Page 1

DP8459 All-Code Data Synchronizer

General Description

The DP8459 Data Synchronizer is an integrated phase

locked loop circuit which has been designed for application

in magnetic hard disk, flexible (floppy) disk, optical disk, and

tape drive memory systems for data re-synchronization and

clock recovery with any standard recording code, operating

to 25 Mb/s. The DP8459 is provided in a 28-pin PCC

package. Zero phase start is employed during both data and

reference clock lock sequences for rapid acquisition. An

optional (Customer-controlled) synchronization field

frequency-acquisition feature guarantees lock, accommodating the preamble types used with GCR (Group Code

Recording), MFM (Modified Frequency Modulation), the

[1,N] run length limited (RLL) codes, and either of the

standard 2,7 RLL codes. Precise synchronization window

generation is achieved via an internal, self-aligning delay line

which remains accurate independent of temperature, power

supply, external component and IC process variations. The

DP8459 also incorporates a digitally controlled ( MICROW-

™

IRE

bus compatible) strobe function with 5-bit resolution

which allows for margin testing, error recovery routines, and

precise window calibration. The PLL filter resides external to

the chip, with two ports provided to allow significant design

flexibility.Synchronizationpattern detection circuitry issues a

PREAMBLE DETECTED signal when a pre-determined

length of the user-selected pattern is encountered. All digital

input and output signals are TTL compatible and a single,

+5V power supply is required. The DP8459V is offered as a

DP8459V-10 (250 Kbit/sec thru 10 Mbits/sec) or

DP8459V-25 (250 Kbits/sec thru 25 Mbit/sec), see AC

Electrical Characteristics.

Features

n Fully integrated dual-gain PLL

n Zero phase start lock sequence

n 250 Kbit/sec–25 Mbit/sec data rate range

n Frequency lock capability (optional) for all standard

recording codes

n Digital window strobe control, 5-bit resolution

n Two-port PLL filter network

n PLL free-run (Coast) control for optical disk defects

n Synchronization pattern (preamble lock) detection

n Non-glitching multiplexed read/write clock output

n +5V supply

n DP8459 supplied in 28-pin plastic chip carrier (PCC)

and 40-pin TapePak packages

ADVANCED

December 1995

DP8459 All-Code Data Synchronizer

DP8459

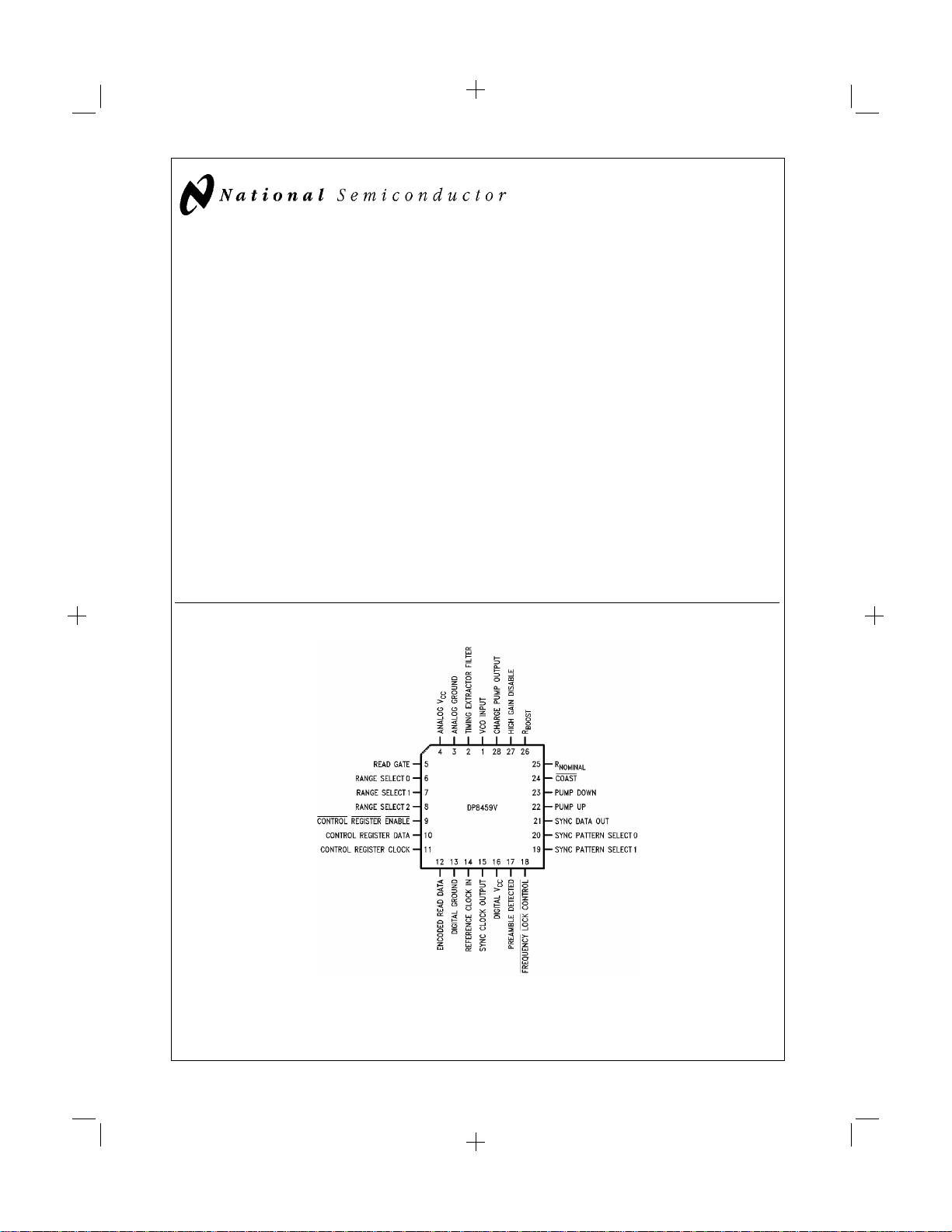

Connection Diagrams

TL/F/9322-6

FIGURE 1. DP8459 in 28-Pin Plastic Chip Carrier (PCC) V-Type Package Order Number DP8459V-10 or DP8459V-25

TapePak®is a registered trademark of National Semiconductor Corporation.

™

MICROWIRE

is a trademark of National Semiconductor Corporation.

