Datasheet dsPIC33FJ64GP206, dsPIC33FJ64GP306, dsPIC33FJ64GP310, dsPIC33FJ64GP706, dsPIC33FJ64GP708 Datasheet

...

dsPIC33FJXXXGPX06/X08/X10

Data Sheet

High-Performance,

16-Bit Digital Signal Controllers

© 2009 Microchip Technology Inc. DS70286C

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

PICSTART, rfPIC, SmartShunt and UNI/O are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

FilterLab, Linear Active Thermistor, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, In-Circuit Serial

Programming, ICSP, ICEPIC, Mindi, MiWi, MPASM, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, nanoWatt XLP,

PICkit, PICDEM, PICDEM.net, PICtail, PIC

32

logo, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB, Select

Mode, Total Endurance, TSHARC, WiperLock and ZENA are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2009, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS70286C-page ii © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

High-Performance, 16-Bit Digital Signal Controllers

Operating Range:

• Up to 40 MIPS operation (at 3.0-3.6V):

- Industrial temperature range

(-40°C to +85°C)

High-Performance DSC CPU:

• Modified Harvard architecture

• C compiler optimized instruction set

• 16-bit wide data path

• 24-bit wide instructions

• Linear program memory addressing up to 4M

instruction words

• Linear data memory addressing up to 64 Kbytes

• 83 base instructions: mostly 1 word/1 cycle

• Sixteen 16-bit General Purpose Registers

• Two 40-bit accumulators:

- With rounding and saturation options

• Flexible and powerful addressing modes:

- Indirect, Modulo and Bit-Reversed

• Software stack

• 16 x 16 fractional/integer multiply operations

• 32/16 and 16/16 divide operations

• Single-cycle multiply and accumulate:

- Accumulator write back for DSP operations

- Dual data fetch

• Up to ±16-bit shifts for up to 40-bit data

Direct Memory Access (DMA):

• 8-channel hardware DMA:

• 2 Kbytes dual ported DMA buffer area

(DMA RAM) to store data transferred via DMA:

- Allows data transfer between RAM and a

peripheral while CPU is executing code

(no cycle stealing)

• Most peripherals support DMA

Interrupt Controller:

• 5-cycle latency

• Up to 63 available interrupt sources

• Up to five external interrupts

• Seven programmable priority levels

• Five processor exceptions

Digital I/O:

• Up to 85 programmable digital I/O pins

• Wake-up/Interrupt-on-Change on up to 24 pins

• Output pins can drive from 3.0V to 3.6V

• All digital input pins are 5V tolerant

• 4 mA sink on all I/O pins

On-Chip Flash and SRAM:

• Flash program memory, up to 256 Kbytes

• Data SRAM, up to 30 Kbytes (includes 2 Kbytes

of DMA RAM):

System Management:

• Flexible clock options:

- External, crystal, resonator, internal RC

- Fully integrated PLL

- Extremely low jitter PLL

• Power-up Timer

• Oscillator Start-up Timer/Stabilizer

• Watchdog Timer with its own RC oscillator

• Fail-Safe Clock Monitor

• Reset by multiple sources

Power Management:

• On-chip 2.5V voltage regulator

• Switch between clock sources in real time

• Idle, Sleep and Doze modes with fast wake-up

Timers/Capture/Compare/PWM:

• Timer/Counters, up to nine 16-bit timers:

- Can pair up to make four 32-bit timers

- 1 timer runs as Real-Time Clock with external

32.768 kHz oscillator

- Programmable prescaler

• Input Capture (up to eight channels):

- Capture on up, down or both edges

- 16-bit capture input functions

- 4-deep FIFO on each capture

• Output Compare (up to eight channels):

- Single or Dual 16-Bit Compare mode

- 16-bit Glitchless PWM mode

© 2009 Microchip Technology Inc. DS70286C-page 1

dsPIC33FJXXXGPX06/X08/X10

Communication Modules:

• 3-wire SPI (up to two modules):

- Framing supports I/O interface to simple

codecs

- Supports 8-bit and 16-bit data

- Supports all serial clock formats and

sampling modes

2

C™ (up to two modules):

•I

- Full Multi-Master Slave mode support

- 7-bit and 10-bit addressing

- Bus collision detection and arbitration

- Integrated signal conditioning

- Slave address masking

• UART (up to two modules):

- Interrupt on address bit detect

- Interrupt on UART error

- Wake-up on Start bit from Sleep mode

- 4-character TX and RX FIFO buffers

- LIN bus support

®

-IrDA

- High-Speed Baud mode

- Hardware Flow Control with CTS and RTS

• Data Converter Interface (DCI) module:

- Codec interface

- Supports I

- Up to 16-bit data words, up to 16 words per

- 4-word deep TX and RX buffers

• Enhanced CAN (ECAN™ module) 2.0B active

(up to 2 modules):

- Up to eight transmit and up to 32 receive buffers

- 16 receive filters and three masks

- Loopback, Listen Only and Listen All

- Wake-up on CAN message

- Automatic processing of Remote

- FIFO mode using DMA

- DeviceNet™ addressing support

encoding and decoding in hardware

2

S and AC’97 protocols

frame

Messages modes for diagnostics and bus

monitoring

Transmission Requests

Analog-to-Digital Converters (ADCs):

• Up to two ADC modules in a device

• 10-bit, 1.1 Msps or 12-bit, 500 ksps conversion:

- Two, four or eight simultaneous samples

- Up to 32 input channels with auto-scanning

- Conversion start can be manual or

synchronized with one of four trigger sources

- Conversion possible in Sleep mode

- ±1 LSb max integral nonlinearity

- ±1 LSb max differential nonlinearity

CMOS Flash Technology:

• Low-power, high-speed Flash technology

• Fully static design

• 3.3V (±10%) operating voltage

• Industrial temperature

• Low-power consumption

Packaging:

• 100-pin TQFP (14x14x1 mm and 12x12x1 mm)

• 80-pin TQFP (12x12x1 mm)

• 64-pin TQFP (10x10x1 mm)

Note: See the device variant tables for exact

peripheral features per device.

DS70286C-page 2 © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

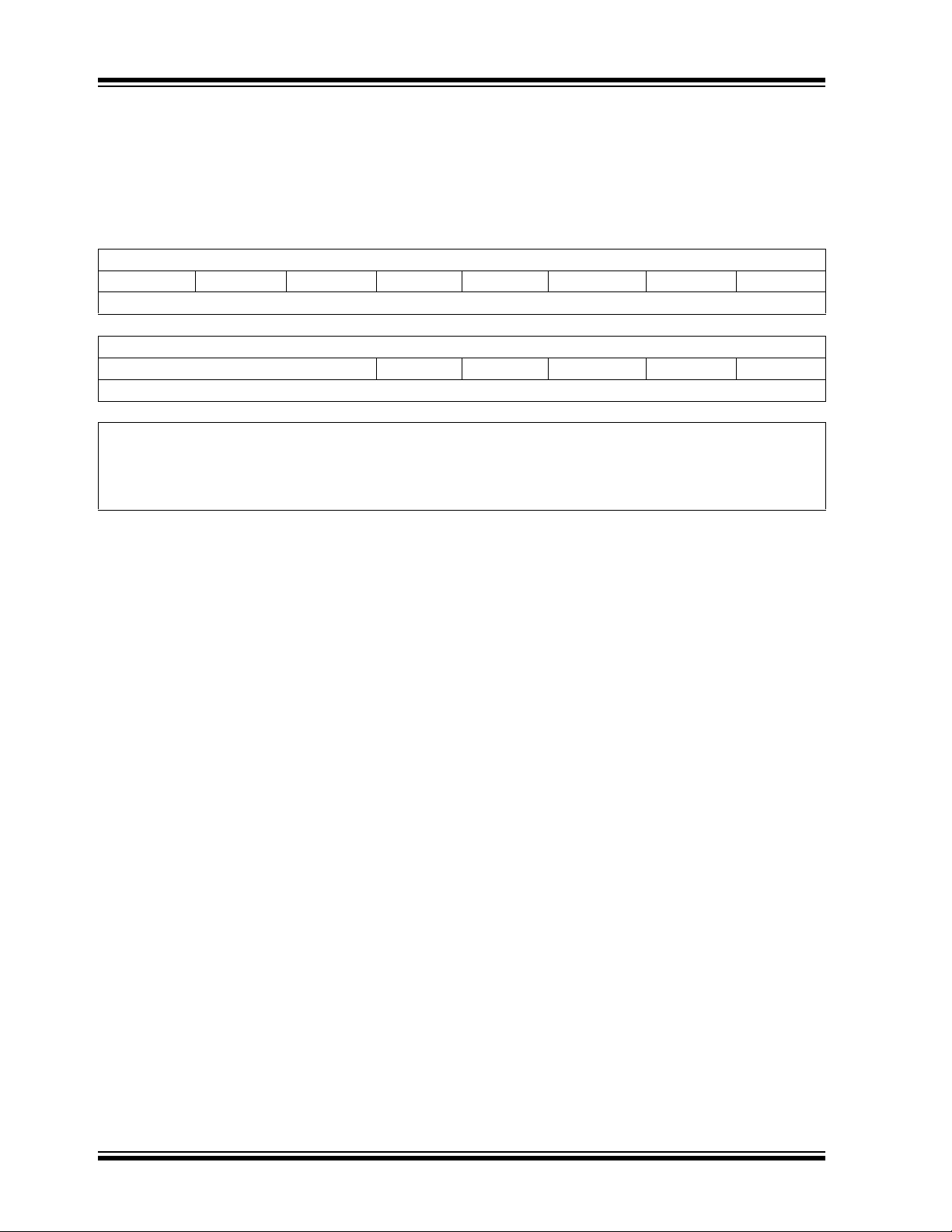

dsPIC33F PRODUCT FAMILIES

The device names, pin counts, memory sizes and

peripheral availability of each family are listed below,

The dsPIC33F General Purpose Family of devices

followed by their pinout diagrams.

are ideal for a wide variety of 16-bit MCU embedded

applications. The controllers with codec interfaces are

well-suited for speech and audio processing

applications.

