Page 1

TL/F/8638

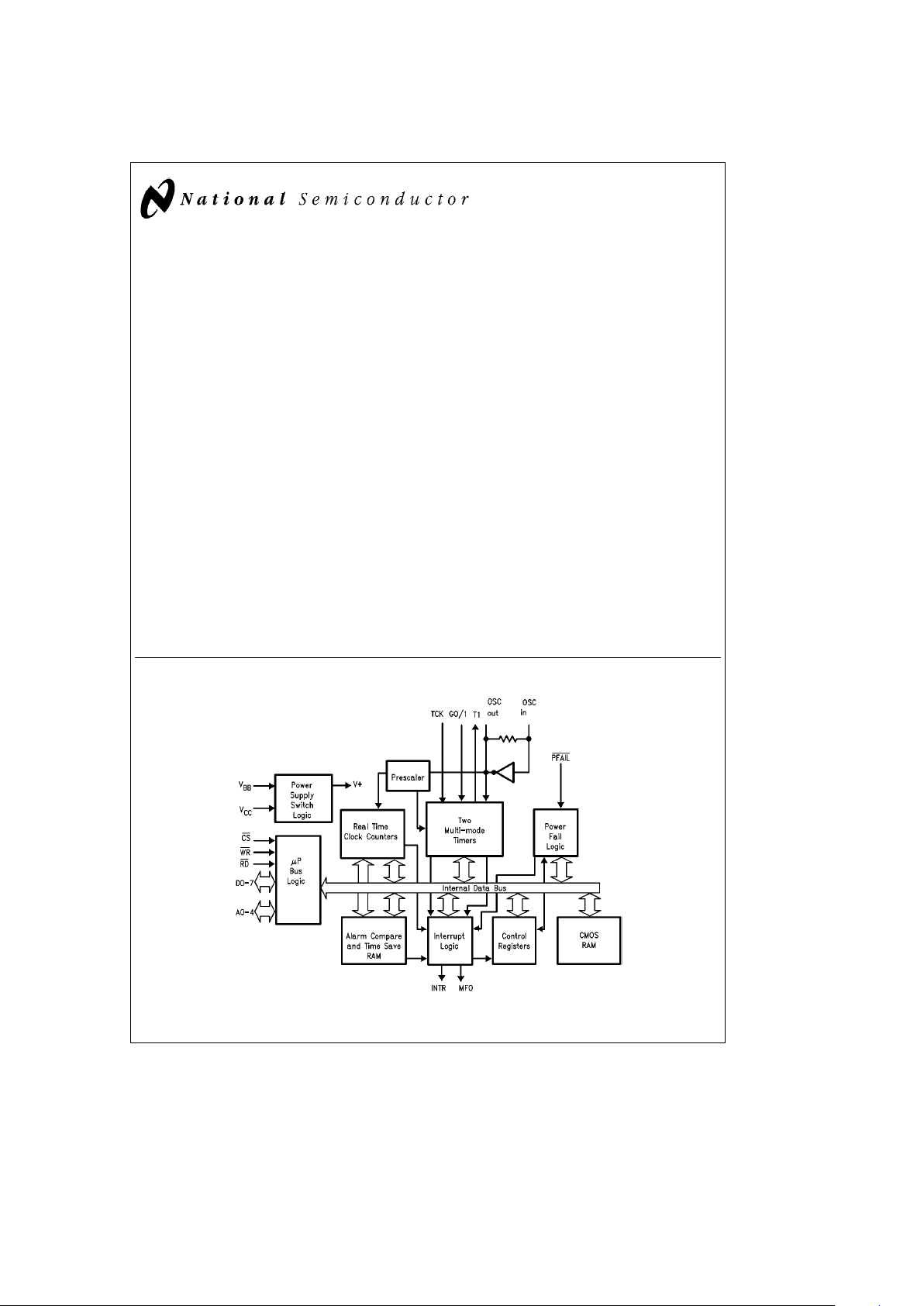

DP8570A Timer Clock Peripheral (TCP)

May 1993

DP8570A Timer Clock Peripheral (TCP)

General Description

The DP8570A is intended for use in microprocessor based

systems where information is required for multi-tasking, data

logging or general time of day/date information. This device

is implemented in low voltage silicon gate microCMOS technology to provide low standby power in battery back-up environments. The circuit’s architecture is such that it looks

like a contiguous block of memory or I/O ports. The address

space is organized as 2 software selectable pages of 32

bytes. This includes the Control Registers, the Clock Counters, the Alarm Compare RAM, the Timers and their data

RAM, and the Time Save RAM. Any of the RAM locations

that are not being used for their intended purpose may be

used as general purpose CMOS RAM.

Time and date are maintained from 1/100 of a second to

year and leap year in a BCD format, 12 or 24 hour modes.

Day of week, day of month and day of year counters are

provided. Time is controlled by an on-chip crystal oscillator

requiring only the addition of the crystal and two capacitors.

The choice of crystal frequency is program selectable.

Two independent multifunction 10 MHz 16-bit timers are

provided. These timers operate in four modes. Each has its

own prescaler and can select any of 8 possible clock inputs.

Thus, by programming the input clocks and the timer counter values a very wide range of timing durations can be

achieved. The range is from about 400 ns (4.915 MHz oscillator) to 65,535 seconds (18 hrs., 12 min.).

Power failure logic and control functions have been integrated on chip. This logic is used by the TCP to issue a power fail

interrupt, and lock out the mp interface. The time power fails

may be logged into RAM automatically when V

BB

l

VCC.

Additionally, two supply pins are provided. When V

BB

l

VCC, internal circuitry will automatically switch from the main

supply to the battery supply. Status bits are provided to indicate initial application of battery power, system power, and

low battery detect. (Continued)

Features

Y

Full function real time clock/calendar

Ð 12/24 hour mode timekeeping

Ð Day of week and day of years counters

Ð Four selectable oscillator frequencies

Ð Parallel Resonant Oscillator

Y

Two 16-bit timers

Ð 10 MHz external clock frequency

Ð Programmable multi-function output

Ð Flexible re-trigger facilities

Y

Power fail features

Ð Internal power supply switch to external battery

Ð Power Supply Bus glitch protection

Ð Automatic log of time into RAM at power failure

Y

On-chip interrupt structure

Ð Periodic, alarm, timer and power fail interrupts

Y

Up to 44 bytes of CMOS RAM

Y

INTR/MFO/T1 pins programmable High/Low and pushpull or open drain

Block Diagram

TL/F/8638– 1

FIGURE 1

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

C

1995 National Semiconductor Corporation RRD-B30M75/Printed in U. S. A.

Page 2

Absolute Maximum Ratings (Notes1&2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (V

CC

)

b

0.5V toa7.0V

DC Input Voltage (VIN)

b

0.5V to V

CC

a

0.5V

DC Output Voltage (V

OUT

)

b

0.5V to V

CC

a

0.5V

Storage Temperature Range

b

65§Ctoa150§C

Power Dissipation (PD) 500 mW

Lead Temperature (Soldering, 10 sec.) 260§C

Operation Conditions

Min Max Unit

Supply Voltage (V

CC

) (Note 3) 4.5 5.5 V

Supply Voltage (VBB) (Note 3) 2.2 V

CC

b

0.4 V

DC Input or Output Voltage

0.0 V

CC

V

(V

IN,VOUT

)

Operation Temperature (T

A

)

b

40

a

85§C

Electr-Static Discharge Rating TBD 1 kV

Transistor Count 15,200

Typical Values

i

JA

DIP Boarde45§C/W

Socket

e

50§C/W

i

JA

PLCC Boarde77§C/W

Socket

e

85§C/W

DC Electrical Characteristics

V

CC

e

5Vg10%, V

BB

e

3V, V

PFAIL

l

VIH,C

L

e

100 pF (unless otherwise specified)

Symbol Parameter Conditions Min Max Units

V

IH

High Level Input Voltage Any Inputs Except OSC IN, 2.0 V

(Note 4) OSC IN with External Clock V

BB

b

0.1 V

V

IL

Low Level Input Voltage All Inputs Except OSC IN 0.8 V

OSC IN with External Clock 0.1 V

V

OH

High Level Output Voltage I

OUT

eb

20 mAV

CC

b

0.1 V

(Excluding OSC OUT) I

OUT

eb

4.0 mA 3.5 V

V

OL

Low Level Output Voltage I

OUT

e

20 mA 0.1 V

(Excluding OSC OUT) I

OUT

e

4.0 mA 0.25 V

I

IN

Input Current (Except OSC IN) V

IN

e

VCCor GND

g

1.0 mA

I

OZ

Output TRI-STATEÉCurrent V

OUT

e

VCCor GND

g

5.0 mA

I

LKG

Output High Leakage Current V

OUT

e

VCCor GND

g

5.0 mA

T1, MFO, INTR Pins Outputs Open Drain

I

CC

Quiescent Supply Current F

OSC

e

32.768 kHz

(Note 7) V

IN

e

VCCor GND (Note 5) 260 mA

V

IN

e

VCCor GND (Note 6) 1.0 mA

V

IN

e

VIHor VIL(Note 6) 12.0 mA

F

OSC

e

4.194304 MHz or

4.9152 MHz

V

IN

e

VCCor GND (Note 6) 8 mA

V

IN

e

VIHor VIL(Note 6) 20 mA

I

CC

Quiescent Supply Current V

BB

e

GND

(Single Supply Mode) V

IN

e

VCCor GND

(Note 7) F

OSC

e

32.768 kHz 80 mA

F

OSC

e

4.9152 MHz or 7.5 mA

4.194304 MHz

I

BB

Standby Mode Battery V

CC

e

GND

Supply Current OSC OUT

e

Open Circuit,

(Note 8) Other Pins

e

GND

F

OSC

e

32.768 kHz 10 mA

F

OSC

e

4.9152 MHz or 400 mA

4.194304 MHz

I

BLK

Battery Supply Leakage 2.2VsV

BB

s

4.0V

Other Pins at GND

V

CC

e

GND, V

BB

e

4.0V 1.5 mA

V

CC

e

5.5V, V

BB

e

2.2V

b

5 mA

Note 1: Absolute Maximum Ratings are those values beyond which damage to the device may occur.

Note 2: Unless otherwise specified all voltages are referenced to ground.

Note 3: For F

OSC

e

4.194304 or 4.9152 MHz, VBBminimume2.8V. In battery backed mode, V

BB

s

V

CC

b

0.4V.

Single Supply Mode: Data retention voltage is 2.2V min.

In single Supply Mode (Power connected to V

CC

pin) 4.5VsV

CC

s

5.5V.

Note 4: This parameter (V

IH

) is not tested on all pins at the same time.

Note 5: This specification tests I

CC

with all power fail circuitry disabled, by setting D7 of Interrupt Control Register 1 to 0.

Note 6: This specification tests I

CC

with all power fail circuitry enabled, by setting D7 of Interrupt Control Register 1 to 1.

Note 7: This specification is tested with both the timers and OSC IN driven by a signal generator. Contents of the Test Register

e

00(H), the MFO pin is not

configured as buffered oscillator out and MFO, T1, INTR, are configured as open drain.

Note 8: This specification is tested with both the timers off, and only OSC IN is driven by a signal generator. Contents of the Test Register

e

00(H) and the MFO

pin is not configured as buffered oscillator out.