© 1996 National Semiconductor Corporation TL/F/9322 http:\\www.national.com 1

PrintDate=1996/07/31 PrintTime=11:05:38 ds009322 Rev. No. 1 Proof 1

Page 2

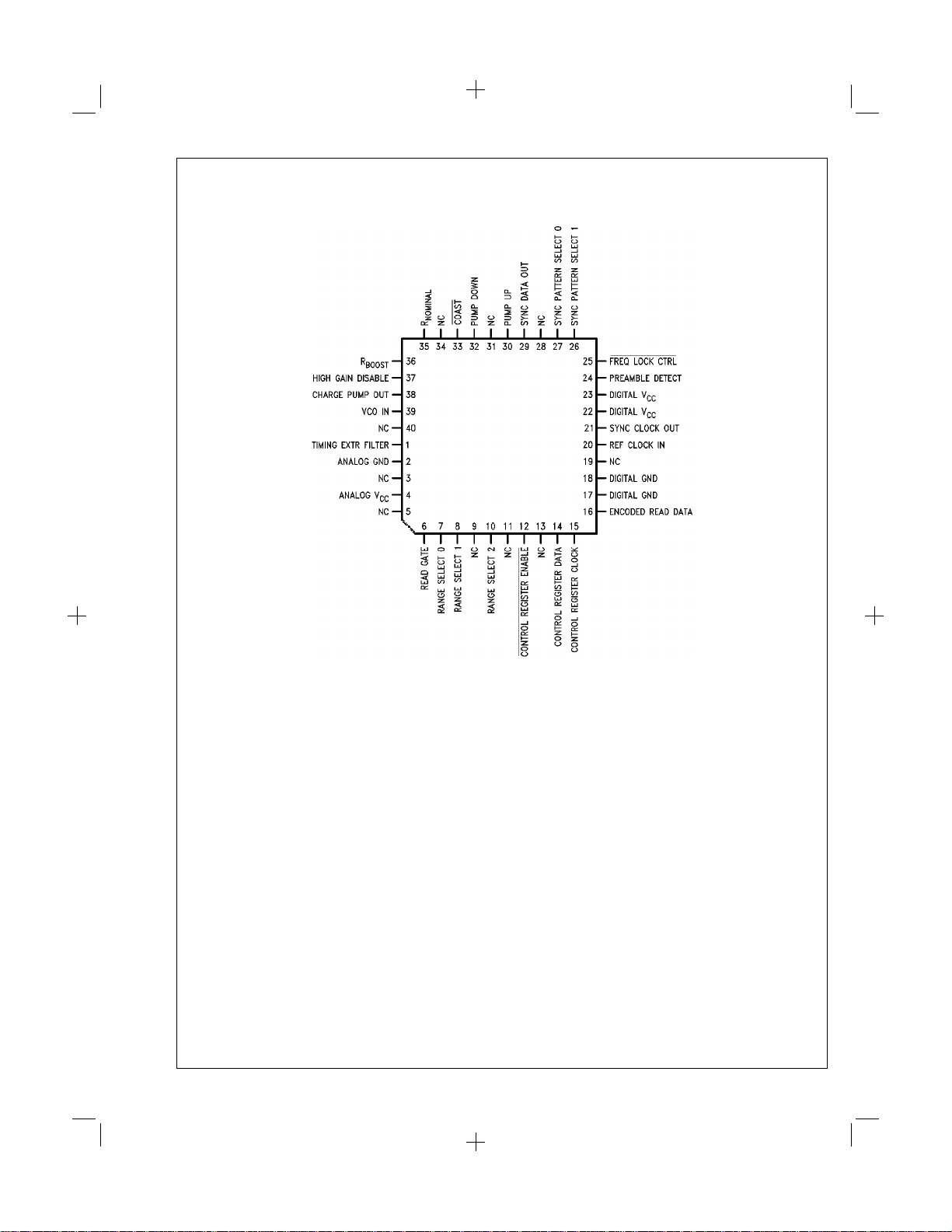

Connection Diagrams

TapePak

®

Top ViewOrder Number DP8459TP-10 or DP8459TP-25See NS Package TP40A

2 http:\\www.national.com

TL/F/9322-39

PrintDate=1996/07/31 PrintTime=11:05:39 ds009322 Rev. No. 1 Proof 2

Page 3

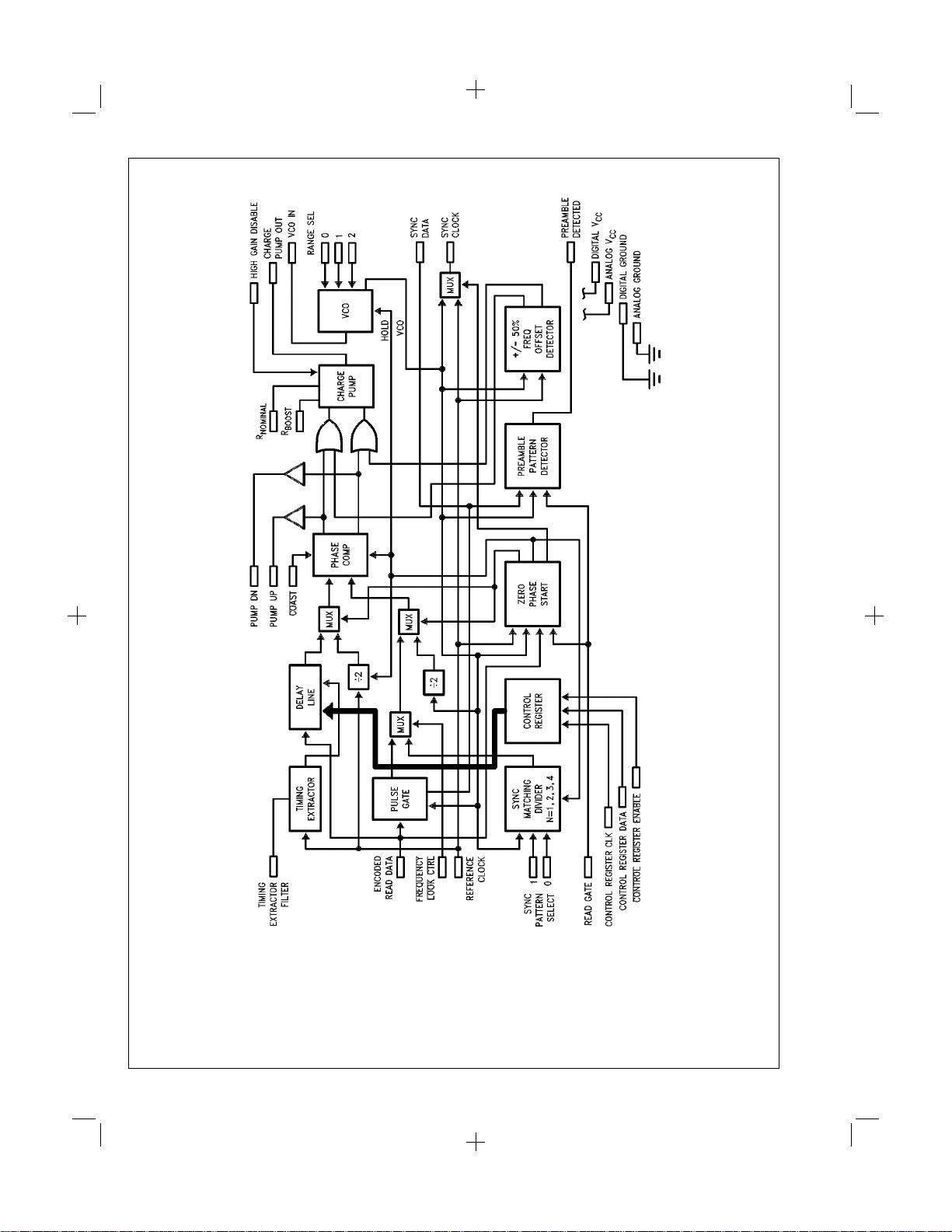

System Diagram

TL/F/9322-8

FIGURE 2. DP8459 System Block Diagram

http:\\www.national.com 3

PrintDate=1996/07/31 PrintTime=11:05:39 ds009322 Rev. No. 1 Proof 3

Page 4

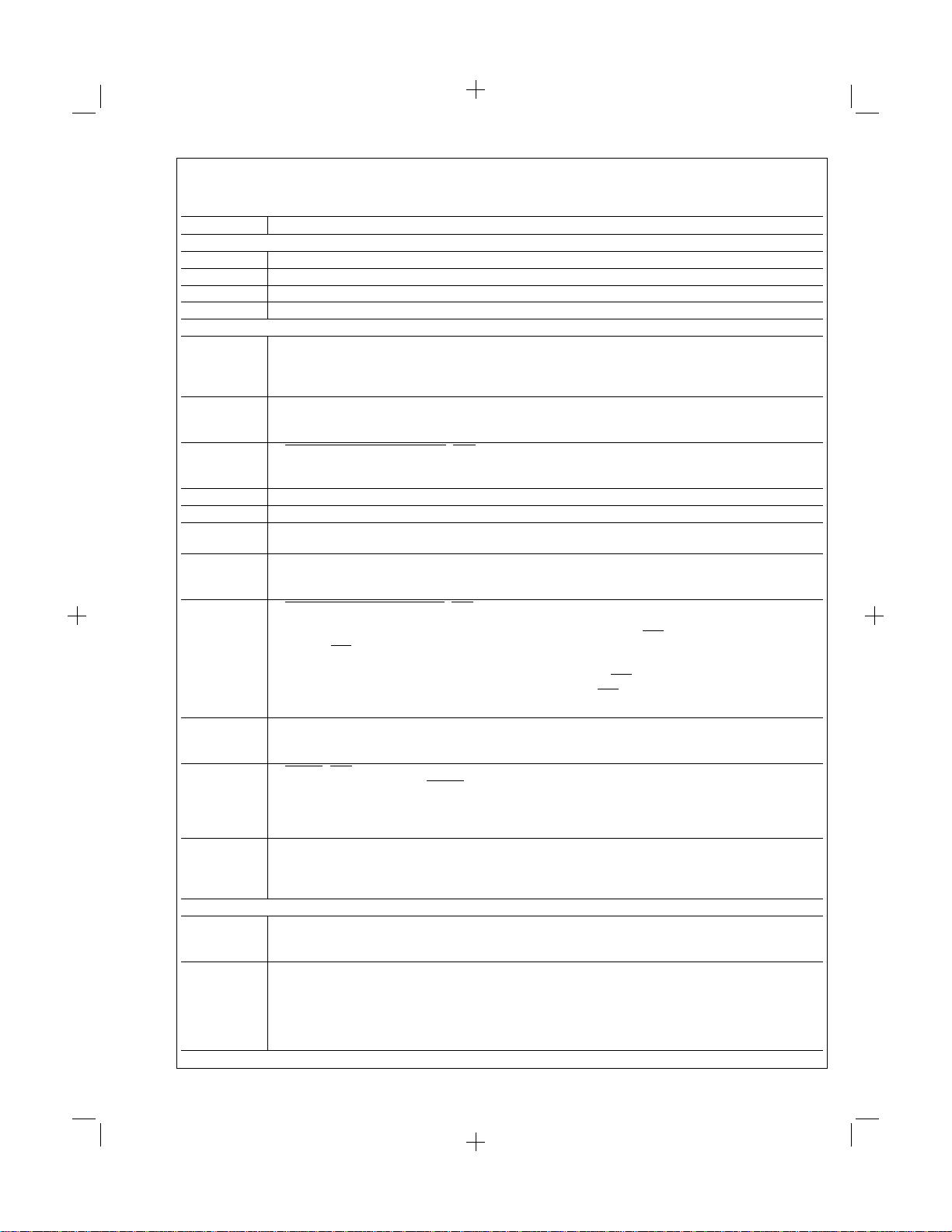

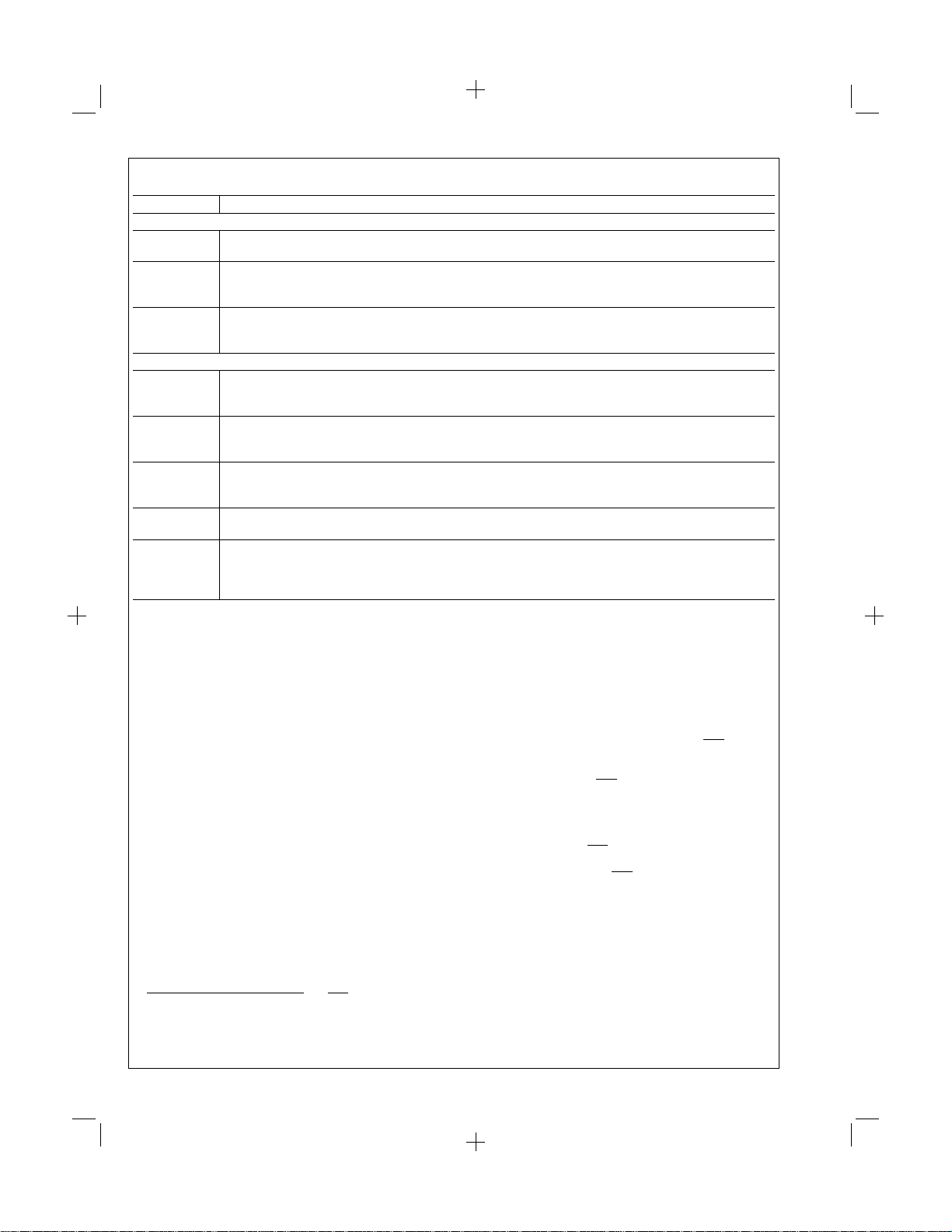

1.0 Pin Descriptions

DP8459 28-pin PCC package

#

Pin

POWER SUPPLY

16 DIGITAL V

4 ANALOG V

13 DIGITAL GROUND.

3 ANALOG GROUND.

TTL LEVEL LOGIC INPUTS

5 READ GATE (RG): Read mode control input, active high (logical-one). Assertion causes the PLL to lock to

the ENCODED READ DATA, employing a zero phase start routine. Deassertion causes the PLL to lock the

REFERENCE CLOCK input, also employing a zero phase start routine. READ GATE timing is allowed to

be fully asynchronous.

6, 7, 8 RANGE SELECT 0, 1, 2 (RS0, RS1, RS2): Control the operating frequency range of the VCO. A 2:1

continuously variable sub-range is available within each of 6 allowed selections, enabling the VCO to

operate at any frequency within a 96:1 range from 500 kHz to 50 MHz.

9 CONTROL REGISTER ENABLE (CRE): A logical Low level allows the CONTROL REGISTER CLOCK to

clock data into the Control Register via the CONTROL REGISTER DATA input; a logical HIGH level

latches the register data and issues the information to the appropriate circuitry.

10 CONTROL REGISTER DATA (CRD): Control Register data input.

11 CONTROL REGISTER CLOCK (CRC): Negative edge triggered Control Register clock input.

12 ENCODED READ DATA (ERD): Incoming TTL-level data derived from the storage media; issued from a

pulse detector circuit. Each positive edge represents a single recorded code bit.

14 REFERENCE CLOCK (RFC): A reference frequency input required for DP8459 operation. The RFC

frequency must be accurate and highly stable (crystal or servo derived) and equivalent to the 2F frequency

for the MFM or [2,7] codes (i.e., equal to, but not derived from the VCO frequency).

18 FREQUENCY LOCK CONTROL (FLC): Selects or de-selects the frequency lock function during a READ

operation. Has no effect with READ GATE deasserted; frequency lock is automatically employed for the full

duration of time READ GATE is deasserted regardless of the level of the FLC input. With READ GATE

high and FLC low (logical-zero) the PLL is forced to lock to the pattern frequency selected via the SYNC

PATTERN SELECT inputs. When high (logical-one) frequency lock action is terminated and the PLL

employs a pulse gate to accommodate random disk data patterns. FLC may be tied to PREAMBLE

DETECTED output pin for self-regulated frequency lock control. FLC timing is allowed to be fully

asynchronous.

20, 19 SYNC PATTERN SELECT 0, 1 (SP0, SP1): Control inputs for selection of the preamble type being

employed. These inputs determine the pattern to which the PLL will frequency-lock during preamble

acquisition (if frequency lock is employed) and for which the PREAMBLE DETECTED circuitry searches.

24 COAST (CST): Control for Coast function. The Coast function may be activated when READ GATE is

either high or low. When the COAST input is low (logical-zero), the phase comparator is disabled and held

in a cleared state, allowing the VCO to coast regardless of ENCODED READ DATA input activity (READ

GATE high) or REFERENCE CLOCK input activity (READ GATE low). No other circuit functions are

disturbed. When high (logical-one), the phase comparator operates normally.

27 HIGH-GAIN DISABLE (HGD): Charge Pump gain switch control. When low (logical-zero), the charge pump

input current is the combined value of the currents at both R

(logical-one), charge pump input current is taken from the R

READ GATE or PREAMBLE DETECTED for self-regulated gain control.

TTL LEVEL LOGIC OUTPUTS

15 SYNCHRONIZED CLOCK (SCK): Issues the VCO signal following READ GATE assertion and completion

of zero phase start sequence; issues REFERENCE CLOCK input signal when READ GATE is deasserted.

Multiplexer switching is achieved without glitches.

17 PREAMBLE DETECTED (PDT): Issues a high level (logical-one) following assertion of READ GATE,

completion of the zero phase start sequence, and the detection of approximately 32 sequential pulses of

1T, 2T or 3T period preamble, or 16 sequential pulses of 4T period preamble, depending on state of SYNC

PATTERN SELECT inputs (T=VCO period). Following preamble detection, the output remains latched

high until de-assertion of READ GATE. The PDT output will be at a logical zero state whenever READ

GATE is inactive.

