Page 1

1-288

H

8 MBd Low Input Current

Optocoupler

Technical Data

HCPL-2300

Features

• Guaranteed Low Thresholds:

IF = 0.5 mA, V

F

≤1.5 V

• High Speed: Guaranteed

5 MBd over Temperature

• Versatile: Compatible with

TTL, LSTTL and CMOS

• Efficient 820 nm AlGaAs

LED

• Internal Shield for

Guaranteed Common Mode

Rejection

• Schottky Clamped, Open

Collector Output with

Optional Integrated Pull-Up

Resistor

• Static and Dynamic

Performance Guaranteed

from -40°C to 85°C

• Safety Approval

UL Recognized -2500 V rms for

1 minute

CSA Approved

VDE 0884 Approved with

V

IORM

= 630 V peak

(Option 060)

Applications

• Ground Loop Elimination

• Computer-Peripheral

Interfaces

• Level Shifting

• Microprocessor System

Interfaces

• Digital Isolation for A/D,

D/A Conversion

• RS-232-C Interface

• High Speed, Long Distance

Isolated Line Receiver

Description

The HCPL-2300 optocoupler

combines an 820 nm AlGaAs

photon emitting diode with an

integrated high gain photon

detector. This combination of

Hewlett-Packard designed and

manufactured semiconductor

devices brings new high

performance capabilities to

designers of isolated logic and

data communication circuits.

The new low current, high speed

AlGaAs emitter manufactured

with a unique diffused junction,

has the virtue of fast rise and fall

times at low drive currents.