2

Page 3

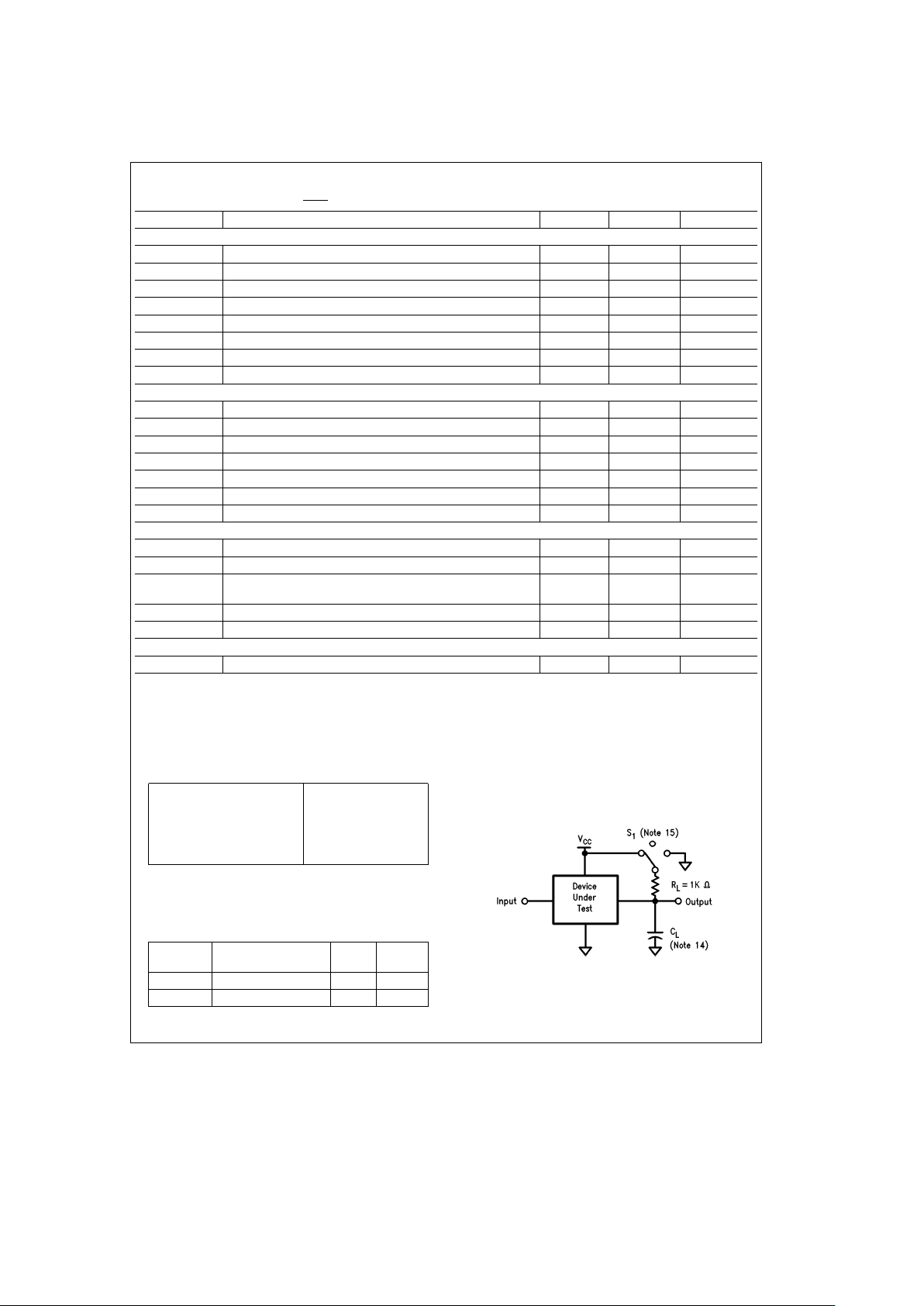

AC Electrical Characteristics

V

CC

e

5Vg10%, V

BB

e

3V, V

PFAIL

l

VIH,C

L

e

100 pF (unless otherwise specified)

Symbol Parameter Min Max Units

READ TIMING

t

AR

Address Valid Prior to Read Strobe 20 ns

t

RW

Read Strobe Width (Note 9) 80 ns

t

CD

Chip Select to Data Valid Time 80 ns

t

RAH

Address Hold after Read (Note 10) 3 ns

t

RD

Read Strobe to Valid Data 70 ns

t

DZ

Read or Chip Select to TRI-STATE 60 ns

t

RCH

Chip Select Hold after Read Strobe 0 ns

t

DS

Minimum Inactive Time between Read or Write Accesses 50 ns

WRITE TIMING

t

AW

Address Valid before Write Strobe 20 ns

t

WAH

Address Hold after Write Strobe (Note 10) 3 ns

t

CW

Chip Select to End of Write Strobe 90 ns

t

WW

Write Strobe Width (Note 11) 80 ns

t

DW

Data Valid to End of Write Strobe 50 ns

t

WDH

Data Hold after Write Strobe (Note 10) 3 ns

t

WCH

Chip Select Hold after Write Strobe 0 ns

TIMER 0/TIMER 1 TIMING

F

TCK

Input Frequency Range DC 10 MHz

t

CK

Propagation Delay Clock to Output Þ 120 ns

t

GO

Propagation Delay G0 to G1

100 ns

to Timer Output (Note 12) O

t

PGW

Pulse Width G0 or G1 É (Note 12) 25 ns

t

GS

Setup Time, G0, G1 to TCK (Note 13) 100 ns

INTERRUPT TIMING

t

ROLL

Clock Rollover to INTR Out is Typically 16.5 ms

Note 9: Read Strobe width as used in the read timing table is defined as the period when both chip select and read inputs are low. Hence read commences when

both signals are low and terminates when either signal returns high.

Note 10: Hold time is guaranteed by design but not production tested. This limit is not used to calculate outgoing quality levels.

Note 11: Write Strobe width as used in the write timing table is defined as the period when both chip select and write inputs are low. Hence write commences when

both signals are low and terminates when either signal returns high.

Note 12: Timers in Mode 3.

Note 13: Guaranteed by design, not production tested. This limit is not used to calculate outgoing quality levels.

AC Test Conditions

Input Pulse Levels GND to 3.0V

Input Rise and Fall Times 6 ns (10% – 90%)

Input and Output

1.3V

Reference Levels

TRI-STATE Reference Active High

a

0.5V

Levels (Note 15) Active Low

b

0.5V

Note 14: C

L

e

100 pF, includes jig and scope capacitance.

Note 15: S1

e

VCCfor active low to high impedance measurements.

S1

e

GND for active high to high impedance measurements.

S1

e

open for all other timing measurements.

Capacitance (T

A

e

25§C, fe1 MHz)

Symbol

Parameter

Typ Units

(Note 16)

C

IN

Input Capacitance 5 pF

C

OUT

Output Capacitance 7 pF

Note 16: This parameter is not 100% tested.

Note 17: Output rise and fall times 25 ns max (10% –90%) with 100 pF load.

TL/F/8638– 23

3

Page 4

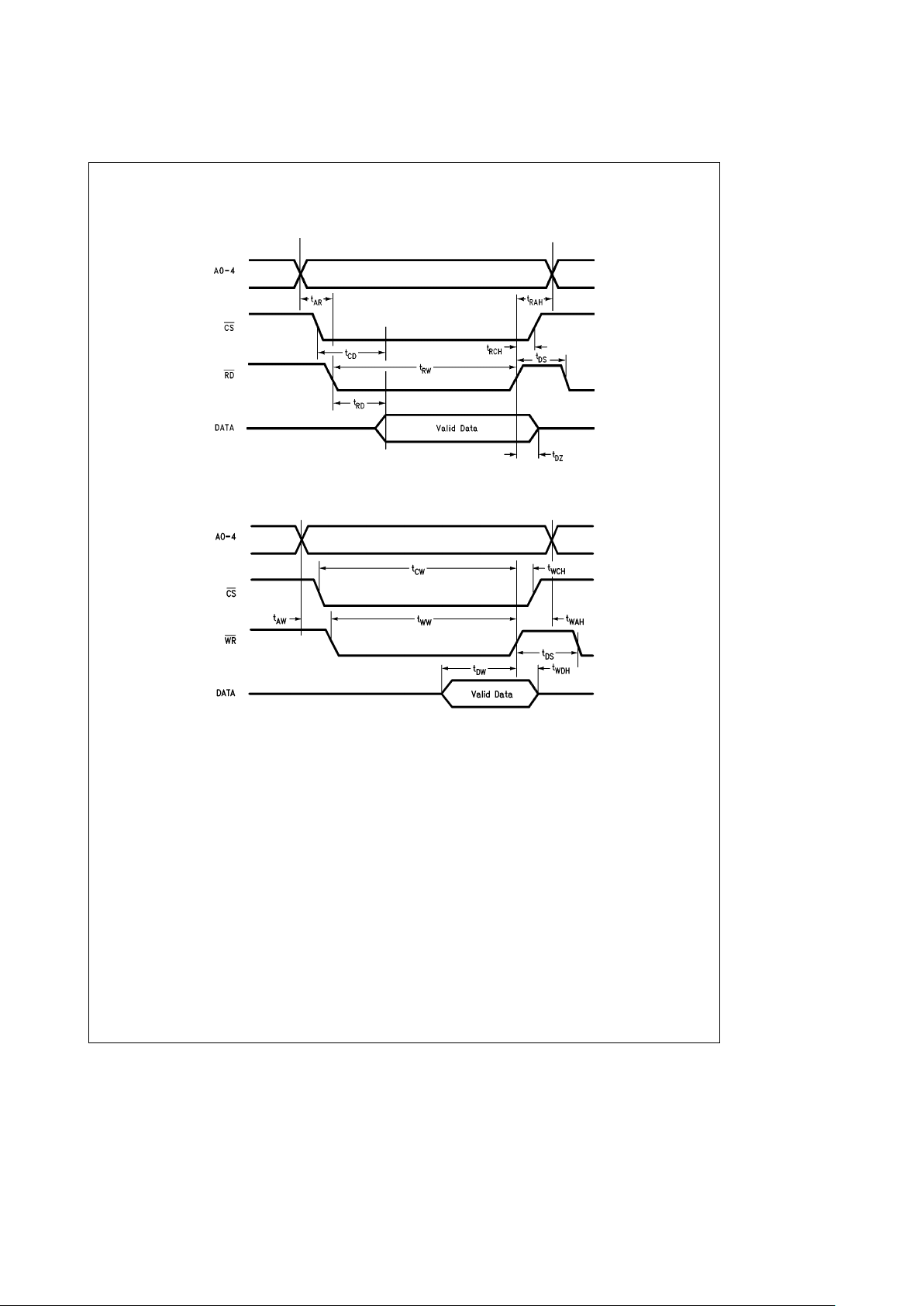

Timing Waveforms

Read Timing Diagram

TL/F/8638– 24

Write Timing Diagram

TL/F/8638– 25

4

Page 5

General Description (Continued)

The DP8570A’s interrupt structure provides four basic types

of interrupts: Periodic, Alarm/Compare, Timer, and Power

Fail. Interrupt mask and status registers enable the masking

and easy determination of each interrupt.

One dedicated general purpose interrupt output is provided.

A second interrupt output is available on the Multiple Function Output (MFO) pin. Each of these may be selected to

generate an interrupt from any source. Additionally, the

MFO pin may be programmed to be either as oscillator output or Timer 0’s output.

Pin Description

CS,RD,WR(Inputs): These pins interface to mP control

lines. The CS

pin is an active low enable for the read and

write operations. Read and Write pins are also active low

and enable reading or writing to the TCP. All three pins are

disabled when power failure is detected. However, if a read

or write is in progress at this time, it will be allowed to complete its cycle.