: 5.0V±5%. (Note 1 )

CC

: 5.0V±5%. (Note 1 )

CC

and R

BOOST

pin only. HGD may be tied either to

NOMINAL

NOMINAL

pins. When high

4 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:05:40 ds009322 Rev. No. 1 Proof 4

Page 5

1.0 Pin Descriptions (Continued)

#

Pin

TTL LEVEL LOGIC OUTPUTS

21 SYNCHRONIZED DATA (SD): A reconstructed replica of the ENCODED READ DATA signal,

22 PUMP UP (PU): Active HIGH whenever the phase comparator issues a pump-up signal to the charge

23 PUMP DOWN (PD): Active HIGH whenever the phase comparator issues a pump-down signal to the

ANALOG SIGNAL PINS

28 CHARGE PUMP OUTPUT: The output of the high-speed, switching bi-directional current source circuitry of

1 VCO INPUT: The high-impedance control voltage input to the voltage controlled oscillator (VCO). The

2 TIMING EXTRACTOR FILTER: A pin for the connection of external, passive components employed to

25 R

26 R

Note 1: These pins should always be tied together; they are not intended to be used with separate power supplies.

time-stabilized and synchronized to the SYNCHRONIZED CLOCK output.

pump. The PU pin is an open-emitter output requiring an external passive pull down resistor whenever in

active use. The output should be allowed to float when not needed.

charge pump. The PD pin is an open-emitter output requiring an external passive pull down resistor

whenever in active use. The output should be allowed to float when not needed.

the charge pump. The external, passive PLL filter network is established between this pin, the VCO INPUT

pin, and ground.

external, passive PLL filter network is established between this pin, the CHARGE PUMP OUTPUT pin, and

ground.

stabilize the delay line timing extraction circuitry. Delay accuracy is not a function of external component

values or tolerances.

: A resistor is tied between this pin and VCCto set the charge pump

NOMINAL

The current is internally multiplied by 2 for charge pump use.

: A resistor is tied between this pin and VCCto set the charge pump

BOOST

resistor is effectively paralleled with the R

R

BOOST

inactive (logical-zero); thus the sum of the resistor currents sets the total input current. The input current is

resistor when the HIGH GAIN DISABLE input is

NOMINAL

nominal

operating current.

boost

(or adder) current. The

multiplied by 2 within the charge pump circuitry.

2.0 Circuit Operation

In the non-Read mode, the DP8459 PLL is locked to the

REFERENCE CLOCK signal. This permits the VCO to remain

at a frequency very close to the encoded data clock rate while

the PLL is “idling” and thus will minimize the frequency step

and associated lock time encountered at the initiation of lock to

ENCODED READ DATA. Frequency acquisition is employed

in the non-Read mode to ensure lock.

Note: The REFERENCE CLOCK signal is employed bycircuitrywhich sets the

time delay of the internal delay line. This requires the REFERENCE CLOCK

signal to be present

DP8459 operation.

at all times

at a stable and accurate frequency for proper

At the assertion of READ GATE, which is allowed to be done

asynchronously (no timing requirements), and following the

completion of two subsequent VCO cycles, the DP8459 VCO

is stopped momentarily and restarted in accurate phase

alignment with the second data bit which arrives following the

VCO pause. This minimization of phase misalignment

between the ENCODED READ DATAand the VCO (referred to

as zero phase start, or ZPS) significantly reduces data lock

acquisition time.

The DP8459 incorporates a preamble-specific frequency

acquisition feature which may be employed at the user’s

option. The frequency acquisition feature is intended

specifically for use within hard or pseudo-hard sectored

systems where READ GATE is asserted only within a

preamble. With the READ GATE active (logical-one) and the

FREQUENCY LOCK CONTROL (FLC) input active

(logical-zero), the DP8459 will be forced to lock to the exact

preamble frequency selected at the SYNC PATTERN SELECT

inputs. The frequency discriminating action of the PLL

http:\\www.national.com 5

provided in this mode produces a lock-in range equivalent to

the available VCO operating range and thus eliminates the

possibility of fractional-harmonic lock. Windowing (pulse gate

action; see Pulse Gate, Section 2.1) is not employed in the

frequency acquisition mode and thus quadrature lock is

prevented (see National Semiconductor Application Note

AN-414, APPS Mass Storage Handbook

#

1, 1986, for an

explanation of typical false lock modes). The DP8459 will

remain in the frequency acquisition mode until the FLC input is

deactivated (logical-one). In ordinary hard sectored or

pseudo-hard sectored operation, the PREAMBLE DETECTED

(PDT) output is tied to the FLC input for automatic switching

from frequency acquisition to phase lock following internal

detection of the selected preamble by the DP8459. The

Customer may choose to intervene in this path and extend the

frequency lock period. However, the DP8459

must

be placed

in the phase lock mode (FLC deactivated—logical-one) prior

to encountering the end of the preamble, or loss of lock will

result. Switching of the FLC input may be done

asynchronously (no set-up or hold timing requirements).

The PREAMBLE DETECTED (PDT) output will become active

(logical-one) following READ GATE assertion, completion of

the ZPS sequence and the subsequent detection of

approximately 32 ENCODED READ DATA(ERD) pulses of the

1T, 2T or 3T preamble types, or 16 ENCODED READ DATA

(ERD) pulses of the 4T preamble type (see specification

tables), and will remain active (logical-one) until deassertion of

READ GATE.

The Customer has the option of employing an elevated PLL

bandwidth during preamble acquisition (or at any other time)

for an extended capture range. An R

pin is provided to

BOOST

PrintDate=1996/07/31 PrintTime=11:05:41 ds009322 Rev. No. 1 Proof 5

Page 6

allow for an increase in charge pump gain above the level set

by the R

(HGD) is inactive (logical-zero), the R

electrically paralleled with the R

charge pump gain. When HIGH GAIN DISABLE is active

(logical-one), only the R

pump current. The Charge Pump throughput gain is I

I

where I

Rp

=

R

R

p

NOM

to configure the system for high gain prior to DP8459 preamble

pin. When the HIGH GAIN DISABLE pin

NOMINAL

NOMINAL

resistor is employed to set the

NOMINAL

=

0.25V

Rp

||R

CC/Rp,Rp

with HGD low.The Customer may choose

BOOST

=

R

NOM

resistor is

BOOST

for an elevated

=

2x

with HGD high, and

CPO

detection by tying the HGD pin to the PDT output pin, or for

high gain only during REFERENCE CLOCK lock by tying the

HGD pin to the READ GATE pin. Other configurations may be

employed, if desired.

The DP8459 issues a clock waveform from the SYNCHRONIZED CLOCK output which is derived from the REFERENCE

CLOCK input when the READ GATE is inactive (logical-zero),

and from the VCO signal following READ GATE assertion

(logical-one) and completion of the zero phase start sequence.

The REFERENCE CLOCK signal is issued from the

SYNCHRONIZED CLOCK output during non-Read activity

and may be used as a write clock, if desired. Once data lock is

achieved and the SYNCHRONIZED CLOCK output is issuing

VCO, the SYNCHRONIZED DATA output and the SYNCHRONIZED CLOCK output are held in a fixed, specified timing

relationship for use by decoding/deserializing circuitry. The

SYNCHRONIZED CLOCK output multiplexer switching is

achieved without glitches, i.e., no pulse is narrower than 50

of the VCO or REFERENCE CLOCK period.

The DP8459 provides a COAST control input which serves to

clear the phase comparator and disable charge pump action

whenever taken to an active, logical-zero level. This function is

made available to allow the PLL to be set to free-run,

undisturbed, while a detectable defect is being read from the

media in a region where re-initiation of the lock procedure is

impractical (e.g., data field). External data controller circuitry is

responsible for the detection of the defect and issuance of the

COAST command. The primary application of this feature is

expected to be optical disk bright-spot avoidance, though it will

lend itself to other applications as well.

As in the previous family of National Semiconductor data

separators/synchronizers, the DP8459 provides phase

comparator activity information to the Customer. The phase

comparator’s pump-up and pump-down outputs are brought

out to separate pins, PUMP UP (PU) and PUMP DOWN (PD).

The outputs are of the open-emitter type, requiring an external

“pull-down” resistor when in active use. These outputs serve to

indicate the relative displacement of the current data bit with

respect to the internal VCO phase (window center). When in

completely stabilized lock with no bit displacement, the

output(s) will issue a pulse of a finite, minimum-valued width

for each arriving data pulse. If any data pulse is displaced with

respect to the VCO phase, the corresponding output pulse will

widen by an amount equivalent to the bit displacement. These

output signals may be integrated over time and employed to

determine the average magnitude of media bit shift.

Additionally, the pulse widening/narrowing effect bit displacement has on the PU/PD outputs produces an amplitude

modulation of the output’s waveform. The waveform envelope,

when observed with a relatively slow oscilloscope time base,

can be employed for observation of PLL dynamics. This is

particularly useful if intrusive probing of the PLL filter nodes is

not desirable.

It is strongly recommended that the PU/PD outputs be left

“floating” (unconnected to any net or circuit element, including

the output pull-down resistor) in any application where they are

not specifically needed. This will serve to minimize

unnecessary, spurious digital switching transients in the

vicinity of the DP8459, and thus improve noise performance.

The DP8459 provides a wide operating data rate range to

facilitate use within a broad base of applications, including

multiple data rate systems or constant density recording

(CDR). In order to achieve the specified 250 kbit /sec to 25

Mbit/sec span, the operation of the VCO has been divided into

6 contiguous frequency sub-ranges, with approximately a 2:1

ratio between adjacent range selections. Three inputs are

provided for selecting of the sub-ranges, RANGE SELECT 0, 1

and 2. Some code type restrictions have been placed on the

higher ranges of operating VCO frequency. See

the operating data rate truth table and allowed code type

versus VCO range selection.

The DP8459 allows for flexible synchronization window strobe

%

control. The inputs CONTROL REGISTER DATA (CRD),

CONTROL REGISTER CLOCK (CRC), and CONTROL

REGISTER ENABLE (CRE) are configured to permit

interfacing of the DP8459 to the MICROWIRE™(or

equivalent) bus for entry of strobe information. Information is

serially shifted into the CONTROL REGISTER via the CRD

and CRC pins whenever the CRE pin is active (logical-zero).

When the CRE pin is inactive (logical-one), CRD and CRC are

ignored. The strobe function allows the Customer to shift the

synchronization window in 31 equal steps of magnitude t

x [1.8%x τ

respect to nominal window position. This function may be

] from approximately 27%early to 27%late with

VCO

employed for margin testing (eg., approximately

error recovery read re-try operations (eg., approximately

±

to

3%). Additionally, this feature allows the Customer to align

the center of the synchronization window to within one half

strobe step of ideal, regardless of the initial performance or

specification of the DP8459. This window centering function

may be performed completely within the drive system itself

(auto-alignment) given the employment of an intelligent

window alignment routine. Such a routine would be configured

to determine the maximum error free early and late window

positions via the strobe function, and then would fix the

DP8459 window in the arithmetic mean position (Section

4.3.3). See

Note: In all DP8459 applications, provision must be made to load the

appropriate information into the Control Register.

Figure 4

for a window strobe truth table.

Figure 3

±

12%)or

for

=

M

S

±

%

2

6 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:05:43 ds009322 Rev. No. 1 Proof 6

