Page 1

June 1998

HA-5147/883

100MHz, Ultra Low Noise, Precision,

High Slew Rate Operational Amplifier

Features

• This Circuit is Processed in Accordance to MIL-STD883 and is Fully Conformant Under the Provisions of

Paragraph 1.2.1.

• High Slew Rate. . . . . . . . . . . . . . . . . . . . . . 28V/µs (Min)

• Wide Gain Bandwidth (A

• Low Noise (at 1kHz). . . . . . . . . . . . . . . 4.5nV/√

≥ 10) . . . . . . . 100MHz (Min)

V

Hz (Max)

• Low Offset Voltage. . . . . . . . . . . . . . . . . . . .100µV (Max)

o

• Low Offset Drift With Temperature. . . . 1.8µV/

C (Max)

• High CMRR. . . . . . . . . . . . . . . . . . . . . . . . . . 100dB (Min)

• High Voltage Gain . . . . . . . . . . . . . . . . . . 700kV/V (Min)

Applications

• High Speed Signal Conditioners

• Wide Bandwidth Instrumentation Amplifiers

• Low Level Transducer Amplifiers

• Fast, Low Level Voltage Comparators

• Highest Quality Audio Preamplifiers

• Pulse/RF Amplifiers

Description

The HA-5147/883 monolithic operational amplifier features

an unparalleled combination of precision DC and wideband

high speed characteristics. Utilizing the Intersil DI technology and advanced processing techniques, this unique

design unites low noise precision instrumentation performance with high speed wideband capability.

This amplifier’s impressive list of features include low V

OS

wide gain-bandwidth, high open loop gain, and high CMRR.

Additionally, this flexible device operates over a wide supply

range while consuming only 120mW of power.

Using the HA-5147/883 allows designers to minimize errors

while maximizing speed and bandwidth in applications

requiring gains greater than ten.

This device is ideally suited for low level transducer signal

amplifier circuits. Other applications which can utilize the

HA-5147/883’s qualities include instrumentation amplifiers,

pulse or RF amplifiers, audio preamplifiers, and signal conditioning circuits.

