Page 1

1-402

High Speed CMOS

Optocouplers

Technical Data

Features

• 1 µm CMOS IC Technology

• Compatibility with All +5 V

CMOS and TTL Logic

Families

• No External Components

Required for Logic Interface

• High Speed: 15 MBd

(HCPL-7100) and 50 MBd

(HCPL-7101) Guaranteed

• Low Power Consumption

• Safety Approvals

UL 1577 (3750 Vac/1 Min)

VDE 0884 (V

IORM

= 848

V peak)

CSA

• 3-State Output

• 3750 Vac/1 Minute Dielectric

Withstand

• High Common Mode

Transient Immunity

Applications

• Multiplexed Data

Transmission

• Computer-Peripheral

Interface

• Microprocessor System

Interface

• Digital Isolation for A/D,

D/A Conversion

• Instrument Input/Output

Isolation

• Motor Control

• Power Inverter

Description

The HCPL-7100/7101 optocoupler combines the latest CMOS IC

technology, a new high-speed

high-efficiency AlGaAs LED, and

an optimized light coupling system

to achieve outstanding performance with very low power

consumption. It requires only two

bypass capacitors for complete

CMOS/TTL compatibility.

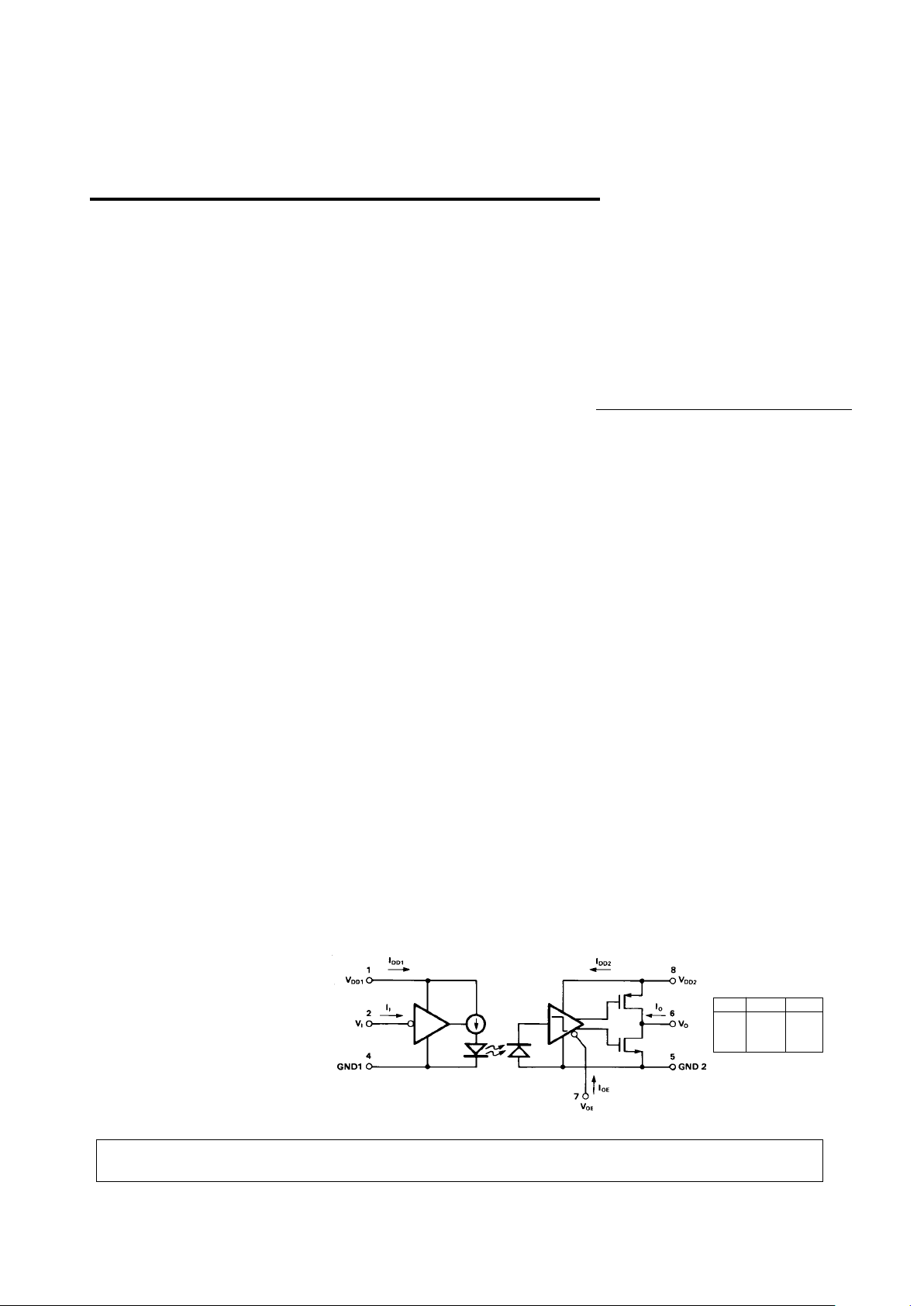

Basic building blocks of the

HCPL-7100/7101 are a CMOS

LED driver IC, an AlGaAs LED,

and a CMOS detector IC. A CMOS

or TTL logic input signal controls

the LED driver IC which supplies

current to the LED. The detector

IC incorporates an integrated

photodiode, a high-speed transimpedance amplifier and a voltage

comparator with hysteresis. The

3-state output is CMOS and TTL

compatible and is controlled by

the output enable pin, VOE.

The HCPL-7100/7101 consumes

very little power, due to the

CMOS IC technology and the light

coupling system. The entire

optocoupler typically uses only 10

mA of supply current, including

the LED current.

