, keeping the output

current below 1 mA will ensure the

best offset performance.

6. Data sheet value is the average change

in offset voltage versus temperature at

TA=25°C, with all other parameters

held constant. This value is expressed

as the change in offset voltage per °C

change in temperature.

7. Data sheet value is the average

magnitude of the change in offset

voltage versus temperature at

TA=25°C, with all other parameters

held constant. This value is expressed

as the change in magnitude per °C

change in temperature.

8. Data sheet value is the average change

in offset voltage versus input supply

voltage at V

parameters held constant. This value

= 5 V, with all other

DD1

is expressed as the change in offset

voltage per volt change of the input

supply voltage.

9. Data sheet value is the average change

in offset voltage versus output supply

voltage at V

= 5 V, with all other

DD2

parameters held constant. This value

is expressed as the change in offset

voltage per volt change of the output

supply voltage.

10. Gain is defined as the slope of the

best-fit line of differential output

voltage (V

differential input voltage (V

over the specified input range.

OUT+

- V

OUT-

) versus

IN+

-V

)

IN-

11. Data sheet value is the average change

in gain versus temperature at

TA=25°C, with all other parameters

held constant. This value is expressed

as the percentage change in gain per

°C change in temperature.

12. Data sheet value is the average

magnitude of the change in gain

versus temperature at TA=25°C, with

all other parameters held constant.

This value is expressed as the

percentage change in magnitude per

°C change in temperature.

13. Data sheet value is the average change

in gain versus input supply voltage at

V

= 5 V, with all other parameters

DD1

held constant. This value is expressed

as the percentage change in gain per

volt change of the input supply

voltage.

14. Data sheet value is the average change

in gain versus output supply voltage at

V

= 5 V, with all other parameters

DD2

held constant. This value is expressed

as the percentage change in gain per

volt change of the output supply

voltage.

15. Nonlinearity is defined as the maximum deviation of the output voltage

from the best-fit gain line (see Note

10), expressed as a percentage of the

full-scale differential output voltage

range. For example, an input range of

± 200 mV generates a full-scale differential output range of 3.2 V (± 1.6 V);

a maximum output deviation of 6.4

mV would therefore correspond to a

nonlinearity of 0.2%.

16. Data sheet value is the average change

in nonlinearity versus temperature at

TA=25°C, with all other parameters

held constant. This value is expressed

as the number of percentage points

that the nonlinearity will change per

°C change in temperature. For

example, if the temperature is

increased from 25°C to 35°C, the

nonlinearity typically will decrease by

0.01 percentage points (10°C times

-0.001 % pts/°C) from 0.2% to 0.19%.

17. Data sheet value is the average change

in nonlinearity versus input supply

voltage at V

= 5 V, with all other

DD1

parameters held constant. This value

is expressed as the number of

percentage points that the nonlinearity

will change per volt change of the

input supply voltage.

18. Data sheet value is the average change

in nonlinearity versus output supply

voltage at V

parameters held constant. This value

= 5 V, with all other

DD2

is expressed as the number of

percentage points that the nonlinearity

will change per volt change of the

output supply voltage.

19. NL

is the nonlinearity specified over

100

an input voltage range of ± 100 mV.

20. Because of the switched-capacitor

nature of the input sigma-delta

converter, time-averaged values are

shown.

21. This parameter is defined as the ratio

of the differential signal gain (signal

applied differentially between pins 2

and 3) to the common-mode gain

(input pins tied together and the signal

applied to both inputs at the same

time), expressed in dB.

22. When the differential input signal

exceeds approximately 300 mV, the

outputs will limit at the typical values

shown.

23. The maximum specified input supply

current occurs when the differential

input voltage (V

IN+

- V

) = 0 V. The

IN-

input supply current decreases

approximately 1.3 mA per 1 V

decrease in V

DD1

.