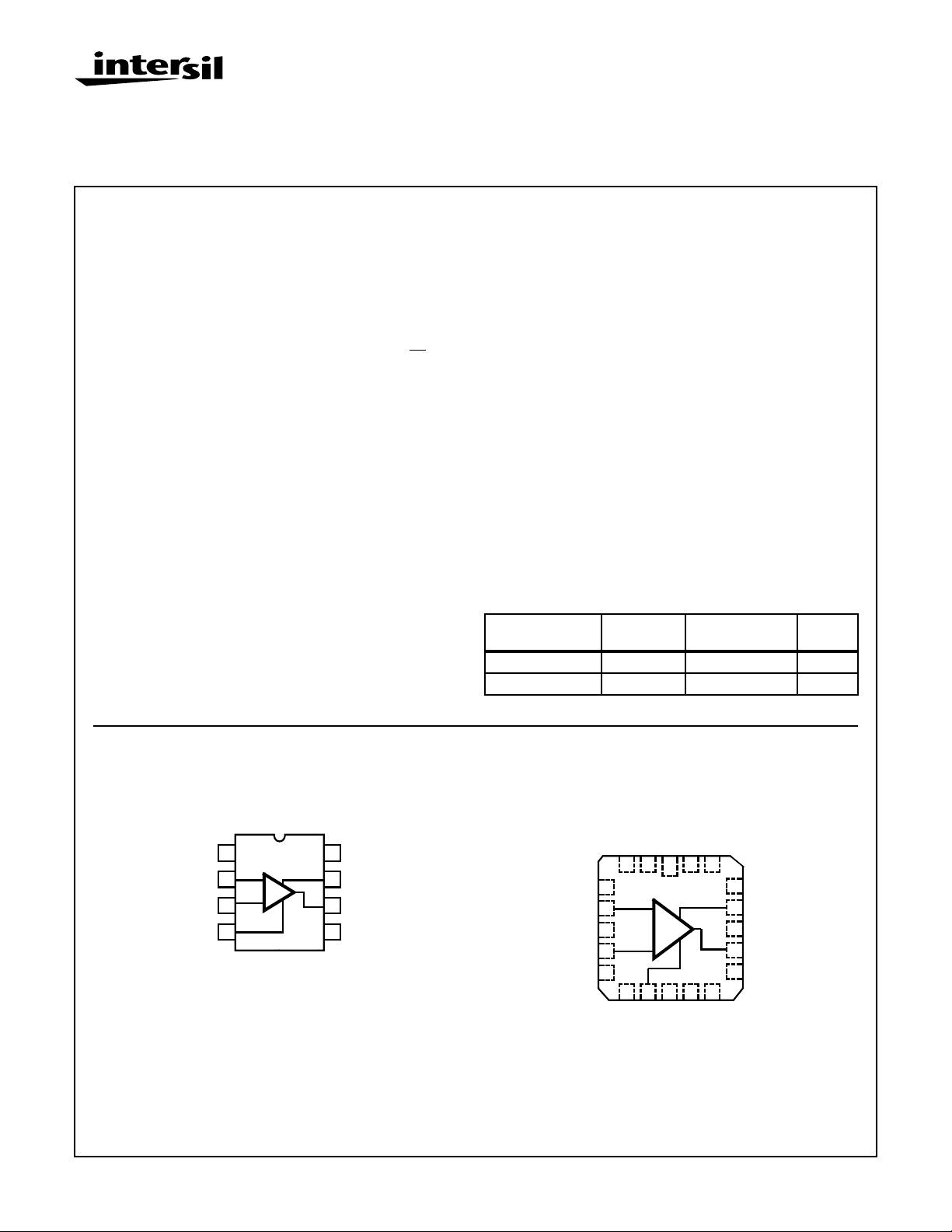

Ordering Information

TEMP.

PART NUMBER

HA4-5147/883 -55 to 125 20 Ld CLCC J20.A

HA7-5147/883 -55 to 125 8 Ld CERDIP F8.3A

RANGE (oC) PACKAGE

PKG.

NO.

,

Pinouts

HA-5147/883

(CERDIP)

TOP VIEW

1

BAL

-IN

2

-

+IN

V-

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

+

3

4

| Copyright © Intersil Corporation 1999

8

BAL

7

V+

6

OUT

NC

5

1

NC

-IN

NC

+IN

NC

HA-5147/883

(CLCC)

TOP VIEW

NC

BALNCNC

3212019

4

5

6

7

8

+

9101112

NCV-NC

BAL

18

NC

V+

17

16

NC

OUT

15

NC

14

13

NC

NC

Spec Number 511009-883

File Number 3715.2

Page 2

HA-5147/883

Absolute Maximum Ratings Thermal Information

Voltage Between V+ and V- Terminals. . . . . . . . . . . . . . . . . . . . 44V

Differential Input Voltage (Note 1). . . . . . . . . . . . . . . . . . . . . . . .0.7V

Voltage at Either Input Terminal . . . . . . . . . . . . . . . . . . . . . . V+ to V-

Input Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25mA

Output Current . . . . . . . . . . . . . . . . . . . Full Short Circuit Protection

ESD Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <2000V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±15V

V

≤ 1/2 (V+ - V-)

INCM

RL≥ 600Ω

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. For differential input voltages greater than 0.7V, the input current must be limited to 25mA to protect the back-to-back input diodes.

2. θJA is measured with the component mounted on an evaluation PC board in free air.

