Page 1

ELM334

1234876

5

Garage Doorman

Description

5

4

7

2

6

3

Features

The ELM334 is a handy circuit for remotely

monitoring the position of your garage door. A twowire interface is all that is needed to convey the

position of the door to two remotely located LEDs,

and to also provide control for an electric opener if

desired.

This circuit continually monitors the state of two

position sensing switches, representing the fully

open and fully closed positions of the door. After

suitable debouncing, the states of these switches

are used to vary the polarity of the two signal wires,

resulting in either the red (open) or green (closed)

LED turning on. When the door is in neither position

(moving), the LEDs rapidly alternate between the

two colours.

If desired, circuitry to detect a short between the

two LED wires can be added and used to operate a

control output. If the door is equipped with a

standard electric opener, this control signal can be

used to operate the door. Refer to the Example

Application section for further details.

Applications

• Low power CMOS design

• Wide supply range - 3.0 to 5.5 volt operation

• Simultaneous monitoring of three inputs

• Fully debounced inputs

• Two wire interface

• Stuck button protection on the control output

• Control function is an optional addition

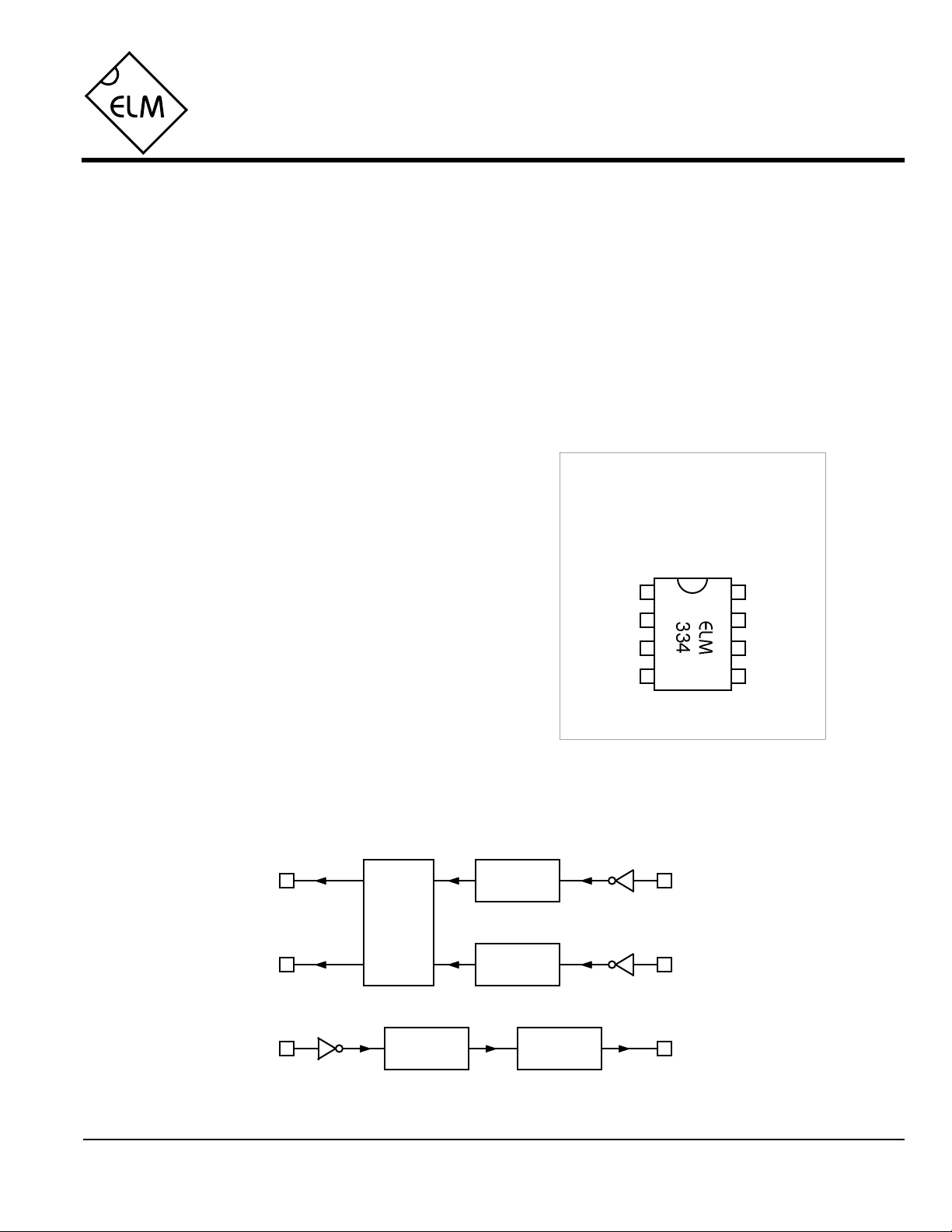

Connection Diagram

PDIP and SOIC

(top view)