24. The maximum specified output supply

current occurs when the differential

input voltage (V

IN+ -VIN-

) = 200 mV,

the maximum recommended operating

input voltage. However, the output

supply current will continue to rise for

differential input voltages up to

approximately 300 mV, beyond which

the output supply current remains

constant.

1-223

Page 9

25. Short circuit current is the amount of

output current generated when either

output is shorted to V

or ground.

DD2

26. IMR (also known as CMR or Common

Mode Rejection) specifies the minimum rate of rise of an isolation mode

noise signal at which small output

perturbations begin to appear. These

output perturbations can occur with

both the rising and falling edges of the

isolation-mode wave form and may be

of either polarity. When the perturbations first appear, they occur only

occasionally and with relatively small

peak amplitudes (typically 20-30 mV

at the output of the recommended

application circuit). As the magnitude

of the isolation mode transients

increase, the regularity and amplitude

of the perturbations also increase. See

applications section for more

information.

27. IMRR is defined as the ratio of

differential signal gain (signal applied

differentially between pins 2 and 3) to

the isolation mode gain (input pins

tied to pin 4 and the signal applied

between the input and the output of

the isolation amplifier) at 60 Hz,

expressed in dB.

28. Output noise comes from two primary

sources: chopper noise and sigmadelta quantization noise. Chopper

noise results from chopper stabilization of the output op-amps. It occurs

at a specific frequency (typically 200

kHz at room temperature), and is not

attenuated by the internal output filter.

A filter circuit can be easily added to

the external post-amplifier to reduce

the total rms output noise. The

internal output filter does eliminate

most, but not all, of the sigma-delta

quantization noise. The magnitude of

the output quantization noise is very

small at lower frequencies (below 10

kHz) and increases with increasing

frequency. See applications section for

more information.

29. Data sheet value is the differential

amplitude of the transient at the

output of the HCPL-7800 when a

1V

, 1 MHz square wave with 5 ns

pk-pk

rise and fall times is applied to both

V

DD1

and V

DD2

.

30. This is a two-terminal measurement:

pins 1-4 are shorted together and pins

5-8 are shorted together.

31. In accordance with UL1577, for

devices with minimum V

3750 V

, each optocoupler is proof-

rms

specified at

ISO

tested by applying an insulation test

voltage greater-than-or-equal-to 4500

V

for one second (leak current

rms

detection limit, I

<5µA). This test

I-O

is performed before the method b,

100% production test for partial

discharge shown in the VDE 0884

Insulation Characteristics Table.

32. Case temperature was measured with a

thermocouple located in the center of

the underside of the package.

+5 V+5 V +15 V

0.1 µF 0.1 µF

HCPL-7800

1

2

3

4

8

7

6

5

10 K

10 K

1500

0.1 µF

+

AD624CD

GAIN = 1000

0.33 µF0.33 µF

0.1 µF

-15 V

V

OUT

1000

500

0

-500

OS

dV – INPUT-REFERRED OFFSET DRIFT – µV

-1000

-40 -20 0 20 40 60 80

T – TEMPERATURE – °C

A

MEAN

± 2 SIGMA

Figure 1. Input Offset Voltage Test Circuit. Figure 2. Input-Referred Offset Drift

vs. Temperature.

100

1-224

Page 10

600

400

MEAN

± 2 SIGMA

400

300

MEAN

± 2 SIGMA

200

0

-200

-400

OS

dV – INPUT-REFERRED OFFSET DRIFT – µV

-600

4.4 4.6 4.8 5.0 5.2 5.4 5.6

V – INPUT SUPPLY VOLTAGE – V

DD1

Figure 3. Input-Referred Offset Drift

vs. V

V

0.01 µF

(V

DD2

= 5 V).

HCPL-7800

1

2

3

4

8

7

6

5

DD1

0.1 µF 0.1 µF

IN

+5 V+5 V +15 V

200

100

0

-100

OS

dV – INPUT-REFERRED OFFSET DRIFT – µV

-200

4.4 4.6 4.8 5.0 5.2 5.4 5.6

V – OUTPUT SUPPLY VOLTAGE – V

DD2

Figure 4. Input-Referred Offset Drift

vs. V

10 K

10 K

DD2

(V

0.33 µF0.33 µF

DD1

= 5 V).