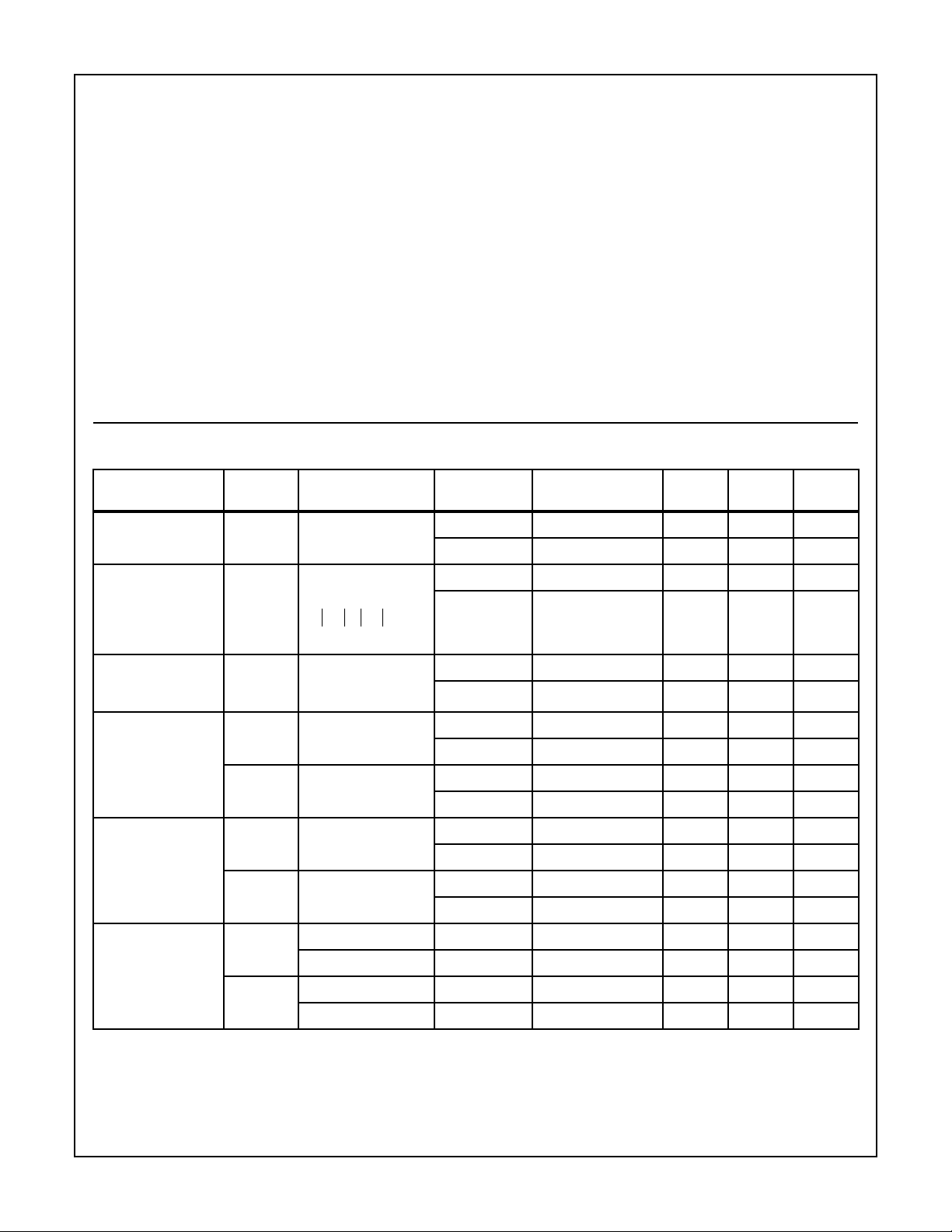

TABLE 1. DC ELECTRICAL PERFORMANCE SPECIFICATIONS

Device Tested at: V

PARAMETER SYMBOL CONDITIONS

Input Offset Voltage V

Input Bias Current I

SUPPLY

= ±15V, R

IO

B

SOURCE

= 50Ω, R

LOAD

= 100kΩ, V

VCM = 0V 1 25 -100 100 µV

VCM = 0V,

RS = 10kΩ, 50Ω

+I

+

BI–B

------------------------------

2

Thermal Resistance (Typical, Note 2) θJA (oC/W) θJC (oC/W)

CERDIP Package . . . . . . . . . . . . . . . . 115 28

CLCC Package . . . . . . . . . . . . . . . . . . 65 15

Package Power Dissipation Limit at 75oC for TJ≤ 175oC

CERDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 870mW

CLCC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.54W

Package Power Dissipation Derating Factor Above 75oC

CERDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.7mW/oC

CLCC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15.4mW/oC

Maximum Junction Temperature (TJ) . . . . . . . . . . . . . . . . . . . 175oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300oC

= 0V, Unless Otherwise Specified.