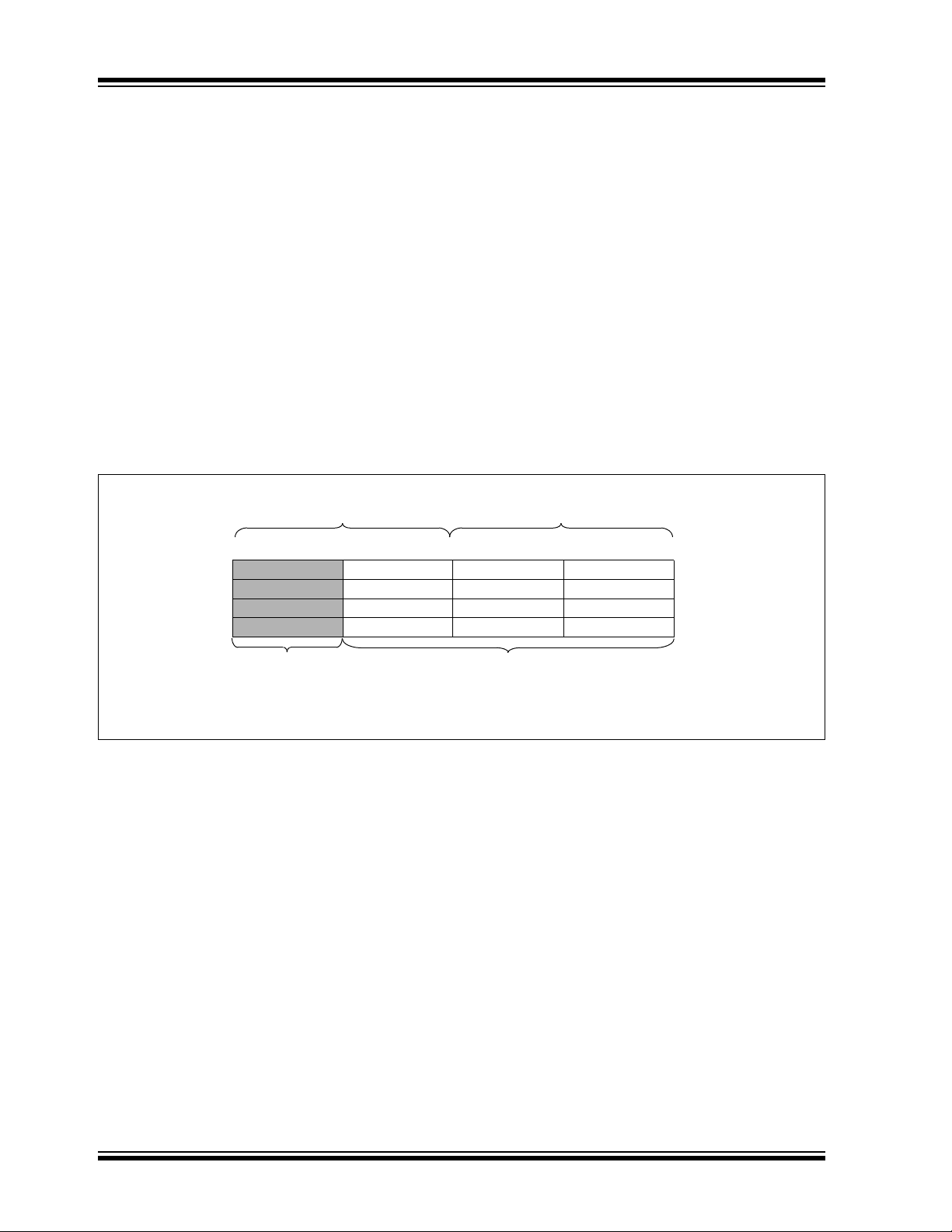

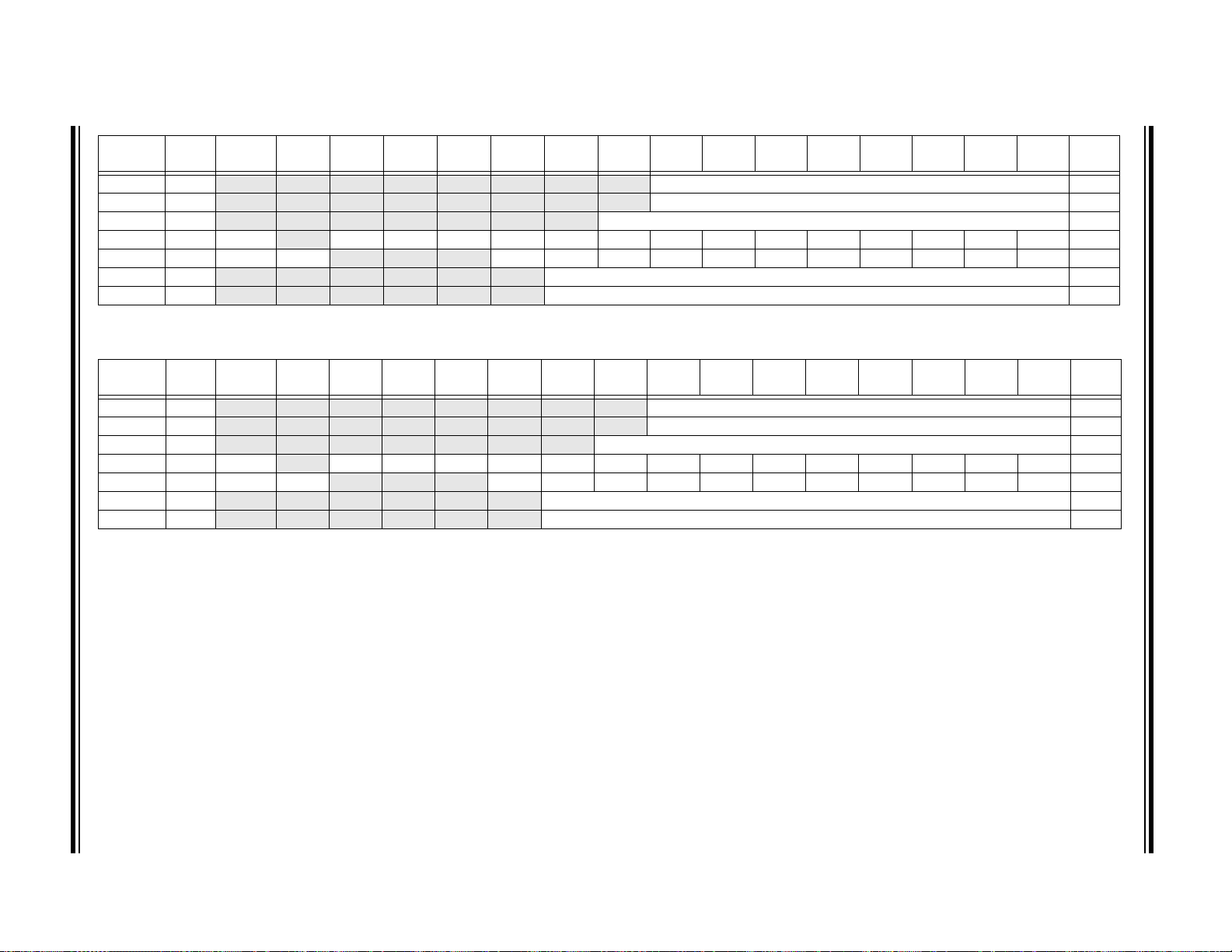

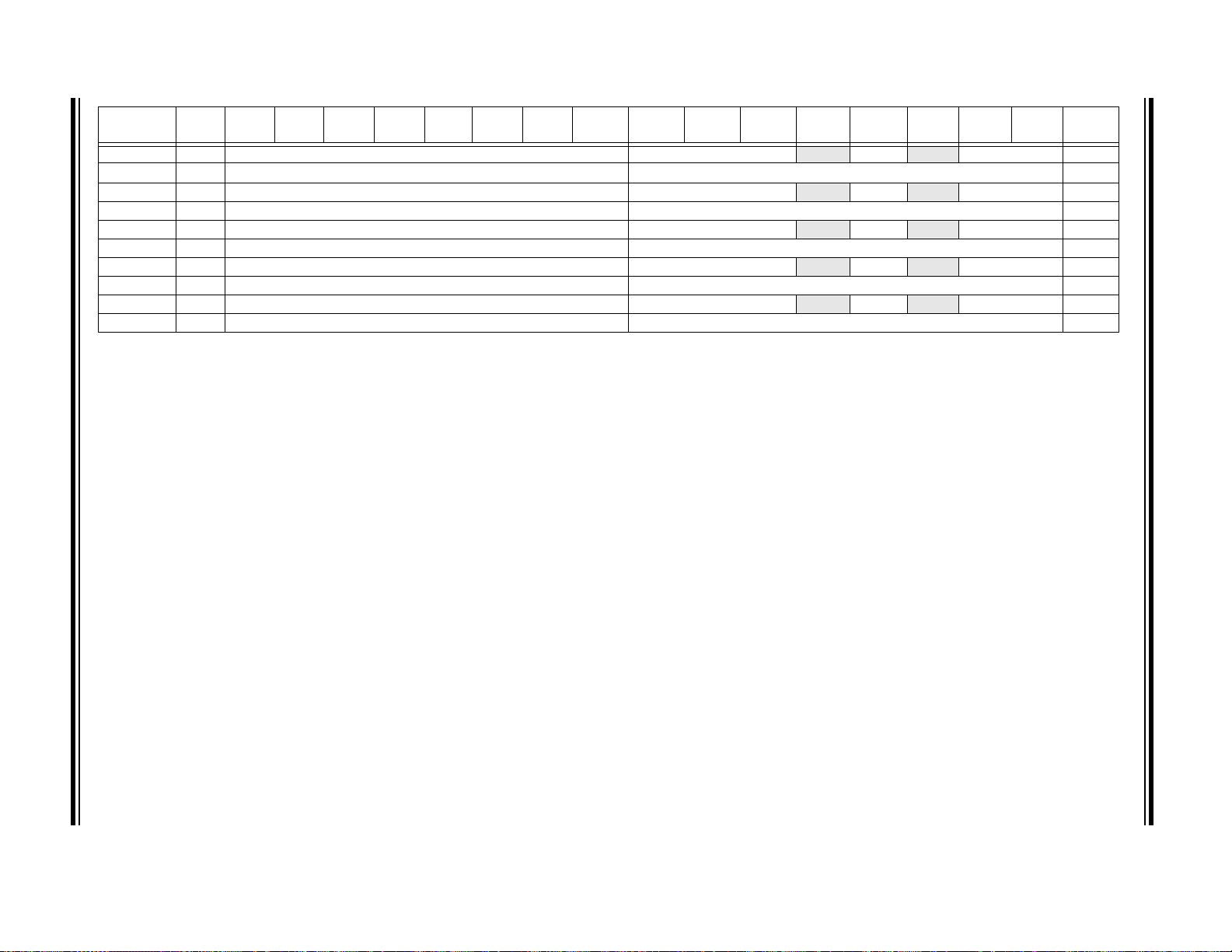

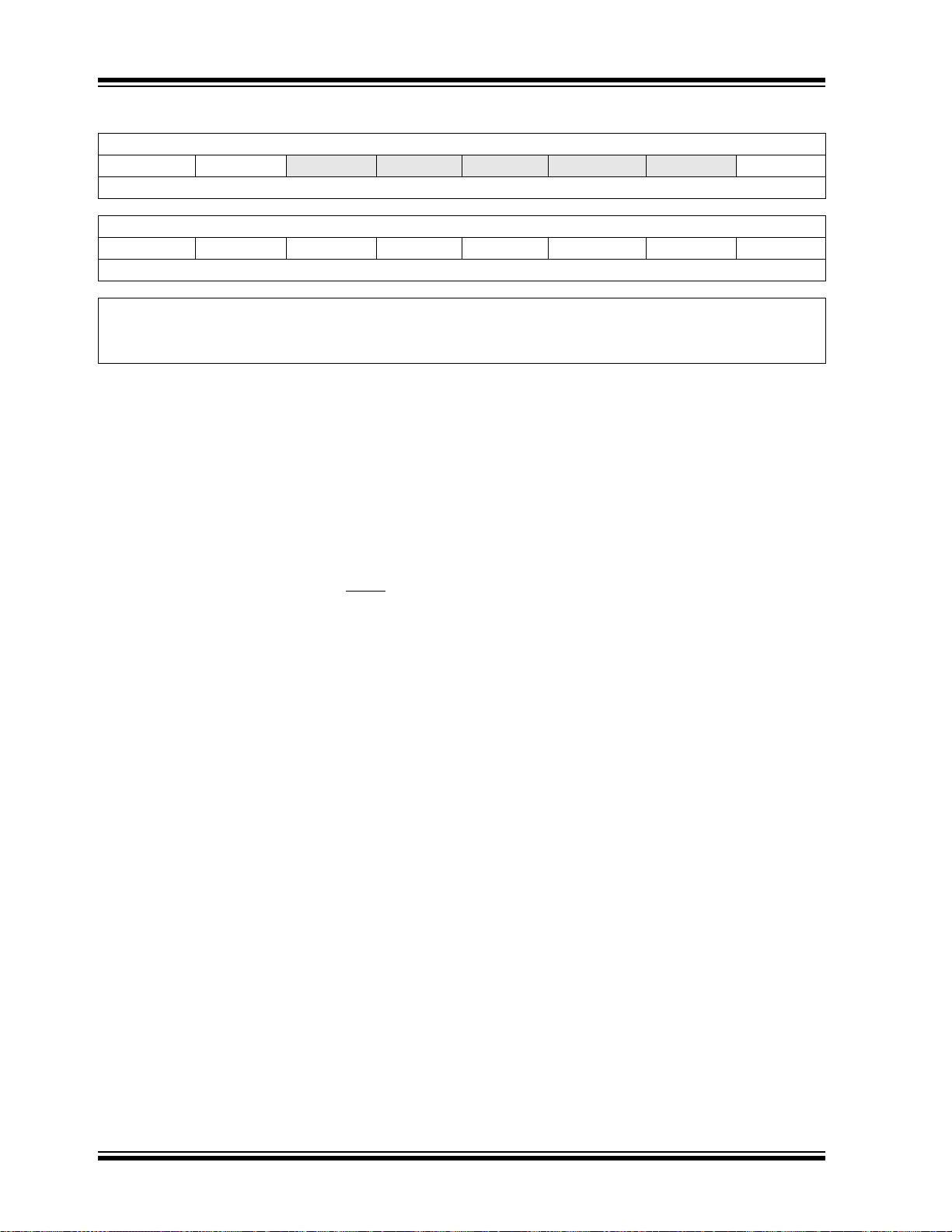

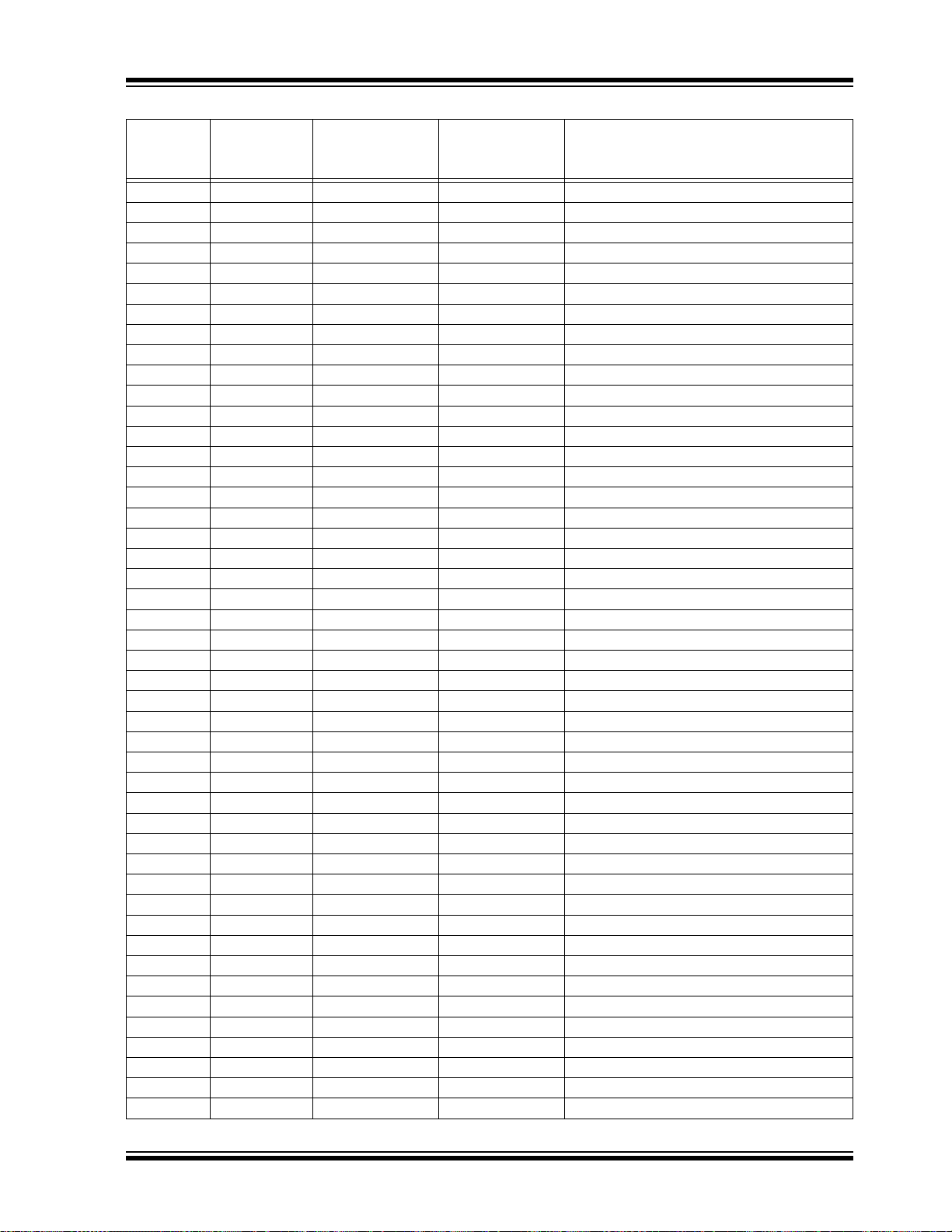

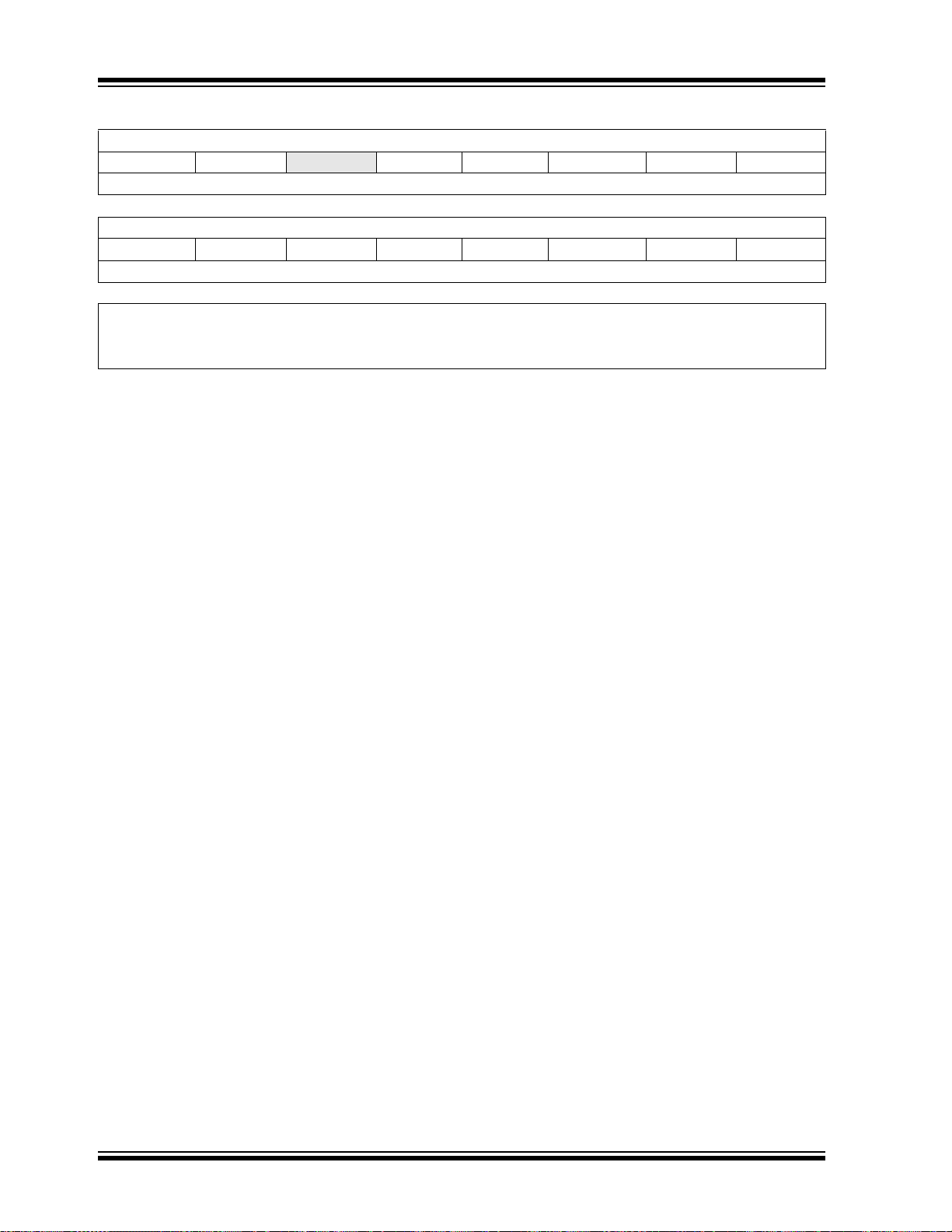

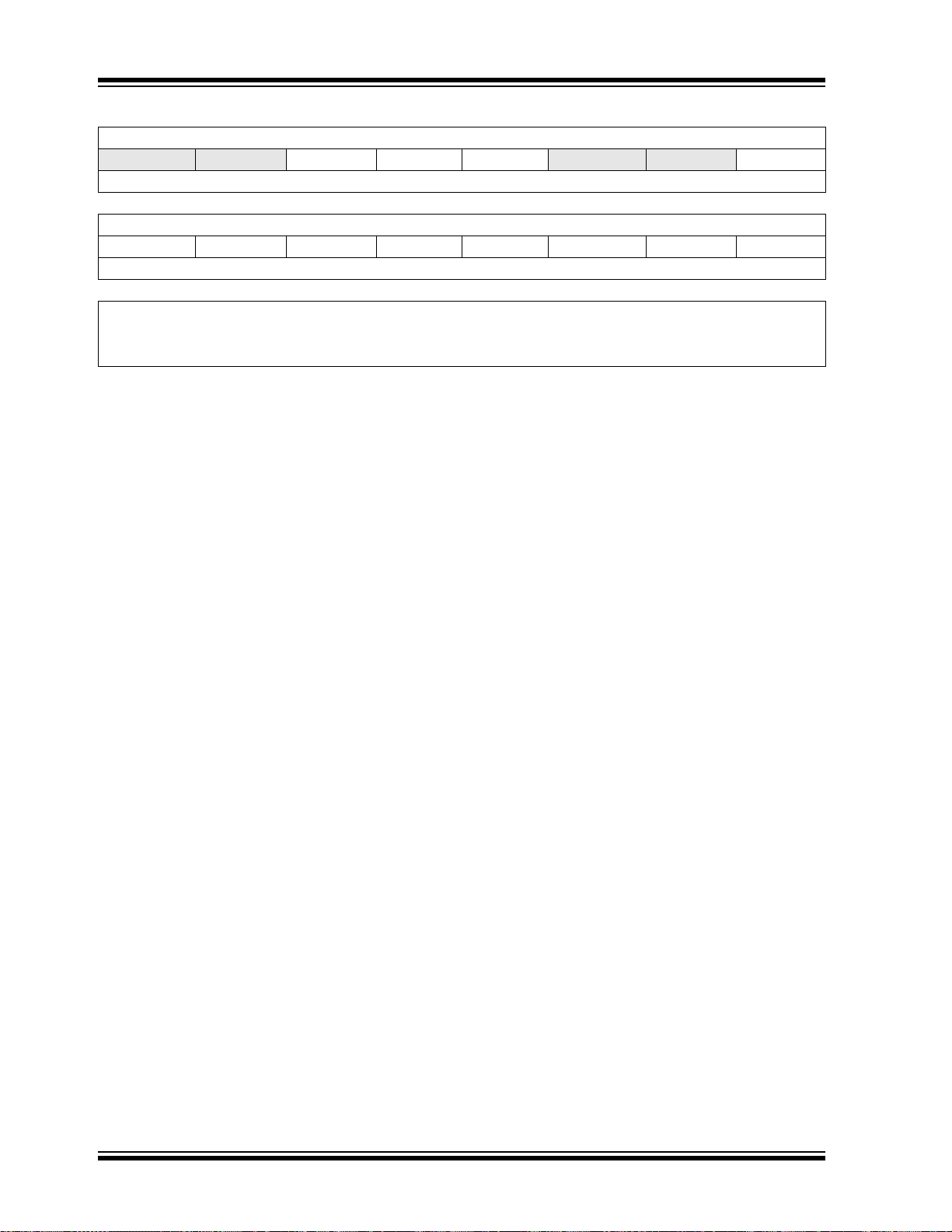

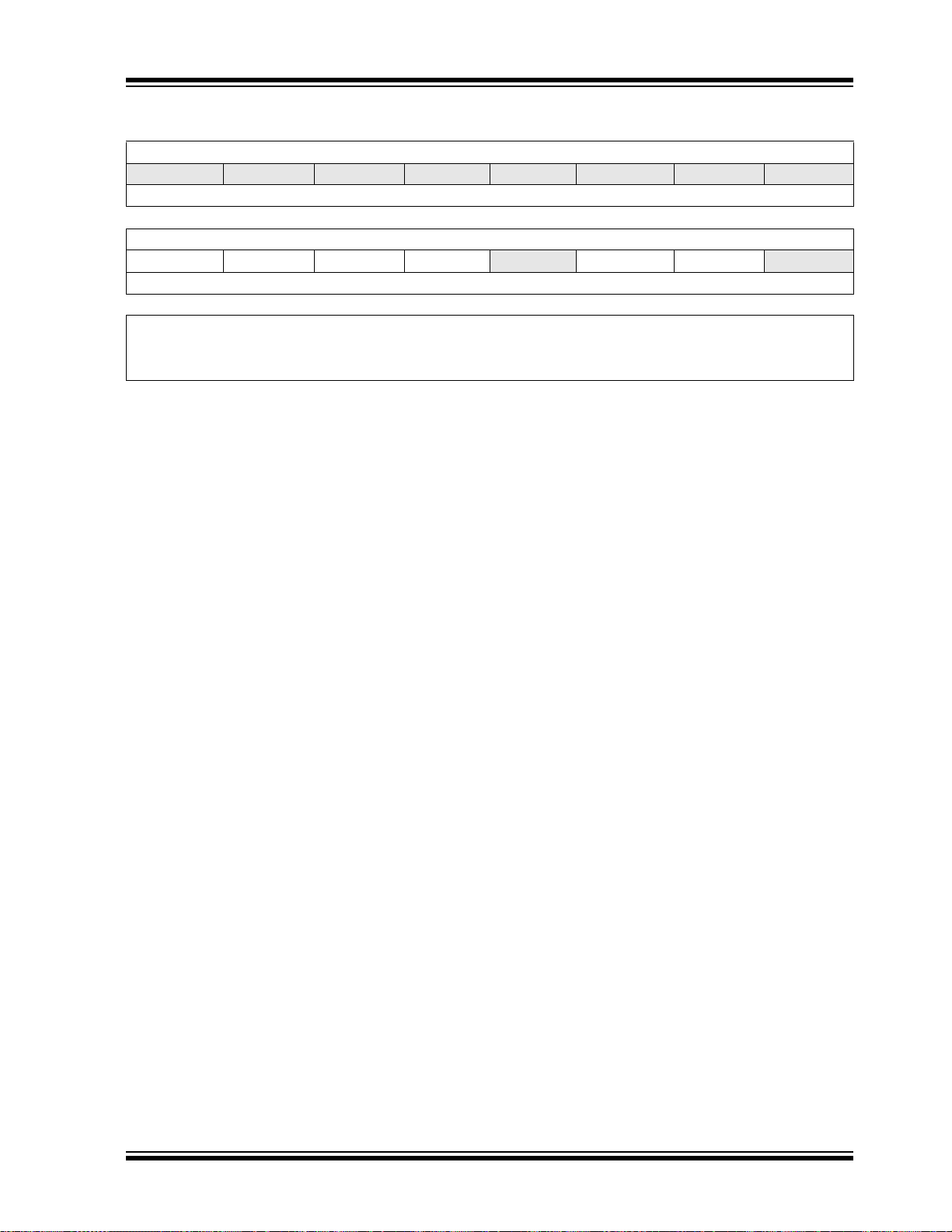

dsPIC33F General Purpose Family Controllers

(2)

Program

Device Pins

dsPIC33FJ64GP206 64 64 8 9 8 8 1 1 ADC, 18 ch221 053 PT

dsPIC33FJ64GP306 64 64 16 9 8 8 1 1 ADC, 18 ch222 053 PT

dsPIC33FJ64GP310 100 64 16 9 8 8 1 1 ADC, 32 ch222 085PF, PT

dsPIC33FJ64GP706 64 64 16 9 8 8 1 2 ADC, 18 ch222 253 PT

dsPIC33FJ64GP708 80 64 16 9 8 8 1 2 ADC, 24 ch222 269 PT

dsPIC33FJ64GP710 100 64 16 9 8 8 1 2 ADC, 32 ch222 285PF, PT

Flash

Memory

(Kbyte)

RAM

(Kbyte)

(1)

16-bit Timer

Input Capture

Output Compare

Codec

Interface

Std. PWM

ADC

UART

SPI

2

C™

I

Enhanced

Packages

CAN™

I/O Pins (Max)

dsPIC33FJ128GP206 64 128 8 9 8 8 1 1 ADC, 18 ch221 053 PT

dsPIC33FJ128GP306 64 128 16 9 8 8 1 1 ADC, 18 ch222 053 PT

dsPIC33FJ128GP310 100 128 16 9 8 8 1 1 ADC, 32 ch222 085PF, PT

dsPIC33FJ128GP706 64 128 16 9 8 8 1 2 ADC, 18 ch222 253 PT

dsPIC33FJ128GP708 80 128 16 9 8 8 1 2 ADC, 24 ch222 269 PT

dsPIC33FJ128GP710 100 128 16 9 8 8 1 2 ADC, 32 ch222 285PF, PT

dsPIC33FJ256GP506 64 256 16 9 8 8 1 1 ADC, 18 ch222 153 PT

dsPIC33FJ256GP510 100 256 16 9 8 8 1 1 ADC, 32 ch222 185PF, PT

dsPIC33FJ256GP710 100 256 30 9 8 8 1 2 ADC, 32 ch222 285PF, PT

Note 1: RAM size is inclusive of 2 Kbytes DMA RAM.

2: Maximum I/O pin count includes pins shared by the peripheral functions.

© 2009 Microchip Technology Inc. DS70286C-page 3

dsPIC33FJXXXGPX06/X08/X10

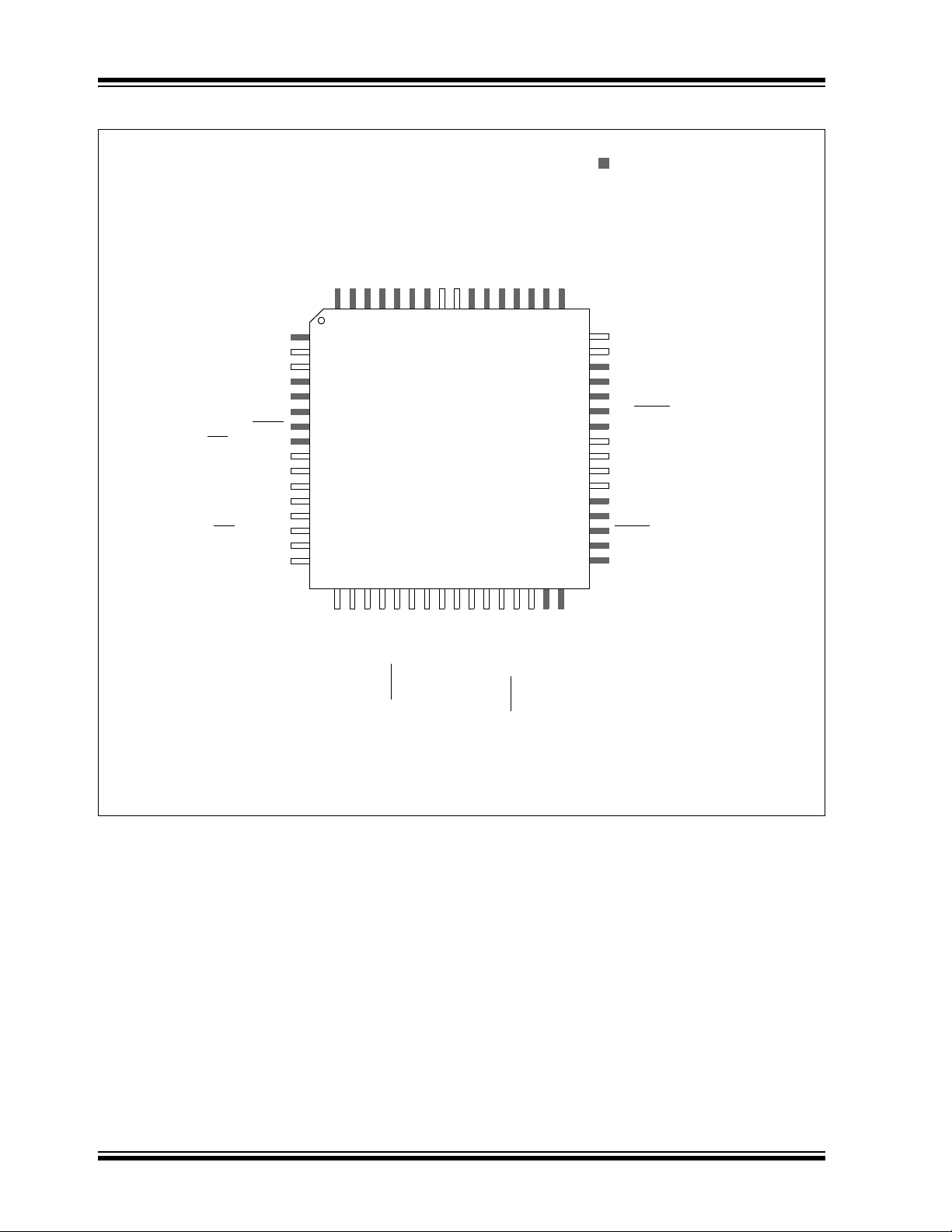

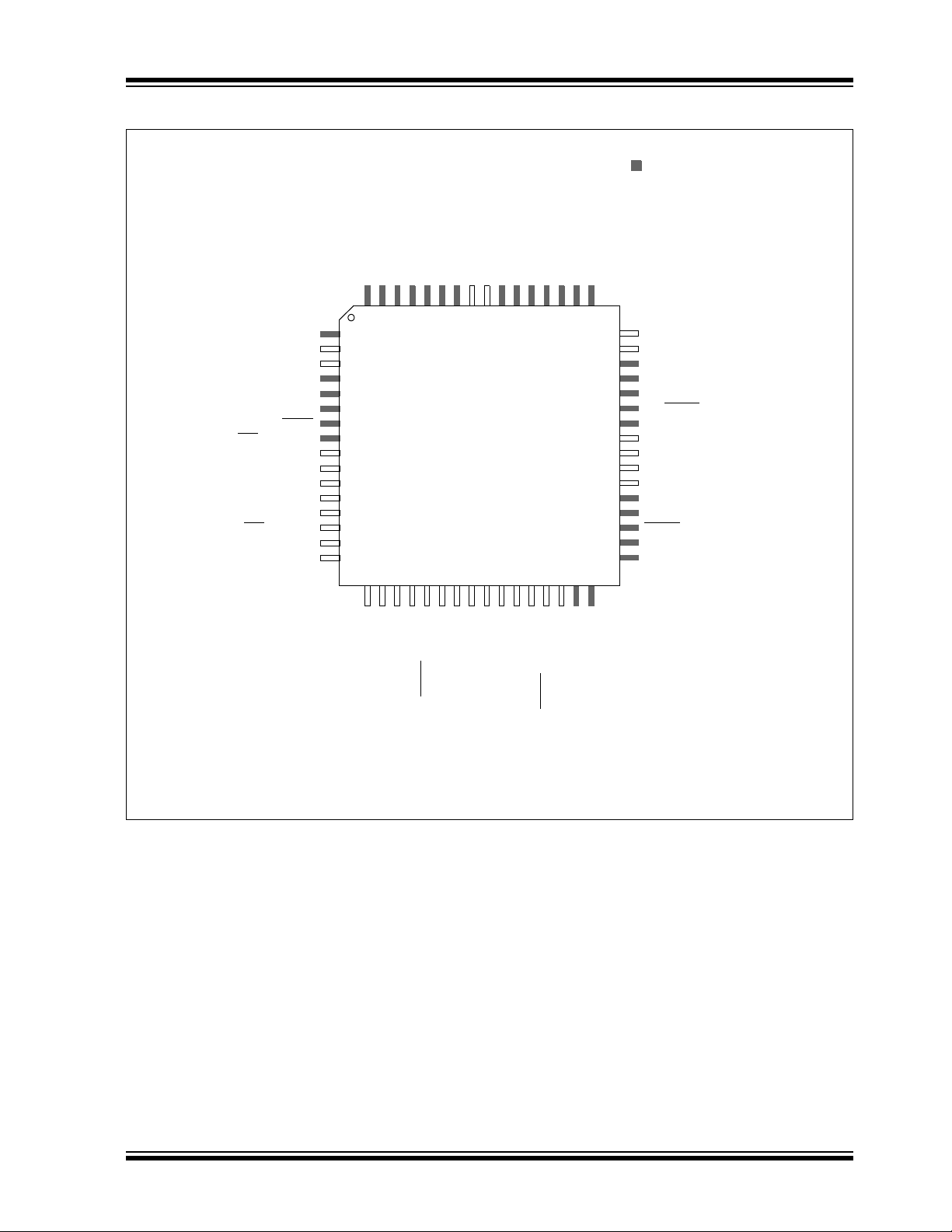

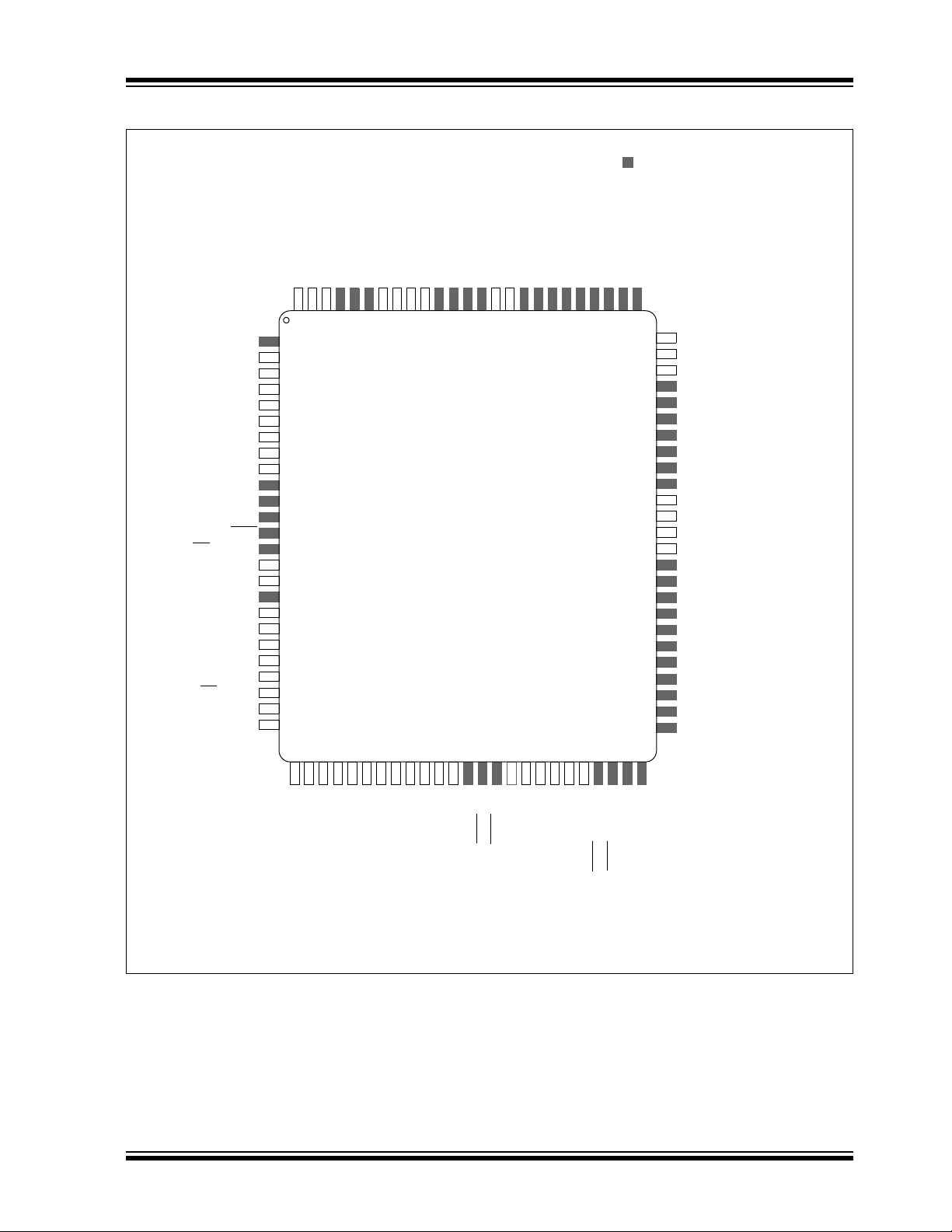

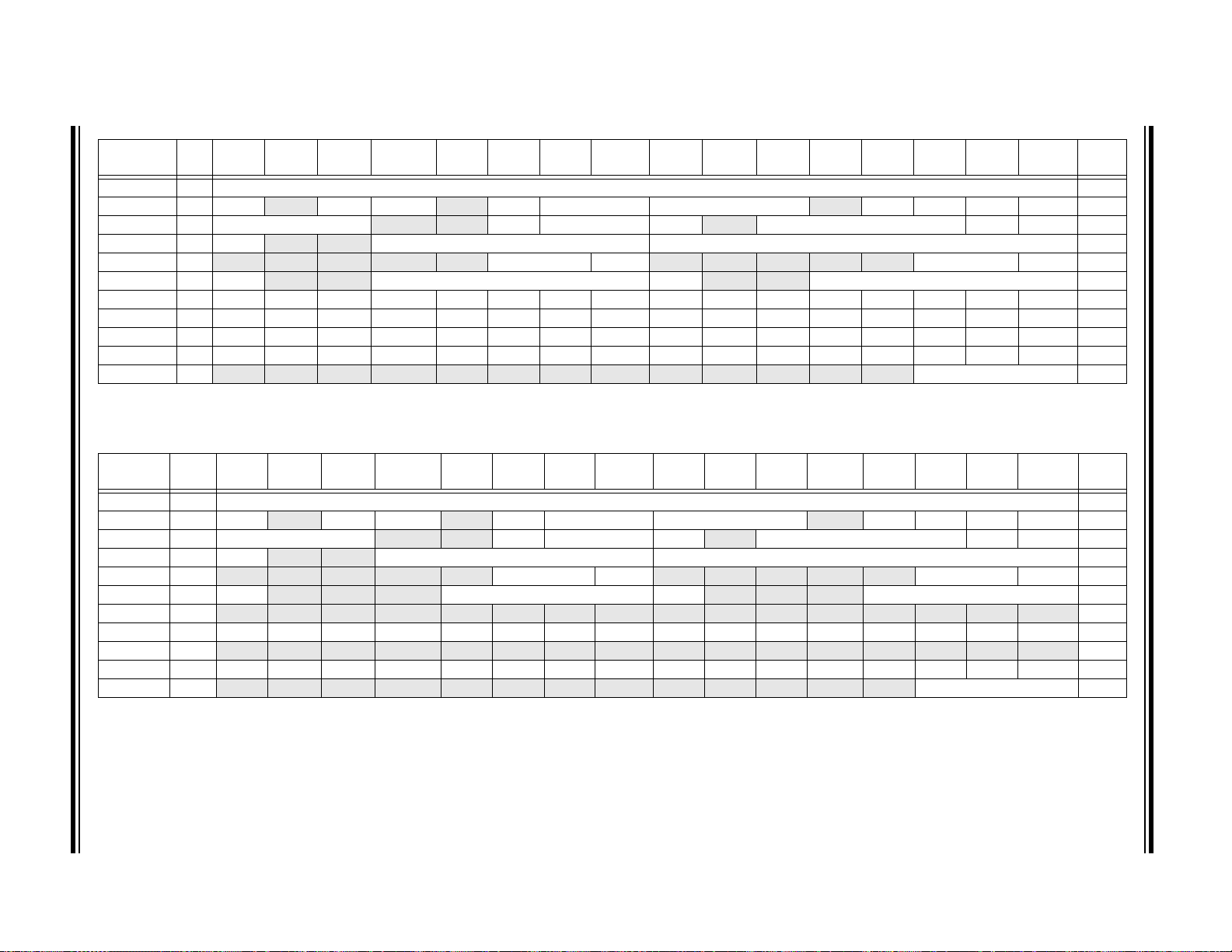

64-Pin TQFP

1

2

3

4

5

6

7

8

9

10

11

12

13

36

35

34

33

32

31

30

29

28

27

26

646362616059585756

14

15

16

171819202122232425

PGEC2/SOSCO/T1CK/CN0/RC14

PGED2/SOSCI/T4CK/CN1/RC13

OC1/RD0

IC4/INT4/RD11

IC2/U1CTS

/INT2/RD9

IC1/INT1/RD8

V

SS

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

U1RTS

/SCK1/INT0/RF6

U1RX/SDI1/RF2

U1TX/SDO1/RF3

COFS/RG15

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

MCLR

VSS

VDD

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

PGEC3/AN1/V

REF-/CN3/RB1

PGED3/AN0/V

REF+/CN2/RB0

OC8/CN16/RD7

CSDO/RG13

CSDI/RG12

CSCK/RG14

V

CAP/VDDCORE

RG1

RF1

RG0

OC2/RD1

OC3/RD2

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

AVDD

AVSS

U2CTS/AN8/RB8

AN9/RB9

TMS/AN10/RB10

TDO/AN11/RB11

V

SS

VDD

TCK/AN12/RB12

TDI/AN13/RB13

U2RTS

/AN14/RB14

AN15/OCFB/CN12/RB15

U2TX/CN18/RF5

U2RX/CN17/RF4

SDA1/RG3

43

42

41

40

39

38

37

44

48

47

46

504951

545352

55

45

SS2

/CN11/RG9

AN5/IC8/CN7/RB5

AN4/IC7/CN6/RB4

IC3/INT3/RD10

VDD

RF0

OC4/RD3

OC7/CN15/RD6

OC6/IC6/CN14/RD5

OC5/IC5/CN13/RD4

dsPIC33FJ64GP206

dsPIC33FJ128GP206

= Pins are up to 5V tolerant

Pin Diagrams

DS70286C-page 4 © 2009 Microchip Technology Inc.

