Page 1

DATE

28-Jan-99

I. These Techincal literature include materials protected under &he copyright of

Sharp

PIease do not reproduce or cause anyone to reproduce them without Sharp’s consent.

2. When using this product,

in these

for any damage

md the instructions included in these specification sheets, and the precautions

specification

resulting

please observe the absolut: maximum ratings

sheets, as well as the precautions mentioned below.

and the instructions for use outlined

Sharp assumes no responsibility

ficm use of the product which dces not comply with the absolute maxirn~m ratings

mentioned below.

(Precautions)

(1) This products is designed for use in the foUowing application areas;

l

0.4 equipment * Audio visual equipment * Home appliance

+ Telecommunication equipment (Terminal) l Measuring equipment

* Tooling machines * Compulers

I

If the use of the product in the above application areas is for equipment listed in paragraphs

(2) or (Z), please be sue to observe the precautions

given

in those respective paragraphs.

(2) Appropriate measures, such as fail-safe design and redundant design considering

the safety design of the overall system and equipment, should be taken to ensure reliability

and safety when &is product is used for equipment which demands high reliability and

safety in function and precision, such as ;

r l Transportation control and safety equipment

(aircraf?, aain, automobile etc.) 1 * Traffic sign& * Gas leakage sensor breakers l Rescue and security equipment

L

l Other

safety equipment

(3) Please do not use this product for equipment which require exnemeiy high rehability

and safety in function and precision, such 5s ;

r

l

Space equipment L * Telecommunication equipment (for trunk lines)

’ Nuclear power control equipment * hfedical equipment

(4) Please contact and consult with a Sharp sales representative if there are any questions

regarding interpretation of the

above three paragraphs.

3. Please contact and consult with a Sharp sales representative for any questions about

Corporation (“S’ha@).

7

I

_I

1

this

product.

** The technical literature is subject to be changed without notice **

Opto-Electronic Devices Division

Electronic Components Group

SH.AFW CORF’ORATION

Page 2

MOD& NJ.

G?viSWT95200A

DG-991015

1 Jan/T8/99

PAGE

l/13

17

GMSIn95200A technical

1. AppliCXian

Thi.~ technicat Litemure appk to the light en&kg diode

1

Chip

type white LED (GaN

2.

Outline dimensions and terminal

3.

Ratings and characteristics

chip LED device)

CO~UXC~~OCS

..,.................~.RefertotheanachedsheetPage2.

. . . . . . . . . . . . . . . . . . . . . . . . . ..‘..........

3-1. Absolute maximum ratings

3-2.

Electra characteristics

3-3.

Optical characteristics

3-1.

Ltious intensity rank

3-J.

Color coordinates ranks

3-6.

Derating curve

3-7.

Characteristics chart

4. Reliability

4-

1. Test items and test conditions

4-2. Failure judgement

5. Incomin_e inspection

5-1.

5-2. Description of inspection and

6. Taping specification

..,,...............I......... --.--..-.-.-...-.-......RefertotheattachedsheetPage6.

criteria

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection method

criteria

..,........*,.................,...........*.

6-I. Taping

6-2. Label

6-3. Dampproof package

7.

Soldc.+g

7-1.

7-2.Mylual soldering

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reflow solderins

7-3. Dip soldering method

8.

Precsutions for use . . . . . . . . . a. . . . . . . . . .

-.......-.g...o.....,-..IRefer to &e attached beet Page 13.

8-l. Precautions maners for designing circuit

8-2.

Cleaning method

9. Environment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~....................

9-I. Ozonosphere destructive chemicals.

9-2. Brornic non-burning materials

Wrature

device MO&I NO.

Refer to the attached sheet Page 3-5

Refer to the attached sheet

Refer to the attached sheet Page 8-I 1.

Refer to the attached sheet

Refer to the attached shett Page 13.

GM5WT952oOA

Page 7.

Page 12.