OUT

GROUP A

SUBGROUPS TEMP. (oC) MIN MAX UNITS

2, 3 125, -55 -300 300 µV

1 25 - 80 nA

2, 3 125, -55 - 150 nA

Input Offset Current I

Common Mode

+CMR V+ = +4.7V,

Range

Large Signal Voltage

+A

Gain

Common Mode

+CMRR ∆VCM = +11V 1 25 100 - dB

Rejection Ratio

-CMRR ∆VCM = -11V 1 25 100 - dB

VCM = 0V,

IO

+RS = 10kΩ,

-RS = 10kΩ

V- = -25.3V

-CMR V+ = +25.3V,

V- = -4.7V

V

VOL

= 0V and +10V,

OUT

RL = 2kΩ

-A

VOL

V

= 0V and -10V,

OUT

RL = 2kΩ

∆VCM = +10V 2, 3 125, -55 100 - dB

∆VCM = -10V 2, 3 125, -55 100 - dB

1 25 -75 75 nA

2, 3 125, -55 -135 135 nA

1 25 10.3 - V

2, 3 125, -55 10.3 - V

1 25 - -10.3 V

2, 3 125, -55 - -10.3 V

4 25 700 - kV/V

5, 6 125, -55 300 - kV/V

4 25 700 - kV/V

5, 6 125, -55 300 - kV/V

Spec Number 511009-883

2

Page 3

TABLE 1. DC ELECTRICAL PERFORMANCE SPECIFICATIONS (Continued)

Device Tested at: V

SUPPLY

= ±15V, R

SOURCE

PARAMETER SYMBOL CONDITIONS

= 50Ω, R

HA-5147/883

= 100kΩ, V

LOAD

GROUP A

SUBGROUPS TEMP. (oC) MIN MAX UNITS

= 0V, Unless Otherwise Specified.

OUT

Output Voltage Swing +V

OUT1RL

= 2kΩ 4 25 11.5 - V

5, 6 125, -55 11.5 - V

-V

OUT1RL

= 2kΩ 4 25 - -11.5 V

5, 6 125, -55 - -11.5 V

+V

-V

Output Current +I

Quiescent Power

Supply Current

OUT2RL

OUT2RL

OUT

-I

OUT

+I

CC

-I

CC

= 600Ω 42510-V

= 600Ω 4 25 - -10 V

V

= -10V 4 25 16.5 - mA

OUT

V

= +10V 4 25 - -16.5 mA

OUT

V

OUT

=0V,I

= 0mA 1 25 - 4 mA

OUT

2, 3 125, -55 - 4 mA

V

OUT

=0V,I

= 0mA 1 25 -4 - mA

OUT

2, 3 125, -55 -4 - mA

Power Supply

Rejection Ratio

Offset Voltage

Adjustment

+PSRR ∆V

-PSRR ∆V

= +14V 1 25 86 - dB

SUP

∆V

= +13.5V 2, 3 125, -55 86 - dB

SUP

= +14V 1 25 86 - dB

SUP

∆V

= +13.5V 2, 3 125, -55 86 - dB

SUP

+VIOAdj Note 3 1 25 VIO-1 - mV

2, 3 125, -55 VIO-1 - mV

-VIOAdj Note 3 1 25 VIO+1 - mV

2, 3 125, -55 VIO+1 - mV

NOTE:

3. Offset adjustment range is [VIO(Measured) ±1mV] minimum referred to output. This test is for functionality only to assure adjustment

through 0V.

TABLE 2. AC ELECTRICAL PERFORMANCE SPECIFICATIONS

Device Tested at: V

SUPPLY

= ±15V, R

SOURCE

PARAMETER SYMBOL CONDITIONS

Slew Rate +SR V

-SR V

Rise and Fall Time t

r

= -3V to +3V 7 25 28 - V/µs

OUT

= +3V to -3V 7 25 28 - V/µs

OUT

V

= 0 to +200mV

OUT

10% ≤ tr≤ 90%

t

V

f

= 0 to -200mV

OUT

10% ≤ tf≤ 90%

Overshoot +OS V

-OS V

= 0 to +200mV 7 25 - 40 %

OUT

= 0 to -200mV 7 25 - 40 %

OUT

= 50Ω, R

LOAD

= 2kΩ, C

LOAD

= 50pF, A

= +10V/V, Unless Otherwise Specified.

