Page 1

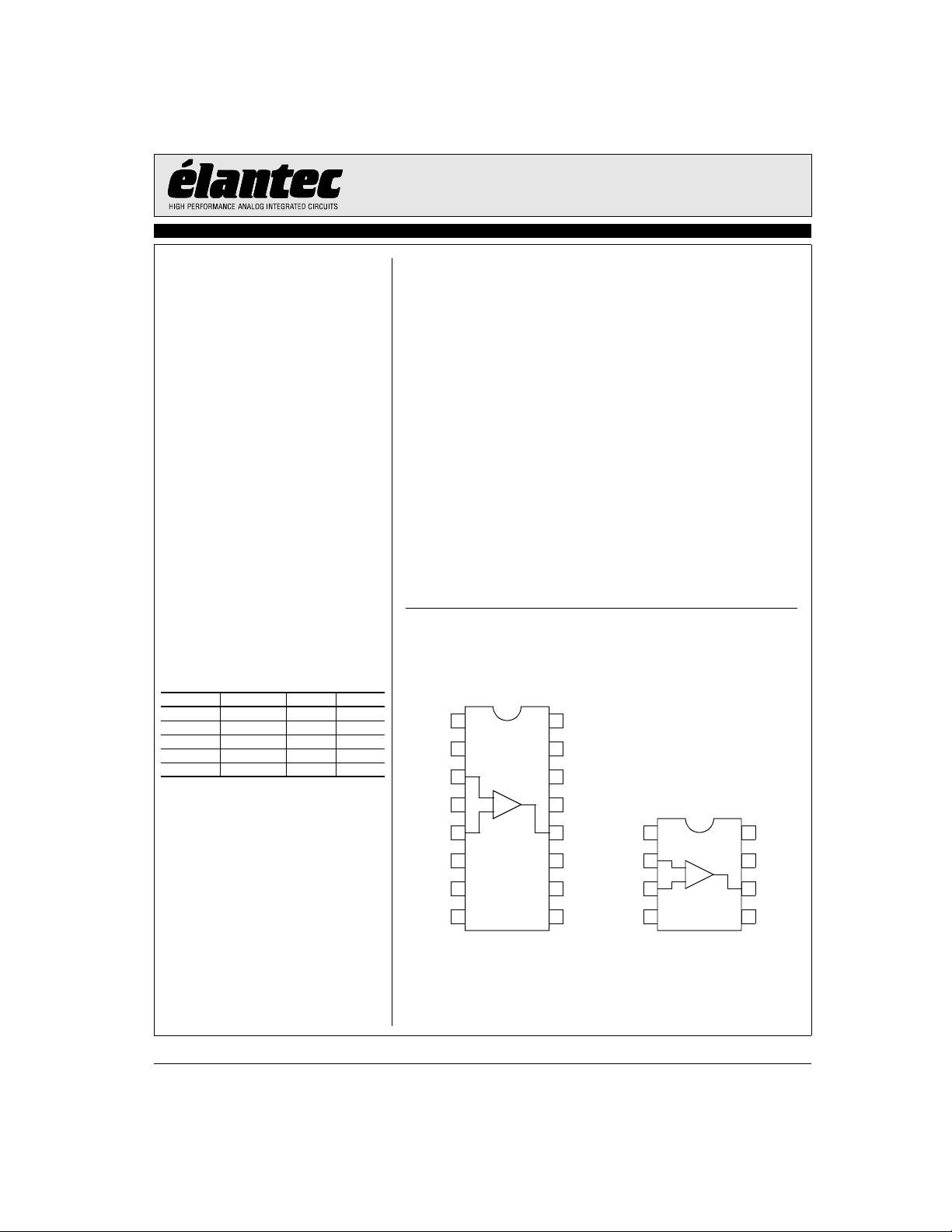

EL2160C

180MHz Current Feedback Amplifier

EL2160C

Features

• 130MHz 3dB bandwidth (AV=+2)

• 180MHz 3dB bandwidth (AV=+1)

• 0.01% differential gain, R

• 0.01° differential phase, R

=500Ω

L

=500Ω

L

• Low supply current, 8.5mA

• Wide supply range, ±2V to ±15V

• 80mA output current (peak)

• Low cost

• 1500V/µs slew rate

• Input common mode range to

within 1.5V of supplies

• 35ns settling time to 0.1%

Applications

• Video amplifiers

• Cable drivers

• RGB amplifiers

• Test equipment amplifiers

• Current to voltage converters

Ordering Information

Part No. Package Tape & Reel Outline#

EL2160CN 8-Pin PDIP - MDP0031

EL2160CS-T7 8-Pin SO 7” MDP0027

EL2160CS-T13 8-Pin SO 13” MDP0027

EL2160CM 16-Pin SO (0.300”) - MDP0027

EL2160CM-T13 16-Pin SO (0.300”) 13” MDP0027

General Description

The EL2160C is a current feedback operational amplifier with -3dB

bandwidth of 130MHz at a gain of +2. Built using the Elantec proprietary monolithic complementary bipolar process, this amplifier uses

current mode feedback to achieve more bandwidth at a given gain than

a conventional voltage feedback operational amplifier.