Page 3

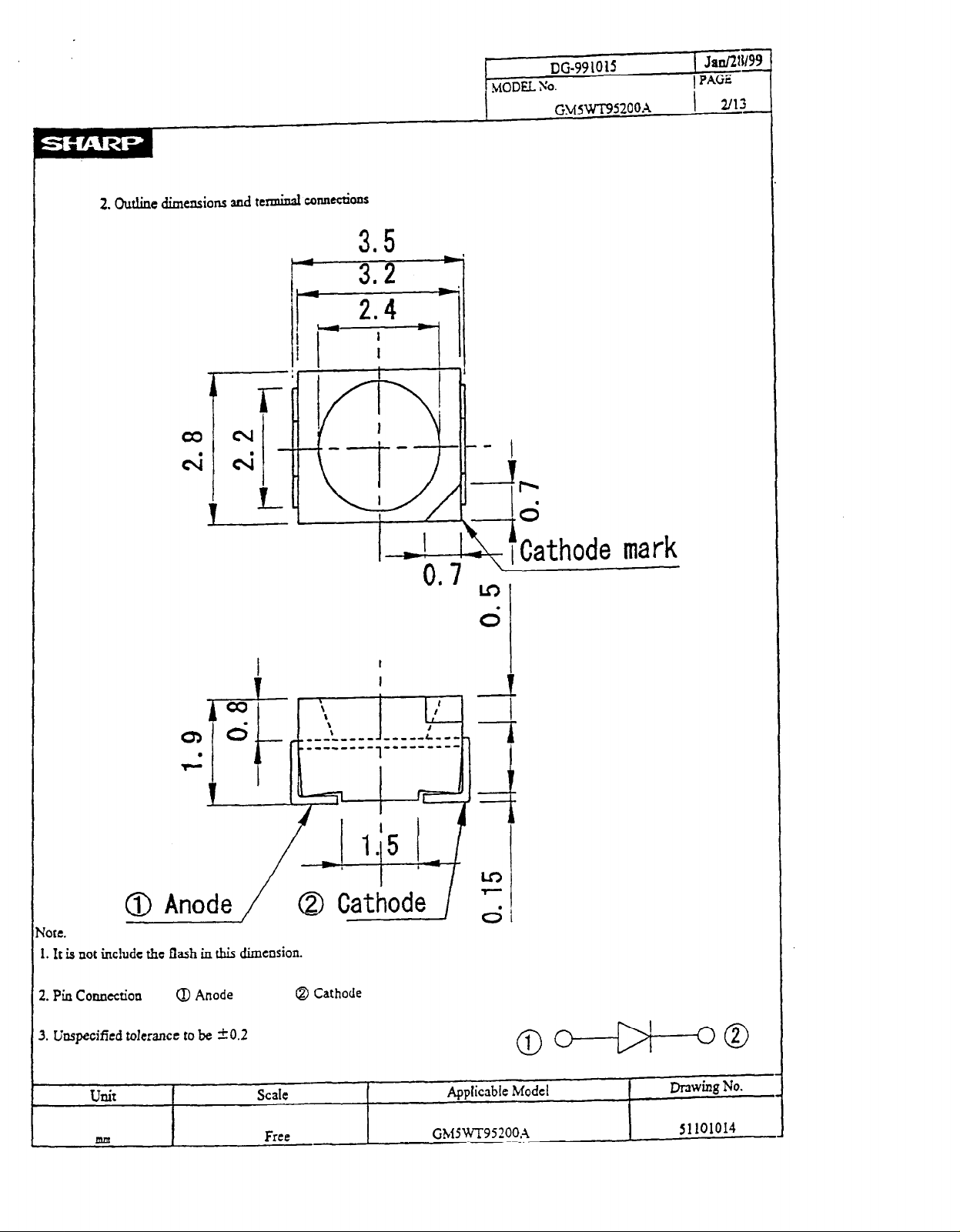

2. Outline dimensions and terminal connections

DG-991015

iMODEL X-a.

GM5WT352OOX

f-

.

1 Jan/21iii%-

) PAGE -

2J13

I -

0 Anode

N

‘OIC.

1

. It is not

2. Pin Connection

include the flash in this dimension.

I

!

I

-p+- \ ’ I

6 .,-.i __-- J _-_-- L,--

aa

.

P

-- IkL

---- -- 1 --------- Ql

3-L

I.2

0 Anode

/I-’ !.I

/ @ Cathode /

@ Cathode

I

~thade mark

Lo

T-

d

3. Unspecified tolerance to be k0.2

unit

BIB

Scale

Free

Applicable Model

Gbt5w-r95?00A

rhwhg No.