World-wide safety approval and

3750 Vac/1 minute dielectric withstand is achieved with our

patented “light-pipe” optocoupler

packaging technology.

The HCPL-7100/7101 provides he

user with an easy-to-use CMOS or

TTL compatible optocoupler

ideally suited for a variety of

applications where high speed

and low power consumption are

desired.

HCPL-7100

HCPL-7101

Schematic

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

H

TRUTH TABLE

(POSITIVE LOGIC)

INPUT ENABLE OUTPUT

HH Z

LH Z

HL H

LL L

5965-3578E

Page 2

1-403

Ordering Information

HCPL-710x

0 = 15 MBd Minimum Data Rate

1 = 50 MBd Minimum Data Rate

Option yyy

300 = Gull Wing Surface Mount Lead Option

500 = Tape/Reel Package Option (1 k min.)

Option data sheets available. Contact your Hewlett-Packard sales representative or authorized distributor for

information.

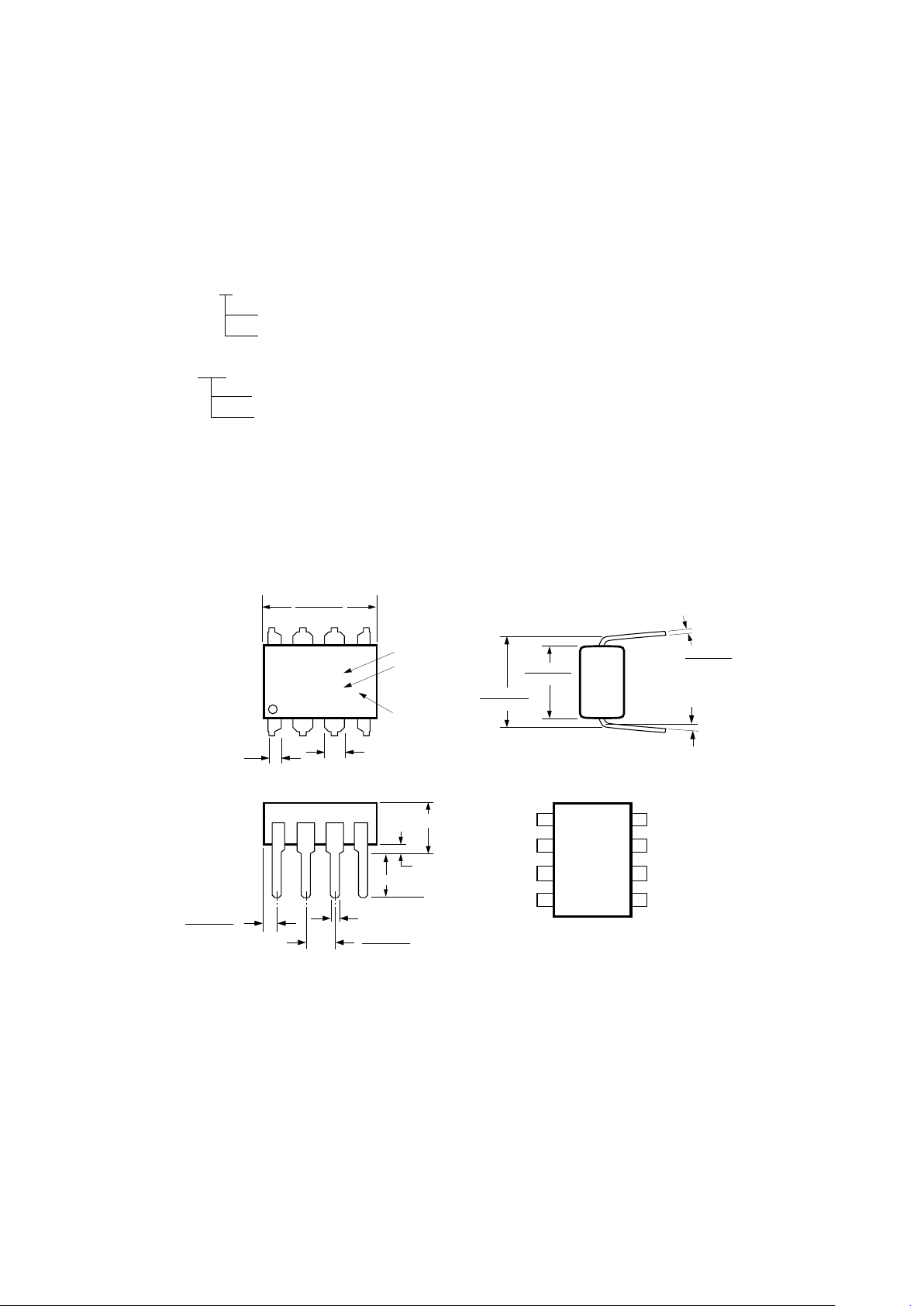

Package Outline Drawings

Standard DIP Package

9.40 (0.370)

9.90 (0.390)

1.78 (0.070) MAX.

1.19 (0.047) MAX.

HP XXXX

YYWW

DATE CODE

0.76 (0.030)

1.40 (0.055)

2.28 (0.090)

2.80 (0.110)

0.51 (0.020) MIN.

0.65 (0.025) MAX.

4.70 (0.185) MAX.

2.92 (0.115) MIN.

* PIN 3 IS THE ANODE OF THE INTERNAL LED AND

MUST BE LEFT UNCONNECTED FOR GUARANTEED

DATA SHEET PERFORMANCE.

DIMENSIONS IN MILLIMETERS AND (INCHES).

