Page 1

1/9

DMV1500M7

®

July 2002 - Ed: 1A

DAMPER + MODULATION DIODE FOR VIDEO

Symbol Parameter

Value

Unit

MODUL DAMPER

V

RRM

Repetitive peak reverse voltage

700 1500 V

I

FSM

Surge non repetitive forward current tp = 10 ms sinusoidal

50 75 A

T

stg

Storage temperature range

-40to+150 °C

T

j

Maximum operating junction temperature

150

ABSOLUTE RATINGS (limiting values, per diode)

Insulated TO-220AB

(Bending option F5 available)

■

700V Modulation diode

■ Fullkitinonepackage

■ High breakdown voltage capability

■ Very fast recovery diode

■

Specified turn on switching characteristics

■ Low static and peak forward voltage dropfor low

dissipation

■ Insulated version:

Insulated voltage = 2500 V

RMS

Capacitance = 7 pF

■

Planar technology allowing high quality and

best electrical characteristics

■

Outstanding performance of well proven DTV

as damper and new faster Turbo 700V

technology as modulation.

FEATURES AND BENEFITS

High voltage semiconductor especially designed

for horizontal deflection stageinstandardandhigh

resolution video display with E/W correction.

The insulated TO-220AB package includes both

theDAMPERdiodeandthe MODULATION diode.

Assembled on automated line, it offers excellent

insulating and dissipating characteristics, thanks

to the internal ceramic insulation layer.

DESCRIPTION

MODUL DAMPER

I

F(AV)