Page 7

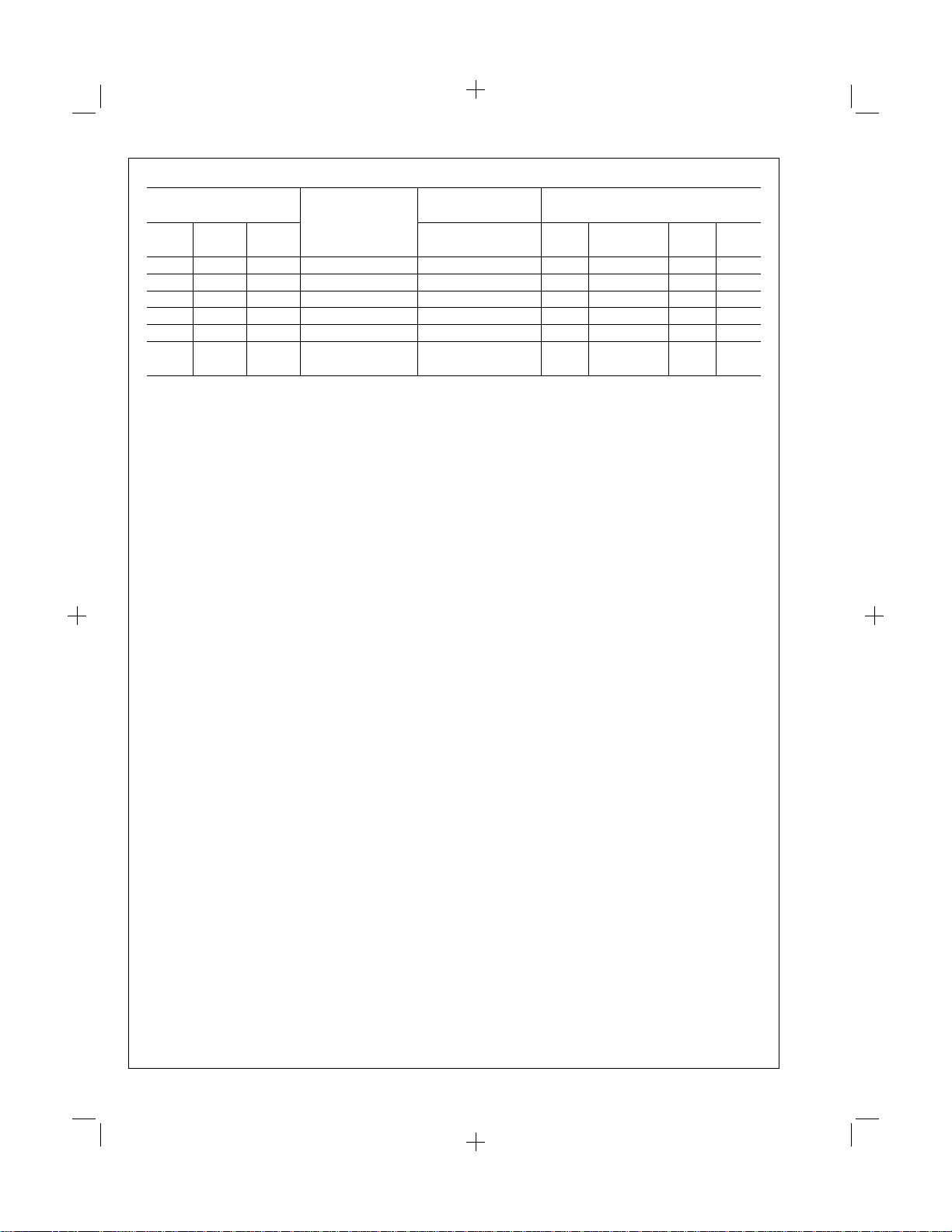

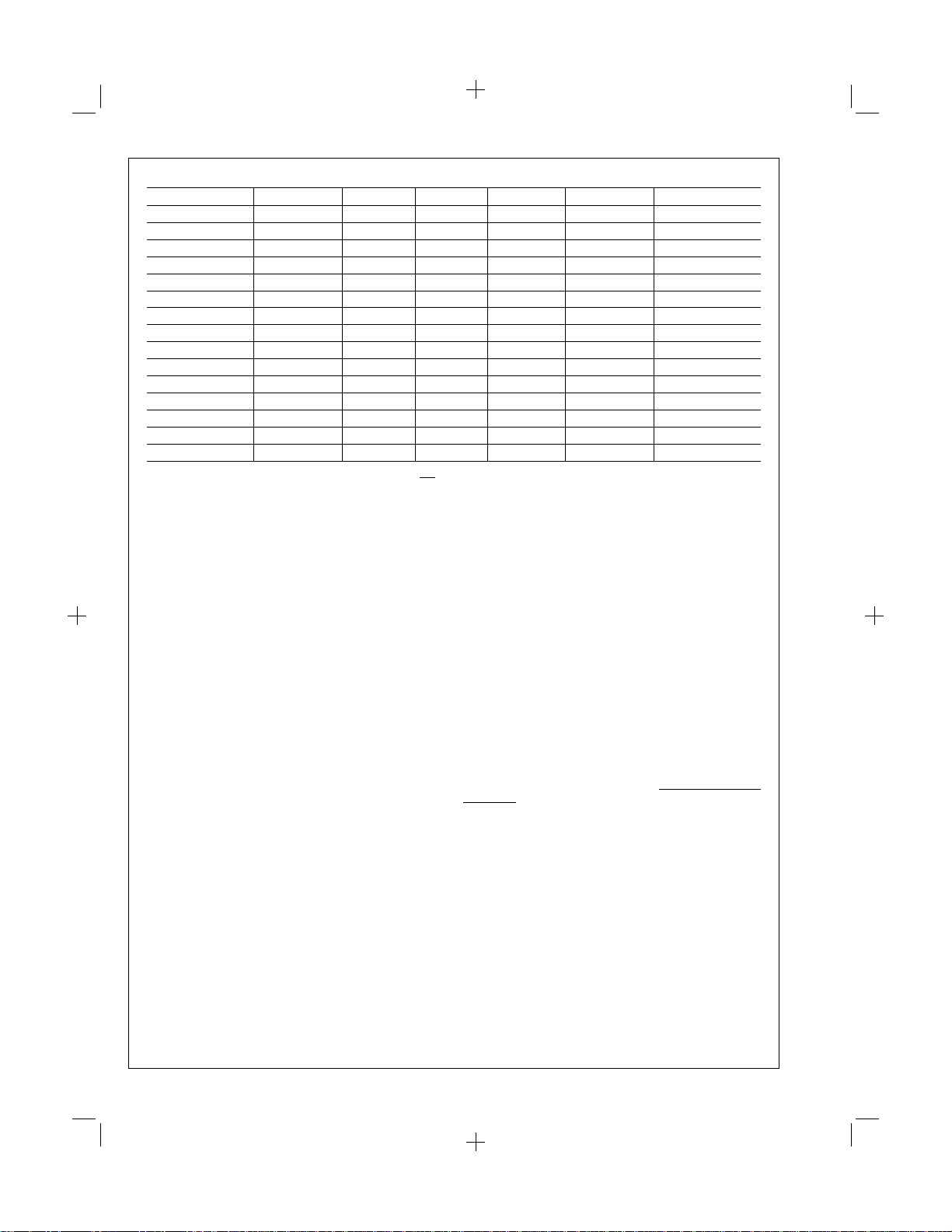

RANGE SELECT Input Equivalent Minimum N (Allowed Code Type)

( Note 1 ) VCO Range NRZ Data Rate

2 1 0 MHz MFM or 2,7 1 2 3 4

(Mbit/sec) (GCR) (MFM; 1, N) (2,7) (2,7)

1 1 X 0.50 ≤ Fvco ≤ 1.25 0.250≤ Fnrz ≤ 0.625

1 0 1 1.25<Fvco ≤ 2.5 0.625<Fnrz ≤ 1.25

1 0 0 2.5<Fvco ≤ 5 1.25<Fnrz ≤ 2.5

01 1 5

01 010

00X20

<

Fvco ≤ 10 2.5<Fnrz ≤ 5

<

Fvco ≤ 20 5<Fnrz ≤ 10 N/A

<

Fvco ≤ 50 10<Fnrz ≤ 25 N/A

√√√√

√√√√

√√√√

√√√√

√√√

√√√

(Note3)

Note 1: N/A—Not Allowed.

Note 2: Operation slightly beyond listed range boundaries may be acceptable in some applications.At or near range boundaries, range selection should be made

to place the operating frequency near the UPPER boundary; e.g., use RS2=0, RS1=1, and RS0=0 for 10 Mb/s.

Note 3: 20 MHz

<

Fvco ≤ 38 MHz for 1, N codes.

FIGURE 3. Code Type Allowance Versus VCO Frequency Range

http:\\www.national.com 7

PrintDate=1996/07/31 PrintTime=11:05:45 ds009322 Rev. No. 1 Proof 7

Page 8

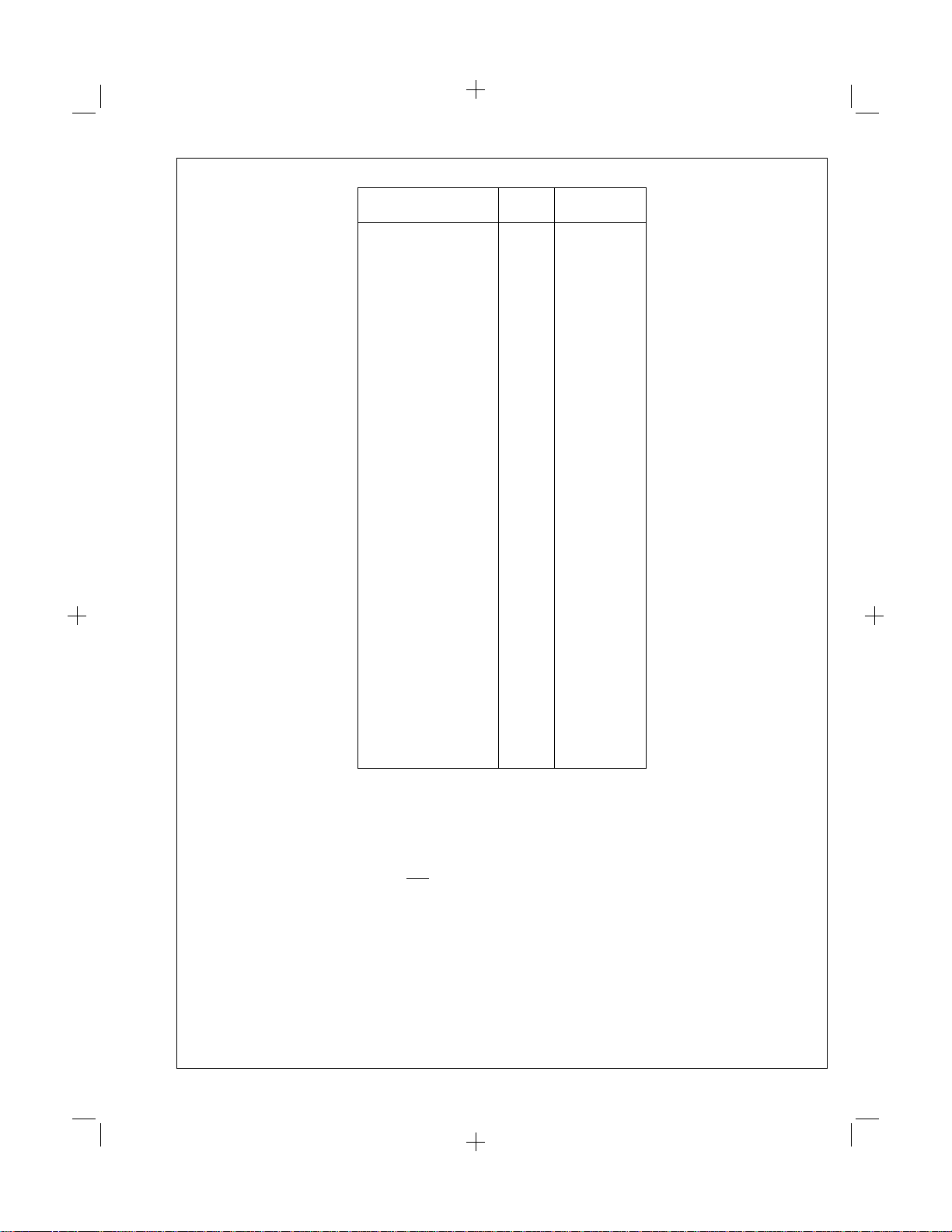

Strobe Bit Strobe Window Strobe

43210Word M T

01111 −15 −0.270 x τ

01110 −14 −0.252 x τ

01101 −13 −0.234 x τ

01100 −12 −0.216 x τ

01011 −11 −0.198 x τ

01010 −10 −0.180 x τ

01001 −9 −0.162 x τ

01000 −8 −0.144 x τ

00111 −7 −0.126 x τ

00110 −6 −0.108 x τ

00101 −5 −0.090 x τ

00100 −4 −0.072 x τ

00011 −3 −0.054 x τ

00010 −2 −0.036 x τ

00001 −1 −0.018 x τ

00000 0 0

10000 0 0

10001 1 0.018 x τ

10010 2 0.036 x τ

10011 3 0.054 x τ

10100 4 0.072 x τ

10101 5 0.090 x τ

10110 6 0.108 x τ

10111 7 0.126 x τ

11000 8 0.144 x τ

11001 9 0.162 x τ

11010 10 0.180 x τ

11011 11 0.198 x τ

11100 12 0.216 x τ

11101 13 0.234 x τ

11110 14 0.252 x τ

11111 15 0.270 x τ

FIGURE 4. Window Strobe Truth Table

Customers who employ the DP8459 in a system without a

MICROWIRE

™

(or functionally equivalent) bus configuration

and who wish to fix the synchronization window in the nominal

position while deselecting the test mode need only load

all-zero’s into the Control Register following power-up; this

may be easily achieved in some system configurations

(requiring no additional hardware) by tying CRE to RG, tying

CRC to ERD and tying CRD to ground, providing the

necessary waveforms are present for register loading prior to

the first read operation.

The DP8459 provides two pins for PLL filtering purposes,

CHARGE PUMP OUTPUT (CPO) and VCO INPUT (VCOI).

These provide the Customer with great flexibility in fliter

design, permitting high-order filter functions for optimization of

PLL lock characteristics and bit jitter rejection. For basic 3rd

order applications, CPO and VCOI may be tied together

(Typical)

S

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

VCO

(single-node) with a simple lead-lag, C||(R+C) filter tied

between these pins and ground. More esoteric filter designs

may be implemented if the pins are electrically separated and

a two-port filter network is established between CPO, VCOI,

and ground. National Semiconductor supplies initial PLL filter

recommendations for the single-node configuration within this

data sheet with the qualifying statement that they are very

general in nature, intended primarily for production testing of

static window margin, and are NOT optimized for any

particular disk system. For optimum performance, the

Customer should pursue a filter design which is individualized

and tailored to the requirements of the specific system

involved. This is particularly true for the two-port filtering

technique. See

Figure 5

for initial single-node filter design

recommendations.

8 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:05:47 ds009322 Rev. No. 1 Proof 8

Page 9

Code MFM MFM MFM 2,7 2,7 Units

Rate 0.500 2 5 10 20 Mbit/sec

VCO freq. 1 4 10 20 40 MHz

Sync bytes 12 12 12 12 12 bytes

pulses/byte 8 8 8 4 4 flux tran’s

sync length 192 48 19.2 9.6 4.8 µs

sync freq 0.500 2 5 5 10 MHz

N

sync

N

max/Nmin

ζ

min

ζ

max

ζ

sync

ω

sync

C1 0.5 0.12 0.05 0.018 8200 pF µF

2 2 2 4 4 none

4/2 4/2 4/2 8/3 8/3 none

0.5 0.5 0.5 0.5 0.5 none

0.7 0.7 0.7 0.8 0.8 none

0.7 0.7 0.7 0.7 0.7 none

35 144 353 606 1230 Krad/sec

*

R1 82 82 82 150 150 Ω

C2 0.01 µF 2700 1000 510 200 pF

Note 1: Preamble (sync) natural frequency chosen yields phase error ≤ 0.01 radians at sync field end, given a 1%frequency step at READ GATE assertion. Rnom

=

Rboost=2.4k for all above loop filter selections. HGD is tied to RG, FLC is tied to PD and CPO is tied to VCOI as well as to the loop flter components.