5678

4321

0.20 (0.008)

0.33 (0.013)

6.10 (0.240)

6.60 (0.260)

5° TYP.

7.36 (0.290)

7.88 (0.310)

1

2

3

4

8

7

6

5

GND1

V

DD1

V

I

*

GND2

V

DD2

V

OE

V

O

PIN ONE

TYPE NUMBER

UL

RECOGNITION

UR

* PIN 3 IS THE ANODE OF THE INTERNAL LED AND

MUST BE LEFT UNCONNECTED FOR GUARANTEED

DATA SHEET PERFORMANCE.

DIMENSIONS IN MILLIMETERS AND (INCHES).

Page 3

1-404

*Refer to Option 300 data sheet for more information.

0.635 ± 0.25

(0.025 ± 0.010)

12° NOM.

0.20 (0.008)

0.33 (0.013)

9.65 ± 0.25

(0.380 ± 0.010)

0.51 ± 0.130

(0.020 ± 0.005)

7.62 ± 0.25

(0.300 ± 0.010)

5

6

7

8

4

3

2

1

9.65 ± 0.25

(0.380 ± 0.010)

6.350 ± 0.25

(0.250 ± 0.010)

1.02 (0.040)

1.19 (0.047)

1.19 (0.047)

1.78 (0.070)

9.65 ± 0.25

(0.380 ± 0.010)

4.83

(0.190)

TYP.

0.380 (0.015)

0.635 (0.025)

PIN LOCATION (FOR REFERENCE ONLY)

1.080 ± 0.320

(0.043 ± 0.013)

4.19

(0.165)

MAX.

1.780

(0.070)

MAX.

1.19

(0.047)

MAX.

2.540

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

TOLERANCES (UNLESS OTHERWISE SPECIFIED):

xx.xx = 0.01

xx.xxx = 0.005

HP XXXX

YYWW

DATE CODE

TYPE NUMBER

UL

RECOGNITION

UR

MOLDED

LEAD COPLANARITY

MAXIMUM: 0.102 (0.004)

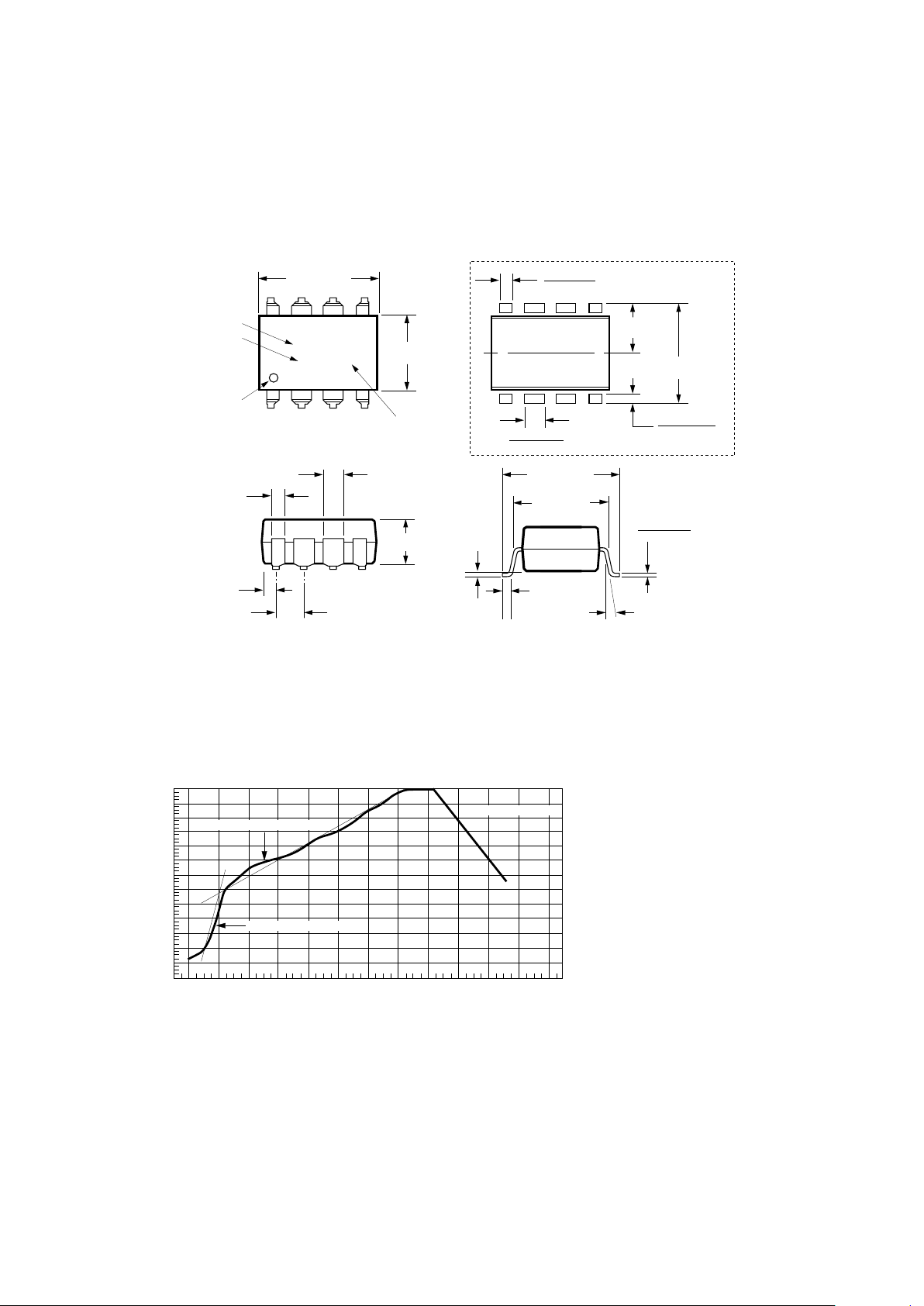

Gull Wing Surface Mount Option 300*

Maximum Solder Reflow Thermal Profile

240

∆T = 115°C, 0.3°C/SEC

0

∆T = 100°C, 1.5°C/SEC

∆T = 145°C, 1°C/SEC

TIME – MINUTES

TEMPERATURE – °C

220

200

180

160

140

120

100

80

60

40

20

0

260

123456789101112

(NOTE: USE OF NON-CHLORINE ACTIVATED FLUXES IS RECOMMENDED.)