VCL

GROUP A

SUBGROUPS TEMP. (oC) MIN MAX UNITS

7 25 - 50 ns

7 25 - 50 ns

Spec Number 511009-883

3

Page 4

HA-5147/883

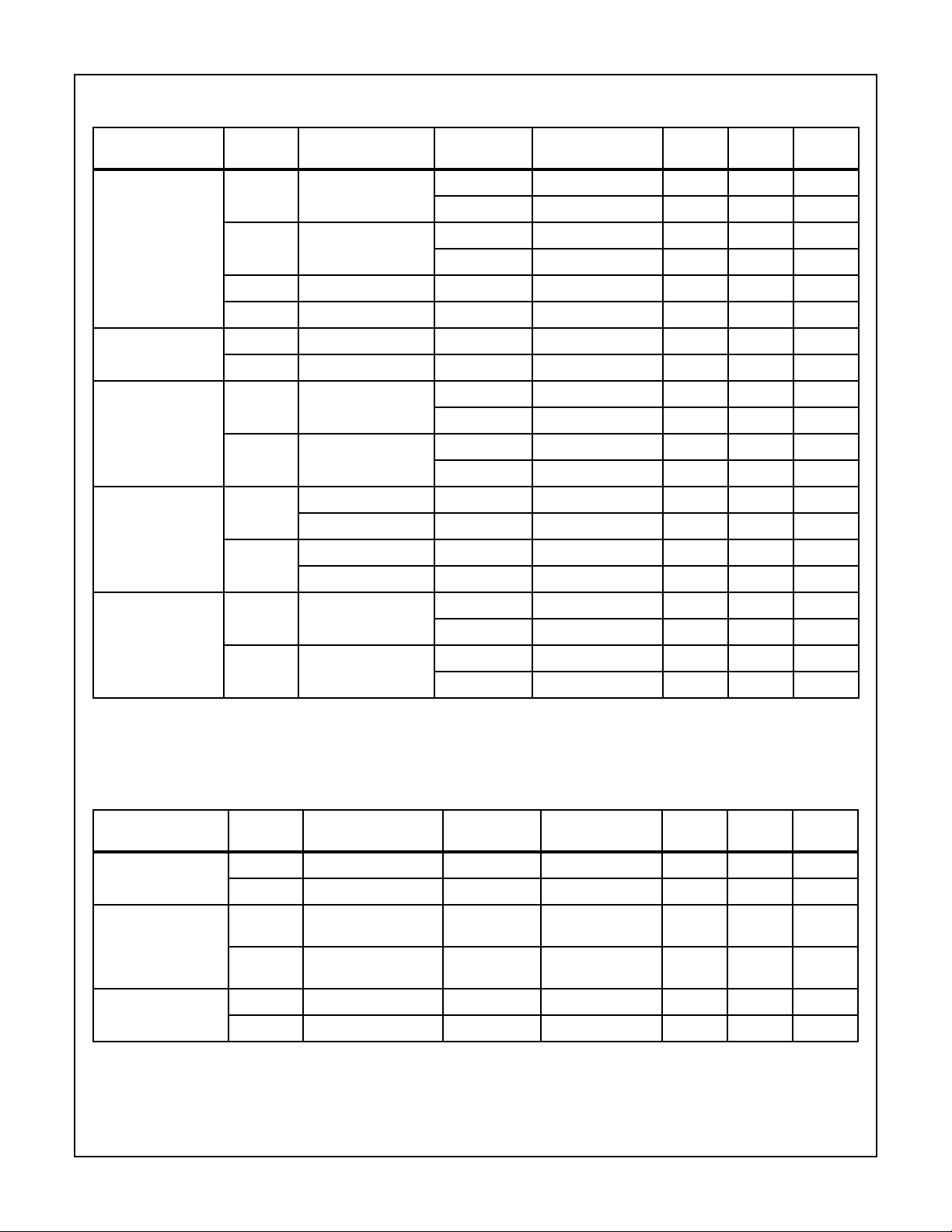

TABLE 3. ELECTRICAL PERFORMANCE SPECIFICATIONS

Device Characterized at: V

PARAMETER SYMBOL CONDITIONS NOTES TEMP. (oC) MIN MAX UNITS

SUPPLY

= ±15V, R

LOAD

= 2kΩ, C

= 50pF, AV = +10V/V, Unless Otherwise Specified.