51101014

Page 4

c

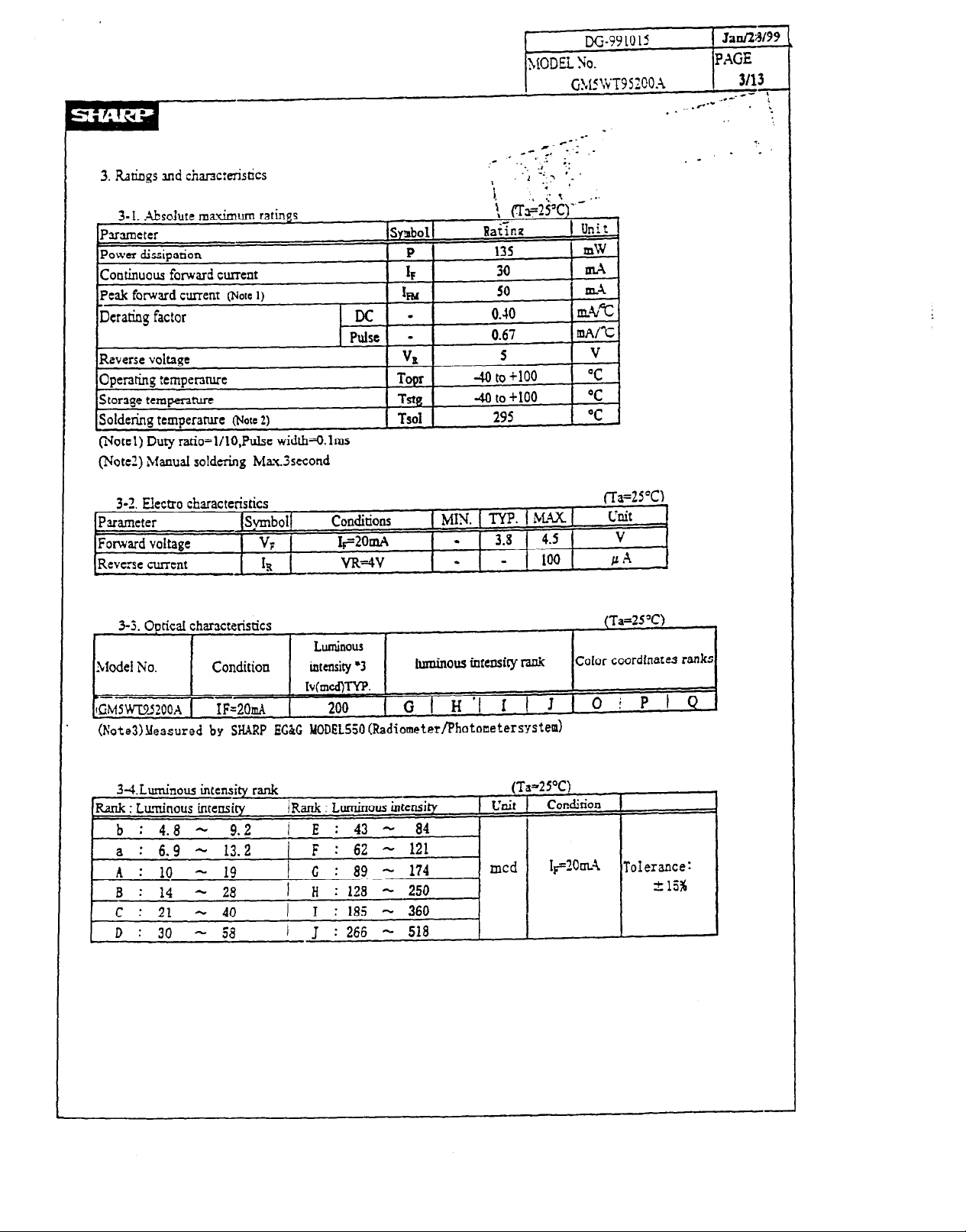

3.