Page 4

1-405

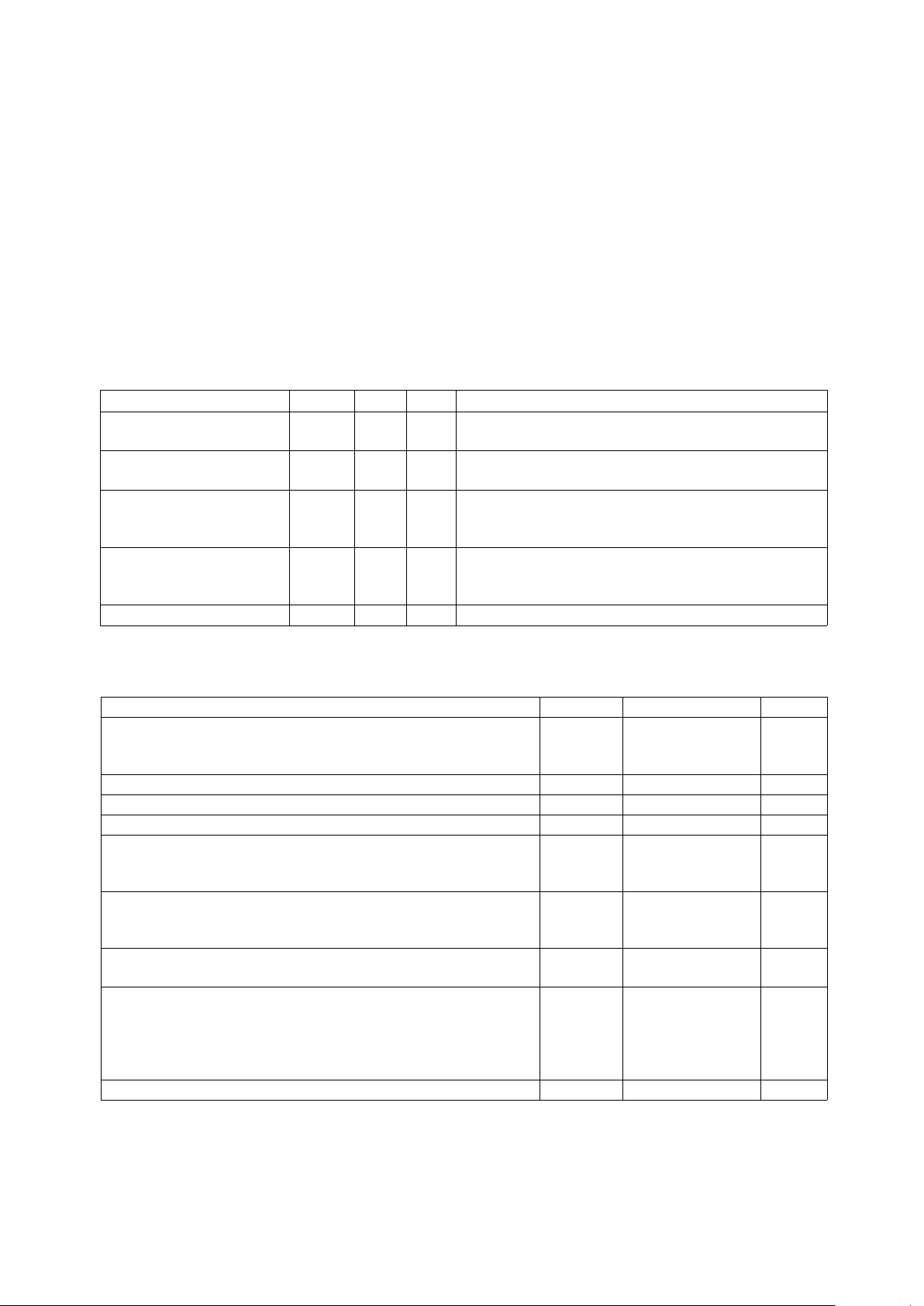

VDE 0884 (06.92) Insulation Characteristics

Description Symbol Characteristic Unit

Installation classification per DIN VDE 0110, Table 1

for rated mains voltage ≤ 300 V rms I-IV

for rated mains voltage ≤ 600 V rms I-III

Climatic Classification 40/85/21

Pollution Degree (DIN VDE 0110, Table 1)* 2

Maximum Working Insulation Voltage V

IORM

848 V peak

Input to Output Test Voltage, Method b**

VPR = 1.875 x V

IORM

, Production test with tp = 1 sec, V

PR

1591 V peak

Partial discharge < 5 pC

Input to Output Test Voltage, Method a**

VPR = 1.5 x V

IORM

, Type and sample test, tp = 60 sec, V

PR

1273 V peak

Partial discharge < 5 pC

Highest Allowable Overvoltage** V

TR

6000 V peak

(Transient Overvoltage, tTR = 10 sec)

Safety-limiting values (Maximum values allowed in the event

of a failure, also see Figure 15)

Case Temperature T

S

175 °C

Input Power P

S,INPUT

80 mW

Output Power P

S,OUTPUT

250 mW

Insulation Resistance at TS, VIO = 500 V R

S

≥ 1 x 10

12

Ω

*This part may also be used in Pollution Degree 3 environments where the rated mains voltage is ≤ 300 V rms (per DIN VDE 0110).