LOAD

Average Offset Voltage

VIOTC VCM = 0V 4 -55 to 125 - 1.8 µV/oC

Drift

Differential Input

R

VCM = 0V 4 25 0.8 - MΩ

IN

Resistance

Low Frequency

E

NP-P

0.1Hz to 10Hz 4 25 - 0.25 µV

P-P

Peak-to-Peak Noise

Input Noise Voltage

Density

E

RS = 20Ω, fO = 10Hz 4 25 - 10 nV/√Hz

N

RS = 20Ω, fO = 100Hz 4 25 - 5.6 nV/√Hz

RS = 20Ω, fO = 1kHz 4 25 - 4.5 nV/√Hz

Input Noise Current

Density

I

RS = 2MΩ, fO = 10Hz 4 25 - 4.0 pA/√Hz

N

RS = 2MΩ, fO = 100Hz 4 25 - 2.3 pA/√Hz

RS = 2MΩ, fO = 1kHz 4 25 - 0.6 pA/√Hz

Gain Bandwidth Product GBWP VO= 100mV, fO=10kHz 4 25 120 - MHz

VO= 100mV, fO=1MHz 4 25 100 - MHz

Full Power Bandwidth FPBW V

Minimum Closed Loop

CLSG RL = 2kΩ, CL = 50pF 4 -55 to 125 ±10 - V/V

= 10V 4, 5 25 445 - kHz

PEAK

Stable Gain

Settling Time t

Output Resistance R

Quiescent Power

OUT

PC V

To 0.1% for a 10V Step 4 25 - 600 µs

S

Open Loop 4 25 - 100 Ω

OUT

=0V,I

= 0mA 4, 6 -55 to 125 - 120 mW

OUT

Consumption

NOTES:

4. Parameters listed in Table 3 are controlled via design or process parameters and are not directly tested at final production. These parameters are lab characterized upon initial design release, or upon design changes. These parameters are guaranteed by characterization based upon data from multiple production runs which reflect lot to lot and within lot variation.

5. Full Power Bandwidth guarantee based on Slew Rate measurement using FPBW = Slew Rate/(2πV

PEAK

).

6. Quiescent Power Consumption based upon Quiescent Supply Current test maximum. (No load on output.)

TABLE 4. ELECTRICAL TEST REQUIREMENTS

MIL-STD-883 TEST REQUIREMENTS SUBGROUPS (SEE TABLES 1 AND 2)

Interim Electrical Parameters (Pre Burn-In) 1

Final Electrical Test Parameters 1 (Note 7), 2, 3, 4, 5, 6, 7

Group A Test Requirements 1, 2, 3, 4, 5, 6, 7

Groups C and D Endpoints 1

NOTE:

7. PDA applies to Subgroup 1 only.

4

Spec Number 511009-883

Page 5

Die Characteristics

HA-5147/883

DIE DIMENSIONS:

104.3 x 65 x 19 mils

2650 x 1650 x 483µm

METALLIZATION:

Type: Al, 1% Cu

Thickness: 16k

Å ± 2kÅ

GLASSIVATION:

Type: Nitride (Si

) over Silox (SiO2, 5% Phos.)

3N4

Silox Thickness: 12kÅ ± 2kÅ

Nitride Thickness: 3.5kÅ ± 1.5kÅ

Metallization Mask Layout

BAL

WORST CASE CURRENT DENSITY:

3.6 x 10

5

A/cm2at 15mA

This de vice meets Glassiv ation Integrity Test Requirement

per MIL-STD-883 Method 2021 and MIL-I-38535 Paragraph

30.5.5.4.

SUBSTRATE POTENTIAL (Powered Up):

V-

TRANSISTOR COUNT:

63

PROCESS:

Bipolar Dielectric Isolation

HA-5147/883

BAL

-IN

+IN

V+

OUT

V-

NC

Spec Number 511009-883

5

Page 6

Burn-In Circuits

HA-5147/883

HA-5147/883 CERDIP

R

2

R

1

V-

D

2

C

2

1

2

-

+

3

4

R

3

8

7

C

6

5

1

V+

D

1

HA-5147/883 CLCC

R

2

32120 19

R

1

R

4

5

6

7

8

3

-

+

9 10111213

18

17

C

16

15

14

1

V+

D

1

NOTE:

R1 = R3 = 1kΩ, ±5%,1/4W (Min.)

R2 = 10kΩ, ±5%,1/4W (Min.)

C1 = C2 = 0.01µF/Socket or 0.1µF/Row (Min.)

D1 = D2 = 1N4002 or Equivalent/Board

|(V+) - (V-)| = 30V

C

2

V-

D

2

Spec Number 511009-883

6

Page 7

HA-5147/883

Typical Performance Information T

= 25oC, V

A

R

1

2

3

4

T

-

+

10kΩ

= ±15V, Unless Otherwise Specified

SUPPLY

V+

8

7

6

5

NOTE: Tested offset adjustment range is |VOS±1mV| minimum referred to output. Typical range is ±4mV with RT = 10kΩ.