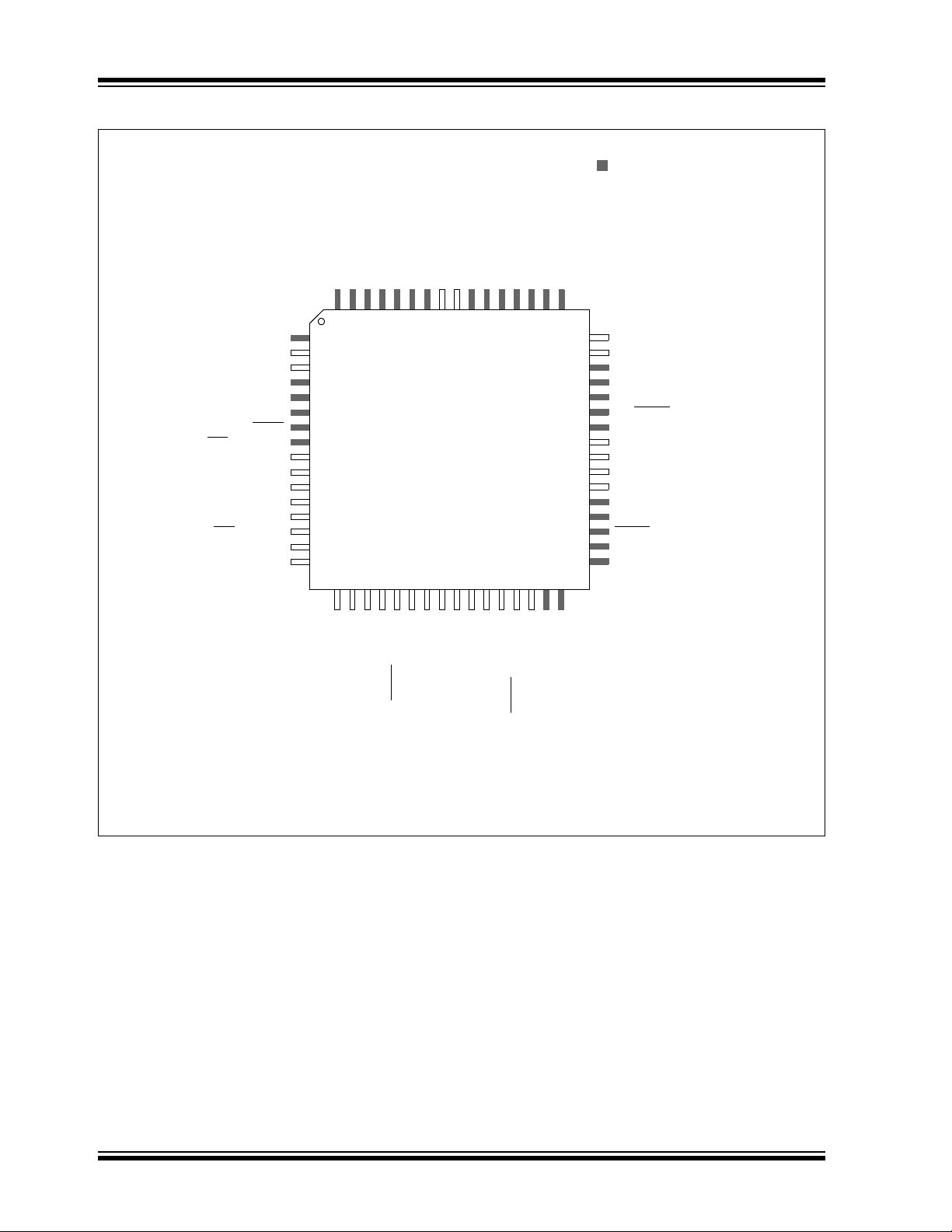

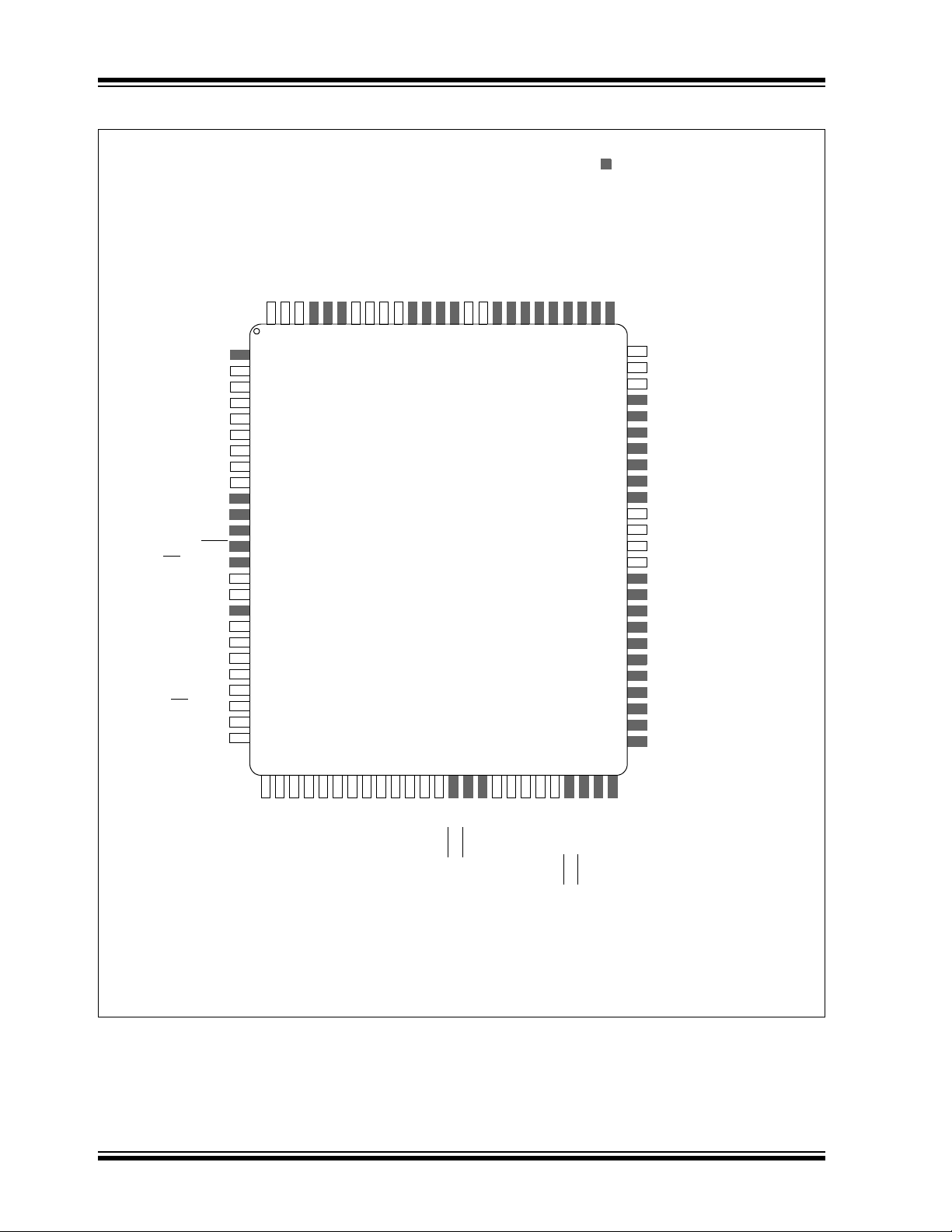

Pin Diagrams (Continued)

64-Pin TQFP

1

2

3

4

5

6

7

8

9

10

11

12

13

36

35

34

33

32

31

30

29

28

27

26

646362616059585756

14

15

16

171819202122232425

PGEC2/SOSCO/T1CK/CN0/RC14

PGED2/SOSCI/T4CK/CN1/RC13

OC1/RD0

IC4/INT4/RD11

IC2/U1CTS

/INT2/RD9

IC1/INT1/RD8

V

SS

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

U1RTS

/SCK1/INT0/RF6

U1RX/SDI1/RF2

U1TX/SDO1/RF3

COFS/RG15

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

MCLR

VSS

VDD

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

PGEC3/AN1/V

REF-/CN3/RB1

PGED3/AN0/V

REF+/CN2/RB0

OC8/CN16/RD7

CSDO/RG13

CSDI/RG12

CSCK/RG14

V

CAP/VDDCORE

RG1

RF1

RG0

OC2/RD1

OC3/RD2

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

AVDD

AVSS

U2CTS/AN8/RB8

AN9/RB9

TMS/AN10/RB10

TDO/AN11/RB11

V

SS

VDD

TCK/AN12/RB12

TDI/AN13/RB13

U2RTS

/AN14/RB14

AN15/OCFB/CN12/RB15

U2TX/SCL2/CN18/RF5

U2RX/SDA2/CN17/RF4

SDA1/RG3

43

42

41

40

39

38

37

44

48

47

46

504951

545352

55

45

SS2

/CN11/RG9

AN5/IC8/CN7/RB5

AN4/IC7/CN6/RB4

IC3/INT3/RD10

VDD

RF0

OC4/RD3

OC7/CN15/RD6

OC6/IC6/CN14/RD5

OC5/IC5/CN13/RD4

dsPIC33FJ64GP306

dsPIC33FJ128GP306

= Pins are up to 5V tolerant

dsPIC33FJXXXGPX06/X08/X10

© 2009 Microchip Technology Inc. DS70286C-page 5

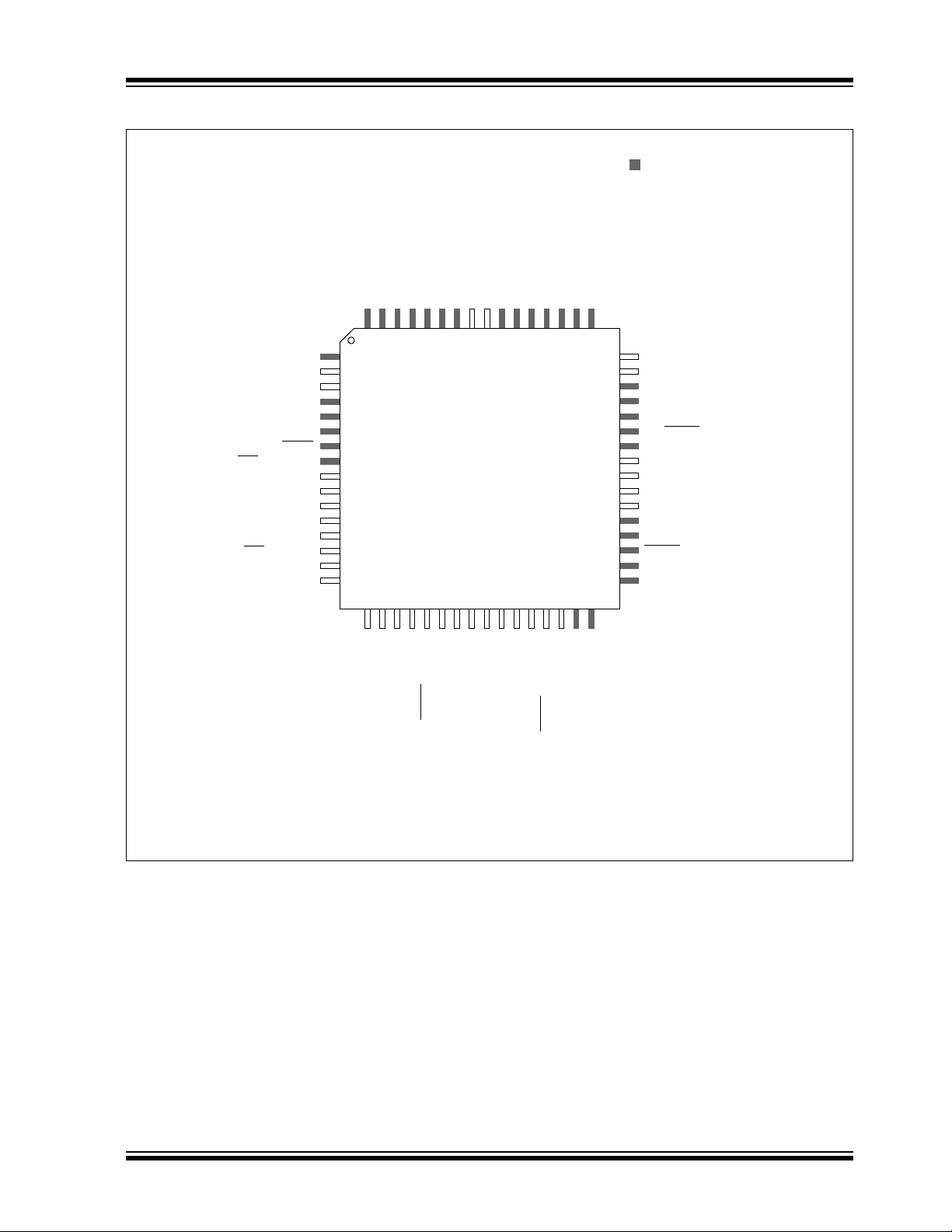

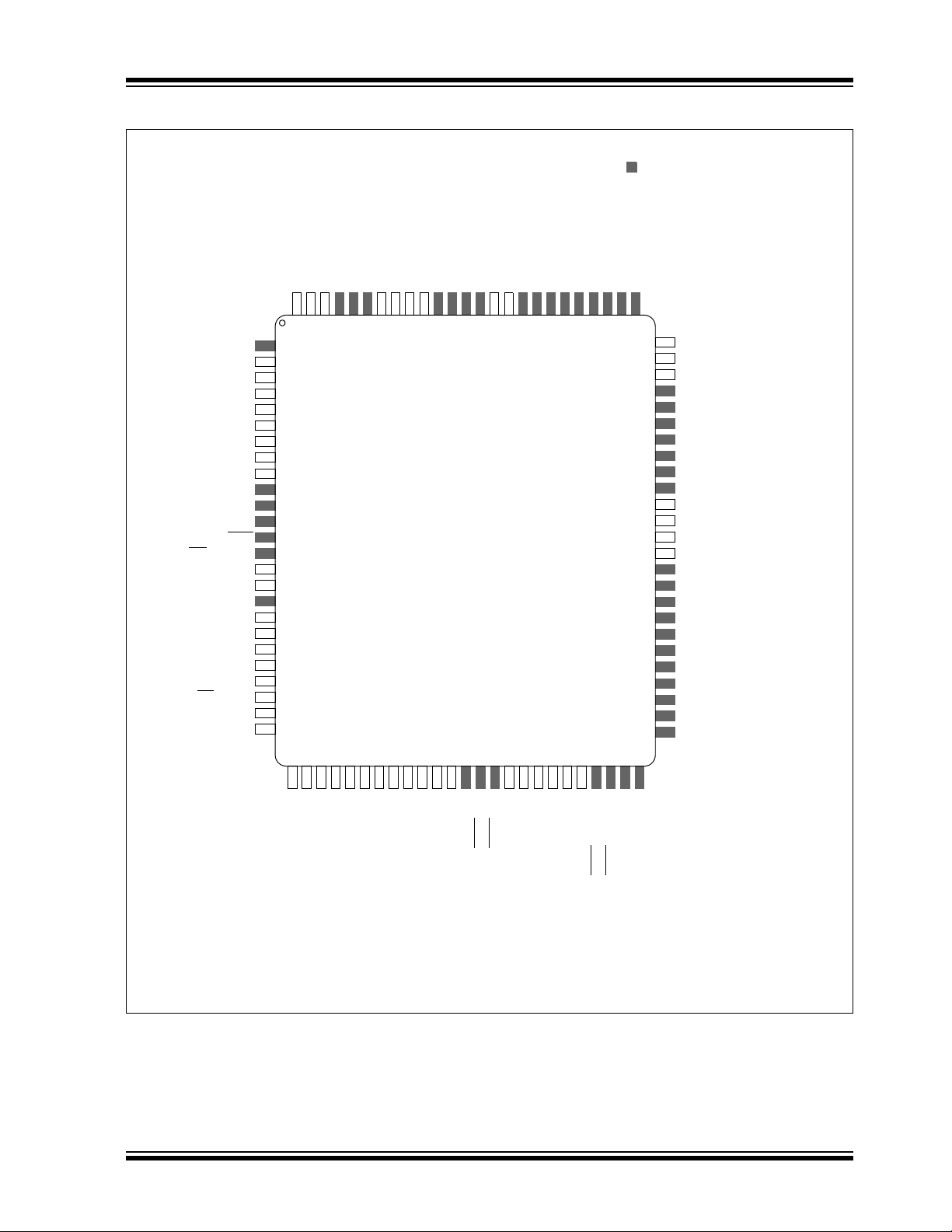

dsPIC33FJXXXGPX06/X08/X10

64-Pin TQFP

1

2

3

4

5

6

7

8

9

10

11

12

13

36

35

34

33

32

31

30

29

28

27

26

646362616059585756

14

15

16

171819202122232425

PGEC2/SOSCO/T1CK/CN0/RC14

PGED2/SOSCI/T4CK/CN1/RC13

OC1/RD0

IC4/INT4/RD11

IC2/U1CTS

/INT2/RD9

IC1/INT1/RD8

V

SS

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

U1RTS

/SCK1/INT0/RF6

U1RX/SDI1/RF2

U1TX/SDO1/RF3

COFS/RG15

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

MCLR

VSS

VDD

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

PGEC3/AN1/V

REF-/CN3/RB1

PGED3/AN0/V

REF+/CN2/RB0

OC8/CN16/RD7

CSDO/RG13

CSDI/RG12

CSCK/RG14

V

CAP/VDDCORE

RG1

C1TX/RF1

RG0

OC2/RD1

OC3/RD2

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

AVDD

AVSS

U2CTS/AN8/RB8

AN9/RB9

TMS/AN10/RB10

TDO/AN11/RB11

V

SS

VDD

TCK/AN12/RB12

TDI/AN13/RB13

U2RTS

/AN14/RB14

AN15/OCFB/CN12/RB15

U2TX/SCL2/CN18/RF5

U2RX/SDA2/CN17/RF4

SDA1/RG3

43

42

41

40

39

38

37

44

48

47

46

504951

545352

55

45

SS2

/CN11/RG9

AN5/IC8/CN7/RB5

AN4/IC7/CN6/RB4

IC3/INT3/RD10

VDD

C1RX/RF0

OC4/RD3

OC7/CN15/RD6

OC6/IC6/CN14/RD5

OC5/IC5/CN13/RD4

dsPIC33FJ256GP506

= Pins are up to 5V tolerant

Pin Diagrams (Continued)

DS70286C-page 6 © 2009 Microchip Technology Inc.

Pin Diagrams (Continued)