A0–A4 (Inputs): These 5 pins are for register selection.

They individually control which location is to be accessed.

These inputs are disabled when power failure is detected.

OSC IN (Input): OSC OUT (Output): These two pins are

used to connect the crystal to the internal parallel resonant

oscillator. The oscillator is always running when power is

applied to V

BB

and VCC, and the correct crystal select bits in

the Real Time Mode Register have been set.

MFO (Output): The multi-function output can be used as a

second interrupt output for interrupting the mP. This pin can

also provide an output for the oscillator or the internal Timer

0. The MFO output can be programmed active high or low,

open drain or push-pull. If in battery backed mode and a

pull-up resistor is attached, it should be connected to a voltage no greater than V

BB

. This pin is configured open drain

during battery operation (V

BB

l

VCC).

INTR (Output): The interrupt output is used to interrupt the

processor when a timing event or power fail has occurred

and the respective interrupt has been enabled. The INTR

output can be programmed active high or low, push-pull or

open drain. If in battery backed mode and a pull-up resistor

is attached, it should be connected to a voltage no greater

than V

BB

. This pin is configured open drain during battery

operation (V

BB

l

VCC). The output is a DC voltage level. To

clear the INTR, writea1totheappropriate bit(s) in the Main

Status Register.

D0–D7 (Input/Output): These 8 bidirectional pins connect

to the host mP’s data bus and are used to read from and

write to the TCP. When the PFAIL

pin goes low and a write

is not in progress, these pins are at TRI-STATE.

PFAIL

(Input): In battery backed mode, this pin can have a

digital signal applied to it via some external power detection

logic. When PFAIL

e

logic 0 the TCP goes into a lockout

mode, in a minimum of 30 ms or a maximum of 63 ms unless

lockout delay is programmed. In the single power supply

mode, this pin is not useable as an input and should be tied

to V

CC

. Refer to section on Power Fail Functional Descrip-

tion.

V

BB

(Battery Power Pin): This pin is connected to a back-

up power supply. This power supply is switched to the internal circuitry when the V

CC

becomes lower than VBB. Utilizing this pin eliminates the need for external logic to switch in

and out the back-up power supply. If this feature is not to be

used then this pin must be tied to ground, the TCP programmed for single power supply only, and power applied to

the V

CC

pin.

TCK, G1, G0, (Inputs), T1 (Output): TCK is the clock input

to both timers when they have an external clock selected. In

modes 0, 1, and 2, G0 and G1 are active low enable inputs

for timers 0 and 1 respectively. In mode 3, G0 and G1 are

positive edge triggers to the timers. T1 is dedicated to the

timer 1 output. The T1 output can be programmed active

high or low, push-pull or open drain. Timer 0 output is available through MFO pin if desired. If in battery backed mode

and a pull-up resistor is attached to T1, it should be connected to a voltage no greater than V

BB

. The T1 pin is con-

figured open drain during battery operation (V

BB

l

VCC).

VCC: This is the main system power pin.

GND: This is the common ground power pin for both V

BB

and VCC.

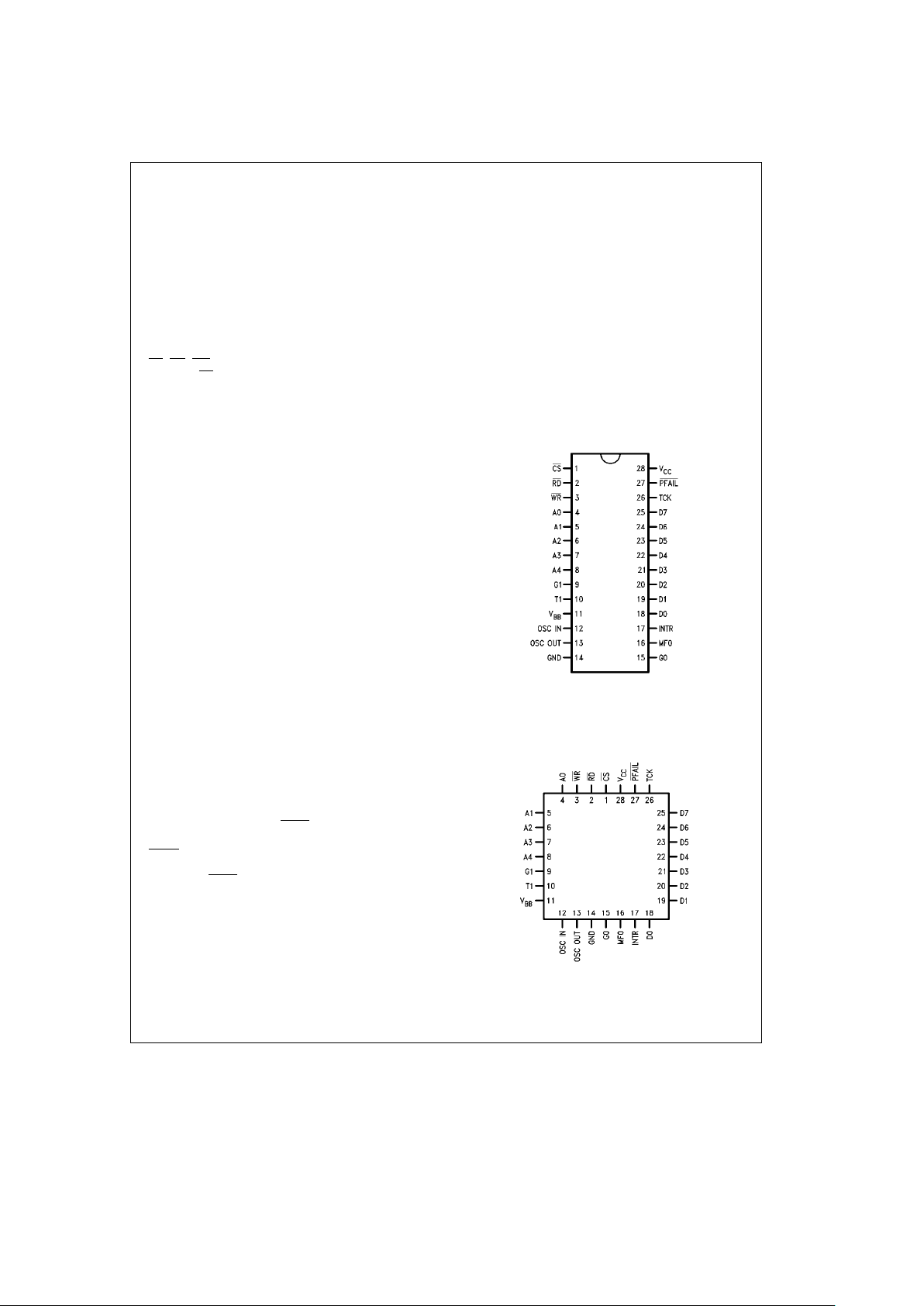

Connection Diagrams

Dual-In-Line

TL/F/8638– 5

Top View

Order Number DP8570AN

See NS Package Number N28B

Plastic Chip Carrier

TL/F/8638– 6

Top View

Order Number DP8570AV

See NS Package Number V28A

5

Page 6

Functional Description

The DP8570A contains a fast access real time clock, two 10

MHz 16-bit timers, interrupt control logic, power fail detect

logic, and CMOS RAM. All functions of the TCP are controlled by a set of nine registers. A simplified block diagram

that shows the major functional blocks is given in

Figure 1

.

The blocks are described in the following sections:

1. Real Time Clock

2. Oscillator Prescaler

3. Interrupt Logic

4. Power Failure Logic

5. Additional Supply Management

6. Timers

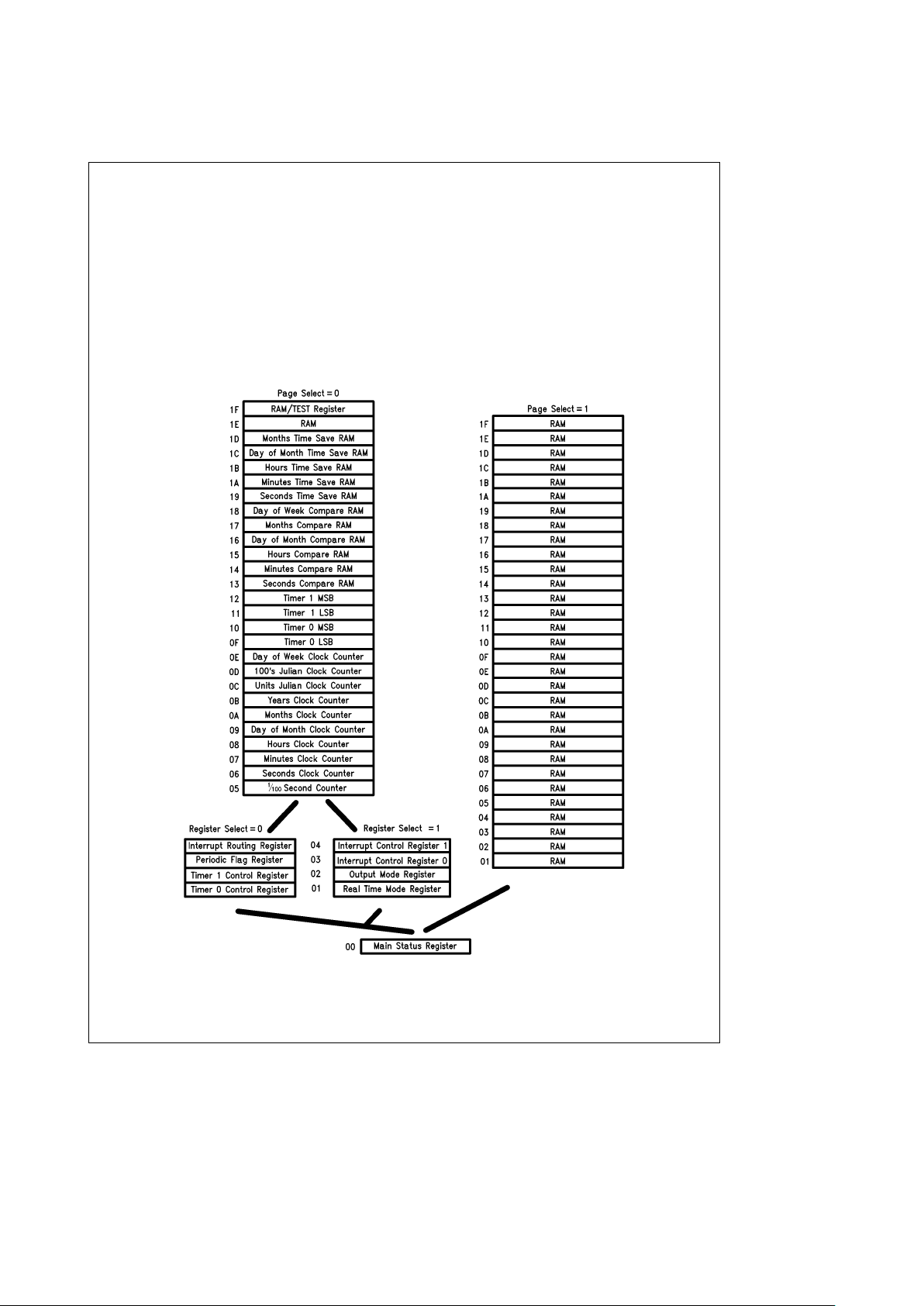

The memory map of the TCP is shown in the memory addressing table. The memory map consists of two 31 byte

pages with a main status register that is common to both

pages. A control bit in the Main Status Register is used to

select either page.

Figure 2

shows the basic concept.