VDD VSS

RLED

GLED

OpenSw

ClosedSw

ControlPB

• Garage door monitoring and control

• Remote signalling and acknowledgement

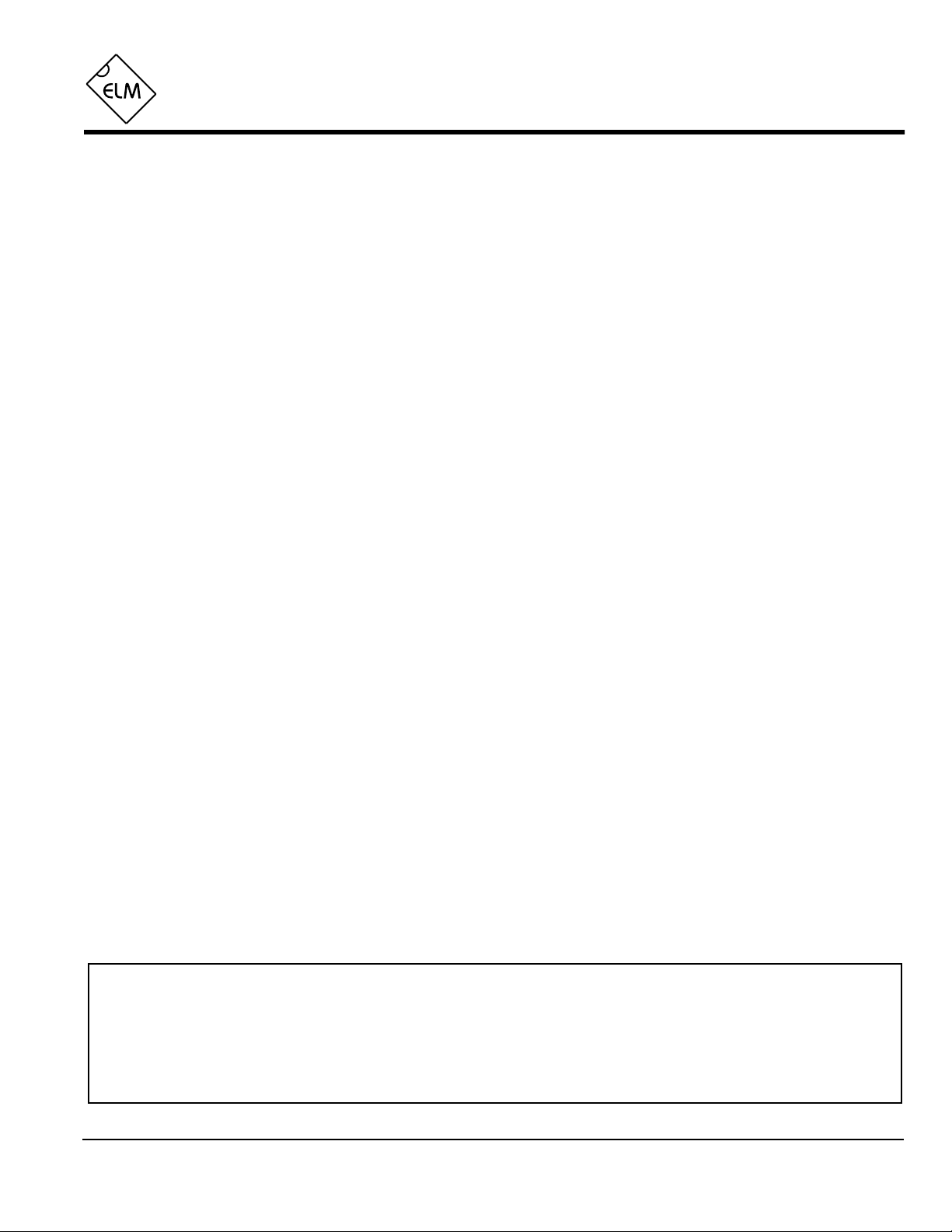

Block Diagram

RLED

PB

ELM334DSB

Elm Electronics – Circuits for the Hobbyist

Debounce

Timers

Drive

Logic

Debounce

Timers

Debounce

Timers

Output

Limitter

< http://www.elmelectronics.com/ >

OpenSw

ClosedSwGLED

Control

1 of 4

Page 2

ELM334

Pin Descriptions

VDD (pin 1)

This pin is the positive supply pin, and should

always be the most positive point in the circuit.

Internal circuitry connected to this pin is used to

provide power on reset of the microprocessor, so

an external reset signal is not required. Refer to

the Electrical Characteristics section for further

information.

RLED (pin 2), and GLED (pin 3)

These two pins are for driving a red and a green

LED through a current limiting resistance.

Typically the LED used will be a dual type, that

appears white if not energized, red if energized

in one polarity, and green if the polarity is

reversed. Alternatively, two discrete LEDs could

be wired ‘back-to-back’. During powerup, the red

LED will be lit for 0.5sec, followed by the green

for 0.5sec, and then the circuit will alternate

between the two for a further 0.5sec.

PB (pin 4)

A momentary low level signal on this pin will

cause the control output to go high, after

approximately 25msec delay due to the internal

debounce circuitry. If unused, this pin should be

connected to VDD.

Control (pin 5)

This output goes to an active high level (VDD), in

response to a valid low level on pin 4. The

duration of the output will be the same as the

input, to a maximum of 500ms. At this point, the

circuit will assume that the button is ‘stuck’, or

there has been a wiring fault, and it will turn the

output off. The state of the RLED and the GLED

lines is not updated if the circuit thinks that the

pushbutton is being pressed.

ClosedSw (pin 6), and OpenSw (pin 7)

These two inputs are for monitoring the position