3A 6A

V

RRM

700 V 1500 V

t

rr

(max) 55 ns 135ns

V

F

(max) 1.55 V 1.65 V

MAIN PRODUCT CHARACTERISTICS

1

2

3

DAMPER MODULATION

123

Page 2

®

DMV1500M7

2/9

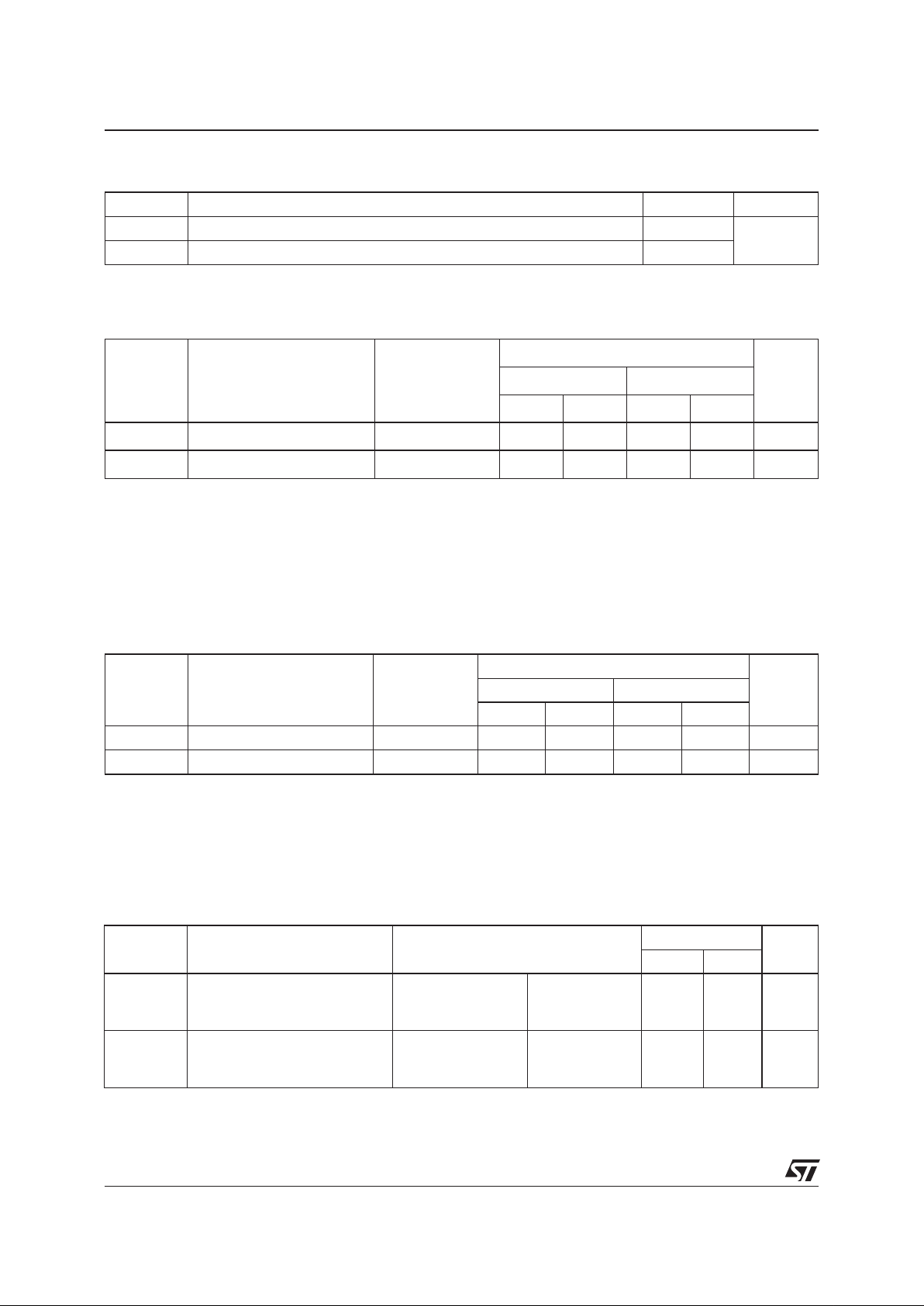

Symbol Parameter Value Unit

R

th(j-c)

Damper junction to case

4.8 °C/W

R

th(j-c)

Modulation junction to case

5.5

THERMAL RESISTANCES

Symbol Parameter Test conditions

Value

UnitTj = 25°C Tj = 125°C

Typ. Max. Typ. Max.

V

F

*

Forward voltage drop I

F

=6A

1.4 2.2 1.2 1.65 V

I

R

**

Reverse leakage current V

R

= 1500V

100 100 1000 µA

Pulse test : * tp = 380 µs, δ <2%

**tp = 5 ms, δ <2%

To evaluate the maximum conduction losses of the DAMPER diode use the following equations :

P=1.37xI

F(AV)

+ 0.047 x I

F2(RMS)

STATIC ELECTRICAL CHARACTERISTICS OF THE DAMPER DIODES

Symbol Parameter

Test

conditions

Value

UnitTj = 25°C Tj = 125°C

Typ. Max. Typ. Max.

V

F

*

Forward voltage drop I

F

=3A

2.0 1.25 1.55 V

I

R

**

Reverse leakage current V

R

= 700V

20450µA

Pulse test : * tp = 380 µs, δ <2%

** tp = 5 ms, δ <2%

To evaluate the maximum conduction losses of the MODULATION diode use the following equations :

P=0.98xI

F(AV)

+0.19xI

F2(RMS)

STATIC ELECTRICAL CHARACTERISTICS OF THE MODULATION DIODE

Symbol Parameter Test conditions

Value

Unit

Typ. Max.

