Page 1

GDC21D601

32-Bit RISC MCU

Ver 1.6

HDS-GDC21D601-9908 / 10

Page 2

GDC21D601

The information contained herein is subject to change without notice.

The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by Hyundai for any infringements of patents or other rights of the third parties

which may result from its use. No license is granted by implication or otherwise under any patent or

patent rights of Hyundai or others.

These Hyundai products are intended for usage in general electronic equipment (office equipment,

communication equipment, measuring equipment, domestic electrification, etc.).

Please make sure that you consult with us before you use these Hyundai products in equipment which

require high quality and / or reliability, and in equipment which could have major impact to the welfare of

human life (atomic energy control, airplane, spaceship, traffic signal, combustion control, all types of

safety devices, etc.). Hyundai cannot accept liability to any damage which may occur in case these

Hyundai products were used in the mentioned equipment without prior consultation with Hyundai.

Copyright 1999 Hyundai Micro Electronics Co.,Ltd.

All Rights Reserved

3

Page 3

GDC21D601

TABLE OF CONTENTS

Section 1. Overview.....................................................................................................................8

1. General Description..............................................................................................................8

2. Feature................................................................................................................................10

3. Package..............................................................................................................................12

4. Pin Assignment...................................................................................................................13

5. Pin Descriptions..................................................................................................................15

Section 2. System Architecture ................................................................................................20

1. Internal Bus Architecture.....................................................................................................20

2. Arbiter .................................................................................................................................20

3. System Decoder .................................................................................................................21

4. Memory Map.......................................................................................................................21

5. Memory Format...................................................................................................................22

6. Boot Mode...........................................................................................................................22

7. Multi-Function Pin ...............................................................................................................23

Section 3. ARM720T Core..........................................................................................................24

1. General Description............................................................................................................24

2. Feature................................................................................................................................24

3. Core Block Diagram............................................................................................................26

Section 4. DRAM Controller......................................................................................................27

1. General Description............................................................................................................27

2. Hardware Interface and Signal Description ........................................................................28

3. Functional Description ........................................................................................................31

4. Register Description............................................................................................................34

Section 5. On-Chip SRAM .........................................................................................................37

1. General Description............................................................................................................37

2. Signal Description...............................................................................................................37

3. Function Description...........................................................................................................37

Section 6. Static Memory Controller........................................................................................38

1. General Description............................................................................................................38

2. Signal Description...............................................................................................................39

3. Functional Description ........................................................................................................43

4. Programmer’ s Model..........................................................................................................45

4

Page 4

GDC21D601

Section 7. MCU Controller.........................................................................................................48

1. General Description............................................................................................................48

2. Signal Description...............................................................................................................48

3. Register Description............................................................................................................49

Section 8. Power Management Unit.........................................................................................54

1. General Description............................................................................................................54

2. Hardware Interface and Signal Description ........................................................................55

3. Operation Modes ................................................................................................................56

4. Register Description............................................................................................................58

5. Power Management Unit Register Map..............................................................................63

6. Test Mode Guide for MCU..................................................................................................64

7. Signal Timing Diagram........................................................................................................66

Section 9. Watchdog Timer.......................................................................................................68

1. General Description............................................................................................................68

2. Hardware Interface and Signal Description ........................................................................69

3. Watchdog Timer Introduction .............................................................................................71

4. Watchdog Timer Operation ................................................................................................72

5. Watchdog Timer Memory Map ...........................................................................................74

6. Watchdog Timer Register Descriptions..............................................................................75

7. Examples of Register Setting..............................................................................................77

Section 10. Interrupt Controller................................................................................................81

1. General Description............................................................................................................81

2. Hardware Interface and Signal Description ........................................................................82

3. Interrupt Controller..............................................................................................................84

4. Interrupt Controller Memory Map........................................................................................86

5. Interrupt Controller Register Descriptions...........................................................................87

Section 11. Real Time Clock .....................................................................................................91

1. General Description............................................................................................................91

2. Signal Description...............................................................................................................92

3. Hardware Interface .............................................................................................................93

4. Functional Description ........................................................................................................94

5. Real Time Clock Memory Map ...........................................................................................95

6. Real Time Clock Register Descriptions..............................................................................95

5

Page 5

GDC21D601

Section 12. General Purpose Timer Unit .................................................................................96

1. General Description............................................................................................................96

2. Hardware Interface and Signal Description ........................................................................97

3. General Purpose Timer Unit Introduction.........................................................................100

4. General Purpose Timer Unit Operation............................................................................101

5. General Purpose Timer Unit Memory Map.......................................................................102

6. General Purpose Timer Unit Register Descriptions..........................................................104

7. Examples of Register Setting............................................................................................108

Section 13. PIO.........................................................................................................................111

1. General Description..........................................................................................................111

2. Signal Description.............................................................................................................112

3. Hardware Interface ...........................................................................................................115

4. Functional Description ......................................................................................................116

5. Programmer’ s Model........................................................................................................117

Section 14. Synchronous Serial Peripheral Interface...........................................................118

1. General Description..........................................................................................................118

2. Signal Description.............................................................................................................119

3. Hardware Interface ...........................................................................................................120

4. Functional Description ......................................................................................................121

5. Register Memory Map.......................................................................................................123

6. SSPI Data Clock Timing Diagram.....................................................................................124

Section 15. UART.....................................................................................................................125

1. General Description..........................................................................................................125

2. Features............................................................................................................................125

3. Signal Description.............................................................................................................126

4. Internal Block Diagram......................................................................................................129

5. Registers Description........................................................................................................130

Section 16. Smart Card Interface............................................................................................142

1. General Description..........................................................................................................142

2. Signal Description.............................................................................................................143

3. Hardware Interface ...........................................................................................................144

4. Functional Description ......................................................................................................145

5. Programmer’ s Model........................................................................................................146

6

Page 6

GDC21D601

Section 17. I2C Controller........................................................................................................149

1. General Description..........................................................................................................149

2. I2C Controller Key Features..............................................................................................150

3. I2C Controller Clocking and Pin Functions........................................................................150

4. I2C Master Mode Transmit / Receive Process..................................................................150

5. I2C Restart Capability (Combined Mode)..........................................................................151

6. I2C Controller Programming Model...................................................................................152

7. I2C Module Signal Description ..........................................................................................154

8. Hardware Interface ...........................................................................................................155

9. Register Memory Map.......................................................................................................156

Section 18. Direct Memory Access Controller ......................................................................157

1. General Description..........................................................................................................157

2. Signal Description.............................................................................................................158

3. Programmer’ s Model........................................................................................................159

4. Address Modes.................................................................................................................163

Section 19. Debug and Test Interface....................................................................................167

1. General Description..........................................................................................................167

2. Software Development Debug and Test Interface............................................................167

3. Test Access Port and Boundary Scan..............................................................................167

Section 20. Electrical Ratings.................................................................................................169

1. Absolute Maximum Ratings..............................................................................................169

2. Thermal Characteristics....................................................................................................169

3. D.C Electrical Characteristics ...........................................................................................169

APENDIX A. Register Map.......................................................................................................170