Page 0 contains all the clock timer functions, while page 1

has scratch pad RAM. The control registers are split into

two separate blocks to allow page 1 to be used entirely as

scratch pad RAM. Again a control bit in the Main Status

Register is used to select either control register block.

TL/F/8638– 4

FIGURE 2. DP8570A Internal Memory Map

6

Page 7

Functional Description (Continued)

INITIAL POWER-ON of BOTH V

BB

and V

CC

VBBand VCCmay be applied in any sequence. In order for

the power fail circuitry to function correctly, whenever power

is off, the V

CC

pin must see a path to ground through a

maximum of 1 MX. The user should be aware that the control registers will contain random data. The first task to be

carried out in an initialization routine is to start the oscillator

by writing to the crystal select bits in the Real Time Mode

Register. If the DP8570A is configured for single supply

mode, an extra 50 mA may be consumed until the crystal

select bits are programmed. The user should also ensure

that the TCP is not in test mode (see register descriptions).

REAL TIME CLOCK FUNCTIONAL DESCRIPTION

As shown in

Figure 2

, the clock has 10 bytes of counters,

which count from 1/100 of a second to years. Each counter

counts in BCD and is synchronously clocked. The count sequence of the individual byte counters within the clock is

shown later in Table VII. Note that the day of week, day of

month, day of year, and month counters all roll over to 1.

The hours counter in 12 hour mode rolls over to 1 and the

AM/PM bit toggles when the hours rolls over to 12

(AM

e

0, PMe1). The AM/PM bit is bit D7 in the hours

counter.

All other counters roll over to 0. Also note that the day of

year counter is 12 bits long and occupies two addresses.

Upon initial application of power the counters will contain

random information.

READING THE CLOCK: VALIDATED READ

Since clocking of the counter occurs asynchronously to

reading of the counter, it is possible to read the counter

while it is being incremented (rollover). This may result in an

incorrect time reading. Thus to ensure a correct reading of

the entire contents of the clock (or that part of interest), it

must be read without a clock rollover occurring. In general

this can be done by checking a rollover bit. On this chip the

periodic interrupt status bits can serve this function. The

following program steps can be used to accomplish this.

1. Initialize program for reading clock.

2. Dummy read of periodic status bit to clear it.

3. Read counter bytes and store.

4. Read rollover bit, and test it.

5. If rollover occured go to 3.

6. If no rollover, done.

To detect the rollover, individual periodic status bits can be

polled. The periodic bit chosen should be equal to the highest frequency counter register to be read. That is if only

SECONDS through HOURS counters are read, then the

SECONDS periodic bit should be used.

READING THE CLOCK: INTERRUPT DRIVEN

Enabling the periodic interrupt mask bits cause interrupts

just as the clock rolls over. Enabling the desired update rate

and providing an interrupt service routine that executes in

less than 10 ms enables clock reading without checking for

a rollover.

READING THE CLOCK: LATCHED READ

Another method to read the clock that does not require

checking the rollover bit is to write a one into the Time

Save Enable bit (D7) of the Interrupt Routing Register, and

then to write a zero. Writing a one into this bit will enable the

clock contents to be duplicated in the Time Save RAM.

Changing the bit from a one to a zero will freeze and store

the contents of the clock in Time Save RAM. The time then

can be read without concern for clock rollover, since internal logic takes care of synchronization of the clock. Because only the bits used by the clock counters will be

latched, the Time Save RAM should be cleared prior to use

to ensure that random data stored in the unused bits do not

confuse the host microprocessor. This bit can also provide

time save at power failure, see the Additional Supply Management Functions section. With the Time Save Enable bit

at a logical 0, the Time Save RAM may be used as RAM if

the latched read function is not necessary.

INITIALIZING AND WRITING TO THE

CALENDAR-CLOCK

Upon initial application of power to the TCP or when making

time corrections, the time must be written into the clock. To

correctly write the time to the counters, the clock would

normally be stopped by writing the Start/Stop

bit in the Real

Time Mode Register to a zero. This stops the clock from

counting and disables the carry circuitry. When initializing

the clock’s Real Time Mode Register, it is recommended

that first the various mode bits be written while maintaining

the Start/Stop

bit reset, and then writing to the register a

second time with the Start/Stop

bit set.

The above method is useful when the entire clock is being

corrected. If one location is being updated the clock need

not be stopped since this will reset the prescaler, and time

will be lost. An ideal example of this is correcting the hours

for daylight savings time. To write to the clock ‘‘on the fly’’

the best method is to wait for the 1/100 of a second periodic interrupt. Then wait an additional 16 ms, and then write

the data to the clock.

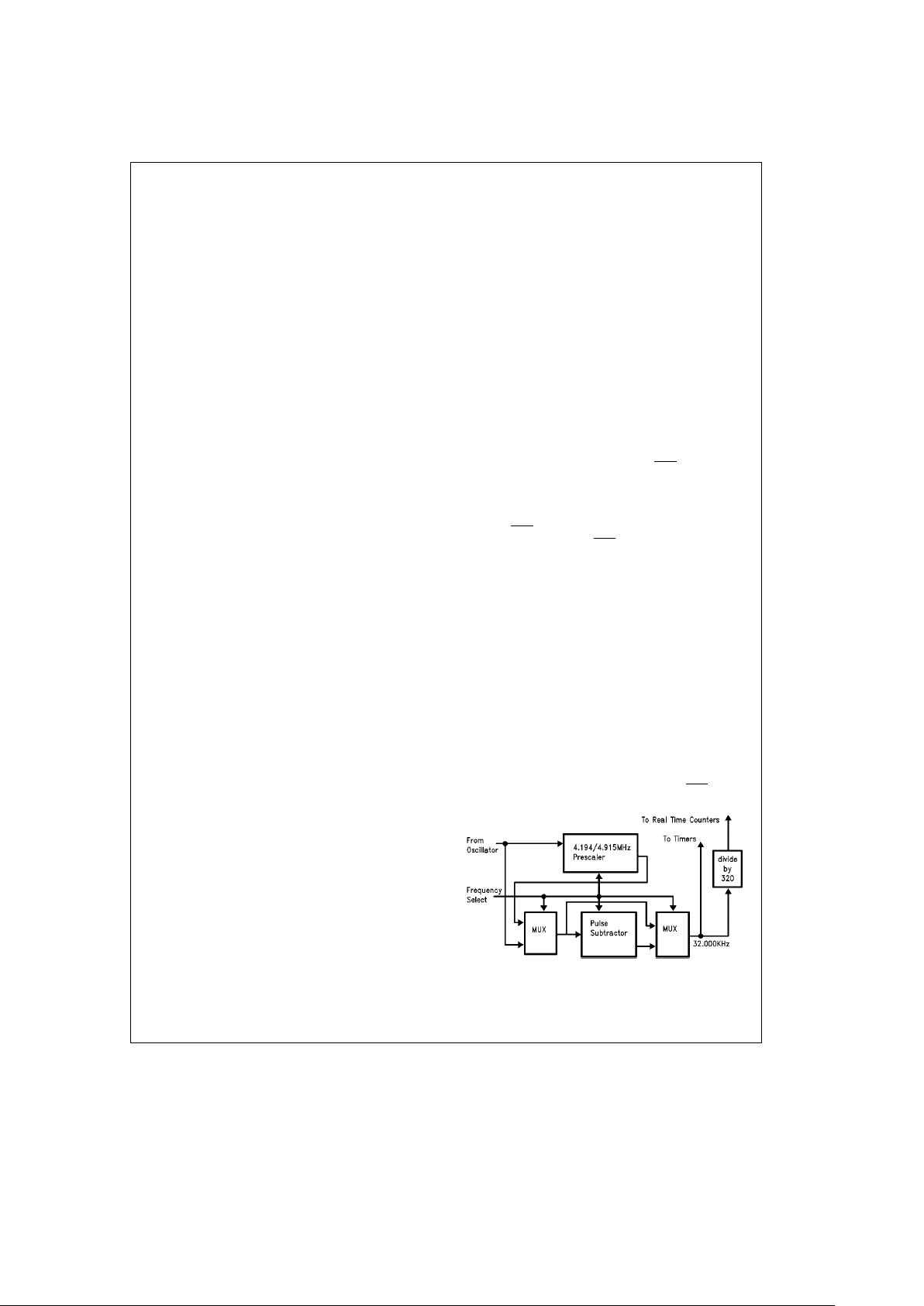

PRESCALER/OSCILLATOR FUNCTIONAL

DESCRIPTION

Feeding the counter chain is a programmable prescaler

which divides the crystal oscillator frequency to 32 kHz and

further to 100 Hz for the counter chain (see

Figure 3

). The

crystal frequency that can be selected are: 32 kHz, 32.768

kHz, 4.9152 MHz, and 4.194304 MHz.

Once 32 kHz is generated it feeds both timers and the

clock. The clock and timer prescalers can be independently

enabled by controlling the timer or clock Start/Stop

bits.

TL/F/8638– 2

FIGURE 3. Programmable Clock Prescaler Block

7

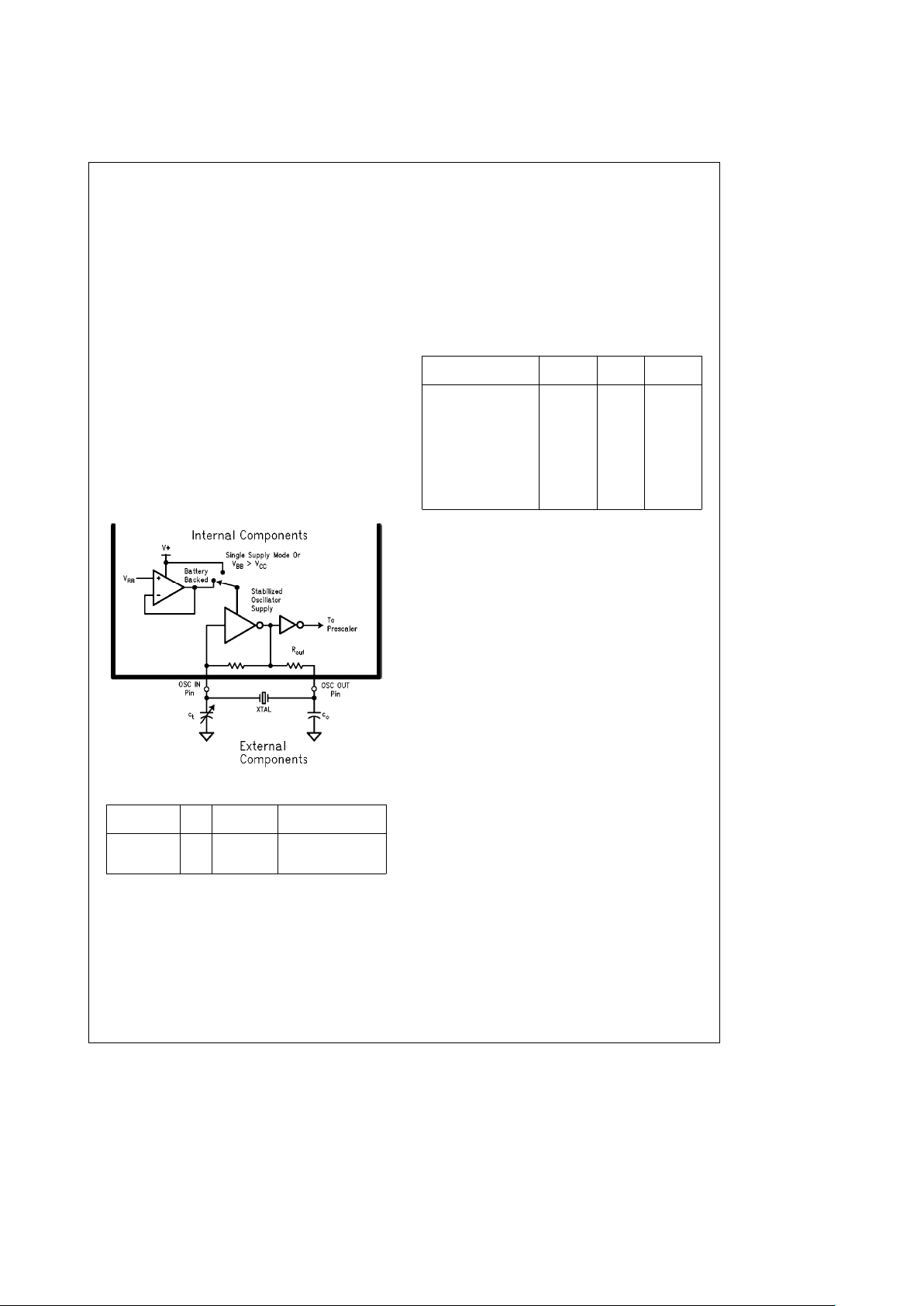

Page 8

Functional Description (Continued)