Figure 6 illustrates the propagation delay vs. input current

characteristic. These unique

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

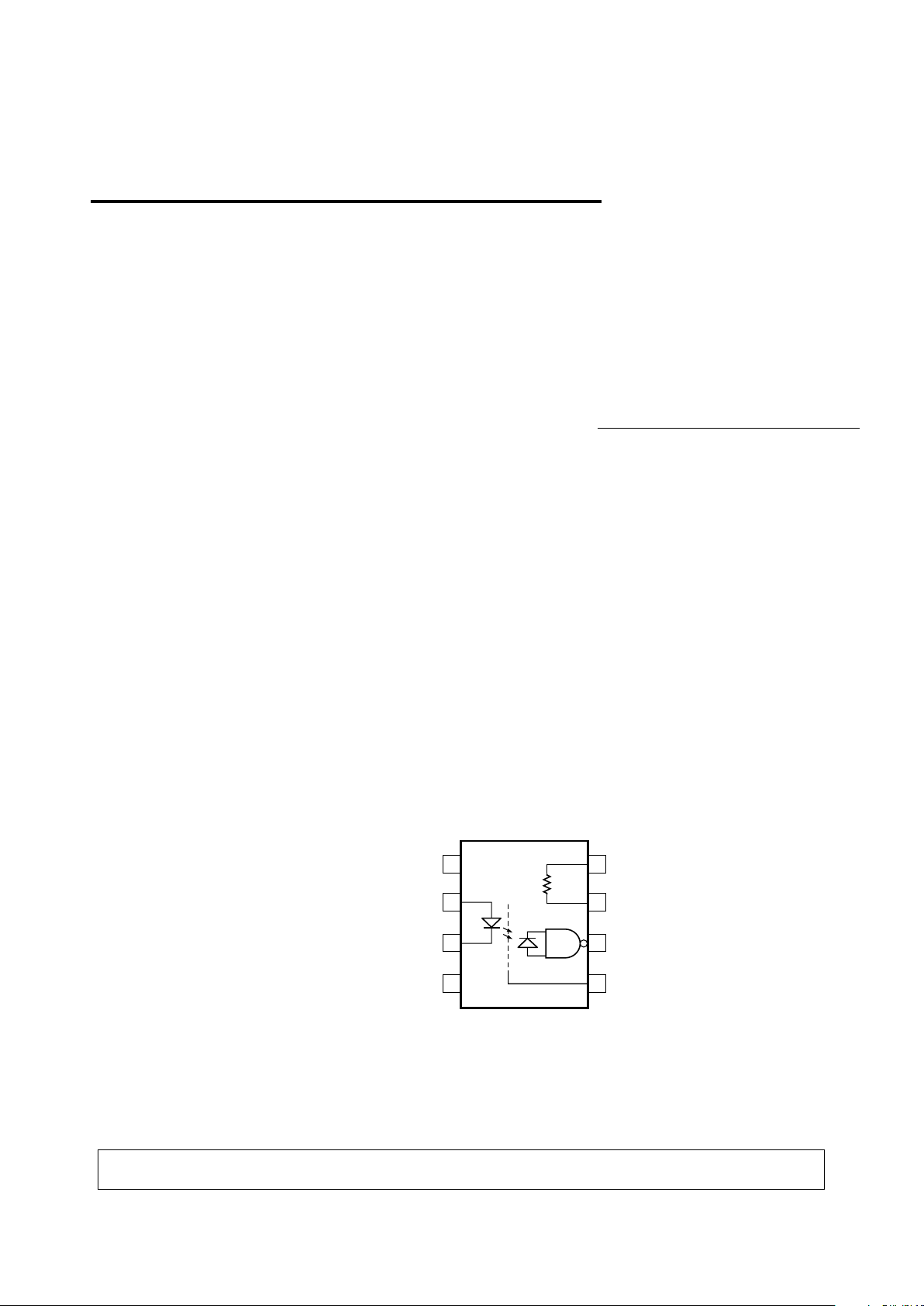

Functional Diagram

A 0.1 pF bypass capacitor must be connected between pins 5 and 8.

8

7

6

1

3

5

2

4

NC

ANODE

CATHODE

NC

V

CC

R

L

V

OUT

GND

5965-3587E

Page 2

1-289

Ordering Information

Specify part number followed by Option Number (if desired).

HCPL-2300# XXX

060 = VDE 0884 V

IORM

= 630 V peak Option

300 = Gull Wing Surface Mount Lead Option

500 = Tape/Reel Package Option (1 K min)

Option data sheets available. Contact your Hewlett-Packard sales representative or authorized distributor for

information.

characteristics enable this device

to be used in an RS-232-C interface with ground loop isolation

and improved common mode

rejection. As a line receiver, the

HCPL-2300 will operate over

longer line lengths for a given

data rate because of lower IF and

VF specifications.

The output of the shielded integrated detector circuit is an open

collector Schottky clamped transistor. The shield, which shunts

capacitively coupled common

mode noise to ground, provides a

guaranteed transient immunity

specification of 100 V/µs. The

output circuit includes an

optional integrated 1000 Ω pullup resistor for the open collector.

This gives designers the flexibility

to use the internal resistor for

pull-up to five volt logic or to use

an external resistor for connection to supply voltages up to 18 V

(CMOS logic voltage).

The Electrical and Switching

Characteristics of the HCPL-2300

are guaranteed over a temperature range of -40°C to 85°C. This

enables the user to confidently

design a circuit which will

operate under a broad range of

operating conditions.