7

Page 7

GDC21D601

GDC21D601

32-Bit RISC MCU

Section 1. Overview

1. General Description

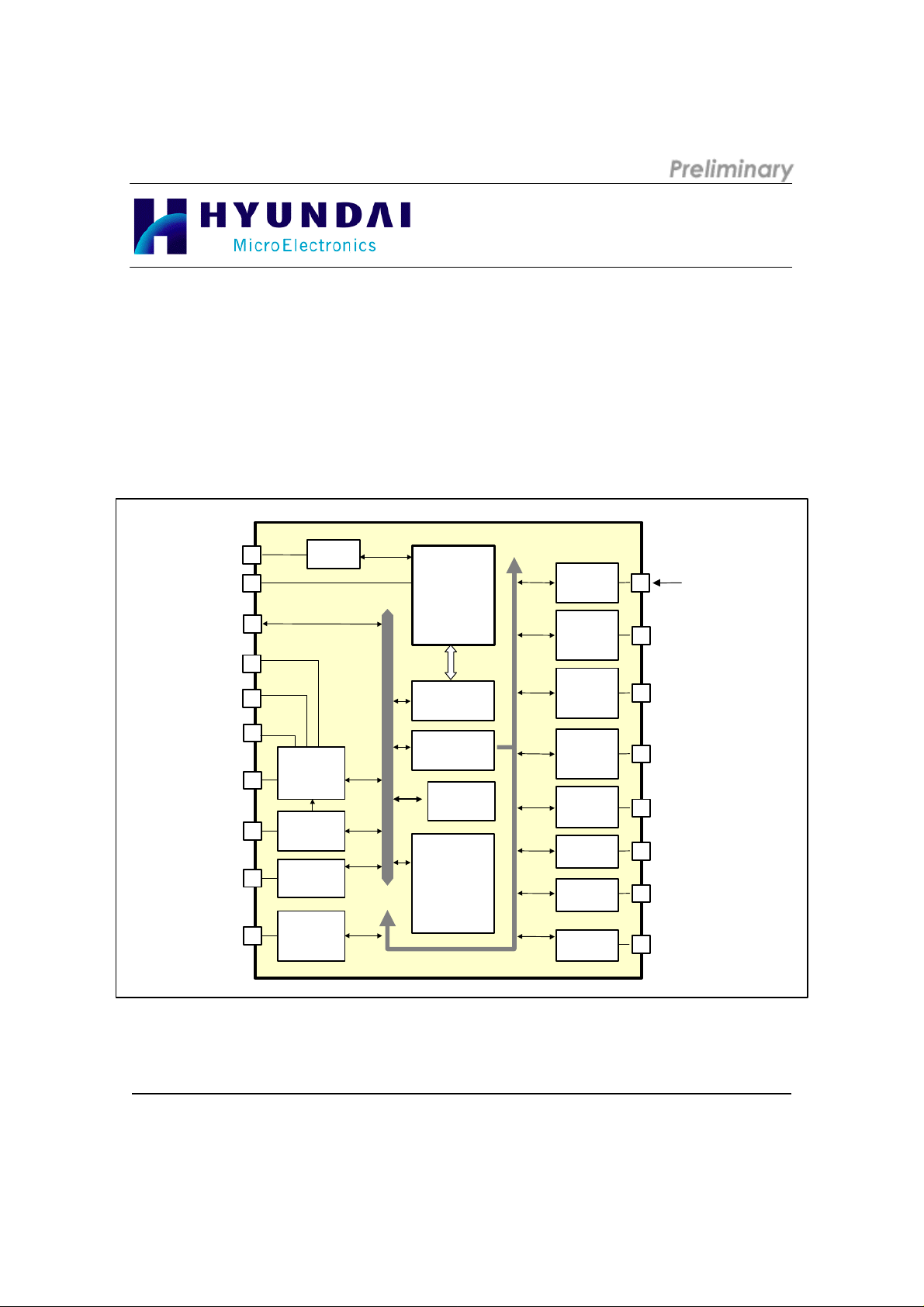

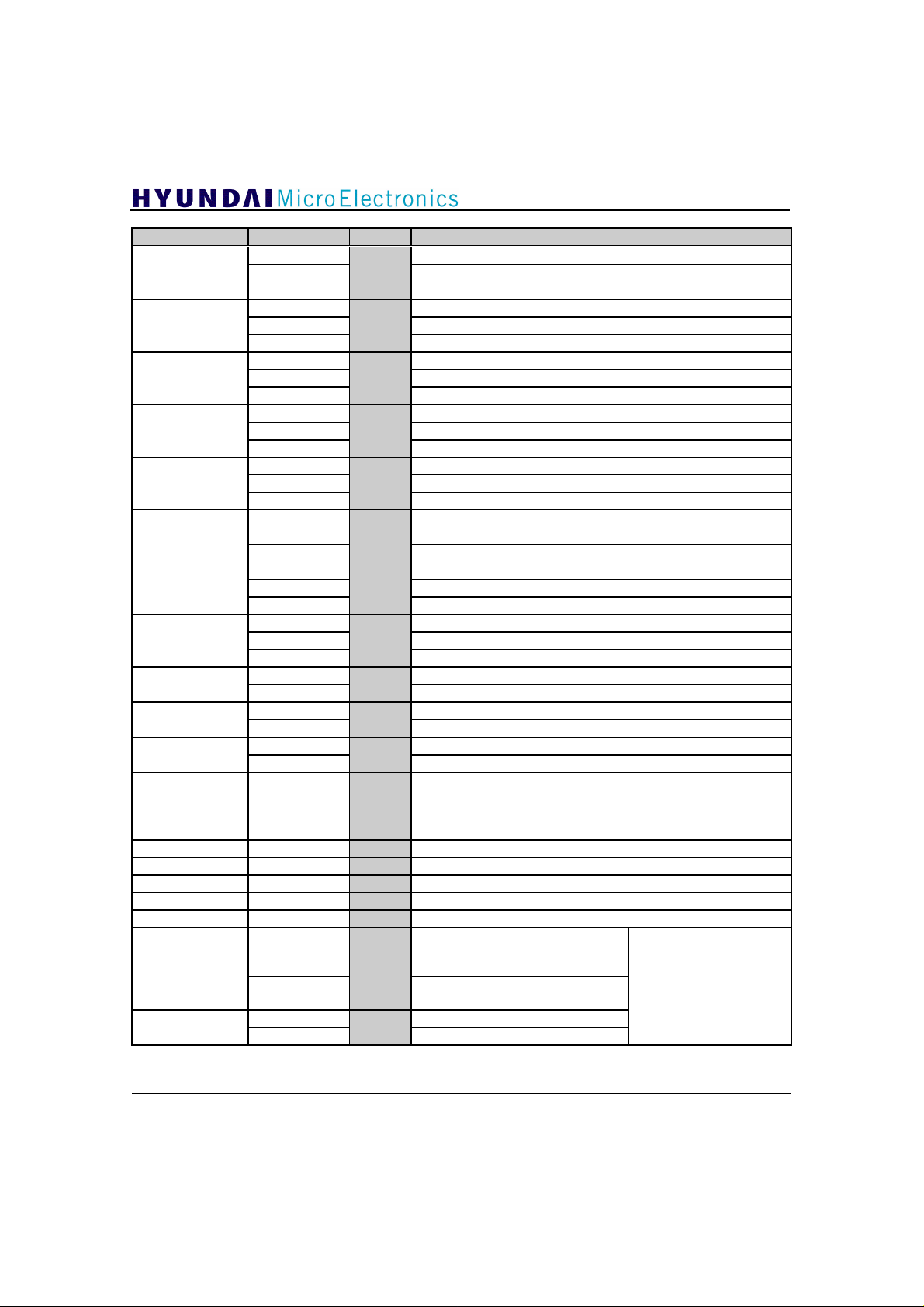

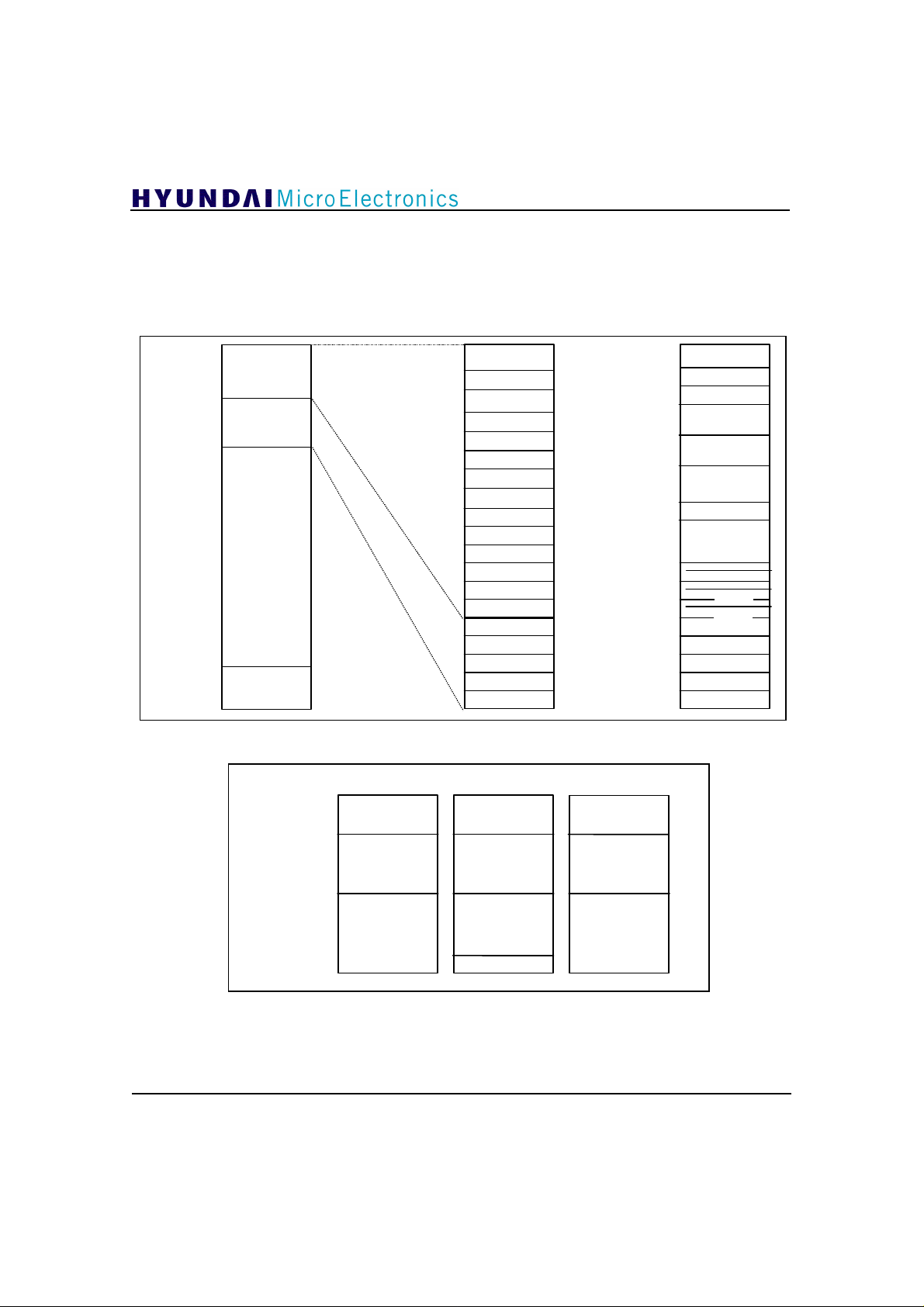

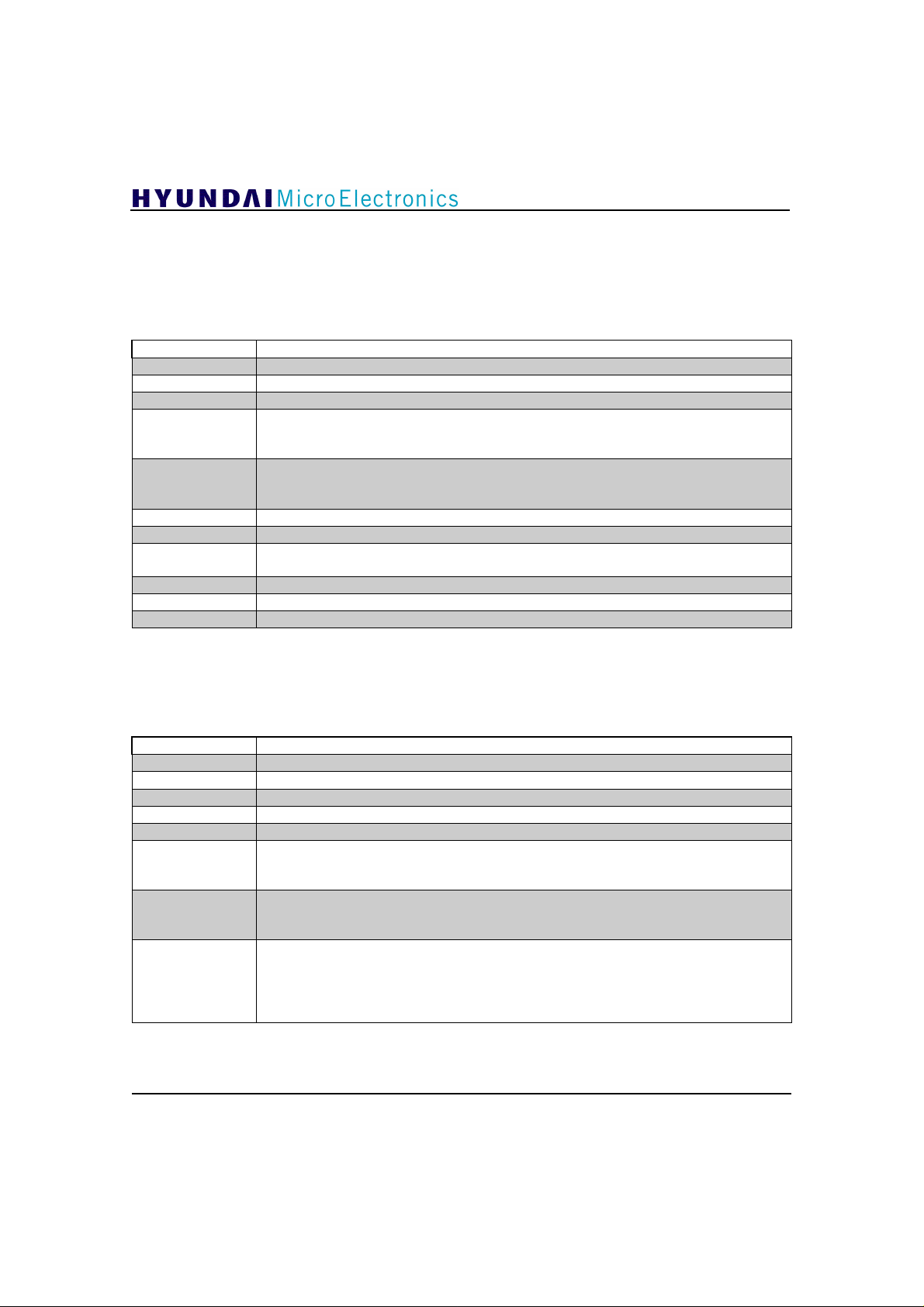

The GDC21D601 is the HME’s 32bit high performance microcontroller unit (MCU). The GDC21D601 contains

ARM720T, which is a general-purpose 32bit microprocessor, and extensive peripherals: 6 channel 16bit Timer,

Watch Dog Timer, 2 channel UART, 2 channel SSPI, 3 channel I2C, Programmable Priority Interrupt Controller,

10 port PIO, 2 channel DMA Controller, External Memory Controller and BUS Controller including chip select

logic.

ARM720T is a 32bit Microprocessor with the CPU of the ARM7TDMI, 8KB Cache, enlarged write buffer and

Memory Management Unit (MMU). The ARM720T is fully software compatible with the ARM processor family.

JTAG[0:4]

RESET

EXPRDY

EXPCLK

Mode[0:2]

DRAM OE, WE

WR[0:3], RD

RD&WR

BCLKOUT / PORT F[5]

BWAIT / PORT F[4]

A[0:31]

D[0:31]

nCS[4:7] / PORT H[4:7]

RAS[0:1] / PORT G[6:7]

CAS[0:3] / PORT G[0:3]

DREQ[0:1] / PORT G[2:3]

DACK[0:1] / PORT G[4:5]

IRQ[0:5] / PORT A[0:5]

nCS[0:3]

Bus

controller

DRAM

controller

DMA

controller

INT

controller

JTAG

ASB

APB

32-bit

ARM 720T

Core

AMBA Logic

APB Bridge

MCU

controller

Internal

SRAM

(8KB)

GDC21D601

RTC

Timer

UART

I2C

controller

SSPI

PIO

PMU

WDT

RTCin/Out (32.768kHz)

PORT B[0:7] / Timer TCIO / PWM

PORT C[0:3] / Timer TCIO / PWM

TCLK A,B,C / PORT C[4:6]

UART channel 0 , 1

SMART Card / UART channel 2

( PORT D[0:7] ,PORT E[0:4] )

I2C channel 0

I2C channel 1

I2C channel 2

SSPI 0, 1

( PORT E[5:7], PORT F[0:4] )

PORT I[0:7]

PORTJ[0:7]

NPDM

WDTOUT

Figure. 1 GDC21D601 Block Diagram

8

Page 8

GDC21D601

The general descriptions of the GDC21D601 like following :

• On-Chip Modular Architecture (using AMBA)

• Utilizes the ARM720T(“ARM7TDMI with 8Kbyte Cache and MMU”) 32bit RISC Family

• 8Kbyte internal SRAM

• support 8bit/16bit/32bit external Data bus width

• Eight Programmable Chip Select Outputs with EXPRDY

• Support Little and Big Endian memory format

• Low Power Consumption using Power Management Unit

• Fully static operation : Max. 80MHz

• Two 32bit DMA Controllers (External request only)

• Programmable Priority Interrupt Controller (6 external sources)

• Two DRAM Banks Support

• Six 16bit Multi Function Timers / Counters for General Purpose Applications

• One 8bit Watch Dog Timer (WDT)

• Real Time Clock : 32.768 KHz

• Three UARTs (Universal Asynchronous Receiver Transmitter) compatible with 16C550 UART, one

UART with Smart card interface

• Two SSPIs (Synchronous Serial Peripheral Interface) with FIFO

• Three I2C Master/Slave Controllers

• Programmable Input/Output (8bit 10 channel)

• 208 MQFP Package

9

Page 9

2. Feature

GDC21D601

• ARM720T Core

- This is an ARM7TDMI CPU core with

. 8KB cache

. enlarged write buffer

. MMU(Memory Management Unit)

. On-chip ICEbreaker debug support

. 32-bit x 8 hardware multiplier

. Thumb decompressor

. High-performance 32-bit RISC architecture

. High-density 16-bit insturction set

Enhanced ARM software toolkit

THUMB code is able to provide up to 65% of

the code size of ARM, and 160% of the

performance of an equivalent ARM processor

connected to a 16-bit memory system.

The MMU supports 4G bytes Virtual address.

The allocation of virtual addresses with

different task ID improves performance in task

switching operations with the cache enabled.

• DMA Controller

- Two Channels with identical function

- Four Gigabytes of address space

- 256 Kbytes transfers to the maximum

- Data Transfer unit : Byte, Half-word, Word

- Two kinds of Bus mode

. Burst mode

. Exception mode(Cycle steal)

- Two kinds of address mode

. Single address mode

. Dual address mode

- Two types of Transfer request source

. External I/O request

. Auto-request

- Two kind of fixed priority for channels

- Interrupted when the data transfers are

complete

• DRAM Controller

- DRAM access

- Support Word, Half-word, and Byte transaction

- CBR refresh in normal operation and self-refresh

in power-down mode

- Support programmable refresh rate

- Support various DRAM access time by setting

the wait count control register

• Static Memory Controller

- Chip Select up to 8 (Each Bank is 256 MByte)

- Exchangeable Chip Select Active High/Low

(CS6 and CS7 only)

- Little-Endian and Big-Endian Memory Support

- Programmable wait-state (up to 16 wait-state)

- Support External BUS Ready Strobe

- Support various type Bus Control timing

- Support Word, Half-word, and Byte transaction

• On-Chip SRAM

- 8k Bytes(2048x32)

- Asynchronous SRAM

- Can write 8/16/32bits data, and read 32bits data

• MCU Controller

- The Memory Map Structure Control signals

- DRAM Power-Down Request and Powr-Down

Ack signal

- Generate the Multi Function Pin control signals

- Device Code : $GDC601

• Power Management Unit

- Power On Reset, WD_OF Reset, and S/W Reset

- Status : RESET, Power Down, RUN_FAST,

RUN_SLOW

- Provide separated clock for each modules on

chip

- Provide BCLKOUT, WD_OF, Power-Down pins

for external devices

• Watch Dog Timer

- Watchdog timer mode & interval timer mode

- Eight counter clock sources

- Generate the Power Down reset or the Watch

Dog Overflow

• Interrupt Controller

- Asynchronous interrupt controller

- Six external interrupt

- Twenty internal interrupt

- Level or edge triggered

- Mask for each interrupt source

Request of IRQ, FIQ for each interrupt source

10

Page 10

GDC21D601

• Real Time Clock

- 32bit counter clocked by a 32.768KHz clock.

- 32bit match register

• Programmable Input Output

- up to 80 pin (8bit 10channel)

- Each pin can be configurable as either input or

output

• Timer

- 6 channel 16-bit up-count

- 4-internal pre-scaleable , 4-external input clock

. 1 interrupt per 1 channel

. 2 inout pin per 1 channel for input capture or

output compare

- Basic function :

. Compare match waveform output

. Input capture

. Match clear

. Capture clear

- Synchronous mode

. Synch. clear at two or more channel

. Synch. write at two or more channel

- PWM waveform output mode

• Synchronous Serial Interface

- Supports full duplex communication

- Sends and receives data continuously, using 16 x

8 bit FIFOs

- Built-in baud rate generator capable of

generation 4 clock rate

- Selectable clock source : either built-in buad-rate

generator or external clock

- 4 independent interrupts : transmit-end, rx-full,

tx-empty and tx-full

• UART

- 2 channel : UART only

. Compatible with 16550

. 16 byte each FIFO for TX / RX

. Start, stop and parity bit can be added or

deleted from/to serial data

. MODEM control functions (CTS, RTS, DSR,

DTR, RI and DCD )

. Fully programmable serial-interface

characteristics

: 5-, 6-, 7- or 8-bit characters

: even, odd or no-parity bit generation and

detection

: 1-, 1.5- or 2-stop bit generation and

detection

• SmartCard Interface

- 1 channel : Support SmartCard Interface

. Supports only asynchronous operation

. Supports cards that have internal reset

capability

. Supports cards that have an active low reset

input

. Supports cards that use the internal clock

. Generate the clock for a card expecting the

external clock

. Use the serial in/out ports for I/O

. Use the PIO ports for other interface signals

like RST, DETECT, etc

• I2C

- 3 channels

- Master / Slave function

- Programmable clock speed

- 8bit data transfer

- Slave clock stretch support

- Maskable interrupt

- Support clock rates up to 1.84MHz Baud

11

Page 11

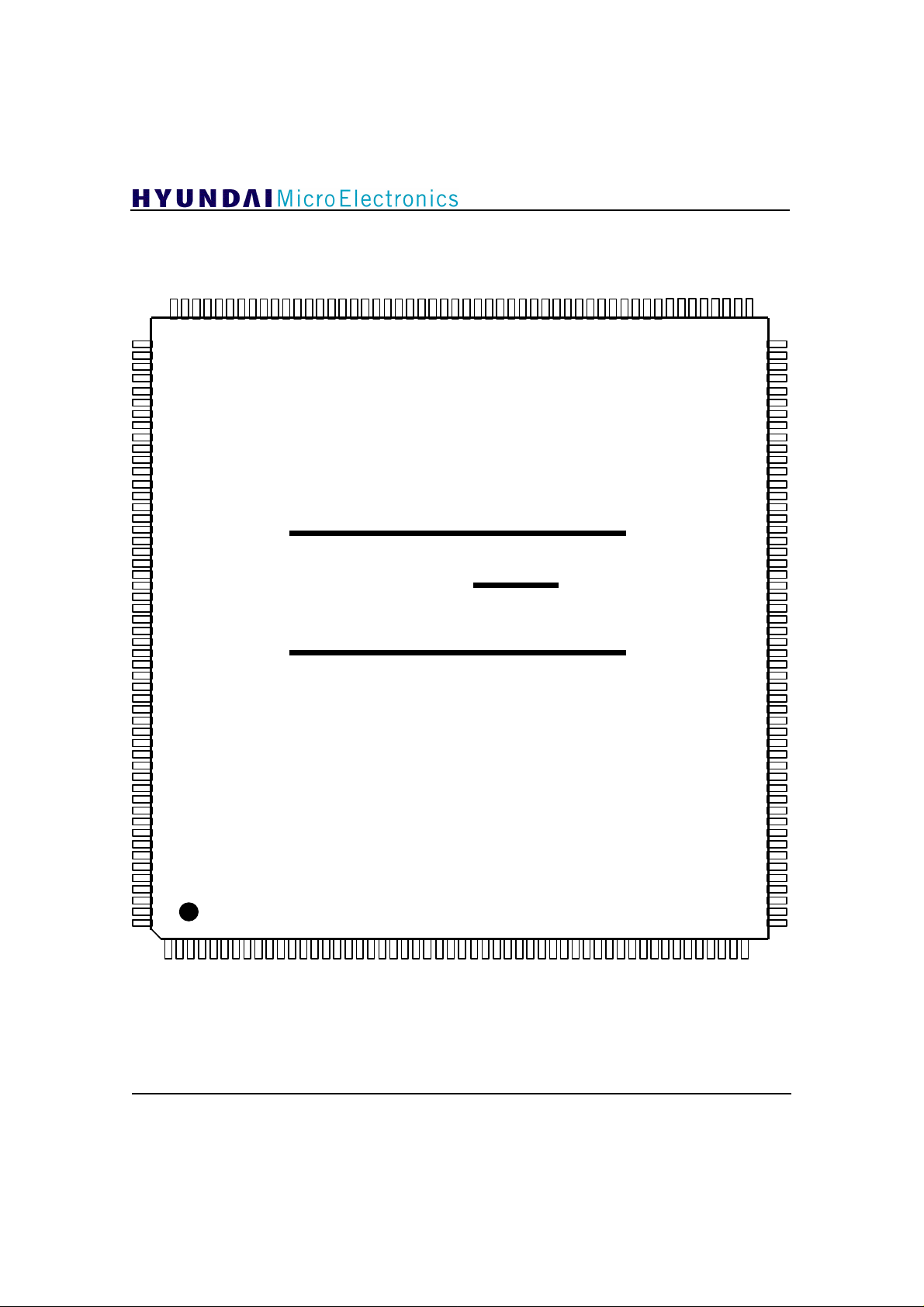

3. Package

9921

Rev. ES

12345678910111213141516171819202122232425262728293031323334353637383940414243

44

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

135

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

134

45464748495051

52

156

155

154

HME

32bit MCU

GDC21D601

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

ARM

GDC21D601R1

(Top View)