Raiogs and charac:erktics

3-

1. Ahsolute maximum ratings

P3rameter

Power dissipation

Continuous fonvard current

Peak forward current @ore

Dcrating factor

Reverse voltage

Operating tempenture

Storage temperature

Soldering temperature

(Hotel) Duty ratio=1/10,Pulse width+.lms

(Note’) Manual soldering Max3second

1)

@ate 2)

(Syabol t

1 P I

IF

hl

DC -

Pulse I -

va

1 Topr 1

1 Tstg 1 40

1 Tsol 1 295

.- ’ .y- ’ : ;.

I

--~

30

50

0.10

0.67

5

40 to +100

to Cl00 1 oc

_ e-1--

--

_, -- .-

_, . .

.‘; -; ‘L .

. . ,-

.

IlLA

llL4

t&4x

IDA/t

1 v

( “C

1 “C

. ..-..-- ‘

..“-- .

. . .’

-

3-2. Elec&o characteristics

,

Parameter

Forward voltage

Reverse current 1s VR=4V w 1 100 I PA 1

3-3. Optid characteristics

I- 7

Model No. Condition intensity ‘3

--

GMSWT%?OOA

(NoteS)Ueasured by SHARP EGBG MODELS50 (RadiometerflhotonetersWem)

3d.Luminous intensity rank

Rank : Luminous

b : 4.8

a : 6.9 - 13.2

A : 10 - 19

8 : 14 - 28

c : 21 - 40

D : 30

/Symbol1

VF I&omt\

IF=20mX 200

intensity /Rank : Luminous intensity

- 9.2 j E : 43 - 84

-

;a

conditions

Luminous

luminous intensity ra&

Iv(mcd)TYP.

G(H’(I(J

/ F : 62 - 121

; i 1;; - 174

i

I I : 185 - 360

1 J : 266 - 518

- 250

1 MIN. lYP. 1 hf.4x.

1 - 3.8 1 4.5

,

1 Unit

mcd

(Ta=tS”C)

1 Lhit

1 V

Ta=T5’C)

-

color coordinates ranks

oiPlQ

olerance:

215%

Page 5

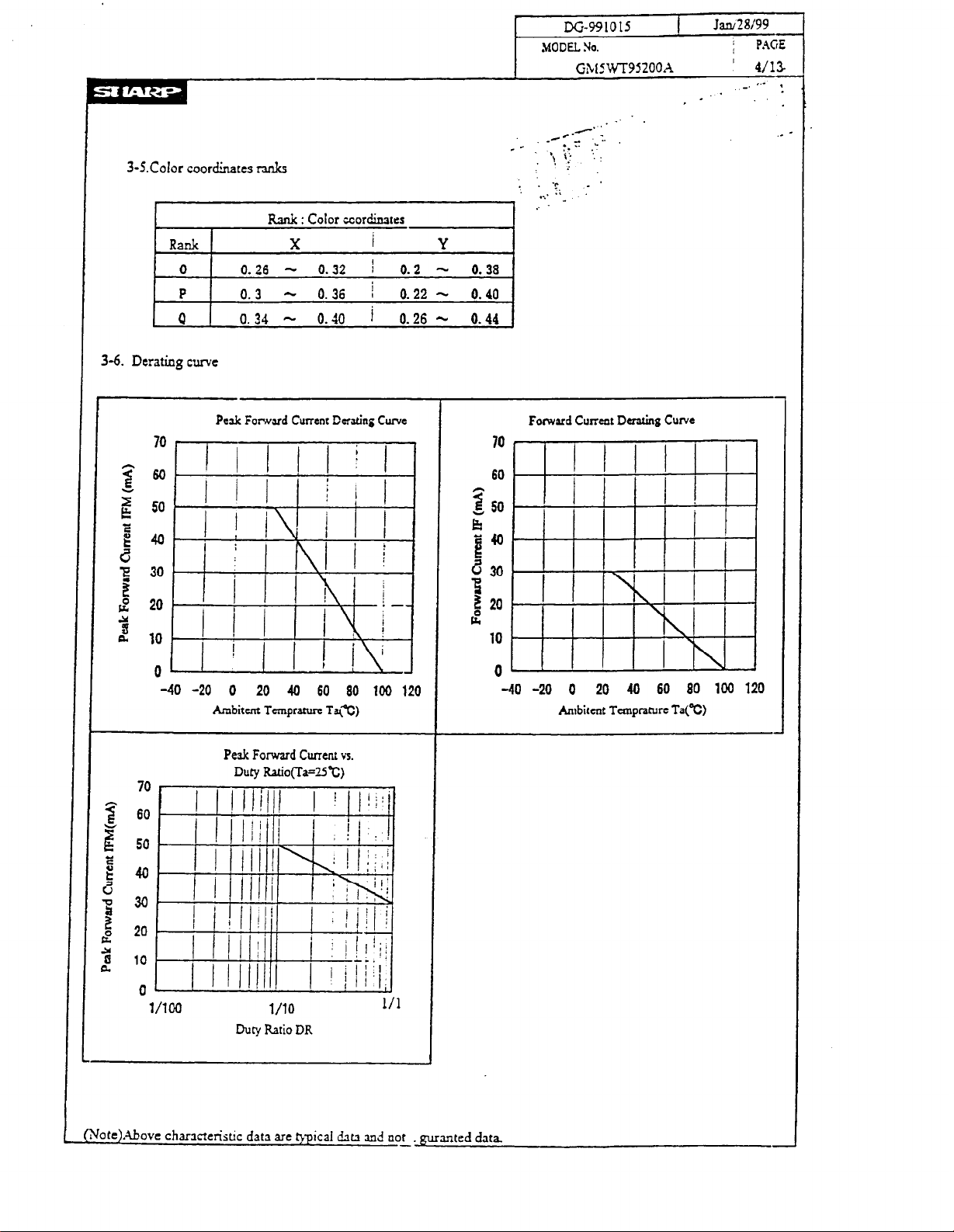

3-S.Color

coordilares ranks

Rank

0 0.26 - 0.32 1 0.2 - 0. 38

P

0

S-6. Derating curve

Rank :

Color coordinstes

X

I

Y

0.3 - 0.36 i 0.22 - 0. 40

0.34 - 0.40 ’ 0.26 - 0.44

DG-991015

.UODEL No.

GiLf5W95200A

c--

.- .-1.

_- :.= i’ .,

‘\ : .:

Jaw28199

j P.G’ 4/13

.;- .

, -

. .

. -.

“- 3

.-

-

Peak Forward Currenr Daating Cum

-40 -20 0

Ambittnr Tcmpraturc T$C)

Pelk Forward Current vs.

20 40 60 80 100

Dub Ratiofla=2%)

120

Fotward Current Dcrafing Curve

60

-40 -20 0 20 40 60 80 100 120

Ambitcnt Tanpraturo Tat%)

- l/lW

l/10

l/1

Duty Ratio DR

(Note Above charxteristic data are t)-pical km and not . gurvlted data

-

-

Page 6

3-7.

Characmistics chart

DG-991015 I

MCDEI. Ya

GMSWT952OOA

Sad2889 _

PACZ

5113

-

Relative Luminous Intesity vs. Fommd Cm

t.TaPt5Q

loooK

1% 0.

0. I

1 10 too

Forward Current I&4) Forward Voltage V,zo

Fonvard Cumt vs. Forward Vduge

1

2 3

. . . .

.‘i ..‘,I, .

;

i’;

I

. (‘.

G

-;*-.- - _ - .’

.. ‘.

.c .

i I_...- * -

w. -

(~~25’~

:

4

. .

5

n

[Aote)Above charxteristic data are typical data and not

gumted dam.

w-r95 _

Page 7

4. Rcliabiliry

The rcliabtity ofptoducrs shall be satisfied with items listed below.

DG-99lOU JaGG

hfODES No.

GSi5i-GT95200.A 6113

PAGE

4-1. Test items and :es concliricns

Test items

r

temperature cycling

Hieh temp’ and ‘@

humidicy storage

High temperature

storage

Low temper3rure

storage

Opcratig test

I

kfechtical shock

Vtiabte frequency

vibration

Soldering heat

5-2. Failure judgemeat criteria (Sotel)