Note 2: Component values are listed for purposes of window specification testing and correlation. These values do not necessarily yield optimum performance in

actual system applications. PLL dynamics and code characteristics are presented for Customer information and convenience only. See Section 3.1.

*

Unless otherwise noted.

FIGURE 5. Test Conditions and Component Values for Static Window Truncation Testing

The DP8459 VCO is constrained at all times to operate within

a frequency swing of approximately

±

50%of the frequency

present at the REFERENCE CLOCK input. Internal frequency

detector/comparator circuitry senses when the VCO overruns

the 50%boundary and forces the charge pump to move the

VCO back toward the REFERENCE CLOCK frequency until

the 50%constraint is again satisfied—thus preventing VCO

runaway in the event of loss of lock or during extended periods

where ENCODED READ DATAis not present.Additionally, this

technique causes the filter node voltage to behave as if a

voltage clamp were present at the Charge Pump Output,

preventing the control voltage, in the event of loss of lock, from

drifting outside of its operating range and inadvertently

extending lock recovery time.

A special test mode feature has been incorporated into the

DP8459 which allows a specific input pin to change function

and act as an excitation source (substitute VCO) for clocking

internal logic circuitry. When the last bit in the CONTROL

REGISTER is taken to a logical ONE, the VCO is stopped, and

the HGD input is redirected to act as a clock source for the

VCO divider circuitry. Additionally, the Delay Line and Timing

Extractor blocks are disabled when the Test Mode is entered,

and thus the device will not function normally and should not

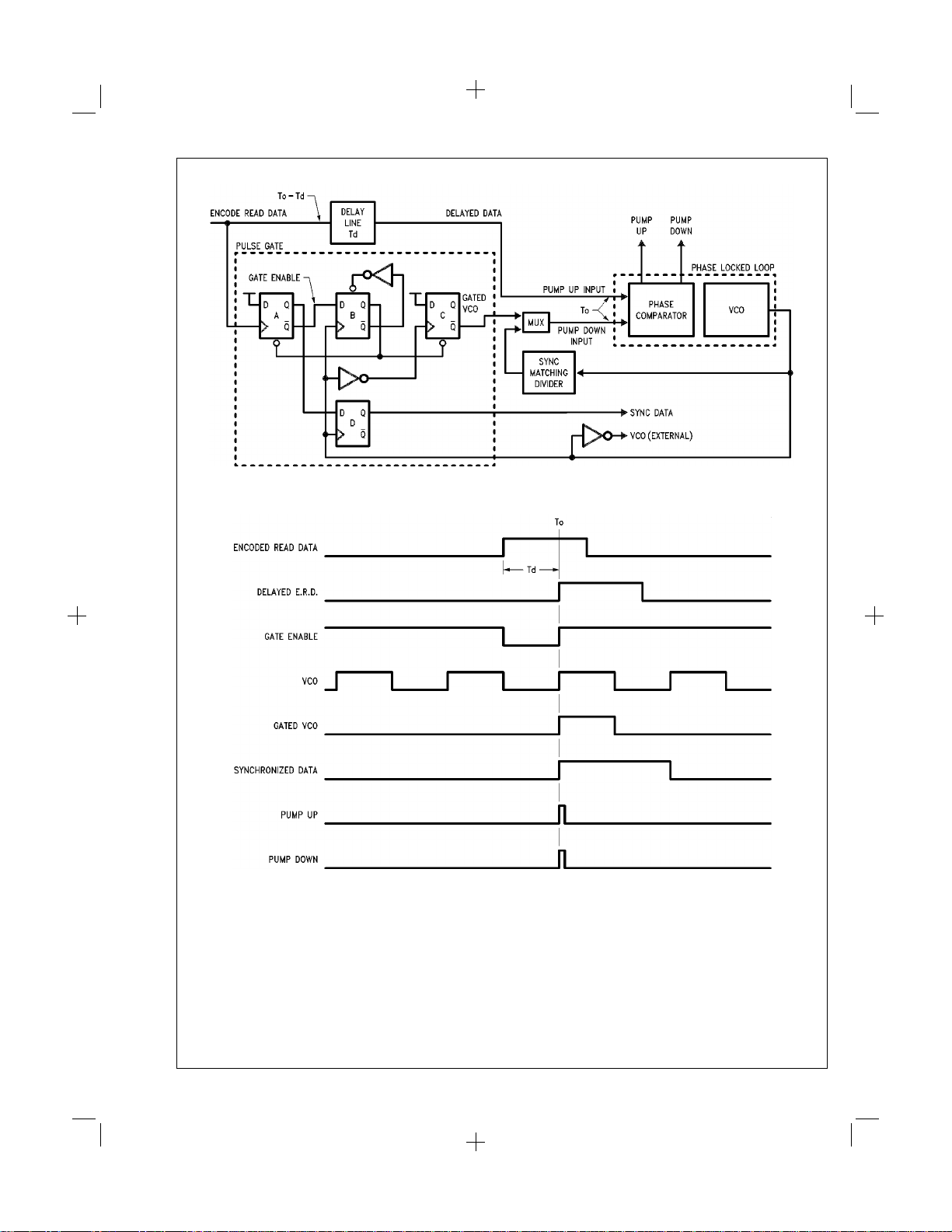

2.1 Functional Block Description

PULSE GATE

The function of the Pulse Gate within the DP8459 is twofold.

First, the block contains the ECL flip-flop which captures each

arriving ENCODED READ DATAbit and transmits the bit to the

SYNCHRONIZED DATA output. The very high switching

speed of the bit-capture ECL flip-flop minimizes the portion of

window margin loss caused by flip-flop metastability at window

boundaries. Second, the Pulse Gate regulates the

transmission of the VCO waveform into the Phase

Comparator, allowing only one VCO pulse to pass with each

arriving ENCODED READ DATA pulse. See

Figure 6

for a

simplified logical representation of the Pulse Gate block. The

one-to-one data/VCO pulse ratio produced by the Pulse Gate

permits the multiple-harmonic nature of encoded data to be

accommodated by the phase/frequency comparator. During

the non-Read mode or during the portion of the Read mode

within which the Customer has set the FREQUENCY LOCK

CONTROL pin to a logical-zero (low), the Pulse Gate is

inactive (bypassed) and the VCO frequency is divided as

appropriate to match the incoming frequency source

(ENCODED READ DATAor the REFERENCE CLOCK input).

be operated in this mode for purposes other than internal gate

exercising. Further information regarding application of the

Test Mode will be furnished at the Customer’s request: contact

National Semiconductor Logic Marketing Group or Logic

Applications Group.

http:\\www.national.com 9

PrintDate=1996/07/31 PrintTime=11:05:48 ds009322 Rev. No. 1 Proof 9

Page 10

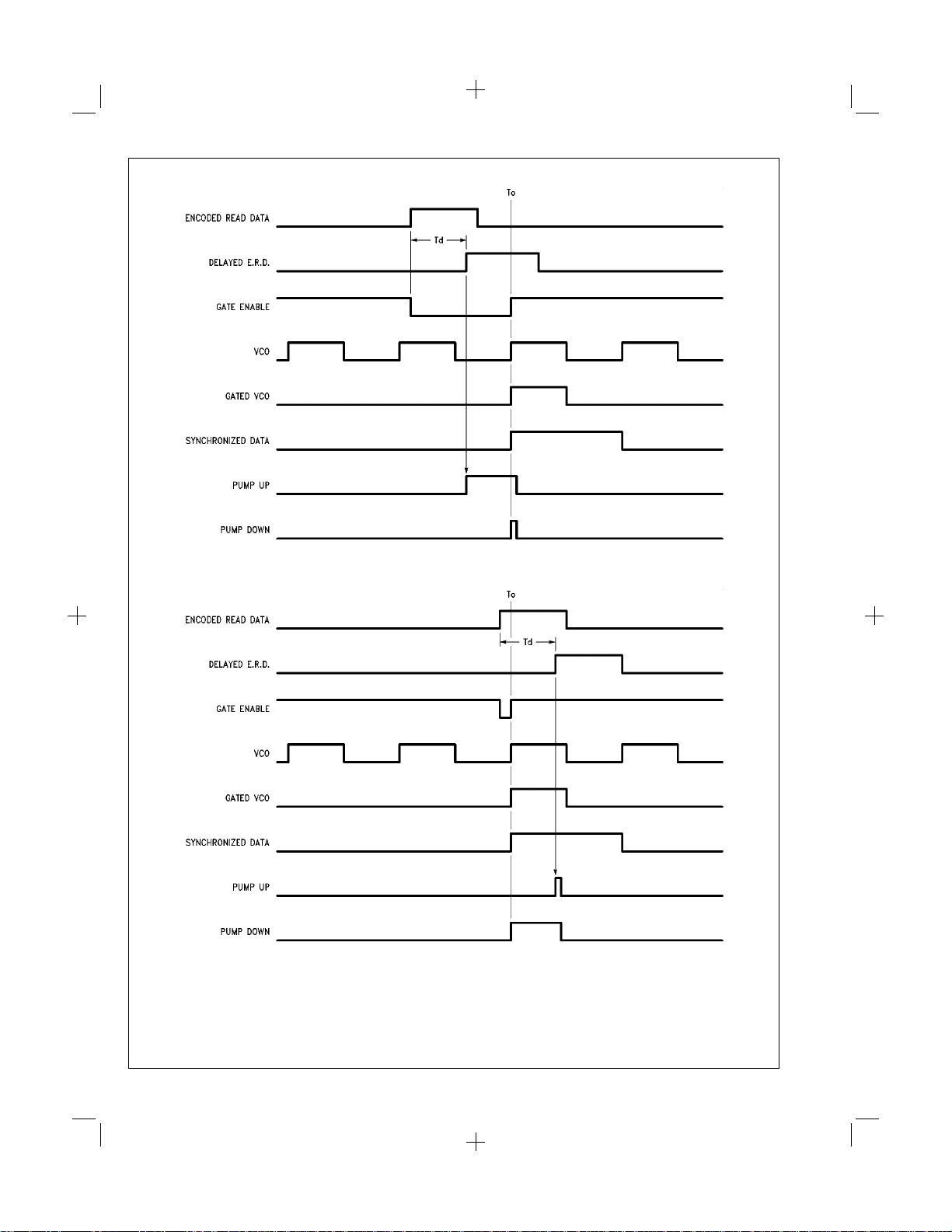

FIGURE 6. Simplified Diagram of Window Generation Circuitry

FIGURE 7. Capture of Nominally Positioned ENCODED READ DATA Pulse

TL/F/9322-11

TL/F/9322-12

10 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:05:49 ds009322 Rev. No. 1 Proof 10

Page 11

FIGURE 8. Capture of Early-Shifted ENCODED READ DATA Pulse

FIGURE 9. Capture of Late-Shifted ENCODED READ DATA Pulse

DELAY LINE

The DP8459 employs an internal silicon delay line to establish

synchronization window alignment. The delay is nominally

equivalent to one half of the period of the REFERENCE

CLOCK waveform, and is variable in fine increments via the

TL/F/9322-13

TL/F/9322-14

Control Register in order to achieve the window strobe

function. The Timing Extractor circuitry derives realtive timing

information soley from the REFERENCE CLOCK signal and

regulates the magnitude of the delay within the Delay Line.

http:\\www.national.com 11

PrintDate=1996/07/31 PrintTime=11:05:49 ds009322 Rev. No. 1 Proof 11

Page 12

The Delay Line thus remains insensitive to the external

components associated with the extractor as well as to supply

voltage, temperature, and IC process variations.

TIMING EXTRACTOR

This block extracts timing information from the REFERENCE

CLOCK input for use by the variable silicon delay line. External

passive components (tied to the Timing Extractor Filter pin) are

associated with this block, although the accuracy of the

circuit’s function remains independent of the general value and

tolerance of the components. The resistor-capacitor net is

employed by the Timing Extractor for stabilization

purposes—no monostable multivibrator (one-shot) circuitry is

employed by the DP8459. Note that the performance of the

delay line is directly dependent upon the accuracy of the

REFERENCE CLOCK input waveform. Either a crystal

reference generator or a stable servo clock source must be

applied to this input. Multiplexing of the REFERENCE CLOCK

waveform between read operations (within multiple data rate

systems) is acceptable, although sufficient Timing Extractor

stabilization time must be allowed following any perturbation at

this pin before a read operation may be performed (see

10

for timing table).

Figure

PHASE COMPARATOR

The DP8459 employs a digital Phase Comparator

(non-harmonic discriminator circuit) which has the capability of

forcing the frequency of the PLL VCO toward the frequency of

the reference input regardless of the magnitude of the

frequency difference. The function of the Phase Comparator

circuit can be represented in a diagrammatically simplified

form as in

Figure 11

.

The Phase Comparator’s action can be disabled at any time

(cleared) via the COAST input pin, allowing the VCO to

free-run.