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

12

Figure 2. Package Outline

Page 12

GDC21D601

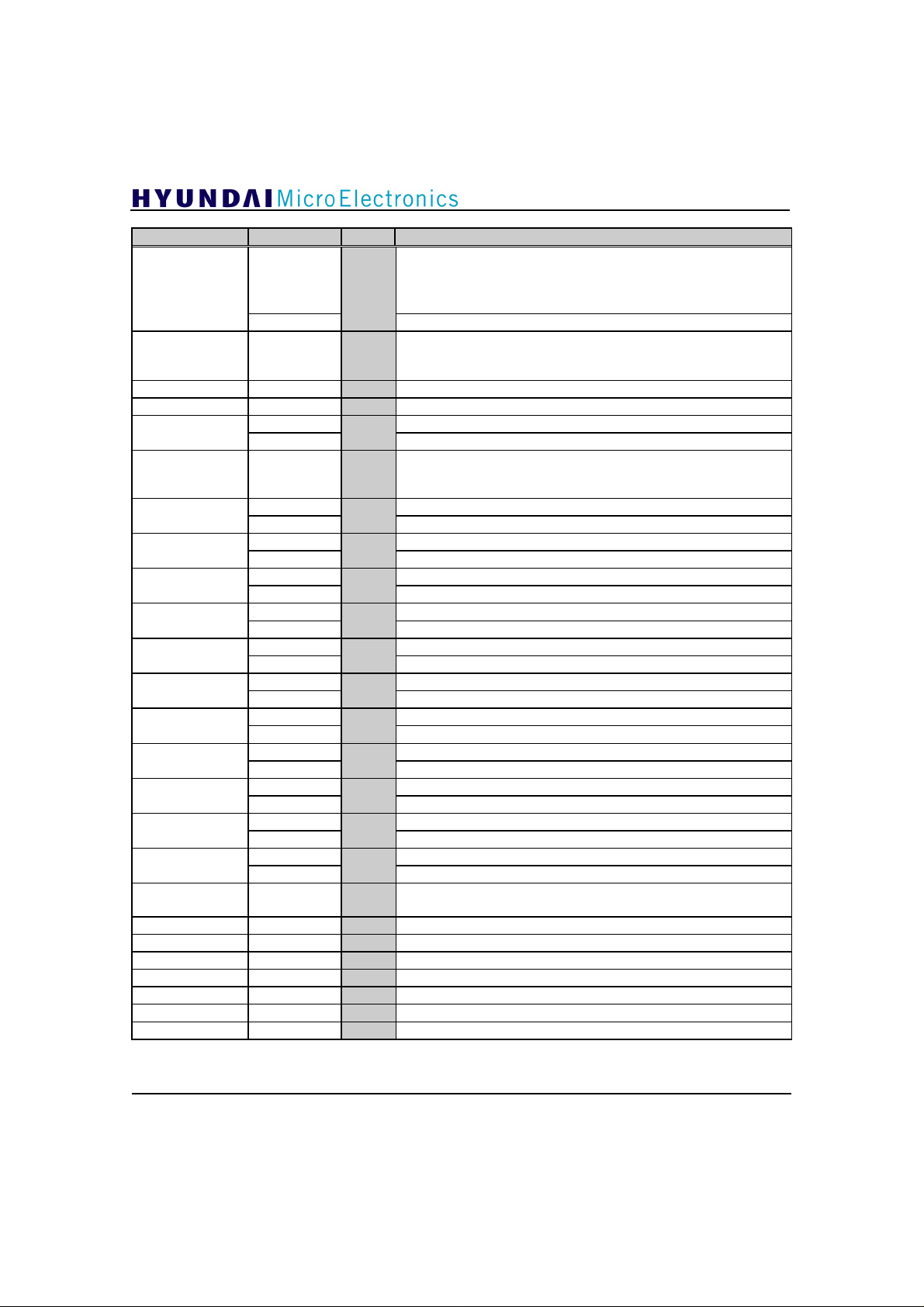

4. Pin Assignment

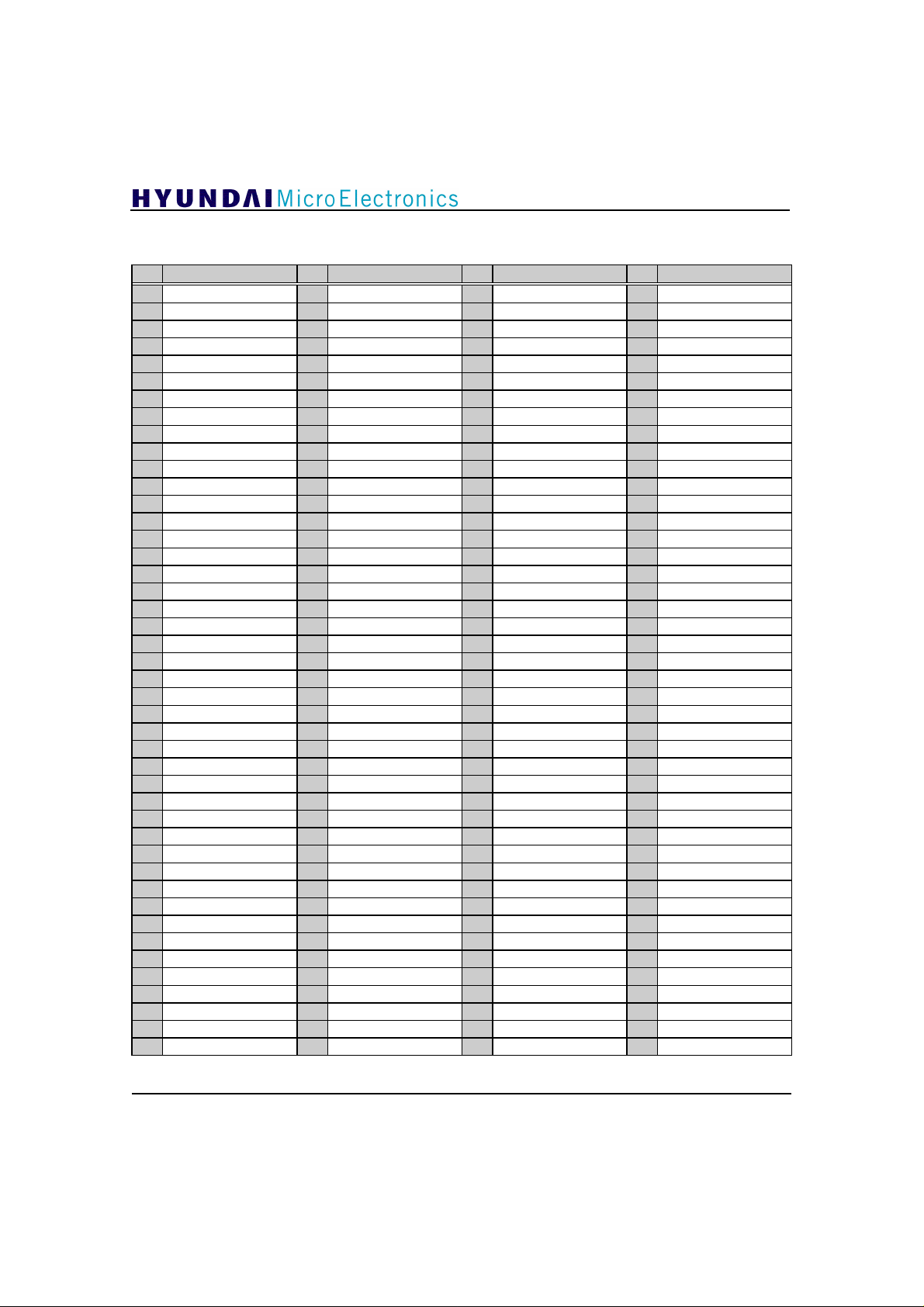

PIN NAME PIN NAME PIN NAME PIN NAME

1 A0 45 IRQ0/PA0 89 VDD 133 NRAS0/PG6

2 A1 46 VDD 90 SMDI/PE2 134 VSS

3 VDD 47 IRQ1/PA1 91 SMDO/PE3 135 NRAS1/PG7

4 A2 48 IRQ2/PA2 92 SMCLK/PE4 136 NCAS0/PH0

5 A3 49 IRQ3/PA3 93 VSS 137 NCAS1/PH1

6 A4 50 VSS 94 SIN0/ PE5 138 NCAS2/PH2

7 VSS 51 IRQ4/PA4 95

8 A5 52 IRQ5/PA5 96 SCLK0/PE7 140 VSS

9 A6 53 PA6 97 VDD 141 XOUT

10 A7 54 PA7 98

11 VDD 55 TCIOA0/PB0 99

12 A8 56 VDD 100

13 A9 57 TCIOB0/PB1 101 VSS 145 NDRAMWE

14 A10 58 TCIOA1/PB2 102

15 VSS 59 TCIOB1/PB3 103 SCS1/PF4 147 NWR0

16 A11 60 VSS 104 BCLKOUT/PF5 148 NWR1

17 A12 61 TCIOA2/PB4 105 NFIQOUT/PF6 149 NWR2

18 VDD 62 TCIOB2/PB5 106 NIRQOUT/PF7 150 VDD

19 A13 63 TCIOA3/PB6 107 VDD 151 NWR3

20 A14 64 VDD 108 I2CSDA0 152 NRD

21 A15 65 TCIOB3/PB7 109 I2CSCL0 153 RDNWR

22 VSS 66 PC0/TCIOA4 110 I2CSDA1 154 VSS

23 A16 67 PC1/TCIOB4 111 VSS 155 NEXPRDY

24 A17 68 VSS 112 I2CSCL1 156 EXPCLK

25 A18 69 PC2/TCIOA5 113 I2CSDA2 157 NCS0

26 VDD 70 PC3/TCIOB5 114 I2CSCL2 158 NCS1

27 A19 71 PC4/TCLKA 115 VDD 159 NCS2

28 A20 72 VDD 116 Mode0/TREQA 160 VDD

29 A21 73 PC5/TCLKB 117 Mode1/TREQB 161 NCS3

30 VSS 74 PC6/TCLKC 118 Mode2/TACK 162 NCS4/PH4

31 A22 75 PC7/TCLKD 119 VSS 163 NCS5/PH5

32 A23 76 RXD0/PD0 120 UCLKOUT 164 VSS

33 WDTOUT 77 VSS 121 UCLKIN 165 CS6/PH6

34 NPDN 78 TXD0/PD1 122 VDD 166 CS7/PH7

35 VSS 79 RXD1/ PD2 123 TEST 167 D31/PJ7

36 RTCOSCIN 80 TXD1/PD3 124 NEXTREQ/PG0 168 VDD

37 RTCOSCOUT 81 VDD 125 NRESET 169 D30/PJ6

38 VDD 82 NCTS/ PD4 126 VSS 170 D29/PJ5

39 NTRST 83 NDSR/ PD5 127 NEXTACK/PG1 171 D28/PJ4

40 TDI 84 NDCD/ PD6 128 NDREQ0/PG2 172 VSS

41 TCK 85 VSS 129 NDACK0/PG3 173 D27/PJ3

42 VSS 86 NRI/ PD7 130 VDD 174 D26/PJ2

43 TDO 87 NDTR/PE0 131 NDREQ1/PG4 175 D25/PJ1

44 TMS 88 NRTS/PE1 132 NDACK1/PG5 176 VDD

SOUT0/PE6

SCS0/PF0/MemByte0

SIN1/PF1/MemByte1

SOUT1/PF2

SCLK1/PF3

139 NCAS3/PH3

142 XIN

143 VDD

144 NDRAMOE

146 VSS

13

Page 13

GDC21D601

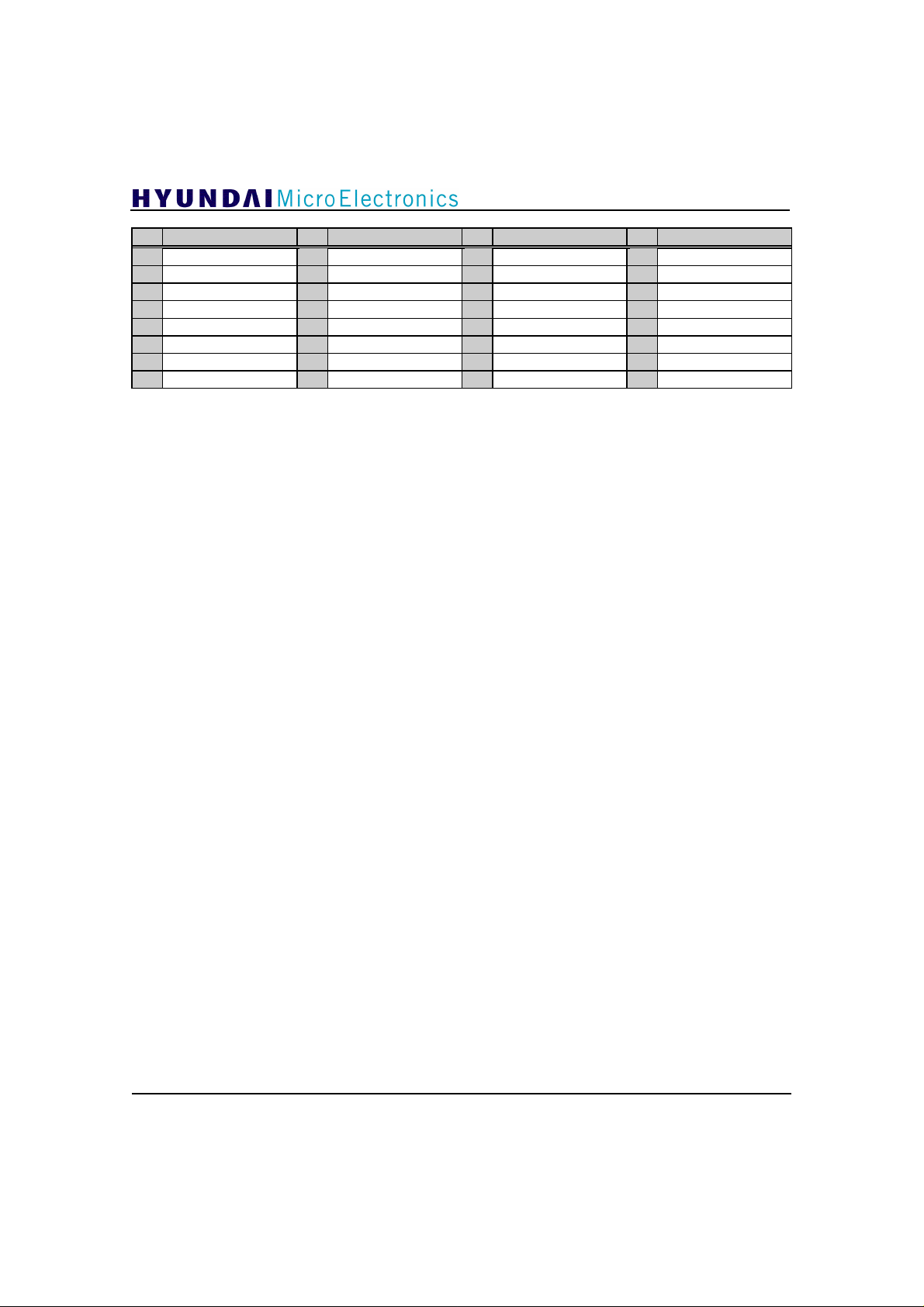

PIN NAME PIN NAME PIN NAME PIN NAME

177 D24/PJ0 185 VDD 193 VDD 201 VDD

178 D23/PI7 186 D17/PI1 194 D11 202 D5

179 D22/PI6 187 D16/PI0 195 D10 203 D4

180 D21/PI5 188 D15 196 D9 204 D3

181 VSS 189 VSS 197 VSS 205 VSS

182 D20/PI4 190 D14 198 D8 206 D2

183 D19/PI3 191 D13 199 D7 207 D1

184 D18/PI2 192 D12 200 D6 208 D0

14

Page 14

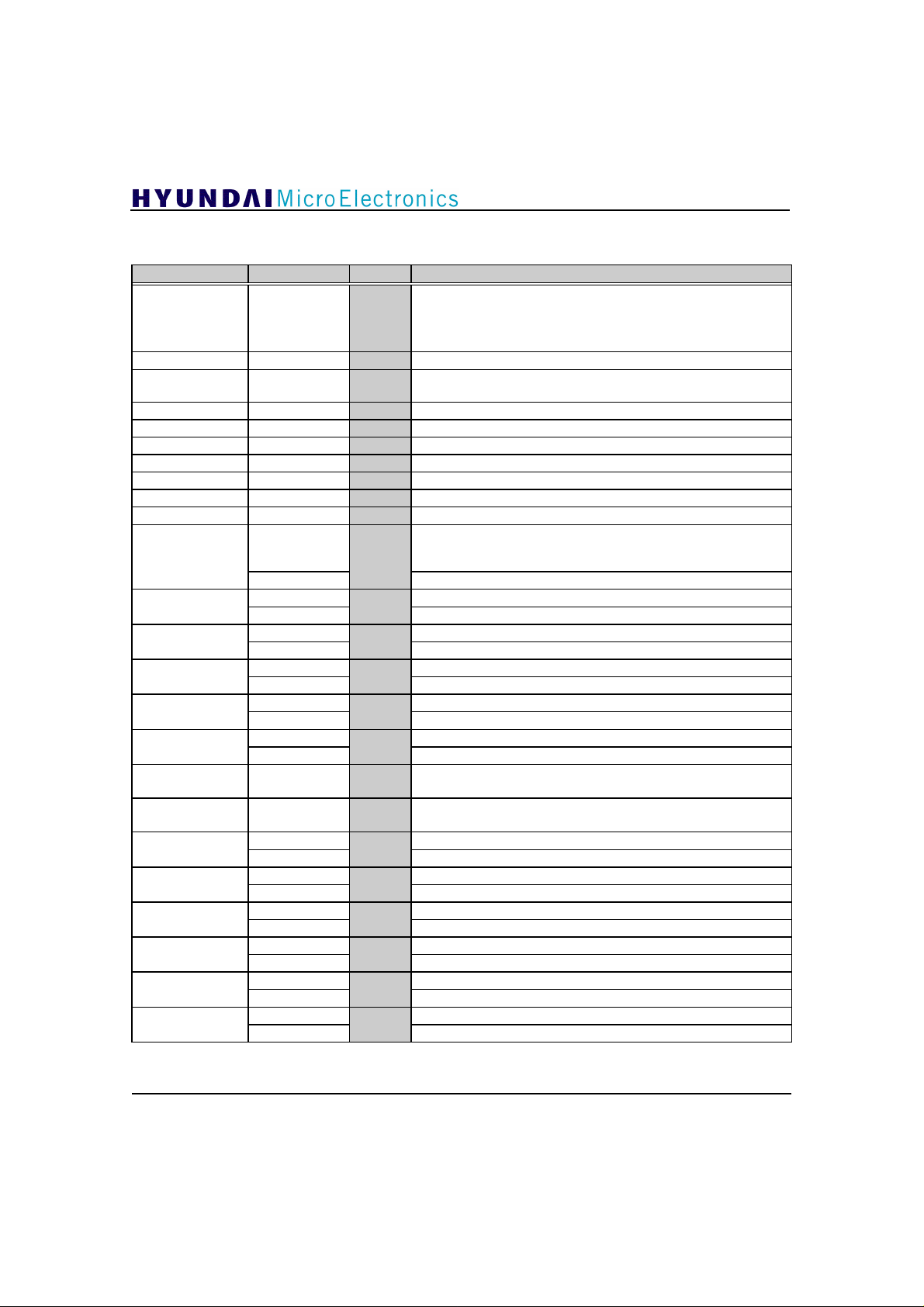

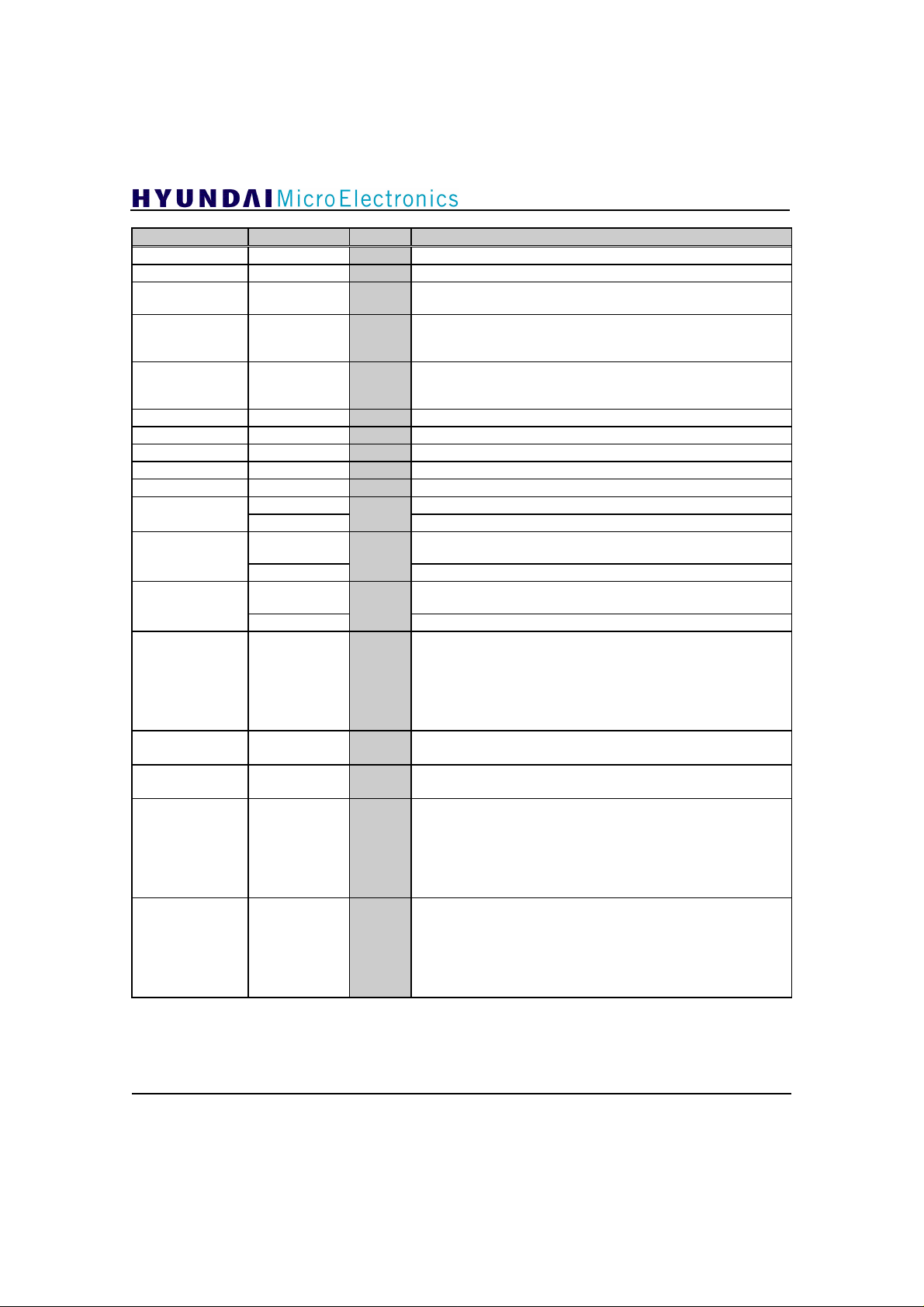

5. Pin Descriptions

PIN NUMBER PIN NAME TYPE DESCRIPTION

1~2, 4~6, 8~10,

12~14, 16~17,

19~21, 23~25,

27~29, 31~32

33 WDTOUT O Watch Dog Timer Overflow Output

34 NPDN O Power Down Signal from PMU block

37 RTCOSCIN I Real Time Clock Oscillator Input 32.768kHz

36 RTCOSCOUT O Real Time Clock Oscillator Output

39 NRST I JTAG Reset

40 TDI I JTAG Data Input

41 TCK I JTAG Clock Input

43 TDO O JTAG Data Output

44 TMS I JTAG Mode Signal

45

53 PA6 I/O PIO Port A[6]

54 PA7 I/O PIO Port A[7]

A[31:0] O Address Bus

Valid After RESET.

When it is LOW, MCU entered the power down mode. When HIGH, normal

IRQ0 External Interrupt Input 0, when PINMUX_PA[0] = 0

PA0

IRQ1 External Interrupt Input 1, when PINMUX_PA[1] = 047

PA1

IRQ2 External Interrupt Input 2, when PINMUX_PA[2] = 048

PA2

IRQ3 External Interrupt Input 3, when PINMUX_PA[3] = 049

PA3

IRQ4 External Interrupt Input 4, when PINMUX_PA[4] = 051

PA4

IRQ5 External Interrupt Input 5, when PINMUX_PA[5] = 052

PA5

TCIOA0 Timer Channel 0 Input Capture A, when PINMUX_PB[0] = 055

PB0

TCIOB0 Timer Channel 0 Input Capture B, when PINMUX_PB[1] = 057

PB1

TCIOA1 Timer Channel 1 Input Capture A, when PINMUX_PB[2] = 058

PB2

TCIOB1 Timer Channel 1 Input Capture B, when PINMUX_PB[3] = 059

PB3

TCIOA2 Timer Channel 2 Input Capture A, when PINMUX_PB[4] = 061

PB4

TCIOB2 Timer Channel 2 Input Capture B, when PINMUX_PB[5] = 062

PB5

I/O

Programmable I/O ports. Each pin can be mapped to specified

function pin name. (External IRQ0,IRQ1,…)

PIO Port A[0], when PINMUX_PA[0] = 1

I/O

PIO Port A[1], when PINMUX_PA[1] = 1

I/O

PIO Port A[2], when PINMUX_PA[2] = 1