Test conditions

-tO~C(jOmin)~+1OOt(3Omin),lCOCy

TazT6$C, NKRK, pI00Oh

Ta=(Tng-maximum ratings),r-1030h

Ta=(Tstg-minimun ratings),r IOCOh

Ta=25’C,Ie(IF-maximum ratings),~lOOOh

I

15 000m/s',0.5ms,3timesJ~X,iY~Zdirection

ZOOmis', 100-2

Refer to the attached sheetgage 12’13 1 time

OOO-100Wsweepfor ZOmin.,4times/yY,Z

Confidence level: 90%

S~plCS

n=22, c4

n=22,c=4 10

n=22, c-0 10

n=22,C=tl IO

~n=22,c=q 10

n=ll,C=o 20

direction

n=I 1, C-0 z”

n=ll,C=o 20

10

Parameter

r

Forward voltage

Reverse cuneat

Luminous intensity

fiote I)Mcasuring conditioa is in accordance with specification.

(Note2)U.S.L. is shown by Upper Specification Limit.

Symbol

VF

IR

IV

Iv > The

Fail judgement criteria (Noted)

v,> U.S.L. x I.2

I,> U.S.L. ' 2.0

first

stage value X 1.5 or The Jirst stage value X 0.5 > Iv

Page 8

DG-991015

MODEL So.

5. hcoming insptc5on

5-I. lrq-mion method

A single sampling pla normal inspection level II based on IS0 2859-I shail be adopted

- -. “M.*y.wU “I yuYb”LA”Y YUY .aI..‘a”

I JaanS

1 PAGE

NO.

inspection items

Criteria

1 Openhon No light emission

2

3

4

5

6

7

8 Resin ff ash

Radiation color Not cmreicl

Taping Product inserted in reverse direction

Label Model number is not printed,or misprinted

Electro-opcical

characteristics

Not conforming to the specification

Outline dimensions Not conforming to the specifhion

Dust and flaw Effect to the specification

-..-. -

0.3mm

or greater &om the product

Defect

AQL

gg 0.1%

Page 9

6. Taping

61 Taping

6-I-LShape and dimension of tapc(TYP.)

MODEL No.

GMSWI95200X

DG-991015

Janf2??i99

P?rGE

a13

Parameter 1 Symbol lDimension

1 Thickness 1 t , 0.3 I

Thickness of the entire tit 1 tt 1

2.3 (With cover

% Mated : Carrier titpe...PS, Cover tape...Polyestcr

tape

Remarks

and

carrier tape

combined

Page 10

6-I-t.Shape and dimension of reel(lYP

MODEL No.

I

GMSW95200X

DG-991015

1 9113

Parameter

Diameter

Frange

Hub

Jotation for part name etc.

% Material : Reel...Polystyrene

Thickness

Inner mace

EXtf

Emal diameter

Soindle hole diameter I C

Key slit f

I

direction

Width 1 E t r--

Depth

I

1 Symbol] Dimension 1 Remarks

rmm--.)

A d I78

t

w IO Dimensinn of shaft core

I

1 s q&o 1

) u t

(Labeling on one side of flange.@art name,quantity,Iot No.)

1.5

- --_--- ---- --

d13 t I

t

2.0

4.5

I

I

I

I

I

Page 11

6-I-3.Taping specification

(1) Lead tape:

End

DG-991015

MODEL No.

GM5WT95200A

~~11 out I-> Bigining

sanRa/99

PAGE

10113

Leading

10 plch or mare

Stuffed

Empty

10 pfi;h or nore ' 40-50 pith

(2) Cover tape stxngth against peeJing:F=O. 148N( 6 =lO”or less)

Cover taue

uuuuuuuduuuu

w Forward

Carrier tape

Tape speed : 5mm/s

(3) Tape strength against bending:

The rndius ofbendiug circle should be 30mm or more.

Lfit is less than 3Omm the cover may peel.

(4) Jointing of tape: There should not be joint

of

cover tape or carrier tape.

(5) Quantity per reel: Average 2,OOOpcs. per reel

(6) Product wcighr

Approx. 0.03 g

(7) others: 0 Ap parent defect of product ahorrId not be packed and product should not upset.

0 There should not be missing above continuous three products.

@ Products should be easily taken out.

@ Products should not be aaached to the cover tape at peeling.