64-Pin TQFP

1

2

3

4

5

6

7

8

9

10

11

12

13

36

35

34

33

32

31

30

29

28

27

26

646362616059585756

14

15

16

171819202122232425

PGEC2/SOSCO/T1CK/CN0/RC14

PGED2/SOSCI/T4CK/CN1/RC13

OC1/RD0

IC4/INT4/RD11

IC2/U1CTS

/INT2/RD9

IC1/INT1/RD8

V

SS

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

U1RTS

/SCK1/INT0/RF6

U1RX/SDI1/RF2

U1TX/SDO1/RF3

COFS/RG15

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

MCLR

VSS

VDD

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

PGEC3/AN1/V

REF-/CN3/RB1

PGED3/AN0/V

REF+/CN2/RB0

OC8/CN16/RD7

CSDO/RG13

CSDI/RG12

CSCK/RG14

V

CAP/VDDCORE

C2TX/RG1

C1TX/RF1

C2RX/RG0

OC2/RD1

OC3/RD2

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

AVDD

AVSS

U2CTS/AN8/RB8

AN9/RB9

TMS/AN10/RB10

TDO/AN11/RB11

V

SS

VDD

TCK/AN12/RB12

TDI/AN13/RB13

U2RTS

/AN14/RB14

AN15/OCFB/CN12/RB15

U2TX/SCL2/CN18/RF5

U2RX/SDA2/CN17/RF4

SDA1/RG3

43

42

41

40

39

38

37

44

48

47

46

504951

545352

55

45

SS2

/CN11/RG9

AN5/IC8/CN7/RB5

AN4/IC7/CN6/RB4

IC3/INT3/RD10

VDD

C1RX/RF0

OC4/RD3

OC7/CN15/RD6

OC6/IC6/CN14/RD5

OC5/IC5/CN13/RD4

dsPIC33FJ64GP706

dsPIC33FJ128GP706

= Pins are up to 5V tolerant

dsPIC33FJXXXGPX06/X08/X10

© 2009 Microchip Technology Inc. DS70286C-page 7

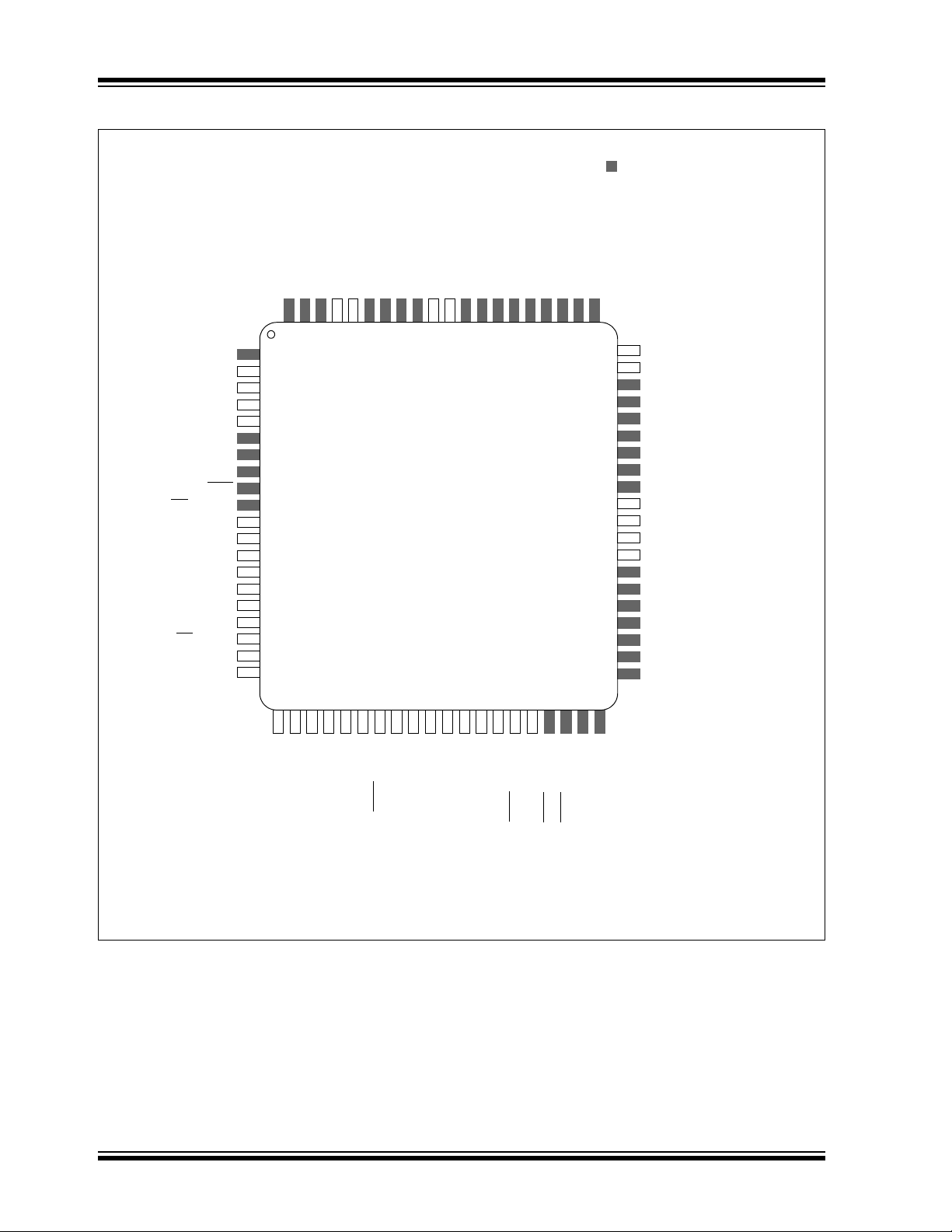

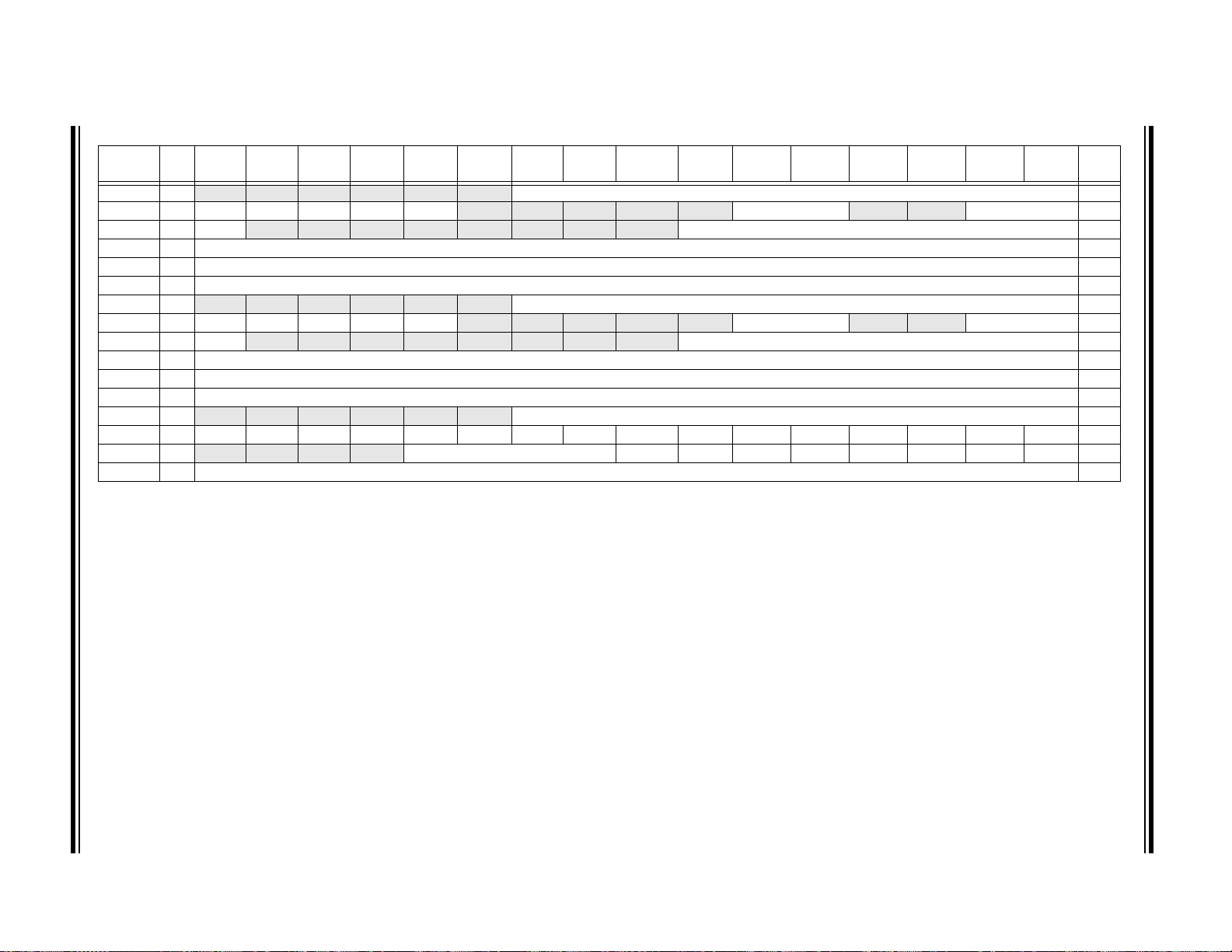

dsPIC33FJXXXGPX06/X08/X10

80-Pin TQFP

727473

7170696867666564636261

20

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

50

49

48

47

46

45

44

21

41

40

39

38

37

36

35

34

2324252627282930313233

dsPIC33FJ64GP708

17

18

19

75

1

57

56

55

54

53

52

51

60

59

58

43

42

767877

792280

IC5/RD12

OC4/RD3

OC3/RD2

OC2/RD1

CSCK/RG14

AN23/CN23/RA7

AN22/CN22/RA6

C2RX/RG0

C2TX/RG1

C1TX/RF1

C1RX/RF0

CSDO/RG13

CSDI/RG12

OC8/CN16/RD7

OC6/CN14/RD5

OC1/RD0

IC4/RD11

IC2/RD9

IC1/RD8

IC3/RD10

V

SS

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

U1RX/RF2

U1TX/RF3

PGEC2/SOSCO/T1CK/CN0/RC14

PGED2/SOSCI/CN1/RC13

V

REF

+/RA10

V

REF

-/RA9

AV

DD

AV

SS

U2CTS/AN8/RB8

AN9/RB9

AN10/RB10

AN11/RB11

V

DD

U2RX/CN17/RF4

IC8/U1RTS

/CN21/RD15

U2TX/CN18/RF5

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

AN17/T3CK/T6CK/RC2

AN18/T4CK/T9CK/RC3

AN19/T5CK/T8CK/RC4

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

MCLR

SS2/CN11/RG9

AN4/CN6/RB4

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

PGEC3/AN1/CN3/RB1

PGED3/AN0/CN2/RB0

V

SS

V

DD

COFS/RG15

AN16/T2CK/T7CK/RC1

TDO/AN21/INT2/RA13

TMS/AN20/INT1/RA12

TCK/AN12/RB12

TDI/AN13/RB13

U2RTS

/AN14/RB14

AN15/OCFB/CN12/RB15

V

DDVCAP

/V

DDCORE

OC5/CN13/RD4

IC6/CN19/RD13

SDA1/RG3

SDI1/RF7

SDO1/RF8

AN5/CN7/RB5

V

SS

OSC2/CLKO/RC15

OC7/CN15/RD6

SCK1/INT0/RF6

IC7/U1CTS/CN20/RD14

SDA2/INT4/RA3

SCL2/INT3/RA2

dsPIC33FJ128GP708

= Pins are up to 5V tolerant

Pin Diagrams (Continued)

DS70286C-page 8 © 2009 Microchip Technology Inc.

Pin Diagrams (Continued)

9294939190898887868584838281807978

20

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

65

64

63

62

61

60

59

26

56

45

44

43

42

41

40

39

2829303132333435363738

17

18

19

21

22

95

1

76

77

72

71

70

69

68

67

66

75

74

73

58

57

24

23

25

969897

99

27

4647484950

55

54

53

52

51

OC6/CN14/RD5

OC5/CN13/RD4

IC6/CN19/RD13

IC5/RD12

OC4/RD3

OC3/RD2

OC2/RD1

AN23/CN23/RA7

AN22/CN22/RA6

AN26/RE2

CSDO/RG13

CSDI/RG12

CSCK/RG14

AN25/RE1

AN24/RE0

RG0

AN28/RE4

AN27/RE3

RF0

V

CAP

/V

DDCORE

PGED2/SOSCI/CN1/RC13

OC1/RD0

IC3/RD10

IC2/RD9

IC1/RD8

IC4/RD11

SDA2/RA3

SCL2/RA2

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

SCK1/INT0/RF6

SDI1/RF7

SDO1/RF8

SDA1/RG3

U1RX/RF2

U1TX/RF3

V

SS

PGEC2/SOSCO/T1CK/CN0/RC14

V

REF

+/RA10

V

REF

-/RA9

AV

DD

AV

SS

AN8/RB8

AN9/RB9

AN10/RB10

AN11/RB11

V

DD

U2CTS/RF12

U2RTS

/RF13

IC7/U1CTS

/CN20/RD14

IC8/U1RTS

/CN21/RD15

V

DD

V

SS

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

U2TX/CN18/RF5

U2RX/CN17/RF4

AN29/RE5

AN30/RE6

AN31/RE7

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

AN18/T4CK/T9CK/RC3

AN19/T5CK/T8CK/RC4

SCK2/CN8/RG6

V

DD

TMS/RA0

AN20/INT1/RA12

AN21/INT2/RA13

AN5/CN7/RB5

AN4/CN6/RB4

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

SDI2/CN9/RG7

SDO2/CN10/RG8

PGEC3/AN1/CN3/RB1

PGED3/AN0/CN2/RB0

COFS/RG15

V

DD

SS2/CN11/RG9

MCLR

AN12/RB12

AN13/RB13

AN14/RB14

AN15/OCFB/CN12/RB15

RG1

RF1

OC8/CN16/RD7

OC7/CN15/RD6

TDO/RA5

INT4/RA15

INT3/RA14

V

SS

V

SS

V

SS

V

DD

TDI/RA4

TCK/RA1

100-Pin TQFP

dsPIC33FJ64GP310

dsPIC33FJ128GP310

100

= Pins are up to 5V tolerant

dsPIC33FJXXXGPX06/X08/X10

© 2009 Microchip Technology Inc. DS70286C-page 9

dsPIC33FJXXXGPX06/X08/X10

9294939190898887868584838281807978

20

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

65

64

63

62

61

60

59

26

56

45

44

43

42

41

40

39

2829303132333435363738

17

18

19

21

22

95

1

76

77

72

71

70

69

68

67

66

75

74

73

58

57

24

23

25

969897

99

27

4647484950

55

54

53

52

51

OC6/CN14/RD5

OC5/CN13/RD4

IC6/CN19/RD13

IC5/RD12

OC4/RD3

OC3/RD2

OC2/RD1

AN23/CN23/RA7

AN22/CN22/RA6

AN26/RE2

CSDO/RG13

CSDI/RG12

CSCK/RG14

AN25/RE1

AN24/RE0

RG0

AN28/RE4

AN27/RE3

C1RX/RF0

V

CAP

/V

DDCORE

PGED2/SOSCI/CN1/RC13

OC1/RD0

IC3/RD10

IC2/RD9

IC1/RD8

IC4/RD11

SDA2/RA3

SCL2/RA2

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

SCK1/INT0/RF6

SDI1/RF7

SDO1/RF8

SDA1/RG3

U1RX/RF2

U1TX/RF3

V

SS

PGEC2/SOSCO/T1CK/CN0/RC14

V

REF

+/RA10

V

REF

-/RA9

AV

DD

AV

SS

AN8/RB8

AN9/RB9

AN10/RB10

AN11/RB11

V

DD

U2CTS/RF12

U2RTS

/RF13

IC7/U1CTS

/CN20/RD14

IC8/U1RTS

/CN21/RD15

V

DD

V

SS

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

U2TX/CN18/RF5

U2RX/CN17/RF4

AN29/RE5

AN30/RE6

AN31/RE7

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

AN18/T4CK/T9CK/RC3

AN19/T5CK/T8CK/RC4

SCK2/CN8/RG6

V

DD

TMS/RA0

AN20/INT1/RA12

AN21/INT2/RA13

AN5/CN7/RB5

AN4/CN6/RB4

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

SDI2/CN9/RG7

SDO2/CN10/RG8

PGEC3/AN1/CN3/RB1

PGED3/AN0/CN2/RB0

COFS/RG15

V

DD

SS2/CN11/RG9

MCLR

AN12/RB12

AN13/RB13

AN14/RB14

AN15/OCFB/CN12/RB15

RG1

C1TX/RF1

OC8/CN16/RD7

OC7/CN15/RD6

TDO/RA5

INT4/RA15

INT3/RA14

V

SS

V

SS

V

SS

V

DD

TDI/RA4

TCK/RA1

100-Pin TQFP

dsPIC33FJ256GP510

100

= Pins are up to 5V tolerant

Pin Diagrams (Continued)

DS70286C-page 10 © 2009 Microchip Technology Inc.

Pin Diagrams (Continued)

9294939190898887868584838281807978

20

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

65

64

63

62

61

60

59

26

56

45

44

43

42

41

40

39

2829303132333435363738

17

18

19

21

22

95

1

76

77

72

71

70

69

68

67

66

75

74

73

58

57

24

23

25

969897

99

27

4647484950

55

54

53

52

51

OC6/CN14/RD5

OC5/CN13/RD4

IC6/CN19/RD13

IC5/RD12

OC4/RD3

OC3/RD2

OC2/RD1

AN23/CN23/RA7

AN22/CN22/RA6

AN26/RE2

CSDO/RG13

CSDI/RG12

CSCK/RG14

AN25/RE1

AN24/RE0

C2RX/RG0

AN28/RE4

AN27/RE3

C1RX/RF0

V

CAP

/V

DDCORE

PGED2/SOSCI/CN1/RC13

OC1/RD0

IC3/RD10

IC2/RD9

IC1/RD8

IC4/RD11

SDA2/RA3

SCL2/RA2

OSC2/CLKO/RC15

OSC1/CLKIN/RC12

V

DD

SCL1/RG2

SCK1/INT0/RF6

SDI1/RF7

SDO1/RF8

SDA1/RG3

U1RX/RF2

U1TX/RF3

V

SS

PGEC2/SOSCO/T1CK/CN0/RC14

V

REF

+/RA10

V

REF

-/RA9

AV

DD

AV

SS

AN8/RB8

AN9/RB9

AN10/RB10

AN11/RB11

V

DD

U2CTS/RF12

U2RTS

/RF13

IC7/U1CTS

/CN20/RD14

IC8/U1RTS

/CN21/RD15

V

DD

V

SS

PGEC1/AN6/OCFA/RB6

PGED1/AN7/RB7

U2TX/CN18/RF5

U2RX/CN17/RF4

AN29/RE5

AN30/RE6

AN31/RE7

AN16/T2CK/T7CK/RC1

AN17/T3CK/T6CK/RC2

AN18/T4CK/T9CK/RC3

AN19/T5CK/T8CK/RC4

SCK2/CN8/RG6

V

DD

TMS/RA0

AN20/INT1/RA12

AN21/INT2/RA13

AN5/CN7/RB5

AN4/CN6/RB4

AN3/CN5/RB3

AN2/SS1

/CN4/RB2

SDI2/CN9/RG7

SDO2/CN10/RG8

PGEC3/AN1/CN3/RB1

PGED3/AN0/CN2/RB0

COFS/RG15

V

DD

SS2/CN11/RG9

MCLR

AN12/RB12

AN13/RB13

AN14/RB14

AN15/OCFB/CN12/RB15

C2TX/RG1

C1TX/RF1

OC8/CN16/RD7

OC7/CN15/RD6

TDO/RA5

INT4/RA15

INT3/RA14

V

SS

V

SS

V

SS

V

DD

TDI/RA4

TCK/RA1

100-Pin TQFP

dsPIC33FJ128GP710

100

dsPIC33FJ256GP710

dsPIC33FJ64GP710

= Pins are up to 5V tolerant

dsPIC33FJXXXGPX06/X08/X10

© 2009 Microchip Technology Inc. DS70286C-page 11

dsPIC33FJXXXGPX06/X08/X10

Table of Contents

dsPIC33F Product Families ................................................................................................................................................................... 3

1.0 Device Overview ........................................................................................................................................................................ 13

2.0 Guidelines for Getting Started with 16-Bit Digital Signal Controllers .......................................................................................... 17

3.0 CPU............................................................................................................................................................................................ 21

4.0 Memory Organization ................................................................................................................................................................. 33

5.0 Flash Program Memory.............................................................................................................................................................. 71

6.0 Reset ......................................................................................................................................................................................... 77

7.0 Interrupt Controller ..................................................................................................................................................................... 81

8.0 Direct Memory Access (DMA) .................................................................................................................................................. 127

9.0 Oscillator Configuration ............................................................................................................................................................ 137

10.0 Power-Saving Features ............................................................................................................................................................ 147

11.0 I/O Ports ................................................................................................................................................................................... 155

12.0 Timer1 ...................................................................................................................................................................................... 157

13.0 Timer2/3, Timer4/5, Timer6/7 and Timer8/9 ............................................................................................................................ 159

14.0 Input Capture............................................................................................................................................................................ 165

15.0 Output Compare ....................................................................................................................................................................... 167

16.0 Serial Peripheral Interface (SPI)............................................................................................................................................... 171

17.0 Inter-Integrated Circuit™ (I

18.0 Universal Asynchronous Receiver Transmitter (UART) ........................................................................................................... 185

19.0 Enhanced CAN (ECAN™) Module ........................................................................................................................................... 191

20.0 Data Converter Interface (DCI) Module.................................................................................................................................... 217

21.0 10-Bit/12-Bit Analog-to-Digital Converter (ADC) ...................................................................................................................... 225

22.0 Special Features ...................................................................................................................................................................... 237

23.0 Instruction Set Summary .......................................................................................................................................................... 245

24.0 Development Support............................................................................................................................................................... 253

25.0 Electrical Characteristics .......................................................................................................................................................... 257

26.0 Packaging Information.............................................................................................................................................................. 297

Appendix A: Revision History............................................................................................................................................................. 307

Index ................................................................................................................................................................................................. 313

The Microchip Web Site ..................................................................................................................................................................... 317

Customer Change Notification Service .............................................................................................................................................. 317

Customer Support .............................................................................................................................................................................. 317

Reader Response .............................................................................................................................................................................. 318

Product Identification System............................................................................................................................................................. 319

2

C™).............................................................................................................................................. 177

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS70286C-page 12 © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

1.0 DEVICE OVERVIEW

Note: This data sheet summarizes the features

of the dsPIC33FJXXXGPX06/X08/X10

family of devices. However, it is not

intended to be a comprehensive reference

source. To complement the information in

this data sheet, refer to the latest family

reference sections of the “dsPIC33F

Family Reference Manual”, which is

available from the Microchip web site

(www.microchip.com).

This document contains device specific information for

the following devices:

• dsPIC33FJ64GP206

• dsPIC33FJ64GP306

• dsPIC33FJ64GP310

• dsPIC33FJ64GP706

• dsPIC33FJ64GP708

• dsPIC33FJ64GP710

• dsPIC33FJ128GP206

• dsPIC33FJ128GP306

• dsPIC33FJ128GP310

• dsPIC33FJ128GP706

• dsPIC33FJ128GP708

• dsPIC33FJ128GP710

• dsPIC33FJ256GP506

• dsPIC33FJ256GP510

• dsPIC33FJ256GP710

The dsPIC33FJXXXGPX06/X08/X10 General Purpose

Family of device includes devices with a wide range of

pin counts (64, 80 and 100), different program memory

sizes (64 Kbytes, 128 Kbytes and 256 Kbytes) and

different RAM sizes (8 Kbytes, 16 Kbytes and

30 Kbytes).

This feature makes the family suitable for a wide variety

of high-performance digital signal control applications.

The device is pin compatible with the PIC24H family of

devices, and also share a very high degree of

compatibility with the dsPIC30F family devices. This

allows for easy migration between device families as may

be necessitated by the specific functionality,

computational resource and system cost requirements of

the application.

The dsPIC33FJXXXGPX06/X08/X10 device family

employs a powerful 16-bit architecture that seamlessly

integrates the control features of a Microcontroller

(MCU) with the computational capabilities of a Digital

Signal Processor (DSP). The resulting functionality is

ideal for applications that rely on high-speed, repetitive

computations, as well as control.

The DSP engine, dual 40-bit accumulators, hardware

support for division operations, barrel shifter, 17 x 17

multiplier, a large array of 16-bit working registers and

a wide variety of data addressing modes, together

provide the dsPIC33FJXXXGPX06/X08/X10 Central

Processing Unit (CPU) with extensive mathematical

processing capability. Flexible and deterministic

interrupt handling, coupled with a powerful array of

peripherals, renders the

dsPIC33FJXXXGPX06/X08/X10 devices suitable for

control applications. Further, Direct Memory Access

(DMA) enables overhead-free transfer of data between

several peripherals and a dedicated DMA RAM.

Reliable, field programmable Flash program memory

ensures scalability of applications that use

dsPIC33FJXXXGPX06/X08/X10 devices.