+

AD624CD

GAIN = 1

-15 V

0.1 µF

0.1 µF

1.5

1.0

0.5

V

OUT

0

dG – GAIN DRIFT– %

-0.5

-1.0

-40 -20 0 20 40 60 80

MEAN

± 2 SIGMA

T – TEMPERATURE – °C

A

100

Figure 5. Gain and Nonlinearity Test Circuit. Figure 6. Gain Drift vs. Temperature.

0.5

0

-0.5

-1.0

dG – GAIN DRIFT– %

-1.5

-2.0

4.4 4.6 4.8 5.0 5.2 5.4 5.6

V – INPUT SUPPLY VOLTAGE – V

DD1

Figure 7. Gain Drift vs.

V

(V

DD2

= 5 V).

DD1

MEAN

± 2 SIGMA

0.5

0.4

0.3

0.2

0.1

dG – GAIN DRIFT– %

0

-0.1

4.4 4.6 4.8 5.0 5.2 5.4 5.6

V – OUTPUT SUPPLY VOLTAGE – V

DD2

Figure 8. Gain Drift vs.

V

(V

DD1

= 5 V).

DD2

MEAN

± 2 SIGMA

0.3

MEAN

0.2

0.1

0

-0.1

ERROR – % OF FULL-SCALE

-0.2

-0.3

-0.2 -0.1 0 0.1 0.2

± 2 SIGMA

V – INPUT VOLTAGE – V

IN

Figure 9. 200 mV Nonlinearity Error

Plot.

1-225

Page 11

0.15

0.10

0.05

0

-0.05

200

-0.10

-40 -20 0 20 40 60 80 100

dNL – 200 mV NON-LINEARITY DRIFT – % PTS

T – TEMPERATURE – °C

A

MEAN

± 2 SIGMA

0.06

0.04

0.02

0

-0.02

-0.04

200

-0.06

dNL – 200 mV NON-LINEARITY DRIFT – % PTS

4.6 4.8 5.0 5.2 5.4 5.6

4.4

V – INPUT SUPPLY VOLTAGE – V

DD1

MEAN

± 2 SIGMA

0.06

0.04

0.02

0

-0.02

200

-0.04

4.4

dNL – 200 mV NON-LINEARITY DRIFT – % PTS

4.6 4.8 5.0 5.2 5.4 5.6

V – OUTPUT SUPPLY VOLTAGE – V

DD2

MEAN

± 2 SIGMA

Figure 10. 200 mV Nonlinearity Drift

vs. Temperature.

0.15

0.10

0.05

0

-0.05

-0.10

ERROR – % OF FULL-SCALE

-0.15

-0.20

-0.10

-0.05 0 0.05 0.10

V – INPUT VOLTAGE – V

IN

MEAN

± 2 SIGMA

Figure 13. 100 mV Nonlinearity Error

Plot.

2

0

-2

Figure 11. 200 mV Nonlinearity Drift

vs. V

(V

DD1

4.0

3.5

3.0

2.5

2.0

O

V – OUTPUT VOLTAGE – V

1.5

1.0

-0.6

= 5 V).

DD2

POSITIVE

OUTPUT

(PIN 7)

NEGATIVE

OUTPUT

(PIN 6)

-0.4 -0.2 0 0.2

V – INPUT VOLTAGE – V

IN

0.4 0.6

Figure 14. Typical Output Voltages vs.

Input Voltage.

10.5

10.0

Figure 12. 200 mV Nonlinearity Drift

vs. V

(V

DD2

0

-200

-400

-600

-800

IN

I – INPUT CURRENT – nA

-1000

-1200

= 5 V).

DD1

-0.1 0 0.1 0.2

-0.2

V – INPUT VOLTAGE – V

IN

Figure 15. Typical Input Current vs.