**Refer to the front of the optocoupler section in the current catalog for a more detailed description of VDE 0884 and other product

safety requirements.

Insulation and Safety Related Specifications

Parameter Symbol Value Units Conditions

Min. External Air Gap L(IO1) 7.4 mm Measured from input terminals to output terminals,

(External Clearance) shortest distance through air

Min. External Tracking L(IO2) 8.0 mm Measured from input terminals to output terminals,

Path (External Creepage) shortest distance path along body

Min. Internal Plastic 0.5 mm Through insulation distance, conductor to conductor,

Gap (Internal Clearance) usually the direct distance between the photoemitter

and photodetector inside the optocoupler cavity

Tracking Resistance CTI 175 V DIN IEC 112/VDE 0303 PART 1

(Comparative

Tracking Index)

Isolation Group IIIa Material Group (DIN VDE 0110, 1/89, Table 1)

Option 300 – surface mount classification is Class A in accordance with CECC 00802.

Note: Optocouplers providing safe electrical separation per VDE 0884 do so only within the safety-limiting values to which they are

qualified. Protective cut-out switches must be used to ensure that the safety limits are not exceeded.

VDE

Approved according to VDE

0884/06.92

Regulatory Information

The HCPL-7100/1 has been

approved by the following

organizations:

UL

Recognized under UL 1577,

Component Recognition Program,

File E55361.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

Page 5

1-406

Parameter Symbol Min. Max. Unit

Storage Temperature T

S

-55 125 °C

Ambient Operating Temperature T

A

-40 85 °C

Supply Voltages V

DD1,2

0.0 5.5 V

Input Voltage V

I

-0.5 V

DD1

+ 0.5 V

Output Voltage V

O

-0.5 V

DD2

+ 0.5 V

Output Enable Voltage V

OE

-0.5 V

DD2

+ 0.5 V

Average Output Current I

O

25 mA

Package Power Dissipation P

PD

220 mW

Lead Solder Temperature T

LS

260 °C

(1.6 mm Below Seating Plane, 10 sec.)

Reflow Temperature Profile See Package Outline Drawings Section

Parameter Symbol Min. Max. Unit Test Conditions

Operating Temperature T

A

-40 85 °C

Supply Voltages V

DD1,2

4.5 5.5 V

Logic High Input Voltage V

IH

2.0 V

DD1

V

Logic Low Input Voltage V

IL

0.0 0.8 V

Logic High Output V

OEH

2.0 V

DD2

V Output in high impedance

Enable Voltage state

Logic Low Output V

OEL

0.0 0.8 V Output enabled

Enable Voltage

Input Signal Rise and tr, t

f

1ms

Fall Times

TTL Fanout N 6 Standard Loads

Absolute Maximum Ratings

Recommended Operating Conditions

Page 6

1-407

Electrical Specifications

Guaranteed across recommended operating conditions. Test conditions represent worst case values for the

parameter under test. Test conditions that are not specified can be anywhere within their operating range.

All typicals are at 25°C and 5 V supplies unless otherwise noted.

Parameter Symbol Min. Typ. Max. Unit Test Conditions Fig. Note

Logic Low Input Supply I

DD1L

5.2 10.0 mA V

DD1

= 5.5 V 1

Current V

I

= V

IL

Logic High Input Supply I

DD1H

0.3 0.6 mA VI = 4.5 V V

DD1

= 5.5 V 1

0.9 1.6 VI = 2.0 V

Logic Low Output I

DD2L

5.0 9.0 mA V

DD2

= 5.5 V

Supply Current V

OE

= V

OEL

VI = V

IL

Logic High Output I

DD2H

5.2 9.0 mA V

DD2

= 5.5 V

Supply Current V

OE

= V

OEL

IO = 0 mA

V

I

= V

IH

Tri-State Output Supply I

DD2Z

5.1 9.0 mA VOE = 4.5 V V

DD2

= 5.5 V

5.6 10.0 VOE = 2.0 V

Input Current I

I

-1 1 µAVI = V

DD1

or GND

V

DD1

= 5.5 V

Output Enable Current I

OE

-1 1 µAVOE = V

DD2

or GND

V

DD2

= 5.5 V

Logic High Output V

OH

4.4 5.0 IO = -20 µAV

DD2

= 4.5 V 6

Voltage V

I

= V

IH

VOE = V

OEL

Logic High Output I

OH

-7.5 -25 mA V

DD2

= 4.5 V 6

Current V

O

= 3.6 V

V

I

= V

IH

VOE = V

OEL

Logic Low Output V

OL

0.0 0.1 IO = 20 µAV

DD2

= 4.5 V 5

Voltage V

I

= V

IL

VOE = V

OEL

Logic Low Output I

OL

10.5 23 mA V

DD2

= 4.5 V 5

Current V

O

= 0.6 V

V

I

= V

IL

VOE = V

OEL

High Impedance I

OZ

-5 5 µAV

DD2

= 5.5 V

State Output V

OE

= V

OEH

Current VO = V

DD2

or GND

Input Capacitance C

I

4.3 pF f = 1 MHz 4

Input-Output R

I-O

10

12

10

13

Ω TA = 25°CV

I-O

= 500 V

dc

2

10

11

TA = 100°C

Input-Output C

I-O

0.7 pF f = 1 MHz 2

Capacitance

*The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to the VDE 0884 Insulation Characteristics Table (if applicable),

your equipment level safety specification, or HP Application Note 1074, “Optocoupler Input-Output Endurance Voltage.”