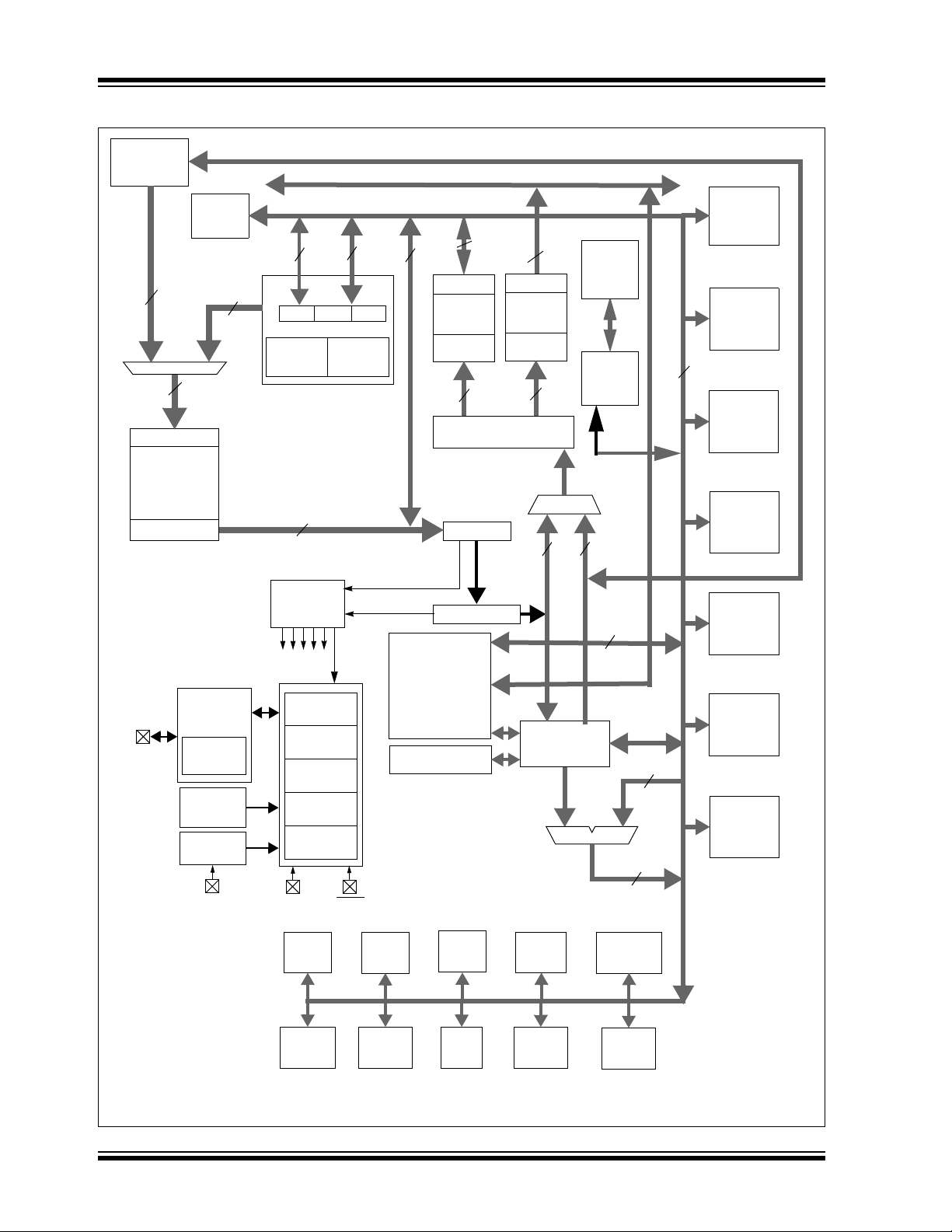

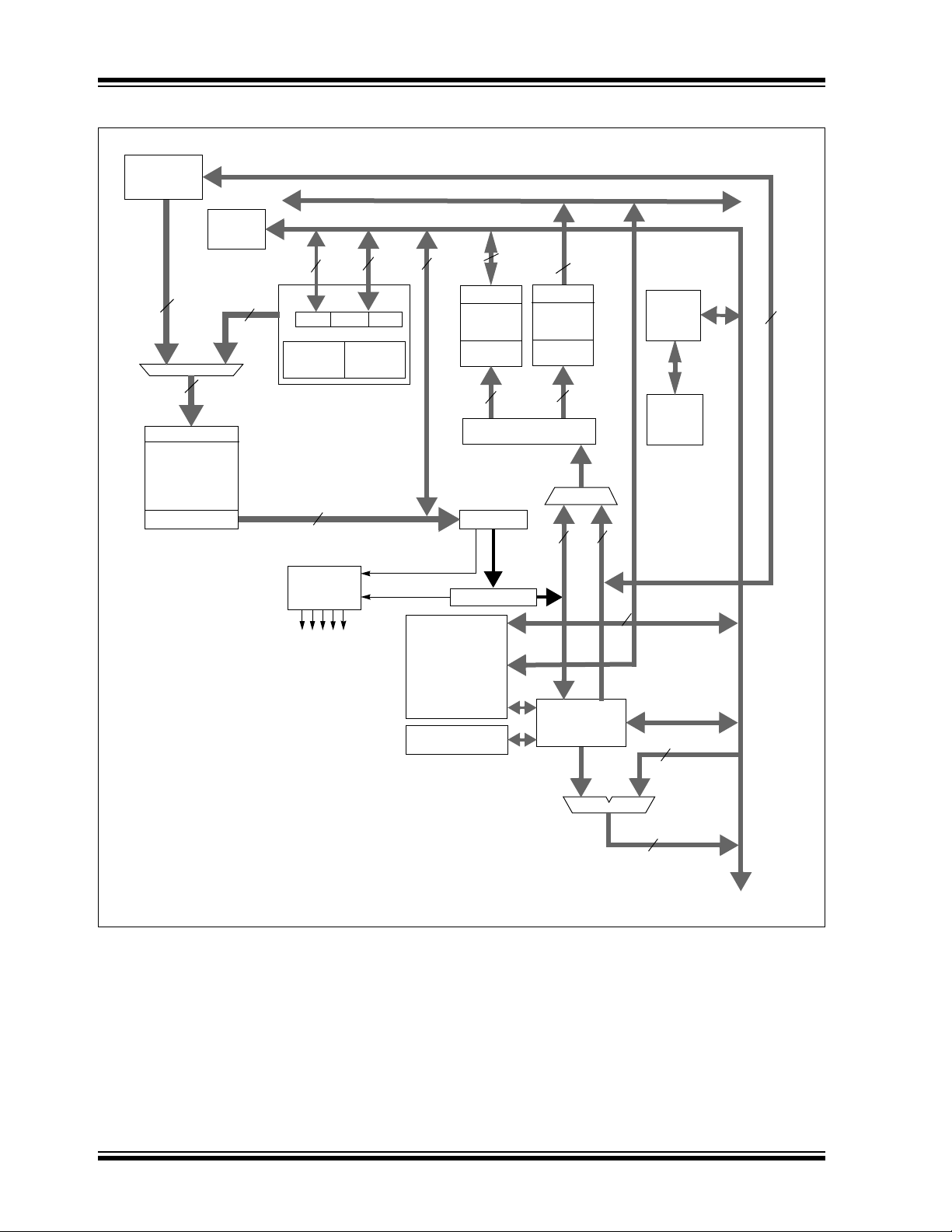

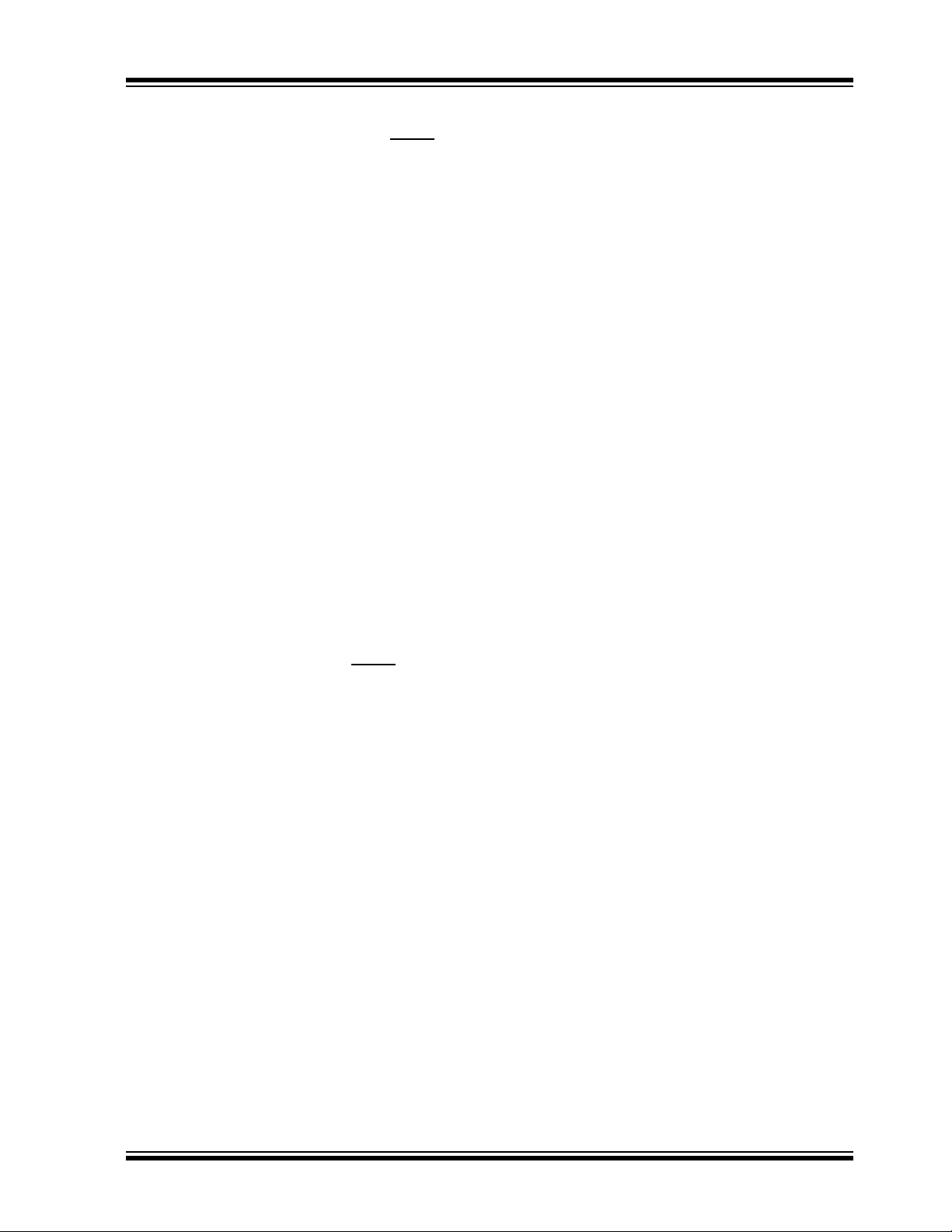

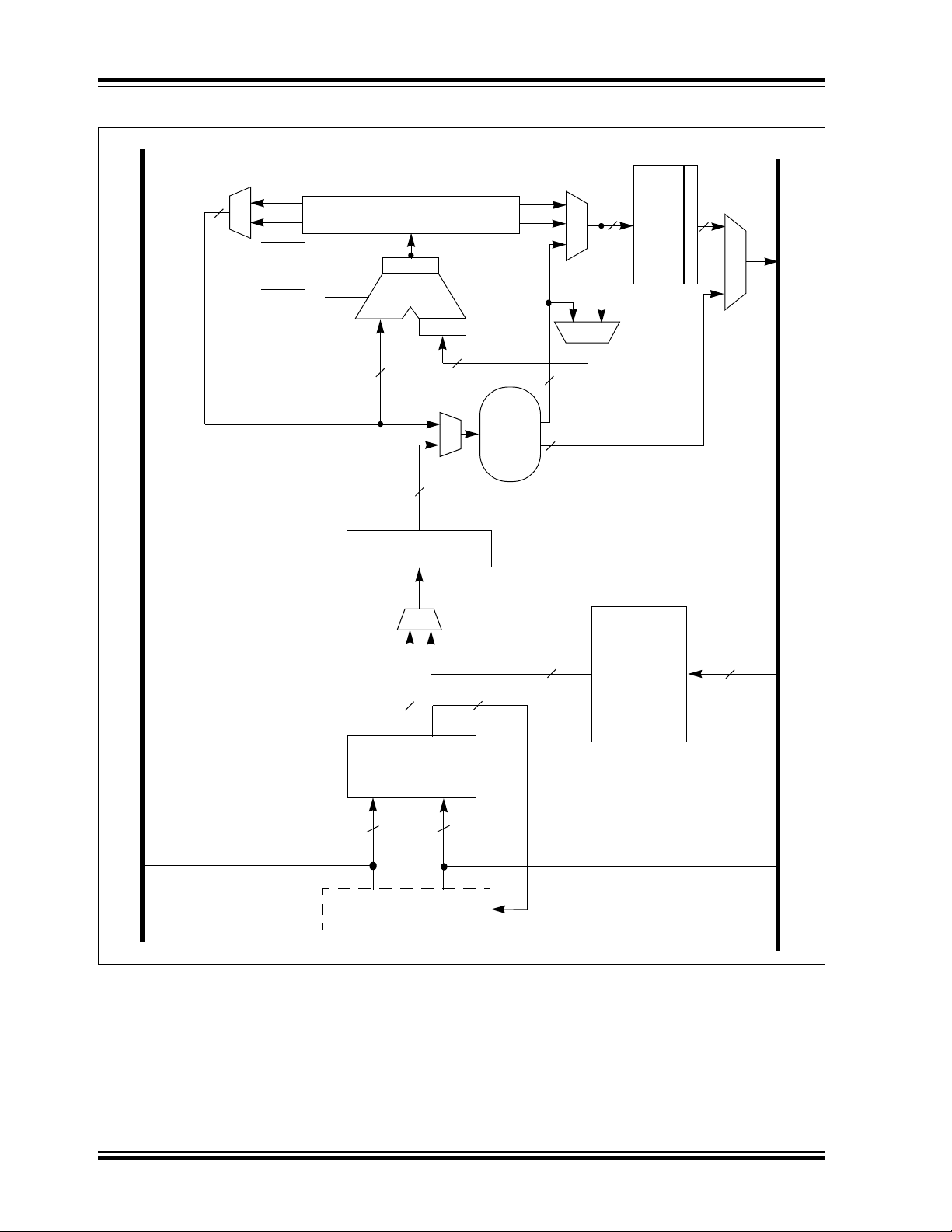

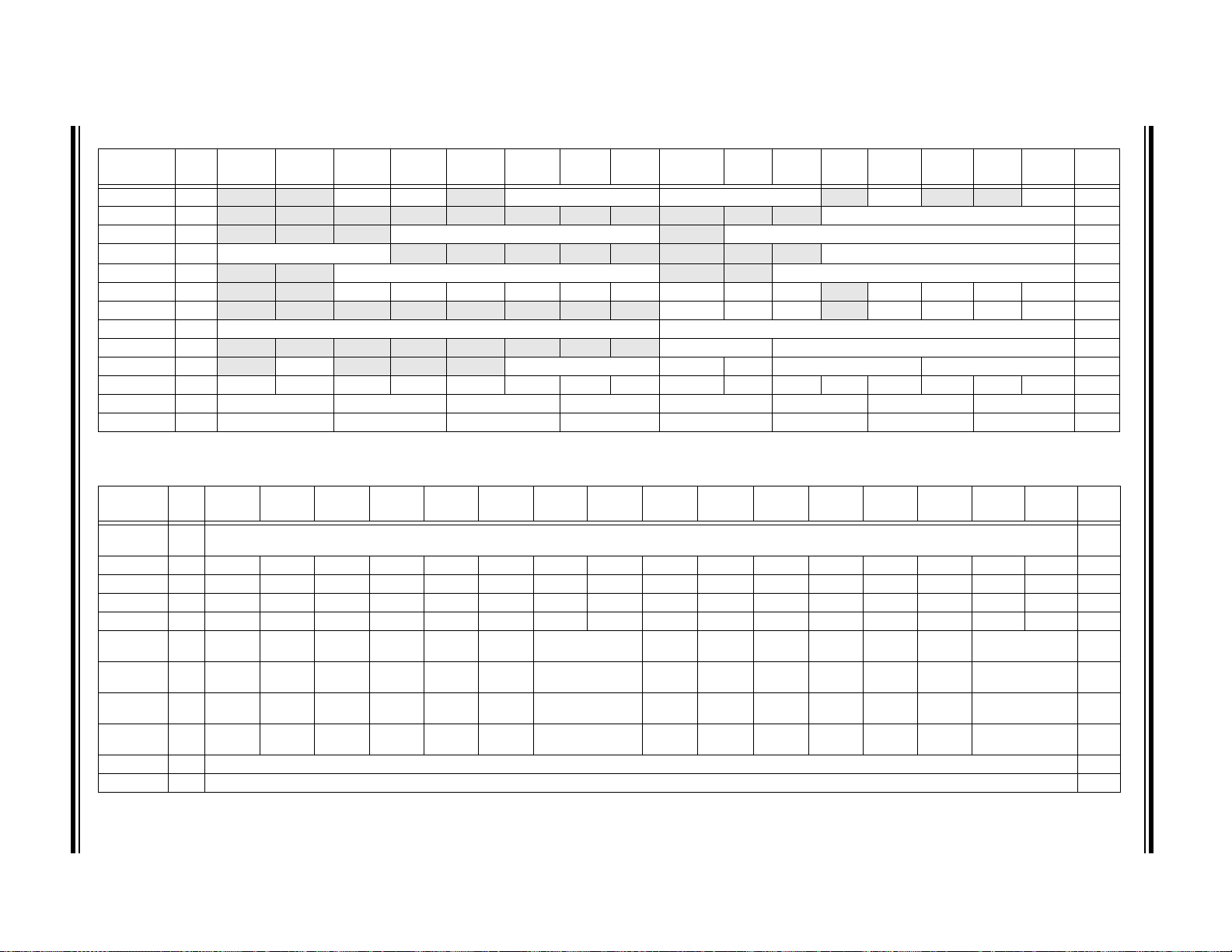

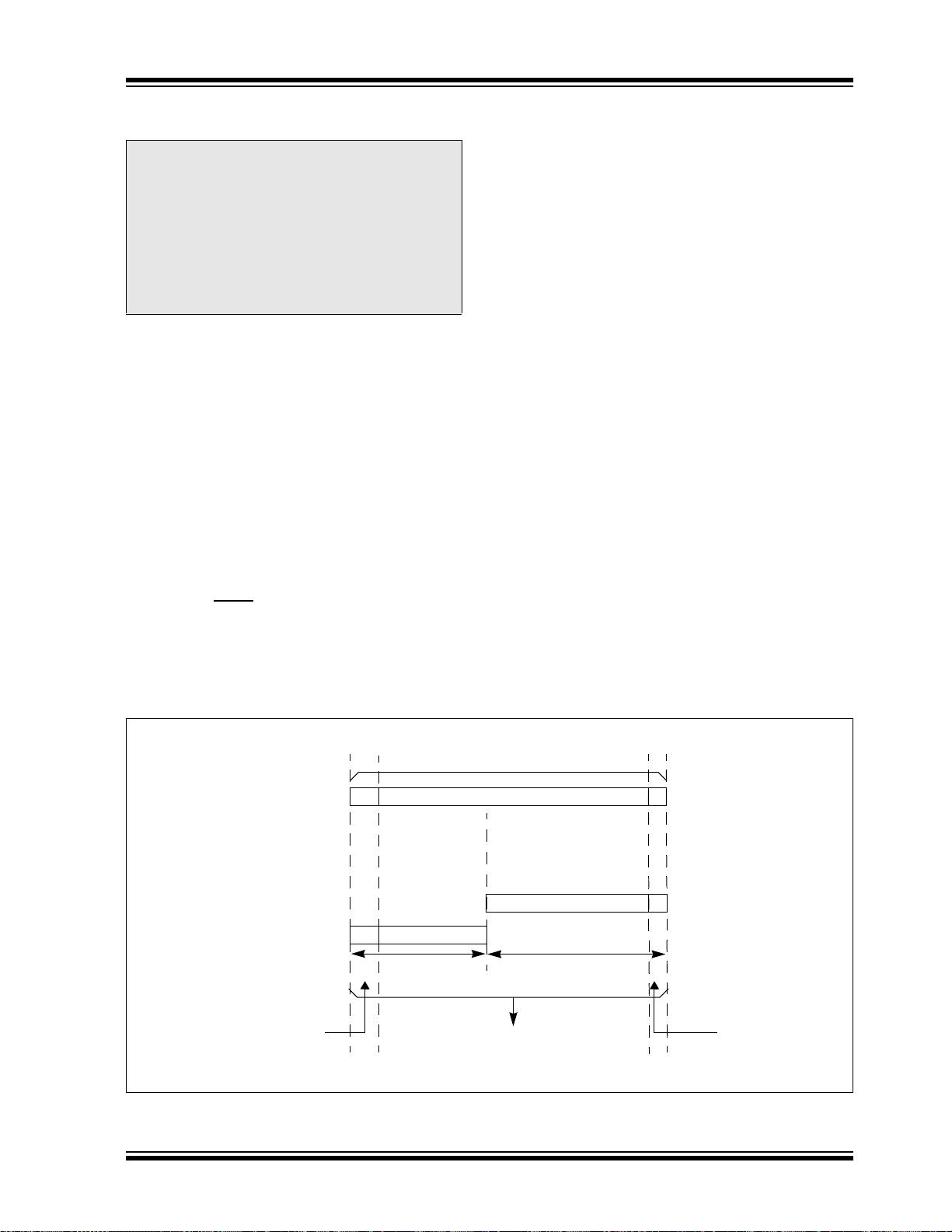

Figure 1-1 illustrates a general block diagram of the

various core and peripheral modules in the

dsPIC33FJXXXGPX06/X08/X10 family of devices.

Table 1-1 provides the functions of the various pins

illustrated in the pinout diagrams.

© 2009 Microchip Technology Inc. DS70286C-page 13

16

OSC1/CLKI

OSC2/CLKO

V

DD, VSS

Timing

Generation

MCLR

Power-up

Timer

Oscillator

Star t- up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

Precision

Reference

Band Gap

FRC/LPRC

Oscillators

Regulator

Voltage

VCAP/VDDCORE

UART1,2

ECAN1,2

DCI

IC1-8

SPI1,2

I2C1,2

OC/

PORTA

Note: Not all pins or features are implemented on all device pinout configurations. See pinout diagrams for the specific pins

and features present on each device.