The oscillator is programmed via the Real Time Mode Register to operate at various frequencies. The crystal oscillator

is designed to offer optimum performance at each frequency. Thus, at 32.768 kHz the oscillator is configured as a low

frequency and low power oscillator. At the higher frequencies the oscillator inverter is reconfigured. In addition to the

inverter, the oscillator feedback bias resistor is included on

chip, as shown in

Figure 4

. The oscillator input may be driven from an external source if desired. Refer to test mode

application note for details. The oscillator stability is enhanced through the use of an on chip regulated power supply.

The typical range of trimmer capacitor (as shown in Oscillator Circuit Diagram

Figure 4

, and in the typical application) at

the oscillator input pin is suggested only to allow accurate

tuning of the oscillator. This range is based on a typical

printed circuit board layout and may have to be changed

depending on the parasitic capacitance of the printed circuit

board or fixture being used. In all cases, the load capaci-

tance specified by the crystal manufacturer (nominal value

11 pF for the 32.768 crystal) is what determines proper oscillation. This load capcitance is the series combination of

capacitance on each side of the crystal (with respect to

ground).

TL/F/8638– 3

FIGURE 4. Oscillator Circuit Diagram

XTAL C

o

C

t

R

OUT

(Switched Internally)

32/32.768 kHz 47 pF 2 pF – 22 pF 150 kX to 350 kX

4.194304 MHz 68 pF 0 pF – 80 pF 500X to 900X

4.9152 MHz 68 pF 29 pF–49 pF 500X to 900X

INTERRUPT LOGIC FUNCTIONAL DESCRIPTION

The TCP has the ability to coordinate processor timing activities. To enhance this, an interrupt structure has been implemented which enables several types of events to cause

interrupts. Interrupts are controlled via two Control Registers in block 1 and two Status Registers in block 0. (See

Register Description for notes on paging and also

Figure 5

and Table I.)

The interrupts are enabled by writing a one to the appropriate bits in Interrupt Control Register 0 and/or 1. Any of the

interrupts can be routed to either the INTR pin or the MFO

pin, depending on how the Interrupt Routing register is programmed. This, for example, enables the user to dedicate

the MFO as a non-maskable interrupt pin to the CPU for

power failure detection and enable all other interrupts to

appear on the INTR pin. The polarity for the active interrupt

can be programmed in the Output Mode Register for either

active high or low, and open drain or push pull outputs.

TABLE I. Registers that are Applicable

to Interrupt Control

Register Name

Register Page

Address

Select Select

Main Status Register X X 00H

Periodic Flag Register 0 0 03H

Interrupt Routing

0 0 04H

Register

Interrupt Control

1 0 03H

Register 0

Interrupt Control

1 0 04H

Register 1

Output Mode

1 0 02H

Register

The Interrupt Status Flag D0, in the Main Status Register,

indicates the state of INTR and MFO outputs. It is set when

either output becomes active and is cleared when all TCP

interrupts have been cleared and no further interrupts are

pending (i.e., both INTR and MFO are returned to their inactive state). This flag enables the TCP to be rapidly polled by

the mP to determine the source of an interrupt in a wiredÐ

OR interrupt system.

Note that the Interrupt Status Flag will only monitor the state

of the MFO output if it has been configured as an interrupt

output (see Output Mode Register description). This is true,

regardless of the state of the Interrupt Routing Register.

Thus the Interrupt Status Flag provides a true reflection of

all conditions routed to the external pins.

Status for the interrupts are provided by the Main Status

Register and the Periodic Flag Register. Bits D1 – D5 of the

Main Status Register are the main interrupt bits.

These register bits will be set when their associated timing

events occur. Enabled Alarm or Timer interrupts that occur

will set its Main Status Register bit to a one. However, an

external interrupt will only be generated if the appropriate

Alarm or Timer interrupt enable bits are set (see

Figure 5

).

Disabling the periodic bits will mask the Main Status Register periodic bit, but not the Periodic Flag Register bits. The

Power Fail Interrupt bit is set when the interrupt is enabled

and a power fail event has occurred, and is not reset until

the power is restored. If all interrupt enable bits are 0 no

interrupt will be asserted. However, status still can be read

from the Main Status Register in a polled fashion (see

Fig-

ure 5

).

To clear a flag in bits D2 –D5 of the Main Status Register a 1

must be written back into the bit location that is to be

cleared. For the Periodic Flag Register reading the status

will reset all the periodic flags.

8

Page 9

Functional Description (Continued)

Interrupts Fall Into Four Categories:

1. The Timer Interrupts: For description see Timer Section.

2. The Alarm Compare Interrupt: Issued when the value in

the time compared RAM equals the counter.

3. The Periodic Interrupts: These are issued at every increment of the specific clock counter signal. Thus, an interrupt is issued every minute, second, etc. Each of these

interrupts occurs at the roll-over of the specific counter.

4. The Power Fail Interrupt: Issued upon recognition of a

power fail condition by the internal sensing logic. The

power failed condition is determined by the signal on the

PFAIL

pin. The internal power fail signal is gated with the

chip select signal to ensure that the power fail interrupt

does not lock the chip out during a read or write.

ALARM COMPARE INTERRUPT DESCRIPTON

The alarm/time comparison interrupt is a special interrupt

similar to an alarm clock wake up buzzer. This interrupt is

generated when the clock time is equal to a value programmed into the alarm compare registers. Up to six bytes

can be enabled to perform alarm time comparisons on the

counter chain. These six bytes, or some subset thereof,

would be loaded with the future time at which the interrupt

will occur. Next, the appropriate bits in the Interrupt Control

Register 1 are enabled or disabled (refer to detailed description of Interrupt Control Register 1). The TCP then compares these bytes with the clock time. When all the enabled

compare registers equal the clock time an alarm interrupt is

issued, but only if the alarm compare interrupt is enabled

can the interrupt be generated externally. Each alarm compare bit in the Control Register will enable a specific byte for

comparison to the clock. Disabling a compare byte is the

same as setting its associated counter comparator to an

‘‘always equal’’ state. For example, to generate an interrupt

at 3:15 AM of every day, load the hours compare with 0 3

(BCD), the minutes compare with 1 5 (BCD) and the faster

counters with 0 0 (BCD), and then disable all other compare

registers. So every day when the time rolls over from

3:14:59.99, an interrupt is issued. This bit may be reset by

writing a one to bit D3 in the Main Status Register at any

time after the alarm has been generated.

If time comparison for an individual byte counter is disabled,

that corresponding RAM location can then be used as general purpose storage.

PERIODIC INTERRUPTS DESCRIPTION

The Periodic Flag Register contains six flags which are set

by real-time generated ‘‘ticks’’ at various time intervals, see

Figure 5

. These flags constantly sense the periodic signals

and may be used whether or not interrupts are enabled.

These flags are cleared by any read or write operation performed on this register.

To generate periodic interrupts at the desired rate, the associated Periodic Interrupt Enable bit in Interrupt Control Register 0 must be set. Any combination of periodic interrupts

may be enabled to operate simultaneously. Enabled periodic interrupts will now affect the Periodic Interrupt Flag in the

Main Status Register. The Periodic Route bit in the Interrupt

Routing Register is used to route the periodic interrupt

events to either the INTR output or the MFO output.

When a periodic event occurs, the Periodic Interrupt Flag in

the Main Status Register is set, causing an interrupt to be

generated. The mP clears both flag and interrupt by writing a

‘‘1’’ to the Periodic Interrupt Flag. The individual flags in the

periodic Interrupt Flag Register do not require clearing to

cancel the interrupt.

If all periodic interrupts are disabled and a periodic interrupt

is left pending (i.e., the Periodic Interrupt Flag is still set), the

Periodic Interrupt Flag will still be required to be cleared to

cancel the pending interrupt.

POWER FAIL INTERRUPTS DESCRIPTION

The Power Fail Status Flag in the Main Status Register

monitors the state of the internal power fail signal. This flag

may be interrogated by the mP, but it cannot be cleared; it is

cleared automatically by the TCP when system power is

restored. To generate an interrupt when the power fails, the

Power Fail Interrupt Enable bit in Interrupt Control Register

1 is set.

The Power Fail Route bit determines which output the interrupt will appear on. Although this interrupt may not be

cleared, it may be masked by clearing the Power Fail Interrupt Enable bit.

POWER FAILURE CIRCUITRY FUNCTIONAL

DESCRIPTION

Since the clock must be operated from a battery when the

main system supply has been turned off, the DP8570A provides circuitry to simplify design in battery backed systems.

This circuitry switches over to the back up supply, and isolates the DP8570A from the host system.

Figure 6

shows a

simplified block diagram of this circuitry, which consists of

three major sections; 1) power loss logic: 2) battery switch

over logic: and 3) isolation logic.

Detection of power loss occurs when PFAIL

is low. Debounce logic provides a 30 ms–63 ms debounce time, which

will prevent noise on the PFAIL

pin from being interpreted

as a system failure. After 30 ms–63 ms the debounce logic

times out and a signal is generated indicating that system

power is marginal and is failing. The Power Fail Interrupt will

then be generated.

9

Page 10

Functional Description (Continued)

TL/F/8638– 7

FIGURE 5. Interrupt Control Logic Overview

10

Page 11

Functional Description (Continued)

TL/F/8638– 8

FIGURE 6. System-Battery Switchover (Upper Left), Power Fail

and Lock-Out Circuits (Lower Right)

The user may choose to have this power failed signal lockout the TCP’s data bus within 30 ms min/63 ms max or to

delay the lock-out to enable mP access after power failure is

detected. This delay is enabled by setting the delay enable

bit in the Routing Register. Also, if the lock-out delay was

not enabled the TCP will disconnect itself from the bus within 30 ms min

x

63 ms max. If chip select is low when a

power failure is detected, a safety circuit will ensure that if a

read or write is held active continuously for greater than

30 ms after the power fail signal is asserted, the lock-out will

be forced. If a lock-out delay is enabled, the DP8570A will

remain active for 480 ms after power fail is detected. This

will enable the mP to perform last minute bookkeeping before total system collapse. When the host CPU is finished

accessing the TCP it may force the bus lock-out before

480 ms has elapsed by resetting the delay enable bit.