Current

3.7 4.7 IO = -6.0 mA

0.15 0.4 I

O

= 6.0 mA

Resistance

Current

4.0 4.8 V IO = -4.0 mA

0.1 0.3 V IO = 4.0 mA

Page 7

1-408

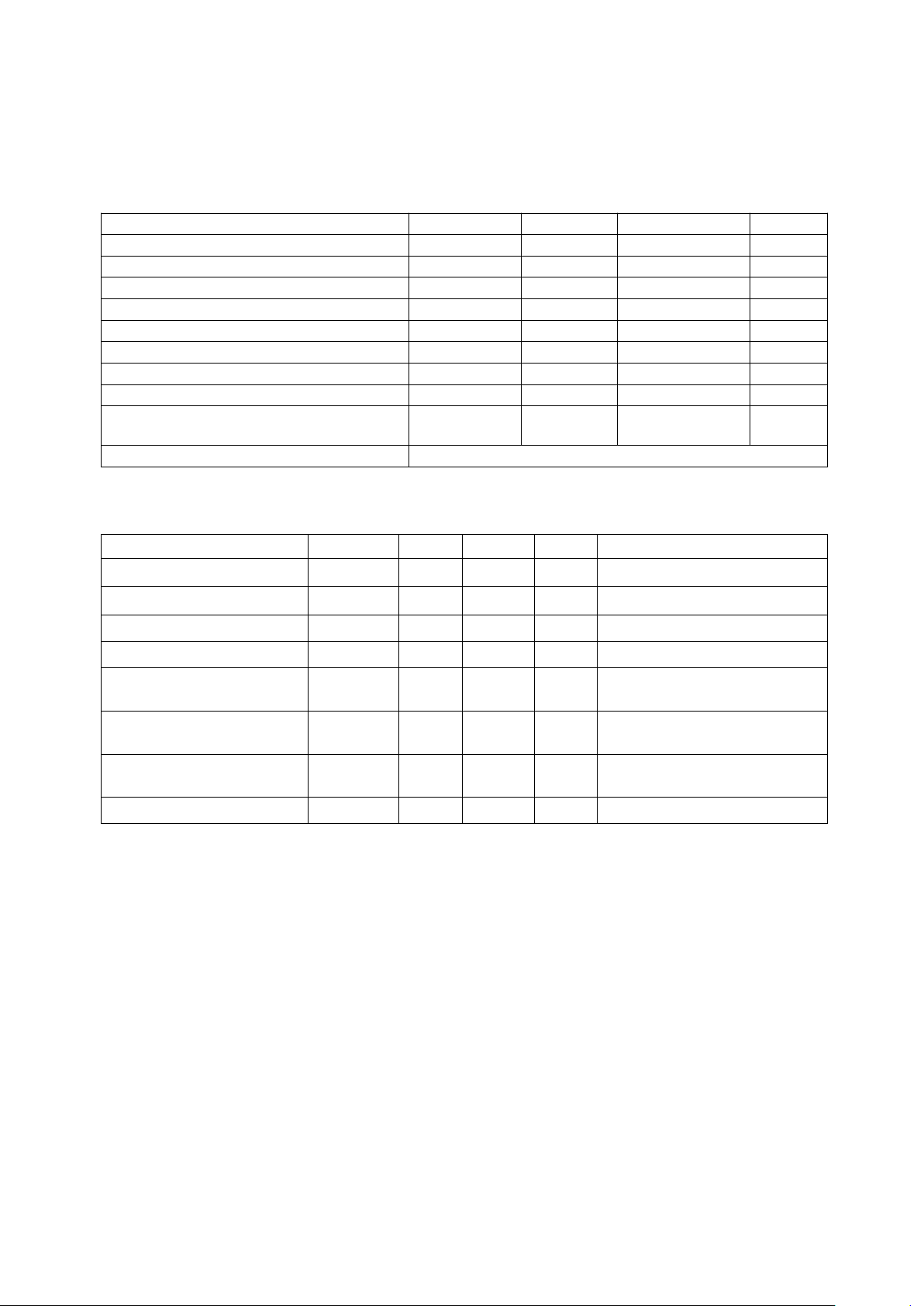

Parameter Symbol Device Min. Typ. Max. Unit Test Conditions Fig. Note

Propagation t

PHL

HCPL-7100 70 ns CL = 50 pF 7, 8 5, 6

Delay Time CMOS Signal Levels

to Logic HCPL-7101 28 40

Low Output

HCPL-7100 70 ns C

L

= 15 pF

TTL Signal Levels

HCPL-7101 40

Propagation t

PLH

HCPL-7100 70 ns CL = 50 pF 7, 8 5, 6

Delay Time CMOS Signal Levels

to Logic HCPL-7101 27 40

High Output

HCPL-7100 70 ns C

L

= 15 pF

TTL Signal Levels

HCPL-7101 40

Pulse Width PWD HCPL-7100 20 ns C

L

= 50 pF 7, 9 6, 7

Distortion CMOS Signal Levels

|t

PHL-tPLH

| HCPL-7101 2 6

HCPL-7100 20 ns C

L

= 15 pF

TTL Signal Levels

HCPL-7101 6

Data Rate HCPL-7100 15 MBd % PWD < 30% 8

HCPL-7101 50 65

Propagation t

PSK

HCPL-7101 10 ns 10 9

Delay Skew

Output Rise t

R

HCPL-7100 12 ns CL = 50 pF 7

Time CMOS Signal Levels

(10-90%) HCPL-7101 10

Output Fall t

F

HCPL-7100 8 ns CL = 50 pF 7

Time CMOS Signal Levels

(90-10%) HCPL-7101 7

Random Jitter RJ HCPL-7101 50 ps rms V

1

= 0-5 V square wave,

f = 25 MHz, input rise/

fall time = 5 ns.