The EL2160C is designed to drive a double terminated 75Ω coax

cable to video levels. Differential gain and phase are excellent when

driving both loads of 500Ω (<0.01%/<0.01°) and double terminated

75Ω cables (0.025%/0.1°).

The amplifier can operate on any supply voltage from 4V (±2V) to

33V (±16.5V), yet consume only 8.5mA at any supply voltage. Using

industry-standard pinouts, the EL2160C is available in 8-pin PDIP and

SO packages, as well as a 16-pin SO (0.300”) package. All are specified for operation over the full -40°C to +85°C temperature range. For

dual and quad applications, please see the EL2260C/EL2460C

datasheet.

Connection Diagrams

+IN

1

NC

2

NC

3

-IN

-

4

NC

+

5

16

NC

15

NC

14

VS+

13

NC

12

OUT

1

NC

8

NC

+IN

VS-

2

-IN

-

+

3

4

8-Pin PDIP/SO16-Pin SO (0.300”)

6

NC

7

VS-

8 9

NC

Note: All information contained in this data sheet has been carefully checked and is believed to be accurate as of the date of publication; however, this data sheet cannot be a “controlled document”. Current revisions, if any, to these

specifications are maintained at the factory and are available upon your request. We recommend checking the revision level before finalization of your design documentation.

© 2001 Elantec Semiconductor, Inc.

11

NC

10

NC

NC

7

VS+

6

OUT

5

NC

September 26, 2001

Page 2

EL2160C

180MHz Current Feedback Amplifier

EL2160C

Absolute Maximum Ratings (T

Voltage between VS+ and VS- +33V

Voltage between +IN and -IN ±6V

Current into +IN or -IN 10mA

Internal Power Dissipation See Curves

= 25°C)

A

Operating Junction Temperature

Plastic Packages 150°C

Output Current ±50mA

Storage Temperature Range -65°C to +150°C

Operating Ambient Temperature Range -40°C to +85°C

Important Note:

All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are at the

specified temperature and are pulsed tests, therefore: TJ = TC = TA.

Open Loop DC Electrical Characteristics

VS = ±15V, R

Parameter Description Conditions Temp

V

OS

TC V

+I

IN

-I

IN

CMRR Common Mode Rejection Ratio

-ICMR -Input Current Common Mode Rejection

PSRR Power Supply Rejection Ratio

-IPSR -Input Current Power Supply Rejection

R

OL

+R

+C

CMIR Common Mode Input Range VS = ±15V 25°C ±13.5 V

V

O

I

SC

I

S

1. Measured from T

2. VCM = ±10V for VS = ±15V and TA = 25°C, VCM = ±3V for VS = ±5V and TA = 25°C

3. The supplies are moved from ±2.5V to ±15V

4. V

5. A heat sink is required to keep junction temperature below absolute maximum when an output is shorted

= 150Ω, T

L

Input Offset Voltage VS = ±5V, ±15V 25°C 2 10 mV

OS

Average Offset Voltage Drift

+Input Current VS = ±5V, ±15V 25°C 0.5 5 µA

-Input Current VS = ±5V, ±15V 25°C 5 25 µA

Transimpedance

IN

IN

+Input Resistance 25°C 1.5 3.0 MΩ

+Input Capacitance 25°C 2.5 pF

Output Voltage Swing R

Output Short Circuit Current

Supply Current VS = ±15V 25°C 8.5 12.0 mA

= ±7V for VS = ±15V, and V

OUT

= 25°C unless otherwise specified.

A

[1]

[2]

[3]

[4]

[5]

to T

MIN

MAX

= ±2V for VS = ±5V

OUT

Limits

UnitMin Typ Max

Full 10 µV/°C

[2]

[3]

VS = ±5V, ±15V 25°C 50 55 dB

VS = ±5V, ±15V 25°C 0.2 5 µA/V

25°C 75 95 dB

25°C 0.2 5 µA/V

VS = ±15V

R

= 400Ω

L

VS = ±5V

R

= 150Ω

L

25°C 500 2000 kΩ

25°C 500 1800 kΩ

VS = ±5V 25°C ±3.5 V

= 400Ω

L

25°C ±12 ±13.5 V

VS =±15V

R

= 150Ω

L

25°C ±12 V

VS =±15V

R

= 150Ω

L

25°C ±3.0 ±3.7 V

VS =±5V

VS = ±5V, 25°C 60 100 150 mA

VS = ±15V

VS = ±5V 25°C 6.4 9.5 mA

2

Page 3

Closed Loop AC Electrical Characteristics

VS = ±15V, AV = +2, R

Parameter Description Conditions

BW -3dB Bandwidth

SR Slew Rate

tr, t

f

t

pd

OS Overshoot

t

s

dG Differential Gain

dP Differential Phase

1. All AC tests are performed on a “warmed up” part, except for Slew Rate, which is pulse tested

2. Slew Rate is with V

3. DC offset from -0.714V through +0.714V, AC amplitude 286mV

= 560Ω, RL = 150Ω, T

F

[1]

[2] [1]

Rise Time, Fall Time

Propagation Delay

[1]

0.1% Settling Time

[3] [1]

[3] [1]

from +10V to -10V and measured at the 25% and 75% points

OUT

= 25°C unless otherwise noted.