t

rr

Reverse recovery time IF= 100mA

I

R

= 100mA

I

RR

= 10mA

Tj = 25°C

750 ns

t

rr

Reverse recovery time IF=1A

dI

F

/dt = -50A/µs

V

R

= 30V

Tj = 25°C

110 135 ns

RECOVERY CHARACTERISTICS OF THE DAMPER DIODE

Page 3

®

DMV1500M7

3/9

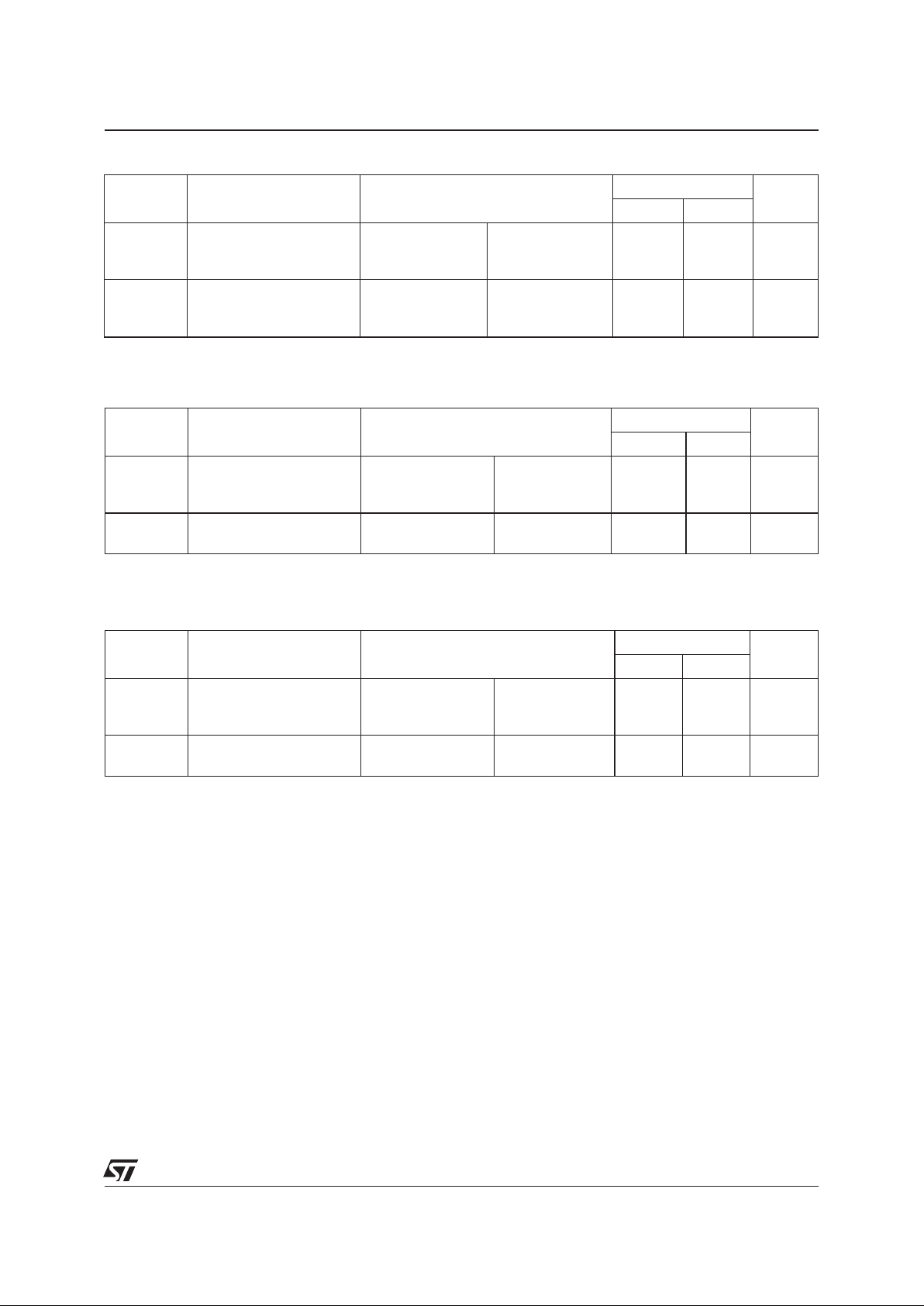

Symbol Parameter Test conditions

Value

Unit

Typ. Max.

t

fr

Forward recovery time IF=6A

dI

F

/dt = 80A/µs

V

FR

=3V

Tj = 100°C

570 ns

V

FP

Peak forward voltage IF=6A

dI

F

/dt = 80A/µs

Tj = 100°C

21 28 V

TURN-ON SWITCHING CHARACTERISTICS OF THE DAMPER DIODE

Symbol Parameter Test conditions

Value

Unit

Typ. Max.

t

rr

Reverse recovery time IF= 100mA

I

R

= 100mA

I

RR

= 10mA

Tj = 25°C

120 360 ns

t

rr

Reverse recovery time IF=1A

dI

F

/dt = -50A/µs

V

R

= 30V

Tj = 25°C

55 ns

RECOVERY CHARACTERISTICS OF THE MODULATION DIODE

Symbol Parameter Test conditions

Value

Unit

Typ. Max.

t

fr

Forward recovery time IF=3A

dI

F

/dt = 80A/µs

V

FR

=2V

Tj = 100°C

240 ns

V

FP

Peak forward voltage IF=3A

dI

F

/dt = 80A/µs

Tj = 100°C

9V

TURN-ON SWITCHING CHARACTERISTICS OF THE MODULATION DIODE

Page 4

®

DMV1500M7

4/9

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

I (A)P

P (W)F(AV)

Fig. 1-1: Power dissipation versus peak forward

current (triangular waveform, δ = 0.45) (damper

diode).