I/O

PIO Port A[3], when PINMUX_PA[3] = 1

I/O

PIO Port A[4], when PINMUX_PA[4] =1

I/O

PIO Port A[5], when PINMUX_PA[5] = 1

Tbclk Clock Input for TIC test

Tfclk Clock Input for TIC test

I/O

PIO Port B[0], when PINMUX_PB[0] = 1

I/O

PIO Port B[1], when PINMUX_PB[1] = 1

I/O

PIO Port B[2], when PINMX_PB[2] = 1

I/O

PIO Port B[3], when PINMUX_PB[3] = 1

I/O

PIO Port B[4], when PINMUX_PB[4] = 1

I/O

PIO Port B[5], when PINMUX_PB[5] = 1

GDC21D601

15

Page 15

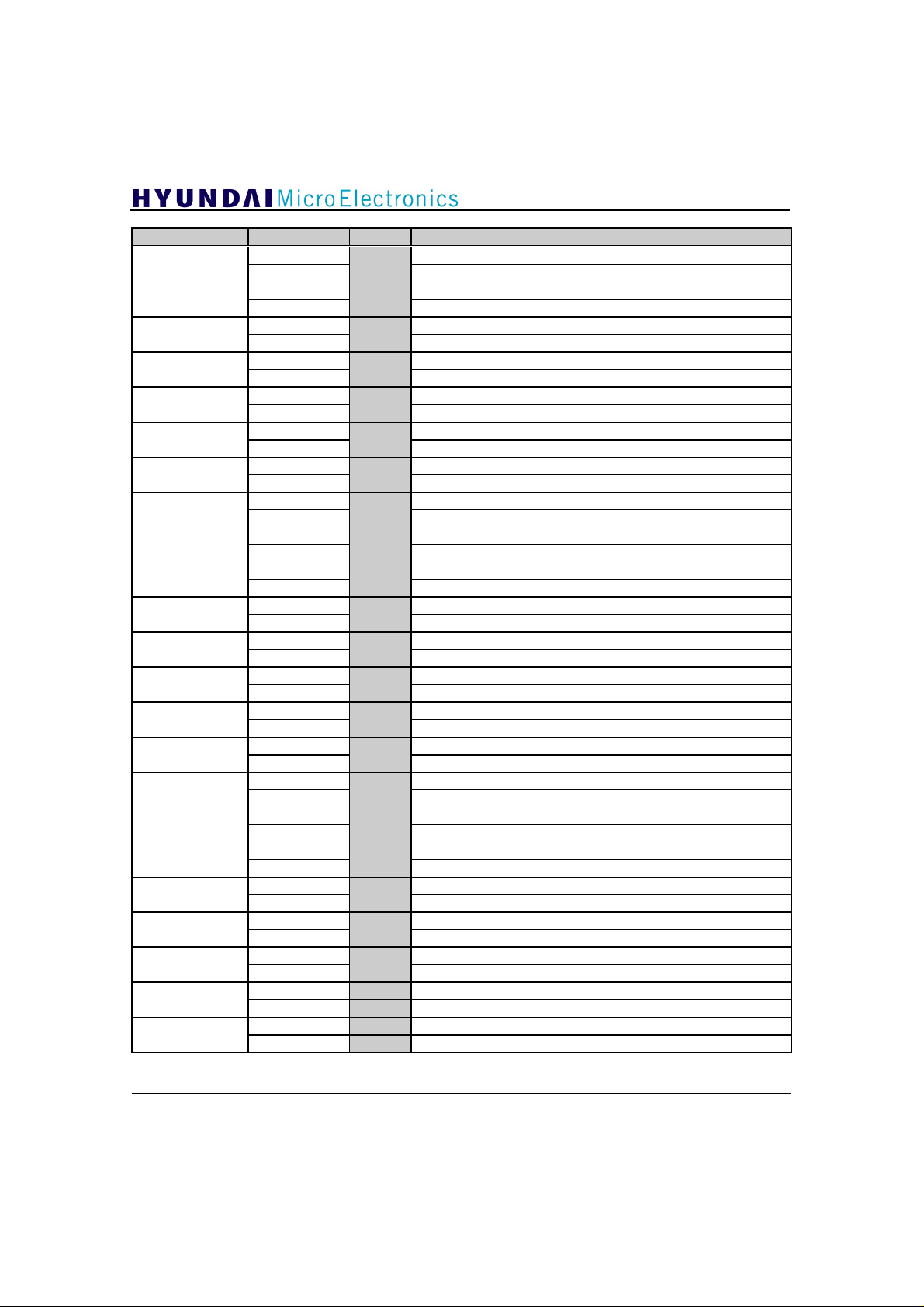

PIN NUMBER PIN NAME TYPE DESCRIPTION

TCIOA3 Timer Channel 3 Input Capture A, when PINMUX_PB[6] = 063

PB6

TCIOB3 Timer Channel 3 Input Capture B, when PINMUX_PB[7] = 065

PB7

PC0 PIO Port C[0], when PINMUX_PC[0] = 066

TCIOA4

PC1 PIO Port C[1], when PINMUX_PC[1] = 067

TCIOB4

PC2 PIO Port C[2], when PINMUX_PC[2] = 069

TCIOA5

PC3 PIO Port C[3], when PINMUX_PC[3] = 070

TCIOB5

PC4 PIO Port C[4], when PINMUX_PC[4] = 071

TCLKA

PC5 PIO Port C[5], when PINMUX_PC[5] = 073

TCLKB

PC6 PIO Port C[6], when PINMUX_PC[6] = 074

TCLKC

PC7 PIO Port C[7], when PINMUX_PC[7] = 075

TCLKD

RXD0 UART Channel 0 Receive Data, when PINMUX_PD[0] = 076

PD0

TXD0 UART Channel 0 Transmit Data, when PINMUX_PD[1] = 078

PD1

RXD1 UART Channel 1 Receive Data, when PINMUX_PD[2] = 079

PD2

TXD1 UART Ch 1 Transmit Data, when PINMUX_PD[3] = 080

PD3

NCTS UART Ch 1 Clear to Send, when PINMUX_PD[4] = 082

PD4

NDSR UART Ch 1 Data Set Ready, when PINMUX_PD[5] = 083

PD5

NDCD UART Ch 1 Data Carrier Detect, when PINMUX_PD[6] = 084

PD6

NRI UART Ch 1 Ring Indicator, when PINMUX_PD[7] = 086

PD7

NDTR UART C 1 Data Terminal Ready, when PINMUX_PE[0] = 087

PE0

NRTS UART Ch 1 Ready to Send Data, when PINMUX_PE[1] = 088

PE1

SMDI Smart Card Interface Data In, when PINMUX_PE[2] = 090

PE2

SMDO I/O Smart Card Interface Data Out, when PINMUX_PE[3] = 091

PE3 PIO Port E[3], when PINMUX_PE[3] =1

SMCLK I/O Smart Card Interface Clock Out, when PINMUX_PE[4] = 092

PE4 PIO Port E[4], when PINMUX_PE[4] = 1

I/O

PIO Port B[6], when PINMUX_PB[6] = 1

I/O

PIO Port B[7], when PINMUX_PB[7] = 1

I/O

Timer Channel 4 Input Capture A, when PINMUX_PC[0] = 1

I/O

Timer Channel 4 Input Capture B, when PINMUX_PC[1] = 1

I/O

Timer Channel 5 Input Capture A, when PINMUX_PC[2] = 1

I/O

Timer Channel 5 Input Capture B, when PINMUX_PC[3] = 1

I/O

External Timer Clock Source A, when PINMUX_PC[4] = 1

I/O

External Timer Clock Source B, when PINMUX_PC[5] = 1

I/O

External Timer Clock Source C, when PINMUX_PC[6] = 1

I/O

External Timer Clock Source D, when PINMUX_PC[7] = 1

I/O

PIO Port D[0], when PINMUX_PD[0] = 1

I/O

PIO Port D[1], when PINMUX_PD[1] =1

I/O

PIO Port D[2], when PINMUX_PD[2] = 1

I/O

PIO Port D[3], when PINMUX_PD[3] =1

I/O

PIO Port D[4], when PINMUX_PD[4] = 1

I/O

PIO Port D[5], when PINMUX_PD[5] = 1

I/O

PIO Port D[6], when PINMUX_PD[6] = 1

I/O

PIO Port D[7], when PINMUX_PD[7] =1

I/O

PIO Port E[0], when PINMUX_PE[0] = 1

I/O

PIO Port E[1], when PINMUX_PE[1] = 1

I/O

PIO Port E[2], when PINMUX_PE[2] = 1

GDC21D601

16

Page 16

PIN NUMBER PIN NAME TYPE DESCRIPTION

94

SIN0 SSI Channel 0 Data In, when PINMUX_PE[5] = 0

I/O

PE5 PIO Port E[5], when PINMUX_PE[5] =1

95

BPROT0

SOUT0 SSI Channel 0 Data Out, when PINMUX_PE[6] = 0

I/O

AMNA BPROT[0] Signal, when PINMUX_PE[8] = 1

PE6 PIO Port E[6], when PINMUX_PE[6] = 1

96

BPROT1

SCLK0 SSI Channel 0 Clock Out, when PINMUX_PE[7] = 0

I/O

AMBA BPROT[1] Signal, when PINMUX_PE[8] = 1

PE7 PIO Port E[7], when PINMUX_PE[7] =1

98

BLOK

SCS0 SSI Channel 0 Channel Control, when PINMUX_PF[0] = 0

I/O

AMBA BLOK Signal Out, when PINMUX_PE[8] = 1

PF0 PIO Port F[0], when PINMUX_PF[0] = 1

99

MemByte0

SIN1 SSI Channel 1 Data In, when PINMUX_PF[1] = 0

I/O

MemByte[0] Signal from EBI Block, when PINMUX_PF[8] = 1

PF1 PIO Port F[1], when PINMUX_PF[1] = 1

100

MemByte1

SOUT1 SSI Channel 1 Data Out, when PINMUX_PF[2] = 0

I/O

MemByte[1] Signal from EBI Block, when PINMUX_PF[8] = 1

PF2 PIO Port F[2], when PINMUX_PF[2] = 1

102

BTRANS0

SCLK1 SSI Channel 1 Clock Out, when PINMUX_PF[3] = 0

I/O

AMBA BTRANS[0] Signal, when PINMUX_PF[8] = 1

PF3 PIO Port F[3], when PINMUX_PF[3] = 1

103

BTRANS[1]