A

VS = ±15V, AV = +2 130 MHz

VS = ±15V, AV = +1 180 MHz

VS = ±5V, AV = +2 100 MHz

VS = ±5V, AV = +1 110 MHz

R

= 400Ω 1000 1500 V/µs

L

R

= 1KΩ, RG = 110Ω

F

R

= 400Ω

[1]

[1]

[1]

L

V

= ±500mV 2.7 ns

OUT

V

= ±500mV 0 %

OUT

V

= ±10V

OUT

AV = -1, RL = 1k

R

= 150Ω 0.025 %

L

R

= 500Ω 0.006 %

L

R

= 150Ω 0.1 °

L

R

= 500Ω 0.005 °

L

, f = 3.58MHz

p-p

EL2160C

EL2160C

180MHz Current Feedback Amplifier

Limits

UnitMin Typ Max

1500 V/µs

3.2 ns

35 ns

3

Page 4

EL2160C

180MHz Current Feedback Amplifier

EL2160C

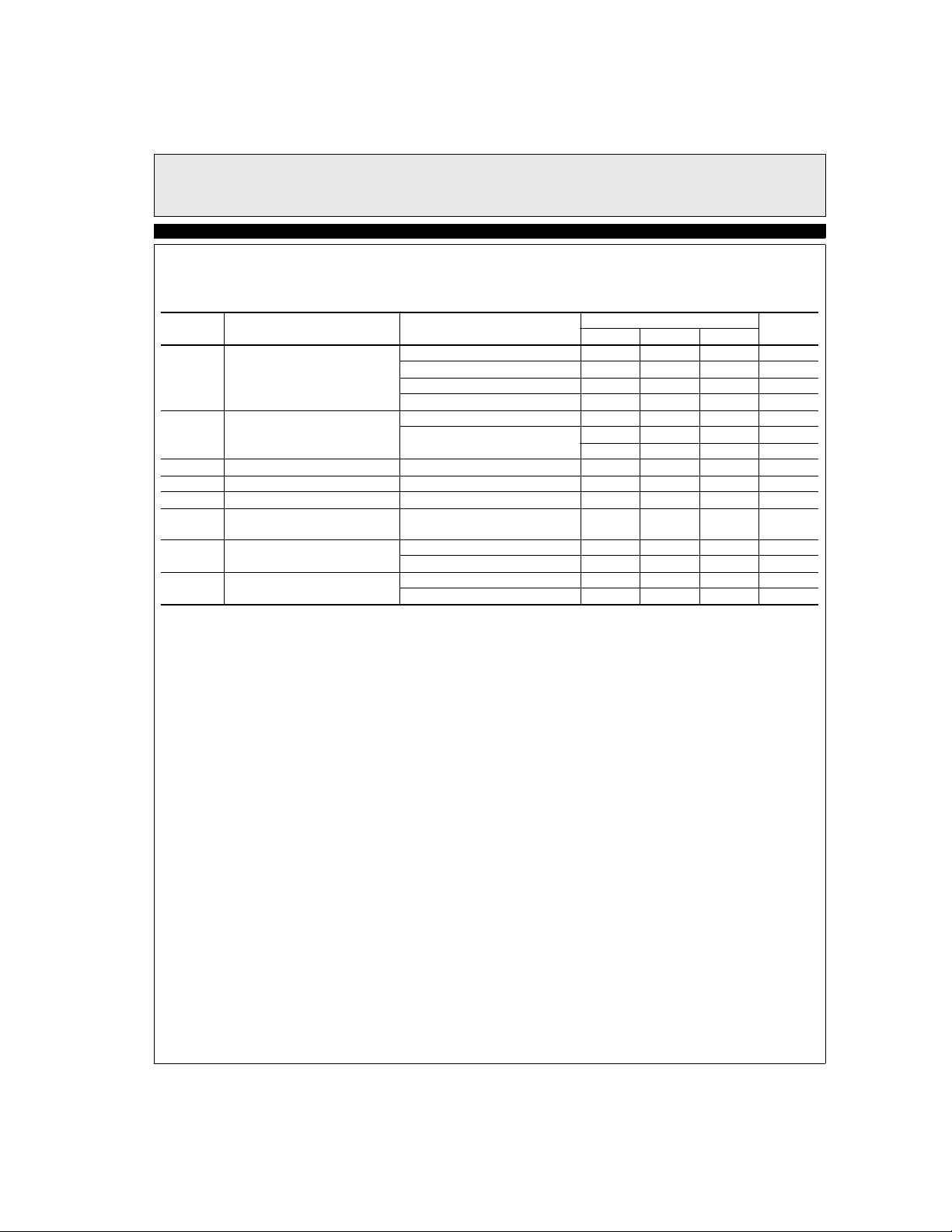

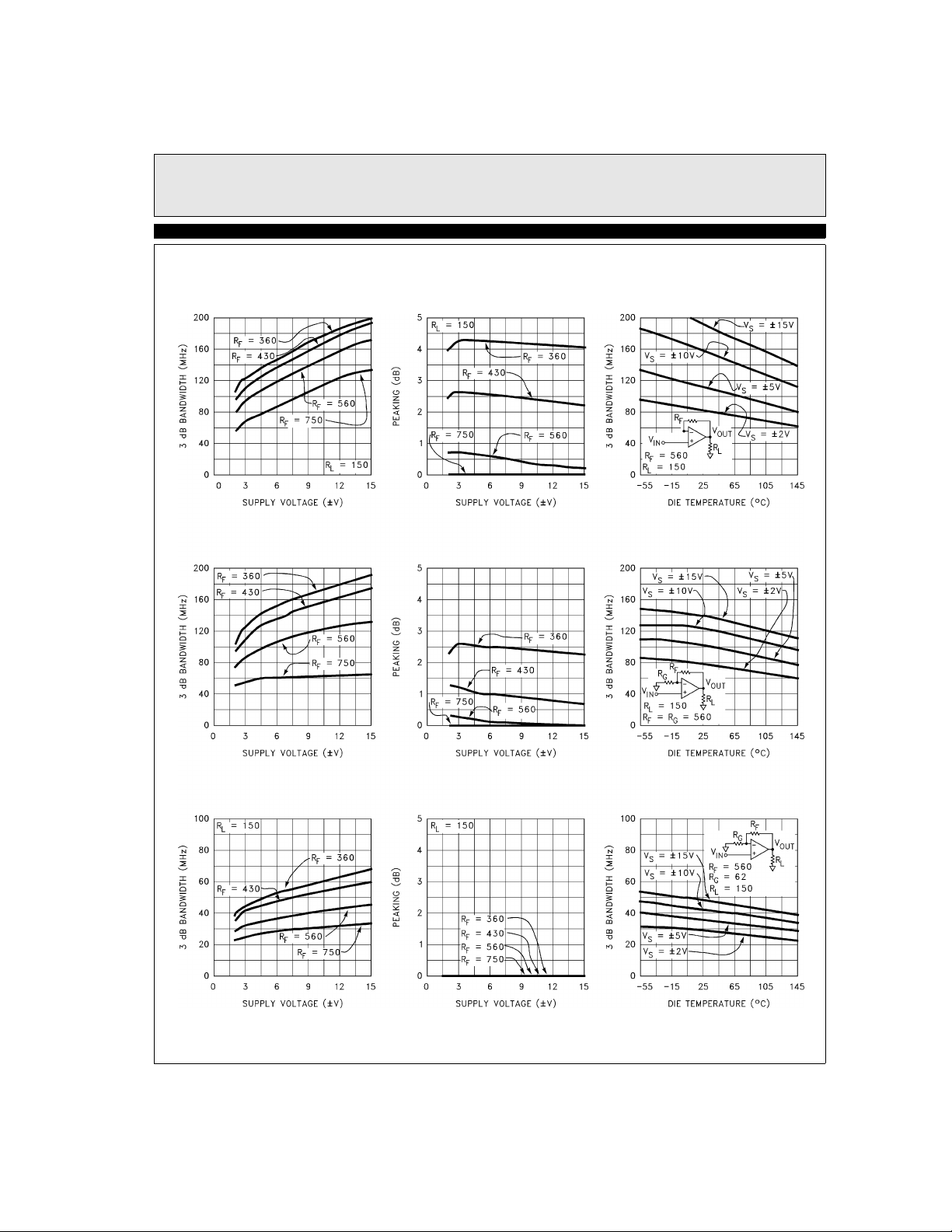

Typical Performance Curves

Non-Inverting Frequency

Response (Gain)

Inverting Frequency

Response (Gain)

Non-Inverting Frequency

Response (Phase)

Inverting Frequency

Response (Phase)