of the door. This is normally done by connecting

magnetic reed type switches between each of

these pins and VSS, with the two switches

mounted at the extreme positions of the door

travel. When fully open, only the OpenSw input

will be at a logic low level (switch closed), and

when fully closed, only the ClosedSw input will

be low. Both switches simultaneously open or

closed will cause the LEDs to alternately flash

red and green as a warning (or as feedback that

the door is moving). Internal circuitry provides a

nominal 0.5sec debounce period on both inputs.

VSS (pin 8)

Circuit common is connected to this pin. This is

the most negative point in the circuit.

Ordering Information

All rights reserved. Copyright ©1999 Elm Electronics.

Every effort is made to verify the accuracy of information provided in this document, but no representation or warranty can be

given and no liability assumed by Elm Electronics with respect to the accuracy and/or use of any products or information

described in this document. Elm Electronics will not be responsible for any patent infringements arising from the use of these

products or information, and does not authorize or warrant the use of any Elm Electronics product in life support devices and/or

systems. Elm Electronics reserves the right to make changes to the device(s) described in this document in order to improve

reliability, function, or design.

ELM334DSB

These integrated circuits are available in either the 300 mil plastic DIP format, or in the 200 mil SOIC surface

mount type of package. To order, add the appropriate suffix to the part number:

300 mil Plastic DIP............................... ELM334P 200 mil SOIC.....................................ELM334SM

Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

2 of 4

Page 3

ELM334

Absolute Maximum Ratings

Stresses beyond those listed here will likely damage

the device. These values are given as a design

guideline only. The ability to operate to these levels

is neither inferred nor recommended.