6-2. Label for reel

C~lJwr9s20M

QUA.TY 2000

Lot number *--r

LOT No. KWBHOI

-=EIAJ C-3> WE M JAPAN

* :Lot number indication

0 Production plant code(to be indicated alphabetically)

@ Production Iot(single or double figures)

0 Year of productioa(tbe last two figures of the year)

@ Month of production

(to be indicated alphabeticaIly with Januuy corresponding to A)

0 Date of producdon(01 - 3 1)

- Model number

- Luminous rank and dominant waveIength rank

+ Production country

Page 12

6-3. Dampproof package

In other to avoid the absorption of humidir)i h tnnspo~ and storage.

the devices are packed in ahxninum sleeve.

r

Do-9910 15

MODELNo.

Label

GWWr952OOX

JwW99

PAGZ

11113

6-El.Strage conditions

Temperature : 5 to 30°C Humidity : less than 6O%RH

6-3-2.Treatment after opening

(1) Please make a soldering within 2 days ah opening under following condition;

Tempezmre : 5 co 30°C Humidity : less than 6O%RH

(2) In case the devices are not used for a long he after opening .the storage in dry box is recommendable.

Or it is

better

to repack he devices with a desicative by the sealer and put them in the some storage

conditions as 7-3- 1. Then they should k ?sed within 2 days.

(3) Please make a soldering afier a following h&king treatmeat if unused term should be over the conditions

of (2)

Reconunenclable conditions:

0 in taping

Temprature:6O”C to 65”C,Time:36 to AS hours

Q in individual (on PWl3 or metallic tray)

Tempmture: 100°C ,Time:2 to 3 houn

Page 13

7. Soldering

7-IRedow SOldeIiq

(1) It is

not

rc=ornmended to exceed the soidering temperarum and time

Caused by subsnare bend or the other mechanical stress &.ng reflow soldering

may happen gold wire disconnection etc. Therefore please

check

and study your

solder reflow machine’s best condition.

(2) Reflow soldering temperamre prome to be done under the following condition.

to be done under the following condition.

MAX 250

GM5%-i95200A

~IOWU

below.

1 1203

Time (s)

Recommendable Thermal Model

(4) Rccommcndable Metal Mask pattern for sLxen print

Recommend O.tmm to 03mm thickness metal mask

for screen print. Caused by solder reflow condition,

solder

paste, substrate and the other martial etc.,

my change solderbility.

Please check and study actual solderbihry before

usage.

Recommended solder pattern

7-2.Manual soldering

(1) It ia recommended to keep the soldering iron temperature at 295x (soldering iron

power ccnsumption 2Ow> and not to solder more than once or for over 3 seconds.

(2) When using a soldering iron, care must be taken not to damage the package.

(Pay attention not to allow any under stress or heat on package.)

7-3. Dip soldering method

To be done under the following condition.

Re-heat temp. : 80 to 120 “c

time : 30 to 120 seconds

Soldering temp. : Max. 260%

: within 5 seconds

time

Center of the product

Page 14

8. Precautions for use

8-1. Precautions matters for designing circuit

(l)This product is not designed as electromagnetic and ionized-particle

diari~n

resistant

UThis LED device applies blue LED & Borescent mattrial to emit white &ht. Therefore, dependhrg on the

vatue

of

operation current, tone of the color may channp slightly. Please check the tone under actual usage

condition in advance.

8-2. Cleaning method

(1) Solvent cleaning

Recommend conditions:

(2) Ultrasonic cIeaning

The affect on the device from ultrasonic bath, uIbasonic output, duration, board size and device mounting method.

Test the cleaning method under actual conditions and cheek for abnotmahties before aotual use.

(3) SoIVenb

Use only the folIowing types of solvent.

water, alcoho1, chIorofluorocabon-based solvent when c!eaning is necessary.

Recommend conditions: RT. 40KHz, 3OW/l, 3 to 5 minutes

9. Environrnenr

9-I. Ozonosphere destructive chemicals.

(I) The device doesn’t contain following substance.

(2) The device doesn’t have a production Line whose process requires foIlowing substance.

Restricted part: CFCa,haIones,CCI~,TtichIoroethane.(MethychIorofotm)

0 Solvent temperature is not more than 45 “c. @ Immersion up to 3 &mites.

9-Z. Bm& non-burning materials

The device doesn’t contain bromic non-burning materisIs(PBBOs,PBBs)

Loading...

Loading...