The battery switch over circuitry is completely independent

of the PFAIL

pin. A separate circuit compares VCCto the

V

BB

voltage. As the main supply fails, the TCP will continue

to operate from the V

CC

pin until VCCfalls below the V

BB

voltage. At this time, the battery supply is switched in, VCCis

disconnected, and the device is now in the standby mode. If

indeterminate operation of the battery switch over circuit is

to be avoided, then the voltage at the V

CC

pin must not be

allowed to equal the voltage at the V

BB

pin.

After the generation of a lock-out signal, and eventual

switch in of the battery supply, the pins of the TCP will be

configured as shown in Table II. Outputs that have a pull-up

resistor should be connected to a voltage no greater than

V

BB

.

TABLE II. Pin Isolation during a Power Failure

Pin

PFAIL

e

Standby Mode

Logic 0 V

BB

l

V

CC

CS,RD,WR Locked Out Locked Out

A0–A4 Locked Out Locked Out

D0–D7 Locked Out Locked Out

Oscillator Not Isolated Not Isolated

TCK, G0, G1 Not Isolated Locked Out

PFAIL

Not Isolated Not Isolated

INTR, MFO

Not Isolated Open Drain

T1

The Timer and Interrupt Power Fail Operation bits in the

Real-Time Mode Register determine whether or not the timers and interrupts will continue to function after a power fail

event.

As power returns to the system, the battery switch over circuit will switch back to V

CC

power as soon as it becomes

greater than the battery voltage. The chip will remain in the

locked out state as long as PFAIL

e

0. When PFAILe1

11

Page 12

Functional Description (Continued)

the chip is unlocked, but only after another 30 ms min

x

63 ms max debounce time. The system designer must ensure that his system is stable when power has returned.

The power fail circuitry contains active linear circuitry that

draws supply current from V

CC

. In some cases this may be

undesirable, so this circuit can be disabled by masking the

power fail interrupt. The power fail input can perform all

lock-out functions previously mentioned, except that no external interrupt will be issued. Note that the linear power fail

circuitry is switched off automatically when using V

BB

in

standby mode.

LOW BATTERY, INITIAL POWER ON DETECT, AND

POWER FAIL TIME SAVE

There are three other functions provided on the DP8570A to

ease power supply control. These are an initial Power On

detect circuit, which also can be used as a time keeping

failure detect, a low battery detect circuit, and a time save

on power failure.

On initial power up the Oscillator Fail Flag will be set to a

one and the real time clock start bit reset to a zero. This

indicates that an oscillator fail event has occurred, and time

keeping has failed.

The Oscillator Fail flag will not be reset until the real-time

clock is started. This allows the system to discriminate between an initial power-up and recovery from a power failure.

If the battery backed mode is selected, then bit D6 of the

Periodic Flag Register must be written low. This will not affect the contents of the Oscillator Fail Flag.

Another status bit is the low battery detect. This bit is set

only when the clock is operating under the V

CC

pin, and

when the battery voltage is determined to be less than 2.1V

(typical). When the power fail interrupt enable bit is low, it

disables the power fail circuit and will also shut off the low

battery voltage detection circuit as well.

To relieve CPU overhead for saving time upon power failure,

the Time Save Enable bit is provided to do this automatically. (See also Reading the Clock: Latched Read.) The Time

Save Enable bit, when set, causes the Time Save RAM to

follow the contents of the clock. This bit can be reset by

software, but if set before a power failure occurs, it will automatically be reset when the clock switches to the battery

supply (not when a power failure is detected by the PFAIL

pin). Thus, writing a one to the Time Save bit enables both a

software write or power fail write.

SINGLE POWER SUPPLY APPLICATIONS

The DP8570A can be used in a single power supply application. To achieve this, the V

BB

pin must be connected to

ground, and the power connected to V

CC

and PFAIL pins.

The Oscillator Failed/Single Supply bit in the Periodic Flag

Register should be set to a logic 1, which will disable the

oscillator battery reference circuit. The power fail interrupt

should also be disabled. This will turn off the linear power

fail detection circuits, and will eliminate any quiescent power

drawn through these circuits. Until the crystal select bits are

initialized, the DP8570A may consume about 50 mA due to

arbitrary oscillator selection at power on.

(This extra 50 mA is not consumed if the battery backed

mode is selected).

TIMER FUNCTIONAL DESCRIPTION

The DP8570A contains 2 independent multi-mode timers.

Each timer is composed of a 16-bit negative edge triggered

binary down counter and associated control. The operation

is similar to existing mP peripheral timers except that several

features have been enhanced. The timers can operate in

four modes, and in addition, the input clock frequency can

be selected from a prescaler over a wide range of frequencies. Furthermore, these timers are capable of generating

interrupts as well as hardware output signals, and both the

interrupt and timer outputs are fully programmable active

high, or low, open drain, or push-pull.

Figure 7

shows the functional block diagram of one of the

timers. The timer consists of a 16-bit counter, two 8-bit input

registers, two 8-bit output registers, clock prescaler, mode

control logic, and output control logic. The timer and the

data registers are organized as two bytes for each timer.

Under normal operations a read/write to the timer locations

will read or write to the data input register. The timer contents can be read by setting the counter Read bit (RD) in the

timer control register.

TIMER INITIALIZATION

The timer’s operation is controlled by a set of registers, as

listed in Table III. These consist of 2 data input registers and

one control register per timer. The data input registers contain the timers count down value. The Timer Control Register is used to set up the mode of operation and the input

clock rate. The timer related interrupts can be controlled by

programming the Interrupt Routing Register and Interrupt

Control Register 0. The timer outputs are configured by the

Output Mode Register.

TABLE III. Timer Associated Registers

Register Name

Register Page

Address

Select Select

Timer 0 Data MSB X 0 10H

Timer 0 Data LSB X 0 0FH

Timer 0 Control Register 0 0 01H

Timer 1 Data MSB X 0 12H

Timer 1 Data LSB X 0 11H

Timer 1 Control Register 0 0 02H

Interrupt Routing Register 0 0 04H

Interrupt Control Reg. 0 1 0 03H

Output Mode Register 1 0 02H

All these registers must be initialized prior to starting the

timer(s). The Timer Control Register should first be set to

select the timer mode with the timer start/stop

bit reset.

Then when the timer is to be started the control register

should be rewritten identically but with the start/stop

bit set.

TIMER OPERATION

Each timer is capable of operation in one of four modes. As

mentioned, these modes are programmed in each timer’s

Control Register which is described later. All four modes

operate in a similar manner. They operate on the two 8-bit

data words stored into the Data Input Register. At the beginning of a counting cycle the 2 bytes are loaded into the timer

and the timer commences counting down towards zero. The

exact action taken when zero is reached depends on the

mode selected, but in general, the timer output will change

state, and an interrupt will be generated if the timer interrupts are unmasked.

12

Page 13

Functional Description (Continued)

INPUT CLOCK SELECTION

The input frequency to the timers may be selected. Each

timer has a prescaler that gives a wide selection of clocking

rates. In addition, the DP8570A has a single external clock

input pin that can be selected for either of the timers. Table

IV shows the range of programmable clocks available and

the corresponding setting in the Timer Control Register.

TABLE IV. Programmable Timer Input Clocks

C2 C1 C0 Selected Clock

0 0 0 External

0 0 1 Crystal Oscillator

0 1 0 (Crystal Oscillator)/4

0 1 1 93.5 ms (10.7 kHz)

1 0 0 1 ms (1 kHz)

1 0 1 10 ms (100 Hz)

1 1 0 1/10 Second (10 Hz)

1 1 1 1 Second (1 Hz)

Note that the second and third selections are not fixed frequencies, but depend on the crystal oscillator frequency

chosen.

Since the input clock frequencies are usually running asynchronously to the timer Start/Stop

control bit, a 1 clock cycle error may result. This error results when the Start/Stop

occurs just after the clock edge (max error). To minimize

this error on all clocks an independent prescaler is used for

each timer and is designed so that its Start/Stop error is

less than 1 clock cycle.

The count hold/gate bit in the Timer Control Register and

the external enable pins, G0/G1, can be used to suspend

the timer operation in modes 0, 1, and 2 (in mode 3 it is the

trigger input). The external pin and the register bit are OR’ed

together, so that when either is high the timers are suspended. Suspending the timer causes the same synchronization

error that starting the timer does. The range of errors is

specified in Table V.

TABLE V. Maximum Synchronization Errors

Clock Selected Error

External

a

Ext. Clock Period

Crystal

a

1 Crystal Clock Period

Crystal/4

a

1 Crystal Clock Period

10.7 kHz

a

32 ms

1 kHz

a

32 ms

100 Hz

a

32 ms

10 Hz

a

32 ms

1Hz

a

32 ms

MODES OF OPERATION

Bits M0 and M1 in the Timer Control Registers are used to

specify the modes of operation. The mode selection is described in Table VI.

TABLE VI. Programmable Timer Modes of Operation

M1 M0 Function Modes

0 0 Single Pulse Generator Mode 0

0 1 Rate Generator, Pulse Output Mode 1

1 0 Square Wave Output Mode 2

1 1 Retriggerable One Shot Mode 3

MODE 0: SINGLE PULSE GENERATOR

When the timer is in this mode the output will be initially low

if the Timer Start/Stop

bit is low (stopped). When this mode

is initiated the timer output will go high on the next falling

edge of the prescaler’s input clock, the contents

TL/F/8638– 9

FIGURE 7. DP8570A Timer Block Diagram

13

Page 14

Functional Description (Continued)

of the input data registers are loaded into the timer. The

output will stay high until the counter reaches zero. At zero

the output is reset. The result is an output pulse whose duration is equal to the input clock period times the count

value (N) loaded into the input data register. This is shown

in

Figure 8

.

Pulse Width

e

Clock PeriodcN

An interrupt is generated when the zero count is reached.

This can be used for one-time interrupts that are set to occur a certain amount of time in the future. In this mode the

Timer Start/Stop

bit (TSS) is automatically reset upon zero

detection. This removes the need to reset TSS before starting another operation.

The count down operation may be temporarily suspended

either under software control by setting the Count Hold/

Gate bit in the timer register high, or in hardware by setting

the G0 or G1 pin high.

The above discussion assumes that the timer outputs were

programmed to be non-inverting outputs (active high). If the

polarity of the output waveform is wrong for the application

the polarity can be reversed by configuring the Output Mode

Register. The drive configuration can also be programmed

to be push pull or open drain.

MODE 1: RATE GENERATOR

When operating in this mode the timer will operate continuously. Before the timer is started its output is low. When the

timer is started the input data register contents are loaded

into the counter on the negative clock edge and the output

is set high (again assuming the Output Mode Register is

programmed active high). The timer will then count down to

zero. Once the zero count is reached the output goes low

for one clock period of the timer clock. Then on the next

clock the counter is reloaded automatically and the countdown repeats itself. The output, shown in

Figure 9

,isa

waveform whose pulse width and period is determined by N,

the input register value, and the input clock period:

Period

e(Na

1) (Clock Period)

Pulse WidtheClock Period

The G0 or G1 pin and the count hold/gate bit can be used

to suspend the appropriate timer countdown when either is

high. Again, the output polarity is controllable as in mode 0.

If enabled, an interrupt is generated whenever the zero

count is reached. This can be used to generate a periodic

interrupt.

MODE 2: SQUARE WAVE GENERATOR

This mode is also cyclic but in this case a square wave

rather than a pulse is generated. The output square wave

period is determined by the value loaded into the timer input

register. This period and the duty cycle are:

Period

e

2(Na1) (Clock Period) Duty Cyclee0.5

When the timer is stopped the output will be low, and when

the Start/Stop

bit is set high the timer’s counter will be loaded on the next clock falling transition and the output will be

set high.