SUGGESTED OFFSET VOLTAGE ADJUSTMENT

AV = +10V/V

V

AC

50Ω

+

-

1.8kΩ

50pF

V

OUT

AC

OUT

200Ω

LARGE AND SMALL SIGNAL RESPONSE TEST CIRCUIT

IN

IN

OUT

Vertical Scale: Input = 0.5V/Div.

Output = 5V/Div.

Horizontal Scale: 500ns/Div.

LARGE SIGNAL RESPONSE

Vertical Scale: Input = 10mV/Div.

Output = 100mV/Div.

Horizontal Scale: 100ns/Div.

SMALL SIGNAL RESPONSE

Spec Number 511009-883

7

Page 8

HA-5147/883

Ceramic Leadless Chip Carrier Packages (CLCC)

j x 45

E1

o

B

h x 45

-E-

E2

e1

o

A

-F-

0.010 E HS S

L

D

D3

0.007 E FM S HS

B1

L2

D1

-H-

D2

B2

J20.A MIL-STD-1835 CQCC1-N20 (C-2)

20 PAD CERAMIC LEADLESS CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.060 0.100 1.52 2.54 6, 7

A1 0.050 0.088 1.27 2.23 -

B-----

B1 0.022 0.028 0.56 0.71 2, 4

E3

E

B2 0.072 REF 1.83 REF B3 0.006 0.022 0.15 0.56 -

D 0.342 0.358 8.69 9.09 D1 0.200 BSC 5.08 BSC D2 0.100 BSC 2.54 BSC D3 - 0.358 - 9.09 2

0.010 E FSS

A1

E 0.342 0.358 8.69 9.09 E1 0.200 BSC 5.08 BSC E2 0.100 BSC 2.54 BSC -

PLANE 2

PLANE 1

E3 - 0.358 - 9.09 2

e 0.050 BSC 1.27 BSC e1 0.015 - 0.38 - 2

h 0.040 REF 1.02 REF 5

j 0.020 REF 0.51 REF 5

L 0.045 0.055 1.14 1.40 L1 0.045 0.055 1.14 1.40 -

e

L3

L2 0.075 0.095 1.91 2.41 L3 0.003 0.015 0.08 0.38 -

ND 5 5 3

NE 5 5 3

N20 203

B3

NOTES:

1. Metallized castellations shall be connected to plane 1 terminals

and extend toward plane 2 across at least two layers of ceramic

or completely across all of the ceramic layers to make electrical

connection with the optional plane 2 terminals.

2. Unless otherwise specified, a minimum clearance of 0.015 inch

(0.38mm) shall be maintained between all metallized features

L1

(e.g., lid, castellations, terminals, thermal pads, etc.)

3. Symbol “N” is the maximum number of terminals. Symbols “ND”

and “NE” are the number of terminals along the sides of length

“D” and “E”, respectively.

4. The required plane 1 terminals and optional plane 2 terminals (if

used) shall be electrically connected.

5. The corner shape (square, notch, radius, etc.) may vary at the

manufacturer’s option, from that shown on the drawing.

6. Chip carriers shall be constructed of a minimum of two ceramic

layers.

7. Dimension “A” controls the overall package thickness . The maximum “A” dimension is package height before being solder dipped.

8. Dimensioning and tolerancing per ANSI Y14.5M-1982.

9. Controlling dimension: INCH.

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

Spec Number 511009-883

8

Page 9

HA-5147/883

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

c1

LEAD FINISH

-DBASE

M

SECTION A-A

METAL

b1

M

(b)

α

E

D

S

S

Q

A

-CL

eA

eA/2

aaa C A - B

M

c

S

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc C A - BMD

-A-

-B-

S

D

A

A

e

S

S

NOTES:

1. Index area:A notch or apin one identificationmark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH

D

F8.3A MIL-STD-1835 GDIP1-T8 (D-4, CONFIGURATION A)

8 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

(c)

SYMBOL

S

eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

S1 0.005 - 0.13 - 7

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 -

ccc - 0.010 - 0.25 -

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

A - 0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 0.405 - 10.29 5

E 0.220 0.310 5.59 7.87 5

e 0.100 BSC 2.54 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.060 0.38 1.52 6

o

α

90

105

o

90

o

105

o

-

M - 0.0015 - 0.038 2, 3

N8 88

Rev. 0 4/94

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice.

Accordingly ,the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may

result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Spec Number 511009-883

9

Loading...

Loading...