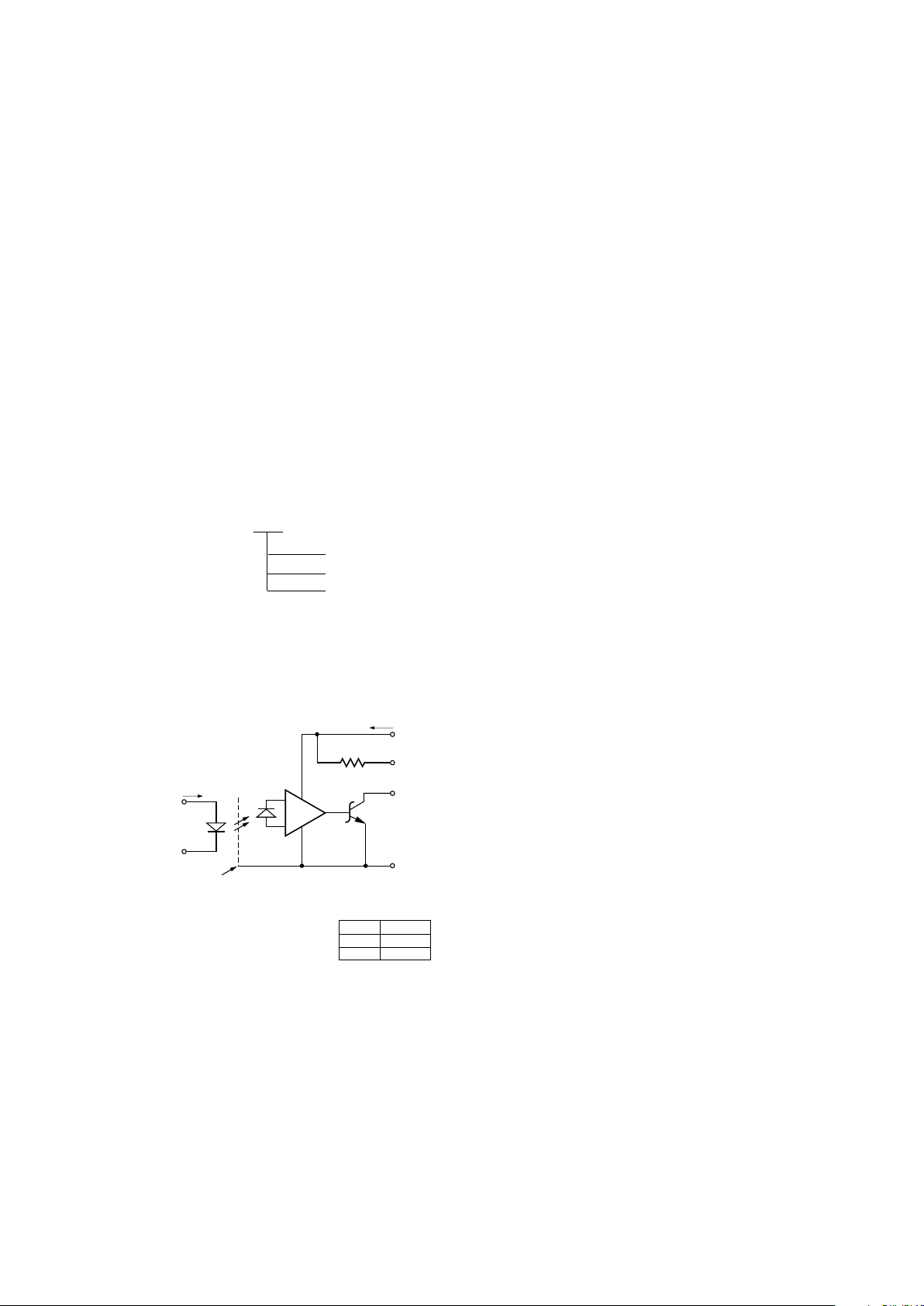

Schematic

I

F

SHIELD

V

F

V

CC

GND

I

CC

+

–

2

3

8

5

V

O

7

6

A 0.1 µF CAPACITOR MUST

BE CONNECTED BETWEEN

PINS 8 AND 5 (SEE NOTE 1).

TRUTH TABLE

(POSITIVE LOGIC)