Frequency Response

for Various R

Frequency Response for

Various RF and R

L

G

R

F

3dB Bandwidth vs Supply

Voltage for AV = -1

Peaking vs Supply Voltage

for AV = -1

4

3dB Bandwidth vs

Temperature for AV = - 1

Page 5

EL2160C

180MHz Current Feedback Amplifier

EL2160C

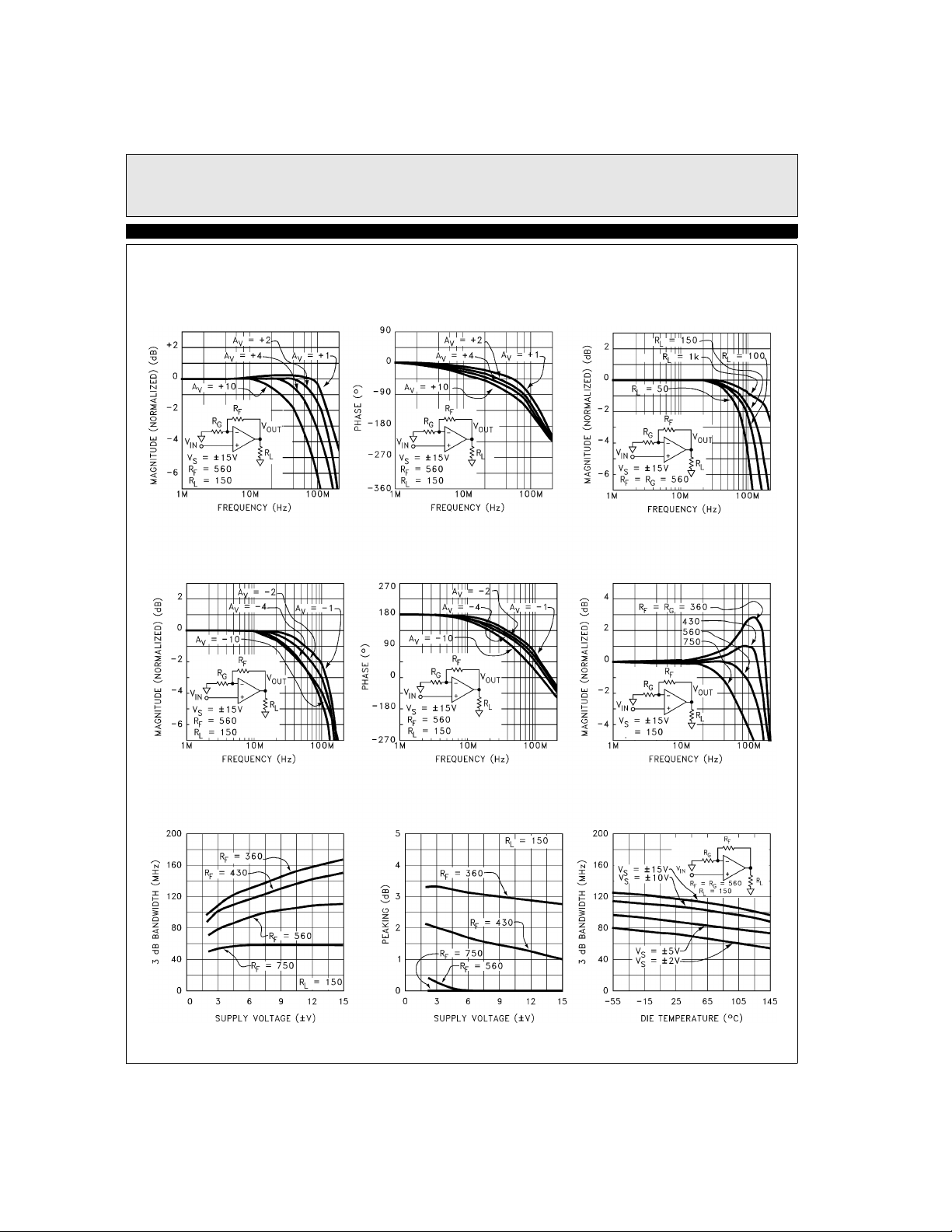

3dB Bandwidth vs Supply

Voltage for AV = +1

3dB Bandwidth vs Supply

Voltage for AV = +2

Peaking vs Supply Voltage

for AV = +1

Peaking vs Supply Voltage

for AV = +2

3dB Bandwidth vs Temperature

for AV = +1

3dB Bandwidth vs Temperature

for AV = +2

3dB Bandwidth vs Supply

Voltage for AV = +10

Peaking vs Supply Voltage

for AV = +10

5

3dB Bandwidth vs Temperature

for AV = +10

Page 6

EL2160C

180MHz Current Feedback Amplifier

EL2160C

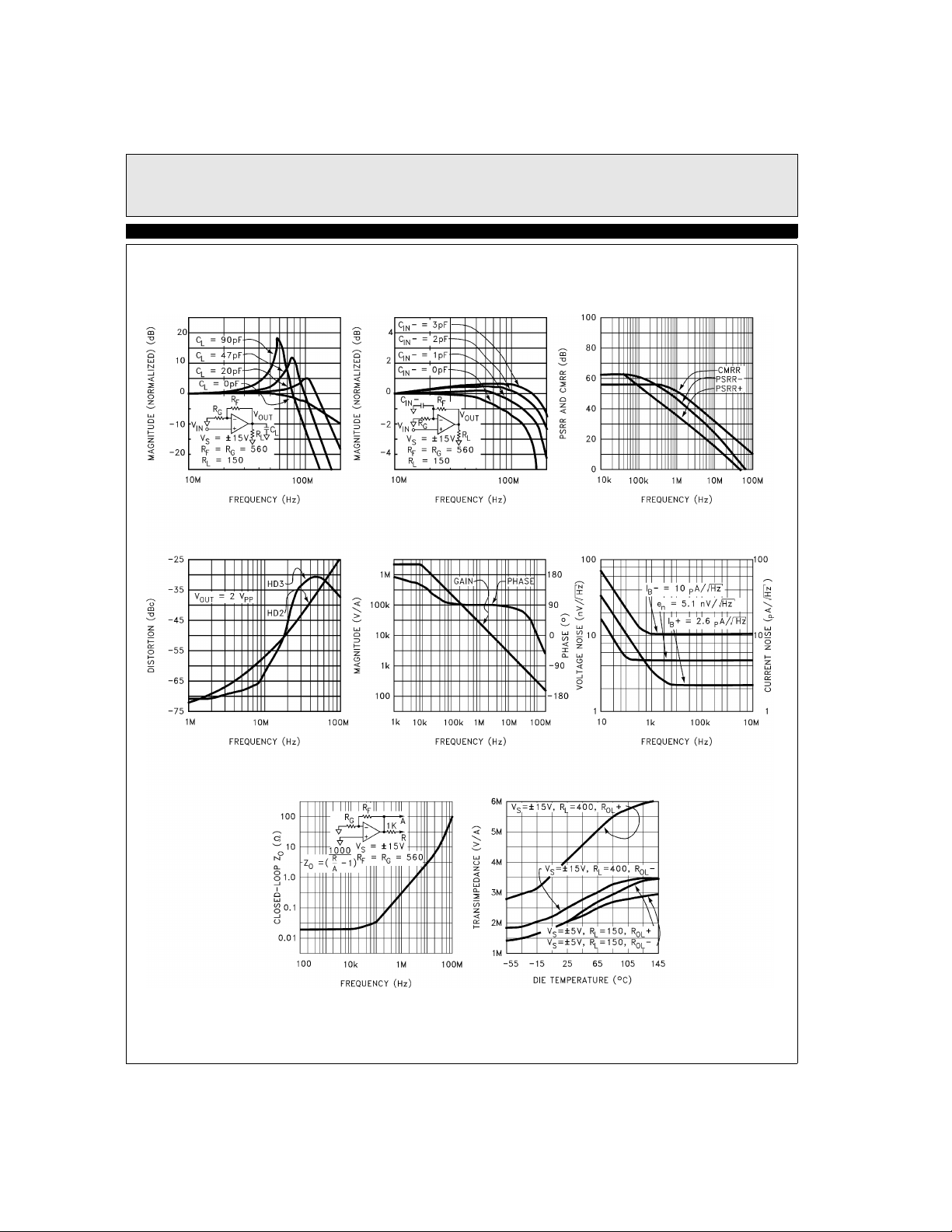

Frequency Response

for Various C

2nd and 3rd Harmonic

Distortion vs Frequency

L

Frequency Response

for Various C

Transimpedance (ROL)

vs Frequency

IN-

PSRR and CMRR

vs Frequency

Voltage and Current Noise

vs Frequency

Closed-Loop Output

Impedance vs Frequency

Transimpedance (ROL)

vs Die Temperature

6

Page 7

EL2160C

180MHz Current Feedback Amplifier

EL2160C

Offset Voltage

vs Die Temperature

(4 Samples)

+Input Resistance

vs Die Temperature

Supply Current

vs Die Temperature

Input Current

vs Die Temperature

Supply Current

vs Supply Voltage

+Input Bias Current

vs Input Voltage

Output Voltage Swing

vs Die Temperature

Short Circuit Current

vs Die Temperature

PSRR & CMRR

vs Die Temperature

7

Page 8

EL2160C

180MHz Current Feedback Amplifier

EL2160C

Differential Gain

vs DC Input Voltage,

RL = 150

Differential Gain

vs DC Input Voltage,

RL = 500

Differential Phase

vs DC Input Voltage,

RL = 150

Differential Phase

vs DC Input Voltage,

RL = 500

Small Signal

Pulse Response

Large Signal

Pulse Response

Slew Rate

vs Supply Voltage

Slew Rate

vs Temperature

Settling Time

vs Settling Accuracy

8

Page 9

EL2160C

180MHz Current Feedback Amplifier

EL2160C

Long Term Settling Error

Burn-In Circuit

Package Power Dissipation vs Ambient Temp.

JEDEC JESD51-3 Low Effective Thermal Conductivity Test Board

1.6

1.344

1.4

1.2

1.250

1

0.8

781m

0.6

Power Dissipation (W)

0.4

0.2

0

0 25 50 75 100 125 15085

SO16 (0.300”)

θJA=93°C/W