Input Voltage.

12.0

11.5

T = 85°C

A

T = 25°C

A

T = -40°C

A

-4

-6

IN

I – INPUT CURRENT – mA

-8

-10

-6 6

-2 0 2 4

-4

V – INPUT VOLTAGE – V

IN

Figure 16. Typical Input Current vs.

Input Voltage.

1-226

9.5

9.0

DD1

I – INPUT SUPPLY CURRENT – mA

8.5

-0.3 0.3-0.4 0.4

V – INPUT VOLTAGE – V

IN

T = -40°C

A

T = 25°C

A

T = 85°C

A

-0.1 0 0.1 0.2

-0.2

Figure 17. Typical Input Supply

Current vs. Input Voltage.

11.0

10.5

DD2

I – OUTPUT SUPPLY CURRENT – mA

10.0

-0.1 0 0.1 0.2

-0.2

-0.3 0.3-0.4 0.4

V – INPUT VOLTAGE – V

IN

Figure 18. Typical Output Supply

Current vs. Input Voltage.

Page 12

330 pF

5.11 K

+5 V

9 V

78L05

IN OUT

0.1 µF

0.1 µF

HCPL-7800

1

2

3

4

PULSE GEN.

-

+

V

IM

0.1 µF

8

7

6

5

Figure 19. Isolation Mode Rejection Test Circuit.

V

IM

330 pF

1.00 K

1.00 K

5.11 K

1000 V

0 V

+15 V

+

-15 V

0.1 µF

OP-42

0.1 µF

V

OUT

t – TIME – µs

10

8

6

4

DELAY TO 90%

RISE/FALL TIME

DELAY TO 50%

DELAY TO 10%

50 mV PERTURBATION

(DEFINITION OF FAILURE)

V

O

0 V

2

0

-20 100-40

20 40 60 80

0

T – TEMPERATURE – °C

A

Figure 20. Typical IMR Failure Waveform. Figure 21. Typical Propagation Delays

and Rise/Fall Time vs. Temperature.

1-227

Page 13

V – RMS INPUT-REFERRED NOISE – mV

N

V

IN

V

OUT

t

PD10

50%

t

t

PD50

PD90

10%

90%

50%

t

R/F

10.0 K

+5 V +15 V

0.1 µF

8

7

6

5

V

IN

0.01 µF

0.1 µF

+5 V

HCPL-7800

1

2

3

4

Figure 22. Propagation Delay and Rise/Fall Time Test Circuit.

0

-1

-2

-3

RELATIVE AMPLITUDE – dB

-4

AMPLITUDE

PHASE

500100

1000

f – FREQUENCY – Hz

5000 10000 50000 100000

0

-5

-10

-15

-30

-45

Ø – PHASE – DEGREES

-60

110

100

90

80

70

-3 dB

f – 3 dB BANDWIDTH – kHz

60

-20-40

2.00 K

2.00 K

10.0 K

3 dB BANDWIDTH

45 DEGREE PHASE

BANDWIDTH

20 40 60 80

0

T – TEMPERATURE – °C

A

+

-15 V

0.1 µF

OP-42

0.1 µF

100

V

OUT

48

44

40

36

32

-45°

28

f – 45 DEGREE PHASE BANDWIDTH – kHz

3.0

2.5

2.0

1.5

1.0

0.5

0

NO BANDWIDTH LIMITING

BANDWIDTH LIMITED TO 100 kHz

BANDWIDTH LIMITED TO 10 kHz

150 200 250

100

500

V – INPUT VOLTAGE – mV

IN

Figure 23. Typical Amplitude and

Phase Response vs. Frequency.

1-228

Figure 24. Typical 3 dB and 45°

Bandwidths vs. Temperature.

Figure 25. Typical RMS Input-Referred

Noise vs. Input Voltage.