R

L

= 10 kΩ,

C

L

= 5 pF.

TTL Threshold Levels.

Propagation t

PZH

13 ns CL = 50 pF 12 6

Delay Time From CMOS Signal Levels

Output Enabled

to Logic High 12 ns C

L

= 15 pF

Output TTL Signal Levels

Propagation t

PZL

11 ns CL = 50 pF 12 6

Delay Time From CMOS Signal Levels

Output Enabled

to Logic Low 10 ns C

L

= 15 pF

Output TTL Signal Levels

Switching Specifications

Guaranteed across recommended operating conditions. Test conditions represent worst case values for the

parameter under test. Test conditions that are not specified can be anywhere within their operating range. All

typicals are at 25°C and 5 V supplies unless otherwise noted.

Page 8

1-409

Package Characteristics

Guaranteed across recommended operating conditions. Test conditions represent worst case value for the

parameter under test. Test conditions that are not specified can be anywhere within their operating range.

All typicals are at TA = 25°C and 5 V supplies unless otherwise noted.

Parameter Sym. Min. Typ. Max. Units Test Conditions Fig. Note

Input-Output V

ISO

3750 V rms t = 1 min., RH < 50%, 2, 3

Momentary TA = 25°C

Withstand Voltage*

Input-Output R

I-O

10

12

10

13

Ω TA = 25°CV

I-O

= 500 Vdc 2

Resistance 10

11

TA =100° C

Input-Output C

I-O

0.7 pF f = 1 MHz 2

Capacitance

*The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to the VDE 0884 Insulation Characteristics Table (if applicable),

your equipment level safety specification or HP Application Note 1074 entitled “Optocoupler Input-Output Endurance Voltage.”

Switching Specifications (cont.)

Guaranteed across recommended operating conditions. Test conditions represent worst case values for the

parameter under test. Test conditions that are not specified can be anywhere within their operating range. All

typicals are at 25°C and 5 V supplies unless otherwise noted.

Parameter Symbol Device Min. Typ. Max. Unit Test Conditions Fig. Note

Propagation t

PHZ

12 ns CL = 50 pF 12 6

Delay Time from CMOS Signal Levels

Logic High to

Output Disabled 12 ns C

L

= 15 pF

TTL Signal Levels

Propagation t

PLZ

9nsC

L

= 50 pF 12 6

Delay Time from CMOS Signal Levels

Logic Low to

Output Disabled 11 ns C

L

= 15 pF

TTL Signal Levels

Common Mode |CMH| HCPL-7100 1000 V/µsVCM = 50 V VI = V

IH

13, 10

V

D

> 3.2 V 14

HCPL-7101 2000 V

CM

= 200 V

Common Mode |CM

L

| HCPL-7100 1000 V/µsVCM = 50 V VI = V

IL

13, 10

VD < 0.8 V 14

HCPL-7101 2000 V

CM

= 200 V

Input Dynamic C

PD1

68 pF 11

Power Dissipation

Capacitance

Output Dynamic C

PD2

10 pF 11

Power Dissipation

Capacitance

Transient

Immunity at

Logic High

Output

Transient

Immunity at

Logic Low

Output

Page 9

1-410

Notes:

1. The LED is OFF when the VI is high and ON when VI is low.

2. Device considered a two terminal device; pins 1-4 shorted together and pins 5-8 shorted together.

3. In accordance with UL 1577, for devices with minimum V

ISO

specified at 3750 V rms, each optocoupler is proof-tested by applying an

insulation test voltage greater than 4500 V rms for one second (leakage current detection limit I

I-O

< 5 µA). This test is performed

before the method b, 100% production test for partial discharge shown in the VDE 0884 Insulation Characteristics Table.

4. CI is the capacitance measured at pin 2 (VI).

5. t

PHL

propagation delay is measured from the 50% level on the falling edge of the VI signal to the logic switching level of the VO signal.

t

PLH

propagation delay is measured from the 50% level on the rising edge of the VI signal to the logic switching level of the VO signal.

6. The logic switching levels are 1.5 V for TTL signals (0-3 V) and 2.5 V for CMOS signals (0-5 V).

7. PWD is defined as |t

PHL

- t

PLH

|. %PWD (percent pulse width distortion) is equal to PWD in ns divided by symbol duration (bit length)

in ns.

8. Minimum data rate is calculated as follows: %PWD/PWD where %PWD is typically chosen by the design engineer (30% is common).

9. t

PSK

is equal to the worst case difference in t

PHL

and/or t

PLH

that will be seen between units at the same temperature, supply voltage,

and output load within the recommended operating condition range.

10. CMH is the maximum common mode voltage slew rate that can be sustained while maintaining VO > 3.2 V. CML is the maximum

common mode voltage slew rate that can be sustained while maintaining VO < 0.8 V. The common mode voltage slew rates apply to

both rising and falling common mode voltage edges.

11. Unloaded dynamic power dissipation is calculated as follows: CPD • V

DD

2 •

f + IDD • VDD where f is switching frequency in MHz.

Figure 1. Recommended Application Circuit.

Figure 2. Recommended Printed Circuit Board Layout.

Page 10

1-411

Figure 5. Typical Logic Low Output Voltage vs. Logic Low

Output Current.

Figure 6. Typical Logic High Output Voltage vs. Logic High

Output Current.