SO8

θJA=160°C/W

Ambient Temperature (°C)

PDIP8

θJA=100°C/W

EL2160C

9

Page 10

EL2160C

180MHz Current Feedback Amplifier

EL2160C

Differential Gain and Phase Test Circuit

Simplified Schematic (One Amplifier)

10

Page 11

Applications Information

EL2160C

EL2160C

180MHz Current Feedback Amplifier

Product Description

The EL2160C is a current mode feedback amplifier that

offers wide bandwidth and good video specifications at a

moderately low supply current. It is built using Elantec's

proprietary complimentary bipolar process and is

offered in industry standard pin-outs. Due to the current

feedback architecture, the EL2160C closed-loop 3dB

bandwidth is dependent on the value of the feedback

resistor. First the desired bandwidth is selected by

choosing the feedback resistor, RF, and then the gain is

set by picking the gain resistor, RG. The curves at the

beginning of the Typical Performance Curves section

show the effect of varying both RF and RG. The 3dB

bandwidth is somewhat dependent on the power supply

voltage. As the supply voltage is decreased, internal

junction capacitances increase, causing a reduction in

closed loop bandwidth. To compensate for this, smaller

values of feedback resistor can be used at lower supply

voltages.

Power Supply Bypassing and Printed Circuit

Board Layout

As with any high frequency device, good printed circuit

board layout is necessary for optimum performance.

Ground plane construction is highly recommended.

Lead lengths should be as short as possible, below ¼.

The power supply pins must be well bypassed to reduce

the risk of oscillation. A 1.0µF tantalum capacitor in

parallel with a 0.01µF ceramic capacitor is adequate for

each supply pin.

For good AC performance, parasitic capacitances should

be kept to a minimum, especially at the inverting input

(see Capacitance at the Inverting Input section). This

implies keeping the ground plane away from this pin.

Carbon resistors are acceptable, while use of wirewound resistors should not be used because of their parasitic inductance. Similarly, capacitors should be low

inductance for best performance. Use of sockets, particularly for the SO package, should be avoided. Sockets

add parasitic inductance and capacitance which will

result in peaking and overshoot.