CHARGE PUMP

The Charge pump is a high speed, switching, dual-gain,

bi-directional current source whose current flow is controlled

by the digital Phase Comparator circuit. The current pulses at

the CHARGE PUMP OUTPUT (CPO) pin thus reflect the

magnitude and sign of the phase error seen at the input of the

Phase Comparator. The CPO pin is connected externally to a

passive component network whose impedance translates the

aggregate current into a voltage for the VCO INPUT while

providing a low-pass filter function for the PLL. The matched

source and sink current generators’ operating currents are set

via the R

from V

CC

R

NOMINAL

into each of these pins is internally multiplied by 2 for Charge

and R

NOMINAL

through external resistors. The bias voltages at the

and R

BOOST

pins, which are supplied current

BOOST

pins are set to 0.75 x VCC; the current

Pump use. The CPO current is defined as follows:

=

I

CPO

/2)/R

(V

CC

NOM

HIGH GAIN DISABLE high (logical-one)

=

I

CPO

/2)/(R

(V

CC

NOM

||R

BOOST

)

HIGH GAIN DISABLE low (logical-zero)

RFC Frequency 1 4 10 20 40 MHz

CT1 0.82 0.2 0.082 0.056 0.027 µF

RT1 68 68 68 68 68 Ω

Settling Time 192 96 19.2 9.6 4.6 µs

Values may be interpolated for intermediate data rates. Timing Extractor settling times are given which indicate time required for the DP8459 to accommodate a

change of Strobe setting from nominal selection to either extreme (early/late), or vice versa, to within approximately 1%of final value.

FIGURE 10. TIMING EXTRACTOR FILTER Component Values for Various Data Rates

TL/F/9322-17

FIGURE 11. Simplified Digital Phase-Frequency Comparator

VOLTAGE CONTROL OSCILLATOR (VCO)

The DP8459 VCO is comprised of two portions—a self

contained, high frequency oscillator (no external components)

whose frequency is regulated by the voltage at the VCO

INPUT pin, and a programmable modulus digital divider. The

oscillator is only required to operate over approximately a 2:1

frequency range; the divider modulus is programmable in

factors of 2. The two blocks work in conjunction to achieve a

continuous range of equivalent VCO operating frequencies

from 500 kHz to 50 MHz. (See

Figure 12.

)

CONTROL REGISTER

Within the DP8459, the Control Register is a MICROWIRE

compatible, 6-bit shift register block with bits 0 through 4

employed to control the window strobe function and bit 5

employed to regulate the device test mode (see

Figures 13

and14). Information is serially shifted into the Control

Register via the CRD and CRC (negative edge clock) pins

whenever the CRE pin is active (logical-zero). When the CRE

pin is inactive (logical-one), CRD and CRC are ignored.

Figure 3

shows the truth table for the VCO range select

function;

Figure 4

shows the truth table for the window strobe

function.

12 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:05:51 ds009322 Rev. No. 1 Proof 12

Page 13

FIGURE 12.

FIGURE 13. Control Register

TL/F/9322-1

TL/F/9322-15

TL/F/9322-10

FIGURE 14. Microwire Compatible Control Register Serial Load Timing Diagram

SYNCHRONIZATION FIELD MATCHING DIVIDER

The Synchronization field Matching Divider is a programmable

modulus counter employed for implementation of the preamble

frequency lock function. It is placed in the VCO feedback path

to match the relative frequency of the VCO seen at the Phase

Comparator to the frequency of the ENCODED READ DATA

(preamble) during the read operation whenever the

FREQUENCY LOCK CONTROL input is active (logic-zero).

The modulus of the divider, M, is determined by the states of

the SYNC PATTERN SELECT 0 and 1 inputs, as defined by

the table in

Figure 15

.

Sync Pattern Sync Matching Expected

Code

Select Divider Modulus Preamble

10 M

0 0 1 GCR

0 1 2 MFM; 1,N

1 0 3 2,7

1 1 4 2,7

FIGURE 15. SYNC PATTERN SELECT Input Truth Table

Prior to the assertion of READ GATE, the divider is held in a

known count state and is enabled at the end of the zero phase

http:\\www.national.com 13

PrintDate=1996/07/31 PrintTime=11:05:52 ds009322 Rev. No. 1 Proof 13

Page 14

start sequence in correct phase relationship with the

ENCODED READ DATA. Re-assertion (logical zero) of the

FREQUENCY LOCK CONTROL pin within a read operation

(following the normal FLC deassertion after lock is achieved) is

permissible; however, it should be noted that the initial phase

error of the Synchronization Field Matching Divider with

respect to the ENCODED READ DATA at FREQUENCY-

LOCK CONTROL re-assertion may be as large as M x τ

in magnitude, possibly resulting in an extended PLL settling

VCO

time.

ZERO PHASE START

The function of the zero phase start (ZPS) block is to clear the

Phase Comparator and freeze the VCO in a known phase

when a transition occurs at the READ GATE input (either high

or low), and restart the VCO in a precise, controlled phase with

respect to the newly selected input (ENCODED READ DATA

or REFERENCE CLOCK

÷

2, respectively). The ZPS circuit

also resets the count state of the Synchronization field

Matching Divider in anticipation of locking to specific preamble

information (when frequency lock is being employed), and

controls the operation of the REFERENCE CLOCK

multiplexer. ZPS operation at READ GATE assertion is aimed

at optimizing initial window alignment and thus minimizing

initial phase step and the resulting phase lock acquisition time.

ZPS is also employed at deassertion of READ GATE;

however, the ZPS phase alignment for the REFERENCE

CLOCK signal at READ GATE deassertion has been made

less stringent than for ENCODED READ DATAat READ GATE

assertion.

PREAMBLE PATTERN DETECTOR

The Preamble Pattern Detector block has a pattern-specific

recognition circuit keyed to search the ENCODED READ

DATAfor the pattern selected at the SYNC PATTERNSELECT

inputs. The pattern search begins following the assertion of

READ GATE and the completion of the zero phase start

2.2 SPECIFICATION TABLES

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage 7V

TTL Inputs 7V

Output Voltages 7V

sequence, and continues until approximately 32 uninterrupted

ENCODED READ DATA pulses of the 1T, 2T or 3T pattern

have been detected, or until 16 uninterrupted ENCODED

READ DATApulses of the 4T pattern have been detected (see

specification tables). When this event occurs, the PREAMBLE

DETECTED output becomes active high (logical-one). The

output will then remain latched in the high state until READ

GATEis deasserted. The PREAMBLE DETECTED output may

be tied to the HIGH GAIN DISABLE input to regulate the gain

of the PLL during the preamble lock sequence, and/or tied to

the FREQUENCY LOCK CONTROL input for self-regulation

of frequency acquisition in hard or pseudo-hard sectored

systems.

±

50%VCO FREQUENCY OFFSET DETECTOR

The Frequency Offset Detector is employed to constrain the

VCO frequency swing, preventing VCO runaway associated

with standard, wide-range voltage controlled oscillators. The

circuitry will sense the relative difference between the

REFERENCE CLOCK frequency and the VCO frequency,

sending a “charge-up” signal to the Charge Pump to correct

the VCO should a limit of approximately −50%in frequency

differential (VCO w.r.t. REF CLOCK) be exceeded, and

sending a “charge-down” signal to the Charge Pump to correct

the VCO should a limit of approximately +50%in frequency

differential be exceeded.The resulting voltage-clampingaction

at the filter node(s) also prevents out-of-range control voltage

straying and thus speeds lock recovery.

SYNCHRONIZATION CLOCK OUTPUT MULTIPLEXER

This block issues the VCO signal following READ GATE

assertion and completion of the zero phase start sequence,

and issues the REFERENCE CLOCK input signal when the

READ GATE is deasserted. Multiplexer switching is achieved

without glitches. The output is intended to be used both for

read and write clock purposes. (Please note output loading

recommendations for this pin in Section 6.)

Input Current

(R

NOM,RBOOST

Storage Temperature −65

Operating Temperature Range 0

, CPO, VCOI, TEF) 2 mA

C to +150˚C

˚

Cto+70˚C

˚

ESD Susceptibility ( Note 3 ) 1500V

Operating Conditions

Symbol Parameter Conditions Min Typ Max Units

V

CC

T

A

I

OH

I

OL

V

IH

V

IL

f

NRZ

PrintDate=1996/07/31 PrintTime=11:05:54 ds009322 Rev. No. 1 Proof 14

Supply Voltage 4.75 5.00 5.25 V

Ambient Temperature 0 25 70

˚

High Logic Level Output Current SYNC CLOCK −2000 µA

Others −400

Low Logic Level Output Current SYNC CLOCK 20 mA

( Note 1 ) Others 8

High Logic Level Input Voltage 2 V

Low Logic Level Input Voltage 0.8 V

Operating Data Rate Range 0.25 25 Mb/s

14 http:\\www.national.com

C

Page 15

Operating Conditions (Continued)

Symbol Parameter Conditions Min Typ Max Units

t

PW-RFC

t

PW-ERD

Width of REFERENCE CLOCK, High or

8ns

Low

Width of ENCODED READ DATA 12 High ns

18 Low

t

PW-CRE

Width of CONTROL REGISTER ENABLE, 40 ns

High or Low ( Note 2 )

t

SU-CRD

CONTROL REGISTER DATA Set-Up Time 20 ns

with Respect to CRC ( Note 2 )

t

H-CRD

CONTROL REGISTER DATA Hold Time 10 ns

with Respect to CRC ( Note 2 )

t

H-CRE

t

SU-CRE

CONTROL REGISTER ENABLE Set-Up

20 ns

Time with Respect to CRC ( Note 2 )

CONTROL REGISTER ENABLE Hold Time 20 ns

with Respect to CRC ( Note 2 )

t

PW-CRC

I

CPIN

Note 1: PUMP UP and PUMP DOWN outputs have no current sinking capability and thus are excluded from this specification.

Note 2: Parameter guaranteed by correlation to characterization data. No outgoing test performed.

Note 3: Human body model; 120 picofarads through 1.5 kΩ.

CONTROL REGISTER CLOCK Pulse

Width, Positive or Negative ( Note 2 )

Combined R

NOM&RBOOST

Input Current 1000 µA

40 ns

AC Electrical Characteristics

Over recommended VCCand operating temperature range.

Symbol Parameter Min Typ Max Units

t

STOP

t

RESTART

t

READ ABORT

t

T

φ Linearity Phase Range for Charge Pump Linearity

K

VCO

f

MAX VCO

t

SD0

t

SD1

t

ZPSR

t

PWPC

∆f

VCO/fRFC

SYNC CLOCK Negative Transitions following READ

23—

GATE until Data Lock ZPS Sequence Begins (VCO

Freezes)

Positive ENCODED READ DATA Transitions following 2 —

VCO Freeze until VCO Restarts

Number of REF CLOCK Cycles following READ GATE

Deactivation until REF CLOCK Lock ZPS Sequence 4 —

Begins

Window Truncation (Half Window Loss);

DP8459V-10 10 Mbit/sec (Note 1 ) 3%x τ

DP8459V-25 20 Mbit/sec (Note 2 ) 4%x τ

±

VCO

VCO

π Radians

3.0 ns

2.5 ns

(wrt VCO)

VCO Gain Constant 1.0 ω

VCO Maximum Frequency; RS0=RS1=RS2

=

70 MHz

1.2 ω

O

1.6 ωORad/Sec V

O

Logical ZERO

Time Skew between SYNC CLOCK Negative Edge

010ns

and SYNC DATA Negative Edge

Time Skew between SYNC CLOCK Negative Edge

010ns

and SYNC DATA Positive Edge

Zero Phase Start Trigger Bit Targeting Accuracy,

2ns

READ GATE Activation (READ) ( Note 4 )

Width of PCT, PU or PD Outputs in Fully Stabilized 10 ns

Lock (ERD Free of Jitter); R-Pull-Down=510Ω

Automatic f

Range Limiting 50

VCO

http:\\www.national.com 15

PrintDate=1996/07/31 PrintTime=11:05:55 ds009322 Rev. No. 1 Proof 15

Page 16

AC Electrical Characteristics (Continued)

Over recommended VCCand operating temperature range.

Symbol Parameter Min Typ Max Units

t

HOLD

t

PDT

L

PDT1

L

PDT2

L

PDT3

L

PDT4

t

S

t

RFC–SCK1

SYNC CLOCK Rest Period (Logical One) at Assertion

or De-Assertion of READ GATE

SCK Negative Edge to PREAMBLE DETECTED

Positive Edge at End of Detection Sequence

Length of Valid 1T Preamble Pattern Required for

Occurrence of PREAMBLE DETECTED

Length of Valid 2T Preamble Pattern Required for

Occurrence of PREAMBLE DETECTED

Length of Valid 3T Preamble Pattern Required for

Occurrence of PREAMBLE DETECTED

Length of Valid 4T Preamble Pattern Required for

Occurrence of PREAMBLE DETECTED

Window Strobe Time Step (M=Hex Value of Bits 0–3

in CONTROL REGISTER; Bit 4=Sign Bit)

Positive Transition Propagation Delay from

REF CLOCK INPUT to SYNC CLOCK OUTPUT, 15 ns

READ GATE Low

t

RFC–SCK0

Negative Transition Propagation Delay from

REF CLOCK INPUT to SYNC CLOCK OUTPUT, 15 ns

READ GATE Low

Note 1: The DP8459V-10 static window specification, tT, applies only to the factory-tested 2,7-code data rate of 10 Mb/s (with RS0,1,2=010) and with the

component values as listed in Figures 5 and 10, test configuration as shown in Figure 23, test procedure as shown in Figure 24, and strobe word M=−2. Significant

variation in t

Note 2: The DP8459V-25 static window specification, t

of 20 Mb/s (with RS0, 1, 2,=000), with the component values as listed in Figures 5 and 10, test configuration as shown in Figure 23, test procedure as shown in

Figure 24, and strobe word M=−3. Significant variation in t

Note 3: I

Note 4: t

completion of a ZPS operation following READ GATE assertion.

as a percentage of the VCO period due to the use of other filters and data rates is not expected.