V

DD2

= 5.0 V

V

DD2

= 5.0 V

Figure 4. Typical Input Voltage Switching Threshold vs.

Input Supply Voltage.

Figure 3. Typical Output Voltage vs. Input Voltage.

V

O

(V)

0

0

VI (V)

5.00

4.00

5.50

1.00

4.001.00 2.00 3.00

2.50

5.00

4.50

3.50

3.00

2.00

1.50

0.50

V

DD1

= 5.0 V

85 °C

-40 °C

25 °C

Page 11

1-412

Figure 8. HCPL-7101 Typical Propagation Delay vs.

Temperature.

Figure 9. HCPL-7101 Typical Pulse Width Distortion vs.

Temperature.

Figure 7. Test Circuit for Propagation Delay, Rise Time and Fall Time.

V

DD1

= 5.0 V

V

DD2

= 5.0 V

V

DD1

= 5.0 V

V

DD2

= 5.0 V

Page 12

1-413

Figure 11. Parallel Data Transmission Example.Figure 10. Propagation Delay Skew Waveform.

Figure 12. Test Circuit for 3-State Output Enable and Disable Propagation Delays.

Page 13

1-414

Figure 15. Dependence of Safety-Limiting Data on

Ambient Temperature.

Figure 13. Test Circuit for Common Mode Transient

Immunity and Typical Waveforms.

Figure 14. Typical Common Mode

Transient Immunity vs. Common Mode

Transient Voltage.

V

DD1

= 5.0 V

V

DD2

= 5.0 V

T

A

= 25 °C

OUTPUT, V

O

V

OL

P

S

– POWER – mW

0

0

TA – TEMPERATURE – °C

180

400

12040 80 160

100

200

300

OUTPUT POWER, P

S

INPUT POWER, P

S

20 60 100 140

175

Page 14

1-415

HCPL-7100/7101

Application Information

The HCPL-7100/7101 is

extremely easy to use. Because

the optocoupler uses high-speed

CMOS IC technology, the inputs

and output are fully compatible

with all +5 V TTL and CMOS

logic. TTL or CMOS logic can be

connected directly to the inputs

and output; no external interface

circuitry is required.

As shown in Figure 1, the only

external components required for

proper operation are two ceramic

bypass capacitors. Capacitor

values should be between 0.01 µF

and 0.1 µF. For each capacitor,

the total lead length between both

ends of the capacitor and the

power-supply pins should not

exceed 20 mm. Figure 2

illustrates the recommended

printed circuit board layout for

the HCPL-7100/7101.

Propagation Delay, PulseWidth Distortion, and

Propagation Delay Skew

Propagation delay is a figure of

merit which describes how

quickly a logic signal propagates

through a system. The propagation delay from low to high (t

PLH

)

is the amount of time required for

an input signal to propagate to

the output, causing the output to

change from low to high.

Similarly, the propagation delay

from high to low (t

PHL

) is the

amount of time required for the

input signal to propagate to the

output, causing the output to

change from high to low (see

Figure 7).

Pulse-width distortion (PWD)

results when t

PLH

and t

PHL

differ in

value. PWD is defined as the

difference between t

PLH

and t

PHL

and often determines the maximum data rate capability of a

transmission system. PWD can be

expressed in percent by dividing

the PWD (in ns) by the minimum

pulse width (in ns) being

transmitted. Typically, PWD on

the order of 20-30% of the

minimum pulse width is tolerable;

the exact figure depends on the

particular application (RS232,

RS422, T-1, etc.).

Propagation delay skew, t

PSK

, is

an important parameter to consider in parallel data applications

where synchronization of signals

on parallel data lines is a concern.

If the parallel data is being sent

through a group of optocouplers,

differences in propagation delays

will cause the data to arrive at the

outputs of the optocouplers at

different times. If this difference

in propagation delays is large

enough, it will determine the

maximum rate at which parallel

data can be sent through the

optocouplers.

Propagation delay skew is defined

as the difference between the

minimum and maximum propagation delays, either t

PLH

or t

PHL

, for

any given group of optocouplers

which are operating under the

same conditions (i.e., the same

supply voltage, output load, and

operating temperature). As illustrated in Figure 10, if the inputs

of a group of optocouplers are

switched either ON or OFF at the

same time, t

PSK

is the difference

between the shortest propagation

delay, either t

PLH

or t

PHL

, and the

longest propagation delay, either

t

PLH

or t

PHL

.

As mentioned earlier, t

PSK

can

determine the maximum parallel

data transmission rate. Figure 11

is the timing diagram of a typical

parallel data application with both

the clock and the data lines being

sent through optocouplers. The

figure shows data and clock

signals at the inputs and outputs

of the optocouplers. To obtain the

maximum data transmission rate,

both edges of the clock signal are

being used to clock the data; if

only one edge were used, the

clock signal would need to be

twice as fast.

Propagation delay skew represents the uncertainty of where an

edge might be after being sent

through an optocoupler. Figure

11 shows that there will be

uncertainty in both the data and

the clock lines. It is important

that these two areas of uncertainty

not overlap, otherwise the clock

signal might arrive before all of

the data outputs have settled, or

some of the data outputs may

start to change before the clock

signal has arrived. From these

considerations, the absolute

minimum pulse width that can be

sent through optocouplers in a

parallel application is twice t

PSK

. A

cautious design should use a

slightly longer pulse width to

ensure that any additional

uncertainty in the rest of the

circuit does not cause a problem.

The HCPL-7101 optocoupler offers

the advantages of guaranteed

specifications for propagation

delays, pulse-width distortion and

propagation delay skew over the

recommended temperature, and

power supply ranges.

Loading...

Loading...