Capacitance at the Inverting Input

Due to the topology of the current feedback amplifier,

stray capacitance at the inverting input will affect the

AC and transient performance of the EL2160C when

operating in the non-inverting configuration. The characteristic curve of gain vs. frequency with variations of

CIN- emphasizes this effect. The curve illustrates how

the bandwidth can be extended to beyond 200MHz with

some additional peaking with an additional 2pF of

capacitance at the VIN- pin for the case of AV = +2.

Higher values of capacitance will be required to obtain

similar effects at higher gains.

In the inverting gain mode, added capacitance at the

inverting input has little effect since this point is at a virtual ground and stray capacitance is therefore not “seen”

by the amplifier.

Feedback Resistor Values

The EL2160C has been designed and specified with

R

=560Ω for A

F

yields extremely flat frequency response with little to no

peaking out to 130MHz. As is the case with all current

feedback amplifiers, wider bandwidth, at the expense of

slight peaking, can be obtained by reducing the value of

the feedback resistor. Inversely, larger values of feedback resistor will cause rolloff to occur at a lower

frequency. By reducing R

extended to 170MHz with under 1dB of peaking. Further reduction of R

195MHz with about 2.5dB of peaking. See the curves in

the Typical Performance Curves section which show

3dB bandwidth and peaking vs. frequency for various

feedback resistors and various supply voltages.

= +2. This value of feedback resistor

V

to 430Ω, bandwidth can be

F

to 360Ω increases the bandwidth to

F

Bandwidth vs Temperature

Whereas many amplifier's supply current and consequently 3dB bandwidth drop off at high temperature, the

EL2160C was designed to have little supply current

variations with temperature. An immediate benefit from

this is that the 3dB bandwidth does not drop off drastically with temperature. With VS = ±15V and AV = +2,

the bandwidth only varies from 150MHz to 110MHz

11

Page 12

EL2160C

180MHz Current Feedback Amplifier

EL2160C

over the entire die junction temperature range of 0°C < T

< 150°C.

Supply Voltage Range

The EL2160C has been designed to operate with supply

voltages from ±2V to ±15V. Optimum bandwidth, slew

rate, and video characteristics are obtained at higher supply voltages. However, at ±2V supplies, the 3dB

bandwidth at AV = +2 is a respectable 70MHz. The following figure is an oscilloscope plot of the EL2160C at

±2V supplies, AV = +2, RF = R

= 560Ω, driving a load

G

of 150Ω, showing a clean ±600mV signal at the output.

If a single supply is desired, values from +4V to +30V

can be used as long as the input common mode range is

not exceeded. When using a single supply, be sure to

either 1) DC bias the inputs at an appropriate common

mode voltage and AC couple the signal, or 2) ensure the

driving signal is within the common mode range of the

EL2160C.

Settling Characteristics

The EL2160C offers superb settling characteristics to

0.1%, typically in the 35ns to 40ns range. There are no

aberrations created from the input stage which often

cause longer settling times in other current feedback

amplifiers. The EL2160C is not slew rate limited, therefore any size step up to ±10V gives approximately the

same settling time.

As can be seen from the Long Term Settling Error curve,

for AV = +1, there is approximately a 0.035% residual

which tails away to 0.01% in about 40µs. This is a thermal settling error caused by a power dissipation

differential (before and after the voltage step). For AV =

-1, due to the inverting mode configuration, this tail does

not appear since the input stage does not experience the

large voltage change as in the non-inverting mode. With

AV = -1, 0.01% settling time is slightly greater than

100ns.

Power Dissipation

The EL2160C amplifier combines both high speed and

large output current drive capability at a moderate supply current in very small packages. It is possible to

exceed the maximum junction temperature allowed

under certain supply voltage, temperature, and loading

conditions. To ensure that the EL2160C remains within

its absolute maximum ratings, the following discussion

will help to avoid exceeding the maximum junction

temperature.

The maximum power dissipation allowed in a package is

determined by its thermal resistance and the amount of

temperature rise according to:

T

–

JMAXTAMAX

DMAX

2V

---------------------------------------------

=

θ

JA

SV(SVOUT

V

OUT

)

---------------×–+×=

R

L

P

The maximum power dissipation actually produced by

an IC is the total quiescent supply current times the total

power supply voltage plus the power in the IC due to the

load, or:

P

DMAX

where IS is the supply current. (To be more accurate, the

quiescent supply current flowing in the output driver

transistor should be subtracted from the first term

because, under loading and due to the class AB nature of

the output stage, the output driver current is now

included in the second term.)

In general, an amplifier's AC performance degrades at

higher operating temperature and lower supply current.

Unlike some amplifiers, the EL2160C maintains almost

constant supply current over temperature so that AC performance is not degraded as much over the entire

operating temperature range. Of course, this increase in

performance doesn't come for free. Since the current has

increased, supply voltages must be limited so that maximum power ratings are not exceeded.

12

Page 13

EL2160C

180MHz Current Feedback Amplifier

EL2160C

The EL2160C consumes typically 8.5mA and maximum

11.0mA. The worst case power in an IC occurs when the

output voltage is at half supply, if it can go that far, or its

maximum values if it cannot reach half supply. If we set

the two P

equations equal to each other, and solve

DMAX

for VS, we can get a family of curves for various loads

and output voltages according to:

RLT

()×

MAX-TAMAX

----------------------------------------------------------

V

S

θ

JA

V

()2( I

OUT

SRL

) V

+××[]÷+=

OUT

The following curves show supply voltage (±VS) vs

R

for various output voltage swings for the 2 dif-

LOAD

ferent packages. The curves assume worst case

conditions of TA = +85°C and IS = 11mA.