SCS1 SSI Channel 1 Channel Control, when PINMUX_PF[4] = 0

I/O

AMBA BTRANS[1] Signal, when PINMUX_PF[8] = 1

PF4 PIO Port F[4], when PINMUX_PF[4] =1

BWAIT

BCLKOUT AMBA BCLK Signal, when PINMUX_PF[5] = 0104

PF5

NFIQOUT AMBA NFIQ Signal, when PINMUX_PF[6] = 0105

PF6

NIRQOUT AMBA NIRQ Signal, when PINMUX_PF[7] = 0106

PF7

I/O

I/O

I/O

AMBA BWAIT Signal, when PINMUX_PF[8] = 1

PIO Port F[5], when PINMUX_PF[5] = 1

PIO Port F[6], when PINMUX_PF[6] =1

PIO Port F[7], when PINMUX_PF[7] = 1

108 I2CSDA0 I/O Data Signal for I2C Channel 0

Pins (108~110,112~114) are required to be pull-up externally.

When bus is free, this pin goes logical “HIGH”

After reset, SDA pins enter Idle state

109 I2CSCL0 I/O Clock Signal for I2C Channel 0

110 I2CSDA1 I/O Data Signal for I2C Channel 1

112 I2CSCL1 I/O Clock Signal for I2C Channel 1

113 I2CSDA2 I/O Data Signal for I2C Channel 2

114 I2CSCL2 I/O Clock Signal for I2C Channel 2

116

Mode0 Boot Mode0, when TEST pin = 0

I

By default, 32-bit access

( MCU can boot from 32- bit Memory)

TREQA

TREQA Signal for TIC Test,

when TEST pin = 1

Mode1 Boot Mode 1117

TREQB

I

TREQB Signal for TIC Test

Mode[0:1] = 00 32-bit

Mode[0:1] = 01 8-bit

Mode[0:1] = 10 16-bit

Mode[0:1] = 11 Reserved

GDC21D601

17

Page 17

GDC21D601

PIN NUMBER PIN NAME TYPE DESCRIPTION

118

120 UCLKIN I UART Clock Oscillator Clock Input

121 UCLKOUT O UART Clock Oscillator Clock Output

123 TEST I Test Input Pin, Select 116~118 pin as Boot Mode or TIC Signal

125 NRESET I System Power On Reset Input

142 XIN I System Clock Input (<80MHz)

141 XOUT O System Clock Oscillator Output

144 NDRAMOE O DRAM Output Enable

145 NDRAMWE O DRAM Write Enable

147 NWR0 O Write Enable 0 for Static Memory(Byte)

148 NWR1 O Write Enable 1 for Static Memory(Byte)

149 NWR2 O Write Enable 2 for Static Memory(Byte)

151 NWR3 O Write Enable 3 for Static Memory(Byte)

Mode 2 Boot Mode 2 (BigEndian Pin)

TACK

NEXTREQ External Master Request Bus Mastership, when PINMUX_PG[0] = 0124

PG0

NEXTACK Bus Granted Signal for External Master, when PINMUX_PG[1] = 0127

PG1

NDREQ0 DMA Channel 0 Request, when PINMUX_PG[2] = 0128

PG2

NDACK0 DMA Channel 0 Acknowledge, when PINMUX_PG[3] = 0129

PG3

NDREQ1 DMA Channel 1 Request, when PINMUX_PG[4] = 0131

PG4

NDACK1 DMA Channel 1 Acknowledge, when PINMUX_PG[5] = 0132

PG5

NRAS0 DRAM Bank #0 RAS Signal, when PINMUX_PG[6] = 0133

PG6

NRAS1 DRAM Bank #1 RAS Signal, when PINMUX_PG[7] = 0135

PG7

NCAS0 DRAM CAS0 Signal, when PINMUX_PH[0] = 0136

PH0

NCAS1 DRAM CAS1 Signal, when PINMUX_PH[1] = 0137

PH1

NCAS2 DRAM CAS2 Signal, when PINMUX_PH[2] = 0138

PH2

NCAS3 DRAM CAS3 Signal, when PINMUX_PH[3] = 0139

PH3

I/O

Big-endian Selection Pin, when this pin = 1(HIGH)

Note) When this pin is HIGH, External Data will be

transferred “Big-endian” format.

TACK Signal for TIC Test

UART block dedicated clock source supported.

(This clock source is used for UART and SMART Card Only)

I/O

PIO Port G[0], when PINMUX_PG[0] = 1

To ensure proper initialization after power is stable,

assert NRESET pin for at least 20µs

I/O

PIO Port G[1] = 1, when PINMUX_PG[1] = 1

I/O

PIO Port G[2], when PINMUX_PG[2] = 1

I/O

PIO Port G[3], when PINMUX_PG[3] = 1

I/O

PIO Port G[4], when PINMUX_PG[4] = 1

I/O

PIO Port G[5], when PINMUX_PG[5] = 1

I/O

PIO Port G[6], when PINMUX_PG[6] = 1

I/O

PIO Port G[7], when PINMUX_PG[7] = 1

I/O

PIO Port H[0], when PINMUX_PH[0] = 1

I/O

PIO Port H[1], when PINMUX_PH[1] = 1

I/O

PIO Port H[2], when PINMUX_PH[2] = 1

I/O

PIO Port H[3], when PINMUX_PH[3] = 1

External TTL oscillator input

18

Page 18

PIN NUMBER PIN NAME TYPE DESCRIPTION

152 NRD O Output Enable Signal for Static Memory

153 RDNWR O Read/Write Signal

155 EXPRDY I Ready Signal Input

When this pin is Low, current memory transfer extended.

156 EXPCLK O Clock Output Signal

Active only during external cycles.

Output is same phase and speed as the bus clock

157 NCS0 O Chip Select Signal for Bank #0

NCS pins are required to be Pull-up for proper operation.

All NCS pins are Active Low See Fig.1 memory Map(Section 2)

158 NCS1 O Chip Select Signal for Bank #1

159 NCS2 O Chip Select Signal for Bank #2

161 NCS3 O Chip Select Signal for Bank #3

162 NCS4 I/O Chip Select Signal for Bank #4, when PINMUX_PH[4] = 0

PH4 PIO Port H[4], when PINMUX_PH[4] = 1

165

166

167, 169~171,

NCS5 Chip Select Signal for Bank #5, when PINMUX_PH[5] = 0163

PH5

CS6 Chip Select Signal for Bank #6, when PINMUX_PH[6] = 0

PH6

CS7 Chip Select Signal for Bank #7, when PINMUX_PH[7] = 0

PH7

D[31:0] I/O Data Bus

I/O

PIO Port H[5], when PINMUX_PH[5] = 1

I/O

CS6 pin can be programmed active HIGH/LOW

PIO Port H[6], when PINMUX_PH[6] = 1

I/O

CS7 pin can be programmed active HIGH/LOW

PIO Port H[7], when PINMUX_PH[7] = 1

173~175, 177~180,

182~184, 186~188,

190~192, 194~196,

198~200, 202~204,

206~208

167, 169~171,

PJ[7:0] I/O PIO Port J[7:0], when PINMUX_PJ[7:0] = 1

173~175, 177

178~180, 182~184,

PI[7:0] I/O PIO Port I[7:0] , when PINMUX_PJ[7:0] = 1

186~187

3, 11, 18, 26, 38,

VDD I Power

46, 56, 64, 72, 81,

89, 97, 107, 115,

122, 130, 143, 150,

160, 168, 176, 185,

193, 201

7, 15, 22, 30, 35,

VSS I Ground

42, 50, 60, 68, 77,

85, 93, 101, 111,

119, 126, 134, 140,

146, 154, 164, 172,

181, 189, 197, 205

GDC21D601

19

Page 19

GDC21D601

Section 2. System Architecture

1. Internal Bus Architecture

The GDC21D601 take the advantage of the AMBA(Advanced Micro-controller Bus Architecture) as the internal

Bus Architecture. The AMBA specification defines an on-chip communication standard for designing highperformance embedded micocontrollers. Two distinct buses are defined within the AMBA:

- the Advanced System Bus (ASB)

- the Advanced Peripheral Bus (APB)

The AMBA ASB is for high-performance system modules. The modules connected to ASB are DRAM Controller,

Static Memory Controller, DMA Controller, On-Chip SRAM, ARM720T CPU Core, Arbiter, Decoder, APB

Bridge, and TIC.

The AMBA APB is for low-power peripherals. AMBA APB is optimized for minimal power consumption and

reduced interface complexity to support peripheral functions. The modules connected to APB are PIO, Interrupt

Controller, PMU, WDT, RTC, Timer, UART, SSPI, and I2C.

See also AMBA Specification Rev. D (ARM IHI 0001D), and AMBA Specification Rev. 2.0 (ARM IHI 0011A)

for detail.

2. Arbiter

The AMBA bus specification is a multi-master bus standard. As a result, a bus arbiter is needed to ensure that only

one bus master has an access to the bus at any particular point of time. Each bus master can request the bus; the

Arbiter decides which has the highest priority and issues a grant signal accordingly. The GDC21D601 can have the

four bus master: ARM720T CPU Core, DMA Controller, TIC, and External Bus Master.

Every system must have a default bus master which grants the use of bus during reset, when no other bus master

requires the bus. During Power On Reset, the arbiter will grant the use of bus to the default bus master and hold all

other grant signals inactive. The ARM720T Core, the default bus master will grant for the use of bus under the

following conditions: Reset, standby, power-down, and no other master requesting the bus

The arbiter processes the requests of the ownership of the ASB and grants one ASB master according to the

arbitration scheme. The arbitration scheme of this implementation is a simple priority encoded scheme where the

highest priority master requesting the ASB is granted. The priority order is as follows:

Case 1) Aripri = ‘0’

1. TIC

2. DMA

3. External BUS Master

4. ARM (default bus master)

Case 2) Aripri = ‘1’

1. TIC

2. External BUS Master

3. DMA

4. ARM (default bus master)

20

Page 20

GDC21D601

3. System Decoder

The decoder in an AMBA system is used to perform a centralized address decoding function, which gives two

main advantages:

- It improves the portability of peripherals, by making them independent of the system memory map.

- It simplifies the design of bus slaves, by centralizing the address decoding and bus control functions.

The decoder performs three main tasks:

- address decoder

- default transfer response

- protection unit

The decoder generates a select signal for each slave on the ASB bus and, under certain circumstances, will not

select any slaves and provide the transac-tion response itself.

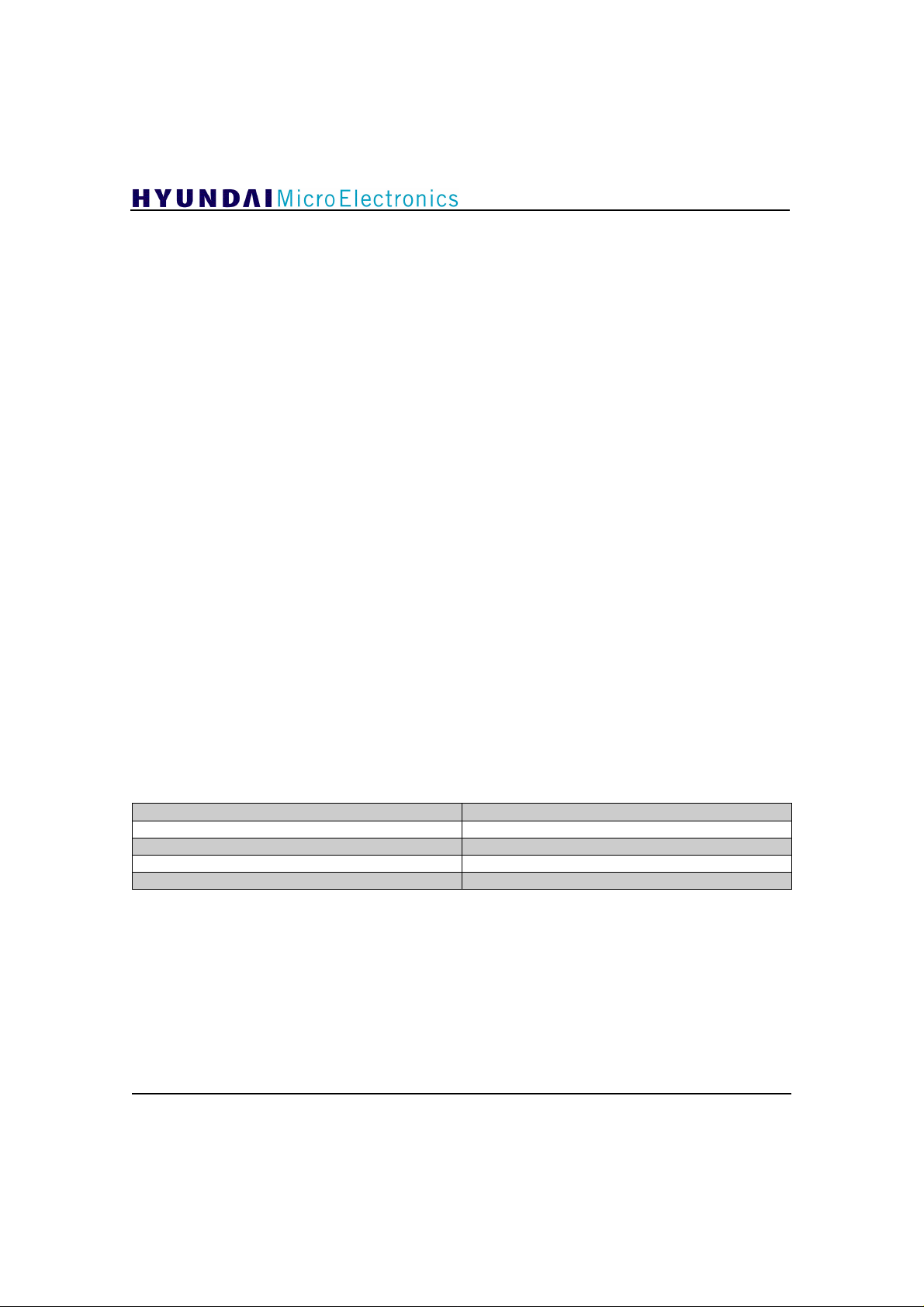

The MCU System Memory Map is shown in Figure 1.

The decoder greatly simplifies the slave interface and removes the need for the slave to understand the different

types of transfer that may occur on the bus.

4. Memory Map

The system decoder controls the memory map of the system and generates a slave select signal for each memory

region.

The ReMap signal is used to provide a different memory map: ROM is required at address 0 when power on reset,

and RAM also may be used at address 0 during normal operation.