LED

ON

OFF

OUTPUT

L

H

R

L

1000 Ω

Page 3

1-290

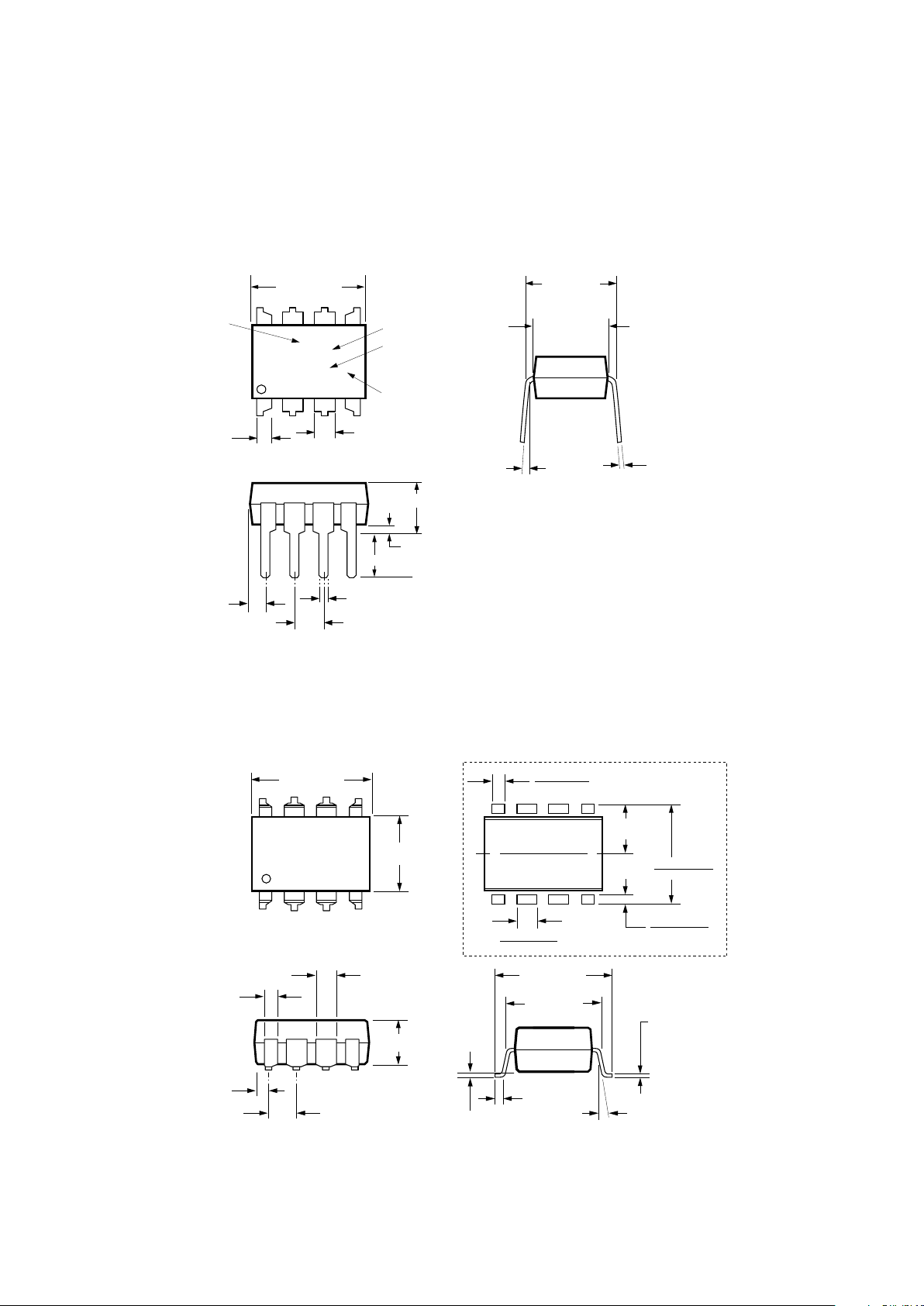

Package Outline Drawings

8-Pin DIP Package (HCPL-2300)

8-Pin DIP Package with Gull Wing Surface Mount Option 300 (HCPL-2300)

0.635 ± 0.25

(0.025 ± 0.010)

12° NOM.

9.65 ± 0.25

(0.380 ± 0.010)

0.635 ± 0.130

(0.025 ± 0.005)

7.62 ± 0.25

(0.300 ± 0.010)

5

6

7

8

4

3

2

1

9.65 ± 0.25

(0.380 ± 0.010)

6.350 ± 0.25

(0.250 ± 0.010)

1.016 (0.040)

1.194 (0.047)

1.194 (0.047)

1.778 (0.070)

9.398 (0.370)

9.906 (0.390)

4.826

(0.190)

TYP.

0.381 (0.015)

0.635 (0.025)

PAD LOCATION (FOR REFERENCE ONLY)

1.080 ± 0.320

(0.043 ± 0.013)

4.19

(0.165)

MAX.

1.780

(0.070)

MAX.

1.19

(0.047)

MAX.

2.54

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

LEAD COPLANARITY = 0.10 mm (0.004 INCHES).

0.254

+ 0.076

- 0.051

(0.010

+ 0.003)

- 0.002)

9.65 ± 0.25

(0.380 ± 0.010)

1.78 (0.070) MAX.

1.19 (0.047) MAX.

HP XXXXZ

YYWW

DATE CODE

1.080 ± 0.320

(0.043 ± 0.013)

2.54 ± 0.25

(0.100 ± 0.010)

0.51 (0.020) MIN.

0.65 (0.025) MAX.

4.70 (0.185) MAX.

2.92 (0.115) MIN.

DIMENSIONS IN MILLIMETERS AND (INCHES).

5678

4321

5° TYP.

OPTION CODE*

UL

RECOGNITION

UR

0.254

+ 0.076

- 0.051

(0.010

+ 0.003)

- 0.002)

7.62 ± 0.25

(0.300 ± 0.010)

6.35 ± 0.25

(0.250 ± 0.010)

TYPE NUMBER

* MARKING CODE LETTER FOR OPTION NUMBERS.

"V" = OPTION 060

OPTION NUMBERS 300 AND 500 NOT MARKED.

Page 4

1-291

Insulation and Safety Related Specifications

Parameter Symbol Value Units Conditions

Min. External Air Gap L(IO1) 7.1 mm Measured from input terminals to output

(External Clearance) terminals, shortest distance through air

Min. External Tracking Path L(IO2) 7.4 mm Measured from input terminals to output

(External Creepage) terminals, shortest distance path along body

Min. Internal Plastic Gap 0.08 mm Through insulation distance, conductor to

(Internal Clearance) conductor, usually the direct distance

between the photoemitter and photodetector

inside the optocoupler cavity

Tracking Resistance CTI 200 Volts DIN IEC 112/VDE 0303 PART 1

(Comparative Tracking Index)

Isolation Group IIIa Material Group (DIN VDE 0110, 1/89, Table 1)

Option 300 – surface mount classification is Class A in accordance with CECC 00802.