Storage Temperature.......................-65°C to +150°C

Note:

Ambient Temperature with

Power Applied....................................-40°C to +85°C

Voltage on VDD with respect to VSS............0 to +7.5V

Voltage on any other pin with

respect to VSS........................... -0.6V to (VDD + 0.6V)

Electrical Characteristics

All values are for operation at 25°C and a 5V supply, unless otherwise noted. For further information, refer to note 1 below.

Characteristic Minimum Typical Maximum ConditionsUnits

Supply Voltage, VDD 3.0 5.0 5.5 V

VDD rate of rise 0.05 V/ms

Average Supply Current, IDD 1.0 2.4 mA

Debounce Period msec25

Pushbutton

Position Switches

msec500

see note 2

VDD = 5V, see note 3

Maximum Control Pulse Width msec500

Input low voltage VSS 0.15 VDD V

Input high voltage VDD V0.85 VDD

Output low voltage 0.6 V

Output high voltage VVDD - 0.7

Notes:

1. This integrated circuit is produced with a Microchip Technology Inc.’s PIC12C5XX as the core embedded

microcontroller. For further device specifications, and possibly clarification of those given, please refer to the

appropriate Microchip documentation.

2. This spec must be met in order to ensure that a correct power on reset occurs. It is quite easily achieved

using most common types of supplies, but may be violated if one uses a slowly varying supply voltage, as

may be obtained through direct connection to solar cells, or some charge pump circuits.

3. Integrated circuit only. Does not include any LED or drive currents.

4. This is the maximum output pulse width, if the pushbutton input remains active. If the pushbutton is released

prior to this time, the output will simply follow the input.

see note 4

Current (sink) = 8.7mA

Current (source) = 5.4mA

ELM334DSB

Elm Electronics – Circuits for the Hobbyist

3 of 4

< http://www.elmelectronics.com/ >

Page 4

Example Application

ELM334

1234876

5

Figure 1 shows the ELM334 in a typical circuit that

provides both monitoring and control. An unregulated

12V supply is used to drive the relay coil and is stepped

down to 5V for the IC. The regulation isn’t essential for

this type of circuit, but it is a convenient means to

reduce the 12V, while providing some filtering from

motor noise, etc.

Operation of the LED portion of this circuit is

straight-forward. The position sensing magnetic reed

switches are connected to the 5.1KΩ pullup resistors in

order to provide a full logic swing input to the ELM334

as they operate. The 2.2KΩ series resistors provide

some protection for the chip as the wires to the switches

are likely to be lengthy, and susceptible to induced

voltages and currents. After processing, the appropriate

voltages appear at pins 2 and 3, driving the LEDs

through the 150Ω current limiting resistors.

+12V

+5V

0.1µF

78L05

0.1µF

The control portion of the circuit may appear to be a

little odd-looking at first. To understand its operation,

note that one of the two driven LEDs is always on,

whether flashing or solid. Due to the connection of the

two NPN transistors then, one of the NPNs is always

biased on, keeping the PNP on, and pin 4 of the

ELM334 at 5V. When the pushbutton is pressed, the

LED circuit is shorted out, and neither NPN can

conduct. The PNP thus shuts off, and pin 4 of the IC

drops to 0V, its active level. With the PB input active, a

high level is output at pin 5, causing the relay to pick up.

Although this circuit was designed for a very

specific purpose, there are likely to be many other

applications that it can be adapted to. Monitoring

thermostats perhaps, or water levels…

+5V

5.1KΩ

2.2KΩ

‘open’

+5V

green

red

Remote LEDs

& Pushbutton Control

10KΩ

10KΩ

2N3904

10KΩ

2N3904

150Ω

150Ω

+5V

+5V

1N4001

2N3906

5.1KΩ

5.1KΩ

Figure 1. Typical Monitoring and Control Circuit

ELM334DSB Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

2.2KΩ

5.1KΩ

2.2KΩ

‘closed’

+12V

12V Relay

To the

motor

control

2N3904

4 of 4

Loading...

Loading...