The ReMap signal is typically provided by a Power Management Unit (PMU) which drives ReMap to LOW at

reset. The signal is only driven to HIGH after a particular register in the PMU is accessed (See Section. 9 Power

Management Unot for detail). When ReMap is HIGH and isram signal is HIGH, then Memory Map Configuration

is MODE A which the internal SRAM is located at address 0x00. And When ReMap is HIGH and drambank0

signal is HIGH, then Memory Map Configuration is Mode B which the DRAM bank #0 is located at address 0x00.

The isram and drambank0 signal come from MCU Controller. See Section 8. MCU Controller for detail.

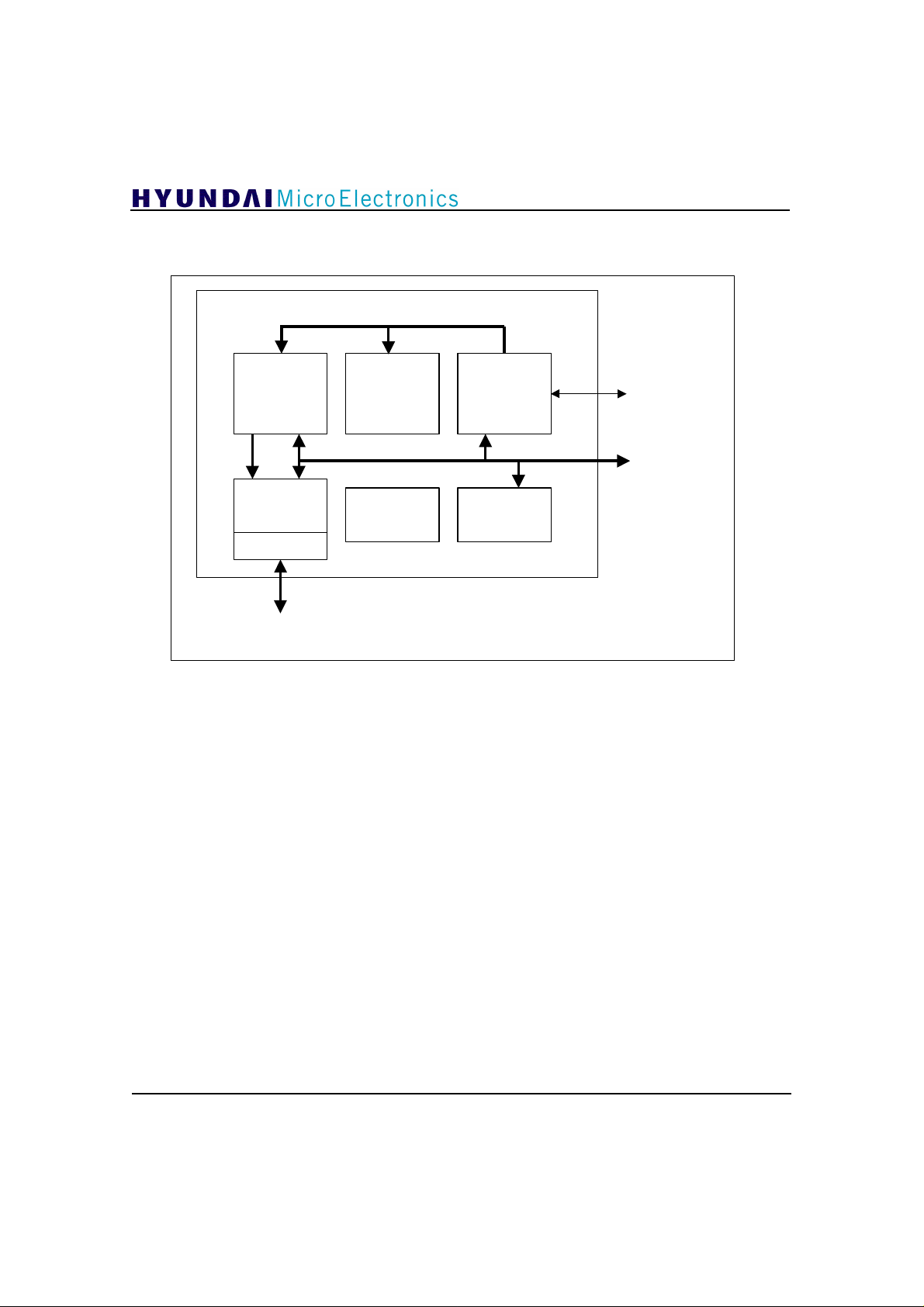

Figure 2. Memory map configuration shows both the Reset (MODE R) and the Normal (MODE B and MODE A)

memory map

Figure 1. shows the system memory map.

21

Page 21

GDC21D601

5. Memory Format

The ARM720T CPU Core supports both the Big-Endian and Little-Endian format. And the GDC21D601 can also

support the Big-Endian and Little-Endian memory format. The GDC21D601 can support the Little-Endian Format

by default. When using the GDC21D601 as Big-Endian format: 1) set Boot Mode 2 pin to VDD, and 2) set the

ARM720T as Big-Endian mode with using Coprocessor instruction. 3) set the Big-Endian flag of the compile

options when compile. The example of the coprocessor instruction is in the below. It is noted that CP15 register

(CPU control register) can only be accessed with MRC and MCR instructions in a Privileged mode. See the

ARM720T Data Sheet (ARM DDI 0087D) for detail. The ARM720T Data Sheet is downloadable from ARM

home page (http://www.arm.com).

For example :

MRC p15, 0, r3, c1, c1

ORR r3, r3, #0x80

MCR p15, 0, r3, c1, c1

Note : The GDC21D601 has a EBI (External Bus Interface) block which can copy the Byte or HalfWord of the lower position in data bus to higher data bus position, so you can use the GDC21D601 as

BigEnd mode by only set the Boot Mode 2 pin to VDD and in this case you may not set the ARM720T

as BigEnd Mode.

6. Boot Mode

The GDC21D601 can support 32/16/8 Bit Boot ROM. By default MCU can boot from 32 bit ROM. In this case

Boot Mode[1:0] (pin number 116 and 117) are “00”. If you want use 16 bit Boot ROM, then you must set Boot

Mode[1:0] are “10”. And in case of Booting from 8 bit ROM, you must set Boot Mode[1:0] are “01”. It is for

reserved in case that Boot Mode[1:0] are “11” . See the Table 1. The Description of the Mode Pin.

In all case of boot mode the wait cycle of Boot area is 3 cycles. If you want to know about boot mode for detail

you must see the Section 6. Static Memory Controller.

Table 1. The Description of the Mode Pin

Mode[1:0] Bus width of Booting ROM

00 32 Bit

01 8 Bit

10 16 Bit

11 Reserved

22

Page 22

GDC21D601

Address

0x00FFFFFF

0x00000FFF

0x00000000

MODE R

MODE A

MODE B

0x01FFFFFF

0x2FFFFFF

nCS0

nCS1

nCS2

On-Chip RAM

nCS0 or

DRAM #0

nCS1

nCS2

nCS2

nCS1

DRAM #0

7. Multi-Function Pin

The GDC21D601 has 80 Bit PIO pins with multiplexed by other functional pins. So you must use properly these

multi-function pins by setting the PINMUX control registers in MCU controller. (See Section 8. MCU Controller

for detail)

0XFFFF FFFF

0XFFFF F000

0XFFFF E000

0X0800 0000

0X0000 0000

APB Register

ASB Register

MEMORY AREA

Chip Select Area

0XFFFF FFFF

FD00

FC00

FB00

FA00

F900

F800

F700

F600

F500

F400

F300

F200

F100

F000

EF00

EE00

ED00

EC00

EB00

Reserved

PIO

I2C2

I2C1

I2C0

SSI

UART2/Smart

UART1

UART0

TIMER

RTC

INTC

WDT

PMU

DMAC

DRAMC

SMI

MCUC

Figure 1. System Memory Map

0XFFFF EAFF

0X6000 0000

0X5000 0000

0X4000 0000

0X3000 0000

0X2000 0000

0X1000 1000

0X1000 0000

0X0800 0000

0X0700 0000

0X0600 0000

0X0500 0000

0X0400 0000

0X0300 0000

0X0200 0000

0X0100 0000

0X0000 0000

Reserved

ARM7 TEST REG

Reserved

DRAM BANK #1

DRAM BANK #0

WINDOW AREA

ON-CHIP RAM

WINDOW AREA

nCS7

nCS6

nCS5

nCS4

nCS3

nCS2

nCS1

nCS0

1. MODE R : Reset Mode : default mode from power-on reset (ReMap is LOW)

2. MODE A : On-Chip SRAM in 0x0000 ~ 0x07FF range : ReMap is HIGH and isram is HIGH

3. MODE B : DRAM Bank #0 in 0x00000000 ~ 0x00FFFFFF range : Remap is HIGH and drambank0 is HIGH

Figure 2. Memory Map Configuration

23

Page 23

GDC21D601

Section 3. ARM720T Core

1. General Description

ARM720T is 32bit microprocessor of general purpose with 8KB cache, enlarged write buffer and Memory

Management Unit (MMU), which are combined in a single chip. The CPU within ARM720T is the ARM7TDMI.

The ARM720T is software compatible with the ARM processor family. The ARM7TDMI is a member of the ARM

family of general purpose 32bit microprocessors, which offers high performance for very low power consumption

and price. This processor employs a unique architectural strategy known as THUMB, which makes it ideally suited

to high volume applications with memory restrictions or applications where code density is an issue.

The key idea behind THUMB is a super reduced instruction set. Essentially, the ARM7TDMI has two instruction

sets, the standard 32bit ARM set and 16bit THUMB set. The THUMB set’s 16bit instruction length allows it to

approach twice the density of standard ARM code while retaining most of the ARM`s performance advantage over

a traditional 16bit processor by using 16bit registers. This is possible because THUMB code operates on the same

32bit register set as ARM code.

See also ARM720T Datasheet (ARM DDI 0087D) for detail.

2. Feature

• 32bit RISC architecture

• Low power consumption

• ARM7TDMI core with;

- On-chip ICEbreaker debug support

- 32bit x 8 hardware multiplier

- Thumb decompressor

• Utilizes the ARM7TDMI embedded processor

- High performance 32 bit RISC architecture

- High density 16 bit instruction set

• Fully static operation : 0 ~ 80MHz

• 3-stage pipeline architecture (Fetch, decode, and execution stage)

• Enhanced ARM software toolkit

• MMU, Write Buffer, 8KB I/D Cache

24

Page 24

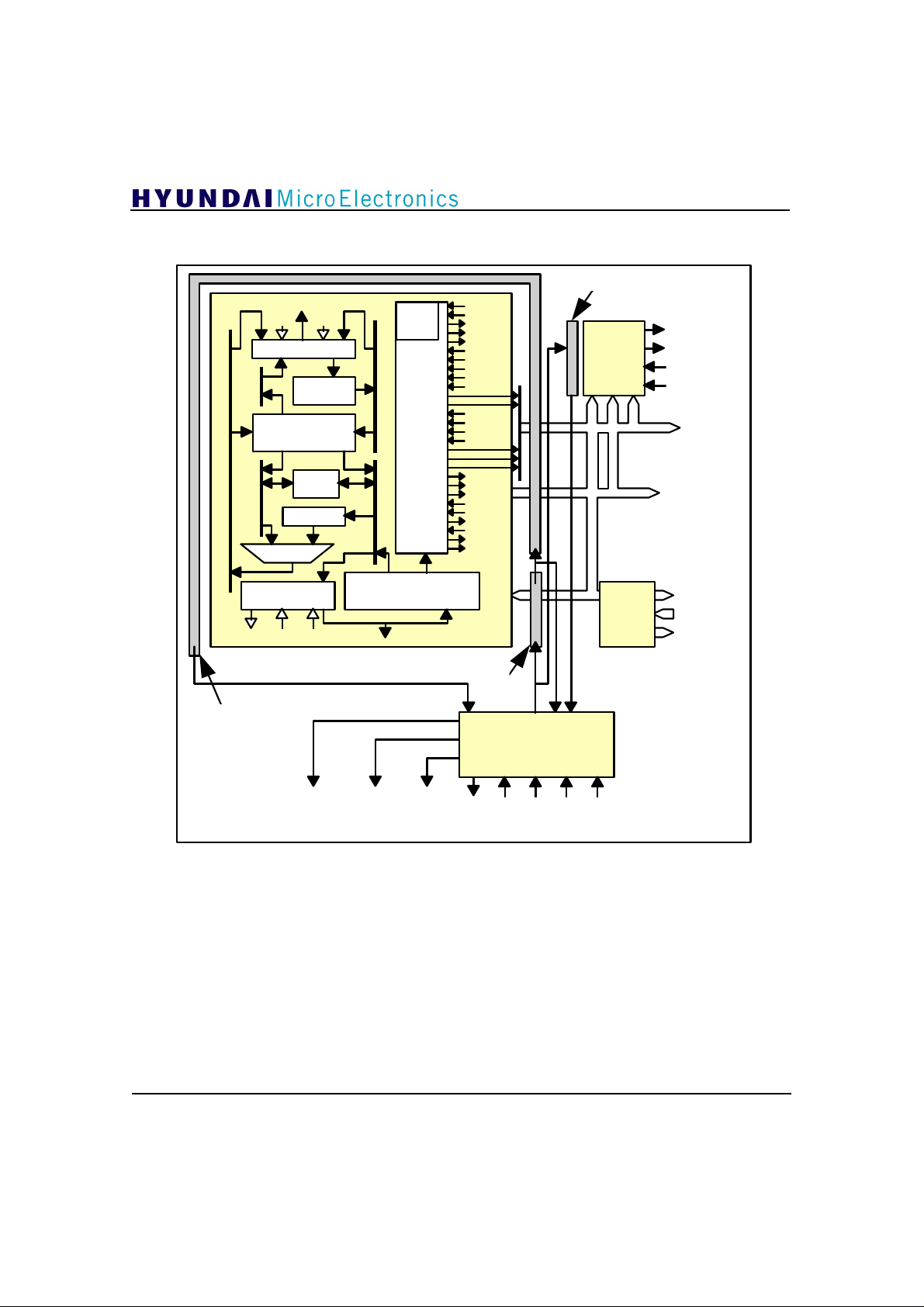

GDC21D601

THUMB code is able to provide up to 65% of the code size of ARM, and 160% of the performance of an

equivalent ARM processor connected to a 16-bit memory system.

Virtual Address Bus

MMU

Data and

Address

Buffers

AMBA Interface

AMBA Bus

Interface

8KB Cache

Internal Data Bus

Control and

Clocking

Logic

ARM7TDMI

CPU

System

Control

Coprocessor

Figure 1. ARM720T Block Diagram

JTAG

Debug

Interface

Coprocessor

Interface

25

Page 25

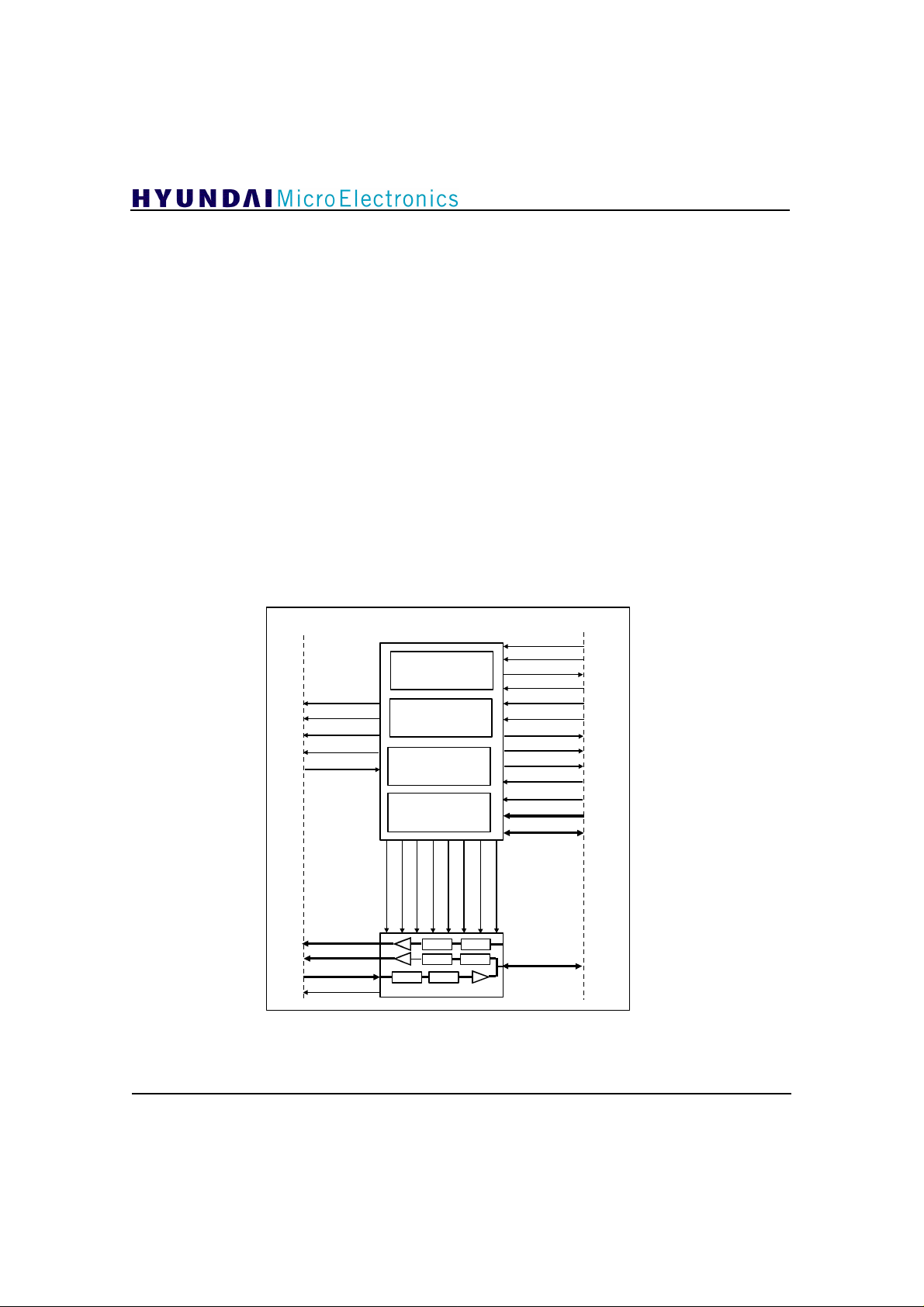

3. Core Block Diagram

A [31:0]