PWM1-8

CN1-23

Instruction

Decode and

Control

PCH PCL

16

Program Counter

16-bit ALU

23

23

24

23

Instruction Reg

PCU

16 x 16

W Register Array

ROM Latch

16

EA MUX

16

16

8

Interrupt

Controller

PSV and Table

Data Access

Control Block

Stac k

Control

Logic

Loop

Control

Logic

Data Latch

Address

Latch

Address Latch

Program Memory

Data Latch

Literal Data

16

16

16

16

Data Latch

Address

Latch

16

X RAM

Y RAM

16

Y Data Bus

X Data Bus

DSP Engine

Divide Support

16

DMA

RAM

DMA

Controller

Control Signals

to Various Blocks

ADC1,2

Timers

PORTB

PORTC

PORTD

PORTE

PORTF

PORTG

Address Generator Units

1-9

dsPIC33FJXXXGPX06/X08/X10

FIGURE 1-1: dsPIC33FJXXXGPX06/X08/X10 GENERAL BLOCK DIAGRAM

DS70286C-page 14 © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

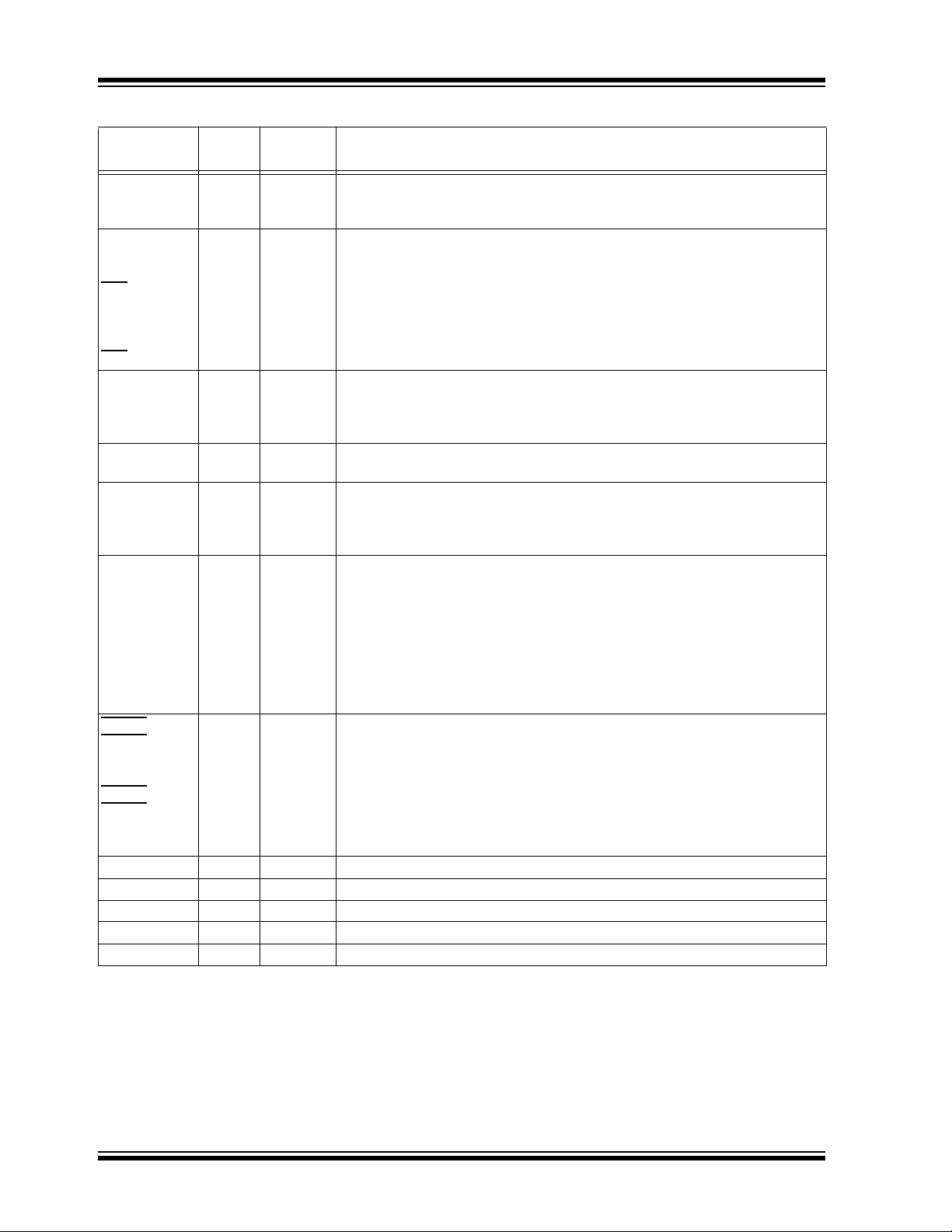

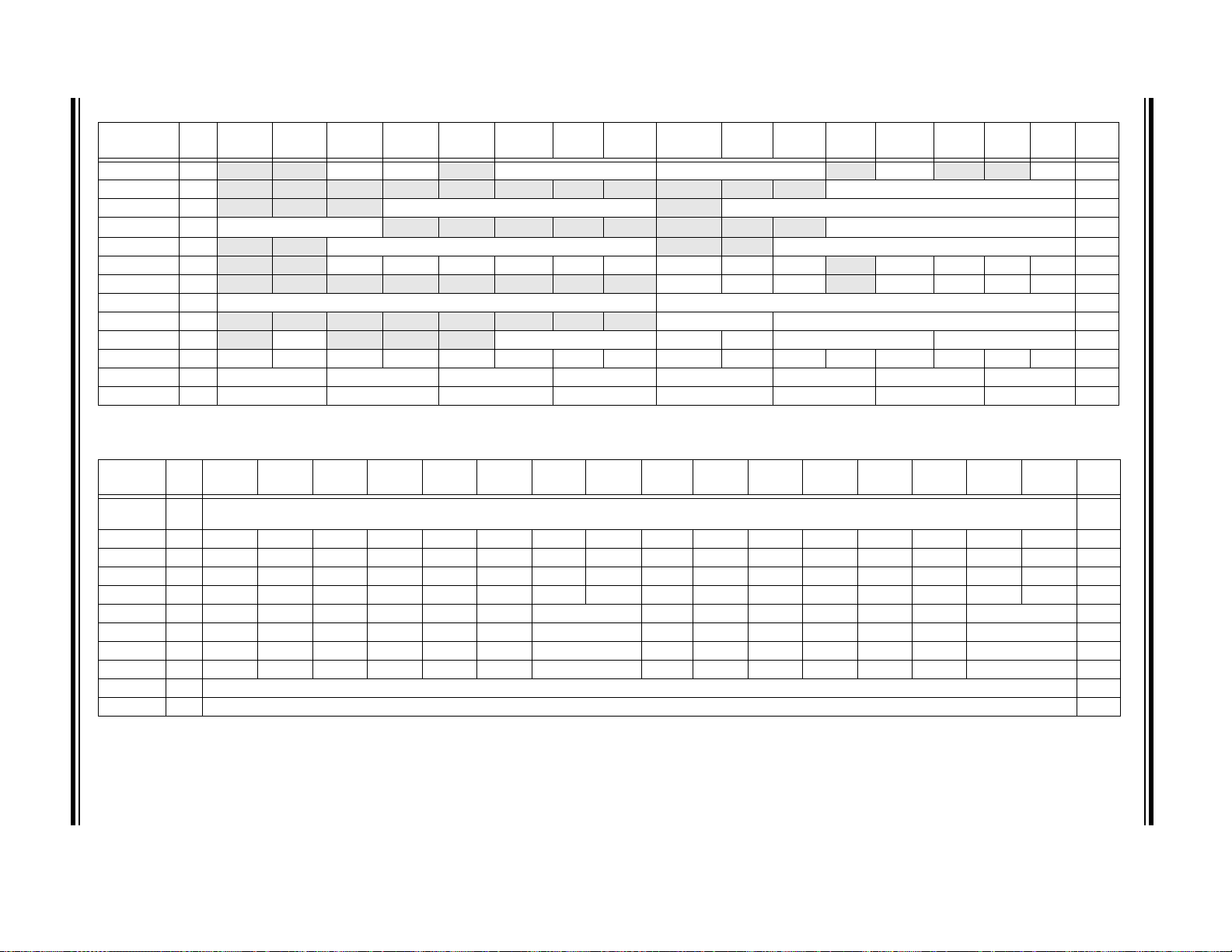

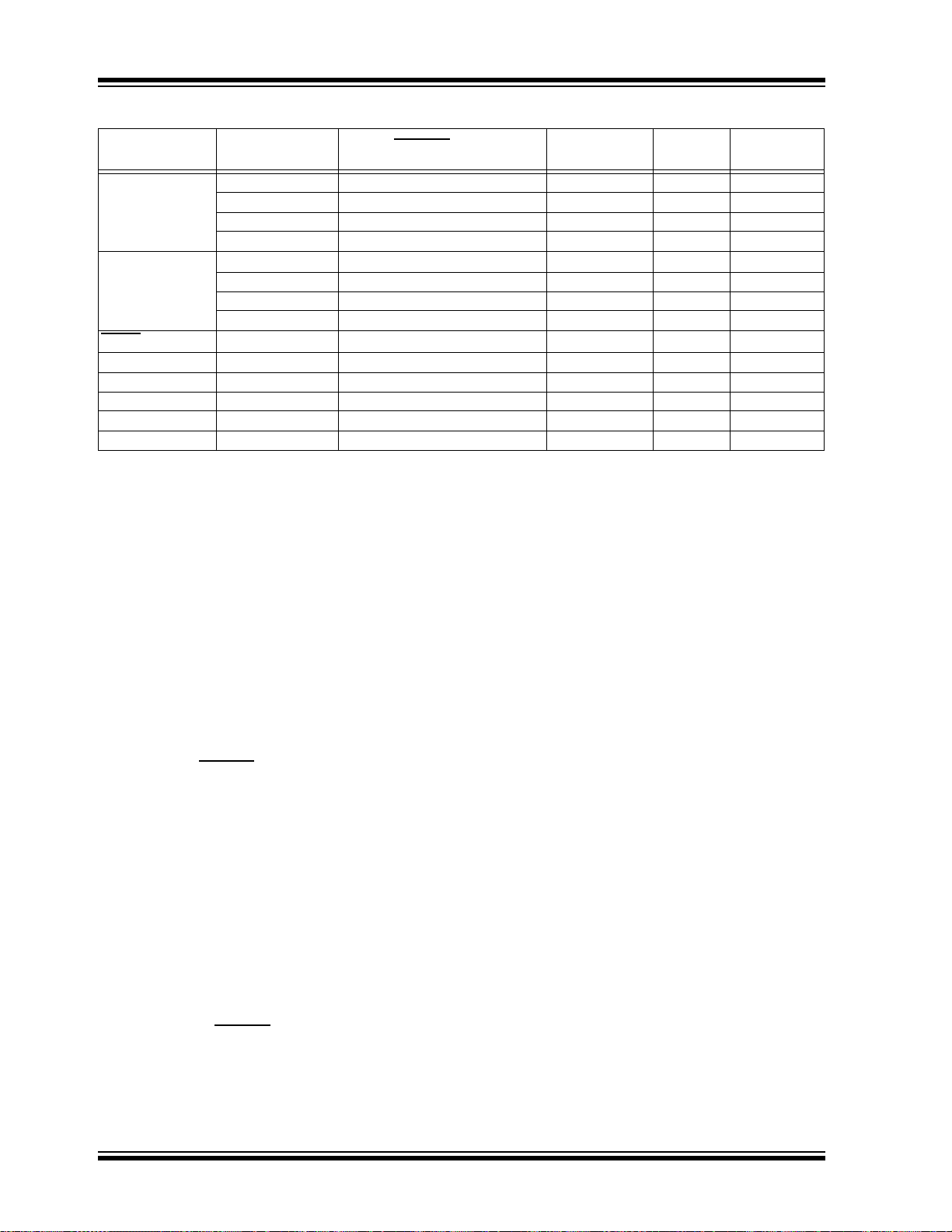

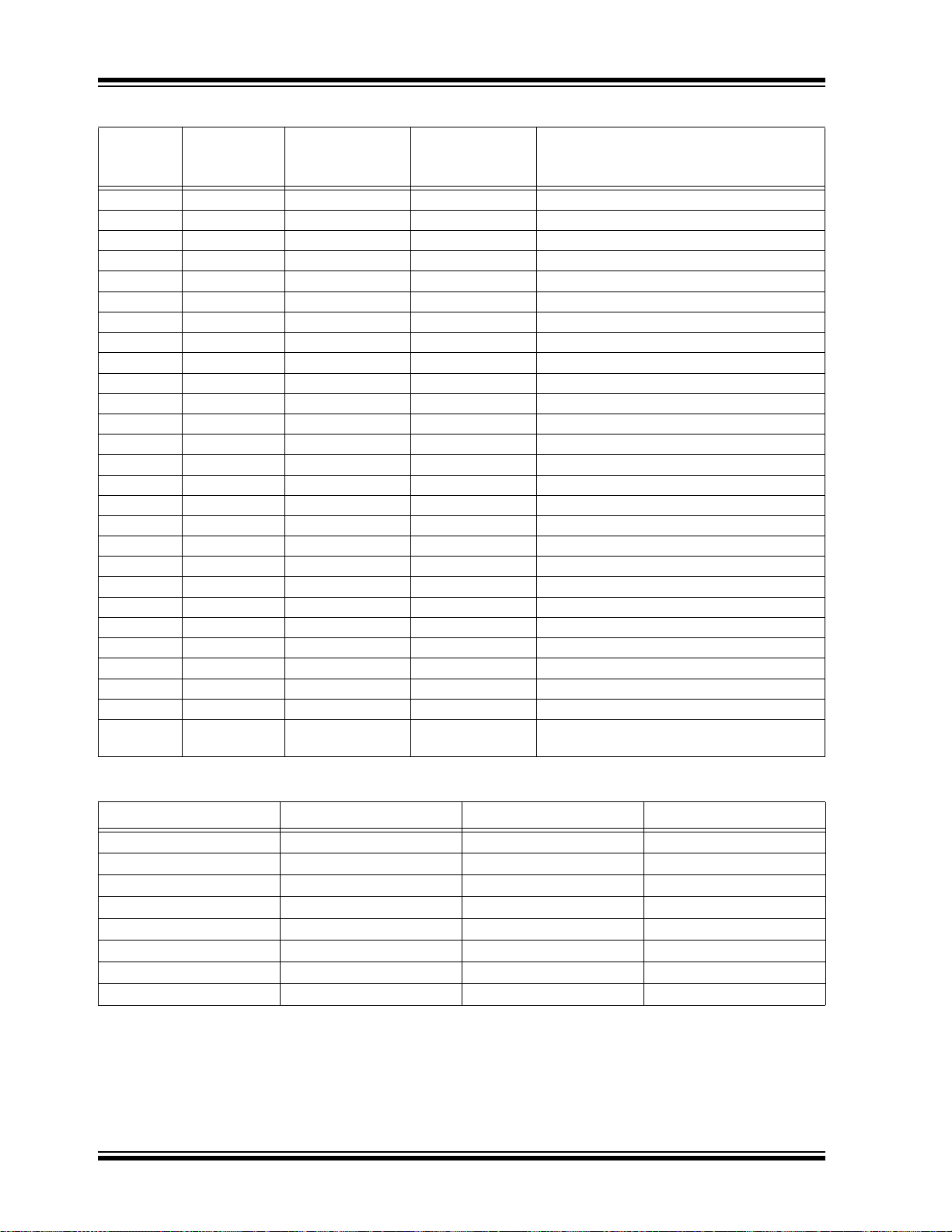

TABLE 1-1: PINOUT I/O DESCRIPTIONS

Pin Name

AN0-AN31 I Analog Analog input channels.

DD P P Positive supply for analog modules. This pin must be connected at all times.

AV

AV

SS P P Ground reference for analog modules.

CLKI

CLKO

CN0-CN23 I ST Input change notification inputs.

COFS

CSCK

CSDI

CSDO

C1RX

C1TX

C2RX

C2TX

PGED1

PGEC1

PGED2

PGEC2

PGED3

PGEC3

IC1-IC8 I ST Capture inputs 1 through 8.

INT0

INT1

INT2

INT3

INT4

MCLR

OCFA

OCFB

OC1-OC8

OSC1

OSC2

RA0-RA7

RA9-RA10

RA12-RA15

RB0-RB15 I/O ST PORTB is a bidirectional I/O port.

RC1-RC4

RC12-RC15

RD0-RD15 I/O ST PORTD is a bidirectional I/O port.

RE0-RE7 I/O ST PORTE is a bidirectional I/O port.

RF0-RF8

RF12-RF13

Legend: CMOS = CMOS compatible input or output; Analog = Analog input; P = Power

ST = Schmitt Trigger input with CMOS levels; O = Output; I = Input

Pin

Type

I

O

I/O

I/O

I

O

I

O

I

O

I/O

I

I/O

I

I/O

I

I

I

I

I

I

I/P ST Master Clear (Reset) input. This pin is an active-low Reset to the device.

I

I

O

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Buffer

Typ e

ST/CMOS—External clock source input. Always associated with OSC1 pin function.

Oscillator crystal output. Connects to crystal or resonator in Crystal Oscillator

mode. Optionally functions as CLKO in RC and EC modes. Always associated

with OSC2 pin function.

Can be software programmed for internal weak pull-ups on all inputs.

ST

ST

ST

—

ST

—

ST

—

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

—

ST/CMOS—Oscillator crystal input. ST buffer when configured in RC mode;

ST

ST

ST

ST

ST

ST

ST

Data Converter Interface frame synchronization pin.

Data Converter Interface serial clock input/output pin.

Data Converter Interface serial data input pin.

Data Converter Interface serial data output pin.

ECAN1 bus receive pin.

ECAN1 bus transmit pin.

ECAN2 bus receive pin.

ECAN2 bus transmit pin.

Data I/O pin for programming/debugging communication channel 1.

Clock input pin for programming/debugging communication channel 1.

Data I/O pin for programming/debugging communication channel 2.

Clock input pin for programming/debugging communication channel 2.

Data I/O pin for programming/debugging communication channel 3.

Clock input pin for programming/debugging communication channel 3.

External interrupt 0.

External interrupt 1.

External interrupt 2.

External interrupt 3.

External interrupt 4.

Compare Fault A input (for Compare Channels 1, 2, 3 and 4).

Compare Fault B input (for Compare Channels 5, 6, 7 and 8).

Compare outputs 1 through 8.

CMOS otherwise.

Oscillator crystal output. Connects to crystal or resonator in Crystal Oscillator

mode. Optionally functions as CLKO in RC and EC modes.

PORTA is a bidirectional I/O port.

PORTC is a bidirectional I/O port.

PORTF is a bidirectional I/O port.

Description

© 2009 Microchip Technology Inc. DS70286C-page 15

dsPIC33FJXXXGPX06/X08/X10

TABLE 1-1: PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RG0-RG3

RG6-RG9

RG12-RG15

SCK1

SDI1

SDO1

SS1

SCK2

SDI2

SDO2

SS2

SCL1

SDA1

SCL2

SDA2

SOSCI

SOSCO

TMS

TCK

TDI

TDO

T1CK

T2CK

T3CK

T4CK

T5CK

T6CK

T7CK

T8CK

T9CK

U1CTS

U1RTS

U1RX

U1TX

U2CTS

U2RTS

U2RX

U2TX

DD P — Positive supply for peripheral logic and I/O pins.

V

V

CAP/VDDCORE P — CPU logic filter capacitor connection.

VSS P — Ground reference for logic and I/O pins.

V

REF+ I Analog Analog voltage reference (high) input.

V

REF- I Analog Analog voltage reference (low) input.

Legend: CMOS = CMOS compatible input or output; Analog = Analog input; P = Power

ST = Schmitt Trigger input with CMOS levels; O = Output; I = Input

Pin

Type

I/O

I/O

I/O

I/O

I

O

I/O

I/O

I

O

I/O

I/O

I/O

I/O

I/O

I

O

I

I

I

O

I

I

I

I

I

I

I

I

I

I

O

I

O

I

O

I

O

Buffer

Typ e

ST

ST

ST

ST

ST

—

ST

ST

ST

—

ST

ST

ST

ST

ST

ST/CMOS—32.768 kHz low-power oscillator crystal input; CMOS otherwise.

ST

ST

ST

—

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

—

ST

—

ST

—

ST

—

PORTG is a bidirectional I/O port.

Synchronous serial clock input/output for SPI1.

SPI1 data in.

SPI1 data out.

SPI1 slave synchronization or frame pulse I/O.

Synchronous serial clock input/output for SPI2.

SPI2 data in.

SPI2 data out.

SPI2 slave synchronization or frame pulse I/O.

Synchronous serial clock input/output for I2C1.

Synchronous serial data input/output for I2C1.

Synchronous serial clock input/output for I2C2.

Synchronous serial data input/output for I2C2.

32.768 kHz low-power oscillator crystal output.

JTAG Test mode select pin.

JTAG test clock input pin.

JTAG test data input pin.

JTAG test data output pin.

Timer1 external clock input.

Timer2 external clock input.

Timer3 external clock input.

Timer4 external clock input.

Timer5 external clock input.

Timer6 external clock input.

Timer7 external clock input.

Timer8 external clock input.

Timer9 external clock input.

UART1 clear to send.

UART1 ready to send.

UART1 receive.

UART1 transmit.

UART2 clear to send.

UART2 ready to send.

UART2 receive.

UART2 transmit.

Description

DS70286C-page 16 © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

2.0 GUIDELINES FOR GETTING STARTED WITH 16-BIT DIGITAL SIGNAL CONTROLLERS

Note: This data sheet summarizes the features

of the dsPIC33FJXXXGPX06/X08/X10

family of devices. It is not intended to be a

comprehensive reference source. To

complement the information in this data

sheet, refer to the “dsPIC33F Family

Reference Manual”, which is available

from the Microchip website

(www.microchip.com).

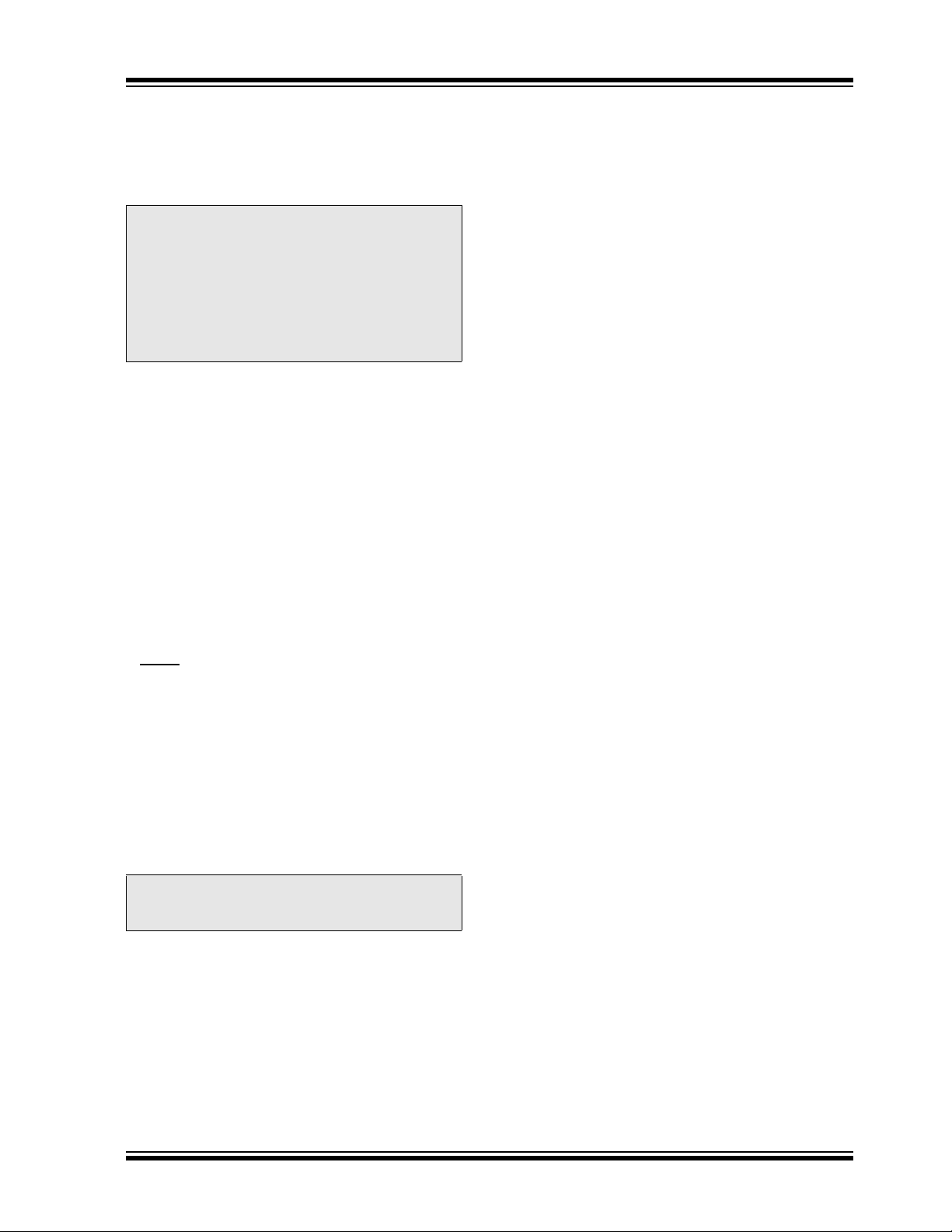

2.1 Basic Connection Requirements

Getting started with the

dsPIC33FJXXXGPX06/X08/X10 family of 16-bit Digital

Signal Controllers (DSCs) requires attention to a

minimal set of device pin connections before

proceeding with development. The following is a list of

pin names, which must always be connected:

DD and VSS pins

• All V

(see Section 2.2 “Decoupling Capacitors”)

• All AV

•V

•MCLR

• PGECx/PGEDx pins used for In-Circuit Serial

• OSC1 and OSC2 pins when external oscillator

Additionally, the following pins may be required:

•V

DD and AVSS pins (regardless if ADC module

is not used)

(see Section 2.2 “Decoupling Capacitors”)

CAP/VDDCORE

(see Section 2.3 “Capacitor on Internal Voltage

Regulator (V

(see Section 2.4 “Master Clear (MCLR) Pin”)

Programming™ (ICSP™) and debugging purposes

(see Section 2.5 “ICSP Pins”)

source is used

(see Section 2.6 “External Oscillator Pins”)

REF+/VREF- pins used when external voltage

reference for ADC module is implemented

Note: The AVDD and AVSS pins must be

CAP/VDDCORE)”)

pin

connected independent of the ADC

voltage reference source.

2.2 Decoupling Capacitors

The use of decoupling capacitors on every pair of

power supply pins, such as V

AVSS is required.

Consider the following criteria when using decoupling

capacitors:

• Value and type of capacitor: Recommendation

of 0.1 µF (100 nF), 10-20V. This capacitor should

be a low-ESR and have resonance frequency in

the range of 20 MHz and higher. It is

recommended that ceramic capacitors be used.

• Placement on the printed circuit board: The

decoupling capacitors should be placed as close

to the pins as possible. It is recommended to

place the capacitors on the same side of the

board as the device. If space is constricted, the

capacitor can be placed on another layer on the

PCB using a via; however, ensure that the trace

length from the pin to the capacitor is within

one-quarter inch (6 mm) in length.

• Handling high frequency noise: If the board is

experiencing high frequency noise, upward of

tens of MHz, add a second ceramic-type capacitor

in parallel to the above described decoupling

capacitor. The value of the second capacitor can

be in the range of 0.01 µF to 0.001 µF. Place this

second capacitor next to the primary decoupling

capacitor. In high-speed circuit designs, consider

implementing a decade pair of capacitances as

close to the power and ground pins as possible.

For example, 0.1 µF in parallel with 0.001 µF.

• Maximizing performance: On the board layout

from the power supply circuit, run the power and

return traces to the decoupling capacitors first,

and then to the device pins. This ensures that the

decoupling capacitors are first in the power chain.

Equally important is to keep the trace length

between the capacitor and the power pins to a

minimum thereby reducing PCB track inductance.

DD, VSS, AVDD and

© 2009 Microchip Technology Inc. DS70286C-page 17

dsPIC33FJXXXGPX06/X08/X10

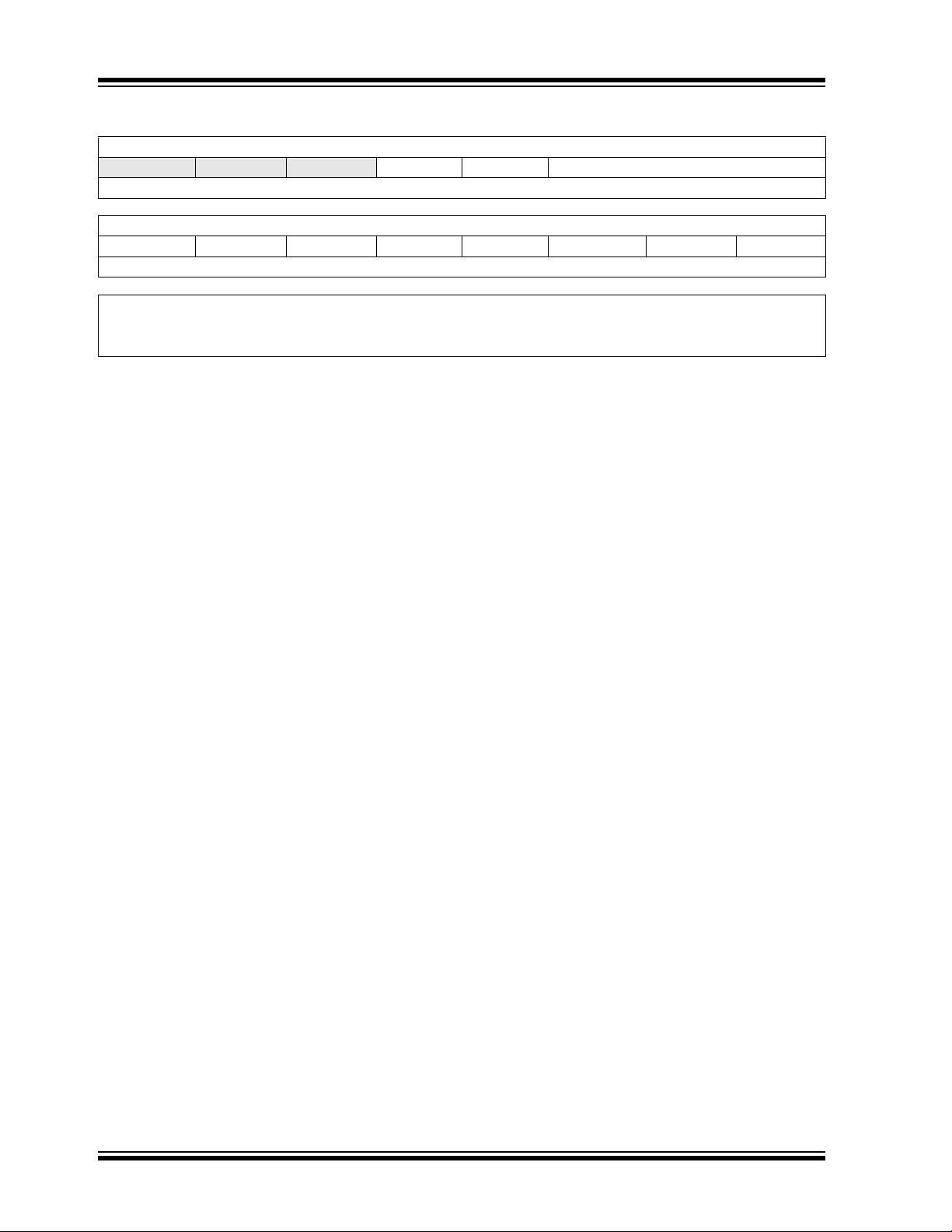

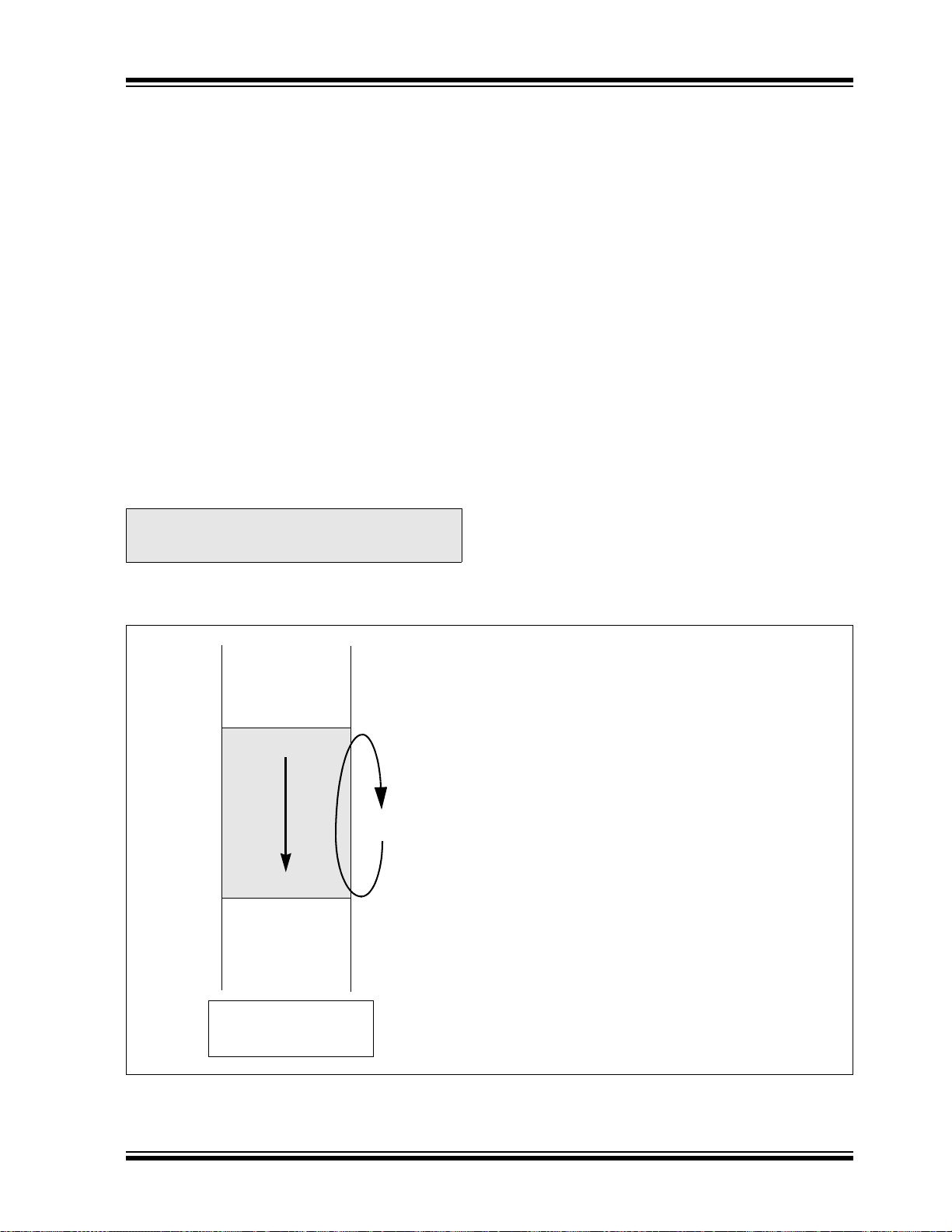

dsPIC33F

VDD

VSS

VDD

VSS

VSS

VDD

AVDD

AVSS

VDD

VSS

0.1 µF

Ceramic

0.1 µF

Ceramic

0.1 µF

Ceramic

0.1 µF

Ceramic

C

R

V

DD

MCLR

0.1 µF

Ceramic

VCAP/VDDCORE

10 Ω

R1

Note 1: R ≤ 10 kΩ is recommended. A suggested

starting value is 10 kΩ. Ensure that the

MCLR

pin VIH and VIL specifications are met.

2: R1 ≤ 470Ω will limit any current flowing into

MCLR

from the external capacitor C, in the

event of MCLR

pin breakdown, due to

Electrostatic Discharge (ESD) or Electrical

Overstress (EOS). Ensure that the MCLR

pin

V

IH and VIL specifications are met.