The output will be toggled after the zero count is detected

and the counter will then be reloaded, and the cycle will

continue. Thus, every N

a

1 counts the output gets toggled,

as shown in

Figure 10

. Like the other modes the timer operation can be suspended either by software setting the count

hold/gate bit (CHG) in the Timer Control Register or by using the gate pins. An interrupt will be generated every falling

edge of the timer output, if enabled.

TL/F/8638– 10

FIGURE 8. Typical Waveforms for Timer Mode 0

(Timer Output Programmed Active High)

TL/F/8638– 11

FIGURE 9. Timing Waveforms for Timer Mode 1

(Timer Output Programmed Active High)

14

Page 15

Functional Description (Continued)

TL/F/8638– 12

FIGURE 10. Timing Waveforms for Timer Mode 2

(Timer Output Programmed Active High)

MODE 3: RETRIGGERABLE ONE SHOT

This mode is different from the previous three modes in that

this is the only mode which uses the external gate to trigger

the output. Once the timer Start/Stop

bit is set the output

stays inactive, and nothing happens until a positive transition is received on the G1 or G0 pins, or the Count Hold/

Gate (CHG) bit is set in the timer control register. When a

transition ocurs the one shot output is set active immediately; the counter is loaded with the value in the input register

on the next transition of the input clock and the countdown

begins. If a retrigger occurs, regardless of the current counter value, the counters will be reloaded with the value in the

input register and the counter will be restarted without

changing the output state. See

Figure 11

. A trigger count

can occur at any time during the count cycle and can be a

hardware or software signal (G0, G1 or CHG). In this mode

the timer will output a single pulse whose width is determined by the value in the input data register (N) and the

input clock period.

Pulse Width

e

Clock PeriodcN

Before entering mode 3, if a spurious edge has occurred on

G0/G1 or the CHG bit is set to logic 1, then a pulse will

appear at MFO or T1 or INTR output pin when the timer is

started. To ensure this does not happen, do the following

steps before entering mode 3: Configure the timer for mode

0, load a count of zero, then start the timer.

The timer will generate an interrupt only when it reaches a

count of zero. This timer mode is useful for continuous

‘‘watch dog’’ timing, line frequency power failure detection,

etc.

READING THE TIMERS

National has discovered that some users may encounter

unacceptable error rates for their applications when reading

the timers on the fly asynchronously. When doing asynchronous reads of the timers, an error may occur. The error is

that a successive read may be larger than the previous

read. Experimental results indicate that the typical error rate

Is approximately one per 29,000 under the following conditions:

Timer clock frequency of 5 MHz.

Computer: 386/33 MHz PC/AT

Program: Microsoft ‘‘C’’ 6.0, reading and saving timer con-

tents in a continuous loop.

Those users who find the error rate unacceptable may reduce the problem effectively to zero by employing a hardware work-around that synchronizes the writing of the read

bit to the timer control register with respect to the decrementing clock. Refer to

Figure 1

in Appendix A, for a sug-

gested hardware work-around.

A software work-around can reduce the errors but not as

substantial as a hardware work-around. Software workarounds are based on observations that the read following a

bad read appeared to be valid.

This problem concerns statistical probability and is similar to

metastability issues. For more information on metastability,

refer to 1991 IEEE transactions on Custom Integrated Circuits Conference. paper by T.J. Gabara of AT&T Bell Laboratories, page 29.4.1.

Normally reading the timer data register addresses, 0FH

and 10H for Timer 0 and 11H and 12H for Timer 1 will result

in reading the input data register which contains the preset

value for the timers.

To read the contents of a timer, the mP first sets the timer

read bit in the appropriate Timer Control Register high. This

will cause the counters contents to be latched to 2-bit – 8-bit

output registers, and will enable these registers to be read if

the mP reads the timers input data register addresses. On

reading the LSB byte the timer read bit is internally reset

and subsequent reads of the timer locations will return the

input register values.

DETAILED REGISTER DESCRIPTION

There are 5 external address bits: Thus, the host microprocessor has access to 32 locations at one time. An internal

switching scheme provides a total of 67 locations.

This complete address space is organized into two pages.

Page 0 contains two blocks of control registers, timers, real

time clock counters, and special purpose RAM, while page

1 contains general purpose RAM. Using two blocks enables

the 9 control registers to be mapped into 5 locations. The

only register that does not get switched is the Main Status

Register. It contains the page select bit and the register

select bit as well as status information.

A memory map is shown in

Figure 2

and register addressing

in Table VII. They show the name, address and page locations for the DP8570A.

TL/F/8638– 13

FIGURE 11. Timing Waveforms for Timer Mode 3, Output Programmed Active High

15

Page 16

Functional Description (Continued)

TABLE VII. Register/Counter/RAM

Addressing for DP8570A

A0-4

PS RS

Description

(Note 1) (Note 2)

CONTROL REGISTERS

00 X X Main Status Register

01 0 0 Timer 0 Control Register

02 0 0 Timer 1 Control Register

03 0 0 Periodic Flag Register

04 0 0 Interrupt Routing Register

01 0 1 Real Time Mode Register

02 0 1 Output Mode Register

03 0 1 Interrupt Control Register 0

04 0 1 Interrupt Control Register 1

COUNTERS (CLOCK CALENDAR)

05 0 X 1/100, 1/10 Seconds (0 – 99)

06 0 X Seconds (0– 59)

07 0 X Minutes (0–59)

08 0 X Hours (1–12, 0 –23)

09 0 X Days of

Month (1–28/29/30/31)

0A 0 X Months (1– 12)

0B 0 X Years (0 –99)

0C 0 X Julian Date (LSB) (0 – 99) (Note 3)

0D 0 X Julian Date (0 –3)

0E 0 X Day of Week (1 –7)

TIMER DATA REGISTERS

0F 0 X Timer 0 LSB

10 0 X Timer 0 MSB

11 0 X Timer 1 LSB

12 0 X Timer 1 MSB

TIME COMPARE RAM

13 0 X Sec Compare RAM (0 – 59)

14 0 X Min Compare RAM (0 – 59)

15 0 X Hours Compare

RAM (1 – 12, 0 – 23)

16 0 X DOM Compare

RAM (1– 28/29/30/31)

17 0 X Months Compare

RAM (1 – 12)

18 0 X DOW Compare RAM (1 –7)

TIME SAVE RAM

19 0 X Seconds Time Save RAM

1A 0 X Minutes Time Save RAM

1B 0 X Hours Time Save RAM

1C 0 X Day of Month Time Save RAM

1D 0 X Months Time Save RAM

1E 0 1 RAM

1F 0 X RAM/Test Mode Register

01– 1F 1 X 2nd Page General Purpose RAM

Note 1: PSÐPage Select (Bit D7 of Main Status Register)

Note 2: RSÐRegister Select (Bit D6 of Main Status Register)

Note 3: The LSB counters count 0– 99 until the hundreds of days counter

reaches 3. Then the LSB counters count to 65 or 66 (if a leap year). The

rollover is from 365/366 to 1.

MAIN STATUS REGISTER

TL/F/8638– 14

The Main Status Register is always located at address 0

regardless of the register block or the page selected.

D0: This read only bit is a general interrupt status bit that is

taken directly from the interrupt pins. The bit is a one when

an interrupt is pending on either the INTR pin or the MFO

pin (when configured as an interrupt). This is unlike D3 – D5

which can be set by an internal event but may not cause an

interrupt. This bit is reset when the interrupt status bits in the

Main Status Register are cleared.

D1–D5: These five bits of the Main Status Register are the

main interrupt status bits. Any bit may be a one when any of

the interrupts are pending. Once an interrupt is asserted the

mP will read this register to determine the cause. These

interrupt status bits are not reset when read. Except for D1,

to reset an interrupt a one is written back to the corresponding bit that is being tested. D1 is reset whenever the PFAIL

pinelogic 1. This prevents loss of interrupt status when

reading the register in a polled mode. D1, D3 –D5 are set

regardless of whether these interrupts are masked or not by

bits D6 and D7 of Interrupt Control Registers 0 and 1.

D6 and D7: These bits are Read/Write bits that control

which register block or RAM page is to be selected. Bit D6

controls the register block to be accessed (see memory

map). The memory map of the clock is further divided into

two memory pages. One page is the registers, clock and

timers, and the second page contains 31 bytes of general

purpose RAM. The page selection is determined by bit D7.

16

Page 17

Functional Description (Continued)

TIMER 0 AND 1 CONTROL REGISTER

TL/F/8638– 15

These registers control the operation of the timers. Each

timer has its own register.

D0: This bit will Start (1) or Stop (0) the timer. When the

timer is stopped the timer’s prescaler and counter are reset,

and the timer will restart from the beginning when started

again. In mode 0 on time out the TSS bit is internally reset.

D1 and D2: These control the count mode of the timers.

See Table VI.

D3–D5: These bits control which clock signal is applied to

the timer’s counter input. There is one external clock input

pin (TCK) and either (or both) timer(s) can be selected to

run off this pin: refer to Table IV for details.

D6: This is the read bit. If a one is written into this location it

will cause the contents of the timer to be latched into a

holding register, which can be read by the mP at any time.

Reading the least significant byte of the timer will reset the

RD bit. The timer read cycle can be aborted by writing RD to

zero.

D7: The CHG bit has two mode dependent functions. In

modes 0 through 2 writing a one to this bit will suspend the

timer operation (without resetting the timer prescaler). However, in mode 3 this bit is used to trigger or re-trigger the

count sequence as with the gate pins. If retriggering is desired using the CHG bit, it is not necessary to write a zero to

this location prior to the re-trigger. The action of further writing a one to this bit will re-trigger the count.

PERIODIC FLAG REGISTER

TL/F/8638– 16

The Periodic Flag Register has the same bit for bit correspondence as Interrupt Control Register 0 except for D6

and D7. For normal operation (i.e., not a single supply application) this register must be written to on initial power up or

after an oscillator fail event. D0–D5 are read only bits, D6

and D7 are read/write.

D0–D5: These bits are set by the real time rollover events:

(Time Change

e

1). The bits are reset when the register is

read and can be used as selective data change flags.

D6: This bit performs a dual function. When this bit is read, a

one indicates that an oscillator failure has occurred and the

time information may have been lost. Some of the ways an

oscillator failure may be caused are: failure of the crystal;

shorting OSC IN or OSC OUT to GND or V

CC

; removal of

crystal; removal of battery when in the battery backed mode

(when a ‘0’ is written to D6); lowering the voltage at the V

BB

pin to a value less than 2.2V when in the battery backed

mode. Bit D6 is automatically set to 1 on initial power-up or

an oscillator fail event. The oscillator fail flag is reset by

writing a one to the clock start/stop

bit in the Real Time

Mode Register, with the crystal oscillating.

When D6 is written to, it defines whether the TCP is being

used in battery backed (normal) or in a single supply mode

application. When set to a one this bit configures the TCP

for single power supply applications. This bit is automatically

set on initial power-up or an oscillator fail event. When set,

D6 disables the oscillator reference circuit. The result is that

the oscillator is referenced to V

CC

. When a zero is written to

D6 the oscillator reference is enabled, thus the oscillator is

referenced to V

BB

. This allows operation in standard battery

standby applications.

At initial power on, if the DP8570A is going to be programmed for battery backed mode, the V

BB

pin should be

connected to a potential in the range of 2.2V to V

CC

b

0.4V.

For single supply mode operation, the VBBpin should be

connected to GND and the PFAIL

pin connected to VCC.