Page 14

FLOATING

POSITIVE

SUPPLY

GATE DRIVE

CIRCUIT

IN

78L05

C1

0.1 µF

OUT

U1

C2

0.1 µF

R5

39 Ω

MOTOR

+

R

HV+

-

SENSE

HV-

Figure 26. Recommended Application Circuit.

C3

0.01 µF

1

2

HCPL-7800

3

4

C5

75 pF

R3

10.0 KΩ

+5 V

8

7

U2

6

5

C4

0.1 µF

2.00 KΩ

75 pF

R1

2.00 KΩ

R2

C6

R4

10.0 KΩ

+15 V

U3

+

-15 V

C8

0.1 µF

MC34081

C7

0.1 µF

V

OUT

400

300

200

– POWER – mW

S

P

100

0

0

OUTPUT POWER, P

INPUT POWER, P

20 60 100 140

TA – TEMPERATURE – °C

S

12040 80 160

S

175

Figure 27. Dependence of SafetyLimiting Parameters on Ambient

Temperature.

Applications Information

Functional Description

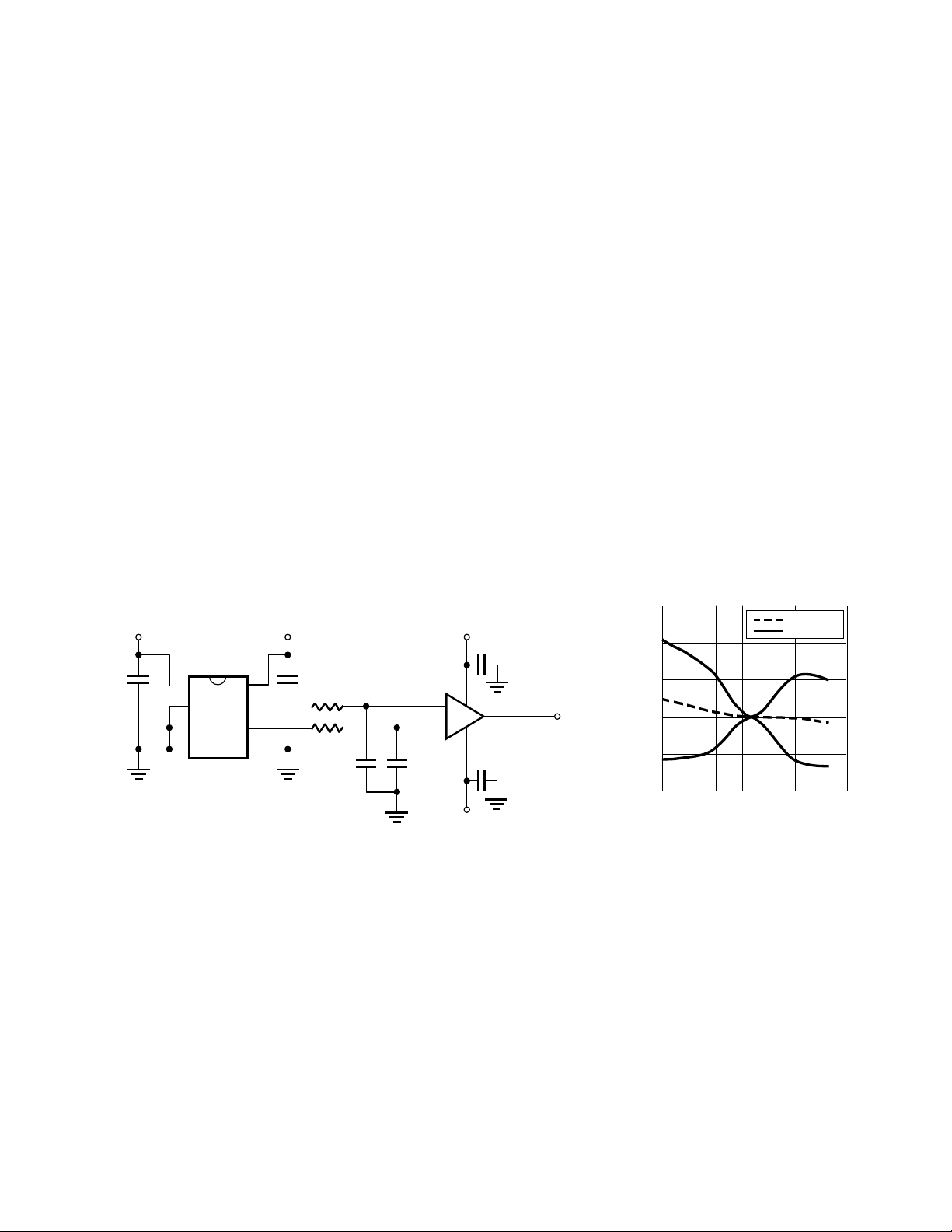

Figure 28 shows the primary

functional blocks of the HCPL-

7800. In operation, the sigmadelta analog-to-digital converter

converts the analog input signal

into a high-speed serial bit

stream, the time average of which

is directly proportional to the

input signal. This high speed

stream of digital data is encoded

and optically transmitted to the

detector circuit. The detected

180

signal is decoded and converted

into accurate analog voltage

levels, which are then filtered to

produce the final output signal.

To help maintain device accuracy

over time and temperature,

internal amplifiers are chopperstabilized. Additionally, the

encoder circuit eliminates the

effects of pulse-width distortion of

the optically transmitted data by

generating one pulse for every

edge (both rising and falling) of

the converter data to be

transmitted, essentially converting

the widths of the sigma-delta

output pulses into the positions

of the encoder output pulses. A

significant benefit of this coding

scheme is that any non-ideal

characteristics of the LED (such

as non-linearity and drift over

time and temperature) have little,

if any, effect on the performance

of the HCPL-7800.