Regulatory Information

The HCPL-2300 has been

approved by the following

organizations:

UL

Recognized under UL 1577,

Component Recognition

Program, File E55361.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

VDE

Approved according to VDE

0884/06.92 (Option 060 only)

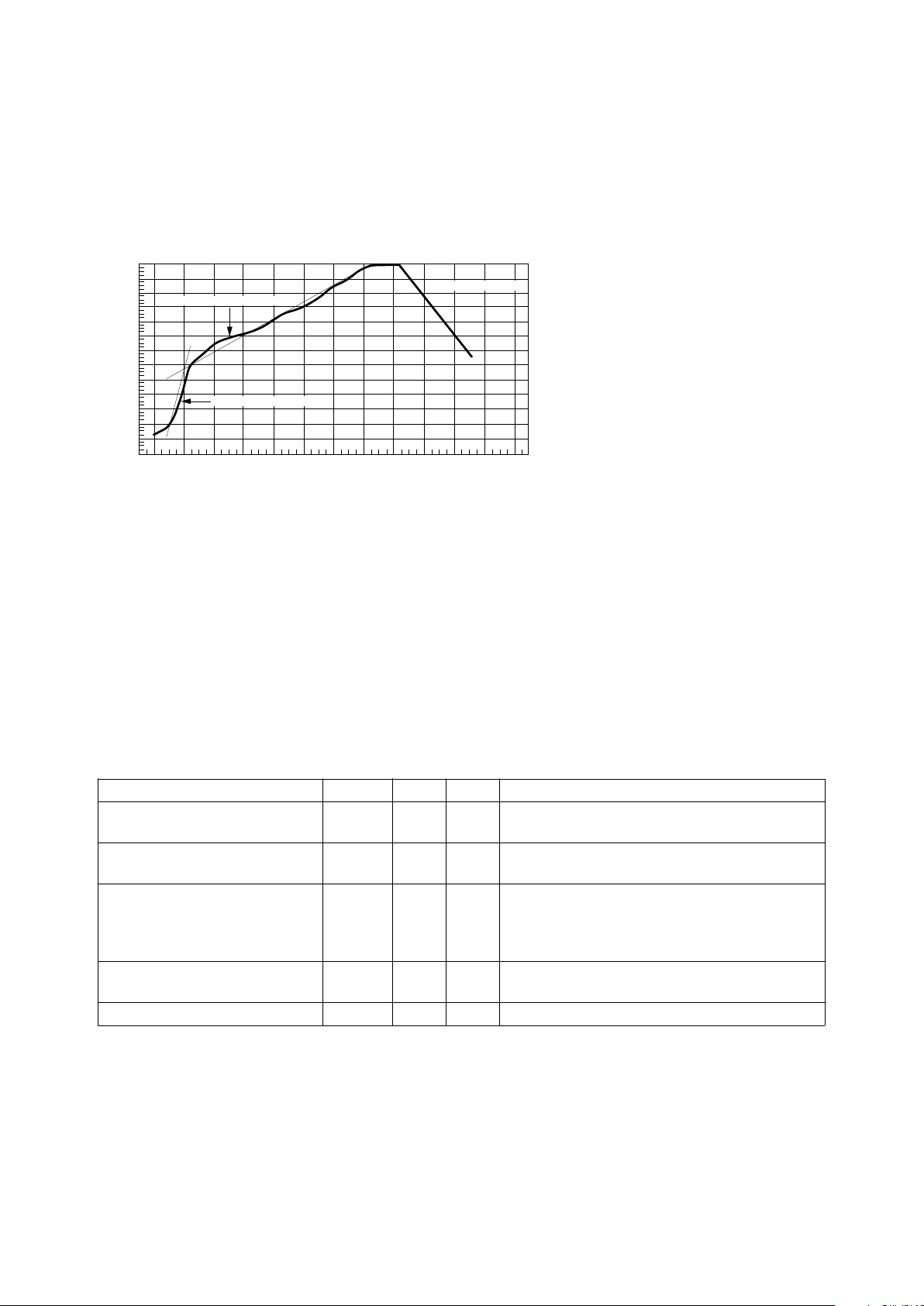

Figure 1. Maximum Solder Reflow Thermal Profile.

(Note: Use of non-chlorine activated fluxes is recommended.)