T

=

/(4xRIN). R

V

IN

CC

(ZPS Read) gauges the accuracy with which the ZPS circuitry aligns the VCO to the triggering ERD bit internally (i.e., initial phase step) at the

ZPSR

IN

=

R

NOM

(HGD High) or R

, incorporates the DP8459V-10 window specification and, in addition, the factory-tested 2,7-code data rate

T

as a percentage of the VCO period due to the use of other filters and data rates is not expected.

T

||R

BOOST

(HGD Low).

NOM

1

⁄

2

3T

VCO

25 ns

33 34 35

ERD

Pulses

32 33 34 ERD

Pulses

31 32 33 ERD

Pulses

15 16 17 ERD

Pulses

M x (1.8%)

xt

RFC

ns

DC Electrical Characteristics Over recommended operating temperature range.

Symbol Parameter Conditions Min Typ Max Units

=

V

IC

V

OH

V

OL

I

IH

I

IL

I

O

I

CPO

I

CPO-OFF

I

VCOI

V

RNOM

V

RBST

I

CC1

Note 1: This value has been chosen to produce a current that closely approximates one-half of the true short-circuit output current, IOS.

Note 2: I

Note 3: I

any given range selection. I

Most of the increase occurs as the −15 step is approached. I

Note 4: PUMP UP and PUMP DOWN outputs have no current sinking capability and thus are excluded from this specification.

Input Clamp Voltage V

High Level Output Voltage V

Low Level Output Voltage ( Note 4 ) V

High Level Input Current V

Low Level Input Current V

Output Drive Current ( Note 1 ) V

CC

CC

CC

CC

CC

CC

Charge Pump Output Current (K1) 100 ≤ IRp≤ 1000 (Note 2 ) 1.7 I

Charge Pump Output Inactive Current 100 ≤ IRp≤ 1000 (Note 2 ) −0.85 +0.85 µA

VCOI Offset Current VCOI Voltage 1.5V −0.25 +0.25 µA

Voltage across R-NOM Resistor 1.2 kΩ≤R-NOM ≤ 12 kΩ Typ.

Voltage across R-BOOST Resistor 1.2 kΩ≤R-BOOST ≤ 12

kΩ

Supply Current, Nominal Strobe V

=

I

Rp

NOM+IBOOST

is measured with the window strobe set at nominal timing (Strobe Bits 0 through 5=0,0,0,0,0,0); VCO operating at maximum allowed frequency within

CC1

.

typically increases by 30 mA when the strobe is set at the maximum early position (M=−15). This is not a linear increase per step.

CC

CC

decreases as the window is moved late.

CC

=

Min, I

−18 mA −1.5 V

I

=

=

=

=

=

=

Min, I

Min, I

Max, V

Max, V

Max, V

=

Max V

OH

=

Max 0.5 V

OL

=

2.7V 20 µA

I

=

0.4V −200 µA

I

=

2.125V −12 −110 mA

O

−2V VCC−1.6V V

CC

−18

Typ.

−18

2.0 I

Rp

0.26 V

%

0.26 V

%

2.5 I

Rp

CC

CC

Typ.

+18

Typ.

+18

Rp

%

%

Max (Note 3 ) 190 mA

16 http:\\www.national.com

µA

V

V

PrintDate=1996/07/31 PrintTime=11:05:57 ds009322 Rev. No. 1 Proof 16

Page 17

External Component Selection

Symbol Parameter Min Typ Max Units

R

NOM

R

BOOST

C

NOM

C

BOOST

R

PU

R

PD

Note 1: The minimum allowed value for the parallel combination of R

Note 2: C

NOM

Charge Pump Nominal Operating 1.2 12 kΩ

Current Setting Resistor ( Note 1 )

Charge Pump Boost Current 1.2

∞

Setting Resistor ( Note 1 )

R

Bypass Capacitor (Note 2 ) 0.01 µF

NOM

R

Bypass Capacitor (Note 2 ) 0.01 µF

BOOST

PUMP UP Open Emitter Output 510 Ω

Pull-Down Resistor

PUMP DOWN Open Emitter Output 510 Ω

Pull-Down Resistor

and C

should be high quality, high frequency type.

BOOST

NOM

and R

BOOST

is 1.2 kΩ.

kΩ

3.0 PLL Applications: Loop Filter Design

In order to maintain greatest design flexibility for the Customer,

all PLL filter components and Charge Pump gain setting

elements reside external to the DP8459. All PLL dynamics are

thus under the control of the system designer. The following is

a brief analysis of the DP8459 PLL; Section 3.1 contains a

derivation of component values based on projected

requirements within an example hard disk drive system.

Figure 16

represents the DP8459 PLL in simplified form.

FIGURE 16. Basic DP8459 Phase Locked Loop Block Diagram

N is defined as the number VCO cycles per recorded

ENCODED READ DATA pulse, or conversely, the ratio of the

VCO frequency to the ENCODED READ DATAfrequency.The

aggregate block gain equation (excluding the loop filter) can be

written as:

=

1.2 V

K

B

CCfO

/(2RpN)

The impedance of the loop filter is

Mathematical gain representations for each block are:

=

K

1/N Pulse Gate equivalent gain

PG

=

1/(2π) Phase Comparator gain

K

PC

=

/2RpCharge Pump gain where R

V

K

CP

CC

HGD high; R

=

K

VCO

frequency)

<<

If C

C1, the impedance Z(s) approximates to

2

p

1.2 ω

=

R

NOM

O

||R

, HGD low

BOOST

VCO gain (ω

O

p

=

operating center

TL/F/9322-18

The overall open loop gain (including the filter) is then

=

,

R

NOM

Substituting KBinto the equation,

The open loop system response G(s) is given by

This last equation reveals the PLL with this filter configuration

is a third order system, which is typically difficult to analyze.

However,if C

third order loop closely resembles that of a second order

<<

C1, it can be argued that the behavior of the

2

=

τ

R

1

pC1

which govern the system response. The closed loop gain H(s)

is

and τ

=

are the pole and zero, respectively,

R

2

1C1

system, allowing for a greatly simplified analysis.

http:\\www.national.com 17

PrintDate=1996/07/31 PrintTime=11:06:00 ds009322 Rev. No. 1 Proof 17

Page 18

Substituting,

The second order characteristic equation can be written as

follows:

2

s

+sKBR1+KB/C

=

1

2

+s2ζωn+ ω

s

2

n

Extracting the component values from these results,

Thus, one is able to select component values in accordance

with specific system requirements, i.e., with given VCO center

frequency (equivalent to REFERENCE CLOCK frequency), R

(in either high or low gain mode), N (the ratio of the VCO

frequency to the ENCODED READ DATA frequency), the

desired natural frequency of the loop, and the desired damping

ratio.

The natural frequency and the damping ratio may be extracted

from the component values to determine system behavior

under various conditions (differing data patterns, i.e., varying N

value; high gain or low gain; read or non-read mode):

=

ω

[1.2 V

n

CCfo

/2RpNC1)]

0.5

Natural frequency Damping ratio

nR1C1

/2

ζ=ω

3.1 2,7 CODE, 10 MBIT/SEC LOOP FILTERDESIGN

EXAMPLE

Initial Requirements and Definitions

This example illustrates a 10 MBit/sec 2,7 hard disk system

employing a 4T preamble field (recorded at

1

frequency, i.e., N=4). The component derivations are not

meant to produce values which will be optimum for all systems

employing this data rate, code, and preamble type; this

exercise is for exemplary purposes only. (See National

Semiconductor Advanced Peripheral Processing Solutions

Mass Storage Handbook

#

1, 1986,AN-413, section 3.4, pages

1-43 through 1-48 for additional information regarding disk

system PLL filter design.)

Although the DP8459 provides a frequency acquisition feature

intended for use within the preamble, this design example will

be approached so as to achieve PLL dynamics which will avoid

the cycle-slipping phenomenon frequency-lock action is

normally employed to accommodate. Thus, the design will be

valid both for systems which do employ frequency lock as well

as for those which do not. Advantages gained by the use of

frequency-lock beyond that of extended lock-in range,

however, such as harmonic false lock avoidance and

quadrature lock avoidance, make the use of this feature

p

strongly advisable even with the intrinsic lock-in range

achieved by design in this example.

The DP8459 is configured here with the FREQ LOCK CONTROL input tied to the PREAMBLE DETECTED output, the

HIGH GAIN DISABLE input tied to the READ GATE input, and

the CHARGE PUMP OUTPUT tied to the VCO INPUT pin as

well as to the external loop filter components (see

This establishes self-regulated frequency lock control, READ

GATE regulated Charge Pump gain, and single node loop

filtering.

⁄4the VCO

Figure 17

).

18 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:06:01 ds009322 Rev. No. 1 Proof 18

Page 19

FIGURE 17. DP8459 in a Typical System Configuration

System constraints:

f

f

f

Code type

N

N

N

=

NRZ DATA

VCO

REFERENCE CLOCK

min

max

preamble

10 Mbit/sec

=

20 MHz

=

3 (highest recorded frequency)

=

8 (lowest recorded frequency)

=

=

4(f

1

⁄2(2, 7)

preamble

=

20 MHz

=

5 MHz)

Preamble Length=11 NRZ bytes (ESDI min.)=8.8 µs

(44 recorded pulses)

Disk formatting=pseudo hard sectored

The DP8459 provides a zero phase start function which

minimizes the initial phase step encountered at the start of

preamble lock acquisition and thus the phase stabilization time

within the preamble is significantly reduced with respect to a

fully random-phase lock sequence. However, the PLL will

encounter a finite frequency step at the start of preamble

acquisition due to variations in disk rotational velocity which

may be as large as

±

1%(more pronounced in exchangable

media systems). The lock-in range of the PLL at the time of

preamble acquisition must then be at least

Given that the PLL lock sequence involves only an adjustment

±

0.01 x f

preamble

.

to a frequency step, the following requirements will be set for

final PLL dynamics within the filter design procedure:

http:\\www.national.com 19

TL/F/9322-19

1. Residual phase error θ

NRZ bytes allowed for PLL stabilization) will be 2 ns or less

at the end of the preamble (a full 11

e

(4%of the total synchronization window).

2. The lock-in range ∆ω

expected frequency step range.

3. The minimum 3 dB bandwidth ω

be twice the expected maximum mechanical vibration

must be at least 1.5 times the

L

in the data field must

−3 dB

frequency (10 kHz).

4. The natural frequency of the loop ω

will be minimized in the data field in order to achieve a high

and damping ratio ζ

n

level of jitter rejection. (Minimum damping ratio ζ will be 0.5

(phase margin of 52

) for adequate stability).

˚

5. Re-lock time to the REFERENCE CLOCK will be

minimized.

First, some definitions will be established. Regarding

requirement

frequency step are

(t)=[ ∆ω/ωn] [1/(1–ζ2)

θ

e

(t)=[∆ω/ωn] [1/(ζ2−1)

θ

e

These equations are plotted in

phase error due to a phase step are

#

1, the equations for phase error due to a

1

:

0.5

sin(1−ζ2)

0.5

ωnt]exp(−ζωnt) for ζ

1;

(t)=[ ∆ω/ωn][ωnt]exp(−ωnt) for ζ=1;

θ

−[ζ/(1−ζ

e

2)0.5

0.5

sinh (ζ2−1)

>

for ζ

Figure 18

(t)=∆θ{ cos (1−ζ2)

θ

e

] sin (1−ζ2)

0.5 ω

1.

1

:

0.5

nt} exp(−ζωnt) for ζ<1;

0.5

ωnt] x exp(−ζωnt)

. The equations for

ωnt

<

PrintDate=1996/07/31 PrintTime=11:06:03 ds009322 Rev. No. 1 Proof 19

Page 20

θe(t)=∆θ[1−ωnt]exp(−ωnt) for ζ=1;

(t)=∆θ {cosh(ζ2−1)

θ

e

2

[ζ/(ζ

−1)

0.5

]sinh(ζ2−1)

0.5

ωnt}exp(−ζωnt) for ζ>1.

0.5

ωnt−

(These equations are plotted in

informational purposes only; an ideal zero phase start function

would not produce a phase step at lock initiation.)