C

R1

R

V

DD

MCLR

dsPIC33F

JP

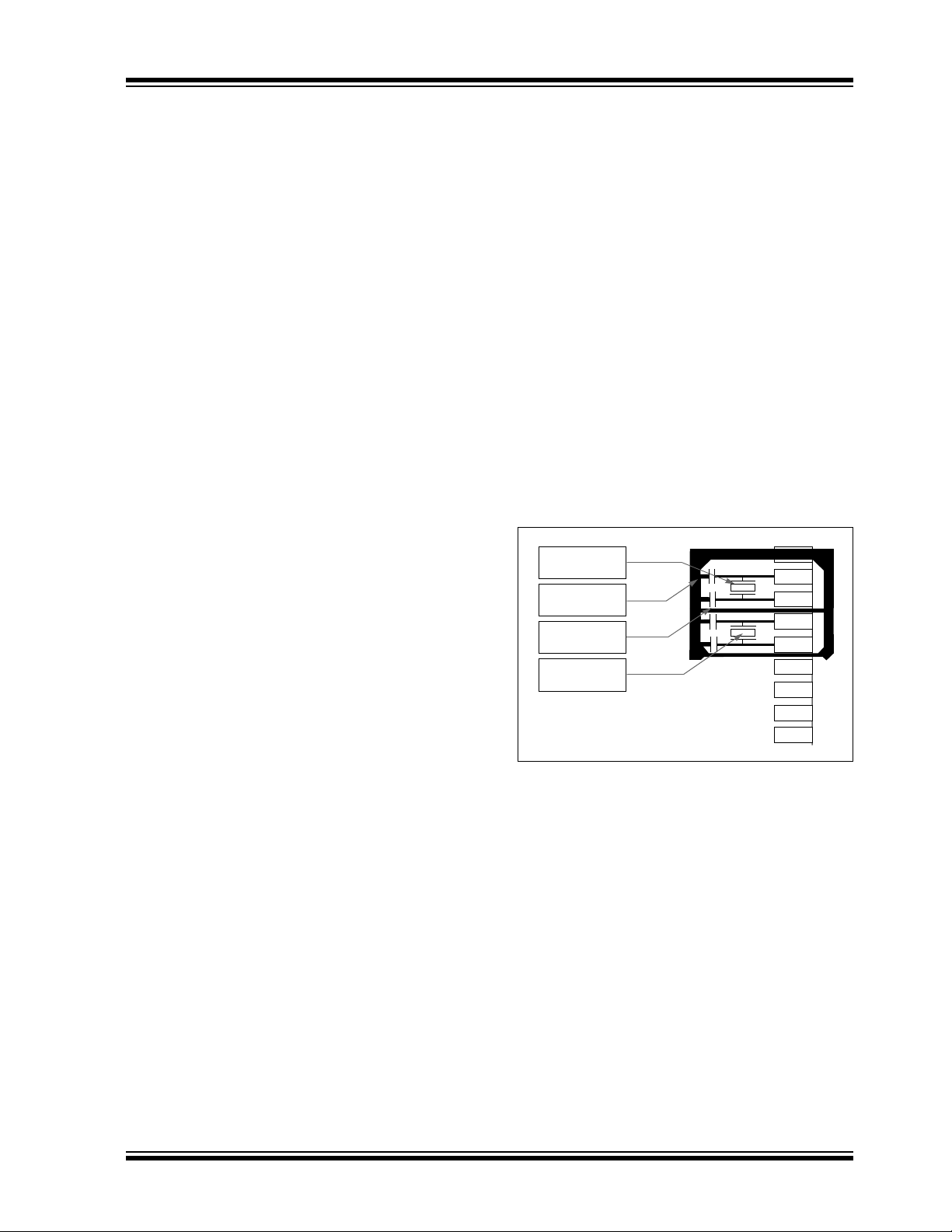

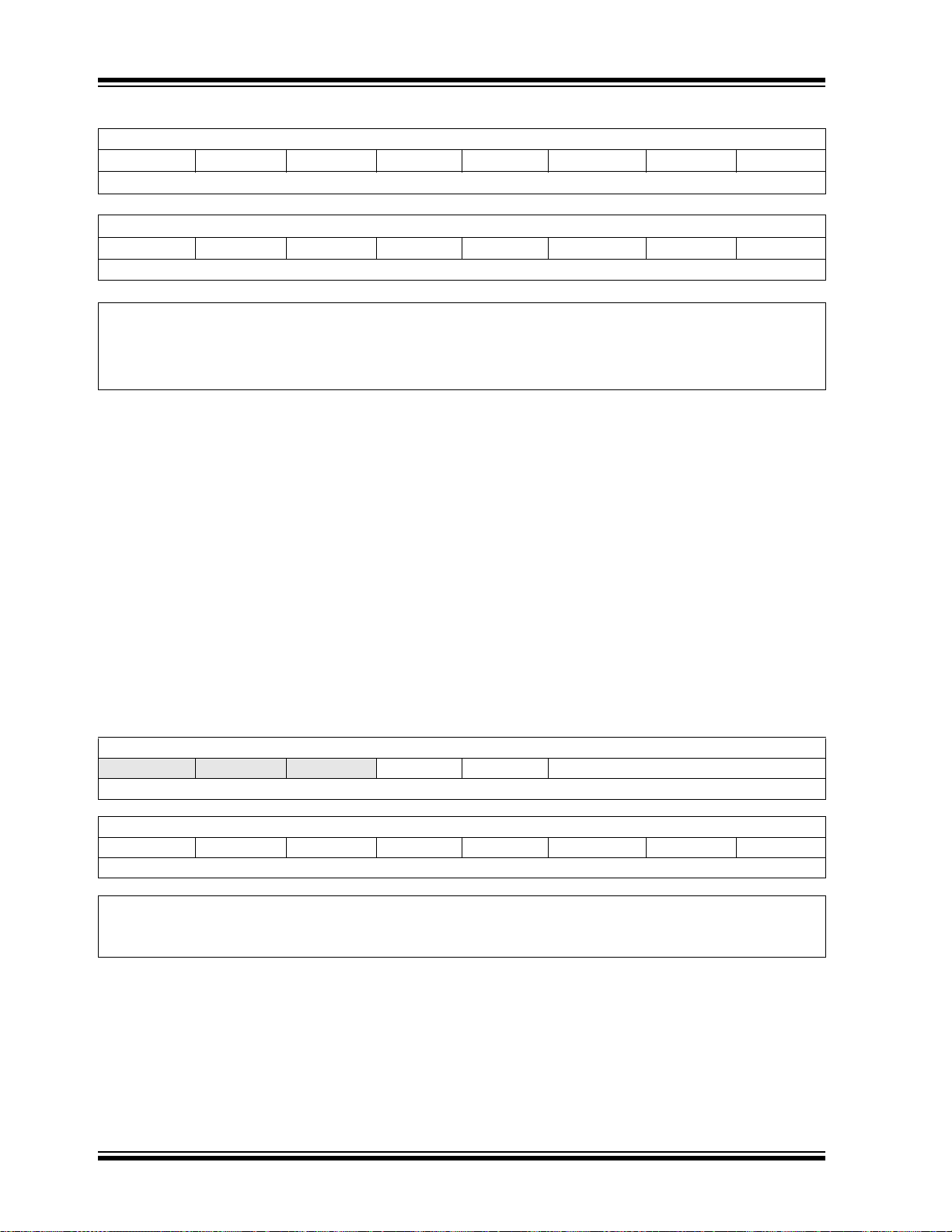

FIGURE 2-1: RECOMMENDED

MINIMUM CONNECTION

2.2.1 TANK CAPACITORS

On boards with power traces running longer than six

inches in length, it is suggested to use a tank capacitor

for integrated circuits including DSCs to supply a local

power source. The value of the tank capacitor should

be determined based on the trace resistance that connects the power supply source to the device, and the

maximum current drawn by the device in the application. In other words, select the tank capacitor so that it

meets the acceptable voltage sag at the device. Typical

values range from 4.7 µF to 47 µF.

2.4 Master Clear (MCLR) Pin

The MCLR pin provides for two specific device

functions:

• Device Reset

• Device programming and debugging

During device programming and debugging, the

resistance and capacitance that can be added to the

pin must be considered. Device programmers and

debuggers drive the MCLR

specific voltage levels (VIH and VIL) and fast signal

transitions must not be adversely affected. Therefore,

specific values of R and C will need to be adjusted

based on the application and PCB requirements.

For example, as shown in Figure 2-2, it is

recommended that the capacitor C, be isolated from

the MCLR

pin during programming and debugging

operations.

Place the components shown in Figure 2-2 within

one-quarter inch (6 mm) from the MCLR

FIGURE 2-2: EXAMPLE OF MCLR PIN

CONNECTIONS

pin. Consequently,

pin.

2.3 Capacitor on Internal Voltage

Regulator (V

A low-ESR (< 5 Ohms) capacitor is required on the

CAP/VDDCORE pin, which is used to stabilize the

V

voltage regulator output voltage. The V

pin must not be connected to VDD, and must have a

capacitor between 4.7 µF and 10 µF, 16V connected to

ground. The type can be ceramic or tantalum. Refer to

Section 25.0 “Electrical Characteristics” for

additional information.

The placement of this capacitor should be close to the

CAP/VDDCORE. It is recommended that the trace

V

length not exceed one-quarter inch (6 mm). Refer to

Section 22.2 “On-Chip Voltage Regulator” for

details.

DS70286C-page 18 © 2009 Microchip Technology Inc.

CAP/VDDCORE)

CAP/VDDCORE

dsPIC33FJXXXGPX06/X08/X10

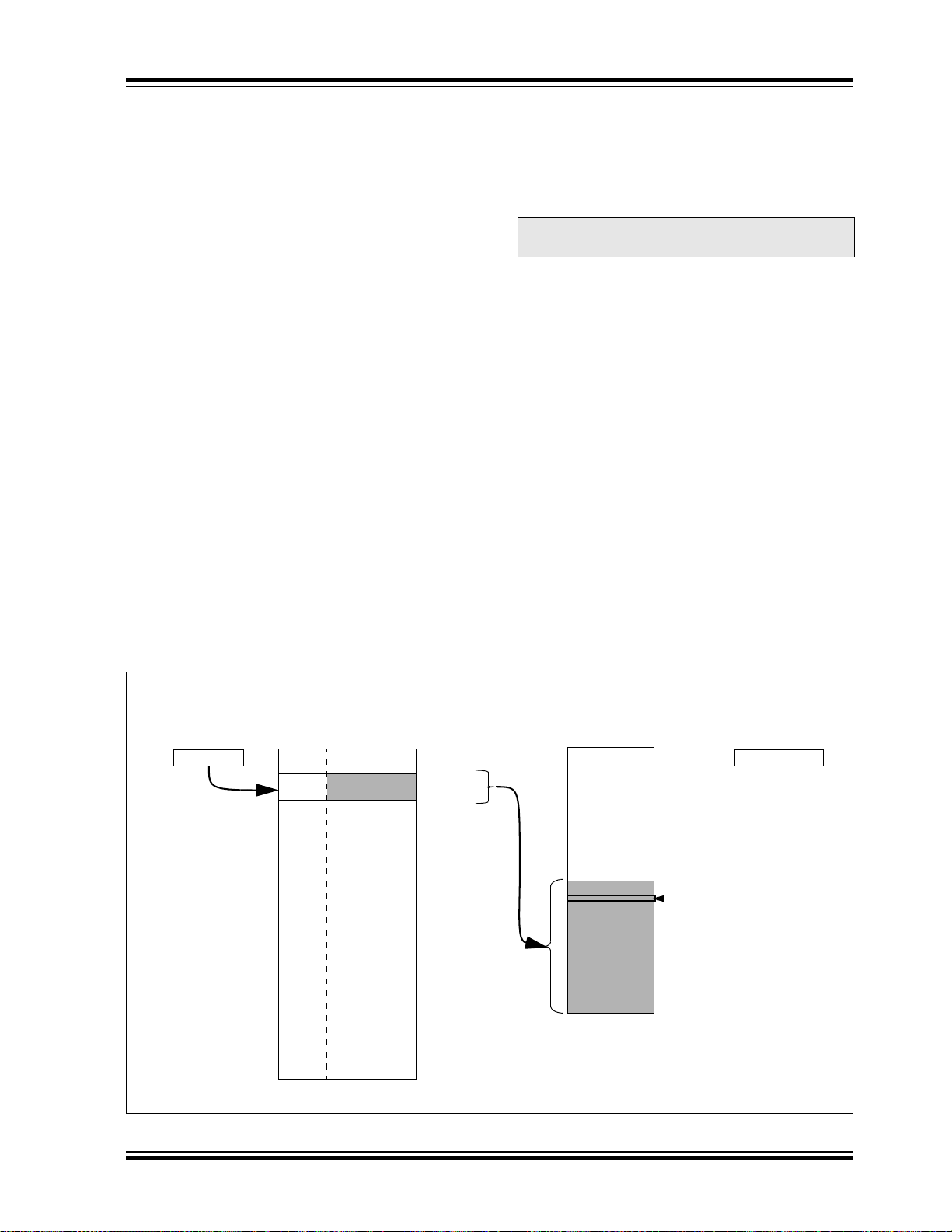

13

Main Oscillator

Guard Ring

Guard Trace

Secondary

Oscillator

14

15

16

17

18

19

20

2.5 ICSP Pins

The PGECx and PGEDx pins are used for In-Circuit

Serial Programming™ (ICSP™) and debugging purposes. It is recommended to keep the trace length

between the ICSP connector and the ICSP pins on the

device as short as possible. If the ICSP connector is

expected to experience an ESD event, a series resistor

is recommended, with the value in the range of a few

tens of Ohms, not to exceed 100 Ohms.

Pull-up resistors, series diodes, and capacitors on the

PGECx and PGEDx pins are not recommended as they

will interfere with the programmer/debugger communications to the device. If such discrete components are

an application requirement, they should be removed

from the circuit during programming and debugging.

Alternatively, refer to the AC/DC characteristics and

timing requirements information in the respective

device Flash programming specification for information

on capacitive loading limits and pin input voltage high

IH) and input low (VIL) requirements.

(V

Ensure that the “Communication Channel Select” (i.e.,

PGECx/PGEDx pins) programmed into the device

matches the physical connections for the ICSP to

®

MPLAB

ICE™.

For more information on ICD 2, ICD 3 and REAL ICE

connection requirements, refer to the following

documents that are available on the Microchip website.

• “MPLAB

• “Using MPLAB

• “MPLAB

• “Using MPLAB

• “MPLAB

• “MPLAB

• “Using MPLAB

ICD 2, MPLAB ICD 3, or MPLAB REAL

®

ICD 2 In-Circuit Debugger User’s

Guide” DS51331

®

®

ICD 2” (poster) DS51265

ICD 2 Design Advisory” DS51566

®

ICD 3 In-Circuit Debugger”

(poster) DS51765

®

ICD 3 Design Advisory” DS51764

®

REAL ICE™ In-Circuit Emulator User’s

Guide” DS51616

®

REAL ICE™” (poster) DS51749

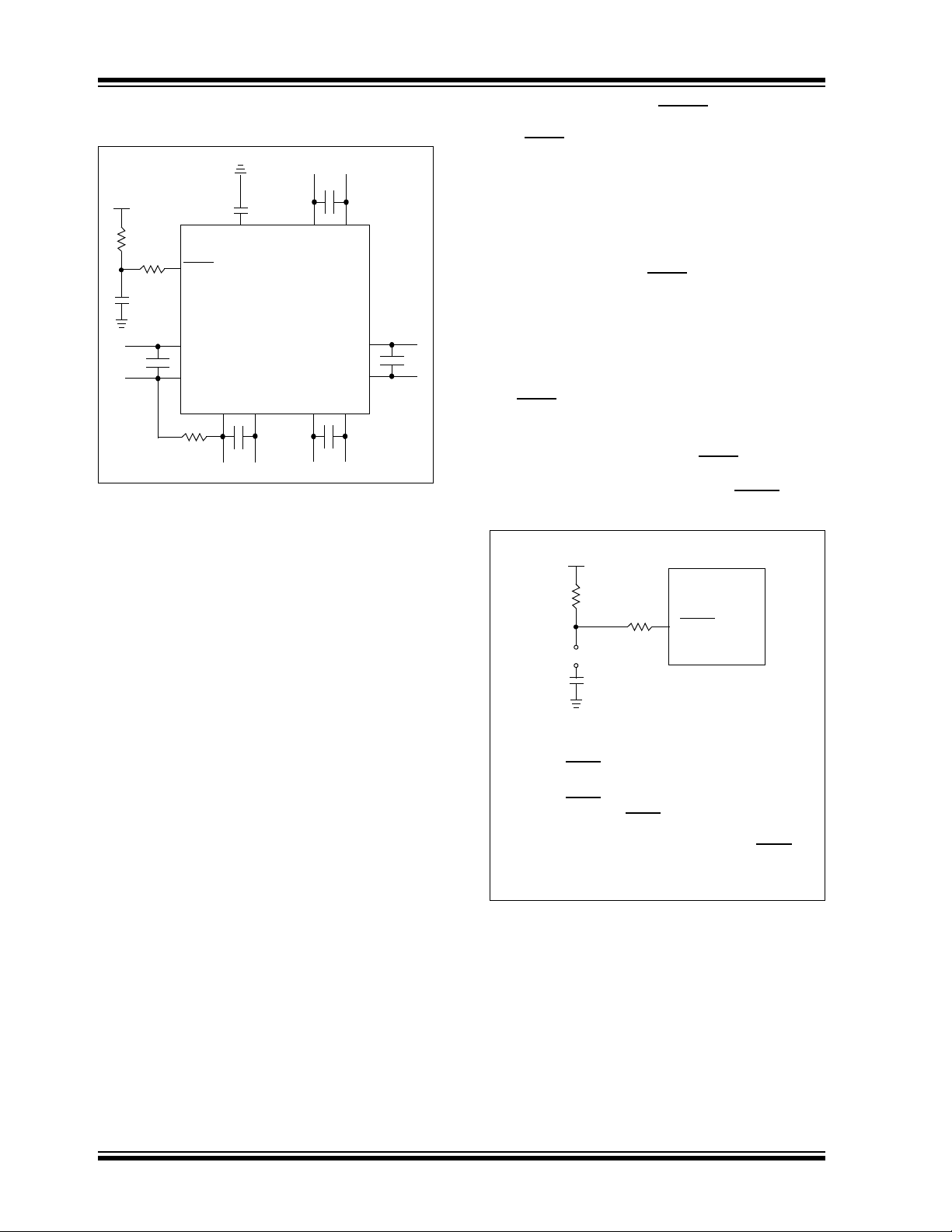

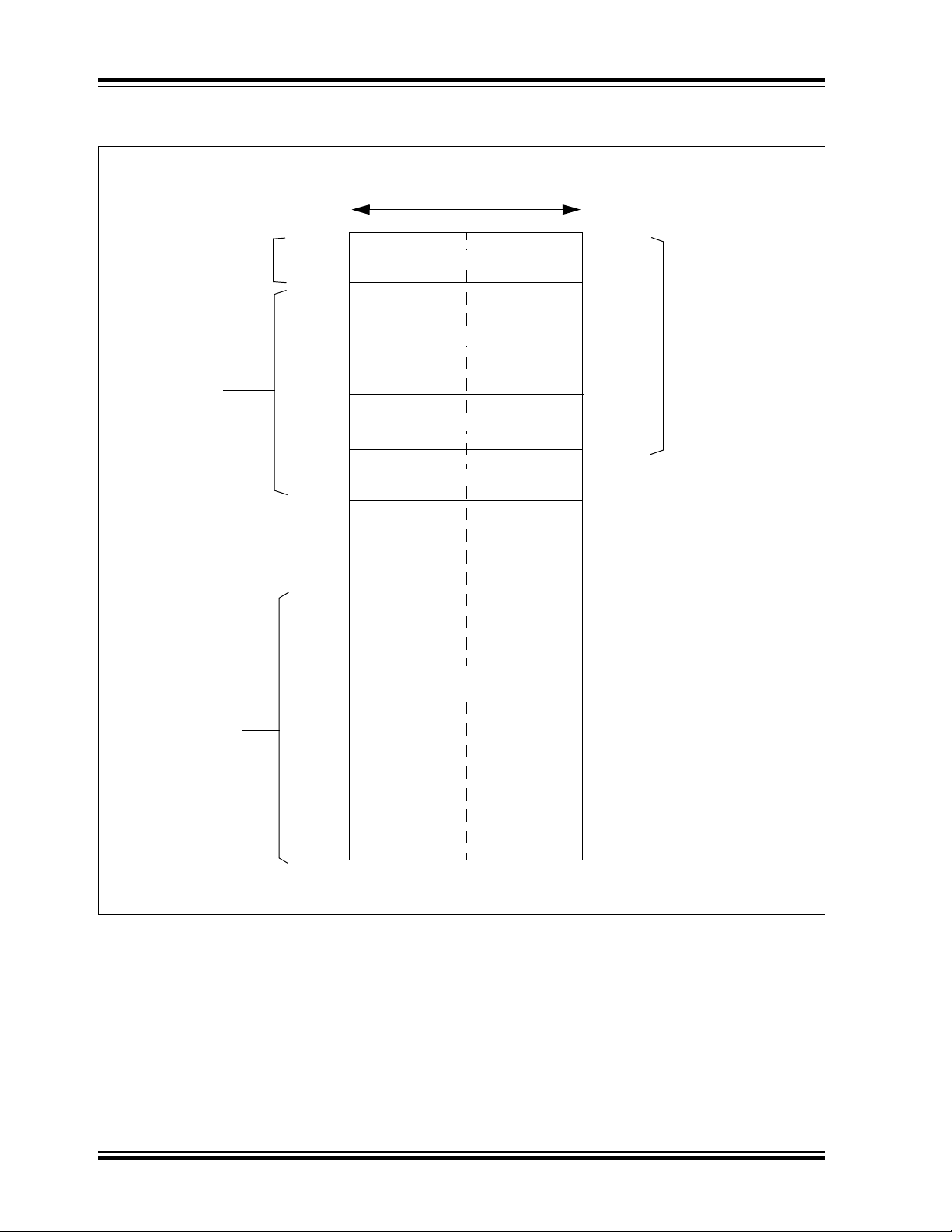

2.6 External Oscillator Pins

Many DSCs have options for at least two oscillators: a

high-frequency primary oscillator and a low-frequency

secondary oscillator (refer to Section 9.0 “Oscillator

Configuration” for details).

The oscillator circuit should be placed on the same

side of the board as the device. Also, place the

oscillator circuit close to the respective oscillator pins,

not exceeding one-half inch (12 mm) distance

between them. The load capacitors should be placed

next to the oscillator itself, on the same side of the

board. Use a grounded copper pour around the

oscillator circuit to isolate them from surrounding

circuits. The grounded copper pour should be routed

directly to the MCU ground. Do not run any signal

traces or power traces inside the ground pour. Also, if

using a two-sided board, avoid any traces on the

other side of the board where the crystal is placed. A

suggested layout is shown in Figure 2-3.

FIGURE 2-3: SUGGESTED PLACEMENT

OF THE OSCILLATOR

CIRCUIT

© 2009 Microchip Technology Inc. DS70286C-page 19

dsPIC33FJXXXGPX06/X08/X10

2.7 Oscillator Value Conditions on Device Start-up

If the PLL of the target device is enabled and

configured for the device start-up oscillator, the

maximum oscillator source frequency must be limited

to 4 MHz < F

start-up conditions. This means that if the external

oscillator frequency is outside this range, the

application must start-up in the FRC mode first. The

default PLL settings after a POR with an oscillator

frequency outside this range will violate the device

operating speed.

Once the device powers up, the application firmware

can initialize the PLL SFRs, CLKDIV and PLLDBF to a

suitable value, and then perform a clock switch to the

Oscillator + PLL clock source. Note that clock switching

must be enabled in the device Configuration word.

2.8 Configuration of Analog and

IN < 8 MHz to comply with device PLL

Digital Pins During ICSP

Operations

If MPLAB ICD 2, ICD 3 or REAL ICE is selected as a

debugger, it automatically initializes all of the A/D input

pins (ANx) as “digital” pins, by setting all bits in the

ADPCFG and ADPCFG2 registers.

The bits in the registers that correspond to the A/D pins

that are initialized by MPLAB ICD 2, ICD 3, or REAL

ICE, must not be cleared by the user application

firmware; otherwise, communication errors will result

between the debugger and the device.

If your application needs to use certain A/D pins as

analog input pins during the debug session, the user

application must clear the corresponding bits in the

ADPCFG and ADPCFG2 registers during initialization

of the ADC module.

When MPLAB ICD 2, ICD 3 or REAL ICE is used as a

programmer, the user application firmware must

correctly configure the ADPCFG and ADPCFG2

registers. Automatic initialization of these registers is

only done during debugger operation. Failure to

correctly configure the register(s) will result in all A/D

pins being recognized as analog input pins, resulting in

the port value being read as a logic ‘0’, which may

affect user application functionality.

2.9 Unused I/Os

Unused I/O pins should be configured as outputs and

driven to a logic-low state.

Alternatively, connect a 1k to 10k resistor to V

unused pins and drive the output to logic low.

DS70286C-page 20 © 2009 Microchip Technology Inc.

SS on

dsPIC33FJXXXGPX06/X08/X10

3.0 CPU

Note: This data sheet summarizes the features

of the dsPIC33FJXXXGPX06/X08/X10

family of devices. However, it is not

intended to be a comprehensive reference

source. To complement the information in

this data sheet, refer to Section 2. “CPU”

(DS70204) in the “dsPIC33F Family Ref-

erence Manual”, which is available from

the Microchip web site

(www.microchip.com).

The dsPIC33FJXXXGPX06/X08/X10 CPU module has a

16-bit (data) modified Harvard architecture with an

enhanced instruction set, including significant support for

DSP. The CPU has a 24-bit instruction word with a variable

length opcode field. The Program Counter (PC) is 23 bits

wide and addresses up to 4M x 24 bits of user program

memory space. The actual amount of program memory

implemented varies by device. A single-cycle instruction

prefetch mechanism is used to help maintain throughput

and provides predictable execution. All instructions execute

in a single cycle, with the exception of instructions that

MOV.D

DO

)

and

change the program flow, the double word move (

instruction and the table instructions. Overhead-free program loop constructs are supported using the

REPEAT

point.

The dsPIC33FJXXXGPX06/X08/X10 devices have sixteen,

16-bit working registers in the programmer’s model. Each of

the working registers can serve as a data, address or

address offset register. The 16th working register (W15)

operates as a software Stack Pointer (SP) for interrupts and

calls.

The dsPIC33FJXXXGPX06/X08/X10 instruction set has

two classes of instructions: MCU and DSP. These two

instruction classes are seamlessly integrated into a single

CPU. The instruction set includes many addressing modes

and is designed for optimum C compiler efficiency. For most

instructions, the dsPIC33FJXXXGPX06/X08/X10 is capable of executing a data (or program data) memory read, a

working register (data) read, a data memory write and a

program (instruction) memory read per instruction cycle. As

a result, three parameter instructions can be supported,

allowing A + B = C operations to be executed in a single

cycle.