240

∆T = 115°C, 0.3°C/SEC

0

∆T = 100°C, 1.5°C/SEC

∆T = 145°C, 1°C/SEC

TIME – MINUTES

TEMPERATURE – °C

220

200

180

160

140

120

100

80

60

40

20

0

260

123456789101112

Thermal Profile (Option #300)

Page 5

1-292

VDE 0884 Insulation Related Characteristics (HCPL-2300 Option 060 ONLY)

Description Symbol Characteristic Units

Installation classification per DIN VDE 0110/1.89, Table 1

for rated mains voltage ≤ 300 V rms I-IV

for rated mains voltage ≤ 450 V rms I-III

Climatic Classification 55/85/21

Pollution Degree (DIN VDE 0110/1.89) 2

Maximum Working Insulation Voltage V

IORM

630 V peak

Input to Output Test Voltage, Method b*

V

IORM

x 1.875 = VPR, 100% Production Test with tm = 1 sec, V

PR

1181 V peak

Partial Discharge < 5 pC

Input to Output Test Voltage, Method a*

V

IORM

x 1.5 = VPR, Type and sample test, tm = 60 sec, V

PR

945 V peak

Partial Discharge < 5 pC

Highest Allowable Overvoltage*

(Transient Overvoltage, t

ini

= 10 sec) V

IOTM

6000 V peak

Safety Limiting Values

(Maximum values allowed in the event of a failure,

also see Figure 11, Thermal Derating curve.)

Case Temperature T

S

175 °C

Input Current I

S,INPUT

230 mA

Output Power P

S,OUTPUT

600 mW

Insulation Resistance at TS, VIO = 500 V R

S

≥ 10

9

Ω

*Refer to the front of the optocoupler section of the current catalog, under Product Safety Regulations section, (VDE 0884), for a

detailed description.

Note: Isolation characteristics are guaranteed only within the safety maximum ratings which must be ensured by protective circuits in

application.

Recommended Operating Conditions

Parameter Symbol Min. Max. Units

Input Voltage, Low Level V

FL

-2.5 0.8 V

Input Current High Level 0°C to 85°CIFH0.5 1.0 mA

-40°C to 85°C 0.5 0.75

Supply Voltage, Output V

CC

4.75 5.25 V

Fan Out (TTL Load) N 5

Operating Temperature T

A

-40 85 °C

Absolute Maximum Ratings

(No Derating Required up to 55°C)

Storage Temperature, TS............................................. -55°C to +125°C

Operating Temperature, TA........................................... -40°C to +85°C

Lead Solder Temperature, max .......................................... 260°C for 10 s

(1.6 mm below seating plane)

Average Forward Input Current - IF............................................ 5 mA

[2]

Reverse Input Voltage, VR..............................................................3.0 V

Supply Voltage, VCC............................................................... 0 V to 7.0 V

Pull-Up Resistor Voltage, VRL............................................. - 0.5 V to V

CC

Output Collector Current, IO............................................ -25 to 25 mA

Input Power Dissipation, PI........................................................10 mW

Output Collector Power Dissipation, PO.....................................40 mW

Output Collector Voltage, VO........................................... -0.5 V to 18 V

Infrared and Vapor Phase Reflow Temperature

(Option #300) ..........................................see Fig. 1, Thermal Profile

Page 6

1-293

DC Electrical Specifications

For -40°C ≤ TA ≤ 85°C, 4.75 V ≤ VCC ≤ 5.25 V, VFL ≤ 0.8 V, unless otherwise specified.

All typicals at TA = 25°C and VCC = 5 V , unless otherwise specified. See note 1.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

High Level Output I

OH

0.05 250 µAVF = 0.8 V, VO = 18 V 4

Current

Low Level Output V

OL

0.4 0.5 V IF = 0.5 mA 3

Voltage IOL (Sinking) = 8 mA

High Level Supply I

CCH

4.0 6.3 mA IF = 0 mA, VCC = 5.25 V

Current

Low Level Supply Current I

CCL

6.2 10.0 mA IF = 1.0 mA, VCC = 5.25 V

Input Forward Voltage V

F

1.0 1.3 1.5 V TA = 25°CIF = 1.0 mA 2

0.85 1.65

Input Diode Temperature ∆V

F

-1.6 mV/°CIF = 1.0 mA

Coefficient

Input Reverse BV

R

3.0 V IR = 10 µA

Breakdown Voltage

Input Capacitance C

IN

18 pF VF = 0 V, f = 1 MHz

Internal Pull-up Resistor R

L

680 1000 1700 Ω TA = 25°C

∆T

A

Switching Specifications

For -40°C ≤ TA ≤ 85°C, 0.5 mA ≤ IFH ≤ 0.75 mA;