FIGURE 18. Transient Phase-Error Versus the Dimensionless Parameter ω

Loop Damping Factors, ζ (from Ref. 4 by Permission of L. A. Hoffman)

Figure 19

t Due to a Step in Frequency for Various

n

and are supplied for

TL/F/9322-20

TL/F/9322-21

FIGURE 19. Phase-Error Versus the Dimensionless Parameter ω

Factors, ζ (from Ref. 4 by Permission of L. A. Hoffman)

Note that the phase error θ

divided (or gated) VCO phase, i.e., 2π radians=N/(20 MHz)

is measured with respect to the

e

=

200 ns in this example.

t Due to a Step inPhase for Various Loop Damping

n

Regarding requirement

#

2, the lock-in range (with no

cycle-slipping) can be shown to be equal to the open loop

transfer function multiplied by the loop filter impedance

evaluated at infinite frequency

20 http:\\www.national.com

∆ω

2

:

≈

±

KBZf(s)|

→

L

∞

s

PrintDate=1996/07/31 PrintTime=11:06:04 ds009322 Rev. No. 1 Proof 20

Page 21

The 3 dB bandwidth for requirement#3 is defined by the

3

equation

:

ω

−3 dB

=

[2ζ2+ 1 +{(2ζ2+1)2+1}

ω

n

0.5]0.5

Requirement#4 has been established in order to maximize the

available window margin via PLL dynamics. Conceptually,

window margin is preserved if the loop phase response to

individually displaced bits (jitter) is not allowed to cause

subsequent windows to be readily shifted from the “average”

position. Any window movement from nominal position can

readily degrade the window margin. It can be seen from

19

that systems employing low values of damping ratio exhibit

Figure

a reduced instantaneous response to phase step and thus

display improved jitter rejection with respect to higher damping

ratio systems. Damping ratio, fortunately, is easily regulated by

loop filter design. It also follows that a low natural frequency

and its associated “slower” instantaneous phase response will

assist in achieving the goal of jitter rejection. However, the

minimum natural frequency limit for the PLL may actually be

imposed on the system by the θ

the ∆ω

requirement, or the ω

L

these produces the highest minimum ω

necessity, dominate in the design. The goal of minimizing the

(t) settling time requirement,

e

requirement. Whichever of

−3 dB

value must, by

n

natural frequency in order to maximize jitter rejection,

therefore, may have to defer to one of these other three

criteria.

Requirement

#

5 is addressed in three ways: 1) the DP8459

itself engages the frequency discriminating action of the Phase

Comparator whenever the READ GATEis deasserted and the

PLL locks to the REFERENCE CLOCK signal, thus

guaranteeing re-lock regardless of the initial frequency step; 2)

tying the HIGH GAIN DISABLE pin to the READ GATE input

places the Charge Pump in the high gain mode whenever the

PLL is locked to the REFERENCE CLOCK, producing an

elevated natural frequency and a more rapid locking action; 3)

N=2 whenever the READ GATE is deasserted, which, in this

example, effectively increases the loop gain by another factor

of 2 with respect to the gain within the preamble, where N=4.

Determining PLL Response Characteristics

It is expected that the minimum value of ω

by the residual phase error requirement of

lock-in range requirement of

#

3. This assumption will be checked at the end of the analysis.

#

2ortheω

will be determined

n

#

1 rather than the

requirement of

−3 dB

System requirements then are as follows:

1. θ

(t) ≤ (2 ns) x (2π rad/ 200 ns)=0.063 radians,

e

where t=preamble length 8.8 µs

≈

±

2. ∆ω

3. ω

L

−3 dB

KBZf(s)|

=

ω

n

≥ 0.015x5MHzx2π=471 Krad/sec

→

∞

s

[2ζ2+1+{(2ζ2+1)2+1}

0.5]0.5

≥ 2x10kHzx2π=126 Kr/s

#

Requirement

1 calls for θe(8.8 µs) ≤ 0.063 radians. Damping

ratio ζ varies as the inverse square root of N (see the equation

for Damping Ratio in Section 3.0) such that ζ

√

(N

MAX/NPREAMBLE

appropriate equation for θe(t) for various values of ωnwith ζ

)xζ

=

√

2 x 0.5=0.707. Solving the

MIN

PREAMBLE

0.707, t=8.8 µs and an expected frequency step of 0.01 x 5

MHzx2π=314 Kr/s:

ω

n

θe(8.8 µs) |te|

200 Kr/s 0.606 rad 19.29 ns

300 Kr/s 0.219 rad 6.97 ns

400 Kr/s 0.056 rad 1.78 ns

500 Kr/s 0.0012 rad 0.038 ns

600 Kr/s −0.0098 rad 0.312 ns

ω

n

θe(8.8 µs) |te|

700 Kr/s −0.008 rad 0.026 ns

400 Kr/s

=

0.056 radian

(8.8µs)|

θ

e

=

t

0.056 radian x 200 ns/2π radian=1.78 ns

e

<

0.063 radian

Thus 400 Kr/s is chosen as the desired natural frequency

within the preamble to satisfy requirement

If the assumption that θ

frequency requirement is correct, then the ∆ω

#

2 and the ω

obtained above. First, examining requirement#2,

−3 dB

Z

(t) dominates the minimum natural

e

requirement of#3 should be met by the ω

=

f

(s)|

R

→

∞

s

1(C2

#

neglected).

1.

requirement of

L

Thus,

=

K

∆ω

L

BR1

Rearranging for R1:

=

R

∆ω

1

L/KB

The equation for R1previously derived shows

=

R

2ζω

1

n/KB

Thus,

=

∆ω

=

In this case, ω

∆ω

L

Thus, requirement

400 Kr/s and ζ=0.707 (preamble), thus

n

=

400Kr/sx2x0.707=566 Kr/s

#

2 is met.

Examining requirement

when N equals its maximum value of 8 (minimum frequency

2ζω

L/KB

=

∆ω

2 ζωn

L

#

3, where ω

n/KB

>

≥ 2x10kHzx2π

−3 dB

471 Kr/s

data pattern; ζ=0.5):

ω

(min)=ωn(preamble) x 1/√(N

n

=

400 Kr/s x 1/

=

ω

ω

−3 dB

n(min)

=

283 Kr/s x 1.817=514 Kr/s

514 Kr/s

Thus requirements

the minimum ω

#

established by#1.

n

Regarding requirement

[2ζ2+1+{(2ζ2+1)2+1}

÷

2π=82 kHz>2x10kHz

1 through#3 are met, and#4 defers to

#

5, the DP8459 has been configured

MAX/NPREAMBLE

√

2=283 Kr/s

externally in this example such that when the READ GATE is

deasserted, the loop gain will be increased by a factor of 2 due

to the Charge Pump gain switching (R

tied to RG) and by an additional factor of 2 due to the decrease

NOM

=

R

in N from 4 (preamble) to a fixed internal value of 2. The

resulting factor of 4 effective gain elevation results in an

increase in both the natural frequency, ω

ratio, ζ,by

√

4=2. Thus, when READ GATE is deasserted,

=

ω

2 x 400 Kr/s=800 Krad/s

n

, and the damping

n

ζ=2 x 0.707=1.414

=

=

2ζω

∆ω

L

=

COMPONENT CALCULATIONS

The formulae for the filter components, derived previously, are

=

2 x 1.414 x 800 Krad/s=2.3 Mr/s

n

A 2:1 ratio of high-to-low Charge Pump gain was chosen for

the derivation of R

ratio, R

must be equal to R

NOM

NOM

and R

. To achieve the 2:1 gain

BOOST

while the parallel

BOOST

0.5]0.5

BOOST

<

2ns

n

)

; HGD

http:\\www.national.com 21

PrintDate=1996/07/31 PrintTime=11:06:07 ds009322 Rev. No. 1 Proof 21

Page 22

combination R

1.2 kΩ as per specification. Note that in the equation for C

NOM

||R

must be equal to or greater than

BOOST

above, the capacitor value is inversely proportional to Rp.

R

can now be calculated:

1

1

Thus, external field interference immunity can be achieved if

C

is maximized through the minimizing of Rp. The selection of

1

=

R

NOM

Charge Pump resistors and the gain ratio. R

R

with READ GATE high, and thus

NOM

=

C

[1.2x5x20MHz/(2 x 2.4k x 4)]/(400 Kr/s)

1

=

0.039 µF

R

=

2.4 kΩ satisfies the requirements for the

BOOST

will be equal to

p

2

A standard value of 100Ω is chosen. Since C2≤ 0.1xC1,C

will be chosen to be 510 pF. A table listing the dynamics of the

PLL under standard operation conditions and with component

values adjusted to industry standards is shown in

Figure 20

Field Preamble Min Freq Data Max Freq Data Ref Clock

N4 8 3 2

CP Gain Low Low Low High

Natural

Freq. 400 Krad/s 283 Krad/s 462 Krad/s 800 Krad/s

ω

n

Damping

Ratio 0.7 0.5 0.8 1.4

ζ

FIGURE 20. 2,7 Code, 10 Mbits/Sec Design Example PLL Dynamics

4.0 Window Margin and Bit Jitter Tolerance

A key performance specification for the DP8459 involves the

integrity of the synchronization window. The synchronization

window is defined as a continuously repeating time cell,

nominally equal in span to the period of the VCO, within which

an ENCODED READ DATA pulse will be recognized

(captured) regardless of its position within the window (see

Figure 21

). The captured ERD bit is then transmitted to the

SYNCHRONIZED DATA output on the next occurring SYNC

CLOCK negative edge. The SYNCHRONIZED DATA and the

SYNC CLOCK are held in a fixed, specified timing relationship

for use by the data controller in deserialization and decoding.

position) is centered about the mean location of the ERD

pulses via the delay line and the time-averaging action of the

PLL. National Semiconductor specifies the static window

truncation (t

maximum expected loss of the synchronization window seen

) of the DP8459 data synchronizer as the

T

adjacent to the ideal window boundary following complete PLL

stabilization with the strobe control setting at the M=−2

position (see

Figure 22

). Static lock conditions are defined as

having been achieved when the PLL has been allowed to

establish fully stabilized lock to a consistent preamble-type

pattern of nominally positioned, non-shifted ERD pulses.

The synchronization window (with strobe setting at nominal

2

.

TL/F/9322-22

FIGURE 21. Synchronization Window

22 http:\\www.national.com

PrintDate=1996/07/31 PrintTime=11:06:08 ds009322 Rev. No. 1 Proof 22

Page 23

FIGURE 22. Window Specification Diagram

4.1 SYNCHRONIZATION WINDOW GENERATION

The DP8459 employs a pulse gate-delay line scheme in the

generation of the synchronization window.

Figure 6

shows a

simplified block diagram of the pulse gate and delay line

circuitry coupled with the phase locked loop. All elements

except the delay line are assumed to be delayless for

simplicity of analysis. The pulse gate allows a single VCO

edge to be transmitted to the pump down input of the phase

comparator for each arriving ENCODED READ DATA pulse,

while the delay line allows the ENCODED READ DATA pulse

to open (enable) the pulse gate at a predetermined time (t

prior to the arrival of the ERD pulse at the pump up input of the

phase comparator.

Figures 7, 8

and9show waveform

diagrams of the capture of nominal, early and late ERD pulses,

respectively. In normal operation where stable lock has been

achieved, the time-integrating action of the PLL has

established time alignment between the waveforms at the

phase comparator inputs, i.e., both events occur at t

,on

o

average. If t

ERD pulse will open the pulse gate at t

the midpoint between VCO edges. ERD pulses are then free to

is set equal to 0.5 x τ

d

, the nominal or average

VCO

− 0.5 x τ

o

VCO

shift to any position (ideally) between VCO edges, that is, they

have an allowed displacement of

while yet opening the pulse gate for the passing of the

±

0.5 τ

from the mean,

VCO

appropriate VCO edge to the phase comparator and at the

same time being properly captured by the data synchronization latch (flip-flop D,

referred to as the synchronization (capture) window.

Any variation in the value of the time delay t

)

d

at which the pulse gate is enabled (t

VCO waveform midpoint, and thus produces a corresponding

Figure 6

). The±0.5 τ

causes the time

d

) to shift away from the

o–td

VCO

shift in the position of the synchronization (capture) window.

This action, when done in a controlled fashion, is known as

window strobing and is useful for purposes of window skew

compensation, determination of system window margin, and

recovery routines for non-readable data (see Section 4.3).

TL/F/9322-23

, precisely

region is

http:\\www.national.com 23

PrintDate=1996/07/31 PrintTime=11:06:09 ds009322 Rev. No. 1 Proof 23

Page 24

Notes: SD and SCK outputs are buffered by Advanced Schottky gates to provide standardized, typical loading conditions.

CRC, CRD, CRE, RG, and ERD are driven by a pattern generator providing the appropriate sequences both to load the control register with the appropriate

strobe position information and to cycle the RG and ERD test routine as per

Figure 24

.

TL/F/9322-24

FIGURE 23. DP8459 Window Measurement Configuration

4.2 WINDOW TRUNCATION TESTING

The DP8459 static window truncation specification is an

aggregate figure within which the window margin loss

contributions from all relevant blocks in the data synchronization chain are combined into the single parameter, t

.

T

The preliminary DP8459 static window specification, t

applies only to the factory-tested data rates of 10 Mb/s

(with RS0,1,2=010) and 20 Mb/s (with RS0,1,2=000), with

the component values as listed for each corresponding

data rate in

in

Figure 23,

Figures 5,

and

10,

test configuration as shown

test procedure as shown in

Figure 24,

strobe word M=−2 for 10 Mbits/sec and M=−3 for 20

Mbits/sec. Significant variation in t

other filters and data rates is not expected.

due to the use of

T

The test algorithm employed in the outgoing factory

measurement (screening) of t

DATA stream consisting of a long synchronization field with a

emulates an ENCODED READ

T

single, movable test bit at its end. This method is referred to as

static

window testing, since the window in which the test bit is

inserted is fully stabilized and unable to react instantaneously

to the phase step introduced by the displaced bit. The standard

screening procedure employed for determining DP8459 static

window truncation is divided into two portions, one which

determines the location of the leading (front) window boundary

and one which determines the trailing (back) window

center of the target window until it resides in a position where

it is able to be detected a large number of times consecutively,

guaranteeing VCO jitter immunity. The time displacement