0.0

0.5

1.0

1.5

2.0

2.5

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

I (A)P

P (W)F(AV)

Fig. 1-2: Power dissipation versus peak forward

current (triangular waveform, δ = 0.45) (modulation diode).

0

1

2

3

4

5

6

7

0 25 50 75 100 125 150

Tamb(°C)

R

th(j-a)=Rth(j-c)

T

δ

=tp/T

tp

I (A)F(AV)

Fig. 2-1: Average forward current versus ambient

temperature (damper diode).

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0 25 50 75 100 125 150

R

th(j-a)=Rth(j-c)

T

δ

=tp/T

tp

I (A)F(AV)

Tamb(°C)

Fig. 2-2: Average forward current versus ambient

temperature (modulation diode).

0.1

1.0

10.0

100.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4

V (V)FM

Tj= 25 °C

(Maximum values)

Tj= 125 °C

(Maximum values)

Tj= 125 °C

(Maximum values)

Tj= 125 °C

(Typical values)

Tj= 125 °C

(Typical values)

I (A)FM

Fig. 3-1: Forward voltage drop versus forward

current (damper diode).

0.1

1.0

10.0

100.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Tj= 25 °C

(Maximum values)

Tj= 125 °C

(Maximum values)

Tj= 125 °C

(Maximum values)

Tj= 125 °C

(Typical values)

Tj= 125 °C

(Typical values)

I (A)FM

V (V)FM

Fig. 3-2: Forward voltage drop versus forward

current (modulation diode).

Page 5

®

DMV1500M7

5/9

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.E-03 1.E-02 1.E-01 1.E+00

t (s)P

T

δ

=tp/T

tp

Zth(j-c)/Rth(j-c)

δ = 0.5

δ = 0.2

δ = 0.1

Single pulse

Fig. 4: Relative variation of thermal impedance

junction to case versus pulse duration.

0

5

10

15

20

25

30

35

40

45

50

1.E-03 1.E-02 1.E-01 1.E+00

t(s)

TC= 25 °C

TC= 50 °C

TC= 100 °C

IM

t

δ=0.5

I (A)M

Fig. 5-1: Non repetitive peak forward current ver-

sus overload duration (damper diode).

0

5

10

15

20

25

30

1.E-03 1.E-02 1.E-01 1.E+00

t(s)

TC= 25 °C

TC= 50 °C

TC= 100 °C

I (A)M

IM

t

δ=0.5

Fig. 5-2: Non repetitive peak forward current versus overload duration (modulation diode).

0

100

200

300

400

500

600

700

800

900

1000

0.1 1.0 10.0

dIF/dt(A/µs)

IF= 6A

T

j

= 125 °C

90% confidence

Q (nC)RR

Fig. 6-1: Reverse recovery charges versus dIF/dt

(damper diode).

0

20

40

60

80

100

120

140

160

180

0.1 1.0 10.0 100.0

dIF/dt(A/µs)

IF= 3A

T

j

= 125 °C

90% confidence

Q (nC)RR

Fig. 6-2: Reverse recovery charges versus dIF/dt

(modulation diode).

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0.1 1.0 10.0

dIF/dt(A/µs)

IF= 6A

T

j

= 125 °C

90% confidence

I (A)RM

Fig. 7-1: Peak reverse recovery current versus

dIF/dt (damper diode).

Page 6

®

DMV1500M7

6/9

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

1.0 10.0 100.0

dIF/dt(A/µs)

IF= 3A

T

j

= 125 °C

90% confidence

I (A)RM

Fig. 7-2: Peak reverse recovery current versus

dIF/dt (modulation diode).

0

5

10

15

20

25

30

35

40

0 20 40 60 80 100 120 140

dIF/dt(A/µs)

IF= 6A

T

j

= 125 °C

90% confidence

V (V)FP

Fig. 8-1: Transient peak forward voltage versus

dIF/dt (damper diode).

0

2

4

6

8

10

12

0 20 40 60 80 100 120 140

dIF/dt(A/µs)

IF= 3A

T

j

= 125 °C

90% confidence

V (V)FP

Fig. 8-2: Transient peak forward voltage versus

dIF/dt (modulation diode).

400

450

500

550

600

650

700

750

800

0 20 40 60 80 100 120 140

dIF/dt(A/µs)

IF= 6A

T

j

= 125 °C

V

FR

= 3 V

90% confidence

tfr(ns)

Fig. 9-1: Forward recovery time versus dIF/dt

(damper diode).