For 0°C ≤ TA ≤ 85°C, 0.5 mA ≤ IFH ≤ 1.0 mA; With 4.75 V ≤ VCC ≤ 5.25 V, VFL ≤ 0.8 V, unless otherwise

specified. All typicals at TA = 25°C and VCC = 5 V, IFH = 0.625 mA, unless otherwise specified. See note 1.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

Propagation Delay Time t

PLH

95 ns CP = 0 pF 5, 6, 8 4, 8

85 160 CP = 20 pF 5, 8

Propagation Delay Time t

PHL

110 ns CP = 0 pF 5, 6, 8 5, 8

35 200 CP = 20 pF 5, 8

Output Rise Time (10-90%) t

r

40 ns CP = 20 pF 7, 8 8

Output Fall Time (90-10%) t

f

20 ns

Common Mode Transient |CMH| 100 400 V/µsVCM = 50 V (peak), 9, 10 6

Immunity at High VO (min.) = 2 V,

Output Level RL = 560 Ω,

IF = 0 mA

Common Mode Transient |CML| 100 400 V/µsVCM = 50 V (peak), 9, 10 7

Immunity at Low VO (max.) = 0.8 V,

Output Level RL = 560 Ω,

IF = 0.5 mA

to Logic High Output Level

to Logic Low Output Level

Page 7

1-294

Notes:

1. Bypassing the power supply line is

required with a 0.1 µF ceramic disc

capacitor adjacent to each optocoupler

as illustrated in Figure 19. The power

supply bus for the optocoupler(s)

should be separate from the bus for

any active loads, otherwise a larger

value of bypass capacitor (up to

0.5 µF) may be needed to suppress

regenerative feedback via the power

supply.

2. Peaking circuits may produce transient

input currents up to 100 mA, 500 ns

maximum pulse width, provided

average current does not exceed 5 mA.

Package Characteristics

For -40°C ≤ TA ≤ 85°C, unless otherwise specified. All typicals at TA = 25°C.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Notes

Input-Output Momentary V

ISO

2500 V rms RH ≤ 50%, t = 1 min, 3, 9

Withstand Voltage* TA = 25°C

Resistance, Input-Output R

I-O

10

12

Ω V

I-O

= 500 V 3

Capacitance, Input-Output C

I-O

0.6 pF f = 1 MHz 3

*The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to the VDE 0884 Insulation Characteristics Table (if applicable),

your equipment level safety specification, or HP Application Note 1074, “Optocoupler Input-Output Endurance Voltage.”

7. CML is the maximum tolerable rate of

fall of the common mode voltage to

assure that the output will remain in a

low logic state (i.e., V

OUT

< 0.8 V).

8. CP is the peaking capacitance. Refer to

test circuit in Figure 8.

9. In accordance with UL 1577, each

optocoupler is momentary withstand

proof tested by applying an insulation

test voltage ≥ 3000 Vrms for 1 second

(leakage detection current limit,

I

I-O

≤ 5 µA). This test is performed

before the 100% production test for

partial discharge (Method b) shown in

the VDE 0884 Insulation Characteristics Table, if applicable.

3. Device considered a two terminal

device: pins 1, 2, 3, and 4 shorted

together, and pins 5, 6, 7, and 8

shorted together.

4. The t

PLH

propagation delay is

measured from the 50% point on the

trailing edge of the input pulse to the

1.5 V point on the trailing edge of the

output pulse.

5. The t

PHL

propagation delay is

measured from the 50% point on the

leading edge of the input pulse to the

1.5 V point on the leading edge of the

output pulse.

6. CMH is the maximum tolerable rate of

rise of the common mode voltage to

assure that the output will remain in a

high logic state (i.e., V

OUT

> 2.0 V).

Figure 3. Typical Output Voltage vs.

Forward Input Current vs.

Temperature.

Figure 2. Typical Input Diode

Forward Characteristics.

Figure 4. Typical Logic High Output

Current vs. Temperature.

Page 8

1-295

Figure 5. Typical Propagation Delay

vs. Temperature and Forward

Current with and without Application

of a Peaking Capacitor.

Figure 6. Typical Propagation Delay

vs. Forward Current.

Figure 7. Typical Rise, Fall Time vs.

Temperature.

Figure 8. Test Circuit for t

PHL

, t

PLH

, tr, and tf. Figure 9. Typical Common Mode

Transient Immunity vs. Common

Mode Transient Amplitude.