1-229

Page 15

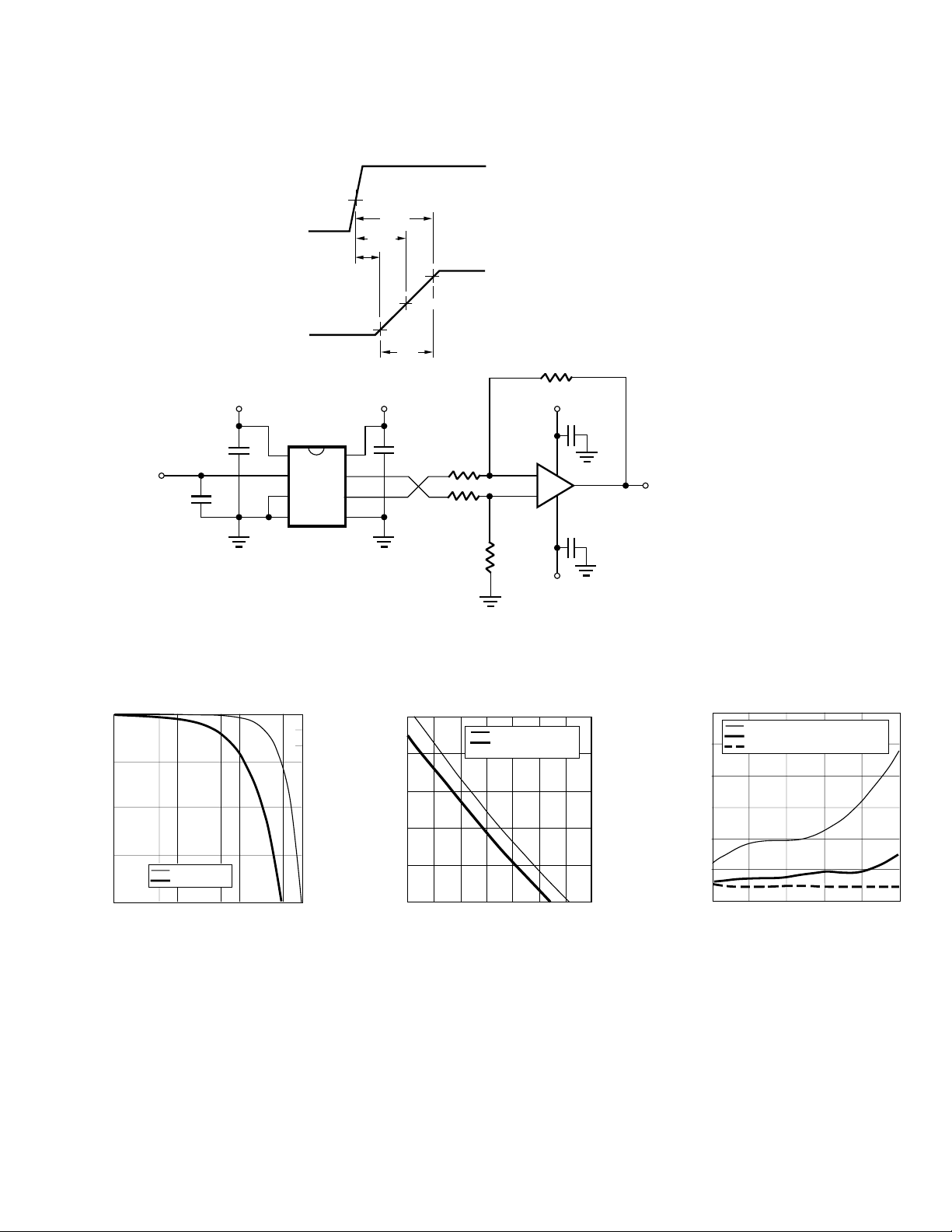

Circuit Information

The recommended application

circuit is shown in Figure 26. A

floating power supply (which in

many applications could be the

same supply that is used to drive

the high-side power transistor) is

regulated to 5 V using a simple

three-terminal voltage regulator.

The input of the HCPL-7800 is

connected directly to the current

sensing resistor. The differential

output of the isolation amplifier is

converted to a ground-referenced

single-ended output voltage with a

simple differential amplifier

circuit. Although the application

circuit is relatively simple, a few

general recommendations should

be followed to ensure optimal

performance.

As shown in Figure 26, 0.1 µF

bypass capacitors should be

located as close as possible to the

input and output power supply

pins of the HCPL-7800. Notice

that pin 2 (V

) is bypassed with

IN+

a 0.01 µF capacitor to reduce

input offset voltage that can be

caused by the combination of

long input leads and the switchedcapacitor nature of the input

circuit.

With pin 3 (V

) tied directly to

IN-

pin 4 (GND1), the power-supply

return line also functions as the

sense line for the negative side of

the current-sensing resistor; this

allows a single twisted pair of

wire to connect the isolation

amplifier to the sense resistor. In

some applications, however,

better performance may be

obtained by connecting pins 2

and 3 (V

IN+

and V

) directly

IN-

across the sense resistor with

twisted pair wire and using a

separate wire for the power

supply return line. Both input

pins should be bypassed with 0.01

µF capacitors close to the

isolation amplifier. In either case,

it is recommended that twistedpair wire be used to connect the

isolation amplifier to the currentsensing resistor to minimize

electro-magnetic interference of

the sense signal.

To obtain optimal CMR performance, the layout of the printed

circuit board (PCB) should

minimize any stray coupling by

maintaining the maximum

possible distance between the

input and output sides of the

circuit and ensuring that any

ground plane on the PCB does not

pass directly below the HCPL-

7800. An example single-sided

PCB layout for the recommended

application circuit is shown in

Figure 29. The trace pattern is

shown in “X-ray” view as it would

be seen from the top of the PCB;

a mirror image of this layout can

be used to generate a PCB.

An inexpensive 78L05 threeterminal regulator is shown in the

recommended application circuit.