Supply Voltage vs R

(8-Pin SO Package)

Supply Voltage vs R

Various V

OUT

for Various V

LOAD

for

LOAD

(PDIP Package)

OUT

The curves do not include heat removal or forcing air, or

the simple fact that the package will probably be

attached to a circuit board, which can also provide some

form of heat removal. Larger temperature and voltage

ranges are possible with heat removal and forcing air

past the part.

Current Limit

The EL2160C has an internal current limit that protects

the circuit in the event of the output being shorted to

ground. This limit is set at 100mA nominally and

reduces with junction temperature. At a junction temperature of 150°C, the current limits at about 65mA. If the

output is shorted to ground, the power dissipation could

be well over 1W. Heat removal is required in order for

the EL2160C to survive an indefinite short.

Driving Cables and Capacitive Loads

When used as a cable driver, double termination is

always recommended for reflection-free performance.

For those applications, the back termination series resistor will decouple the EL2160C from the capacitive cable

and allow extensive capacitive drive. However, other

applications may have high capacitive loads without termination resistors. In these applications, an additional

small value (5Ω–50Ω) resistor in series with the output

will eliminate most peaking. The gain resistor, RG, can

be chosen to make up for the gain loss created by this

additional series resistor at the output.

13

Page 14

EL2160C

180MHz Current Feedback Amplifier

EL2160C

EL2160C Macromodel

* Revision A, November 1993

* AC Characteristics used CIN- (pin 2) = 1 pF; R

* Connections: +input

* | -input

* | | +Vsupply

* | | | -Vsupply

* | | | | output

* | | | | |

.subckt EL2160C/EL 3 2 7 4 6

*

* Input Stage

*

e1 10 0 3 0 1.0

vis 10 9 0V

h2 9 12 vxx 1.0

r1 2 11 130

l1 11 12 25nH

iinp 3 0 0.5µA

iinm 2 0 5µA

r12 3 0 2Meg

*

* Slew Rate Limiting

*

h1 13 0 vis 600

r2 13 14 1K

d1 14 0 dclamp

d2 0 14 dclamp

*

* High Frequency Pole

*

*e2 30 0 14 0 0.00166666666

l3 30 17 0.43µH

c5 17 0 0.27pF

r5 17 0 500

*

* Transimpedance Stage

*

g1 0 18 17 0 1.0

ro1 18 0 2Meg

cdp 18 0 2.285pF

*

* Output Stage

*

q1 4 18 19 qp

q2 7 18 20 qn

q3 7 19 21 qn

q4 4 20 22 qp

r7 21 6 4

r8 22 6 4

ios1 7 19 2mA

ios2 20 4 2mA

*

* Supply Current

*

ips 7 4 3mA

*

* Error Terms

*

ivos 0 23 2mA

vxx 23 0 0V

e4 24 0 3 0 1.0

e5 25 0 7 0 1.0

= 560Ω

F

14

Page 15

e6 26 0 4 0 1.0

r9 24 23 562

r10 25 23 1K

r11 26 23 1K

*

* Models

*

.model qn npn (is=5e-15 bf=100 tf=0.1ns)

.model qp pnp (is=5e-15 bf=100 tf=0.1ns)

.model dclamp d (is=1e-30 ibv=0.266 bv=2.24 n=4)

.ends

EL2160C Macromodel

EL2160C

EL2160C

180MHz Current Feedback Amplifier

15

Page 16

EL2160C

180MHz Current Feedback Amplifier

EL2160C

16

Page 17

EL2160C

180MHz Current Feedback Amplifier

EL2160C

17

Page 18

EL2160C

180MHz Current Feedback Amplifier

EL2160C

General Disclaimer

Specifications contained in this data sheet are in effect as of the publication date shown. Elantec, Inc. reserves the right to make changes in the circuitry or specifications contained herein at any time without notice. Elantec, Inc. assumes no responsibility for the use of any circuits described

herein and makes no representations that they are free from patent infringement.

WARNING - Life Support Policy

Elantec, Inc. products are not authorized for and should not be used

within Life Support Systems without the specific written consent of

Elantec, Inc. Life Support systems are equipment intended to sup-

Elantec Semiconductor, Inc.

675 Trade Zone Blvd.

Milpitas, CA 95035

Telephone: (408) 945-1323

(888) ELANTEC

Fax: (408) 945-9305

European Office: +44-118-977-6020

Japan Technical Center: +81-45-682-5820

port or sustain life and whose failure to perform when properly used

in accordance with instructions provided can be reasonably

expected to result in significant personal injury or death. Users contemplating application of Elantec, Inc. Products in Life Support

Systems are requested to contact Elantec, Inc. factory headquarters

to establish suitable terms & conditions for these applications. Elantec, Inc.’s warranty is limited to replacement of defective

components and does not cover injury to persons or property or

other consequential damages.

September 26, 2001

18

Printed in U.S.A.

Loading...

Loading...