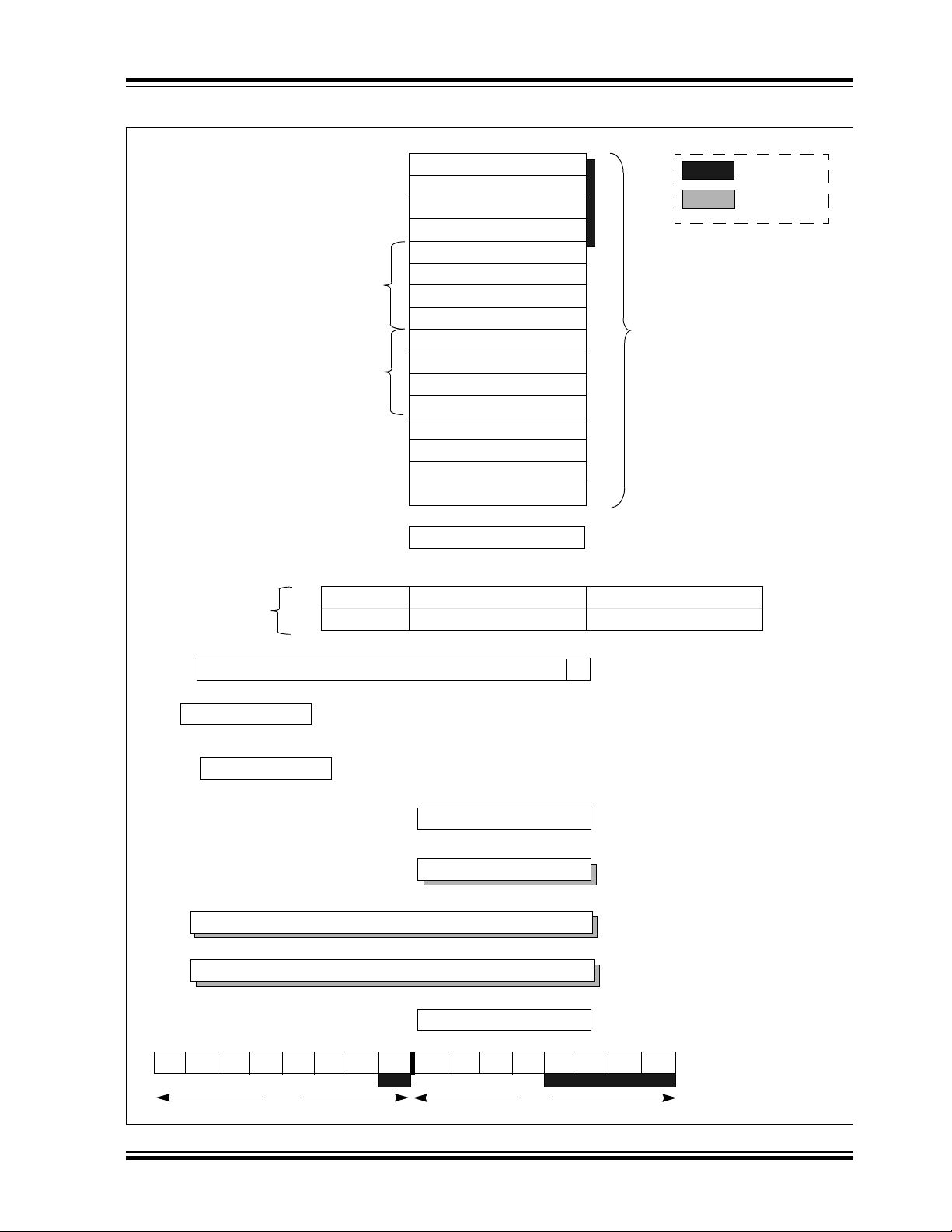

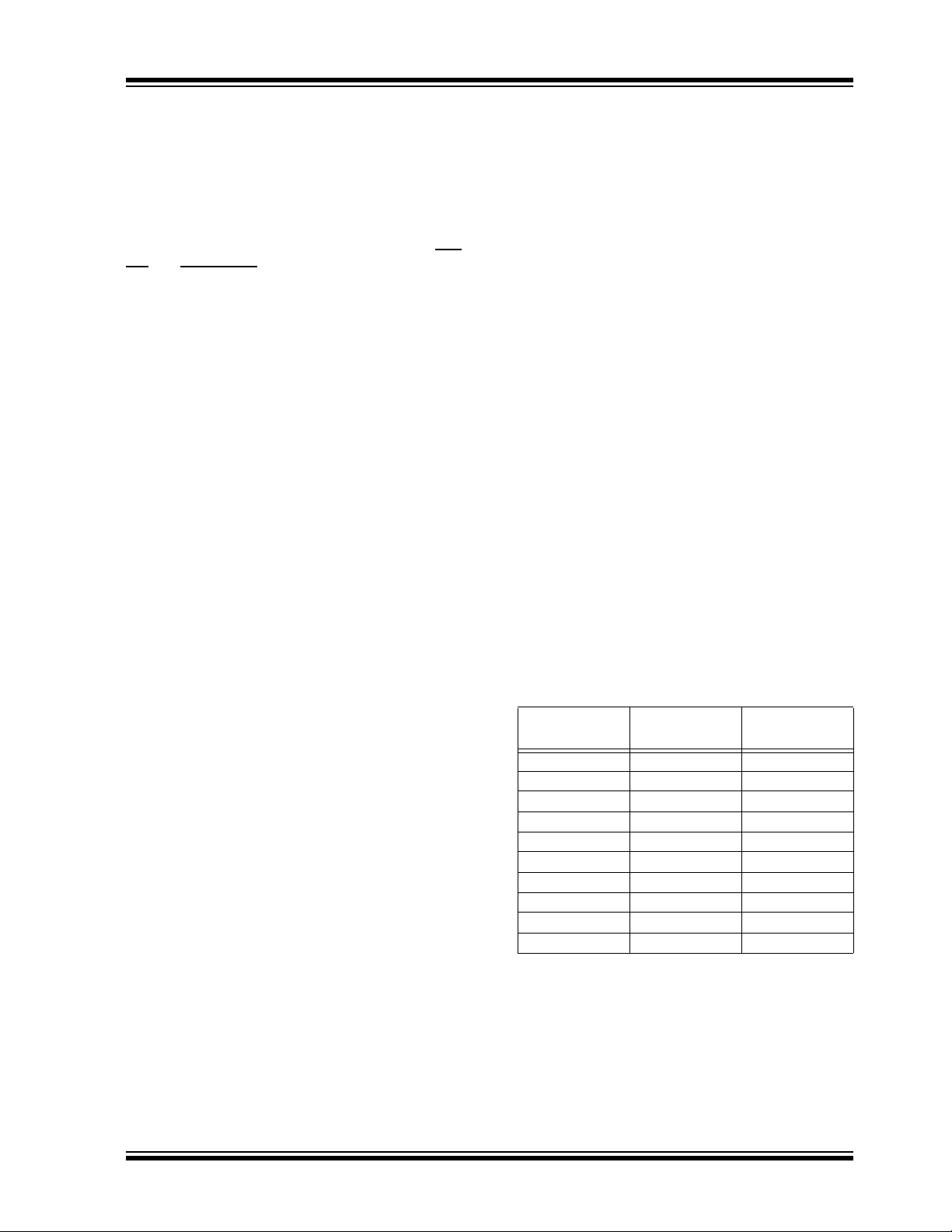

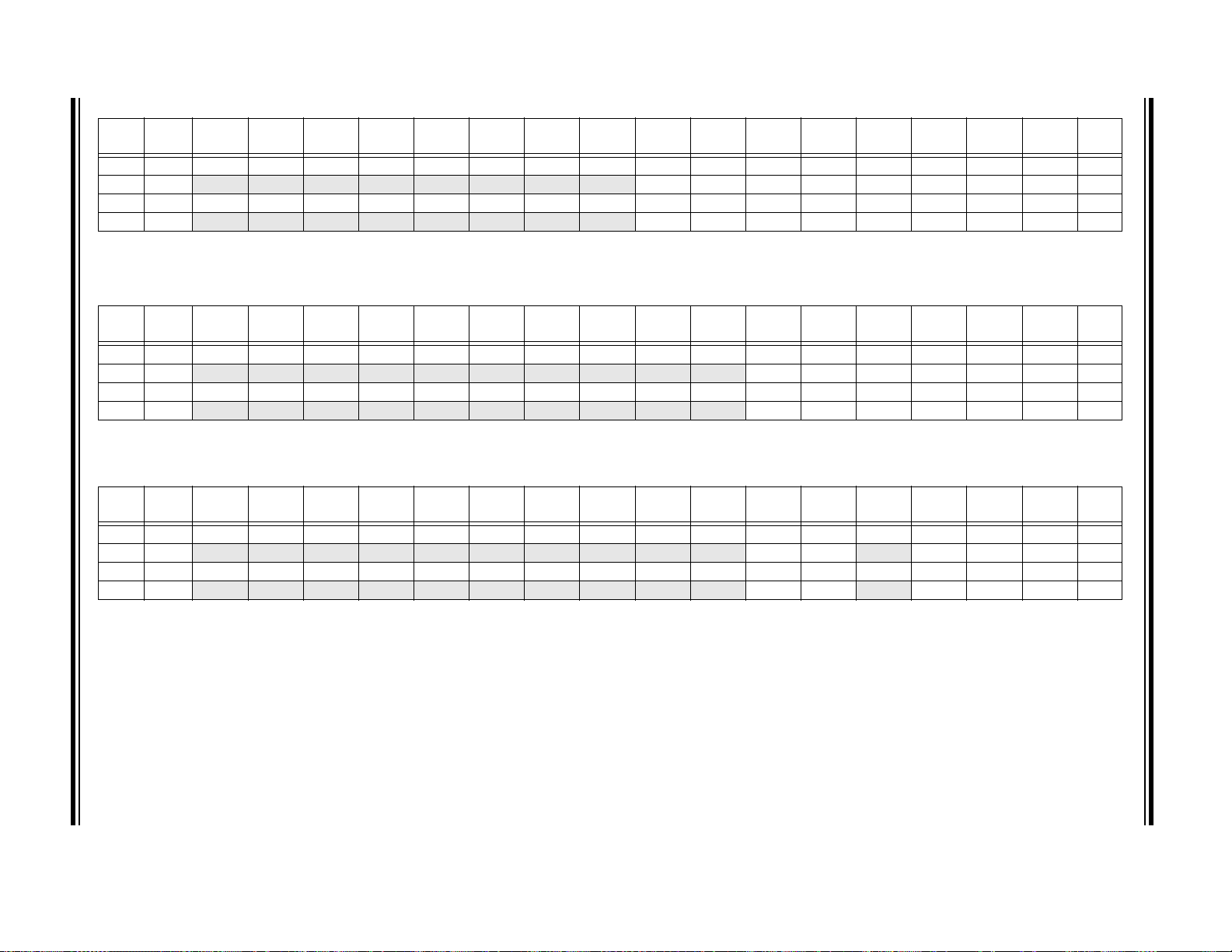

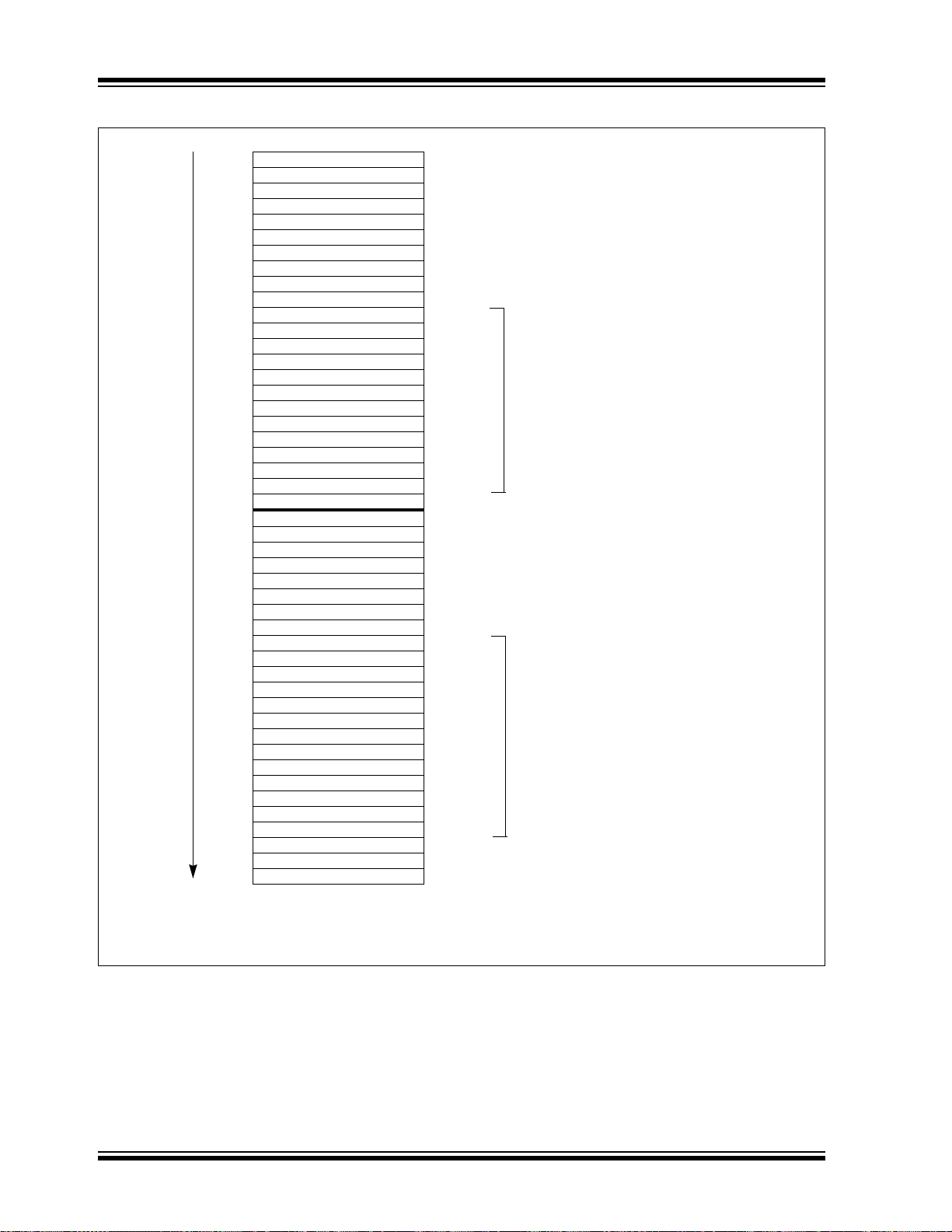

A block diagram of the CPU is shown in Figure 3-1. The

programmer’s model for the

dsPIC33FJXXXGPX06/X08/X10 is shown in Figure 3-2.

instructions, both of which are interruptible at any

3.1 Data Addressing Overview

The data space can be addressed as 32K words or

64 Kbytes and is split into two blocks, referred to as X and

Y data memory. Each memory block has its own independent Address Generation Unit (AGU). The MCU class of

instructions operates solely through the X memory AGU,

which accesses the entire memory map as one linear data

space. Certain DSP instructions operate through the X and

Y AGUs to support dual operand reads, which splits the

data address space into two parts. The X and Y data space

boundary is device-specific.

Overhead-free circular buffers (Modulo Addressing mode)

are supported in both X and Y address spaces. The Modulo

Addressing removes the software boundary checking overhead for DSP algorithms. Furthermore, the X AGU circular

addressing can be used with any of the MCU class of

instructions. The X AGU also supports Bit-Reversed

Addressing to greatly simplify input or output data

reordering for radix-2 FFT algorithms.

The upper 32 Kbytes of the data space memory map can

optionally be mapped into program space at any 16K program word boundary defined by the 8-bit Program Space

Visibility Page (PSVPAG) register. The program to data

space mapping feature lets any instruction access program

space as if it were data space. The data space also includes

2 Kbytes of DMA RAM, which is primarily used for DMA

data transfers, but may be used as general purpose RAM.

3.2 DSP Engine Overview

The DSP engine features a high-speed, 17-bit by 17-bit

multiplier, a 40-bit ALU, two 40-bit saturating accumulators and a 40-bit bidirectional barrel shifter. The barrel

shifter is capable of shifting a 40-bit value, up to 16 bits

right or left, in a single cycle. The DSP instructions operate

seamlessly with all other instructions and have been

designed for optimal real-time performance. The

instruction and other associated instructions can concurrently fetch two data operands from memory while multiplying two W registers and accumulating and optionally

saturating the result in the same cycle. This instruction

functionality requires that the RAM memory data space be

split for these instructions and linear for all others. Data

space partitioning is achieved in a transparent and flexible

manner through dedicating certain working registers to

each address space.

MAC

3.3 Special MCU Features

The dsPIC33FJXXXGPX06/X08/X10 features a 17-bit by

17-bit, single-cycle multiplier that is shared by both the

MCU ALU and DSP engine. The multiplier can perform

signed, unsigned and mixed-sign multiplication. Using a

17-bit by 17-bit multiplier for 16-bit by 16-bit multiplication

not only allows you to perform mixed-sign multiplication, it

also achieves accurate results for special operations,

such as (-1.0) x (-1.0).

The dsPIC33FJXXXGPX06/X08/X10 supports 16/16 and

32/16 divide operations, both fractional and integer. All

divide instructions are iterative operations. They must be

executed within a

tion time of 19 instruction cycles. The divide operation can

be interrupted during any of those 19 cycles without loss

of data.

A 40-bit barrel shifter is used to perform up to a 16-bit, left

or right shift in a single cycle. The barrel shifter can be used

by both MCU and DSP instructions.

REPEAT

loop, resulting in a total execu-

© 2009 Microchip Technology Inc. DS70286C-page 21

Instruction

Decode and

Control

PCH PCL

Program Counter

16-bit ALU

24

23

Instruction Reg

PCU

16 x 16

W Register Array

ROM Latch

EA MUX

Interrupt

Controller

Stac k

Control

Logic

Loop

Control

Logic

Data Latch

Address

Latch

Control Signals

to Various Blocks

Literal Data

16

16

16

To Peripheral Modules

Data Latch

Address

Latch

16

X RAM

Y RAM

Address Generator Units

16

Y Data Bus

X Data Bus

DMA

Controller

DMA

RAM

DSP Engine

Divide Support

16

16

23

23

16

8

PSV and Table

Data Access

Control Block

16

16

16

16

Program Memory

Data Latch

Address Latch

dsPIC33FJXXXGPX06/X08/X10

FIGURE 3-1: dsPIC33FJXXXGPX06/X08/X10 CPU CORE BLOCK DIAGRAM

DS70286C-page 22 © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

PC22

PC0

7

0

D0D15

Program Counter

Data Table Page Address

STATUS Register

Working Registers

DSP Operand

Registers

W1

W2

W3

W4

W5

W6

W7

W8

W9

W10

W11

W12/DSP Offset

W13/DSP Write Back

W14/Frame Pointer

W15/Stack Pointer

DSP Address

Registers

AD39 AD0AD31

DSP

Accumulators

AccA

AccB

7

0

Program Space Visibility Page Address

Z

0

OA OB SA SB

RCOUNT

15

0

REPEAT Loop Counter

DCOUNT

15

0

DO Loop Counter

DOSTART

22

0

DO Loop Start Address

IPL2 IPL1

SPLIM

Stack Pointer Limit Register

AD15

SRL

PUSH.S Shadow

DO Shadow

OAB SAB

15

0

Core Configuration Register

Legend

CORCON

DA DC

RA

N

TBLPAG

PSVPAG

IPL0 OV

W0/WREG

SRH

DO Loop End Address

DOEND

22

C

FIGURE 3-2: dsPIC33FJXXXGPX06/X08/X10 PROGRAMMER’S MODEL

© 2009 Microchip Technology Inc. DS70286C-page 23

dsPIC33FJXXXGPX06/X08/X10

3.4 CPU Control Registers

CPU control registers include:

• SR: CPU STATUS REGISTER

• CORCON: CORE CONTROL REGISTER

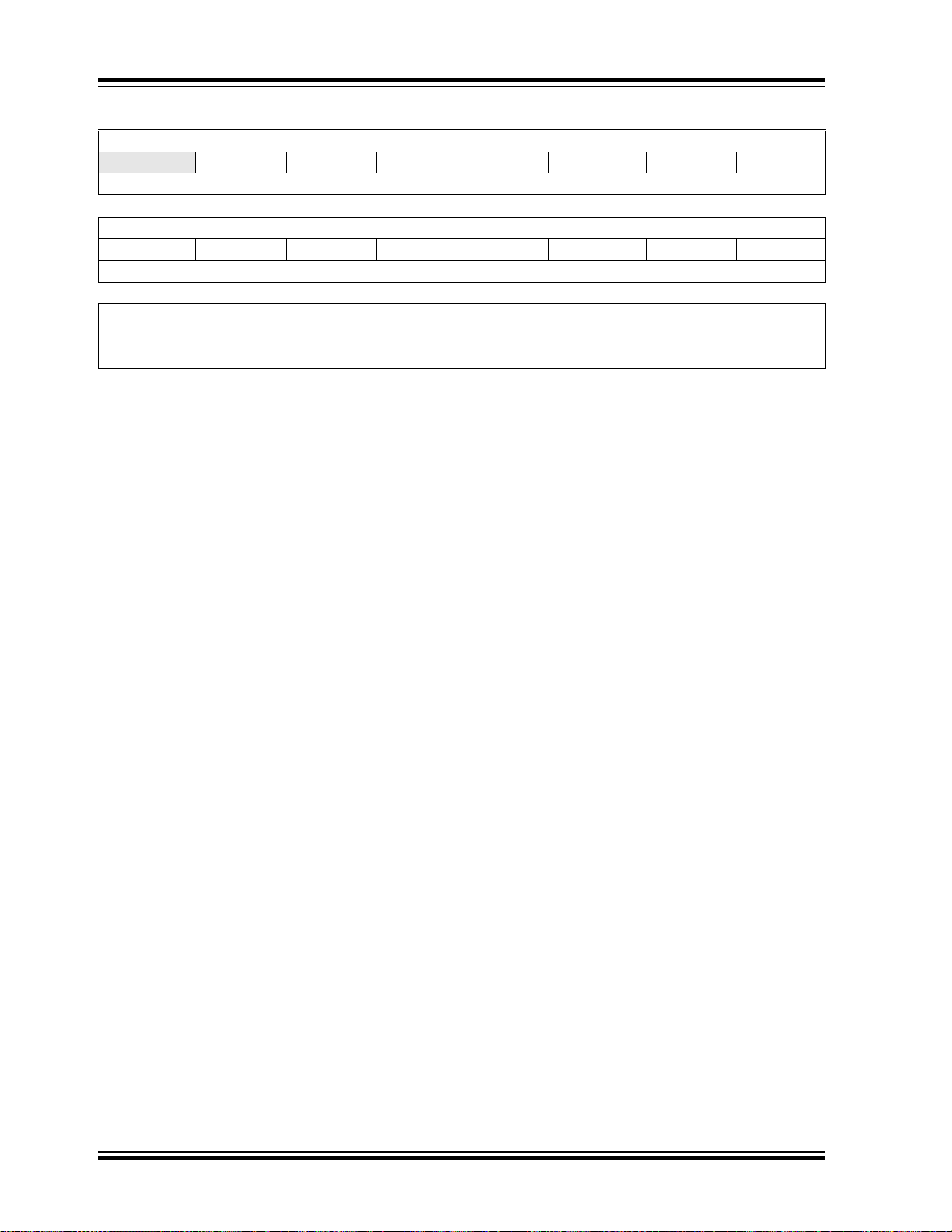

REGISTER 3-1: SR: CPU STATUS REGISTER

R-0 R-0 R/C-0 R/C-0 R-0 R/C-0 R -0 R/W-0

OA OB SA

(1)

bit 15 bit 8

SB

(1)

OAB SAB DA DC

R/W-0

(2)

IPL<2:0>

R/W-0

(3)

(2)

R/W-0

(3)

R-0 R/W-0 R/W-0 R/W-0 R/W-0

RA N OV Z C

bit 7 bit 0

Legend:

C = Clear only bit R = Readable bit U = Unimplemented bit, read as ‘0’

S = Set only bit W = Writable bit -n = Value at POR

‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 15 OA: Accumulator A Overflow Status bit

1 = Accumulator A overflowed

0 = Accumulator A has not overflowed

bit 14 OB: Accumulator B Overflow Status bit

1 = Accumulator B overflowed

0 = Accumulator B has not overflowed

bit 13 SA: Accumulator A Saturation ‘Sticky’ Status bit

(1)

1 = Accumulator A is saturated or has been saturated at some time

0 = Accumulator A is not saturated

bit 12 SB: Accumulator B Saturation ‘Sticky’ Status bit

(1)

1 = Accumulator B is saturated or has been saturated at some time

0 = Accumulator B is not saturated

bit 11 OAB: OA || OB Combined Accumulator Overflow Status bit

1 = Accumulators A or B have overflowed

0 = Neither Accumulators A or B have overflowed

bit 10 SAB: SA || SB Combined Accumulator ‘Sticky’ Status bit

1 = Accumulators A or B are saturated or have been saturated at some time in the past

0 = Neither Accumulator A or B are saturated

Note: This bit may be read or cleared (not set). Clearing this bit will clear SA and SB.

bit 9 DA: DO Loop Active bit

1 = DO loop in progress

0 = DO loop not in progress

Note 1: This bit may be read or cleared (not set).

2: The IPL<2:0> bits are concatenated with the IPL<3> bit (CORCON<3>) to form the CPU Interrupt Priority

Level. The value in parentheses indicates the IPL if IPL<3> = 1. User interrupts are disabled when

IPL<3> = 1.

3: The IPL<2:0> Status bits are read only when NSTDIS = 1 (INTCON1<15>).

DS70286C-page 24 © 2009 Microchip Technology Inc.

dsPIC33FJXXXGPX06/X08/X10

REGISTER 3-1: SR: CPU STATUS REGISTER (CONTINUED)

bit 8 DC: MCU ALU Half Carry/Borrow bit

1 = A carry-out from the 4th low-order bit (for byte sized data) or 8th low-order bit (for word sized data)

of the result occurred

0 = No carry-out from the 4th low-order bit (for byte sized data) or 8th low-order bit (for word sized

data) of the result occurred

bit 7-5 IPL<2:0>: CPU Interrupt Priority Level Status bits

111 = CPU Interrupt Priority Level is 7 (15), user interrupts disabled

110 = CPU Interrupt Priority Level is 6 (14)

101 = CPU Interrupt Priority Level is 5 (13)

100 = CPU Interrupt Priority Level is 4 (12)

011 = CPU Interrupt Priority Level is 3 (11)

010 = CPU Interrupt Priority Level is 2 (10)

001 = CPU Interrupt Priority Level is 1 (9)

000 = CPU Interrupt Priority Level is 0 (8)

bit 4 RA: REPEAT Loop Active bit

1 = REPEAT loop in progress

0 = REPEAT loop not in progress

bit 3 N: MCU ALU Negative bit

1 = Result was negative

0 = Result was non-negative (zero or positive)

bit 2 OV: MCU ALU Overflow bit

This bit is used for signed arithmetic (2’s complement). It indicates an overflow of the magnitude which

causes the sign bit to change state.

1 = Overflow occurred for signed arithmetic (in this arithmetic operation)

0 = No overflow occurred

bit 1 Z: MCU ALU Zero bit

1 = An operation which affects the Z bit has set it at some time in the past

0 = The most recent operation which affects the Z bit has cleared it (i.e., a non-zero result)

bit 0 C: MCU ALU Carry/Borrow

1 = A carry-out from the Most Significant bit of the result occurred

0 = No carry-out from the Most Significant bit of the result occurred

Note 1: This bit may be read or cleared (not set).

2: The IPL<2:0> bits are concatenated with the IPL<3> bit (CORCON<3>) to form the CPU Interrupt Priority

Level. The value in parentheses indicates the IPL if IPL<3> = 1. User interrupts are disabled when

IPL<3> = 1.

3: The IPL<2:0> Status bits are read only when NSTDIS = 1 (INTCON1<15>).

bit

(2)

© 2009 Microchip Technology Inc. DS70286C-page 25

dsPIC33FJXXXGPX06/X08/X10

REGISTER 3-2: CORCON: CORE CONTROL REGISTER

U-0 U-0 U-0 R/W-0 R/W-0 R-0 R-0 R-0

— — —USEDT

(1)

DL<2:0>

bit 15 bit 8

R/W-0 R/W-0 R/W-1 R/W-0 R/C-0 R/W-0 R/W-0 R/W-0

SATA SATB SATDW ACCSAT IPL3

(2)

PSV RND IF

bit 7 bit 0

Legend: C = Clear only bit

R = Readable bit W = Writable bit -n = Value at POR ‘1’ = Bit is set

0’ = Bit is cleared ‘x = Bit is unknown U = Unimplemented bit, read as ‘0’

bit 15-13 Unimplemented: Read as ‘0’

bit 12 US: DSP Multiply Unsigned/Signed Control bit