ALE ABE

Address Register

P

C

b

u

Incrementer

s

A

L

U

b

u

s

Register Bank

(31 x 32-bit registers)

(6 status registers)

A

Multiplier

b

u

s

Barrel Shifter

32-bit ALU

Write Data Register

nENOUT nENINDBE

32 x 8

m

Address

B

Instruction Pipeline

& Read Data Register

& Thumb Instruction Decoder

I

n

c

r

e

e

n

t

e

r

b

u

s

b

u

s

D [31:0]

Scan

Control

Instruction

Decoder

&

Control

Logic

DBGRQI

BREAKPTI

DBGACK

ECLK

nEXEC

ISYNC

BL [3:0]

APE

MCLK

nWAIT

nIRQ

nFIQ

nRESET

ABORT

SEQ

LOCK

nCPI

CPA

CPB

nM [4:0]

TBE

TBIT

HIGHZ

Core

ScanChain2

ICE

Breaker

Bus

Splitter

GDC21D601

RANGEOUT0

RANGEOUT1

ESTERN1

EXTERN0

nRW

MAS [1:0]

nTRANS

nMREQ

nOPC

A [0:31]

D [0:31]

DIN [0:31]

DOUT [0:31]

Scan

Chain 0

Scan

Chain 1

TAP Controller

TASPM [3:0]IR [3:0]SCREG [3:0]

Figure 2. ARM7TDMI Core Block Diagram

TCKTMSnTRSTTDITDO

26

Page 26

GDC21D601

Section 4. DRAM Controller

1. General Description

The DRAM controller interfaces the AMBA Advanced System Bus (ASB) to external DRAM memory banks. The

DRAM controller provides the following features:

• Up to two banks of DRAM support.

• Fast page-mode sequential access support.

• EDO DRAM support

• Word, Half-word and Byte transaction support.

• Little / Big Endian Format support.

• DRAM refresh controller using CAS-before-RAS (CBR) refresh mode.

• Programmable refresh rate.

• Power-down mode where all DRAM accesses (including self-refresh) are disabled.

• Programmable DRAM timing control.

• Row/column addresses multiplexes according to DRAM capacity.

Chip PAD

nDRAMWE

nDRAMOE

nRAS[1:0]

nCAS[3:0]

nCASFB[3:0]

Aout[23:0]

DataOut[31:0]

DataIn[31:0]

nOutEn[3:0]

DRAM Controller

Main State Machine

Address Generator

EBI Signal Control

nDRAMALatch

&

Control

Refresh

Timer & Controller

ASB Interface

&

nDRAMAMUX

nDRAMA[12:0]

nDRAMOutLEn

nDRAMInLEn[3:0]

nDRAMOutEn[3:0]

Lat

Lat

mux

Lat

nDRAMInEn

DRAMByte[1:0]

mux

mux

ASB Bus

BCLK

PDREQ

PDACK

DSELDRAM

DSELREG

BnRES

BLAST

BERROR

BWAIT

BWRITE

BSIZE[1:0]

BA[29:0]

BD[31:0]

BD[31:0]

Figure 1. DRAM Controller Module Block Diagram

27

Page 27

GDC21D601

2. Hardware Interface and Signal Description

The DRAM Controller module is connected to the ASB bus. Table 1. DRAM interface ASB signal descriptions

shows the internal bus interface signals to the DRAM controller.

Table 1. DRAM Interface ASB Signal Descriptions

NAME DESCRIPTION

BA [27:0] System address bus (excluding high order bits).

BCLK The ASB clock timing all bus transfers.

BD [7:0] Bidirectional system data bus.

BERROR Error slave response signal. It is driven to phase 1 if the DRAM controller is selected. This

signal will be asserted, when an access to the DRAM is attempted while the DRAM

controller is in its Power Down mode.

BLAST Last transfer of burst slave response signal. It can be driven to phase 1 if the DRAM

controller is selected. It is asserted in order to indicate a 256-word boundary to force a non-

sequential access.

BnRES These signals indicate the reset status of the ASB.

BSIZE [1:0] These signals indicate the size of the transfer that may be byte, half-word, or word.

BWAIT Wait slave response signal. It is driven to phase 1 when the DRAM controller is selected. It

is asserted while the DRAM transaction is uncompleted.

BWRITE When this signal is HIGH, it indicates a write transfer and when LOW a read.

DSELDRAM When this signal is HIGH, it indicates that the DRAM is selected.

DSELREG When this signal is HIGH, it indicates that the DRAM configuration register is selected.

Table 2. DRAM interface External DRAM signal descriptions describes the DRAM controller connections to

external devices of the system and to EBI (External Bus Interface) block .

Table 2. External DRAM Signal Descriptions

NAME DESCRIPTION

nRAS[1:0] Active LOW Row Address Strobes, one for each DRAM bank.

NCAS[3:0] Active LOW Column Address Strobes, one for each byte.

NDRAMOE Active LOW Output Enable.

NDRAMWE Active LOW Write Enable.

nCASFB[3:0] This is the nCAS[3:0] signal fed back from the output of the nCAS[3:0] pads.

PDREQ Power Down Request. This signal indicates that the DRAM controller should enter into its

low-power state, causing the DRAMs to enter into self-refresh state if refresh is enabled.

When it is deasserted, the DRAM controller will exit from low power state.

PDACK Power Down Acknowledge. This signal is asserted when the DRAM controller has

successfully entered into its low-power mode. At this point BCLK may be stopped safely. It

is deasserted when the DRAM controller has successfully exited from its low power state.

DRAMAMUX DRAM Address Multiplex Select. When this signal is HIGH, it indicates to the EBI that the

DRAMA[12:0] address should be used to generate DRAMA[12:0]. This signal provides the

support for a shared EBI, and may not be needed in a system where the DRAM controller

does not share the EBI with other memory controllers. DRAMAMUX is LOW when

DRAM accesses are not performed.

28

Page 28

GDC21D601

NAME DESCRIPTION

NDRAMALatch DRAM Address Latch. When this signal is LOW, it opens the EBI address latch. This

signal is HIGH when DRAM operations do not occur. This signal provides support for a

shared EBI and may not be needed in a system where the DRAM controller does not share

the EBI with other memory controllers.

DRAMA[12:0] These multiplexed address lines are connected to the DRAM Address.

NDRAMInEn DRAM Input Enable. When this signal is LOW, it enables the EBI drivers from latched XD

to BD. This signal is HIGH when DRAM read operations are not performed.

NDRAMInLEn[3:0] DRAM Input Latch Enable. When this signal is HIGH, it shuts the EBI latches on XD. This

signal is LOW when DRAM read operations are not performed.

NDRAMOutEn DRAM Output Enable. When this signal is HIGH, it disables the EBI drivers from latched

BD to XD. This signal is low when DRAM write operations are not performed.

NDRAMOutLen DRAM Output Latch Enable. When this signal is LOW, it opens the EBI latches on BD.

This signal is HIGH when DRAM write operations are not performed.

Accesses to the DRAM Controller module are generated as a result of the address decode put out on the ASB

address bus by the current bus master (which could be the ARM CPU or the DMA engine, for example).

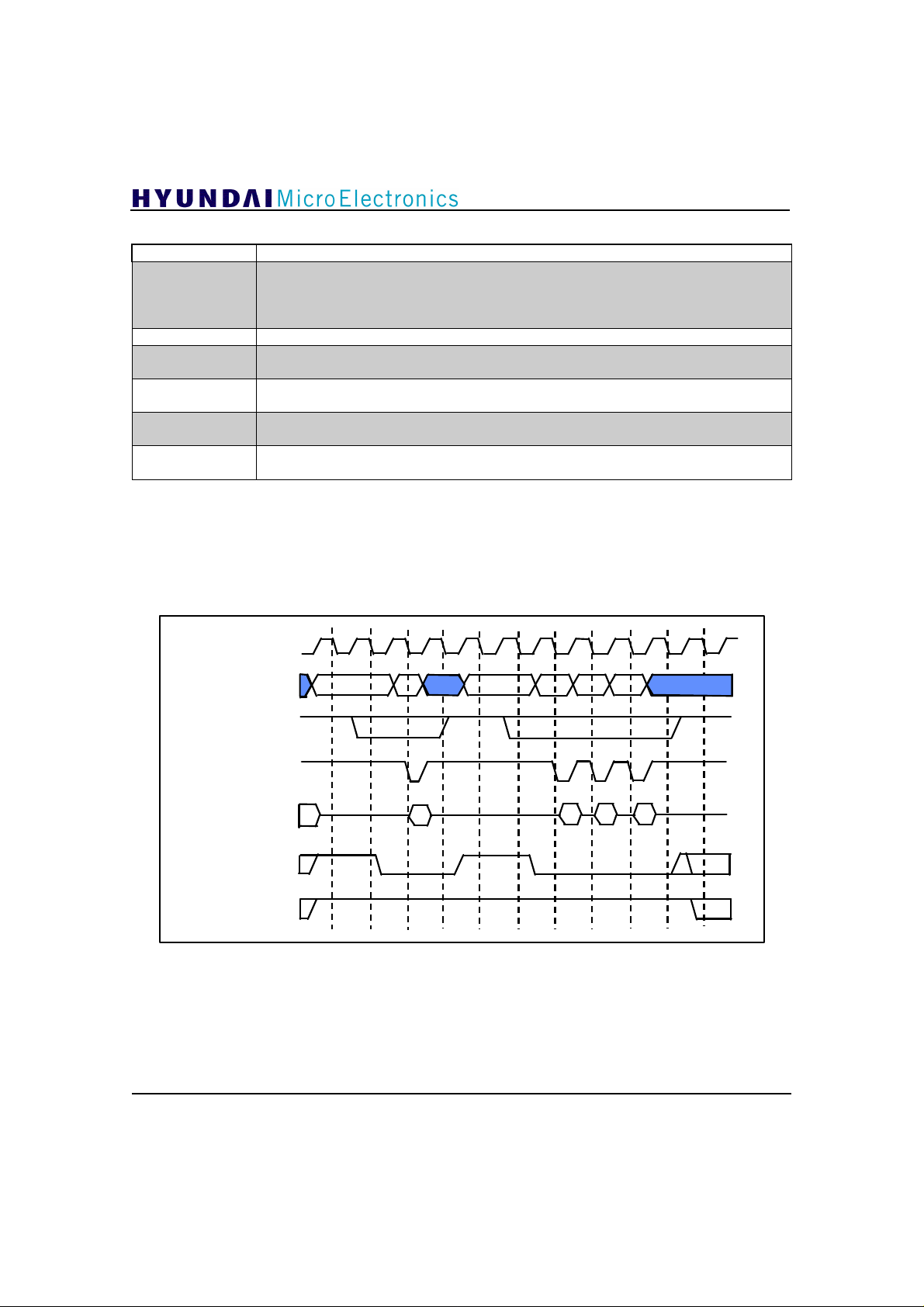

The following three diagrams show the timing of the external interface for read, write and refresh cycles

(Figure 2, 3, 4).

BCLK

DRAMA[12:0]

nRAS[1:0]

nCAS[1:0]

XData[31:0]

nOE

nWE

row

Figure 2. DRAM External Signal Timing: Read Cycles

col row col1 col2

col3

29

Page 29

BCLK

GDC21D601

DRAMA[12:0]

nRAS[1:0]

nCAS[1:0]

XData[31:0]

nOE

nWE

BCLK

nRAS[1:0]

nCAS[1:0]

row

col row col1 col2

Data

Data1

col3

Data2 Data3

Figure 3. DRAM External Signal Timing: Write Cycles

30

nOE

nWE

Figure 4. DRAM Controller Refresh Cycle

Page 30

GDC21D601

3. Functional Description

3.1 Introduction

The DRAM controller provides connections allowing a direct interface to up to two banks of DRAM. Each bank is

32/16/8 bits wide and up to 256MB in size. Two RAS lines are provided (one per bank) and four CAS lines (one

per byte line).

3.2 Functional BreakDown

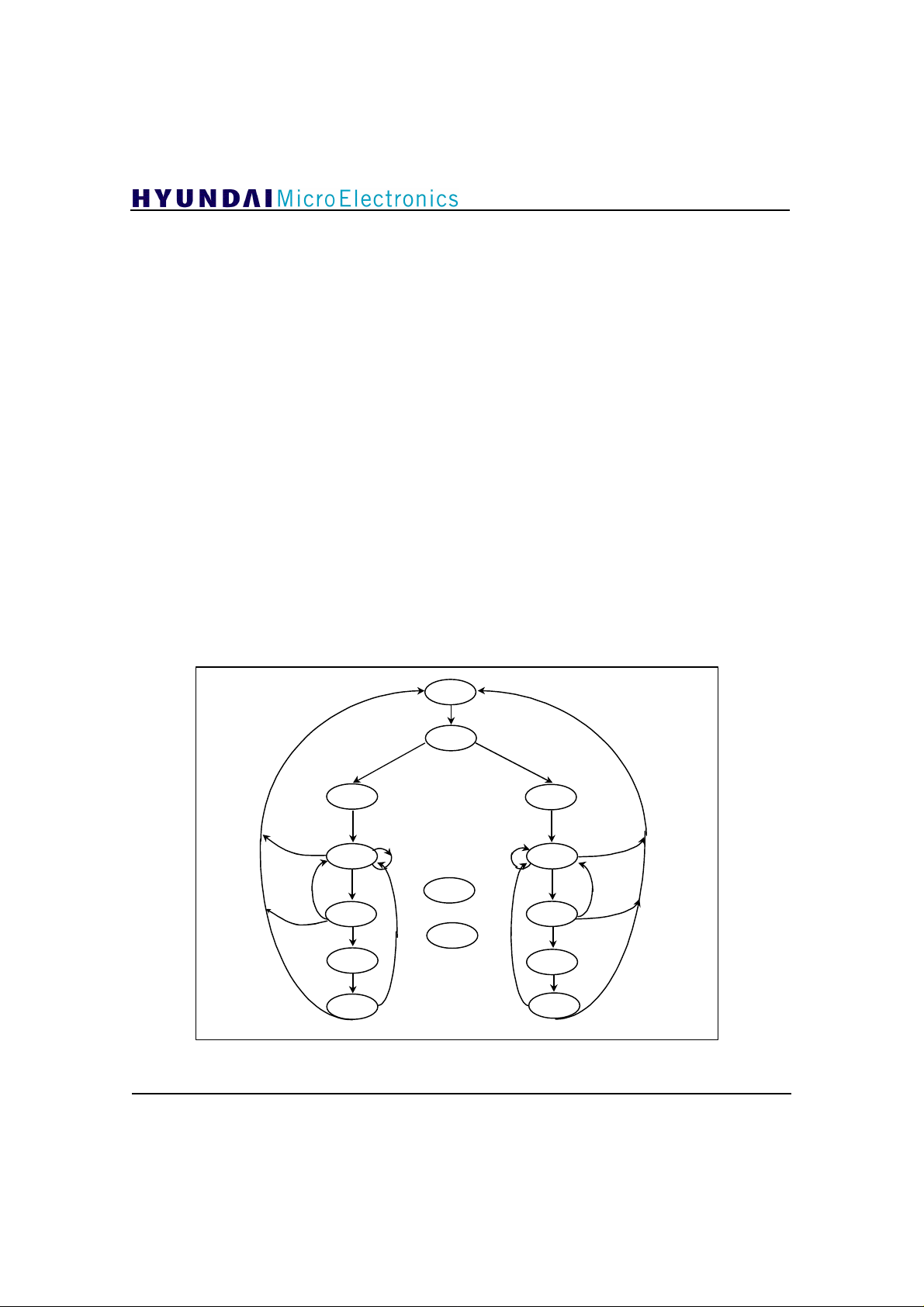

The DRAM controller consists of four main blocks: the Main State Machine & Control Block, the EBI Signal

Control Block, the ASB Interface & Address Generation Block, and the Refresh Timer & Counter Block.