D7: Writing a one to this bit enables the test mode register

at location 1F (see Table VII). This bit should be forced to

zero during initialization for normal operation. If the test

mode has been entered, clear the test mode register before

leaving test mode. (See separate test mode application

note for further details.)

INTERRUPT ROUTING REGISTER

TL/F/8638– 17

D0–D4: The lower 5 bits of this register are associated with

the main interrupt sources created by this chip. The purpose

of this register is to route the interrupts to either the MFO

(multi-function pin), or to the main interrupt pin. When any

bit is set the associated interrupt signal will be sent to the

MFO pin, and when zero it will be sent to the INTR pin.

17

Page 18

Functional Description (Continued)

D5: The Delay Enable bit is used when a power fail occurs.

If this bit is set, a 480 ms delay is generated internally before

the mP interface is locked out. This will enable the mPto

access the registers for up to 480 ms after it receives a

power fail interrupt. After a power failure is detected but

prior to the 480 ms delay timing out, the host mP may force

immediate lock out by resetting the Delay Enable bit. Note if

this bit is a 0 when power fails then after a delay of 30 ms

min/63 ms max the mP cannot read the chip.

D6: This read only bit is set and reset by the voltage at the

V

BB

pin. It can be used by the mP to determine whether the

battery voltage at the V

BB

pin is getting too low. A compara-

tor monitors the battery and when the voltage is lower than

2.1V (typical) this bit is set. The power fail interrupt must be

enabled to check for a low battery voltage.

D7: Time Save Enable bit controls the loading of real-timeclock data into the Time Save RAM. When a one is written

to this bit the Time Save RAM will follow the corresponding

clock registers, and when a zero is written to this bit the time

in the Time Save RAM is frozen. This eliminates any synchronization problems when reading the clock, thus negating the need to check for a counter rollover during a read

cycle.

This bit must be set to a one prior to power failing to enable

the Time Save feature. When the power fails this bit is automatically reset and the time is saved in the Time Save RAM.

REAL TIME MODE REGISTER

TL/F/8638– 18

D0–D1: These are the leap year counter bits. These bits are

written to set the number of years from the previous leap

year. The leap year counter increments on December 31st

and it internally enables the February 29th counter state.

This method of setting the leap year allows leap year to

occur whenever the user wishes to, thus providing flexibility

in implementing Japanese leap year function.

LY1 LY0

Leap Year

Counter

0 0 Leap Year Current Year

0 1 Leap Year Last Year

1 0 Leap Year 2 Years Ago

1 1 Leap Year 3 Years Ago

D2: The count mode for the hours counter can be set to

either 24 hour mode or 12 hour mode with AM/PM indicator.

A one will place the clock in 12 hour mode.

D3: This bit is the master Start/Stop

bit for the clock. When

a one is written to this bit the real time counter’s prescaler

and counter chain are enabled. When this bit is reset to zero

the contents of the real time counter is stopped and the

prescaler is cleared. When the TCP is initially powered up

this bit will be held at a logic 0 until the oscillator starts

functioning correctly after which this bit may be modified. If

an oscillator fail event occurs, this bit will be reset to logic 0.

D4: This bit controls the operation of the interrupt output in

standby mode. If set to a one it allows Alarm, Periodic, and

Power Fail interrupts to be functional in standby mode. Timer interrupts will also be functional provided that bit D5 is

also set. Note that the MFO and INTR pins are configured

as open drain in standby mode.

If bit D4 is set to a zero then interrupt control register 0 and

bits D6 and D7 of interrupt control register 1 will be reset

when the TCP enters the standby mode (V

BB

l

VCC). They

will have to be re-configured when system (V

CC

) power is

restored.

D5: This bit controls the operation of the timers in standby

mode. If set to a one the timers will continue to function

when the TCP is in standby mode. The input pins TCK, G0,

G1 are locked out in standby mode, and cannot be used.

Therefore external control of the timers is not possible in

standby mode. Note also that MFO and T1 pins are automatically reconfigured open drain during standby.

D6 and D7: These two bits select the crystal clock frequency as per the following table:

XT1 XT0

Crystal

Frequency

0 0 32.768 kHz

0 1 4.194304 MHz

1 0 4.9152 MHz

1 1 32.000 kHz

All bits are Read/Write, and any mode written into this register can be determined by reading the register. On initial

power up these bits are random.

OUTPUT MODE REGISTER

TL/F/8638– 19

18

Page 19

Functional Description (Continued)

D0: This bit, when set to a one makes the T1 (timer 1)

output pin active high, and when set to a zero, it makes this

pin active low.

D1: This bit controls whether the T1 pin is an open drain or

push-pull output. A one indicates push pull.

D2: This bit, when set to a one makes the INTR output pin

active high, and when set to a zero, it makes this pin active

low.

D3: This bit controls whether the INTR pin is an open drain

or push-pull output. A one indicates push-pull.

D4: This bit, when set to a one makes the MFO output pin

active high, and when set to a zero, it makes this pin active

low.

D5: This bit controls whether the MFO pin is an open drain

or push-pull output. A one indicates push-pull.

D6 and D7: These bits are used to program the signal appearing at the MFO output, as follows:

D7 D6 MFO Output Signal

0 0 2nd Interrupt

0 1 Timer 0 Waveform

1 X Buffered Crystal Oscillator

INTERRUPT CONTROL REGISTER 0

TL/F/8638– 20

If battery backed mode is selected and the DP8570A is in

standby (V

BB

l

VCC), then all bits are controlled by D4 of

the Real Time Mode Register.

D0–D5: These bits are used to enable one of the selected

periodic interrupts by writing a one into the appropriate bit.

These interrupts are issued at the rollover of the clock. For

example, the minutes interrupt will be issued whenever the

minutes counter increments. In all likelihood the interrupt

will be enabled asynchronously with the real time change.

Therefore, the very first interrupt will occur in less than the

periodic time chosen, but after the first interrupt all subsequent interrupts will be spaced correctly. These interrupts

are useful when minute, second, real time reading, or task

switching is required. When all six bits are written to a 0 this

disables periodic interrupts from the Main Status Register

and the interrupt pin.

D6 and D7: These are individual timer enable bits. A one

written to these bits enable the timers to generate interrupts

to the mP.

INTERRUPT CONTROL REGISTER 1

TL/F/8638– 21

D0–D5: Each of these bits are enable bits which will enable

a comparison between an individual clock counter and its

associated compare RAM. If any bit is a zero then that

clock-RAM comparator is set to the ‘‘always equal’’ state

and the associated TIME COMPARE RAM byte can be used

as general purpose RAM. However, to ensure that an alarm

interrupt is not generated at bit D3 of the Main Status Register, all bits must be written to a logic zero.

D6: In order to generate an external alarm compare interrupt to the mP from bit D3 of the Main Status Register, this

bit must be written to a logic 1. If battery backed mode is

selected and the DP8570A is in standby (V

BB

l

VCC), then

this bit is controlled by D4 of the Real Time Mode Register.

D7: The MSB of this register is the enable bit for the Power

Fail Interrupt. When this bit is set to a one an interrupt will

be generated to the mP when PFAIL

e

0. If battery backed

mode is selected and the DP8570A is in standby

(V

BB

l

VCC), then this bit is controlled by D4 of the Real

Time Mode Register.

This bit also enables the low battery detection analog circuitry.

If the user wishes to mask the power fail interrupt, but utilize

the analog circuitry, this bit should be enabled, and the

Routing Register can be used to route the interrupt to the

MFO pin. The MFO pin can then be left open or configured

as the Timer 0 or buffered oscillator output.

19

Page 20

Control and Status Register Address Bit Map

D7 D6 D5 D4 D3 D2 D1 D0

1. Reset by

Main Status Register PS

e

0RSe0 ADDRESSe00H

writing

R/W R/W R/W

1

R/W

1

R/W

1

R/W

1

R

2

R

3

1 to bit.

Page Register Timer 1 Timer 0 Alarm Periodic Power Fail Interrupt

2. Set/reset by

Select Select Interrupt Interrupt Interrupt Interrupt Interrupt Status

voltage at

PFAIL pin.

3. Reset when

all pending

interrupts

are removed.

Timer 0 Control Register PS

e

0RSe0 Addresse01H

Count Hold Timer Input Clock Input Clock Input Clock Mode Mode Timer

All Bits R/W

Gate Read Select C2 Select C1 Select C0 Select M1 Select M0 Start/Stop

Timer 1 Control Register PSe0RS

e

0 Addresse02H

Count Hold Timer Input Clock Input Clock Input Clock Mode Mode Timer

All Bits R/W

Gate Read Select C2 Select C1 Select C0 Select M1 Select M0 Start/Stop

Periodic Flag Register PSe0RS

e

0 Addresse03H

4. Read Osc fail

R/W R/W

4

R

5

R

5

R

5

R

5

R

5

R

5

Write 0 Batt-

Test Osc. Fail/ 1 ms 10 ms 100 ms Seconds 10 Second Minute

Backed Mode

Mode Single Supply Flag Flag Flag Flag Flag Flag

Write 1 Single

Supply Mode

5. Reset by

positive edge

of read.

Interrupt Routing Register PS

e

0RS

e

0 Addresse04H

R/W R

6

R/W R/W R/W R/W R/W R/W

Time Save Low Battery

Power Fail Timer 1 Timer 0 Alarm Periodic Power Fail 6. Set and reset

by V

BB

Enable Flag

Delay Int. Route Int. Route Int. Route Int. Route Int. Route

voltage.

Enable MFO/INT

MFO/INT MFO/INT MFO/INT MFO/INT

Real Time Mode Register PSe0RS

e

1 Addresse01H

Crystal Crystal Timers EN Interrupt EN Clock 12/24 Hr. Leap Year Leap Year

All Bits R/W

Freq. XT1 Freq. XT0 on Back-Up on Back-Up Start/Stop

Mode MSB LSB

Output Mode Register PSe0RS

e

1 Addresse02H

MFO as MFO as MFO MFO INTR INTR T1 T1

All Bits R/W

Crystal Timer 0 PP/OD

Active HI/LO PP/OD Active HI/LO PP/OD Active HI/LO

Interrupt Control Register 0 PSe0RS

e

1 Addresse03H

Timer 1 Timer 0 1 ms 10 ms 100 ms Seconds 10 Second Minute

Interrupt Interrupt Interrupt Interrupt Interrupt Interrupt Interrupt Interrupt All Bits R/W

Enable Enable Enable Enable Enable Enable Enable Enable

Interrupt Control Register 1 PSe0RS

e

1 Addresse04H

Power Fail Alarm DOW Month DOM Hours Minute Second

Interrupt Interrupt Interrupt Interrupt Interrupt Interrupt Interrupt Interrupt All Bits R/W

Enable Enable Enable Enable Enable Enable Enable Enable

20

Page 21

Application Hints

Suggested Initialization Procedure for DP8570A in battery backed applications that use the V

BB

pin

1. Enter the test mode by writinga1tobitD7inthePeriodic Flag Register.

2. Write zero to the RAM/TEST mode Register located in

page 0, address HEX 1F.

3. Leave the test mode by writinga0tobitD7inthePeriodic Flag Register. Steps 1, 2, 3 guarantee that if the test

mode had been entered during power on (due to random

pulses from the system), all test mode conditions are

cleared. Most important is that the OSC Fail Disable bit is

cleared. Refer to AN-589 for more information on test

mode operation.

4. After power on (V

CC

and VBBpowered), select the correct crystal frequency bits (D7, D6 in the Real Time Mode

Register) as shown in Table I.

TABLE I

Frequency D7 D6

32.768 kHz 0 0

4.194304 MHz 0 1

4.9152 MHz 1 0

32.0 kHz 1 1