Page 9

1-296

Applications

The HCPL-2300 optocoupler has

the unique combination of low

0.5 mA LED operating drive

current at a 5 MBd speed

performance. Low power supply

current requirement of 10 mA

maximum at 5.25 V and the

ability to provide isolation

between logic systems fulfills

numerous applications ranging

from logic level translations, line

receiver and party line receiver

applications, microprocessor I/O

port isolation, etc. The open collector output allows for wired-OR

arrangement. Specific interface

circuits are illustrated in Figures

12-16, and 18 with corresponding component values, performance data and recommended

layout in Figures 17 and 19.

For -40°C to 85°C operating

temperature range, a mid-range

LED forward current (IF) of

0.625 mA is recommended in

order to prevent overdriving the

integrated circuit detector due to

increased LED efficiency at

temperatures between 0°C and

-40°C. For narrower temperature

range of 0°C to 85°C, a suggested

operating LED current of

0.75 mA is recommended for the

mid-range operating point and for

minimal propagation delay skew.

A peaking capacitance of 20 pF

in parallel with the current

limiting resistor for the LED

shortens t

PHL

by approximately

33% and t

PLH

by 13%. Maintaining LED forward voltage (VF)

below 0.8 V will guarantee that

the HCPL-2300 output is off.

The recommended shunt drive

technique for TTL/LSTTL/CMOS

of Figure 12 provides for optimal

speed performance, no leakage

current path through the LED,

and reduced common mode

influences associated with series

switching of a “floating” LED.

Alternate series drive techniques

with either an active CMOS

inverter or an open collector TTL/

LSTTL inverter are illustrated in

Figures 13 and 14 respectively.

Open collector leakage current of

250 µA has been compensated by

the 3.16 KΩ resistor (Figure 14)

at the expense of twice the

operating forward current.

An application of the HCPL-2300

as an unbalanced line receiver for

use in long line twisted wire pair

communication links is shown in

Figure 15. Low LED IF and V

F

allow longer line length, higher

speed and multiple stations on

the line in comparison to higher

IF, VF optocouplers. Greater

speed performance along with

nearly infinite common mode

immunity are achieved via the

balanced split phase circuit of

Figure 16. Basic balanced

differential line receiver can be

accomplished with one HCPL2300 in Figure 16, but with a

typical 400 V/µs common mode

immunity. Data rate versus

distance for both the above

unbalanced and balanced line

receiver applications are compared in Figure 17. The RS-232-C

interface circuit of Figure 18

Figure 10. Test Circuit for Common Mode Transient Immunity and Typical Waveforms.

Figure 11. Thermal Derating Curve,

Dependence of Safety Limiting Value

with Case Temperature per

VDE 0884.

OUTPUT POWER – P

S

, INPUT CURRENT – I

S

0

0

TS – CASE TEMPERATURE – °C

20050

400

12525 75 100 150

600

800

200

100

300

500

700

PS (mW)

I

S

(mA)

175

Page 10

1-297

Figure 14. Series Drive from Open Collector TTL/LSTTL

Units.

Figure 13. Active CMOS Series Drive Circuit.

Figure 12. Recommended Shunt Drive Circuit for Interfacing between TTL/LSTTL/CMOS Logic Systems.

provides guaranteed minimum

common mode immunity of

100 V/µs while maintaining the

2:1 dynamic range of IF.

A recommended layout for use

with an internal 1000 Ω resistor

or an external pull-up resistor

and required VCC bypass capacitor is given in Figure 19. V

CC1

is

used with an external pull-up

resistor for output voltage levels

(VO) greater than or equal to 5 V.

As illustrated in Figure 19, an

optional VCC and GND trace can

be located between the input and

the output leads of the HCPL2300 to provide additional noise

immunity at the compromise of

insulation capability (V

I-O

).

Page 11

1-298

Figure 15. Application of HCPL-2300 as Isolated, Unbalanced Line Receiver(s).

Figure 16. Application of Two HCPL-2300 Units Operating as an Isolated, High Speed, Balanced, Split Phase Line

Receiver with Significantly Enhanced Common Mode Immunity.

REFERENCE FIGURE 17 FOR DATA RATE vs. LINE DISTANCE L.

REFERENCE FIGURE 17 FOR DATA RATE vs. LINE DISTANCE L.

Page 12

1-299

Figure 19. Recommended Printed Circuit Board Layout.

Figure 18. RS-232-C Interface Circuit with HCPL-2300.

0°C < TA < 85°C.

Figure 17. Typical Point to Point Data Rate vs. Length of

Line for Unbalanced (Figure 15) and Balanced (Figure 16)

Line Receivers Using HCPL-2300 Optocouplers.

RS-232-C

SIGNAL

3 V – 25 V

-3 V – -25 V

(FIGURE 16)

(FIGURE 15)

Loading...

Loading...