3.3 Main State Machine

This block contains the main DRAM timing control state machine and the decode for the external strobe signals

for the DRAM interface. The state machine generates the timing for the nCAS and nRAS strobes, and the

multiplexing of the DRAM row and column address lines for standard DRAM cycles and refresh cycles. The

nDRAMWE and nDRAMOE signals are asserted appropriately depending on the access type. Word, Half-word,

and Byte accesses are decoded from the lower bits of the BA address bus in order to assert the appropriate nCAS

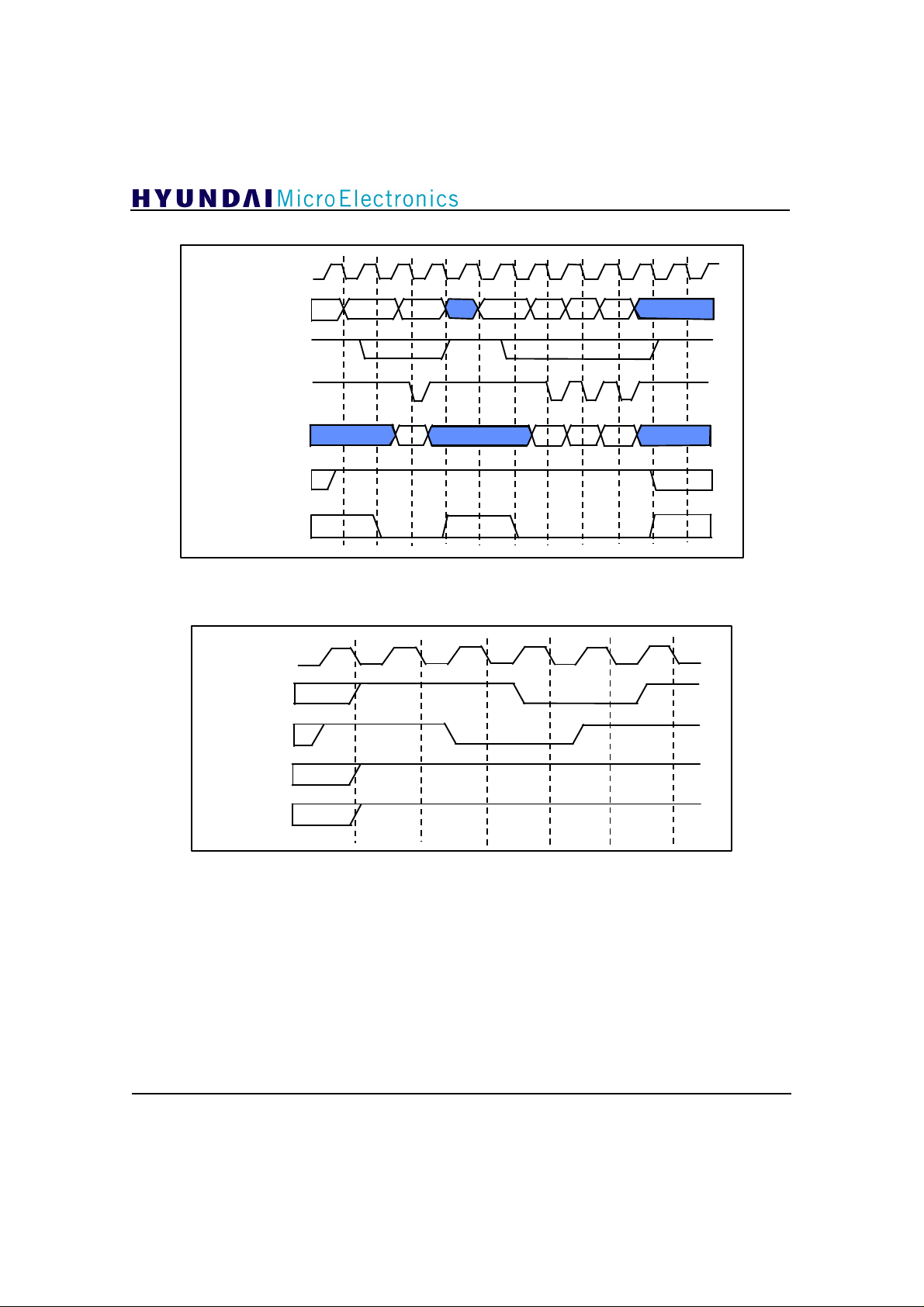

line(s). For word accesses all four nCAS lines are asserted. Figure 5. Descibes the Main State Machine Diagram.

Local arbitration for refresh cycles is also carried out here as refresh requests are received from the refresh timer

block. The block also supports the self refresh DRAM; enter to and exit from this self refresh state are initiated by

the PDRREQ signal. This is illustrated in Figure 6. DRAM signal timing: power down mode.

RefReq or

!DSEL

r_IDLE

DSEL

r_RnR

CAS

r_RnC1

CAS

r_RnC2

r_RnC3

r_RnC4

!BWRITE

r_WAIT

RAS

r_CRWAIT

r_CWWAIT

BWRITE

r_WnR

r_WnC1

r_WnC2

r_WnC3

r_WnC4

Figure 5. Main State Machine Diagram

CAS

CAS

RefReq or

!DSELD1

31

Page 31

GDC21D601

3.4 EBI Control Block

This also generates the control signals required by the EBI(External Bus Interface). The EBI control signals are

divided into three main groups; those related to the control of the Address path, the DataIn path, and the DataOut

path.

Address Path Control

There are three signazls related to the address path of the EBI:

nDRAMALATCH used to open the address latch of the EBI. This can be used to hold the external address XA

while internal accesses are performed. When this signal is asserted (active LOW) the EBI

address latch should be opened. When a DRAM access is not performed, the DRAM

controller will de-assert this signal. In a shared EBI scheme, other memory

controllers(Static Memory controller,...) must exhibit this behavior when they do not

perform memory accesses.

DRAMAMUX used to select the DRAMA[12:0] address as the address to be used on XA. This signal will

be asserted (active HIGH) when a DRAM access occurs, and will be de-asserted when the

transfer is completed.

DRAMA[12:0] the multiplexed row/column address used to access the DRAM.

DataIn and DataOut Path Control

There are four signals related to the data path of the EBI:

nDRAMOUTEN used to enable the EBIs data drivers onto XData. When this signal is de-asserted (HIGH),

the EBI should disable its drive onto XData. This signal is de-asserted during read cycles

and is asserted at other times. In a shared EBI scheme, other memory controllers must

exhibit this behavior when they do not perform memory accesses.

nDRAMOUTLEN used to latch the value of BD into the EBIs data output latches. When this signal is asserted

(active LOW), the EBI data output latch is opened. This signal will be asserted during

DRAM write transfers, and is de-asserted at other times.

nDRAMINEN used to enable the EBI data drivers onto BD. When this signal is asserted (active LOW), the

EBI should be driven onto BD. This signal is asserted during DRAM read transfers and is

de-asserted at other times.

nDRAMINLEN[3:0] used to latch the value of XData into the EBI data input latches. When this signal is de-

asserted (HIGH), the EBI data input latch is shut. Four signals are provided to enable

latching of byte / half-word data. nDRAMINLEN[0] is used to latch the data on M_D[7:0].

This signal is normally asserted and will be de-asserted during DRAM read transfers to latch

the current data on XData.

32

Page 32

GDC21D601

3.5 Refresh Control Block

The refresh timer is a 7-bit timer counter which counts down and generates a refresh request when it reaches zero,

at this point it is reloaded with the value in the refresh control register. This allows refresh frequencies from the

Refresh Control Register and BCLK input clock.

3.6 ASB Interface Block

The ASB interface provides the interaction with the main AMBA bus. The DRAM controller will initiate a DRAM

access when the DSELDRAM signal is asserted, or access the control registers when the DSELREG strobe is

asserted. The timing of the ASB transfers is described in detail in the AMBA Specification rev. D. At a 256-word

boundary, the BLAST signal will be asserted to indicate to the bus master that the burst sequence should be broken

within the page boundary.

This block also generates the row and column addresses. During burst mode accesses, the column address is

provided by a 10-bit column address incrementor to provide adequate column address timing.

BCLK

PDREQ

PDACK

nRAS[1:0]

nCAS[3:0]

nOE

nWE

Figure 6. DRAM Signal Timing : Power Down Mode

33

Page 33

GDC21D601

4. Register Description

4.1 Memory Map

The base address (=DRAM REG Base) of the DRAM controller register bank is 0xFFFFED00.

Table 5. Memory Map of the Dram Controller Peripheral

ADDRESS WRITE LOCATION READ LOCATION INITIAL

Base + 0x0 DRAM Refresh Control Register (RCR) N/A 16’h0000

Base + 0x4 DRAM Control Register for CPU DRAM Control Register for CPU 7’ b0000000

Base + 0x8 DRAM Control Register for DMA DRAM Control Register for DMA 6’b000000

Base + 0xC DRAM Test Control Register (TCR) N/A 4’b0000

4.2 DRAM Refresh Control Register(RCR)

The DRAM refresh period register is an 16-bit write register which enables the refresh and selects the refresh

period used by the DRAM controller for its periodic CAS-before-RAS refresh. The value in the DRAM refresh

period register is only cleared by a Power On Reset (BnRES = 0).

15 8 7 6 0

REFCNT

Figure 7. DRAM Controller Refresh Register

RFSHEN RFDIV

REFCNT DRAM Refresh Clock Divisor. Refresh Clock is setting by this bit field :

RefClock = BCLK/REFCNT

The REFCNT field should not be programmed with zero since this results in no initiated refresh

cycles.

RFSHEN DRAM refresh enable. Setting this bit enables periodic refresh cycles to be generated by the DRAM

controller at the rate set by the RFDIV field. Setting this bit also enables self-refresh mode when the

DRAM controller is in the power down state.

RFDIV This 7-bit field sets the DRAM refresh rate. The refresh period is deriven from internally generated

clock and is given by the following formula:

Frequency (KHz) = 2*[RefClock /(RFDIV + 1)]

or

RFDIV = ( RefClock / 0.5*Refresh frequency (KHz) ) - 1

The RFDIV field should not be programmed with zero since this results in no initiated refresh cycles.

34

Page 34

GDC21D601

4.3 DRAM Control Register for CPU (DRAMConCPU)

This Register controls the DRAM control signals when DRAM accessed by CPU. In normal condition, the

DRAM access time is changed by the bus master is CPU or DMA Controller. In case of bus master is DMA

Controller, the transfer timing should be properly set to the external I/O device and DRAM, so for the optimal

system performance the DRAM access by the CPU is set in this DRAM Control Register for CPU

(DRAMConCPU) and in case of the DRAM access by the DMA Controller DRAM control signals are controlled

by the DRAM Control Register for DMA (DRAMConDMA).

15 7 6 5 4 3 2 1 0

Reserved DMAEn TRP TCP WaitCnt BankSize

Figure 8. DRAM Control Register for CPU (DRAMConCPU)

DMAEn If DMA transfer, then the DRAM control signals are controlled by DRAM Control Register for DMA

(DRAMDonDMA) by this bit setting. When this bit is ‘0’ , then the DRAM control signals are

controlled by bit fields in this Control Register (DRAMConCPU) during DRAM access.

TRP Control the timing of difference between the RAS and CAS signal by this bit field setting. When this

bit is ‘0’ , then DRAM access are absolutely no wait, so DRAM access time is very short, but should

be considered the operating frequency of the MCU and DRAM access time.

TCP Control the timing of the Low phase of CAS signals. When this bit is ‘1’ , then the Low phase of the

CAS signals are enlarged to one cycle of BCLK. When this bit is ‘0’ , then the Low phase of the CAS

signals are half clock of BCLK.

WaitCnt This bit fields control the DRAM access time. The wait state is inserted in ASB BUS by the value of

these WaitCnt fields. (00=0-wait, 01=1-wait, 10=2-wait, 11=3-wait)

BankSize These bits indicate the data width of the DRAM Bank. The data width of the DRAM by BankSize are

shown Table 6.

Table 6. Data width of the DRAM by BankSize[1:0] fields

BankSize[1:0] Data Width of DRAM

00 Byte

01 Half Word

10 Word

11 Reserved

35

Page 35

GDC21D601

4.4 DRAM Control Register for DMA

This Register controls the DRAM control signals when DRAM accessed by DMA.

Setting the register is effective only when the DMAEn bit set by DRAMConCPU(DRAM Control register from

CPU).

15 6 5 4 3 2 1 0

Reserve TRP TCP WaitCnt BankSize

Figure 9. DRAM Control Register for DMA (DRAMConDMA)

4.5 DRAM Test Control(TCR)

The DRAM test control register is for test and should not be used during normal operation. It is a write-only

register with the following format.

15 4 3 2 1 0

Reserved TESTINC FORCEADV FORCESIZE

Figure 10. DRAM Test Control Register

TESTINC Test increment (TESTINC). This bit puts the column address increment into a test mode. In

this mode each nibble of the column address increment increments independently. Resets it to

0.

FORCEADV Force refresh advance (FORCEREFADV). This bit forces the refresh counter to advance every

BCLK. Resets it to 0.

FORCESIZE[1:0] Force access size. These bits force the size of accesses to the DRAM bank. When this is set to

10 (default), the ASB B_SIZE is used to determine the size of the access. When this is set to

00 or 01, a byte or half-word access is forced respectively. Resets it to 10.

36

Page 36

GDC21D601

Section 5. On-Chip SRAM

1. General Description

The GDC21D601 has 8-kbytes of on-chip RAM. The on-chip RAM is linked to the CPU and direct memory access

controller(DMAC) with 32-bit data bus. The CPU and DMA Controller can write data into the on-chip RAM in

byte, half-word, or word units.

2. Signal Description

Table 1. Signal Descriptions

NAME TYPE DESCRIPTION

BA[31:0] I System address bus.

BD[31:0] I/O Bi-directional system data bus.

BWAIT I/O LOW during phase one of BCLK.

BLAST I/O LOW during phase one of BCLK.

BERROR I/O LOW during phase one of BCLK.

BWRITE I When this signal is HIGH, it indicates a write transfer and when LOW a read.

DSELMEM I When this signal is HIGH, it indicates that on-chip RAM is selected.

BnRES I These signals indicate the reset status of the ASB.

3. Function Description

On-Chip SRAM can read data from SRAM and can write data into SRAM in a single clock cycle through ASB bus.

And SRAM is single module which have 32 bit data bus and control lines.

The data in the On-chip RAM can always be accessed in one cycle that make the RAM ideal for use as a program

area, stack area, or data area, which requires high-speed access. The contents of the on-chip RAM are held in both

standby and power-down modes.

Memory area 0x10000000 to 0x10001FFF is allocated to the on-chip RAM as default. When isram signal from

MCU Controller is set to HIGH, memory area 0x00000000 to 0x00001FFF can be allocated to the on-chip RAM.

37

Page 37

GDC21D601

Section 6. Static Memory Controller

1. General Description

The Static Memory Controller interfaces the AMBA Advanced System Bus (ASB) to the External Bus Interface

(EBI); controlling the external SRAM, ROM, Flash Memory or off-chip peripherals. Eight separate chip select

banks are provided by this block. Each bank is 256MB in size and can be programmed individually to support:

• 8-, 16- or 32-bit wide, Little-Endian and Big-Endian Memory Format

• variable wait states (up to 16 waits)

• exchangeable active low/high chip select signal (only for CS6 and CS7)

• various type control signal timing

• bus transfers can be extended using the EXPRDY input signal. EXPRDY signal can be used by

exchangeablely active HIGH or LOW in according to control register setting.

Chip PAD

EXPRDY

EXPCLK

MODE[1:0]

RnW

nWEN[3:0]

nSRAMOE

nCS[5:0]

CS[7:6]

nWEF[3:0]

Aout[23:0]

DataOut[31:0]

DataIn[31:0]

nOutEn[3:0]

Static Memory Controller

Main State Machine

Bank Config. Reg.

ASB Interface

&

Chip Select encode

EBI Signal Control

MemByte[1:0]

nSRAMA[1:0]

nSRAMALatch

nSRAMAMUX

Lat

Lat

mux

nSRAMInEn

nSRAMOutLEn

nSRAMInLEn[3:0]

nSRAMOutEn[3:0]

mux

mux

Lat

BA[26:24, 4:0]

ASB Bus

BCLK

BnRES

DSELSMI

DSELREG

BTRAN[1:0]

BWRITE

BSIZE[1:0]

BLAST

BERROR

BWAIT

BD[31:0]

BD[31:0]

Figure 1. Static Memory Controller Block Diagram

38

Page 38

GDC21D601

2. Signal Description

The Static Memory Controller module is connected to the ASB bus. In Table 1. Static Memory Controller ASB

signal descriptions show the internal bus interface signals(AMBA signals) to the Static Memory Controller