0

20

40

60

80

100

120

140

160

180

200

0 20 40 60 80 100 120 140 160 180 200

dIF/dt(A/µs)

IF= 3A

T

j

= 125 °C

V

FR

= 2 V

90% confidence

tfr(ns)

Fig. 9-2: Forward recovery time versus dIF/dt

(modulation diode).

0.0

0.2

0.4

0.6

0.8

1.0

1.2

25 50 75 100 125

Tj(°C)

V

FP

Q

RR

I

RM

I , V , Q [Tj] / I , V , Q [Tj=125°C]RM FP RR RM FP RR

Fig. 10: Relative variations of dynamic parame-

ters versus junction temperature.

Page 7

®

7/9

DMV1500M7

DMV1500M 7 / F5

DAMPER AND MODULATION DIODES FOR VIDEO

LEAD BENDING (OPTION)

V = 700V (Modulation diode)RRM

ORDERING INFORMATION

1

10

100

1 10 100 1000

V (V)R

F= 1 MHz

V

osc

= 30 mV

T

j

= 25 °C

Damper diode

Modulation diode

C(pF)

Fig. 11: Junction capacitance versus reverse voltage

applied (typical values)

Page 8

®

DMV1500M7

8/9

PACKAGE MECHANICAL DATA

TO-220AB F5 OPTION

REF.

DIMENSIONS

Millimeters Inches

Min. Max. Min. Max.

A 15.20 15.90 0.598 0.625

a1 24.16 26.90 0.951 1.059

a3 1.65 2.41 0.064 0.094

B 10.00 10.40 0.393 0.409

b1 0.61 0.88 0.024 0.034

b2 1.23 1.32 0.048 0.051

C 4.40 4.60 0.173 0.181

c1 0.49 0.70 0.019 0.027

c2 2.40 2.72 0.094 0.107

e 2.40 2.70 0.094 0.106

F 6.20 6.60 0.244 0.259

I 3.75 3.85 0.147 0.151

L 2.65 2.95 0.104 0.116

I2 1.14 1.70 0.044 0.066

l3 1.14 1.70 0.044 0.066

l4 15.80 16.80 0.622 0.661

16.40 typ. 0.645 typ.

M1 2.92 3.30 0.114 0.129

R1 1.40 typ. 0.055 typ.

R2 1.40 typ. 0.055 typ.

c2

B

a1

C

b2

l2

c2

a3

R2

R1

l3

b1

l4

A

F

L

I

e

c1

M1

Ø

■

Cooling method: by conduction (c)

■

Recommended torque value: 0.8 m.N.

■

Maximum torque value: 1 m.N.

2.2mm

2.54mm

1mm

3.1mm

PRINTED CIRCUIT LAYOUT FOR F5 LAYOUT

Page 9

®

DMV1500M7

9/9

Informationfurnished is believed to be accurate andreliable. However, STMicroelectronics assumes no responsibility forthe consequences of

useof such information nor for anyinfringement of patents or other rights ofthird parties which may result fromits use. No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

Type Marking Package Weight Base qty Delivery mode

DMV1500M7

DMV1500M7F5

DMV1500M7 TO-220AB 2.2g 50 Tube

■

Epoxy meets UL94, V0

PACKAGE MECHANICAL DATA

TO-220AB

M

B

l4

C

b2

a2

l2

c2

l3

b1

a1

A

F

L

I

e

c1

REF.

DIMENSIONS

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 15.20 15.90 0.598 0.625

a1 3.75 0.147

a2 13.00 14.00 0.511 0.551

B 10.00 10.40 0.393 0.409

b1 0.61 0.88 0.024 0.034

b2 1.23 1.32 0.048 0.051

C 4.40 4.60 0.173 0.181

c1 0.49 0.70 0.019 0.027

c2 2.40 2.72 0.094 0.107

e 2.40 2.70 0.094 0.106

F 6.20 6.60 0.244 0.259

I 3.75 3.85 0.147 0.151

I4 15.80 16.40 16.80 0.622 0.646 0.661

L 2.65 2.95 0.104 0.116

l2 1.14 1.70 0.044 0.066

l3 1.14 1.70 0.044 0.066

M 2.60 0.102

■ Cooling method: by conduction (c)

■

Recommended torque value: 0.8 m.N.

■

Maximum torque value: 1 m.N.

Loading...

Loading...