Because the performance of the

isolation amplifier can be affected

by changes in the power supply

voltages, using regulators with

tighter output voltage tolerances

will result in better overall circuit

performance. Many different

regulators that provide tighter

output voltage tolerances than the

78L05 can be used, including:

TL780-05 (Texas Instruments),

LM340LAZ-5.0 and LP2950CZ-

5.0 (National Semiconductor).

The op-amp used in the external

post-amplifier circuit should be of

sufficiently high precision so that

it does not contribute a significant

amount of offset or offset drift

relative to the contribution from

the isolation amplifier. Generally,

op-amps with bipolar input stages

exhibit better offset performance

than op-amps with JFET or

MOSFET input stages.

In addition, the op-amp should

also have enough bandwidth and

slew rate so that it does not

adversely affect the response

speed of the overall circuit. The

post-amplifier circuit includes a

pair of capacitors (C5 and C6)

that form a single-pole low-pass

filter; these capacitors allow the

bandwidth of the post-amp to be

adjusted independently of the gain

and are useful for reducing the

output noise from the isolation

amplifier. Many different op-amps

could be used in the circuit,

including: MC34082A (Motorola),

TL032A, TLO52A, and TLC277

(Texas Instruments), LF412A

(National Semiconductor).

The gain-setting resistors in the

post-amp should have a tolerance

of 1% or better to ensure

adequate CMRR and adequate

gain tolerance for the overall

circuit. Resistor networks can be

used that have much better ratio

tolerances than can be achieved

using discrete resistors. A resistor

network also reduces the total

number of components for the

circuit as well as the required

board space.

The current-sensing resistor

should have a relatively low value

of resistance to minimize power

dissipation, a fairly low

inductance to accurately reflect

high-frequency signal components, and a reasonably tight

tolerance to maintain overall

circuit accuracy. Although

decreasing the value of the sense

resistor decreases power

dissipation, it also decreases the

full-scale input voltage making

iso-amp offset voltage effects

more significant. These two

1-230

Page 16

conflicting considerations,

therefore, must be weighed

against each other in selecting an

appropriate sense resistor for a

particular application. To

maintain circuit accuracy, it is

recommended that the sense

resistor and the isolation amplifier

circuit be located as close as

possible to one another. Although

it is possible to buy currentsensing resistors from established

vendors (e.g., the LVR-1, -3 and

-5 resistors from Dale), it is also

possible to make a sense resistor

using a short piece of wire or

even a trace on a PC board.

Figures 30 and 31 illustrate the

response of the overall isolation

amplifier circuit shown in Figure

26. Figure 30 shows the response

of the circuit to a ± 200 mV 20

kHz sine wave input and Figure

31 the response of the circuit to a

± 200 mV 20 kHz square wave

input. Both figures demonstrate

the fast, well-behaved response of

the HCPL-7800.

Figure 32 shows how quickly the

isolation amplifier recovers from

an overdrive condition generated

by a 2 kHz square wave swinging

between 0 and 500 mV (note that

the time scale is different from

the previous figures). The first

wave form is the output of the

application circuit with the filter

capacitors removed to show the

actual response of the isolation

amplifier. The second wave form

is the response of the same circuit

with the capacitors installed. The

recovery time and overshoot are

relatively independent of the

amplitude and polarity of the

overdrive signal, as well as its

duration.

For more information, refer to

Application Note 1059.

VOLTAGE

REGULATOR

ISO-AMP

INPUT

Figure 28. HCPL-7800 Block Diagram.

Figure 29. PC Board Trace Pattern and Loading Diagram Example.

Σ∆

MODULATOR

CLOCK

GENERATOR

ENCODER

LED DRIVE

CIRCUIT

ISOLATION

BOUNDARY

DETECTOR

CIRCUIT

VOLTAGE

REGULATOR

DECODER

AND D/A

FILTER

ISO-AMP

OUTPUT

1-231

Page 17

Figure 30. Application Circuit Sine Wave Response.

Figure 31. Application Circuit Square Wave Response.

Figure 32. Application Circuit Overload Recovery Waveform.

1-232

Loading...

Loading...